1. Introduction

Aluminium matrix composites are lightweight materials consisting of an aluminium alloy and at least one reinforcing component. Depending on the type of reinforcement they can be classified into:

Continuous fibre-reinforced AMCs.

Whisker-reinforced or short fibre-reinforced AMCs.

Particle-reinforced AMCs.

Hybrid AMCs with different types of reinforcement.

The type, proportion, and kind of reinforcements significantly influence the properties of such composites. In the majority of cases, an increase of the strength, the Young’s modulus, and the wear resistance is aimed for. Consequently, most of AMCs are particle reinforced. Typical particle reinforcements are silicon carbide and aluminium oxide, but titanium diboride, boron carbide, titanium aluminide, or titanium dioxide can also be used [

1]. The fabrication is realised by casting processes (e.g., stir casting, squeeze casting, in-situ-casting, spray casting, infiltration), powder metallurgy routes, friction stir processing [

2], or selective laser melting [

3].

Aluminium matrix composites exhibit a high potential for tribological applications, for example brake discs, brake drums, and cylinder working surfaces of combustion engines. However, there are abrasive and adhesive wear mechanisms depending on the applied load and the properties of the tribological system. An increase of the particle proportion can significantly reduce the wear rate [

4]. This can be referred to the behaviour of the ceramic particles acting as load-bearing components. Furthermore, the contact area between the AMC part and the counterpart is markedly reduced [

2]. However, the surface structure of the friction partners strongly affects the mechanisms of action in tribological systems.

In general, the surface properties of components influence the functional behaviour of technical systems significantly. In addition to the material, the manufacturing processes are a key factor for the surface integrity. Especially, a mechanical surface modification exhibits a very high potential for a customised improvement of the performance, resulting from changes in the surface structure and the surface layer. There are three basic effects that are involved in mechanical surface modification processes [

5]:

A plastic deformation of the roughness peaks can result in a smoothing effect.

The forces acting parallel and perpendicular to the surface lead, in combination with a plastic deformation of the surface, to a stretched area with maximum strains at the surface.

A Hertzian pressure yields to a maximum deformation below the surface.

These effects often involve a decrease of the surface roughness values, work hardening, strong compressive residual stresses, and a grain refinement in the surface layer. Consequently, appropriate mechanical modifications of the surface contribute to an enhancement of the fatigue properties, corrosion resistance, tribological behaviour, and wear resistance.

However, there are many different technologies for a mechanical surface modification, which can be subdivided in burnishing, shot peening, and machine hammer peening processes. The surface properties depend strongly on the specific process parameters and can be varied in a large range.

AlMangour and Yang [

6] investigated the surface quality and the mechanical properties after shot peening of stainless steel. The results showed a significant reduction of the surface roughness values. Furthermore, the properties of the surface layer could be modified markedly. The crystalline grain size was approximately halved, but the micro-strain and the absolute values of the compressive residual stresses could be increased considerably. The modified surface properties led to a reduction of the wear volume loss in tribomechanical tests.

However, Scheel et al. [

7] studied the influence of different mechanical processes on a modification of the surface. For high strength aluminium alloys, a burnishing process led to stronger and deeper residual stresses compared to shot peening. Consequently, specimens modified by a burnishing process performed better in high cycle fatigue tests in comparison to untreated and shot peened specimens respectively.

For a surface modification of rotationally symmetric components, burnishing processes are preferred because of the simple integration in lathes. Many research studies deal with the burnishing of different alloys, but there is only little information about burnishing of aluminium materials.

El-Axir et al. [

8] studied the ball burnishing of the alloy 2014, using a hardened steel ball with a diameter of 8 mm. The surface roughness values could be reduced markedly. For a higher burnishing speed and a burnishing feed in the range of 0.15 mm to 0.25 mm, the smallest surface roughness values were achieved. Moreover, for low speeds multiple burnishing passes should be applied, yet for higher speeds surface deterioration occurs after repeated burnishing.

El-Tayeb et al. [

9] investigated the ball burnishing of the alloy 6061 with hardened steel balls. The results show an important influence of the burnishing force and the burnishing speed on the surface roughness. For optimal parameters, an arithmetic mean surface roughness

Ra of 0.09 µm was achieved.

Nestler and Schubert [

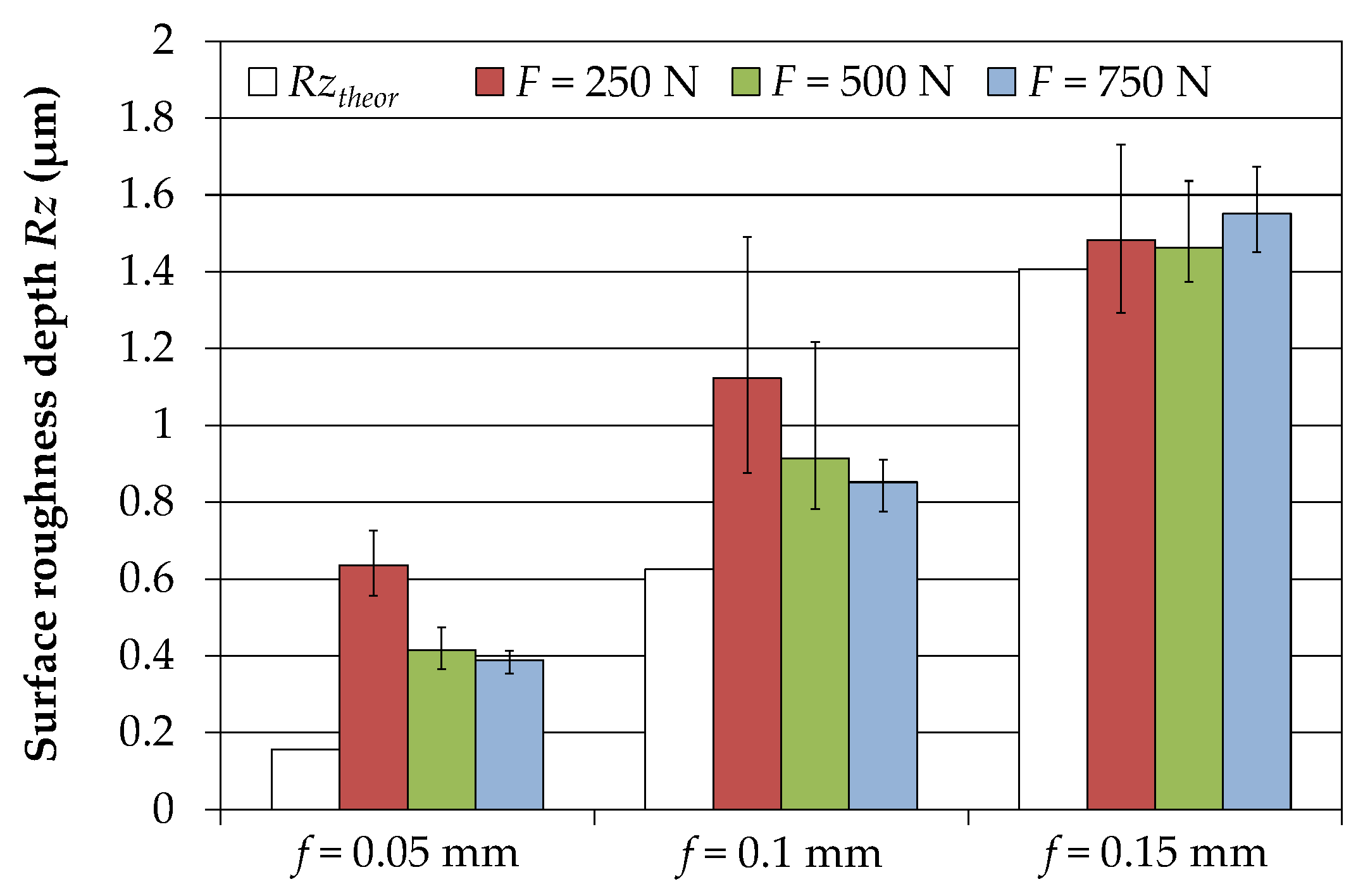

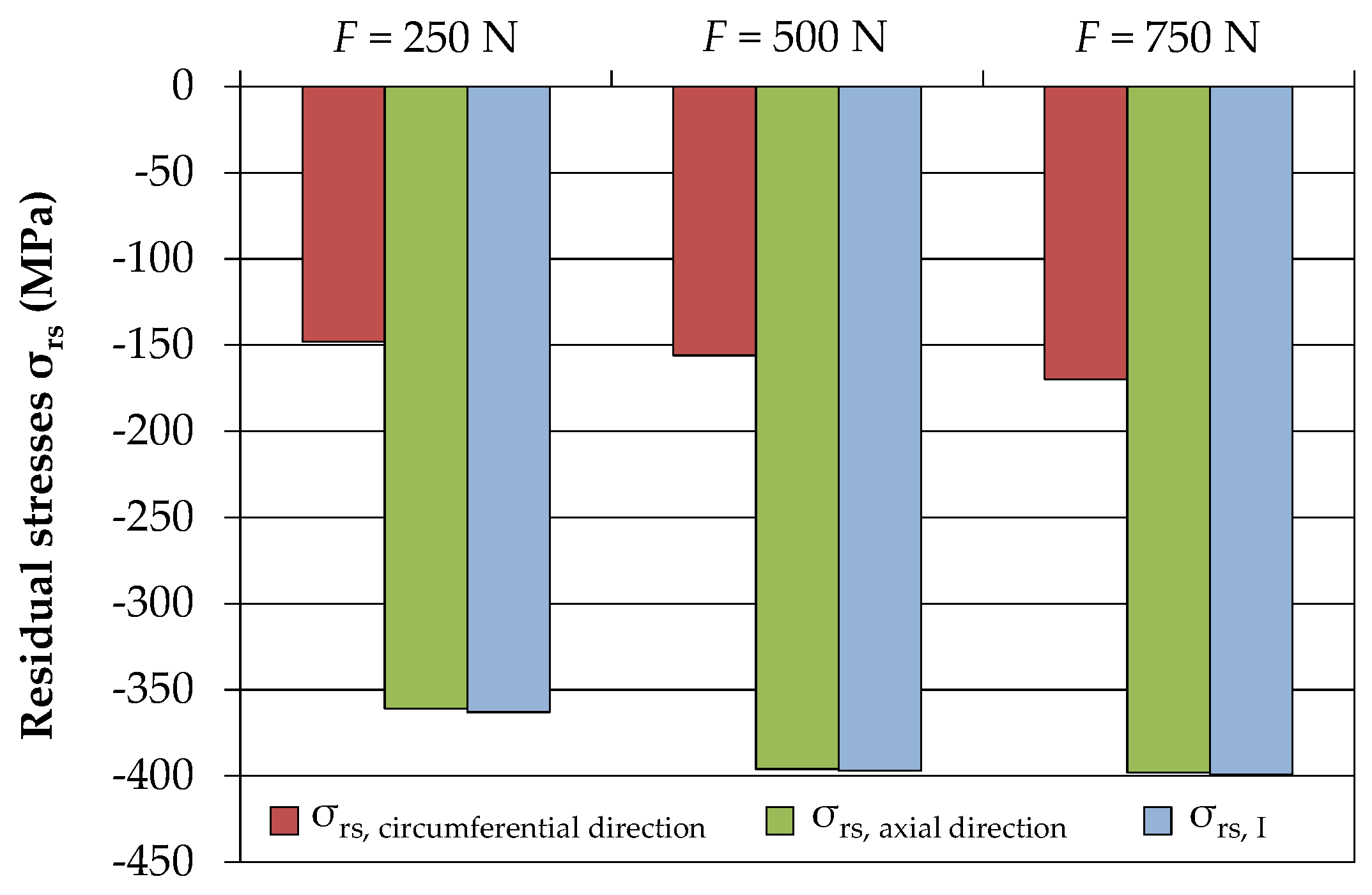

10] studied the influence of the machining parameters in diamond smoothing of aluminium matrix composites (AMCs). This process is characterised by a sliding relative movement of the diamond body and the workpiece instead of a primarily rolling relative movement of the roller body and the workpiece. The surface roughness values could be reduced markedly by diamond smoothing, especially for the smallest feed applied. In this case, mean surface roughness values after smoothing were about 0.04 µm for

Ra and 0.7 µm for

Rz using a diamond body with a spherical radius of 2 mm. Furthermore, residual stresses in the matrix alloy of about −400 MPa could be gained. The speed varied did not show any significant influence on the surface properties.

However, there are no studies in roller burnishing of heterogeneous materials like aluminium matrix composites, although they gain more and more in importance. Consequently, appropriate parameters for roller burnishing of particle-reinforced AMCs have to be found. The focus of the research is on the surface structure and the residual stress state. Both aspects can influence the functional behaviour, especially fatigue properties or corrosion resistance, markedly.

2. Materials and Methods

For the experiments an aluminium matrix composite consisting of the alloy AA2124 and SiC particles with a volume proportion of 25% was used. The AMC is produced by a powder metallurgy route comprising a high energy mixing process and subsequent hot isostatic pressing for powder consolidation. Afterwards, the billets are extruded to bars applying an extrusion ratio of about 50:1. For an increase of the material strength, the bars are heat treated to the condition T4 (solution annealed, quenched and naturally aged).

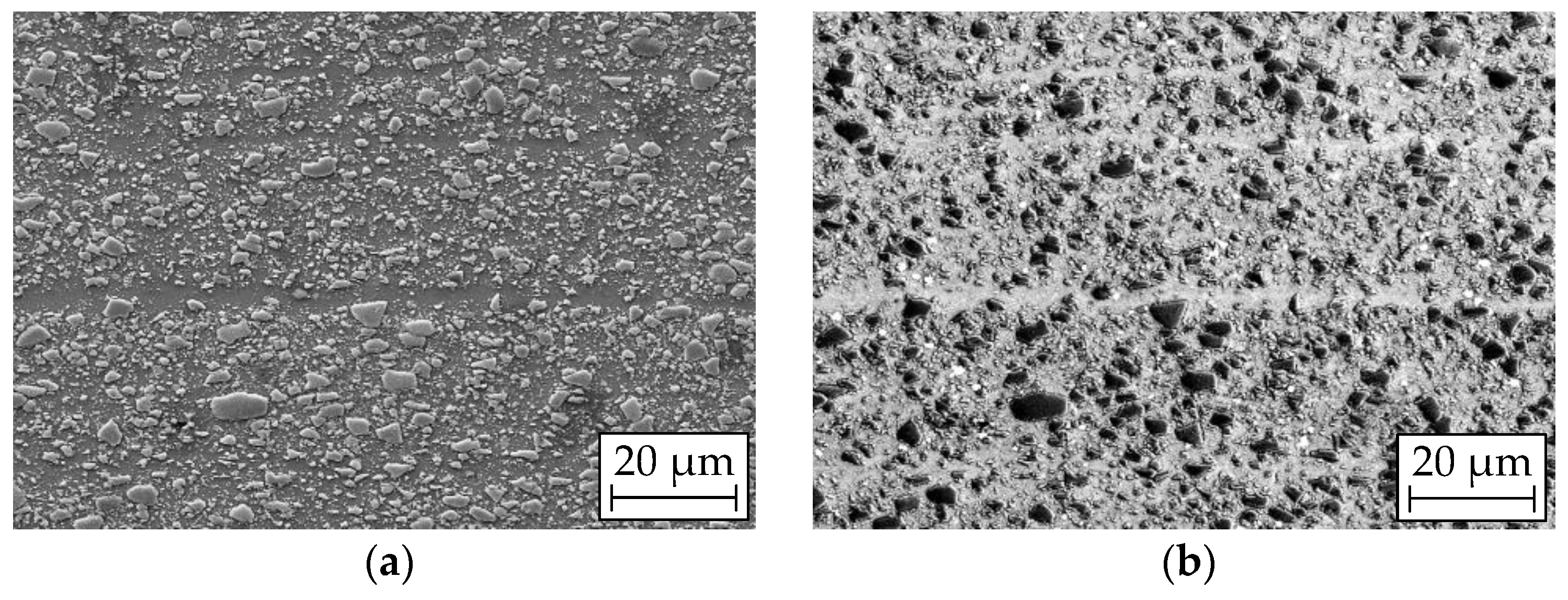

Figure 1 shows the microstructure of the material in the longitudinal direction.

The mean particle size lies in the range of 2 µm to 3 µm. However, there are many smaller and some larger particles, too. The cross-section polish for the longitudinal direction reveals a slight banding, resulting from the extrusion process.

Table 1 represents the mechanical properties of the material identified for the longitudinal direction (hardness excluded).

The finally premachined specimens for the investigations in roller burnishing exhibit a diameter of 23 mm and a length of 20 mm. Both faces are chamfered with an angle of 45° and a size of 1 mm. For clamping, one face of each specimen comprises a blind hole with a diameter of 8 mm, and on the opposite side there is a small centre hole. The values for the surface roughness depth Rz before roller burnishing were in the range of about 5 µm to 7 µm.

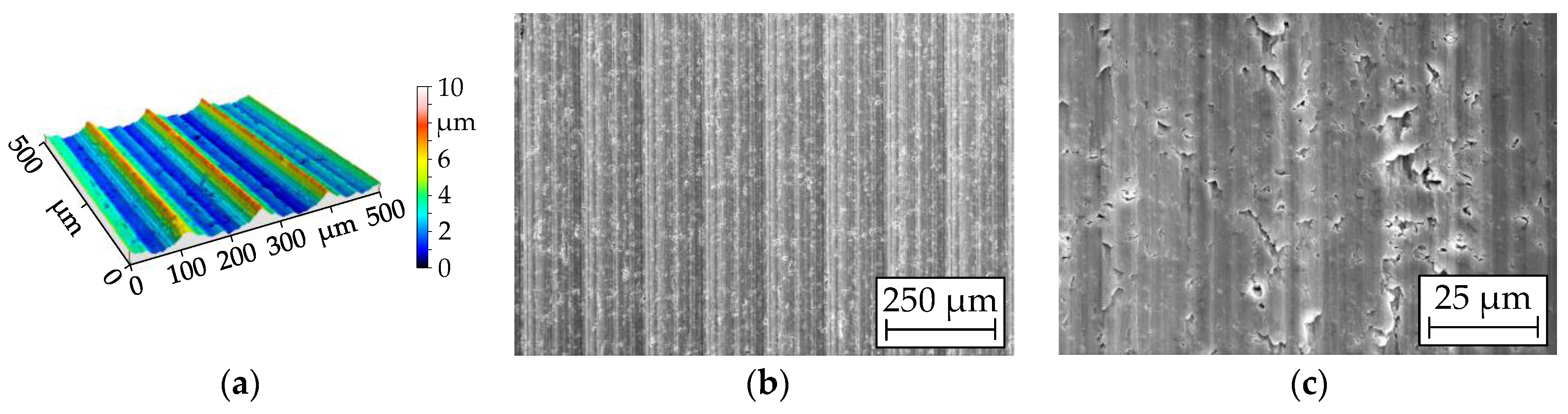

The experiments were carried out on a precision lathe of the type SPINNER PD 32 (SPINNER Werkzeugmaschinen GmbH, Sauerlach, Germany). A clamping of the specimens with a mandrel allowed machining the complete cylindrical length. Because of the high forces in roller burnishing, for this process clamping was supported by an additional live centre on the opposite side. The turning tools for premachining were carried by the disc turret (BARUFFALDI S.p.a., Tribiano (MI), Italy). Because of the highly abrasive effect of the hard ceramic particles CVD (chemical vapour deposition), diamond tipped indexable inserts were used. The turning tools exhibit a polished rake face and a very sharp cutting edge with a rounding of about 3 µm. For final premachining, an insert of the type VCGW 110304 (DTS GmbH – Diamond Tooling Systems, Kaiserslautern, Germany) screwed on a tool holder of the kind SVVCN 1212 F11 (WNT Deutschland GmbH, Kempten, Germany) was applied. Final premachining was realised with a feed of f = 0.14 mm, a cutting speed of vc = 150 m/min, and a depth of cut of ap = 0.25 mm.

For burnishing, a discoid roller body with a radius of 21 mm in the rolling direction and a radius of 2 mm perpendicular to the rolling direction was used. The roller body consists of cemented carbide to withstand the hard ceramic particles in the AMC. The burnishing tool (BAUBLIES AG, Renningen-Malmsheim, Germany) was mounted on a three-axis force dynamometer of the type Kistler 9257A (Kistler Instrumente AG, Winterthur, Switzerland) to monitor the rolling force. This force can be varied by a change of the helical compression spring, its pretension, and the infeed. The tool was adjusted to an angle of 90° between the direction of the burnishing force and the feed direction, which corresponds to the axial direction of the specimens.

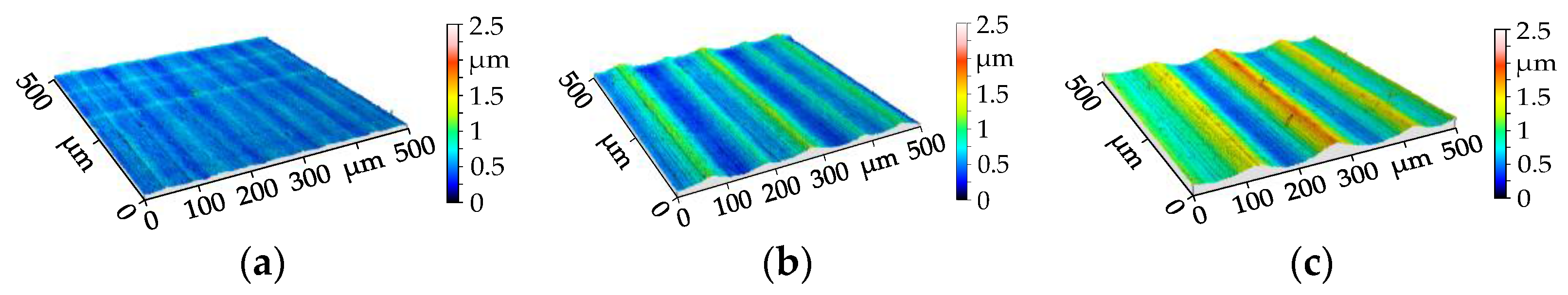

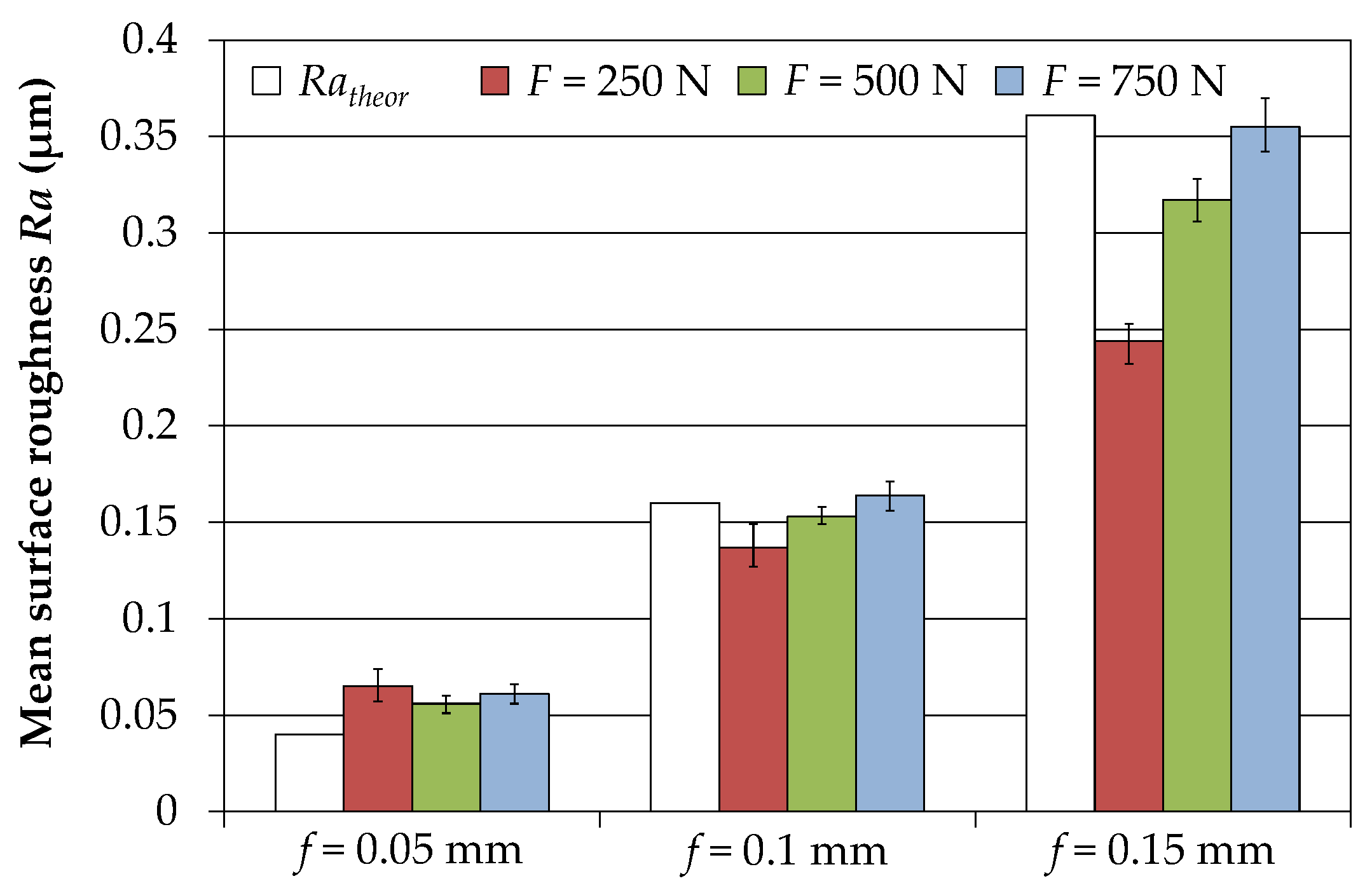

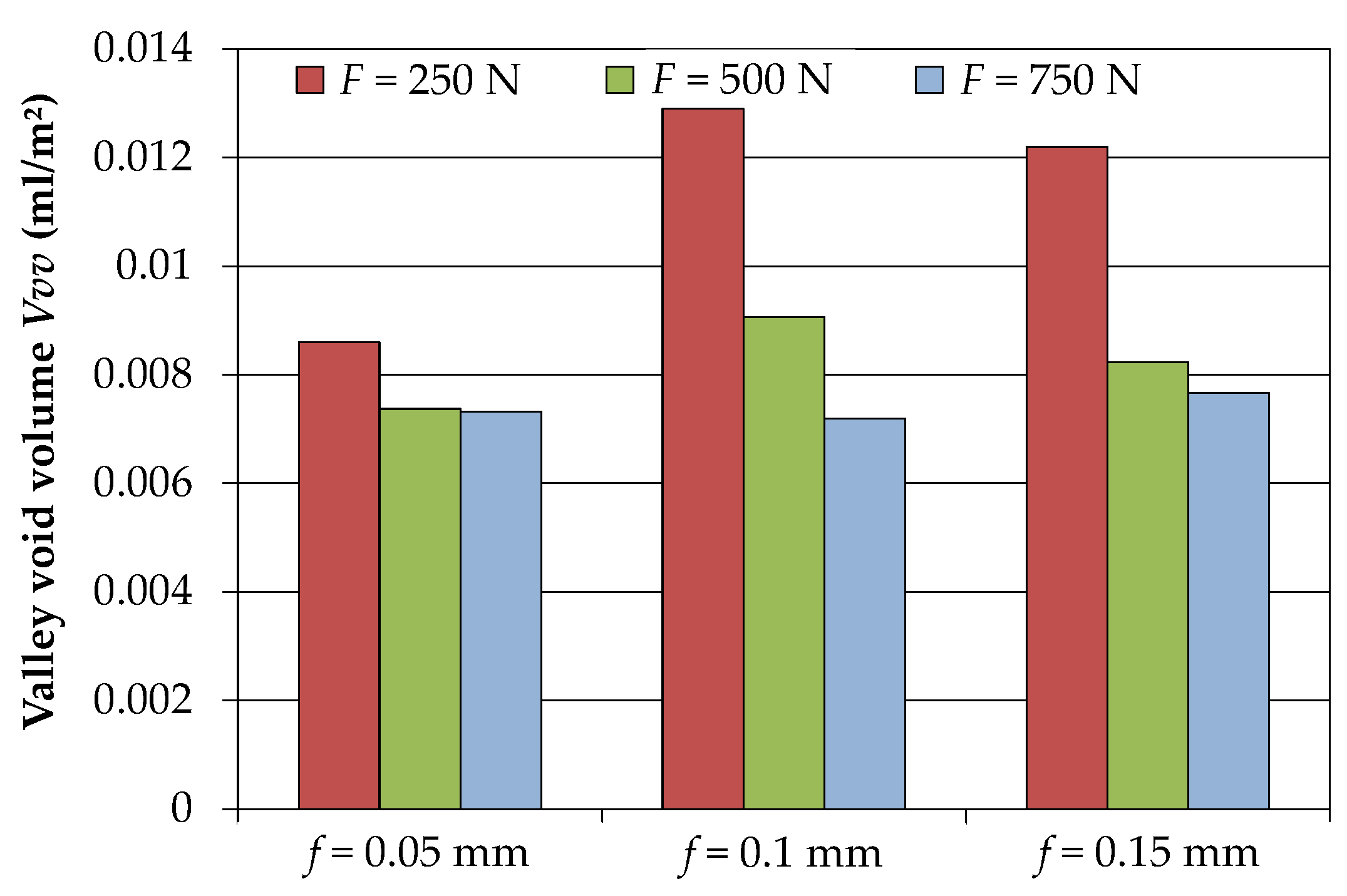

For all experiments, the rolling speed was kept constant at 150 m/min. The final rolling force was adjusted by the infeed amounting to about 0.2 mm. The feed was varied in the range of 0.05 mm to 0.15 mm and the rolling force from 250 N to 750 N using a full factorial design for these both parameters. For each combination of parameters tested, three specimens were machined to assess the process stability. The process parameters for roller burnishing are presented in

Table 2. An emulsion cooling with a concentration of approximately 5% was used to reduce the tendency for adhesion of the aluminium based material on the indexable inserts and the roller body.

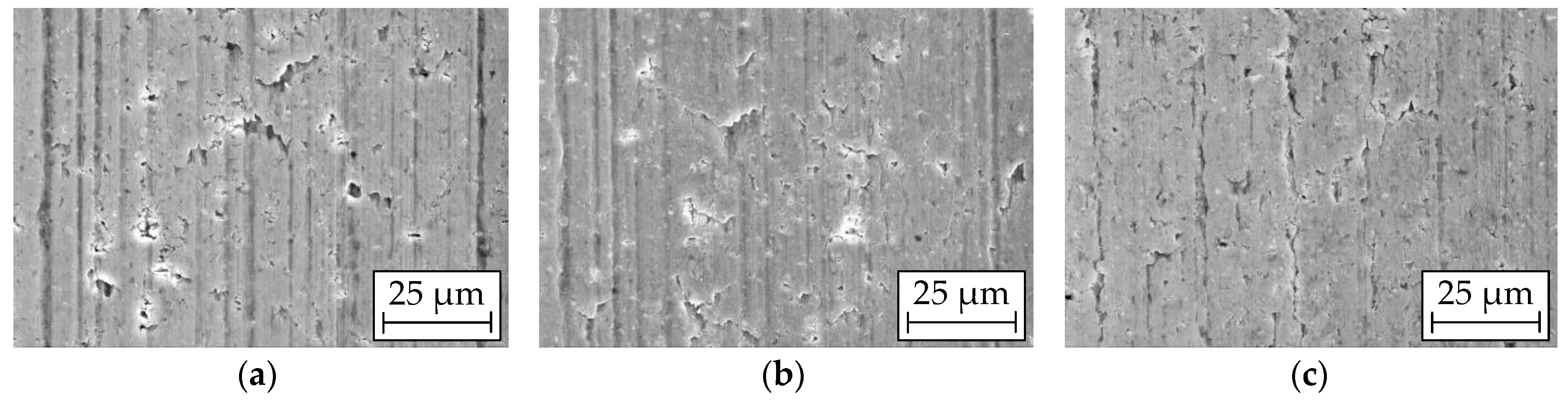

The surface roughness in the axial direction was measured using a stylus instrument of the type Mahr LD 120 (Mahr GmbH, Göttingen, Germany). The measuring length is 4 mm and filtering of the profile is done in accordance to ISO 11562. Because of the comparatively strong influence of surface imperfections on the roughness values, each specimen was measured thrice at different positions. Additionally, for each parameter combination tested, one three-dimensional surface profile was generated with the same measurement equipment including a supplemental cross table. For these measurements, the distance of the measuring points is 1 µm for the circumferential and the axial direction. The measuring field has a size of 2 mm in the axial direction and 0.5 mm in the circumferential direction. For a detailed examination of the surfaces, the 3D profiles were leveled by the subtraction method. Afterwards, a form removal was done by applying a fifth degree polynomial filter (Digital Surf, Besançon, France). These data were used for detailed 3D images of the surface structure, representing a smaller area than measured. A characterisation of the porosity of the surfaces generated by roller burnishing requires further mathematical procedures. After using a robust Gaussian filter with a cut-off wavelength of 0.08 mm, a line by line leveling followed to remove the kinematic roughness.

Furthermore, SEM (scanning electron microscope) micrographs (Carl Zeiss AG, Oberkochen, Germany) of the specimens’ surfaces were obtained using a Zeiss LEO 1455VP microscope to characterise the surface structure and the imperfections. The residual stresses in the surface layer were determined by X-ray diffraction analysis performed with a Siemens D5000 diffractometer (Siemens Aktiengesellschaft, Munich, Germany). The measurements were done with a cobalt anode in the lattice planes {420} of the aluminium alloy using sin² ψ method. Thereby, an area with a diameter of about 2 mm was detected.