Interface Characteristic of Explosive-Welded and Hot-Rolled TA1/X65 Bimetallic Plate

Abstract

:1. Introduction

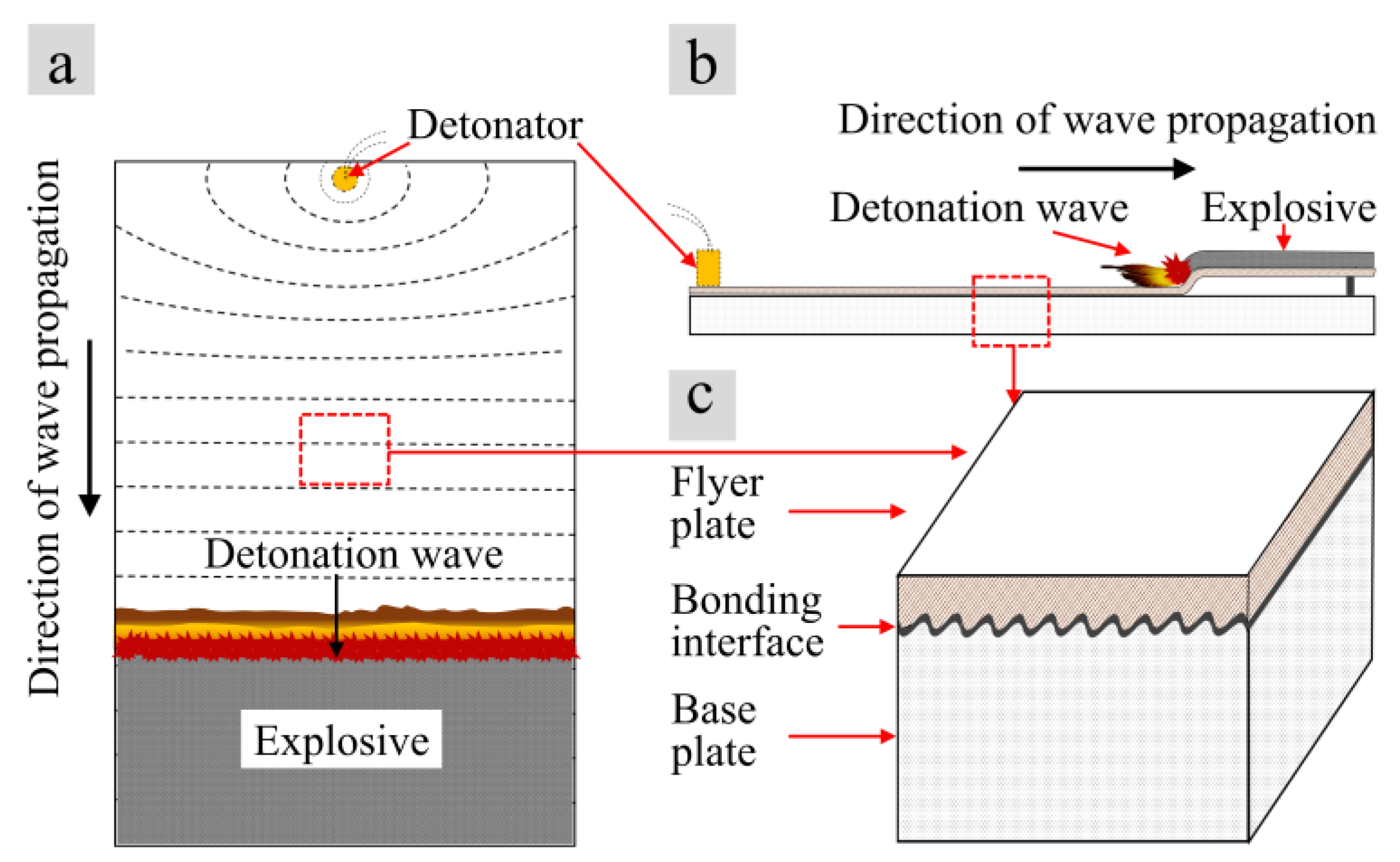

2. Experimental Materials and Methods

2.1. Materials

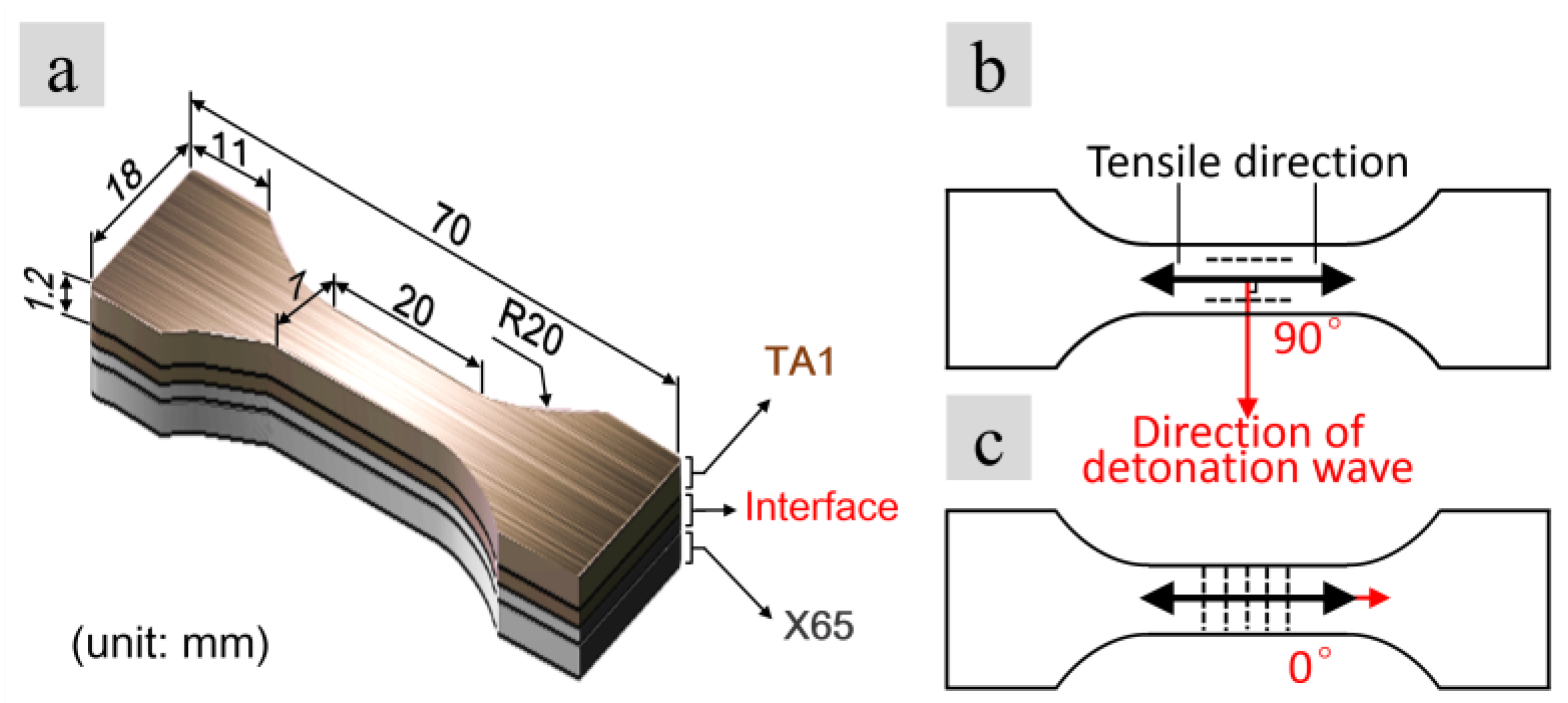

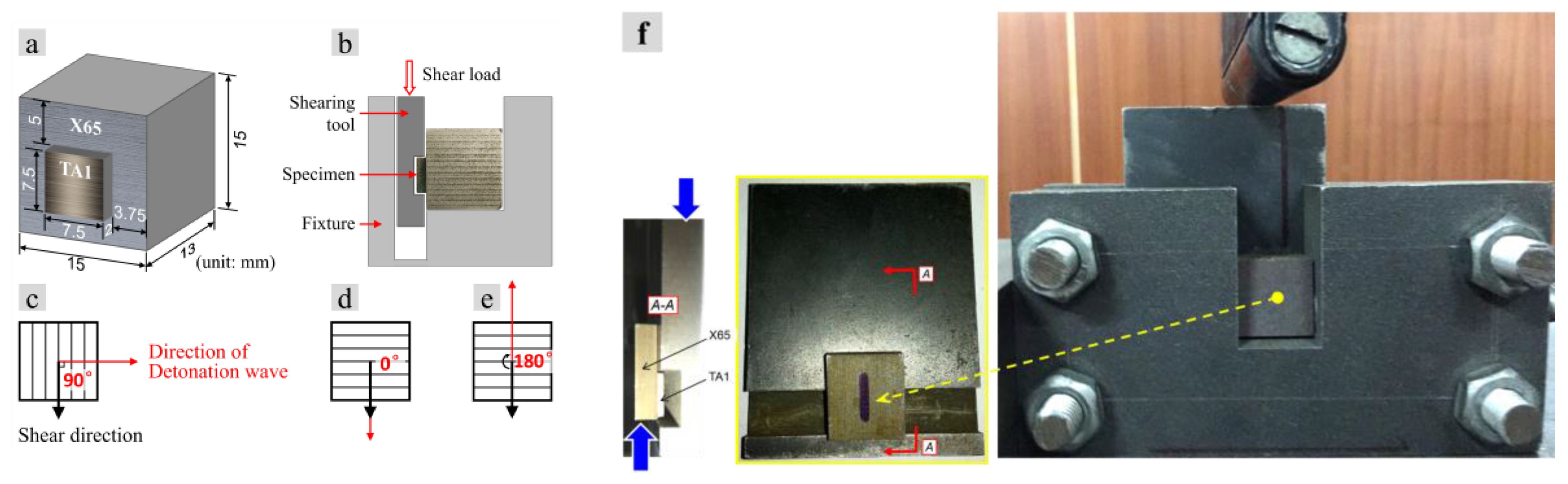

2.2. Experimental Methods

3. Results and Discussion

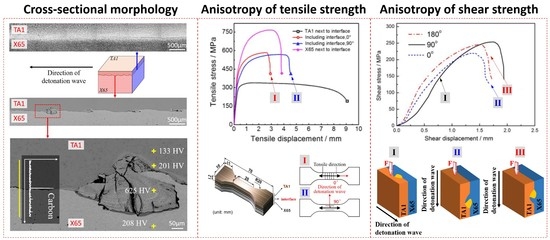

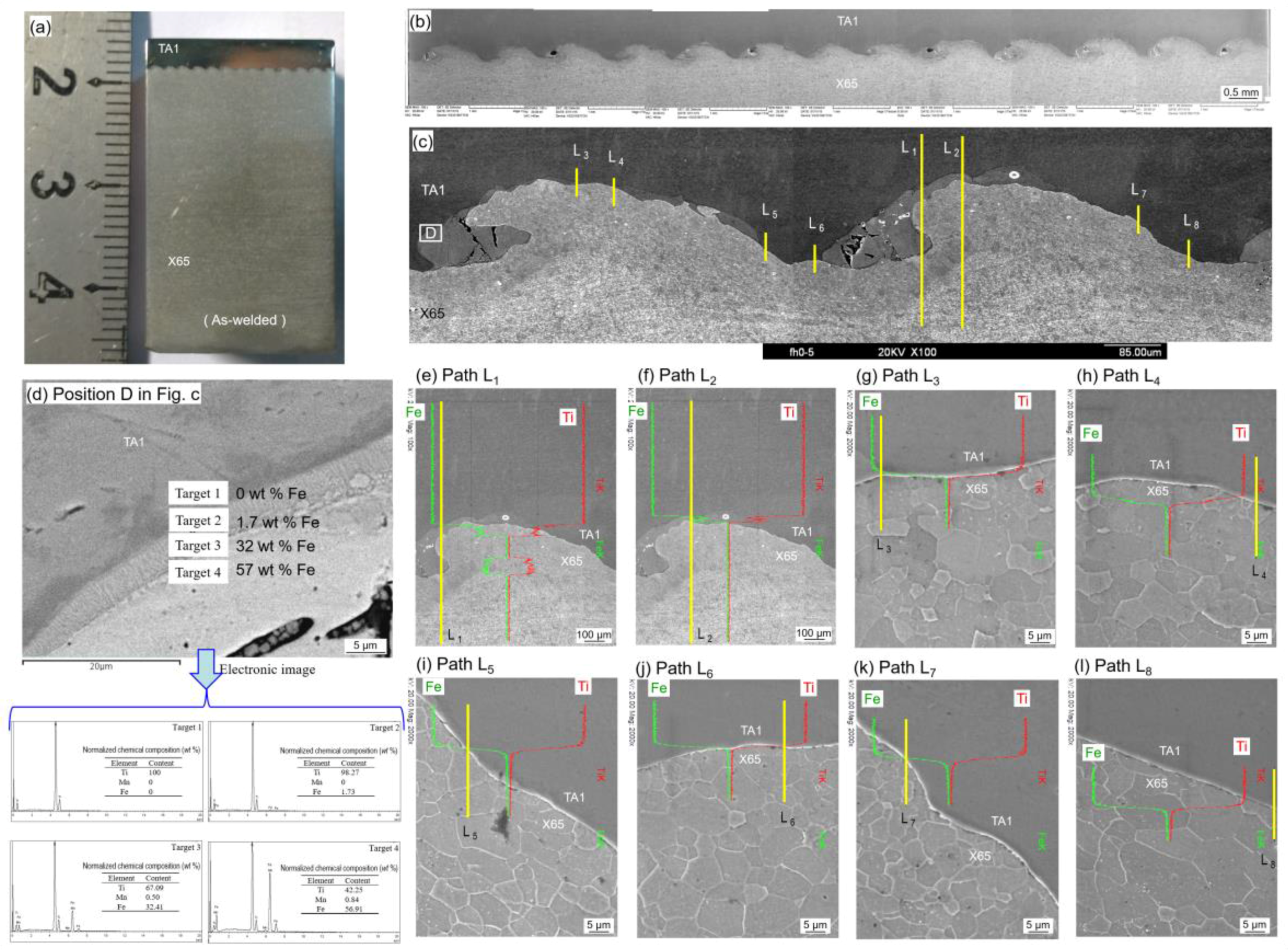

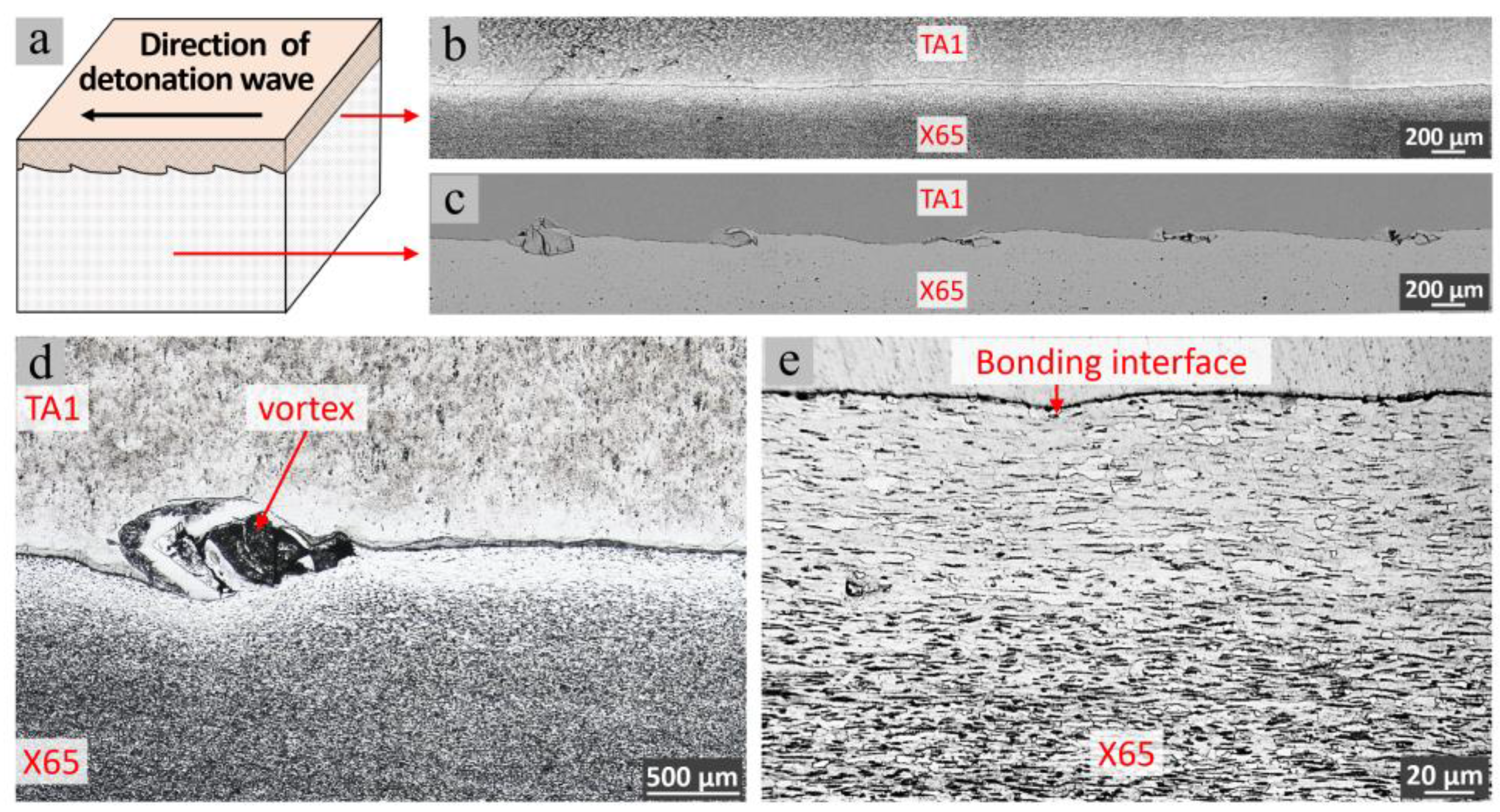

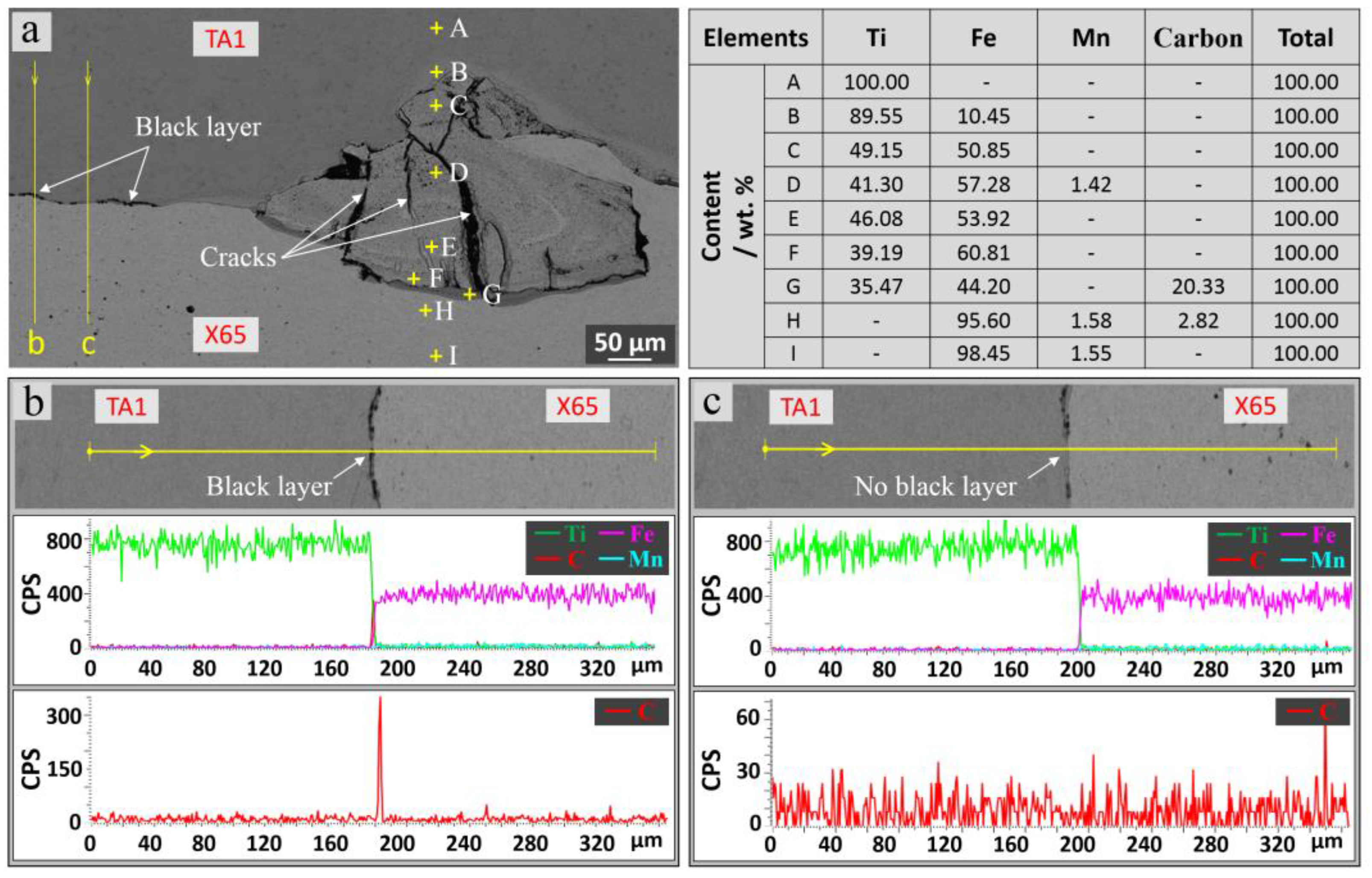

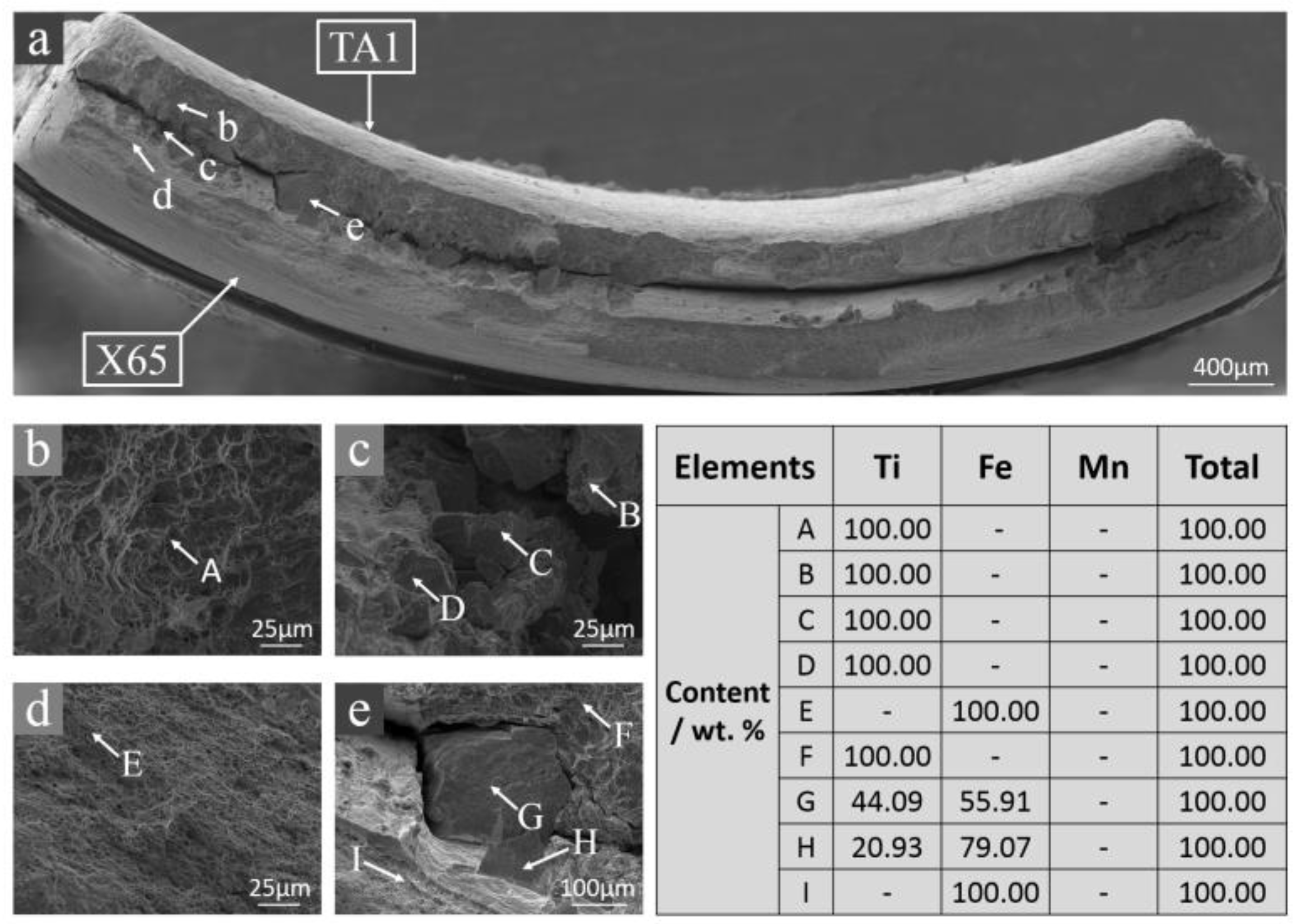

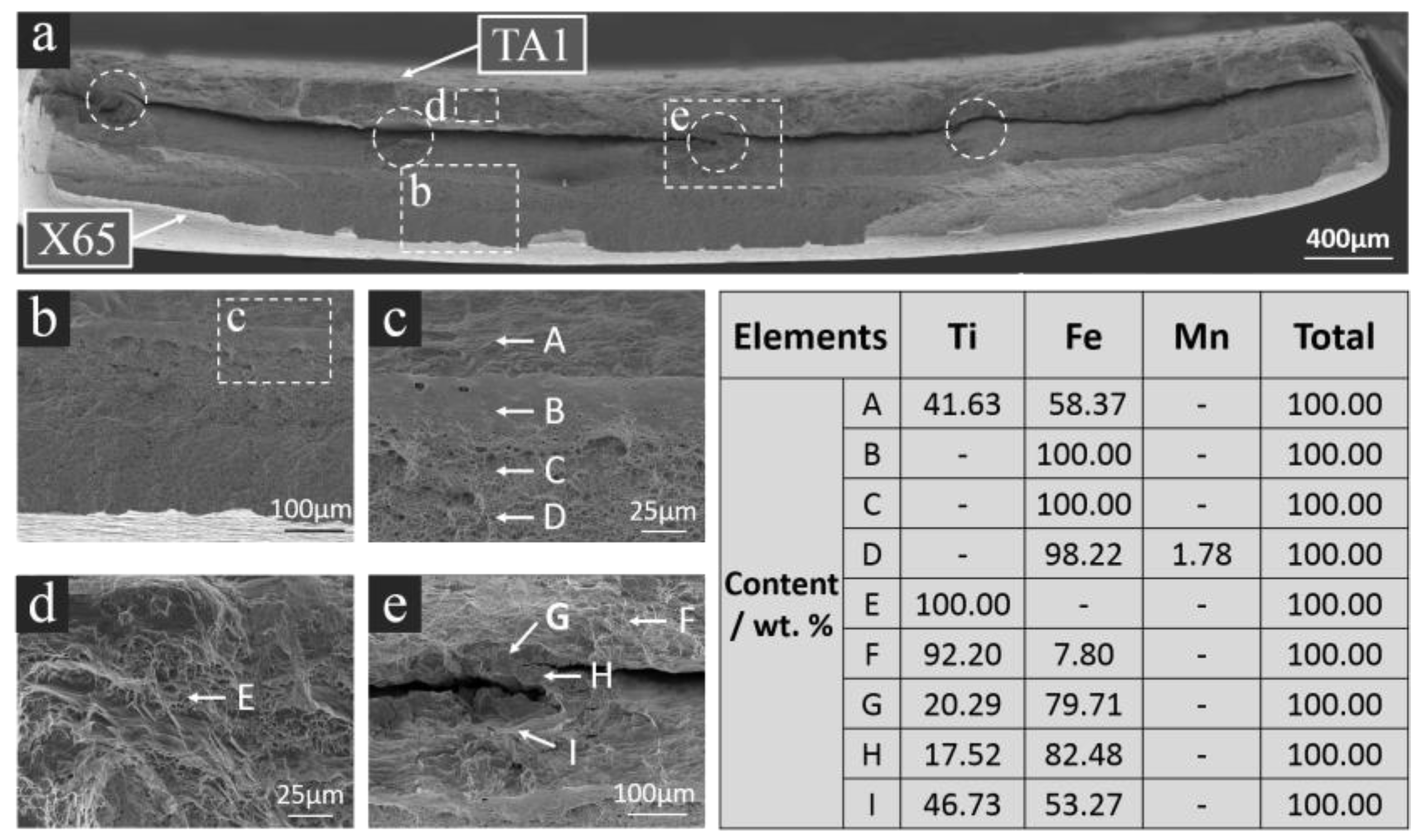

3.1. Microstructure Observation and Composition Analysis

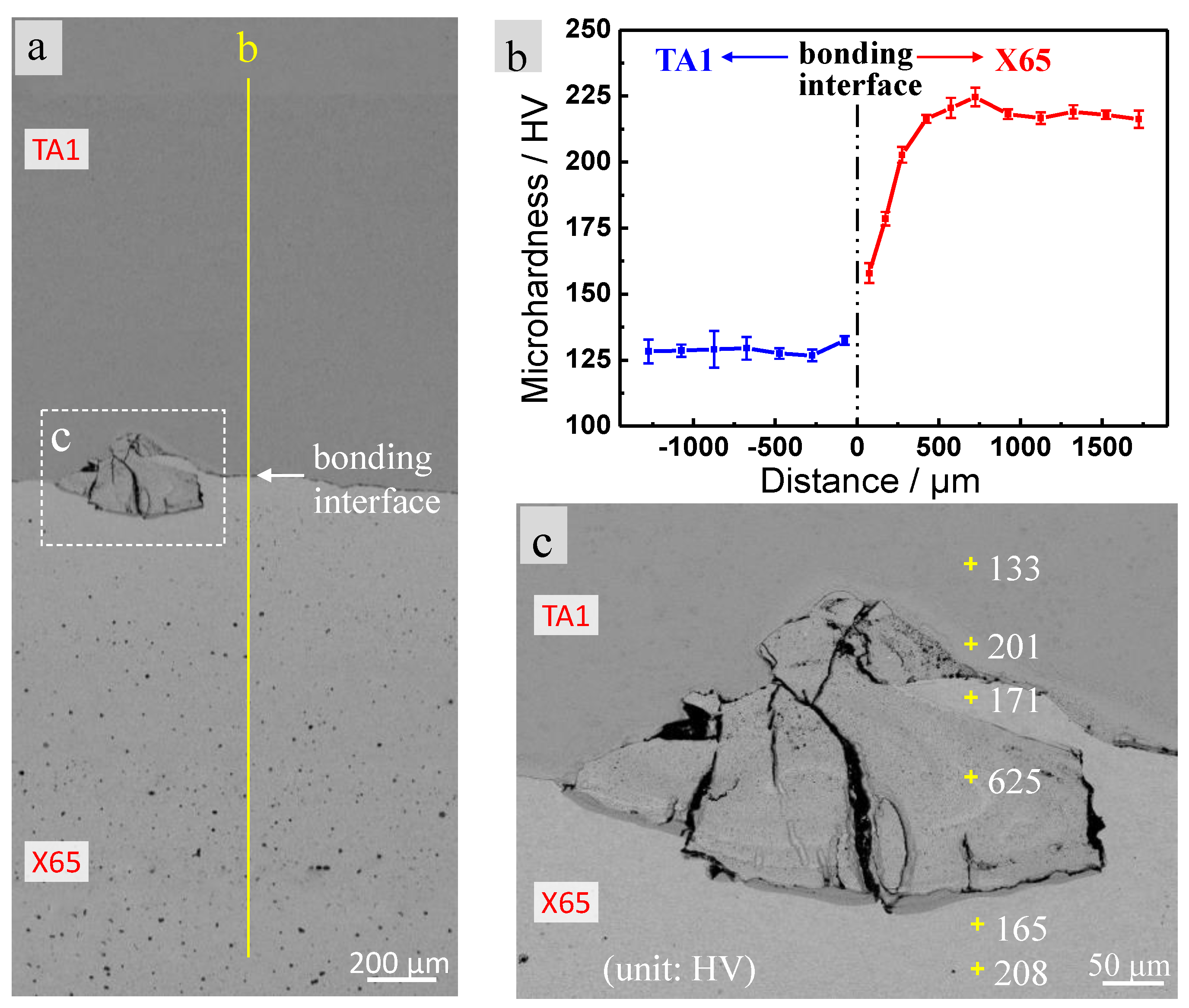

3.2. Microhardness Distribution

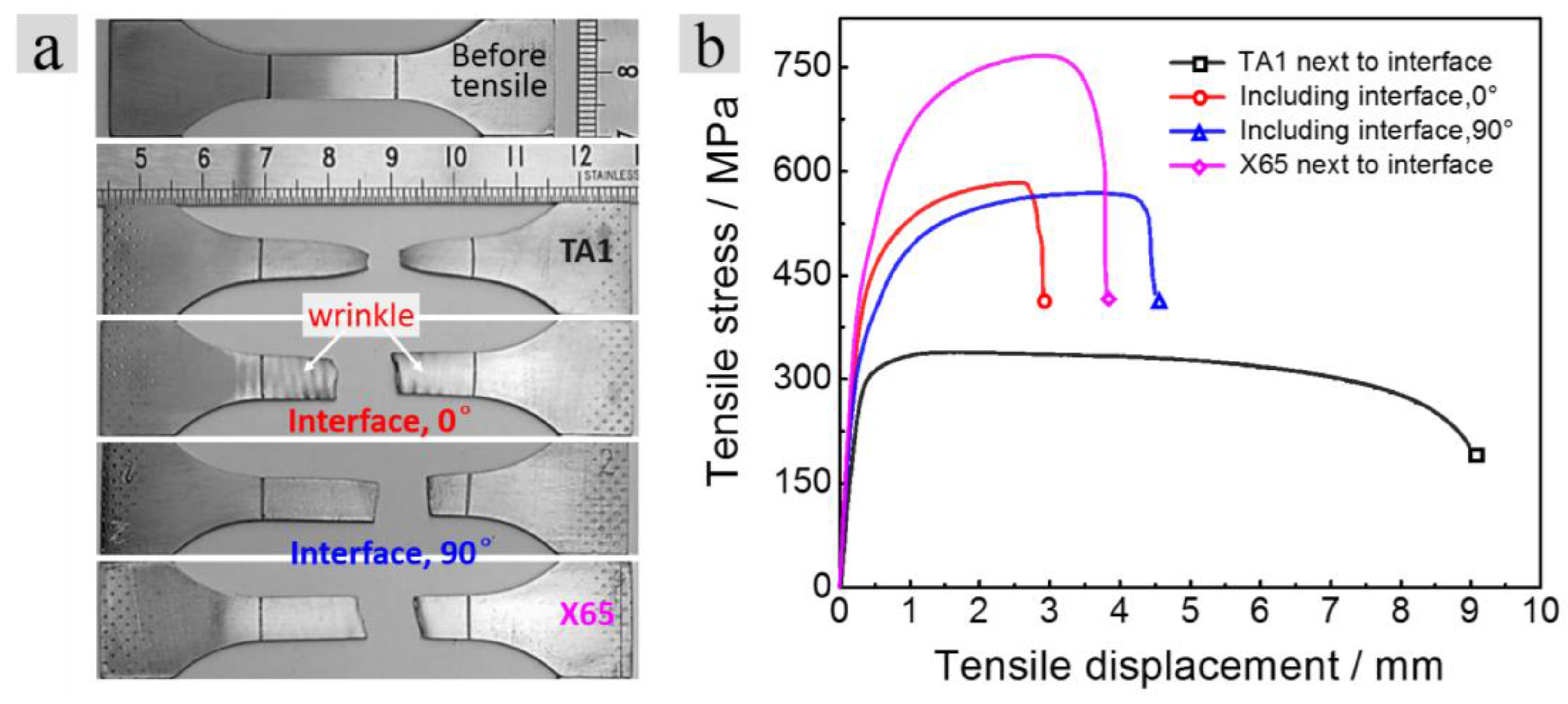

3.3. Stratified-Tensile Tests

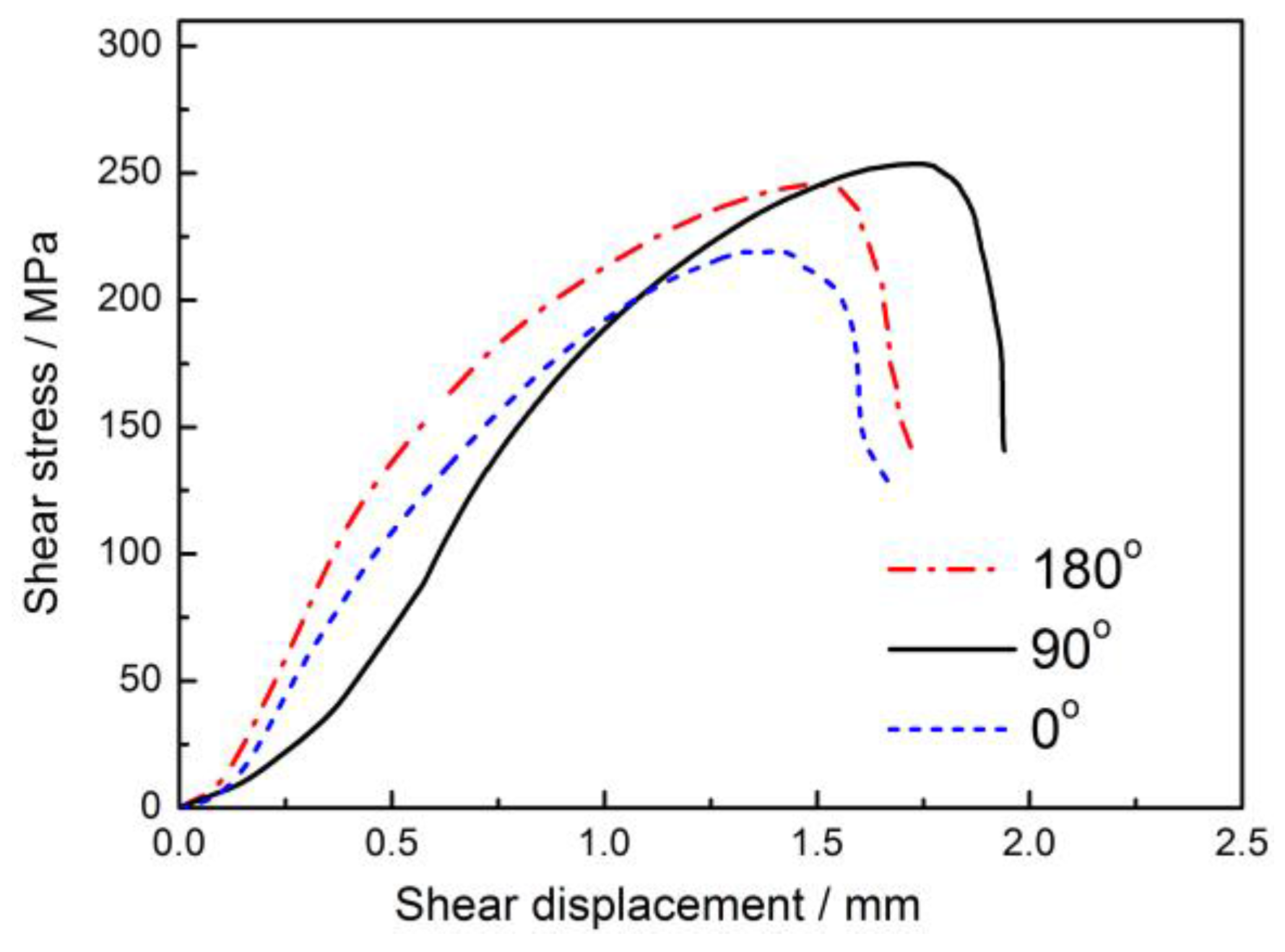

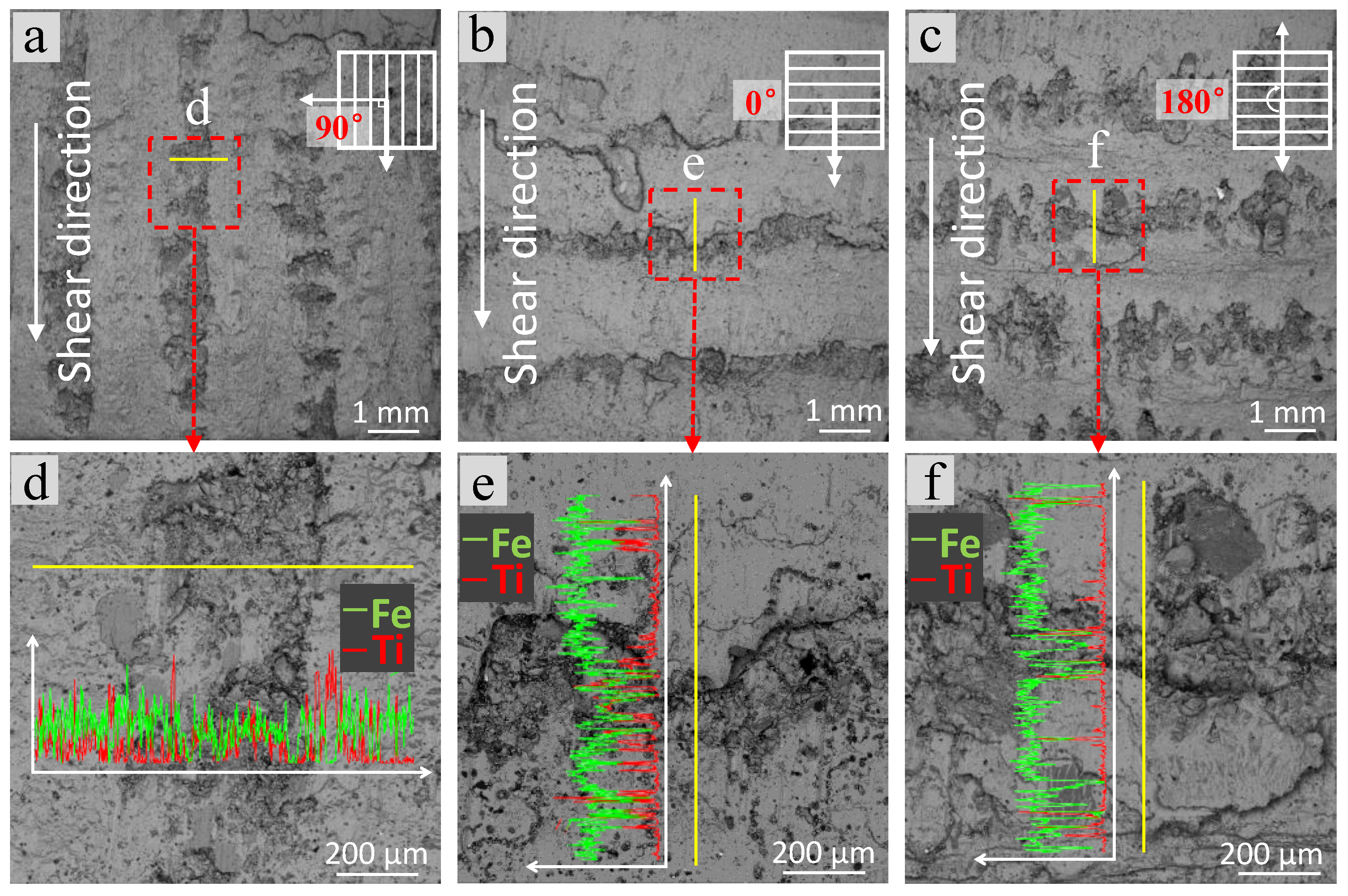

3.4. Compression-Shear Tests

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gulenc, B. Investigation of interface properties and weldability of aluminum and copper plates by explosive welding method. Mater. Des. 2008, 29, 275–278. [Google Scholar] [CrossRef]

- Loureiro, A.; Mendes, R.; Ribeiro, J.B.; Leal, R.M. Effect of explosive ratio on explosive welding quality of copper to aluminium. Ciência Tecnologia dos Materiais 2017, 29, 46–50. [Google Scholar] [CrossRef]

- Mendes, R.; Ribeiro, J.B.; Loureiro, A. Effect of explosive characteristics on the explosive welding of stainless steel to carbon steel in cylindrical configuration. Mater. Des. 2013, 51, 182–192. [Google Scholar] [CrossRef] [Green Version]

- Kwiecień, M.; Majta, J.; Dziedzic, D. Shear deformation and failure of explosive welded inconel-microalloyed steels bimetals. Arch. Civ. Mech. Eng. 2014, 14, 32–39. [Google Scholar] [CrossRef]

- Athar, M.M.H.; Tolaminejad, B. Weldability window and the effect of interface morphology on the properties of Al/Cu/Al laminated composites fabricated by explosive welding. Mater. Des. 2015, 86, 516–525. [Google Scholar] [CrossRef]

- Chen, P.; Feng, J.; Zhou, Q.; An, E.; Li, J.; Yuan, Y.; Ou, S. Investigation on the explosive welding of 1100 aluminum alloy and AZ31 magnesium alloy. J. Mater. Eng. Perform. 2016, 25, 2635–2641. [Google Scholar] [CrossRef]

- Tricarico, L.; Spina, R. Experimental investigation of laser beam welding of explosion-welded steel/aluminum structural transition joints. Mater. Des. 2010, 31, 1981–1992. [Google Scholar] [CrossRef]

- Bataev, I.A.; Bataev, A.A.; Mali, V.I.; Pavliukova, D.V. Structural and mechanical properties of metallic-intermetallic laminate composites produced by explosive welding and annealing. Mater. Des. 2012, 35, 225–234. [Google Scholar] [CrossRef]

- Aceves, S.M.; Espinosa-Loza, F.; Elmer, J.W.; Huber, R. Comparison of Cu, Ti and ta interlayer explosively fabricated aluminum to stainless steel transition joints for cryogenic pressurized hydrogen storage. Int. J. Hydrogen Energ. 2015, 40, 1490–1503. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Gloc, M.; Wachowski, M.; Plocinski, T.; Kurzydlowski, K.J. Microstructural and microanalysis investigations of bond titanium grade1/low alloy steel st52-3N obtained by explosive welding. J. Alloys Compd. 2016, 671, 446–451. [Google Scholar] [CrossRef]

- Borchers, C.; Lenz, M.; Deutges, M.; Klein, H.; Gärtner, F.; Hammerschmidt, M.; Kreye, H. Microstructure and mechanical properties of medium-carbon steel bonded on low-carbon steel by explosive welding. Mater. Des. 2016, 89, 369–376. [Google Scholar] [CrossRef]

- Carvalho, G.H.S.F.L.; Mendes, R.; Leal, R.M.; Galvão, I.; Loureiro, A. Effect of the flyer material on the interface phenomena in aluminium and copper explosive welds. Mater. Des. 2017, 122, 172–183. [Google Scholar] [CrossRef]

- Akbari-Mousavi, S.A.A.; Barrett, L.M.; Al-Hassani, S.T.S. Explosive welding of metal plates. J. Mater. Process. Technol. 2008, 202, 224–239. [Google Scholar] [CrossRef]

- Amani, H.; Soltanieh, M. Intermetallic phase formation in explosively welded Al/Cu bimetals. Metall. Mater. Trans. B 2016, 47, 2524–2534. [Google Scholar] [CrossRef]

- Raghukandan, K. Analysis of the explosive cladding of Cu-low carbon steel plates. J. Mater. Process. Technol. 2003, 139, 573–577. [Google Scholar] [CrossRef]

- Rao, N.V.; Reddy, G.M.; Nagarjuna, S. Structure and properties of explosive clad hsla steel with titanium. Trans. Indian Inst. Metals 2014, 67, 67–77. [Google Scholar]

- Groschopp, J.; Heyne, V.; Hofmann, B. Explosively clad titanium steel composite. Weld. Int. 2010, 1, 879–883. [Google Scholar] [CrossRef]

- Malyutina, Y.N.; Skorohod, K.A.; Shevtsova, K.E.; Chesnokova, A.V. Multilayered titanium-steel composite produced by explosive welding. AIP Conf. Proc. 2015, 1683. [Google Scholar] [CrossRef]

- Nishida, M.; Chiba, A.; Honda, Y.; Hirazumi, J.I.; Horikiri, K. Electron microscopy studies of bonding interface in explosively welded Ti/steel clads. ISIJ Int. 1995, 35, 217–219. [Google Scholar] [CrossRef]

- Xie, M.X.; Zhang, L.J.; Zhang, G.F.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater. Des. 2015, 87, 181–197. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E.; Sili, A.M. Full-field analysis of Al/Fe explosive welded joints for shipbuilding applications. Mar. Struct. 2018, 57, 207–218. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Fricke, W.; Guglielmino, E. Low-Cycle Fatigue Life Prediction of Fillet-Welded Joints in Ship Details. In Proceedings of the 18th International Conference on Ships and Shipping Research, Bari, Italy, 22–24 June 2005; Ali, M., Esposito, F., Eds.; Springer: London, UK, 2015. [Google Scholar]

- Corigliano, P.; Crupi, V.; Fricke, W.; Friedrich, N.; Guglielmino, E. Experimental and numerical analysis of fillet-welded joints under low-cycle fatigue loading by means of full-field techniques. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1327–1338. [Google Scholar] [CrossRef]

- Crupi, V.; Guglielmino, E.; Sili, A.; Tata, M.E.; Costanza, G. Metallurgical characterization of an explosion welded aluminum/steel joint. La Metall. Italiana 2016, 11, 17–22. [Google Scholar]

- Sudha, C.; Prasanthi, T.N.; Paul, V.T.; Saroja, S.; Vijayalakshmi, M. Assessment of mechanical property of Ti-5Ta-2Nb and 304L SS explosive clad and correlation with microstructure. Procedia Eng. 2014, 86, 42–50. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.J.; Xie, M.X.; Yang, H.X.; Yin, X.Q.; Zhang, J.X. Microstructure and property inhomogeneity investigations of bonded Zr/Ti/steel trimetallic sheet fabricated by explosive welding. J. Alloys Compd. 2017, 698, 835–851. [Google Scholar] [CrossRef]

- Sudha, C.; Prasanthi, T.N.; Paul, V.T.; Saroja, S.; Vijayalakshmi, M. Metastable phase transformation in Ti-5Ta-2Nb alloy and 304L austenitic stainless steel under explosive cladding conditions. Metall. Mater. Trans. A 2012, 43, 3596–3607. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, C.; Murugesan, S.; Paul, V.T.; Saroja, S. Reverse transformation of deformation-induced phases and associated changes in the microstructure of explosively clad Ti-5Ta-2Nb and 304L SS. Metall. Mater. Trans. A 2015, 46, 4429–4435. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, C.; Parida, P.K.; Dasgupta, A.; Saroja, S. Prediction and confirmation of phases formed in the diffusion zone of Ti-5Ta-2Nb/304L SS explosive clads. Metall. Mater. Trans. A 2015, 46, 1519–1534. [Google Scholar] [CrossRef]

- Saksl, K.; Ostroushko, D.; Mazancová, E.; Szulc, Z.; Milkovič, O.; Ďurišin, M.; Balga, D.; Ďurišin, J.; Rütt, U.; Gutowski, O. Local structure of explosively welded titanium-stainless steel bimetal. Int. J. Mater. Res. 2015, 106, 621–627. [Google Scholar] [CrossRef]

- Somasundaram, S.; Krishnamurthy, R.; Kazuyuki, H. Effect of process parameters on microstructural and mechanical properties of Ti-SS 304L explosive cladding. J. Cent. South Univ. 2017, 24, 1245–1251. [Google Scholar] [CrossRef]

- Kurek, A.; Wachowski, M.; Niesłony, A.; Płociński, T.; Kurzydłowski, K.J. Fatigue tests and metallographic of explosively cladded steel-titanium bimetal. Arch. Metall. Mater. 2014, 59, 1565–1570. [Google Scholar] [CrossRef]

- Sudha, C.; Prasanthi, T.N.; Saroja, S.; Vijayalakshmi, M. Effect of heat treatment on the microstructure and microchemistry of explosive welded joints of Ti-5Ta-1.8Nb and 304L SS. Indian Weld. J. 2011, 44, 53–68. [Google Scholar] [CrossRef]

- Wachowski, M.; Gloc, M.; Ślęzak, T.; Płociński, T.; Kurzydłowski, K.J. The effect of heat treatment on the microstructure and properties of explosively welded titanium-steel plates. J. Mater. Eng. Perform. 2017, 26, 945–954. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; C. Sudha, R.; Saroja, S. Explosive cladding and post-weld heat treatment of mild steel and titanium. Mater. Des. 2016, 93, 180–193. [Google Scholar] [CrossRef]

- Zhao, G.; Huang, Q.; Zhou, C.; Yang, X.; Liu, G.; Lifeng, M.A. Investigation of hot rolling influence on the explosive-welded clad plate. Mater. Sci. 2016, 22, 486–490. [Google Scholar] [CrossRef]

- Karolczuk, A.; Kowalski, M.; Kluger, K.; Żok, F. Identification of residual stress phenomena based on the hole drilling method in explosively welded steel-titanium composite. Arch. Metall. Mater. 2014, 59, 1119–1123. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, C.; Saroja, S. Effect of alloying elements on interdiffusion phenomena in explosive clads of 304L SS/Ti-5Ta-2Nb alloy. J. Mater. Sci. 2016, 51, 5290–5304. [Google Scholar] [CrossRef]

- Jiang, H.; Yan, X.; Liu, J.; Zeng, S.; Duan, X. Diffusion behavior and mathematical model of ti-steel explosive clad plate during heat treatment. Rare Metal Mater. Eng. 2015, 44, 972–976. [Google Scholar]

- Zu, G.; Sun, X.; Zhang, J.; University, N. Interfacial bonding mechanism and mechanical performance of Ti/steel bimetallic clad sheet produced by explosive welding and annealing. Rare Rare Metal Mater. Eng. 2017, 46, 906–911. [Google Scholar]

- Chu, Q.; Zhang, M.; Li, J.; Yan, C. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding. Mater. Sci. Eng. A 2017, 689, 323–331. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Yu, H.; Zhao, F.; Wu, Z. Numerical simulation of Ti/Al bimetal composite fabricated by explosive welding. Metals 2017, 7, 407. [Google Scholar] [CrossRef]

- Chu, Q.L.; Zhang, M.; Li, J.H.; Jin, Q.; Fan, Q.Y.; Xie, W.W.; Luo, H.; Bi, Z.Y. Experimental investigation of explosion-welded CP-Ti/Q345 bimetallic sheet filled with Cu/V based flux-cored wire. Mater. Des. 2015, 67, 606–614. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.J.; Jiang, G.C.; Xie, M.X.; Yin, X.Q.; Zhang, J.X. Narrow gap multi-pass laser butt welding of explosion welded CP-Ti/Q235b bimetallic sheet by using a copper interlayer. J. Alloys Compd. 2017, 701, 587–602. [Google Scholar] [CrossRef]

- Bai, Q.L.; Zhang, L.J.; Xie, M.X.; Yang, H.X.; Zhang, J.X. An investigation into the inhomogeneity of the microstructure and mechanical properties of explosive welded H62-brass/Q235b-steel clad plates. Int. J. Adv. Manuf. Technol. 2016, 90, 1351–1363. [Google Scholar] [CrossRef]

- Jiang, H.T.; Kang, Q.; Yan, X.Q. A novel diffusion model considering curvature radius at the bonding interface in a titanium/steel explosive clad plate. Int. J. Min. Metall. Mater. 2015, 22, 956–965. [Google Scholar] [CrossRef]

- Acarer, M.; Gülenç, B.; Findik, F. The influence of some factors on steel/steel bonding quality on there characteristics of explosive welding joints. J. Mater. Sci. 2004, 39, 6457–6466. [Google Scholar] [CrossRef]

- Bataev, I.A.; Bataev, A.A.; Mali, V.I.; Burov, V.G.; Prikhod’Ko, E.A. Formation and structure of vortex zones arising upon explosion welding of carbon steels. Phys. Met. Metallogr. 2012, 113, 233–240. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.A.; Sartangi, P.F. Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater. Des. 2009, 30, 459–468. [Google Scholar] [CrossRef]

- Song, J.; Kostka, A.; Veehmayer, M.; Raabe, D. Hierarchical microstructure of explosive joints: Example of titanium to steel cladding. Mater. Sci. Eng. A 2011, 528, 2641–2647. [Google Scholar] [CrossRef]

- Raghukandan, K.; Rathinasabapathi, M.; Vaidyanathan, P.V.; Balasubramanian, V. An experimental investigation on the effect of h/D ratio on dynamic form—Cladding of domes. J. Mater. Process. Technol. 1997, 63, 55–59. [Google Scholar] [CrossRef]

- Zhang, L.J.; Pei, Q.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Study on the microstructure and mechanical properties of explosive welded 2205/X65 bimetallic sheet. Mater. Des. 2014, 64, 462–476. [Google Scholar] [CrossRef]

- Chiba, A.; Nishida, M.; Morizono, Y.; Imamura, K. Bonding characteristics and diffusion barrier effect of the tic phase formed at the bonding interface in an explosively welded titanium/high-carbon steel clad. J. Phase Equilibria 1995, 16, 411–415. [Google Scholar] [CrossRef]

- Bazarnik, P.; Adamczyk-Cieślak, B.; Gałka, A.; Płonka, B.; Snieżek, L.; Cantoni, M.; Lewandowska, M. Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater. Des. 2016, 111, 146–157. [Google Scholar] [CrossRef]

- Rao, N.V.; Sarma, D.S.; Nagarjuna, S.; Reddy, G.M. Influence of hot rolling and heat treatment on structure and properties of hsla steel explosively clad with austenitic stainless steel. Metal Sci. J. 2009, 25, 1387–1396. [Google Scholar] [CrossRef]

| Elements | C | Si | N | H | O | Fe | Ti |

|---|---|---|---|---|---|---|---|

| Content | ≤0.05 | ≤0.1 | ≤0.03 | ≤0.015 | ≤0.15 | ≤0.15 | Balance |

| Elements | C | Si | Mn | Ni | Cr | Cu | Mo | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0.053 | 0.33 | 1.18 | 0.16 | 0.07 | 0.14 | 0.06 | 0.031 | 0.016 | ≤0.005 | Balance |

| 90° | 0° | |

|---|---|---|

| TA1 adjacent to TA1/X65 interface | T1-1a, T1-1b, T1-1c | T1-2a, T1-2b, T1-2c |

| Region including TA1/X65 interface | T2-1a, T2-1b, T2-1c | T2-2a, T2-2b, T2-2c |

| X65 adjacent to TA1/X65 interface | T3-1a, T3-1b, T3-1c | T3-2a, T3-2b, T3-2c |

| Angles between Shear Direction and Detonation Wave Propagation Direction | 0° | 90° | 180° |

|---|---|---|---|

| Sample numbers | 0-B1, 0-B2, 0-B3 | 90-A1, 90-A2, 90-A3 | 180-C1, 180-C2, 180-C3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.-X.; Shang, X.-T.; Zhang, L.-J.; Bai, Q.-L.; Xu, T.-T. Interface Characteristic of Explosive-Welded and Hot-Rolled TA1/X65 Bimetallic Plate. Metals 2018, 8, 159. https://doi.org/10.3390/met8030159

Xie M-X, Shang X-T, Zhang L-J, Bai Q-L, Xu T-T. Interface Characteristic of Explosive-Welded and Hot-Rolled TA1/X65 Bimetallic Plate. Metals. 2018; 8(3):159. https://doi.org/10.3390/met8030159

Chicago/Turabian StyleXie, Miao-Xia, Xiang-Tao Shang, Lin-Jie Zhang, Qing-Lin Bai, and Ting-Ting Xu. 2018. "Interface Characteristic of Explosive-Welded and Hot-Rolled TA1/X65 Bimetallic Plate" Metals 8, no. 3: 159. https://doi.org/10.3390/met8030159