Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Base Materials and Welding Conditions

2.2. Characterisation Methods

3. Results and Discussion

3.1. Position of the Materials

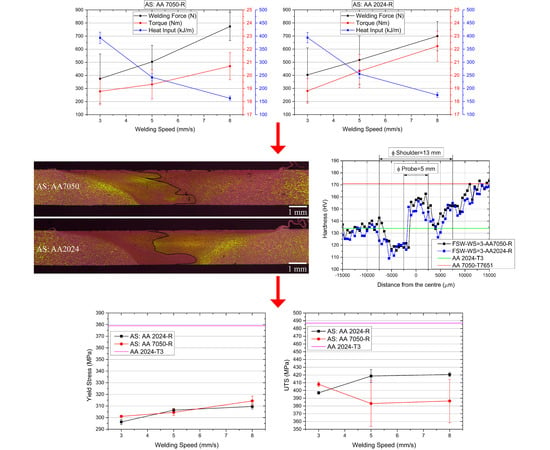

3.1.1. Process Analysis

3.1.2. Microstructural Analysis

3.1.3. Microhardness Analysis

3.1.4. Mechanical Characterisation

3.2. Direction of the Materials

3.2.1. Process Analysis

3.2.2. Microstructural Analysis

3.2.3. Microhardness Analysis

3.2.4. Mechanical Characterisation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, G.; Shi, G.; Bellinger, N.C. 6—Assessing the riveting process and the quality of riveted joints in aerospace and other applications A2—Chaturvedi, M.C. In Welding and Joining of Aerospace Materials; Woodhead Publishing: Sawston, UK, 2012; pp. 181–214. [Google Scholar]

- Kwakernaak, A.; Hofstede, J.; Poulis, J.; Benedictus, R. 8—Improvements in bonding metals for aerospace and other applications A2—Chaturvedi, M.C. In Welding and Joining of Aerospace Materials; Woodhead Publishing: Sawston, UK, 2012; pp. 235–287. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Improvements to Friction Welding. Patent EP 065,326,5A2, 6 December 1991. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Sheikhi, S.; dos Santos, J.F.; Bolfarini, C. Preliminary study on the microstructure and mechanical properties of dissimilar friction stir welds in aircraft aluminium alloys 2024-T351 and 6056-T4. J. Mater. Process. Technol. 2008, 206, 132–142. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B 2008, 148, 82–87. [Google Scholar] [CrossRef]

- Da Silva, A.A.M.; Arruti, E.; Janeiro, G.; Aldanondo, E.; Alvarez, P.; Echeverria, A. Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 aluminium alloys friction stir welds. Mater. Des. 2011, 32, 2021–2027. [Google Scholar] [CrossRef]

- Barbini, A.; Carstensen, J.; dos Santos, J.F. Influence of a non-rotating shoulder on heat generation, microstructure and mechanical properties of dissimilar AA2024/AA7050 FSW joints. J. Mater. Sci. Technol. 2018, 34, 119–127. [Google Scholar] [CrossRef]

- Fuller, C.B.; Mahoney, M.W.; Calabrese, M.; Micona, L. Evolution of microstructure and mechanical properties in naturally aged 7050 and 7075 Al friction stir welds. Mater. Sci. Eng. A 2010, 527, 2233–2240. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, T.; Zhou, W.L.; Li, Z.Y.; Huang, Y.X.; Feng, J.C. Microstructural characteristics and mechanical properties of 7050-T7451 aluminum alloy friction stir-welded joints. J. Mater. Eng. Perform. 2016, 25, 2542–2550. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Genevois, C.; Fabrègue, D.; Deschamps, A.; Poole, W.J. On the coupling between precipitation and plastic deformation in relation with friction stir welding of AA2024 T3 aluminium alloy. Mater. Sci. Eng. A 2006, 441, 39–48. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yang, B.; Reynolds, A.P.; Taylor, R. Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater. Sci. Eng. A 2002, 323, 160–166. [Google Scholar] [CrossRef]

- Bousquet, E.; Poulon-Quintin, A.; Puiggali, M.; Devos, O.; Touzet, M. Relationship between microstructure, microhardness and corrosion sensitivity of an AA 2024-T3 friction stir welded joint. Corros. Sci. 2011, 53, 3026–3034. [Google Scholar] [CrossRef]

- Carlone, P.; Palazzo, G.S. Influence of process parameters on microstructure and mechanical properties in AA2024-T3 friction stir welding. Metallogr. Microstruct. Anal. 2013, 2, 213–222. [Google Scholar] [CrossRef]

- Khandkar, M.Z.H.; Khan, J.A.; Reynolds, A.P. Prediction of temperature distribution and thermal history during friction stir welding: Input torque based model. Sci. Technol. Weld. Join. 2003, 8, 165–174. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Tongne, A.; Desrayaud, C.; Jahazi, M.; Feulvarch, E. On material flow in friction stir welded Al alloys. J. Mater. Process. Technol. 2017, 239, 284–296. [Google Scholar] [CrossRef]

- Cui, S.; Chen, Z.W.; Robson, J.D. A model relating tool torque and its associated power and specific energy to rotation and forward speeds during friction stir welding/processing. Int. J. Mach. Tools Manuf. 2010, 50, 1023–1030. [Google Scholar] [CrossRef]

- Chen, Z.W.; Pasang, T.; Qi, Y. Shear flow and formation of nugget zone during friction stir welding of aluminium alloy 5083-O. Mater. Sci. Eng. A 2008, 474, 312–316. [Google Scholar] [CrossRef]

- Arbegast, W.J. A flow-partitioned deformation zone model for defect formation during friction stir welding. Scr. Mater. 2008, 58, 372–376. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Hardness recovery mechanism in the heat-affected zone during long-term natural aging and its influence on the mechanical properties and fracture behavior of friction stir welded 2024Al–T351 joints. Acta Mater. 2014, 73, 227–239. [Google Scholar] [CrossRef]

- Tabor, D. The physical meaning of indentation and scratch hardness. Br. J. Appl. Phys. 1956, 7, 159. [Google Scholar] [CrossRef]

| Mechanical Properties of AA 2024-T3 | |||||||

|---|---|---|---|---|---|---|---|

| Hardness, Vickers | Yield Strength (MPa) | Tensile Strength (UTS) (MPa) | Elongation at Break (%) | ||||

| 134 | L | T | D | L | T | D | 20.15 |

| 379 | 319 | 325 | 487 | 474 | 468 | ||

| Mechanical properties of AA 7050-T7651 | |||

|---|---|---|---|

| Hardness, Vickers | Yield Strength (MPa) | UTS (MPa) | Elongation at Break (%) |

| 171 | 490 | 552 | 11 |

| Specimen ID | Welding Speed (mm/s) | Material in the Advancing Side (AS) | Direction of the Materials with Respect to the Welding Direction |

|---|---|---|---|

| FSW-WS = 3-AA2024-R | 3 | AA2024-T3 | Rolling |

| FSW-WS = 3-AA7050-R | 3 | AA7050-T7651 | Rolling |

| FSW-WS = 3-AA2024-P | 3 | AA2024-T3 | Perpendicular |

| FSW-WS = 3-AA7050-P | 3 | AA7050-T7651 | Perpendicular |

| FSW-WS = 5-AA2024-R | 5 | AA2024-T3 | Rolling |

| FSW-WS = 5-AA7050-R | 5 | AA7050-T7651 | Rolling |

| FSW-WS = 5-AA2024-P | 5 | AA2024-T3 | Perpendicular |

| FSW-WS = 5-AA7050-P | 5 | AA7050-T7651 | Perpendicular |

| FSW-WS = 8-AA2024-R | 8 | AA2024-T3 | Rolling |

| FSW-WS = 8-AA7050-R | 8 | AA7050-T7651 | Rolling |

| FSW-WS = 8-AA2024-P | 8 | AA2024-T3 | Perpendicular |

| FSW-WS = 8-AA7050-P | 8 | AA7050-T7651 | Perpendicular |

| Specimen ID | Bending Test Results | |

|---|---|---|

| Begin of the Weld | End of the Weld | |

| FSW-WS = 3-AA2024-R | V | V |

| FSW-WS = 3-AA7050-R | V | X |

| FSW-WS = 5-AA2024-R | V | V |

| FSW-WS = 5-AA7050-R | X | X |

| FSW-WS = 8-AA2024-R | V | V |

| FSW-WS = 8-AA7050-R | X | X |

| Specimen ID | Fracture Location |

|---|---|

| FSW-WS = 3-AA2024-R | AS-TMAZ |

| FSW-WS = 3-AA7050-R | RS-TMAZ |

| FSW-WS = 5-AA2024-R | AS-TMAZ |

| FSW-WS = 5-AA7050-R | SZ |

| FSW-WS = 8-AA2024-R | AS-TMAZ |

| FSW-WS = 8-AA7050-R | SZ |

| Specimen ID | Bending Test Results | |

|---|---|---|

| Begin of the Weld | End of the Weld | |

| FSW-WS = 3-AA2024-R | V | V |

| FSW-WS = 3-AA2024-P | V | X |

| FSW-WS = 5-AA2024-R | V | V |

| FSW-WS = 5-AA2024-P | V | X |

| FSW-WS = 8-AA2024-R | V | V |

| FSW-WS = 8-AA2024-P | X | X |

| Specimen ID | Fracture Location |

|---|---|

| FSW-WS = 3-AA2024-R | AS-TMAZ |

| FSW-WS = 3-AA2024-P | SZ |

| FSW-WS = 3-AA7050-P | SZ |

| FSW-WS = 5-AA2024-R | AS-TMAZ |

| FSW-WS = 5-AA2024-P | AS-TMAZ |

| FSW-WS = 5-AA7050-P | RS-TMAZ |

| FSW-WS = 8-AA2024-R | AS-TMAZ |

| FSW-WS = 8-AA2024-P | AS-TMAZ |

| FSW-WS = 8-AA7050-P | SZ |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbini, A.; Carstensen, J.; Dos Santos, J.F. Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding. Metals 2018, 8, 202. https://doi.org/10.3390/met8040202

Barbini A, Carstensen J, Dos Santos JF. Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding. Metals. 2018; 8(4):202. https://doi.org/10.3390/met8040202

Chicago/Turabian StyleBarbini, Alessandro, Jan Carstensen, and Jorge F. Dos Santos. 2018. "Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding" Metals 8, no. 4: 202. https://doi.org/10.3390/met8040202

APA StyleBarbini, A., Carstensen, J., & Dos Santos, J. F. (2018). Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding. Metals, 8(4), 202. https://doi.org/10.3390/met8040202