Modeling Bake Hardening Effects in Steel Sheets—Application to Dent Resistance

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Tensile Tests and Thermal Treatment

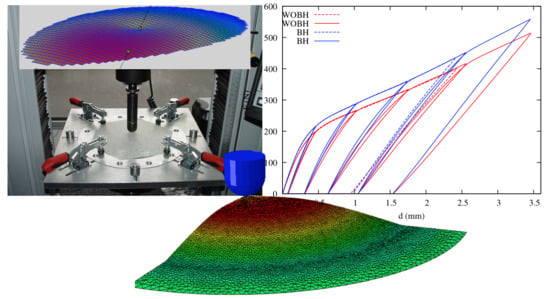

2.2. Dent Resistance

2.2.1. Pre-Strain

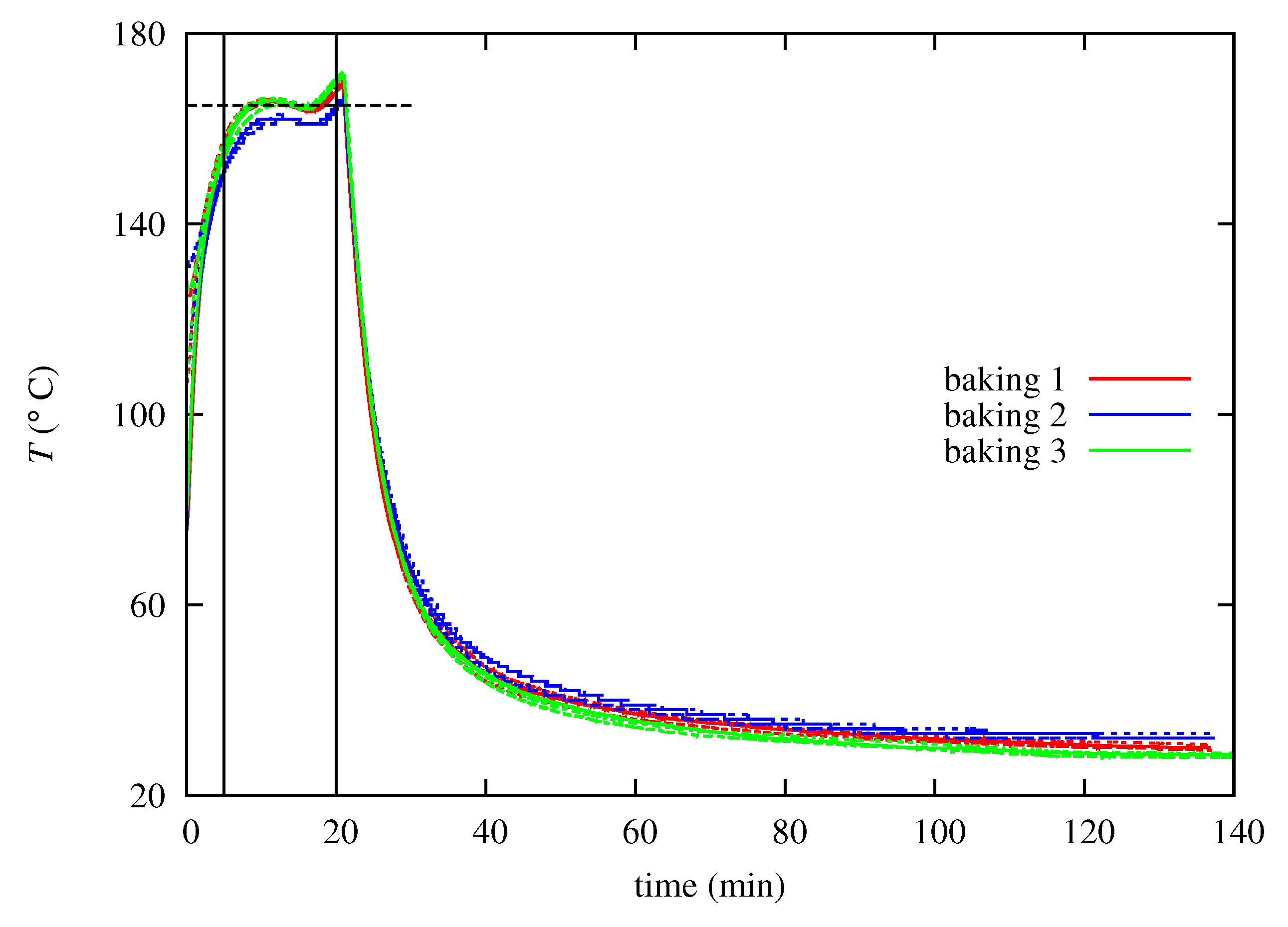

2.2.2. Heat Treatment

2.2.3. Dent Tests

3. Experimental Results

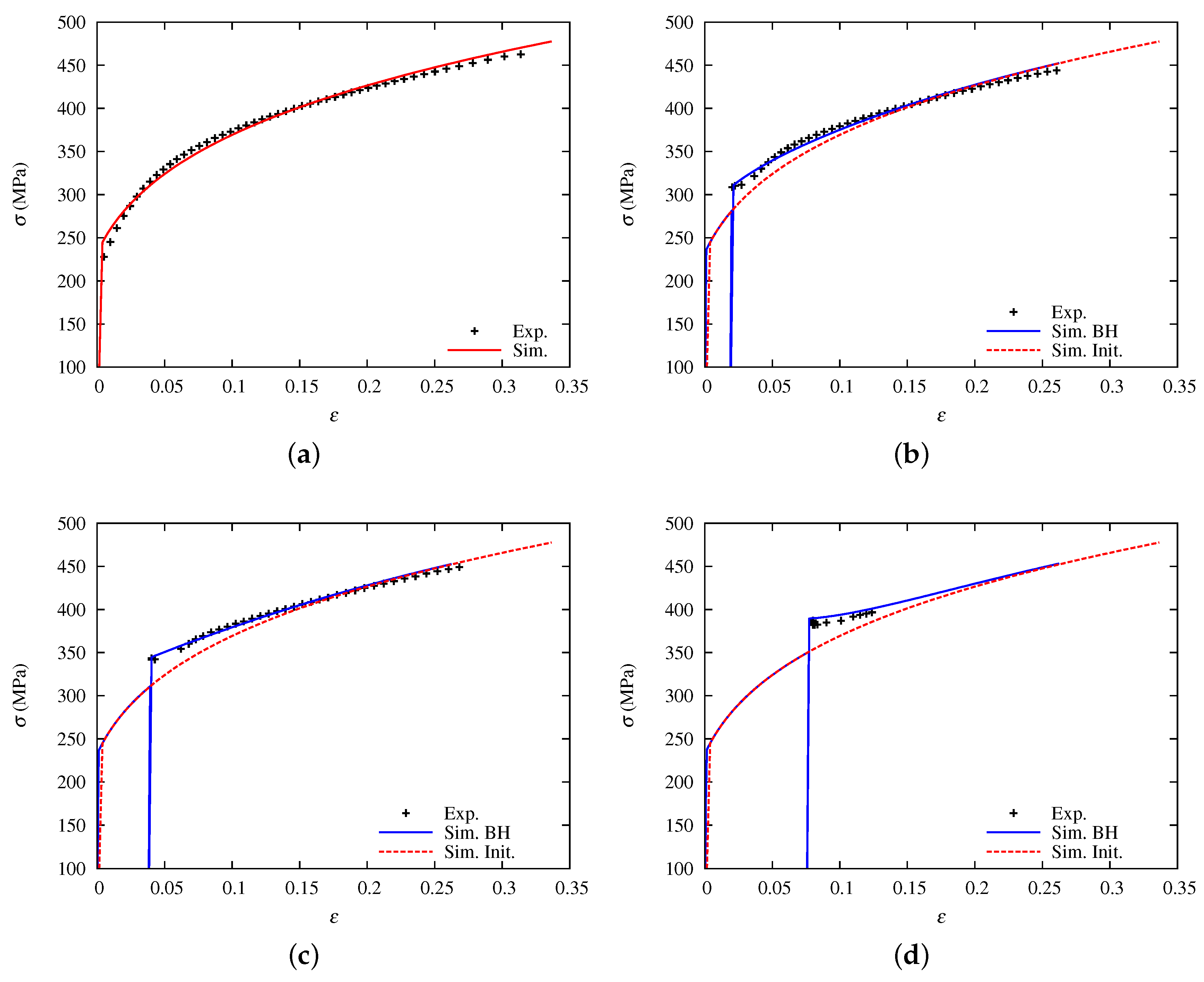

3.1. Mechanical Behavior in Tension

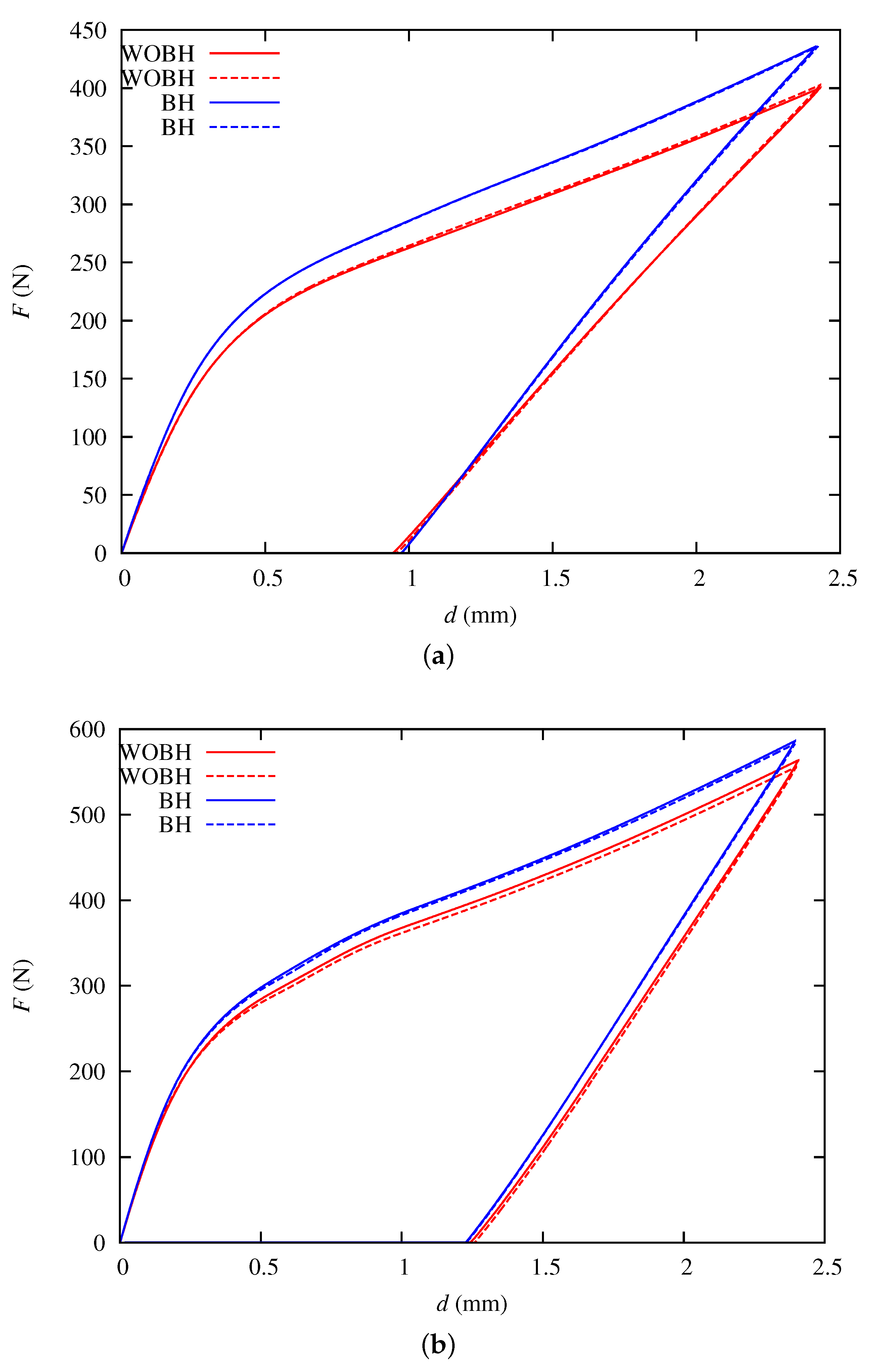

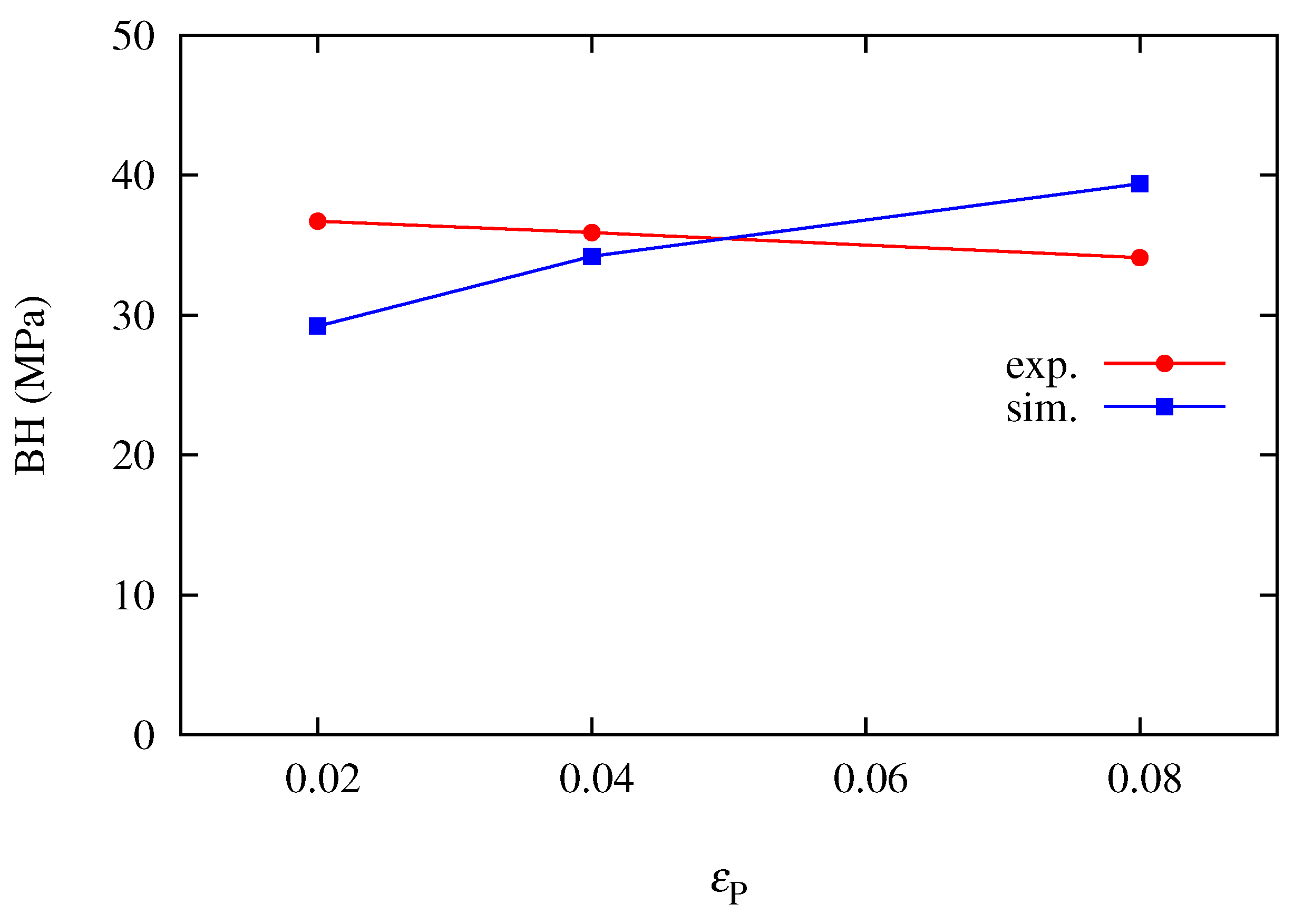

3.2. Dent Resistance of Bulged Specimen

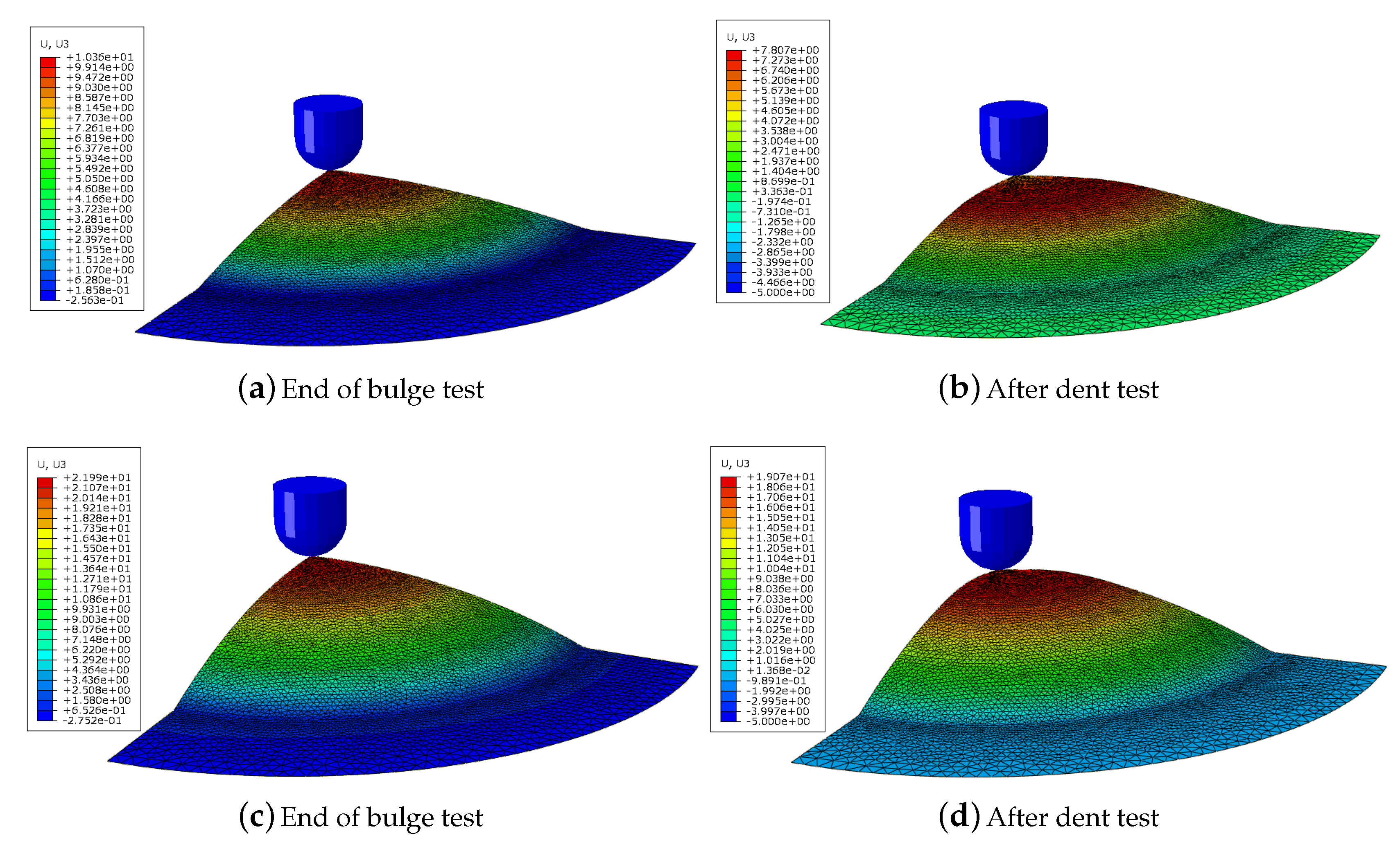

4. Numerical Simulation of the Multi-Step Process

4.1. BH Modeling and Material Parameter Identification

4.2. Numerical Simulation of the Dent Test

4.3. Sensitivity of Dent Resistance to BH Effect

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asnafi, N. On strength, stiffness and dent resistance of car body panels. J. Mater. Process. Technol. 1995, 49, 13–31. [Google Scholar] [CrossRef]

- Ekstrand, G.; Asnafi, N. On testing of the stiffness and the dent resistance of autobody panels. Mater. Des. 1998, 19, 145–156. [Google Scholar] [CrossRef]

- Holmberg, S.; Thilderkvist, P. Influence of material properties and stamping conditions on the stiffness and static dent resistance of automotive panels. Mater. Des. 2002, 23, 681–691. [Google Scholar] [CrossRef]

- Holmberg, S.; Nejabat, B. Numerical assessment of stiffness and dent properties of automotive exterior panels. Mater. Des. 2004, 25, 361–368. [Google Scholar] [CrossRef]

- Shen, H.; Li, S.; Chen, Q. Numerical analysis of panels’ dent resistance considering the Bauschinger effect. Mater. Des. 2010, 31, 870–876. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, M.G.; Barlat, F.; Chung, K.H.; Kim, D.J. Effect of nonlinear multi-axial elasticity and anisotropic plasticity on quasi-static dent properties of automotive steel sheets. Int. J. Solids Struct. 2016, 87, 254–266. [Google Scholar]

- Kvackaj, T.; Mamuzic, I. Development of bake hardening effect by plastic deformation and annealing conditions. Metallurgija 2006, 45, 51–55. [Google Scholar]

- De, A.K.; Vandeputte, S.; De Cooman, B.C. Static strain aging behavior of ultra low carbon bake hardening steel. Metall. Mater. Trans. A 1999, 41, 831–837. [Google Scholar] [CrossRef]

- Kuang, C.F.; Li, J.; Zhang, S.G.; Wang, J.; Liu, H.F.; Volinsky, A.A. Effects of quenching and tempering on the microstructure and bake hardening behavior of ferrite and dual phase steels. Mater. Sci. Eng. A 2014, 613, 178–183. [Google Scholar] [CrossRef]

- Ormsuptave, N.; Uthaisangsuk, V. Modeling of bake-hardening effect for fine grain bainite-aided dual phase steel. Mater. Des. 2017, 118, 314–329. [Google Scholar] [CrossRef]

- Ramazani, A.; Bruehl, S.; Gerber, T.; Bleck, W.; Prahl, U. Quantification of bake hardening effect in DP600 and TRIP700 steels. Mater. Des. 2014, 57, 479–486. [Google Scholar] [CrossRef]

- Sha, M.H.; Shi, G.D.; Wang, Y.; Qiao, J. Paint-bake response of AZ80 and AZ31 Mg alloys. Trans. Nonferrous Met. Soc. China 2010, 20, 571–575. [Google Scholar] [CrossRef]

- Berbenni, S.; Favier, V.; Lemoine, X.; Berveiller, M. A micromechanical approach to model the bake hardening effect for low carbon steels. Scr. Mater. 2004, 51, 303–308. [Google Scholar] [CrossRef]

- Vasilyev, A.A.; Lee, H.C.; Kuzmin, N.L. Nature of strain aging stages in bake hardening steel for automotive application. Mater. Sci. Eng. A 2008, 485, 282–289. [Google Scholar] [CrossRef]

- Woo, C.J. Effect of Prestrain on Aging and Bake Hardening of Cold-Rolled, Continuously Annealed Steel Sheets. Metall. Mater. Trans. A 1998, 29, 463–467. [Google Scholar]

- Kilic, S.; Ozturk, F.; Sigirtmac, T.; Tekin, G. Effects of Pre-strain and Temperature on Bake Hardening of TWIP900cr Steel. Int. J. Iron Steel Res. 2015, 22, 361–365. [Google Scholar] [CrossRef]

- Ballarin, V.; Soler, M.; Perlade, A.; Lemoine, X.; Forest, S. Mechanisms and Modeling of Bake-Hardening Steels: Part I. Metall. Mater. Trans. A 2009, 40, 1367–1374. [Google Scholar] [CrossRef]

- Ballarin, V.; Perlade, A.; Lemoine, X.; Bouaziz, O.; Forest, S. Mechanisms and Modeling of Bake-Hardening Steels: Part II. Complex Loading Paths. Metall. Mater. Trans. A 2009, 40, 1375–1382. [Google Scholar] [CrossRef]

- Dehghani, K.; Shafiei, A. Predicting the bake hardenability of steels using neural network modeling. Mater. Lett. 2008, 62, 173–178. [Google Scholar]

- Dehghani, K.; Nekahi, A. Artificial neural network to predict the effect of thermomechanical treatments on bake hardenability of low carbon steels. Mater. Des. 2010, 31, 2224–2229. [Google Scholar]

- Nekahi, A.; Dehghani, K. Modeling the thermomechanical effects on baking behavior of low carbon steels using response surface methodology. Mater. Des. 2010, 31, 3845–3851. [Google Scholar] [CrossRef]

- Thuillier, S.; Manach, P.Y. Comparison of the work-hardening of metallic sheets using tensile and shear strain paths. Int. J. Plast. 2009, 25, 733–751. [Google Scholar] [CrossRef]

- Zang, S.L.; Thuillier, S.; Le Port, A.; Manach, P.Y. Prediction of anisotropy and hardening for metallic sheets in tension, simple shear and biaxial tension. Int. J. Mech. Sci. 2011, 53, 338–347. [Google Scholar] [CrossRef]

- Zang, S.; Lee, M.G.; Sun, L.; Kim, J.H. Measurement of the bauschinger behavior of sheet metals by three-point bending springback test with pre-strained strips. Int. J. Plast. 2014, 59, 84–107. [Google Scholar] [CrossRef]

- Morestin, F.; Boivin, M. On the necessity of taking into account the variation in the Young modulus with plastic strain in elastic-plastic software. Nucl. Eng. Des. 1996, 162, 107–116. [Google Scholar] [CrossRef]

- Jung, J.; Jun, S.; Lee, H.S.; Kim, B.M.; Lee, M.G.; Kim, J.K. Anisotropic Hardening Behaviour and Springback of Advanced High-Strength Steels. Metals 2017, 7, 480. [Google Scholar] [CrossRef]

- Seo, K.Y.; Kim, J.H.; Lee, H.S.; Kim, J.H.; Kim, B.M. Effect of Constitutive Equations on Springback Prediction Accuracy in the TRIP1180 Cold Stamping. Metals 2018, 8, 18. [Google Scholar] [CrossRef]

| (MPa) | (MPa) | ||

|---|---|---|---|

| 220 | 350 | 1.75 | 0.66 |

| E (MPa) | (MPa) | K (MPa) | n | (MPa) | ||

|---|---|---|---|---|---|---|

| 219,700 | 0.29 | 235.9 | 607.7 | 0.23 | 21.5 | 22.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thuillier, S.; Zang, S.-L.; Troufflard, J.; Manach, P.-Y.; Jegat, A. Modeling Bake Hardening Effects in Steel Sheets—Application to Dent Resistance. Metals 2018, 8, 594. https://doi.org/10.3390/met8080594

Thuillier S, Zang S-L, Troufflard J, Manach P-Y, Jegat A. Modeling Bake Hardening Effects in Steel Sheets—Application to Dent Resistance. Metals. 2018; 8(8):594. https://doi.org/10.3390/met8080594

Chicago/Turabian StyleThuillier, Sandrine, Shun-Lai Zang, Julien Troufflard, Pierre-Yves Manach, and Anthony Jegat. 2018. "Modeling Bake Hardening Effects in Steel Sheets—Application to Dent Resistance" Metals 8, no. 8: 594. https://doi.org/10.3390/met8080594