Effect of Deformation Temperature on the Portevin-Le Chatelier Effect in Medium-Mn Steel

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

2.2. Thermomechanical Rolling

2.3. Experimental Procedures

3. Results

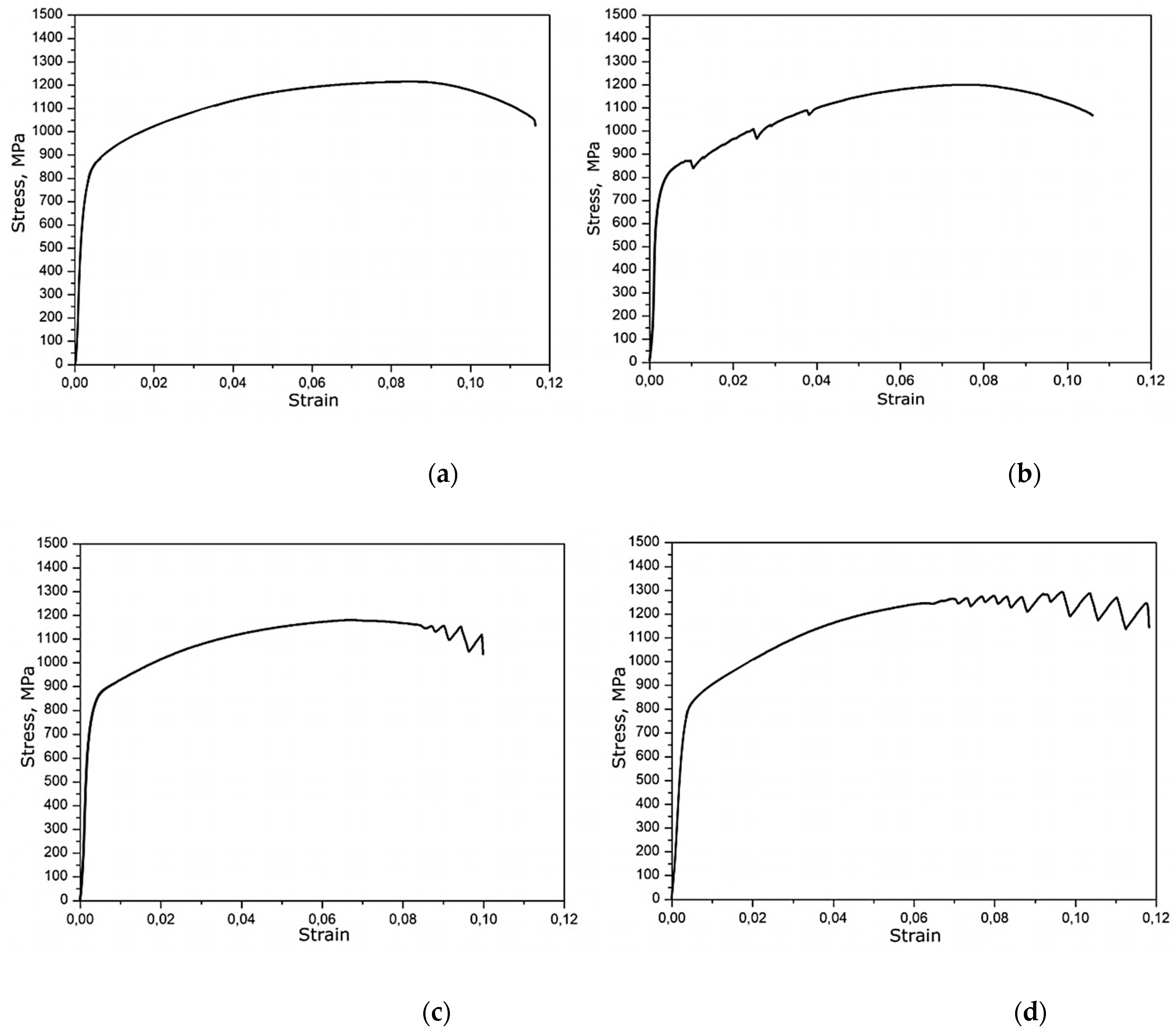

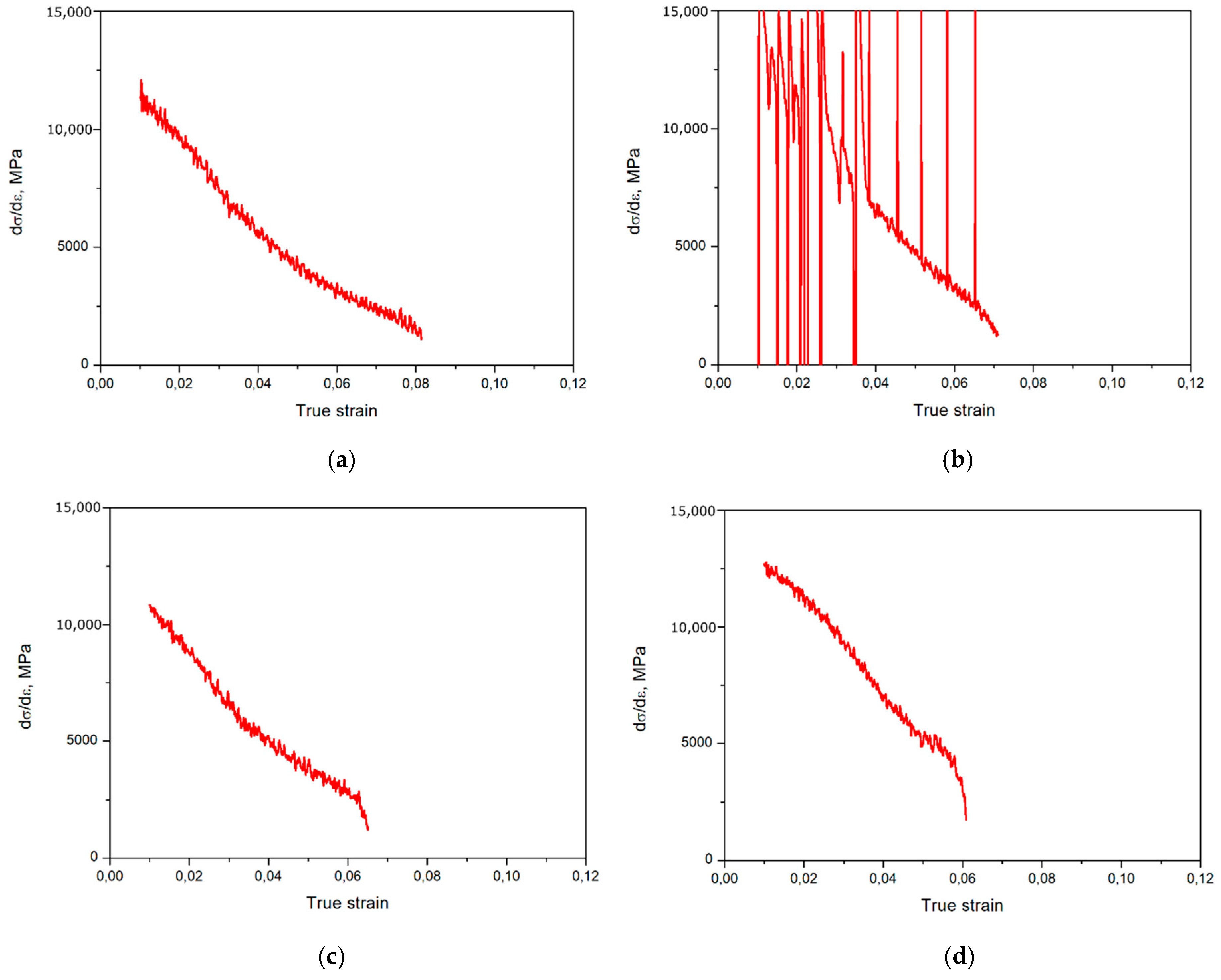

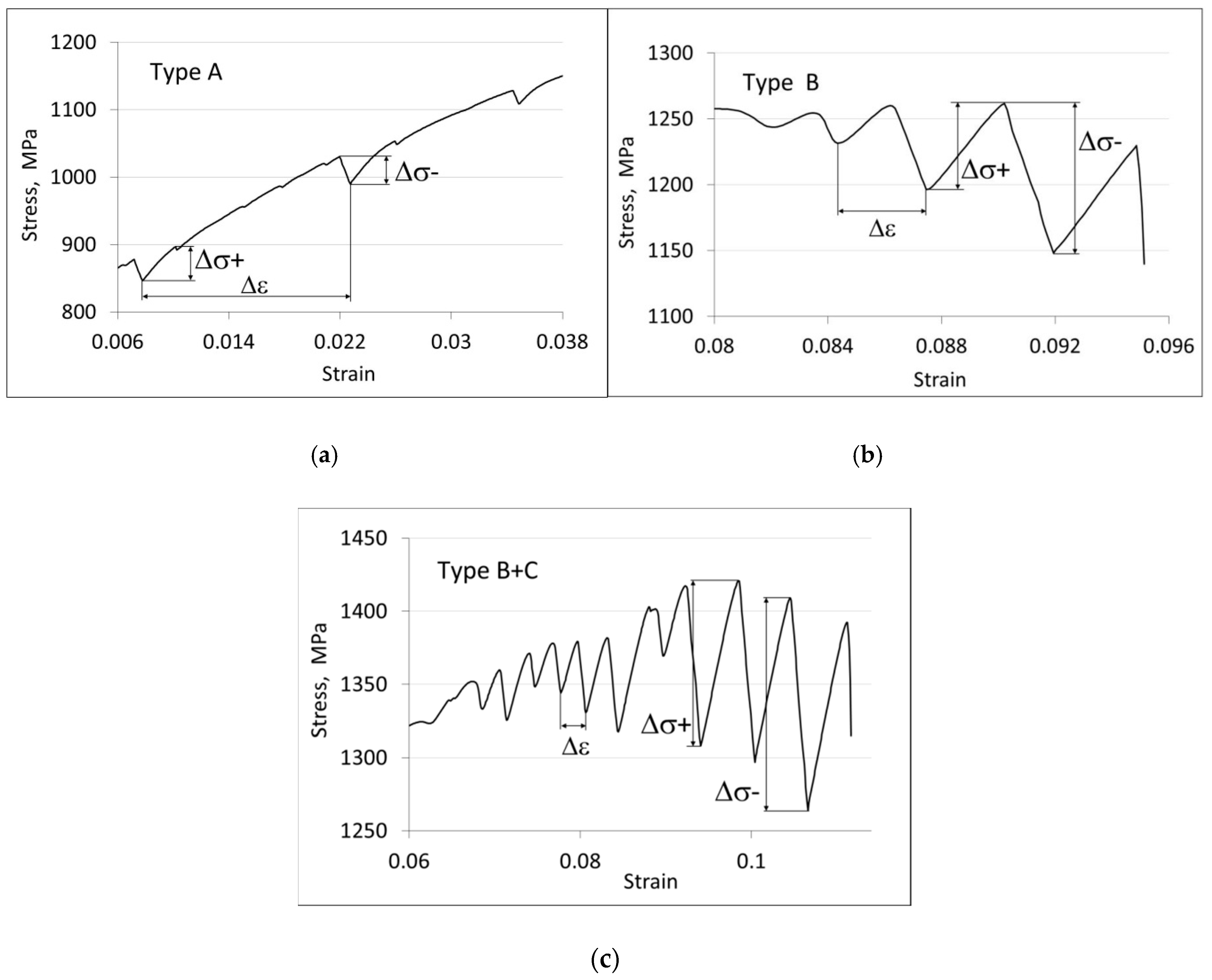

3.1. Mechanical Behavior

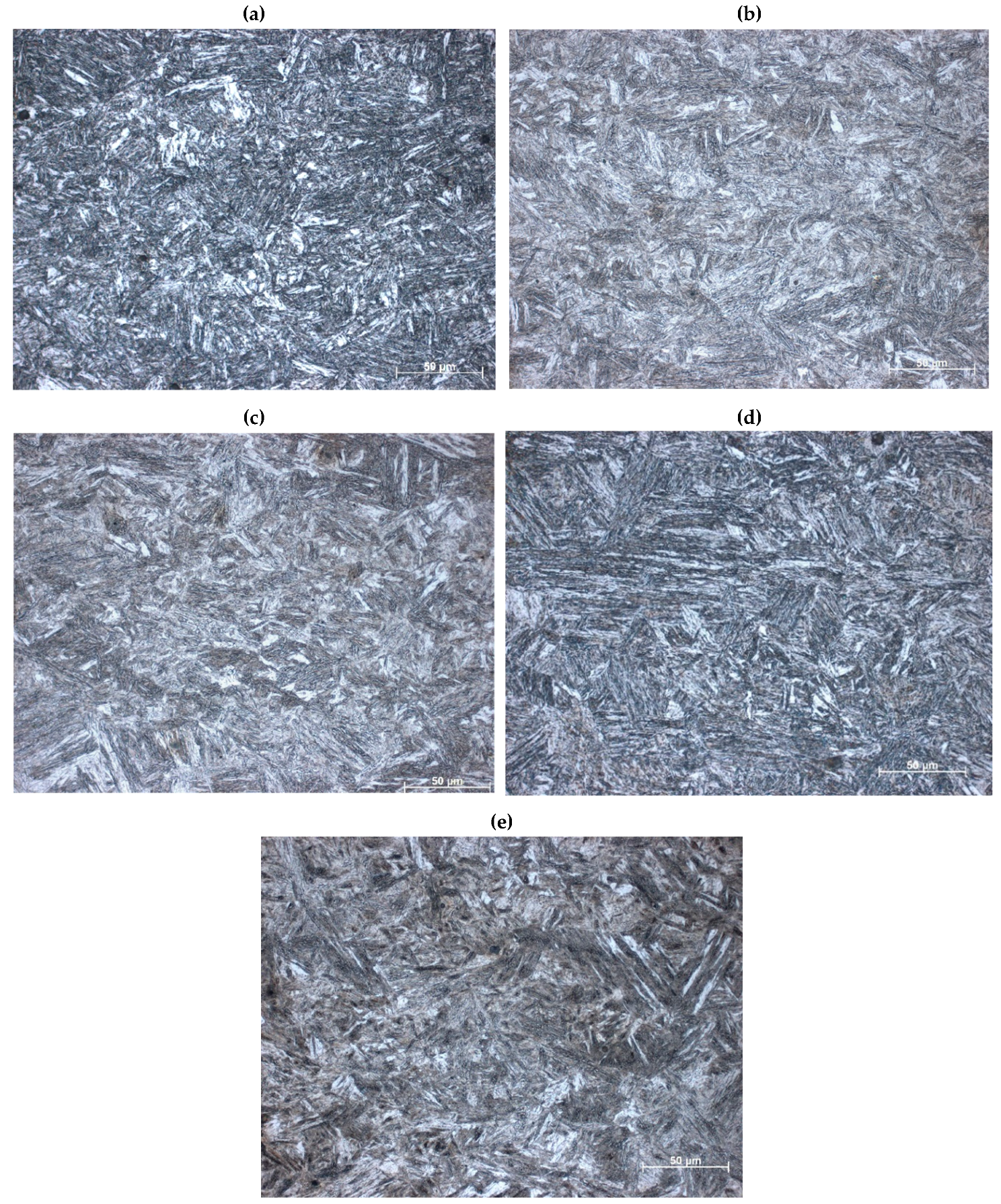

3.2. Microstructure

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Impact toughness of medium-Mn transformation-induced plasticity-aided steels. Steel Res. Int. 2015, 86, 1151–1160. [Google Scholar] [CrossRef]

- Steineder, K.; Krizan, D.; Schneider, R.; Beal, C.; Sommitsch, C. On the microstructural characteristics influencing the yielding behavior of ultra-fine grained medium-Mn steels. Acta Mater. 2017, 139, 39–50. [Google Scholar] [CrossRef]

- Marcisz, J.; Stępień, J. Short-time ageing of MS350 maraging steel with and without plastic deformation. Arch. Metall. Mater. 2014, 59, 513–520. [Google Scholar] [CrossRef]

- Grajcar, A.; Radwanski, K. Microstructural comparison of the thermomechanically treated and cold deformed Nb-microalloyed TRIP steel. Mater. Tehnol. 2014, 48, 679–683. [Google Scholar]

- Li, X.; Song, R.; Zhou, N.; Li, J. An ultrahigh strength and enhanced ductility cold-rolled medium-Mn steel treated by intercritical annealing. Scr. Mater. 2018, 154, 30–33. [Google Scholar] [CrossRef]

- Li, Z.C.; Ding, H.; Cai, Z.H. Mechanical properties and austenite stability in hot-rolled 0.2C–1.6/3.2Al–6Mn–Fe TRIP steel. Mater. Sci. Eng. A 2015, 639, 559–566. [Google Scholar] [CrossRef]

- Mishra, G.; Chandan, A.K.; Kundu, S. Hot rolled and cold rolled medium manganese steel: Mechanical properties and microstructure. Mater. Sci. Eng. A 2017, 701, 319–327. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Kozłowska, A. Microstructure-property relationships in thermomechanically processed medium-Mn steels with increased Al content. Metals 2018, 8. [Google Scholar] [CrossRef]

- Opiela, M. Thermomechanical treatment of Ti-Nb-V-B micro-alloyed steel forgings. Mater. Tehnol. 2014, 48, 587–591. [Google Scholar]

- Steineder, K.; Beal, C.; Krizan, D.; Dikovits, M.; Sommitsch, C.; Schneider, R. Hot deformation behavior of a 3rd generation advanced high strength steel with a medium-Mn content. Key Eng. Mater. 2015, 651–653, 120–125. [Google Scholar] [CrossRef]

- Opiela, M.; Grajcar, A. Hot deformation behavior and softening kinetics of Ti-V-B microalloyed steels. Arch. Civil Mechan. Eng. 2012, 12, 327–333. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hidaka, S.; Tanino, H.; Kobayashi, J. Warm Formability of 0.2 Pct C-1.5 Pct Si-5 Pct Mn Transformation-Induced Plasticity-aided steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 2237–2246. [Google Scholar] [CrossRef]

- Chiang, J.; Lawrence, B.; Boyd, J.D.; Pilkey, A.K. Effect of microstructure on retained austenite stability and work hardening of TRIP steels. Mater. Sci. Eng. A 2011, 528, 4516–4521. [Google Scholar] [CrossRef]

- Callahan, M.; Hubert, O.; Hild, F.; Perlade, A.; Schmitt, J.H. Coincidence of strain-induced TRIP and propagative PLC bands in medium Mn steels. Mater. Sci. Eng. A 2017, 703, 391–400. [Google Scholar] [CrossRef]

- Sun, B.; Vanderesse, N.; Fazeli, F.; Scott, C.; Chen, J.; Bocher, P.; Jahazi, M.; Yue, S. Discontinuous strain-induced martensite transformation related to the Portevin-Le Chatelier effect in a medium manganese steel. Scr. Mater. 2017, 133, 9–13. [Google Scholar] [CrossRef]

- Yang, F.; Luo, H.; Pu, E.; Zhang, S.; Dong, H. On the characteristics of Portevin–Le Chatelier bands in cold-rolled 7Mn steel showing transformation-induced plasticity. Int. J. Plast. 2018, 103, 188–202. [Google Scholar] [CrossRef]

- Wang, X.G.; Wang, L.; Huang, M.X. Kinematic and thermal characteristics of Luders and Portevin-Le Chatelier bands in a medium Mn transformation-induced plasticity steel. Acta Mater. 2017, 124, 17–29. [Google Scholar] [CrossRef]

- Allain, S.; Cugy, P.; Scott, C.; Chateau, J.P.; Rusinek, A.; Deschamps, A. The influence of plastic instabilities on the mechanical properties of a high-manganese austenitic FeMnC steel. Int. J. Mater. Res. 2008, 99. [Google Scholar] [CrossRef]

- Chen, L.; Kim, H.S.; Kim, S.K.; De Cooman, B.C. Localized deformation due to Portevin–LeChatelier effect in 18Mn–0.6C TWIP austenitic steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, S.I.; Hwang, B. Effect of strain rate on tensile and serration behaviors of an austenitic Fe-22Mn-0.7C twinning-induced plasticity steel. Mater. Sci. Eng. A 2018, 711, 22–28. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Yuan, G.; Kang, J.; Wang, Y.; Misra, R.D.K.; Wang, G. Significance of cold rolling reduction on Lüders band formation and mechanical behavior in cold-rolled intercritically annealed medium-Mn steel. Mater. Sci. Eng. A 2018, 737, 176–181. [Google Scholar] [CrossRef]

- Kim, Y.; Kang, N.; Park, Y.; Choi, I.; Kim, G.; Kim, S.; Cho, K. Effects of the strain induced martensite transformation on the delayed fracture for Al-added TWIP steel. J. Korean Inst. Met. Mater. 2008, 46, 780–787. [Google Scholar]

- Kusakin, P.S.; Kaibyshev, R.O. High-Mn Twinning Induced Plasticity Steels: Microstructure and mechanical properties. Rev. Adv. Mater. Sci. 2016, 44, 326–360. [Google Scholar]

- Field, D.M.; Van Aken, D.C. Dynamic strain ageing phenomena and tensile response of medium-Mn TRIP steel. Metall. Mater. Trans. A 2018, 49A, 1152–1166. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H. Microstructures and mechanical properties of 7Mn steel manufactured by different rolling processes. Metals 2017, 7. [Google Scholar] [CrossRef]

- Gibbs, P.J.; De Moor, E.; Merwin, M.J.; Clausen, B.; Speer, J.G.; Matlock, D.K. Austenite stability effects on tensile behavior of manganese-enriched-austenite transformation-induced plasticity steel. Metall. Mater. Trans. A 2011, 42, 3691–3702. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, J.; Kane, S.N.; De Cooman, B.C. On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 2011, 59, 6809–6819. [Google Scholar] [CrossRef]

- Min, J.; Hector, L.G., Jr.; Zhang, L.; Sund, L.; Carsley, J.E.; Lin, J. Plastic instability at elevated temperatures in a TRIP-assisted steel. Mater. Des. 2016, 95, 370–386. [Google Scholar] [CrossRef]

- Ozgowicz, W.; Grzegorczyk, B.; Pawełek, A.; Wajda, W.; Skuza, W.; Piątkowski, A.; Ranachowski, Z. An analysis of the Portevin-Le Chatelier effect and cracking of CuSn6P alloy at elevated temperature of deformation applying the acoustic emission method. Eng. Fract. Mechan. 2016, 167, 112–122. [Google Scholar] [CrossRef]

- Meng, X.; Liu, B.; Luo, L.; Ding, Y.; Rao, X.X.; Hu, B.; Liu, Y.; Lu, J. The Portevin-Le Chatelier effect of gradient nanostructured 5182 aluminum alloy by surface mechanical attrition treatment. J. Mater. Sci. Technol. 2018, 34, 2307–2315. [Google Scholar] [CrossRef]

- Ozgowicz, W.; Grzegorczyk, B.; Pawełek, A.; Piątkowski, A.; Ranachowski, Z. Influence of the strain rate on the PLC effect and acoustic emission in single crystals of the CuZn30 alloy compressed at an elevated temperature. Mater. Tehnol. 2015, 49, 197–202. [Google Scholar] [CrossRef]

- Górka, J. Welding thermal cycle-triggered precipitation processes in steel S700MC subjected to the thermo-mechanical control processing. Arch. Metall. Mater. 2017, 62, 321–326. [Google Scholar] [CrossRef] [Green Version]

- Kurc-Lisiecka, A.; Piwnik, J.; Lisiecki, A. Laser welding of new grade of advanced high strength steel strenx 1100 MC. Arch. Metall. Mater. 2017, 62, 1651–1657. [Google Scholar] [CrossRef]

- Sun, B.; Fazeli, F.; Scott, C.; Guo, B.; Aranas, C., Jr.; Chu, X.; Jahazi, M.; Yue, S. Microstructural characteristics and tensile behavior of medium manganese steels with different manganese additions. Mater. Sci. Eng. A 2018, 729, 496–507. [Google Scholar] [CrossRef]

- Kamoutsi, H.; Gioti, E.; Haidemenopoulos, G.N.; Cai, Z.; Ding, H. Kinetics of solute partitioning during intercritical annealing of a medium-Mn steel. Metall. Mater. Trans. A 2015, 46, 4841–4846. [Google Scholar] [CrossRef]

- Cottrell, A.H. A note on the Portevin-le Chatelier effect. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1953, 44, 829–832. [Google Scholar] [CrossRef]

- Mc Cormick, P.G. Theory of flow localization due to dynamic strain ageing. Acta Mater. 1988, 36, 3061–3067. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Kozłowska, A. Effects of temperature and time of isothermal holding on retained austenite stability in medium-Mn steels. Appl. Sci. 2018, 8. [Google Scholar] [CrossRef]

- Gomez, M.; Garcia, C.I.; De Ardo, A.J. The role of new ferrite on retained austenite stabilization in Al-TRIP steels. ISIJ Int. 2010, 50, 139–146. [Google Scholar] [CrossRef]

- Jacques, P.J.; Girault, E.; Mertens, A.; Verlinden, B.; Van Humbeeck, J.; Delannay, F. The developments of cold-rolled TRIP-assisted multiphase steels. Al-alloyed TRIP-assisted multiphase steels. ISIJ Int. 2001, 41, 1068–1074. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H. On factors affecting the phase transformation and mechanical properties of cold-rolled transformation-induced-plasticity-aided steel. Metall. Mater. Trans. A 2008, 39, 2513–2527. [Google Scholar] [CrossRef]

- Sachdev, A.K. Dynamic strain aging of various steels. Metall. Trans. A 1982, 13, 1793–1797. [Google Scholar] [CrossRef]

- Aydemir, B.; Zeytin, H.K.; Guven, G. Investigation of Portevin-Le Chatelier effect of hot-rolled Fe-13Mn-0.2C-1Al-1Si TWIP steel. Mater. Tehnol. 2016, 50, 511–516. [Google Scholar] [CrossRef]

- Kral, L.; Million, B.; Cermak, J. Diffusion of carbon and manganese in Fe-Mn-C. Defect Diffus. Forum 2007, 263, 153–158. [Google Scholar] [CrossRef]

- Jung, I.C.; De Cooman, B.C. Temperature dependence of the flow stress of Fe-18Mn-0.6C-xAl twinning-induced plasticity steel. Acta Mater 2013, 61, 6724–6735. [Google Scholar] [CrossRef]

- Hickel, T.; Sandlöbes, S.; Marceau, R.K.W.; Dick, A.; Bleskov, I.; Neugebauer, J.; Raabe, D. Impact of nanodiffusion on the stacking fault energy in high-strength steels. Acta Mater. 2014, 75, 147–155. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Barlat, F.; Kim, D.; Lee, M.G. Experiment and modeling to investigate the effect of stress state, strain and temperature on martensitic phase transformation in TRIP-assisted steel. Acta Mater. 2015, 97, 435–444. [Google Scholar] [CrossRef]

- Zhang, M.; Li, L.; Ding, J.; Wu, Q.; Wang, Y.D.; Almer, J.; Guo, F.; Ren, Y. Temperature-dependent micromechanical behavior of medium-Mn transformation-induced-plasticity steel studied by in situ synchrotron X-ray diffraction. Acta Mater. 2017, 141, 294–303. [Google Scholar] [CrossRef]

| C % | Mn % | Al % | Si % | Mo % | P % | S % |

|---|---|---|---|---|---|---|

| 0.16 | 4.7 | 1.6 | 0.22 | 0.20 | 0.008 | 0.004 |

| Deformation Temperature [°C] | UTS [MPa] | YS [MPa] | TE [%] | YS/UTS [MPa] |

|---|---|---|---|---|

| 20 | 1215 | 882 | 11.5 | 0.73 |

| 60 | 1200 | 856 | 10.3 | 0.71 |

| 100 | 1180 | 873 | 9.8 | 0.74 |

| 140 | 1223 | 841 | 11.4 | 0.69 |

| Deformation Temperature [°C] | Serration Type | εcr | Δσ+max [MPa] | Δσ-max [MPa] | [MPa] | [MPa] | |

|---|---|---|---|---|---|---|---|

| 60 | A | 0.007 | 79 | 41 | 45 | 14 | 0.005 |

| 100 | B | 0.080 | 82 | 114 | 46 | 67 | 0.003 |

| 140 | B+C | 0.060 | 129 | 126 | 68 | 64 | 0.004 |

- εcr—critical strain for initiation of the PLC effect

- Δσ+max—maximum increase of the oscillation stress

- Δσ-max—maximum decrease of the oscillation stress

- —mean value of the stress increase in a range of oscillations

- —mean value of the stress decrease in a range of oscillations

- —mean value of the strain period between successive oscillations

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzegorczyk, B.; Kozłowska, A.; Morawiec, M.; Muszyński, R.; Grajcar, A. Effect of Deformation Temperature on the Portevin-Le Chatelier Effect in Medium-Mn Steel. Metals 2019, 9, 2. https://doi.org/10.3390/met9010002

Grzegorczyk B, Kozłowska A, Morawiec M, Muszyński R, Grajcar A. Effect of Deformation Temperature on the Portevin-Le Chatelier Effect in Medium-Mn Steel. Metals. 2019; 9(1):2. https://doi.org/10.3390/met9010002

Chicago/Turabian StyleGrzegorczyk, Barbara, Aleksandra Kozłowska, Mateusz Morawiec, Rafał Muszyński, and Adam Grajcar. 2019. "Effect of Deformation Temperature on the Portevin-Le Chatelier Effect in Medium-Mn Steel" Metals 9, no. 1: 2. https://doi.org/10.3390/met9010002