Effects of Tool Edge Geometry on Chip Segmentation and Exit Burr: A Finite Element Approach

Abstract

:1. Introduction

2. Finite Element Based Orthogonal Cutting Model

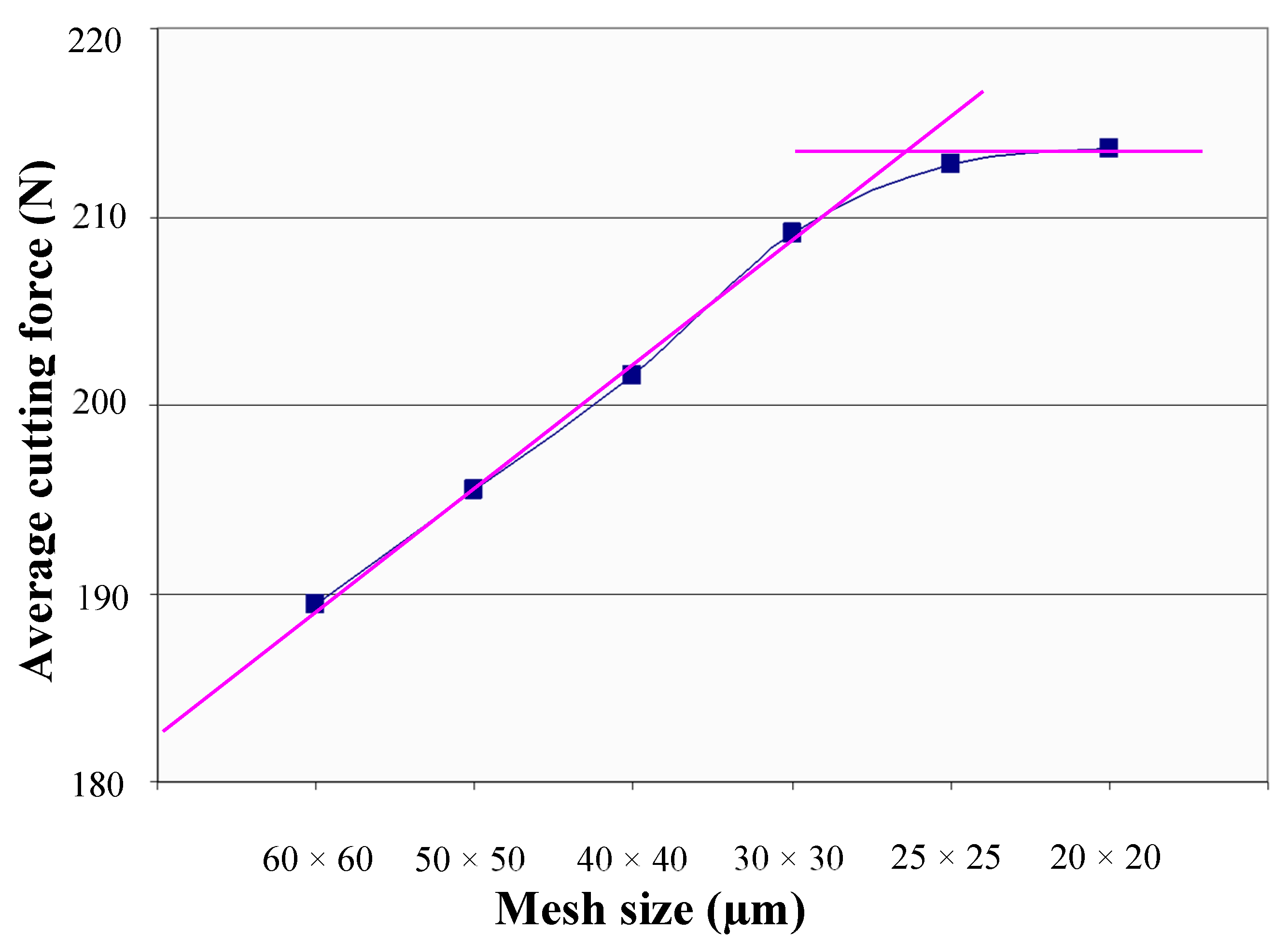

2.1. Geometrical Model, Mesh, Constraints, and Hypothesis

2.2. Material Behavior, Chip Separation, Friction, and Thermal Models

3. Results and Analysis

3.1. Finite Element Analysis and Discussion

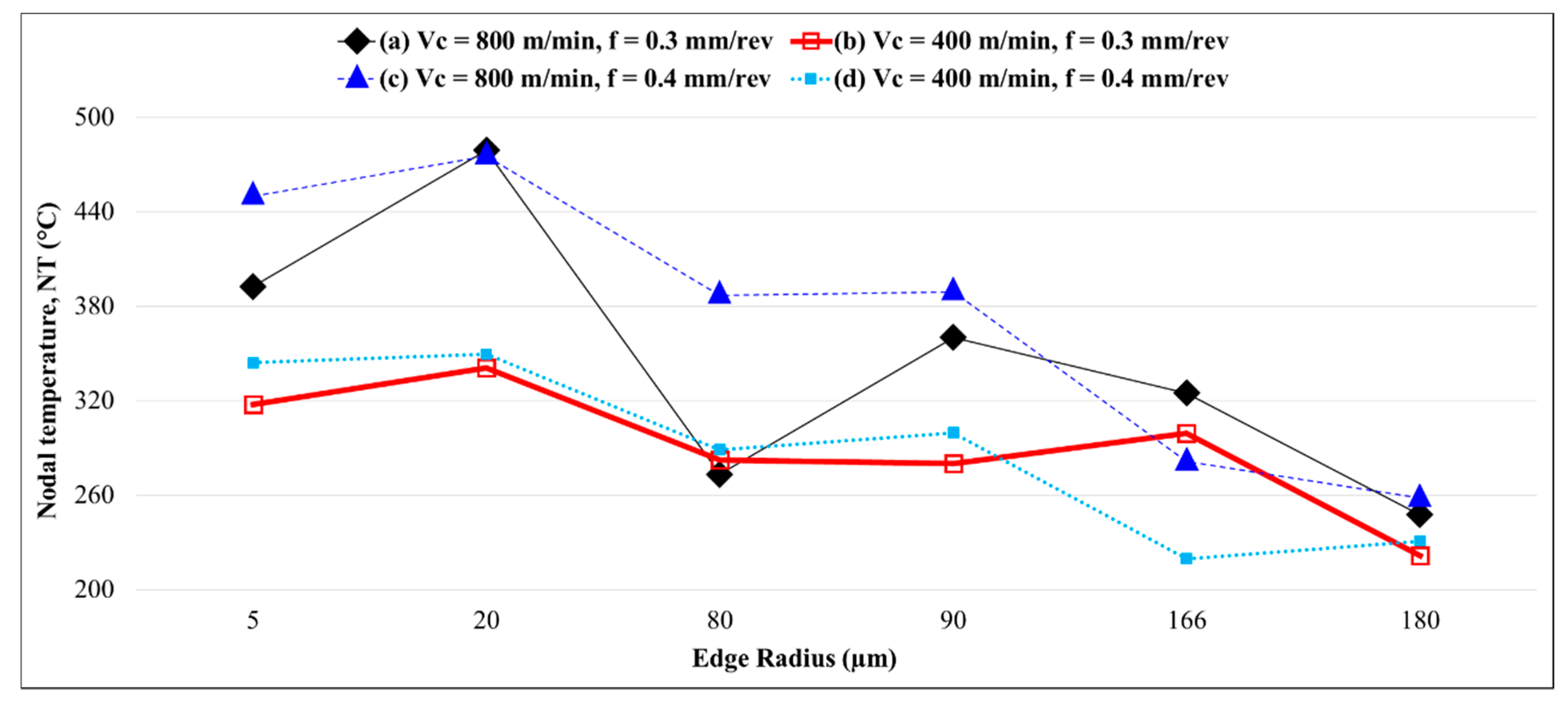

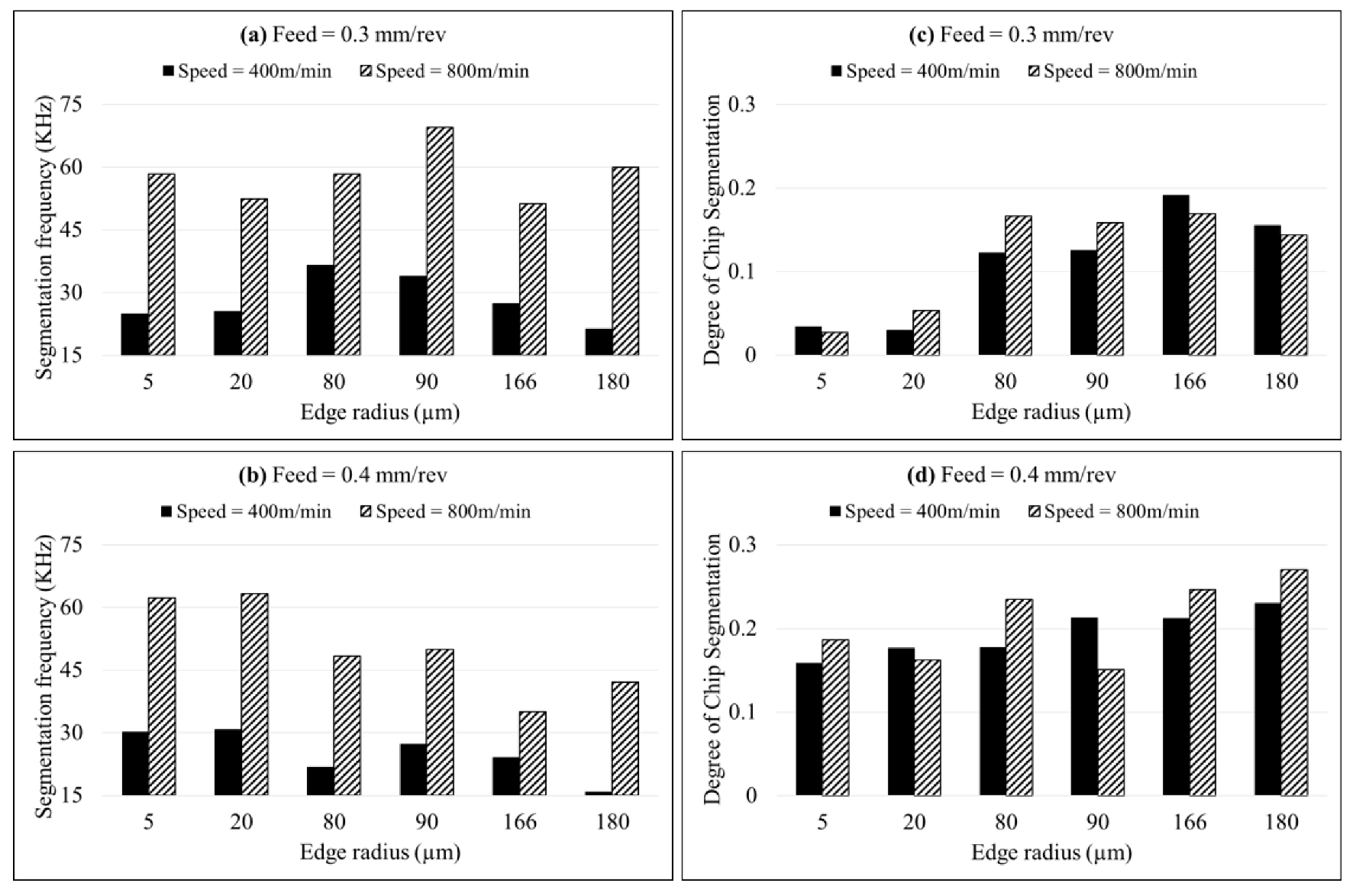

3.1.1. Cutting Parameters and Tool Geometry Effects on Chip Segmentation Frequency and Segmentation Intensity

3.1.2. Cutting Parameters and Tool Geometry Effects on End (Exit) Burr Formation

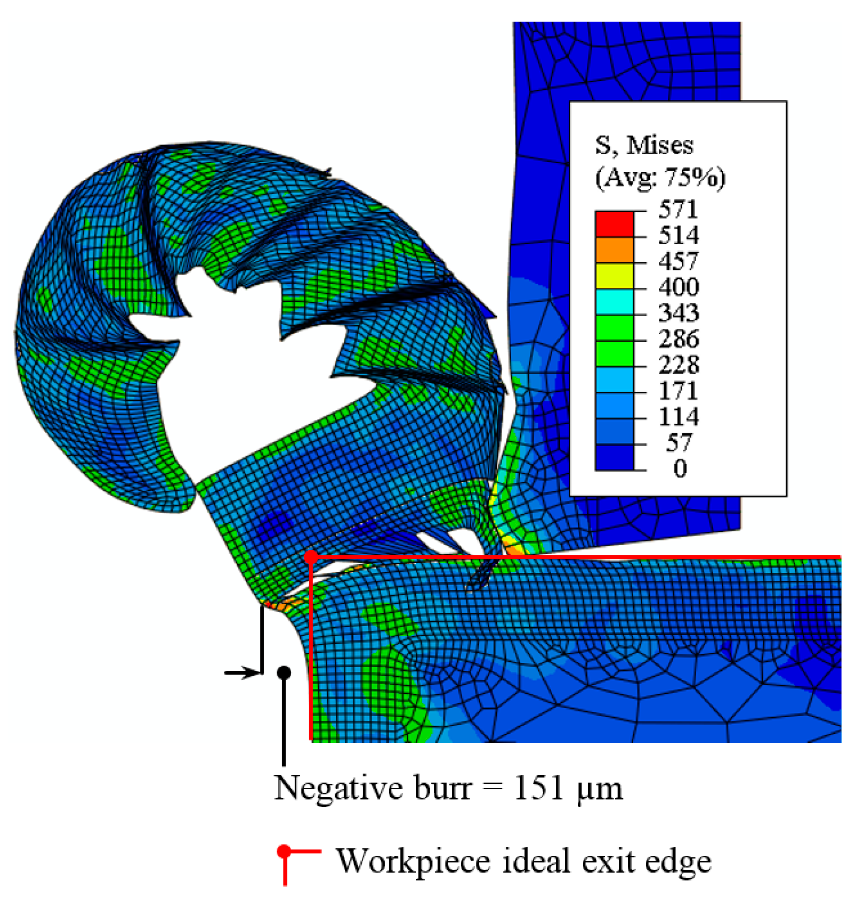

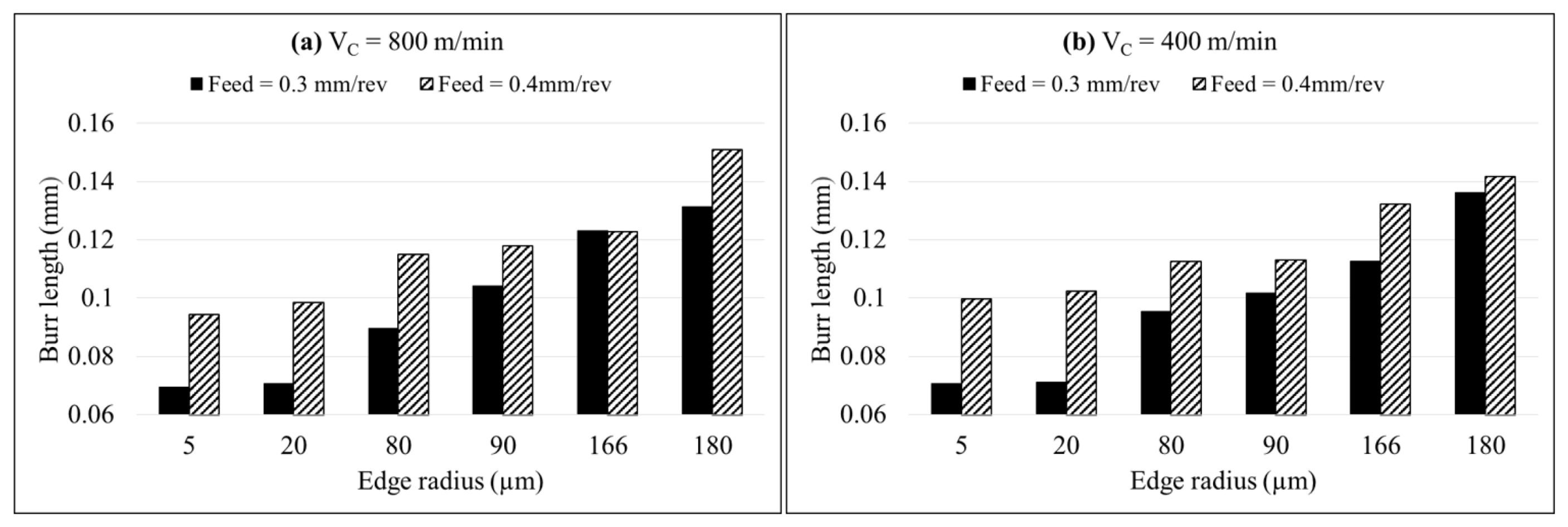

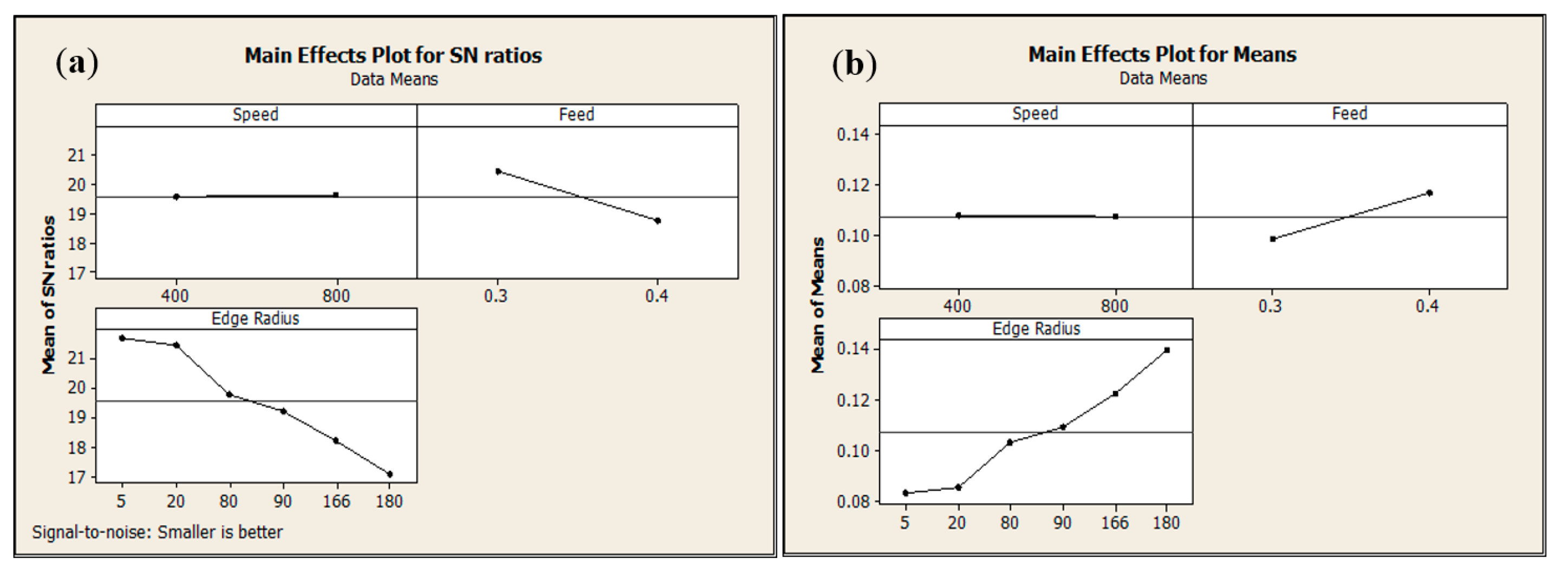

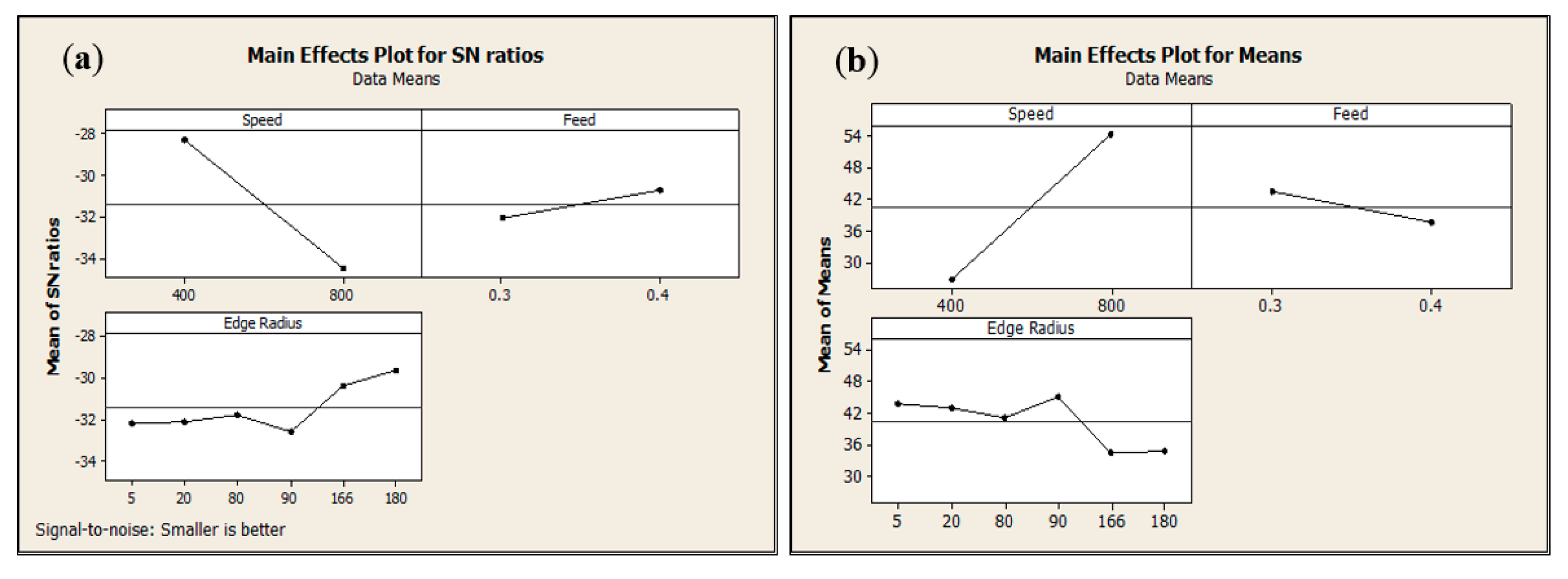

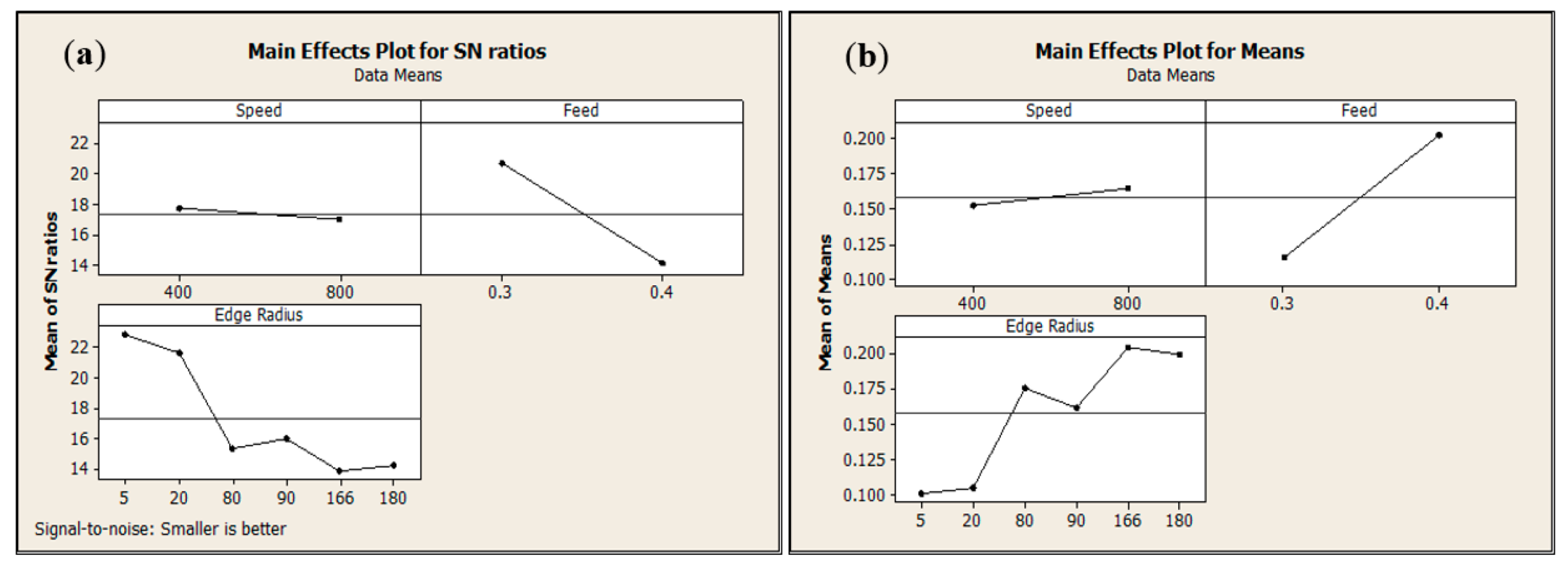

3.2. Statistical Analysis and Optimization

3.2.1. Statistical Analyses on Burr Optimization

3.2.2. Statistical Analyses of Segmented Chip Morphology (Segmentation Frequency and Degree of Chip Segmentation)

4. Conclusions

- Machining operations performed with chamfer (T-land) edges can be represented with equivalent hone (round) edge radii.

- Only negative burr with a boot-type chip was witnessed for all investigated parametric cutting combinations of speed, feed, and tool edge geometry in machining of AA2024-T351.

- The negative shear zone is wider for cutting performed at higher cutting feed accompanied with larger tool edge radii. This promotes the material’s early ductile failure, initiation, and progression of fracture in the chip separation zone far ahead of the tool tip location. Consequently, the material escapes the cutting process and the tool pushes away the boot-type chip (combination of chip and uncut workpiece material), and a longer negative end burr (deformed workpiece exit edge) appears at the exit edge of the workpiece. Statistical analyses show that tool edge radius is the major contributor (74%), while feed rate contributes up to 17.4% in generating burr. Cutting speed variation has been found to have negligible effects on burr quantification.

- Pivot point (the highly stressed point in the negative shear zone) location on the exit edge of the workpiece shows a direct relation in quantifying burr lengths. The distant location of the pivot point from the machined surface results in longer burr lengths, and vice versa.

- Higher cutting speeds enhance thermal softening and more frequent generation of chip shear bands (high frequency of chip segmentation). Finite-element-based parametric analyses and subsequent application of statistical optimization approaches show that speed is the highest contributor (76%) among the cutting parameters in generating highly segmented chips, significantly more so than feed and tool edge radii. Any variation in the latter parameters were found to have insignificant effects in this area.

- Wider workpiece materials undergo severe plastic deformation when machining is performed at higher cutting feeds complemented with larger tool edge radii. The material stiffness degrades easily, leading to crack initiation and propagation in primary and secondary shear zones, resulting in highly segmented chips (chips with a higher degree of chip segmentation). However, cutting speeds, on the other hand, did not been noticeably effect the degree of chip segmentation. Statistical analyses show that feed and tool edge radius both dominantly effect the phenomena, with contributions of 43.9% and 36.4%, respectively.

- Optimum cutting parametric combinations of feed, speed, and tool edge radius to minimize chip segmentation and exit burr formation have been presented. Furthermore, quadratic regression models have been proposed to quantify segmentation frequencies, degree of segmentation, and exit burr lengths as functions of cutting speed, feed, and tool edge radius.

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Initial yield stress (MPa) |

| aP | Cutting depth (mm) |

| B | Hardening modulus (MPa) |

| C | Strain rate dependency coefficient |

| Cp | Specific heat (Jkg−1 °C−1) |

| D | Damage evolution parameter |

| D1 D5 | Coefficients of Johnson–Cook material shear failure initiation criterion |

| E | Young’s modulus (MPa) |

| f | Feed rate (mm/rev) |

| Gf | Fracture energy (N/m) |

| KC I, II | Fracture toughness () for failure mode I and mode II |

| lβ | Chamfer length |

| m | Thermal softening coefficient |

| n | Work-hardening exponent |

| P | Hydrostatic pressure (MPa) |

| Heat generation rate due to plastic deformation W/m3 | |

| Heat generation rate due to friction W/m3 | |

| rβ | Hone edge radius |

| req | Equivalent edge radius |

| T | Temperature at a given calculation instant (°C) |

| Tm | Melting temperature (°C) |

| Tr | Room temperature (°C) |

| Equivalent plastic displacement (mm) | |

| Equivalent plastic displacement at failure (mm) | |

| VC | Cutting speed (m/min) |

| Stress, MPa | |

| Johnson-Cook equivalent stress (MPa) | |

| Yield stress (MPa) | |

| Tf | Frictional shear stress, MPa |

| Stress triaxiality | |

| Equivalent plastic strain | |

| Plastic strain rate (s−1) | |

| Reference strain rate (10−3 s−1) | |

| Equivalent plastic strain at failure | |

| Equivalent plastic strain increment | |

| Plastic strain at damage initiation | |

| ηp | Inelastic heat fraction |

| ηf | Frictional work conversion factor |

| ω | Damage initiation criterion |

| ν | Poisson’s ratio |

| αd | Expansion coefficient (µm m−1 °C−1) |

| λ | Thermal conductivity (W m−1 C−1) |

| ρ | Density (kg/m3) |

| γo | Rake angle (degrees) |

| γβ | Chamfer angle (degrees) |

| β0 | Constant of regression model equation |

| βi and βj | Coefficient of linear terms of regression model equation |

| βij | Coefficient of quadratic terms of regression model equation |

| xi and xj | Explicative variables (control factors) |

| ε | Random error |

| ANOVA | Analysis of variance |

| DOE | Design of experiment |

| RSM | Response surface methodology |

| DF | Degrees of freedom |

| MS | Mean squares (variance) |

| SS | Sum of squares |

| S/N ratio | Signal-to-noise ratio |

| PP | Percent contribution |

| P-value | Probability of significance |

| F-value | Fisher coefficient (variance ratio) |

References

- Xiuli, F.; Wenxing, L.; Yongzhi, P.; Wentao, L. Morphology evolution and micro-mechanism of chip formation during high speed machining. Int. J. Adv. Manuf. Technol. 2018, 98, 165–175. [Google Scholar] [CrossRef]

- Ijaz, H.; Zain-ul-abdein, M.; Saleem, W.; Asad, M.; Mabrouki, T. Numerical simulation of the effects of elastic anisotropy and grain size upon the machining of AA2024. Mach. Sci. Technol. 2018, 22, 522–542. [Google Scholar] [CrossRef]

- Régnier, T.; Fromentin, G.; Marcon, B.; Outeiro, J.; D’Acunto, A.; Crolet, A.; Grunder, T. Fundamental study of exit burr formation mechanisms during orthogonal cutting of AlSi aluminium alloy. J. Mater. Process. Technol. 2018, 257, 112–122. [Google Scholar] [CrossRef]

- Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D. The influence of burr formation and feed rate on the fatigue life of drilled titanium and aluminium alloys used in aircraft manufacture. CIRP Ann. Manuf. Tech. 2018, 67, 103–108. [Google Scholar] [CrossRef]

- Mabrouki, T.; Courbon, C.; Zhang, Y.; Rech, J.D.; Asad, M.; Hamdi, H.; Belhadi, S.; Salvatore, F. Some insights on the modelling of chip formation and its morphology during metal cutting operations. C. R. Mec. 2016, 344, 335–354. [Google Scholar] [CrossRef]

- Aurich, J.C.; Dornfeld, D.A.; Arrazola, P.J.; Frankea, V.; Leitza, L.; Min, S. Burrs—Analysis, control and removal. CIRP Ann. Manuf. Tech. 2009, 58, 519–542. [Google Scholar] [CrossRef]

- Niknam, S.A.; Davoodi, B.; Davim, J.P.; Victor, S. Mechanical deburring and edge-finishing processes for aluminum parts—A review. Int. J. Adv. Manuf. Technol. 2018, 95, 1101–1125. [Google Scholar] [CrossRef]

- Uysal, A.; Jawahir, I.S. A slip-line model for serrated chip formation in machining of stainless steel and validation. Int. J. Adv. Manuf. Technol. 2019, 101, 2449–2464. [Google Scholar] [CrossRef]

- Jafarian, F.; Ciaran, M.I.; Umbrello, D.; Arrazola, P.J.; Filice, L.; Amirabadi, H. Finite element simulation of machining Inconel alloy including microstructure changes. Int. J. Mech. Sci. 2014, 88, 110–121. [Google Scholar] [CrossRef]

- Harzallah, M.; Pottier, T.; Senatore, J.; Mousseigne, M.; Germain, G.; Landon, Y. Numerical and experimental investigations of Ti-6Al-4V chip generation and thermo-mechanical couplings in orthogonal cutting. Int. J. Mech. Sci. 2017, 134, 189–202. [Google Scholar] [CrossRef]

- Mabrouki, T.; Girardin, F.; Asad, M.; Rigal, J.F. Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351). Int. J. Mach. Tools Manuf. 2008, 481, 187–197. [Google Scholar] [CrossRef]

- Hernández, Y.S.; Vilches, F.J.T.; Gamboa, C.B.; Hurtado, L.S. Experimental Parametric Relationships for Chip Geometry in Dry Machining of the Ti6Al4V Alloy. Materials 2018, 11, 1260. [Google Scholar] [CrossRef] [PubMed]

- Saleem, W.; Asad, M.; Zain-ul-abdein, M.; Ijaz, H.; Mabrouki, T. Numerical investigations of optimum turning parameters—AA2024-T351 aluminum alloy. Mach. Sci. Technol. 2016, 20, 634–654. [Google Scholar] [CrossRef]

- Saleem, W.; Zain-ul-abdein, M.; Ijaz, H.; Mahfouz, A.S.B.; Ahmed, A.; Asad, M.; Mabrouki, T. Computational analysis and artificial neural network optimization of dry turning parameters—AA2024-T351. Appl. Sci. 2017, 7, 642. [Google Scholar] [CrossRef]

- Hua, J.; Shivpuri, R.; Cheng, X.; Bedekar, V.; Matsumoto, Y.; Hashimoto, F.; Watkins, T.R. Effect of feed rate, workpiece hardness and cutting edge on subsurface residual stress in the hard turning of bearing steel using chamfer + hone cutting edge geometry. Mater. Sci. Eng. A 2005, 394, 238–248. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Umer, U.; Mohany, A. A model for machining with nano-additives based minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2019, 102, 2013–2028. [Google Scholar] [CrossRef]

- Asad, M.; Ijaz, H.; Saleem, W.; Mahfouz, A.S.B.; Ahmad, Z.; Mabrouki, T. Finite Element Analysis and Statistical Optimization of End-Burr in Turning AA2024. Metals 2019, 9, 276. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; He, N. Investigation on the burr formation mechanism in micro cutting. Precis. Eng. 2017, 47, 191–196. [Google Scholar] [CrossRef]

- Denkena, B.; Koehler, J.; Rehe, M. Influnce of the honed cutting edge on tool wear and surface integrity in slot milling of 42CrMo4 steel. Procedia CIRP 2012, 1, 190–195. [Google Scholar] [CrossRef]

- Zanger, F.; Kacaras, A.; Bächle, M.; Schwabe, M.; León, F.P.; Schulze, V. FEM simulation and acoustic emission based characterization of chip segmentation frequency in machining of Ti-6Al-4V. Procedia CIRP 2018, 72, 1421–1426. [Google Scholar] [CrossRef]

- Mabrouki, T.; Rigal, J.F. A contribution to a qualitative understanding of thermo-mechanical effects during chip formation in hard turning. J. Mater. Process. Technol. 2006, 176, 214–221. [Google Scholar] [CrossRef]

- Mahnama, M.; Movahhedy, M.R. Prediction of machining chatter based on FEM simulation of chip formation under dynamic conditions. Int. J. Mach. Tools Manuf. 2010, 50, 611–620. [Google Scholar] [CrossRef]

- Asad, M.; Mabrouki, T.; Rigal, J.F. Finite-element-based hybrid dynamic cutting model for aluminium alloy milling. Proc. IMechE Part. B J. Eng. Manuf. 2010, 224, 1–13. [Google Scholar] [CrossRef]

- Yameogo, D.; Haddag, B.; Makich, H.; Nouari, M. Prediction of the cutting forces and chip morphology when machining the Ti6Al4V alloy using a microstructural coupled model. Procedia CIRP 2017, 58, 335–340. [Google Scholar] [CrossRef]

- Subbiah, S.; Melkote, S.N. Effect of finite edge radius on ductile fracture ahead of the cutting tool edge in micro-cutting of Al2024-T3. Mater. Sci. Eng. A 2008, 474, 283–300. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–782. [Google Scholar] [CrossRef]

- Grzesik, W.; Nieslony, P. A computational approach to evaluate temperature and heat partition in machining with multilayer coated tools. Int. J. Mach. Tools Manuf. 2003, 43, 1311–1317. [Google Scholar] [CrossRef]

- Özel, T. The influence of friction models on finite element simulations of machining. Int. J. Mach. Tools Manuf. 2006, 46, 518–530. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, J.; Zhang, F.; Butt, S.I. Identification of a new friction model at tool-chip interface in dry orthogonal cutting. Int. J. Adv. Manuf. Technol. 2017, 89, 921–932. [Google Scholar] [CrossRef]

- Asad, M.; Mabrouki, T.; Rigal, J.F. On the tool vibration effects during down-cut peripheral milling process. Int. J. Interact. Des. Manuf. 2010, 4, 215–225. [Google Scholar] [CrossRef]

- Ozel, T. Modeling of hard part machining: Effect of insert edge preparation in CBN cutting tools. J. Mater. Process. Technol. 2003, 141, 284–293. [Google Scholar] [CrossRef]

- Niknam, S.A.; Songmene, V. Statistical investigation on burrs thickness during milling of 6061-T6 aluminium alloy. In Proceedings of the CIRP, 1st International Conference on Virtual Machining Process Technology, Montreal, QC, Canada, 28 May–1 June 2012. [Google Scholar]

| Tool Edge Geometry | Equivalent Radius, req (µm) | “Chip Separation Zone” Width (µm) |

|---|---|---|

| Hone edge (rβ = 5 µm) | 5 | 20 |

| Hone edge (rβ = 20 µm) | 20 | 20 |

| Chamfer length (lβ) = 0.1 mm, chamfer angle (γβ) = 15° | 80 | 80 |

| Chamfer length (lβ) = 0.1 mm, chamfer angle (γβ) = 25° | 90 | 80 |

| Chamfer length (lβ) = 0.2 mm, chamfer angle (γβ) = 15° | 166 | 170 |

| Chamfer length (lβ) = 0.2 mm, chamfer angle (γβ) = 25° | 180 | 170 |

| Level | Factors | ||

|---|---|---|---|

| Tool Edge Equivalent Radius, req (µm) | Cutting Speed, VC (m/min) | Feed Rate, f (mm/rev) | |

| 1 | 5 | 800 | 0.3 |

| 2 | 5 | 400 | 0.3 |

| 3 | 20 | 800 | 0.3 |

| 4 | 20 | 400 | 0.3 |

| 5 | 80 | 800 | 0.3 |

| 6 | 80 | 400 | 0.3 |

| 7 | 90 | 800 | 0.3 |

| 8 | 90 | 400 | 0.3 |

| 9 | 166 | 800 | 0.3 |

| 10 | 166 | 400 | 0.3 |

| 11 | 180 | 800 | 0.3 |

| 12 | 180 | 400 | 0.3 |

| 13 | 5 | 800 | 0.4 |

| 14 | 5 | 400 | 0.4 |

| 15 | 20 | 800 | 0.4 |

| 16 | 20 | 400 | 0.4 |

| 17 | 80 | 800 | 0.4 |

| 18 | 80 | 400 | 0.4 |

| 19 | 90 | 800 | 0.4 |

| 20 | 90 | 400 | 0.4 |

| 21 | 166 | 800 | 0.4 |

| 22 | 166 | 400 | 0.4 |

| 23 | 180 | 800 | 0.4 |

| 24 | 180 | 400 | 0.4 |

| Parameters | Workpiece (AA2024-T351) | Insert (Tungsten Carbide) |

|---|---|---|

| Density, ρ | 2700 | 11,900 |

| Young’s modulus, E | 73,000 | 534,000 |

| Poisson’s ratio, ν | 0.33 | 0.22 |

| Fracture energy, Gf | 20 × 103 | X |

| Specific heat, Cp | 0.557 T + 877.6 | 400 |

| Expansion coefficient, αd | 8.91−3 T + 22.2 | X |

| Thermal conductivity, λ | 25 ≤ T ≤ 300: λ = 0.247T + 114.4 300 ≤ T ≤ Tm: λ = −0.125T + 226 | 50 |

| Meting temperature, Tm | 520 | X |

| Room temperature, Tr | 25 | 25 |

| Fracture toughness (KIC and KIIC) | 26 and 37 | X |

| A | B | n | C | m | D1 | D2 | D3 | D4 | D5 |

|---|---|---|---|---|---|---|---|---|---|

| 352 | 440 | 0.42 | 0.0083 | 1 | 0.13 | 0.13 | −1.5 | 0.011 | 0 |

| Levels | Numerically Computed Cutting Forces (N) | Experimentally Registered Cutting Forces (N) | Numerically Computed Chip Segmentation Frequency (kHz) | Experimentally Registered Chip Segmentation Frequency (kHz) |

|---|---|---|---|---|

| 3 | 669 | 769 | 53 | 90 |

| 4 | 657 | 769 | 26 | 37 |

| 15 | 840 | 976 | 63 | 65 |

| 16 | 833 | 978 | 31 | 32 |

| Level | Factors | Numerically Computed Exit Burr Lengths (µm) | ||

|---|---|---|---|---|

| Tool Edge Equivalent Radius, req (µm) | Cutting Speed, VC (m/min) | Feed Rate, f (mm/rev) | ||

| 1 | 5 | 800 | 0.3 | 69.5 |

| 2 | 5 | 400 | 0.3 | 70.6 |

| 3 | 20 | 800 | 0.3 | 70.9 |

| 4 | 20 | 400 | 0.3 | 71.2 |

| 5 | 80 | 800 | 0.3 | 89.6 |

| 6 | 80 | 400 | 0.3 | 95.4 |

| 7 | 90 | 800 | 0.3 | 104.3 |

| 8 | 90 | 400 | 0.3 | 101.8 |

| 9 | 166 | 800 | 0.3 | 123.2 |

| 10 | 166 | 400 | 0.3 | 112.6 |

| 11 | 180 | 800 | 0.3 | 131.5 |

| 12 | 180 | 400 | 0.3 | 136.2 |

| 13 | 5 | 800 | 0.4 | 94.3 |

| 14 | 5 | 400 | 0.4 | 99.8 |

| 15 | 20 | 800 | 0.4 | 98.6 |

| 16 | 20 | 400 | 0.4 | 102.3 |

| 17 | 80 | 800 | 0.4 | 115.2 |

| 18 | 80 | 400 | 0.4 | 112.6 |

| 19 | 90 | 800 | 0.4 | 118 |

| 20 | 90 | 400 | 0.4 | 113 |

| 21 | 166 | 800 | 0.4 | 122.7 |

| 22 | 166 | 400 | 0.4 | 132.1 |

| 23 | 180 | 800 | 0.4 | 150.9 |

| 24 | 180 | 400 | 0.4 | 141.8 |

| Level | Factor (Speed) | Factor (Feed) | Factor (Edge Radius) |

|---|---|---|---|

| 1 | 0.107385925 | 0.098054667 | 0.083556375 |

| 2 | 0.107456283 | 0.116787542 | 0.08575725 |

| 3 | - | - | 0.10319225 |

| 4 | - | - | 0.1092785 |

| 5 | - | - | 0.122657 |

| 6 | - | - | 0.14008525 |

| Difference | 7.03583 × 10−5 | 0.018732875 | 0.056528875 |

| Rank | 3 | 2 | 1 |

| Source | DF | SS | MS | F-Value | P-Value | PP% | Remarks |

|---|---|---|---|---|---|---|---|

| Regression | 7 | 0.011474 | 0.001639 | 41.56 | 0 | - | Significant |

| Speed | 1 | 0 | 0 | 0.001 | 0.997 | 0 | Insignificant |

| Feed | 1 | 0.002106 | 0.002048 | 51.94 | 0.000002 | 17.39776952 | Significant |

| Edge Radius | 1 | 0.009051 | 0.00898 | 227.7 | 0 | 74.77075589 | Significant |

| Edge Radius × Edge Radius | 1 | 0.000011 | 0.000011 | 0.29 | 0.598 | 0.090871541 | Insignificant |

| Speed × Feed | 1 | 0 | 0 | 0.01 | 0.918 | 0 | Insignificant |

| Speed × Edge Radius | 1 | 0.000018 | 0.000018 | 0.46 | 0.508 | 0.148698885 | Insignificant |

| Feed × Edge Radius | 1 | 0.000288 | 0.000288 | 7.29 | 0.016 | 2.379182156 | Significant |

| Error | 16 | 0.000631 | 0.000039 | - | - | 5.212722016 | - |

| Total | 23 | 0.012105 | - | - | - | 100 | - |

| Source | DF | SS | MS | F-Value | P-Value | PP % | Remarks |

|---|---|---|---|---|---|---|---|

| Regression | 7 | 0.049389 | 0.007056 | 12.91 | 0 | - | Significant |

| Speed | 1 | 0.00037 | 0.000374 | 0.68 | 0.42 | 0.636493437 | Significant |

| Feed | 1 | 0.004971 | 0.004976 | 9.11 | 0.008 | 8.551375342 | Insignificant |

| Edge Radius | 1 | 0.04362 | 0.043299 | 79.25 | 0 | 75.03741549 | Insignificant |

| Edge Radius × Edge Radius | 1 | 0.000044 | 0.000044 | 0.08 | 0.781 | 0.075691111 | Insignificant |

| Speed × Feed | 1 | 0.00037 | 0.00037 | 0.68 | 0.423 | 0.636493437 | Insignificant |

| Speed × Edge Radius | 1 | 0.00001 | 0.00001 | 0.02 | 0.894 | 0.017202525 | Insignificant |

| Feed × Edge Radius | 1 | 0.000005 | 0.000005 | 0.01 | 0.924 | 0.008601263 | Insignificant |

| Error | 16 | 0.008742 | 0.000546 | - | - | 15.03844764 | - |

| Total | 23 | 0.058131 | - | - | - | 100 | - |

| Source | DF | SS | MS | F Value | P-Value | PP % | Remarks |

|---|---|---|---|---|---|---|---|

| Regression | 7 | 5480.35 | 782.91 | 25.99 | 0 | - | Significant |

| Speed | 1 | 4569.18 | 4537.35 | 150.65 | 0 | 76.6351629 | Significant |

| Feed | 1 | 196.94 | 213.16 | 7.08 | 0.017 | 3.303115435 | Insignificant |

| Edge Radius | 1 | 320.62 | 302.58 | 10.05 | 0.006 | 5.377500105 | Insignificant |

| Edge Radius × Edge Radius | 1 | 64.15 | 64.15 | 2.13 | 0.164 | 1.075936098 | Insignificant |

| Speed × Feed | 1 | 34.82 | 34.82 | 1.16 | 0.298 | 0.584007715 | Insignificant |

| Speed × Edge Radius | 1 | 29.98 | 29.98 | 1 | 0.333 | 0.502830307 | Insignificant |

| Feed × Edge Radius | 1 | 264.65 | 264.65 | 8.79 | 0.009 | 4.438760535 | Insignificant |

| Error | 16 | 481.92 | 30.12 | - | - | 8.082854627 | - |

| Total | 23 | 5962.25 | - | - | - | 100 | - |

| Source | DF | SS | MS | F Value | P-Value | PP % | Remarks |

|---|---|---|---|---|---|---|---|

| Regression | 7 | 108782 | 15540.3 | 12.2 | 0 | - | Significant |

| Speed | 1 | 29698 | 28782.6 | 22.59 | 0 | 22.99140667 | Significant |

| Feed | 1 | 992 | 882 | 0.69 | 0.418 | 0.767980181 | Insignificant |

| Edge Radius | 1 | 68989 | 68900.8 | 54.07 | 0 | 53.4094604 | Insignificant |

| Edge Radius × Edge Radius | 1 | 25 | 25.5 | 0.02 | 0.889 | 0.019354339 | Insignificant |

| Speed × Feed | 1 | 1247 | 1246.9 | 0.98 | 0.337 | 0.965394441 | Insignificant |

| Speed × Edge Radius | 1 | 5282 | 5282.4 | 4.15 | 0.059 | 4.089184795 | Insignificant |

| Feed × Edge Radius | 1 | 2548 | 2547.6 | 2 | 0.177 | 1.972594256 | Insignificant |

| Error | 16 | 20387 | 1274.2 | - | - | 15.78307657 | - |

| Total | 23 | 129170 | - | - | - | 100 | - |

| Source | DF | SS | MS | F Value | P-Value | PP % | Remarks |

|---|---|---|---|---|---|---|---|

| Regression | 7 | 0.08866 | 0.012666 | 14.49 | 0 | - | Significant |

| Speed | 1 | 0.000865 | 0.000864 | 0.99 | 0.335 | 0.842710312 | Significant |

| Feed | 1 | 0.045057 | 0.044174 | 50.54 | 0 | 43.89595207 | Insignificant |

| Edge Radius | 1 | 0.037425 | 0.038387 | 43.92 | 0 | 36.46061669 | Insignificant |

| Edge Radius × Edge Radius | 1 | 0.002218 | 0.002218 | 2.54 | 0.131 | 2.160845633 | Insignificant |

| Speed × Feed | 1 | 0.000025 | 0.000025 | 0.03 | 0.867 | 0.024355789 | Insignificant |

| Speed × Edge Radius | 1 | 0 | 0 | 0 | 0.998 | 0 | Insignificant |

| Feed × Edge Radius | 1 | 0.003071 | 0.003071 | 3.51 | 0.079 | 2.991865166 | Insignificant |

| Error | 16 | 0.013984 | 0.000874 | - | - | 13.62365434 | - |

| Total | 23 | 0.102645 | - | - | - | 100 | - |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asad, M. Effects of Tool Edge Geometry on Chip Segmentation and Exit Burr: A Finite Element Approach. Metals 2019, 9, 1234. https://doi.org/10.3390/met9111234

Asad M. Effects of Tool Edge Geometry on Chip Segmentation and Exit Burr: A Finite Element Approach. Metals. 2019; 9(11):1234. https://doi.org/10.3390/met9111234

Chicago/Turabian StyleAsad, Muhammad. 2019. "Effects of Tool Edge Geometry on Chip Segmentation and Exit Burr: A Finite Element Approach" Metals 9, no. 11: 1234. https://doi.org/10.3390/met9111234