The Influence of Segregation Bands and Hot Rolling on the Precipitation of Secondary Phases during Aging at 750 °C for Nickel Alloy 625

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

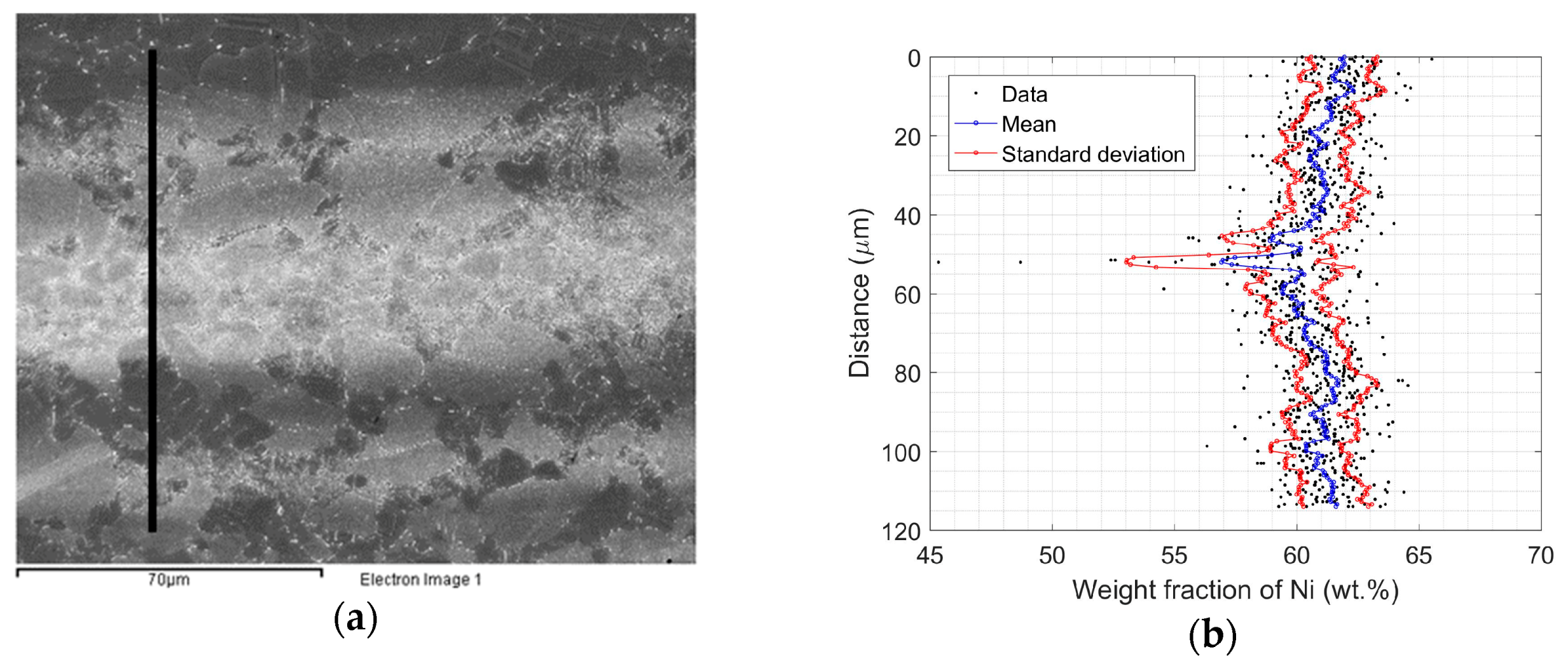

3.1. Microstructure Evolution during Hot Rolling

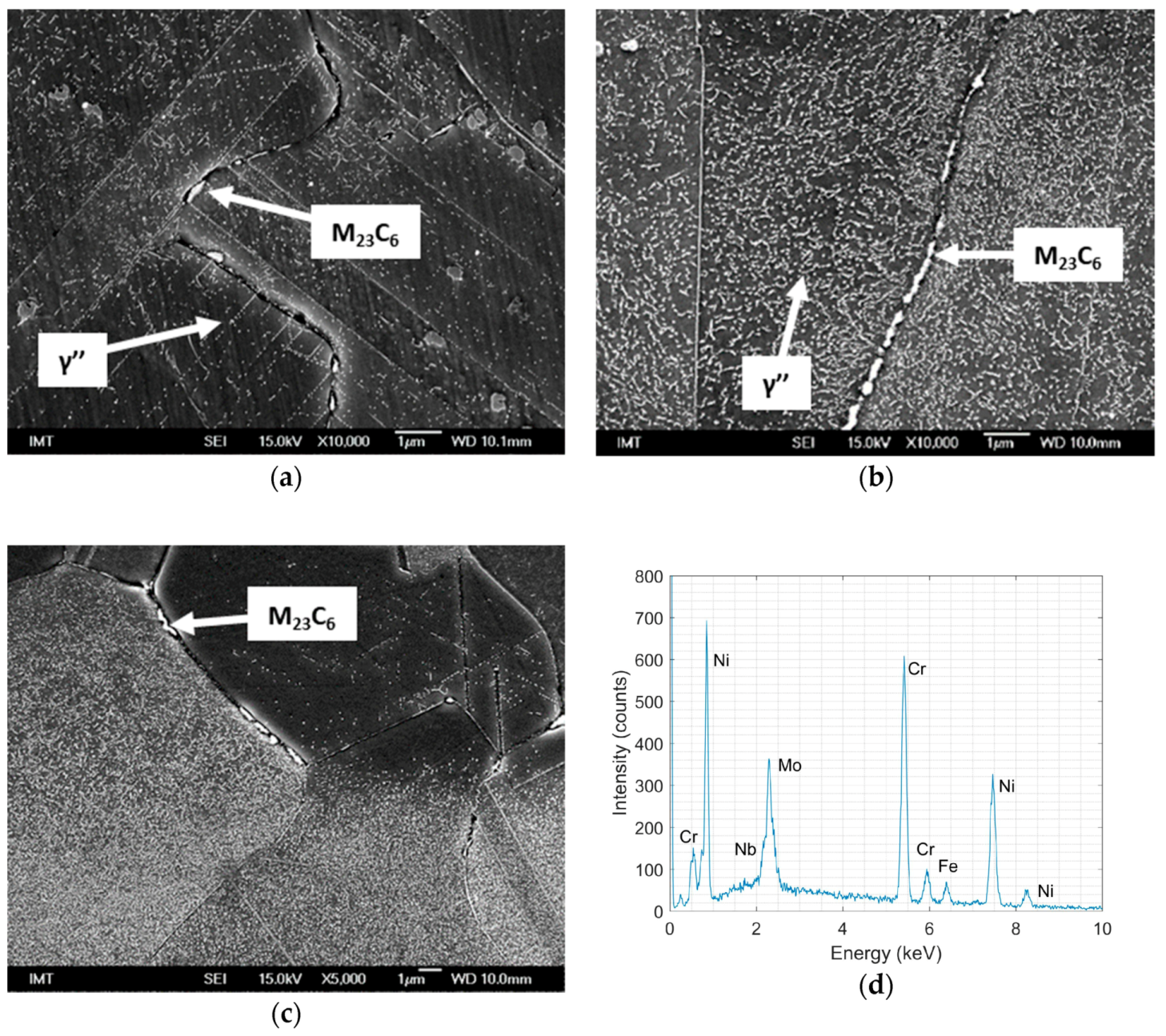

3.2. The Precipitation of Secondary Phases during Aging at 750 °C

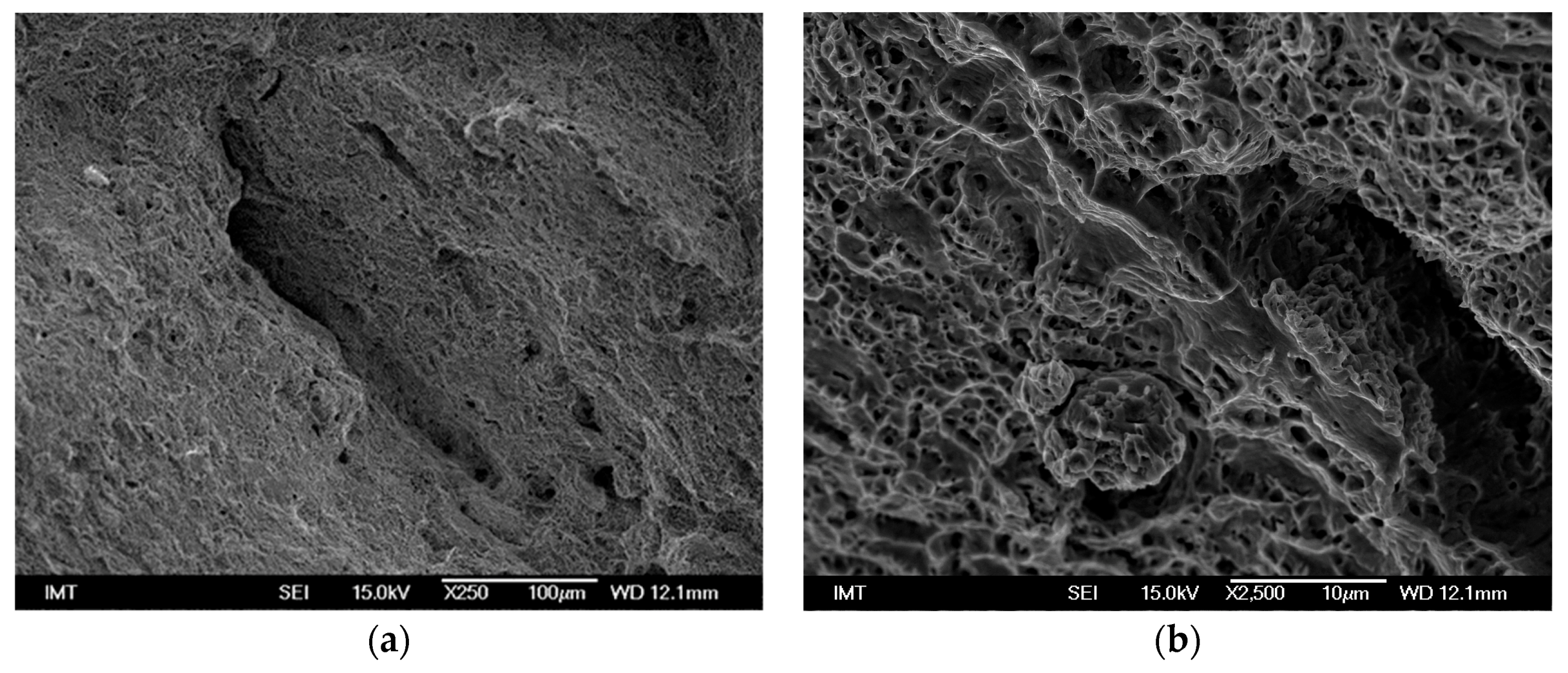

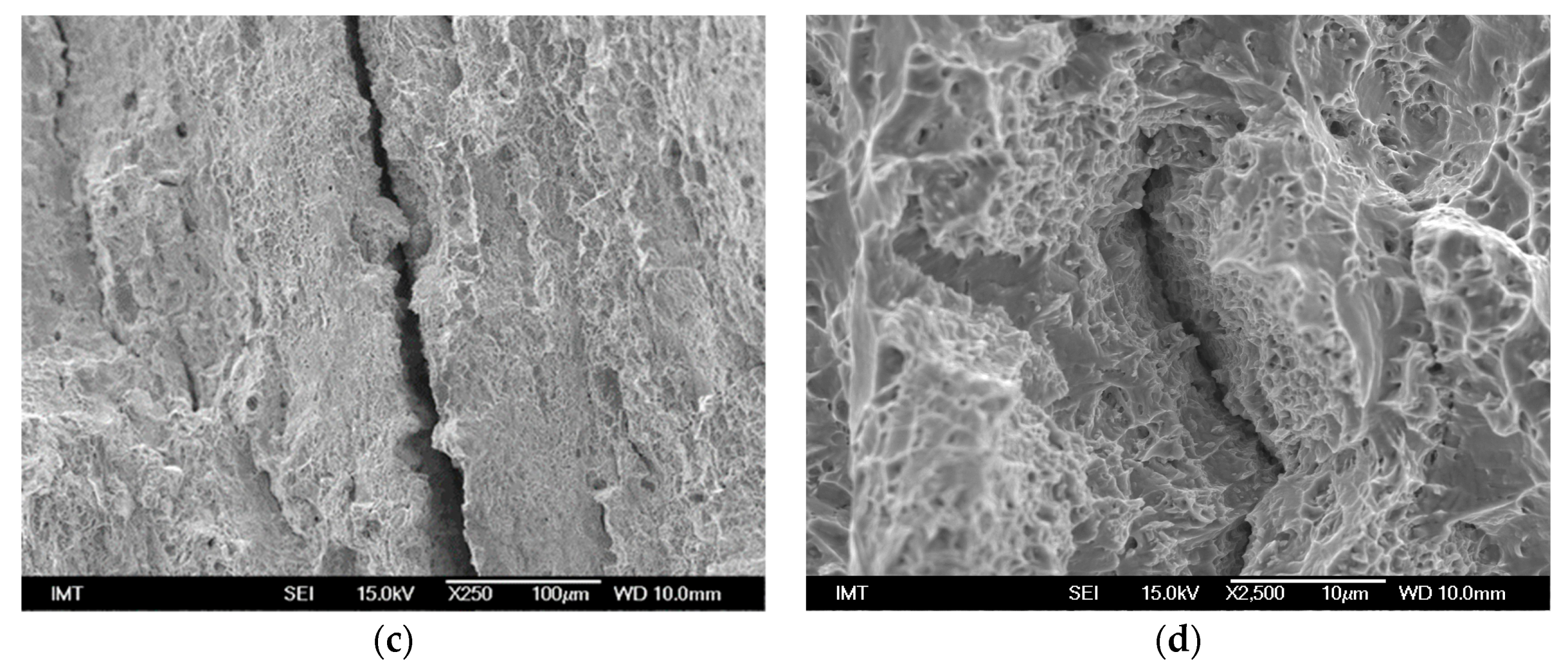

3.3. Influence of the Segregation Bands, Prior Hot Rolling and Aging on the Room-Temperature Tensile Strength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sundararaman, M.; Mukhopadhyay, P. Heterogeneous Precipitation of the γ″ Phase in Inconel 625. Mater. Sci. Forum 1985, 3, 273–280. [Google Scholar] [CrossRef]

- Aaronson, H.I.; Enomoto, M.; Lee, J.K. Mechanisms of Diffusional Phase Transformations in Metals and Alloys; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9781420063004. [Google Scholar]

- Prikhodko, S.V.; Ardell, A.J. Coarsening of γ′ in Ni-Al alloys aged under uniaxial compression: III. Characterization of the morphology. Acta Mater. 2003, 51, 5021–5036. [Google Scholar] [CrossRef]

- Matysiak, H.; Zagorska, M.; Balkowiec, A.; Adamczyk-Cieslak, B.; Cygan, R.; Cwajna, J.; Nawrocki, J.; Kurzydłowski, K.J. The Microstructure Degradation of the IN 713C Nickel-Based Superalloy After the Stress Rupture Tests. J. Mater. Eng. Perform. 2014, 23, 3305–3313. [Google Scholar] [CrossRef]

- Eiselstein, H.L.; Tillack, D.J. The Invention and Definition of Alloy 625. In Superalloys 718, 625 and Various Derivatives (1991); TMS: Warrendale, PA, USA, 1991; pp. 1–14. [Google Scholar]

- Cortial, F.; Corrieu, J.M.; Vernot-Loier, C. Influence of heat treatments on microstructure, mechanical properties, and corrosion resistance of weld alloy 625. Metall. Mater. Trans. A 1995, 26, 1273–1286. [Google Scholar] [CrossRef]

- Shankar, V.; Bhanu Sankara Rao, K.; Mannan, S. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Sundararaman, M.; Kumar, L.; Prasad, G.E.; Mukhopadhyay, P.; Banerjee, S. Precipitation of an intermetallic phase with Pt2Mo-type structure in alloy 625. Metall. Mater. Trans. A 1999, 30, 41–52. [Google Scholar] [CrossRef]

- Evans, N.D.; Maziasz, P.J.; Shingledecker, J.P.; Yamamoto, Y. Microstructure evolution of alloy 625 foil and sheet during creep at 750 °C. Mater. Sci. Eng. A 2008, 498, 412–420. [Google Scholar] [CrossRef]

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural Evolutions During Thermal Aging of Alloy 625: Impact of Temperature and Forming Process. Metall. Mat. Trans. A 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Moore, I.J.; Burke, M.G.; Palmiere, E.J. Modelling the nucleation, growth and coarsening kinetics of γ″(D022) precipitates in the Ni-base Alloy 625. Acta Mater. 2016, 119, 157–166. [Google Scholar] [CrossRef]

- Tian, Y.; Ouyang, B.; Gontcharov, A.; Gauvin, R.; Lowden, P.; Brochu, M. Microstructure evolution of Inconel 625 with 0.4 wt% boron modification during gas tungsten arc deposition. J. Alloys Compd. 2017, 694, 429–438. [Google Scholar] [CrossRef]

- Cieslak, M.J.; Headley, T.J.; Romig, A.D.; Kollie, T. A melting and solidification study of alloy 625. Metall. Trans. A 1988, 19, 2319–2331. [Google Scholar] [CrossRef]

- Hin Ac, C.; Brechet, Y.; Maugis Cd, P.; Soisson, F. Heterogeneous precipitation on dislocations: Effect of the elastic field on precipitate morphology. Philos. Mag. 2008, 88, 1555–1567. [Google Scholar] [CrossRef]

- Qin, H.; Bi, Z.; Yu, H.; Feng, G.; Du, J.; Zhang, J. Influence of stress on γ″ precipitation behavior in Inconel 718 during aging. J. Alloys Compd. 2018, 740, 997–1006. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Liu, Y.; Guo, Q.; Huang, Y.; Li, H.; Yu, J. Effect of hot deformation on γ″ and δ phase precipitation of Inconel 718 alloy during deformation&isothermal treatment. J. Alloys Compd. 2017, 716, 65–72. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.M.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef]

- Humphreys, F.L. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 0080982697. [Google Scholar]

- Tian, B.; Zickler, G.A.; Lind, C.; Paris, O. Local microstructure and its influence on precipitation behavior in hot deformed Nimonic 80a. Acta Mater. 2003, 51, 4149–4160. [Google Scholar] [CrossRef]

- Li, D.; Guo, Q.; Guo, S.; Peng, H.; Wu, Z. The microstructure evolution and nucleation mechanisms of dynamic recrystallization in hot-deformed Inconel 625 superalloy. Mater. Des. 2011, 32, 696–705. [Google Scholar] [CrossRef]

- Tehovnik, F.; Burja, J.; Podgornik, B.; Godec, M.; Vode, F. Microstructural evolution of Inconel 625 during hot rolling. Mater. Tehnol. 2015, 49, 801–806. [Google Scholar] [CrossRef]

- Guo, Q.; Li, D.; Peng, H.; Guo, S.; Hu, J.; Du, P. Nucleation mechanisms of dynamic recrystallization in Inconel 625 superalloy deformed with different strain rates. Rare Met. 2012, 31, 215–220. [Google Scholar] [CrossRef]

- Krakow, R.; Bennett, R.J.; Johnstone, D.N.; Vukmanovic, Z.; Solano-Alvarez, W.; Lainé, S.J.; Einsle, J.F.; Midgley, P.A.; Rae, C.M.F.; Hielscher, R. On three-dimensional misorientation spaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 2017, 473, 20170274. [Google Scholar] [CrossRef] [PubMed]

- Barr, C.M.; Leff, A.C.; Demott, R.W.; Doherty, R.D.; Taheri, M.L. Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 2018, 144, 281–291. [Google Scholar] [CrossRef]

- Prithiv, T.S.; Bhuyan, P.; Pradhan, S.K.; Subramanya Sarma, V.; Mandal, S. A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater. 2018, 146, 187–201. [Google Scholar] [CrossRef]

- Sharma, N.K.; Shekhar, S. Cut-off deviation for CSL boundaries in recrystallized face-centered cubic materials. Philos. Mag. 2017, 97, 2004–2017. [Google Scholar] [CrossRef]

- McCarley, J.; Tin, S. Understanding the effects of recrystallization and strain induced boundary migration on ∑3 twin boundary formation in Ni-base superalloys during iterative sub-solvus annealing. Mater. Sci. Eng. A 2019, 740–741, 427–438. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Zaefferer, S.; Raabe, D. Coupling of Electron Channeling with EBSD: Toward the Quantitative Characterization of Deformation Structures in the SEM. Jom 2013, 65, 1229–1236. [Google Scholar] [CrossRef]

- Zhang, J.-L.; Zaefferer, S.; Raabe, D. A study on the geometry of dislocation patterns in the surrounding of nanoindents in a TWIP steel using electron channeling contrast imaging and discrete dislocation dynamics simulations. Mater. Sci. Eng. A 2015, 636, 231–242. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.; Zhang, M.; Yao, Z. Evolution of twins and substructures during low strain rate hot deformation and contribution to dynamic recrystallization in alloy 617B. Mater. Sci. Eng. A 2016, 649, 369–381. [Google Scholar] [CrossRef]

- Zupanič, F.; Bončina, T.; Križman, A.; Tichelaar, F. Structure of continuously cast Ni-based superalloy Inconel 713C. J. Alloys Compd. 2001, 329, 290–297. [Google Scholar] [CrossRef]

- Mu, Y.; Wang, C.; Zhou, W.; Zhou, L. Effect of Nb on δ Phase Precipitation and the Tensile Properties in Cast Alloy IN625. Metals 2018, 8, 86. [Google Scholar] [CrossRef]

- Hu, Y.L.; Lin, X.; Yu, X.B.; Xu, J.J.; Lei, M.; Huang, W.D. Effect of Ti addition on cracking and microhardness of Inconel 625 during the laser solid forming processing. J. Alloys Compd. 2017, 711, 267–277. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Katz, M.B.; Williams, M.E. Precipitation and dissolution of δ and γ″ during heat treatment of a laser powder-bed fusion produced Ni-based superalloy. Scr. Mater. 2018, 154, 83–86. [Google Scholar] [CrossRef]

| Alloy | Cr | Mo | Fe | Nb | Ti | Al | Si | Mn | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Used alloy | 21.5 | 8.2 | 5.0 | 3.4 | 0.14 | 0.09 | 0.08 | 0.05 | 0.009 | Bal. |

| Inconel 625 | 20.0–23.0 | 8.0–10.0 | 5.0 max. | 3.15–4.15 | 0.4 max. | 0.4 max. | 0.5 max. | 0.5 max. | 0.1 max | Bal. |

| Temperature of Hot Rolling | 1050 °C | 1050 °C | 1050 °C | 1150 °C | 1150 °C | 1150 °C |

|---|---|---|---|---|---|---|

| Level of deformation (%) | 4.6 | 12.7 | 23.5 | 5.7 | 14.4 | 25.2 |

| Strain rate (s−1) | 1.63 | 2.7 | 3.66 | 1.81 | 2.87 | 3.8 |

| Phases | Ni | Cr | Mo | Fe | Nb | Ti | Si |

|---|---|---|---|---|---|---|---|

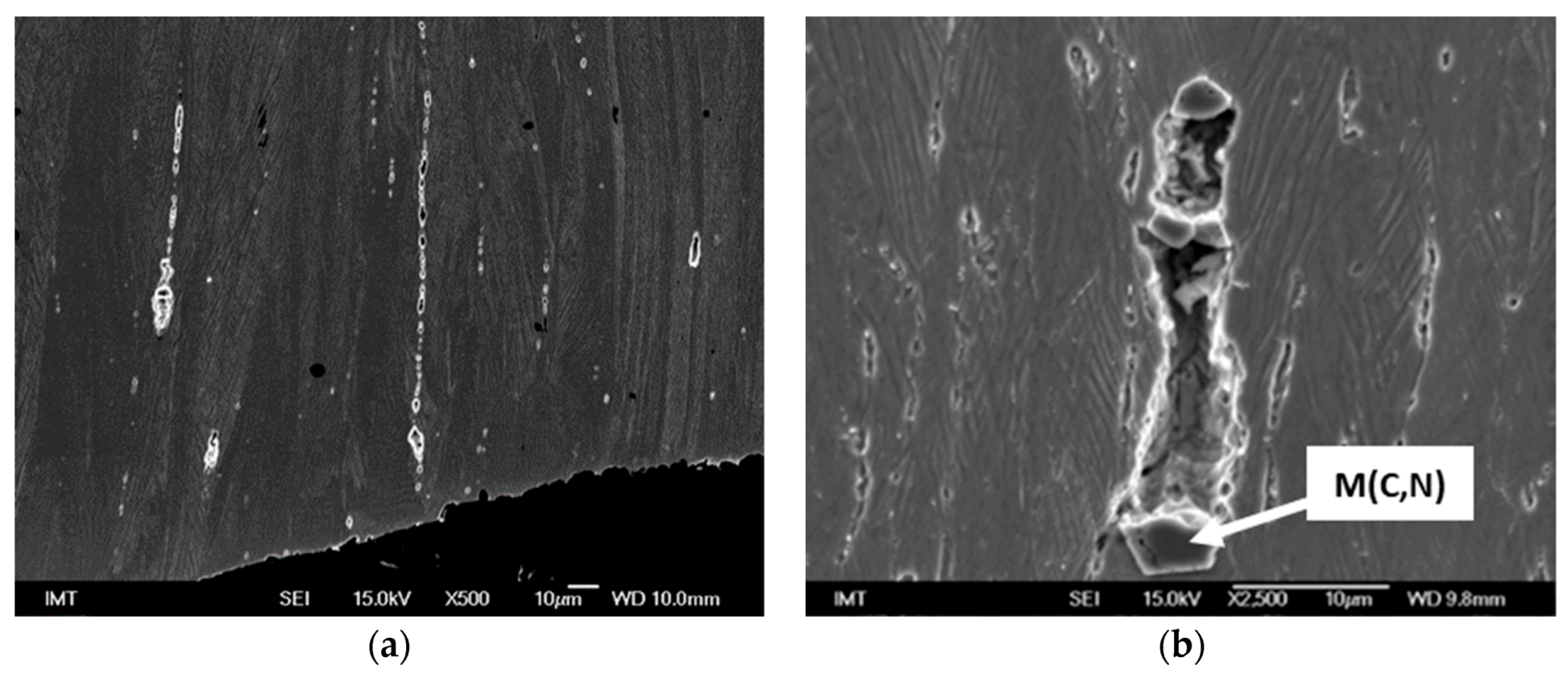

| M(C,N) (Figure 6a) | Bal. | 2.0 | 0.0 | 0.0 | 38.7 | 55.6 | - |

| MC (Figure 7a) | Bal. | 2.8 | 3.0 | 0.6 | 83.1 | 4.5 | - |

| Laves (Figure 7a) | Bal. | 11.8 | 26.8 | 1.5 | 33.2 | - | 0.6 |

| M23C6 (Figure 8d) | Bal. | 33.8 | 12.0 | 3.9 | 3.8 | - | - |

| δ (Figure 13e) | Bal. | 16.0 | 9.6 | 2.8 | 9.5 | - | - |

| Location | Size of γ″ PhaseParticles (nm) |

|---|---|

| Deformed grain in the segregation band (Figure 11c) | 79.7 ± 11.9 |

| Recrystallized grain in the segregation band (Figure 11d) | 77.5 ± 11.6 |

| Deformed grain, the inner edge of the segregation band (Figure 11e) | 80.4 ± 16.9 |

| Recrystallized grain, the inner edge of the segregation band (Figure 11f) | 196.2 ± 63.1 |

| Recrystallized grain in the inner edge of the segregation band (twin) (Figure 11f) | 72.7 ± 15.9 |

| Deformed grain in the outer edge of the segregation band (Figure 11a) | 66.6 ± 14.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malej, S.; Medved, J.; Šetina Batič, B.; Tehovnik, F.; Vode, F.; Burja, J.; Godec, M. The Influence of Segregation Bands and Hot Rolling on the Precipitation of Secondary Phases during Aging at 750 °C for Nickel Alloy 625. Metals 2019, 9, 314. https://doi.org/10.3390/met9030314

Malej S, Medved J, Šetina Batič B, Tehovnik F, Vode F, Burja J, Godec M. The Influence of Segregation Bands and Hot Rolling on the Precipitation of Secondary Phases during Aging at 750 °C for Nickel Alloy 625. Metals. 2019; 9(3):314. https://doi.org/10.3390/met9030314

Chicago/Turabian StyleMalej, Simon, Jožef Medved, Barbara Šetina Batič, Franc Tehovnik, Franci Vode, Jaka Burja, and Matjaž Godec. 2019. "The Influence of Segregation Bands and Hot Rolling on the Precipitation of Secondary Phases during Aging at 750 °C for Nickel Alloy 625" Metals 9, no. 3: 314. https://doi.org/10.3390/met9030314