Evaluation of the Effectiveness of a Soil Treatment Using Calcium Carbonate Precipitation from Cultivated and Lyophilized Bacteria in Soil’s Compaction Water

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biotechnological Solutions

2.2. Soils Description

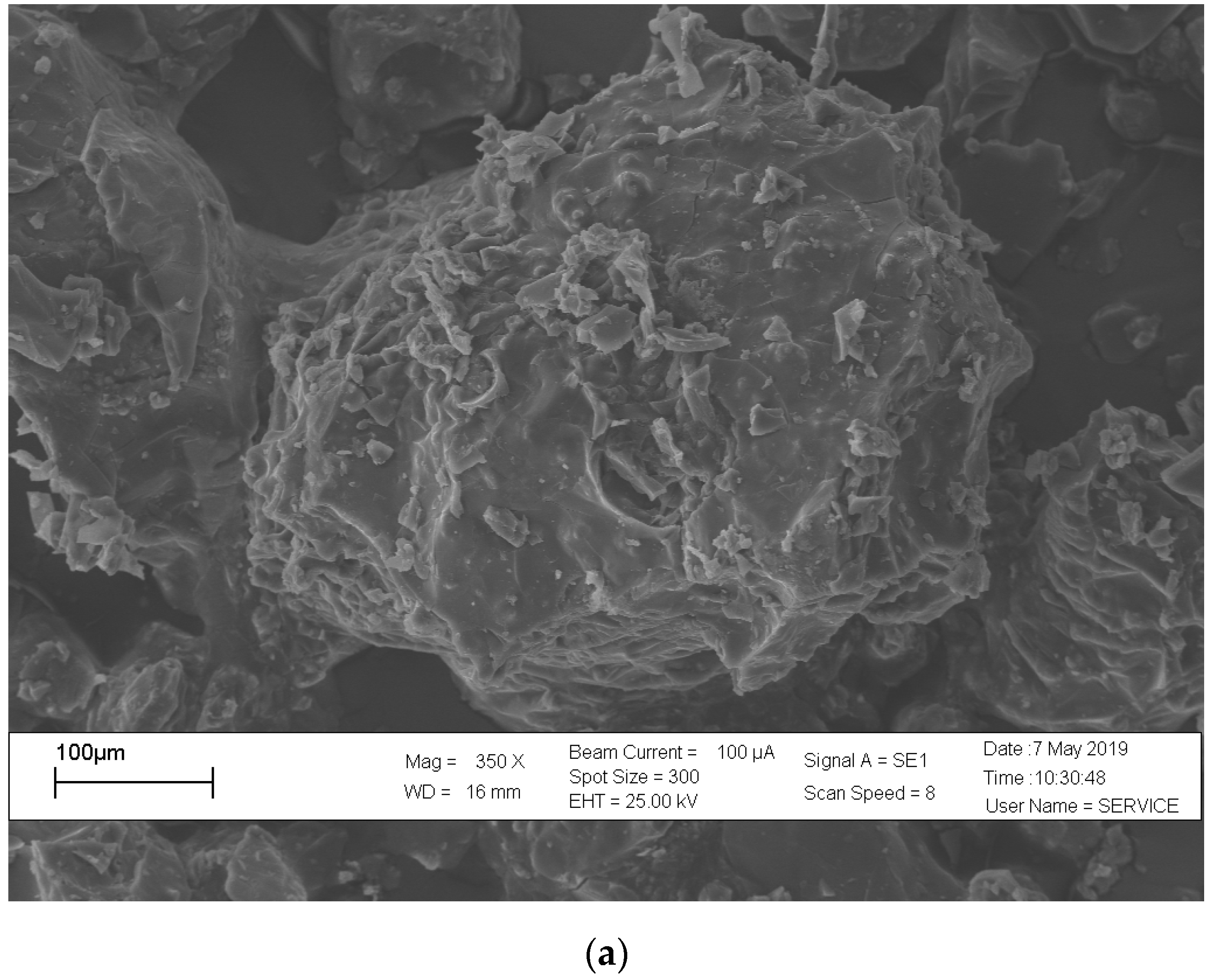

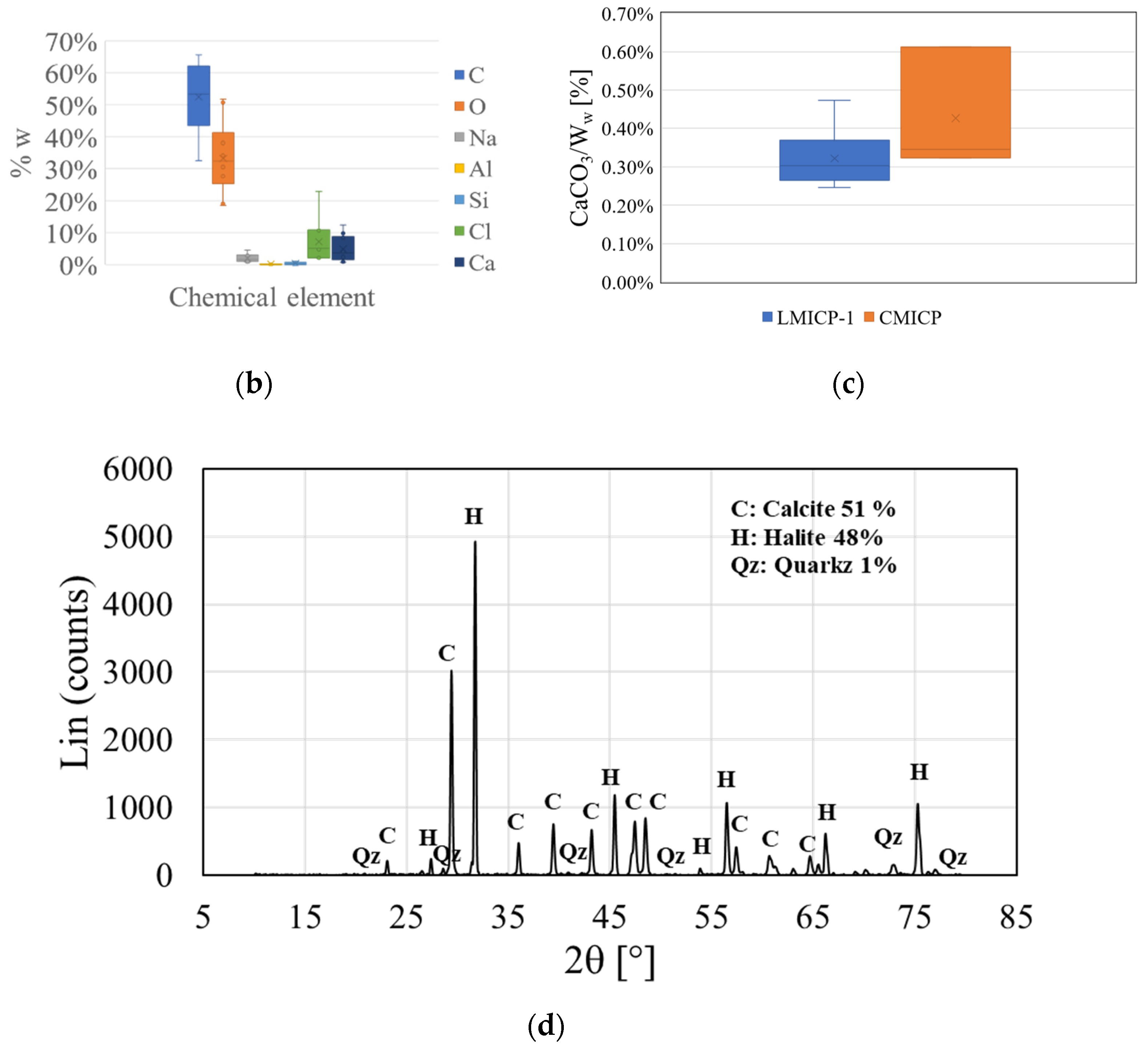

2.2.1. Lampa Clay

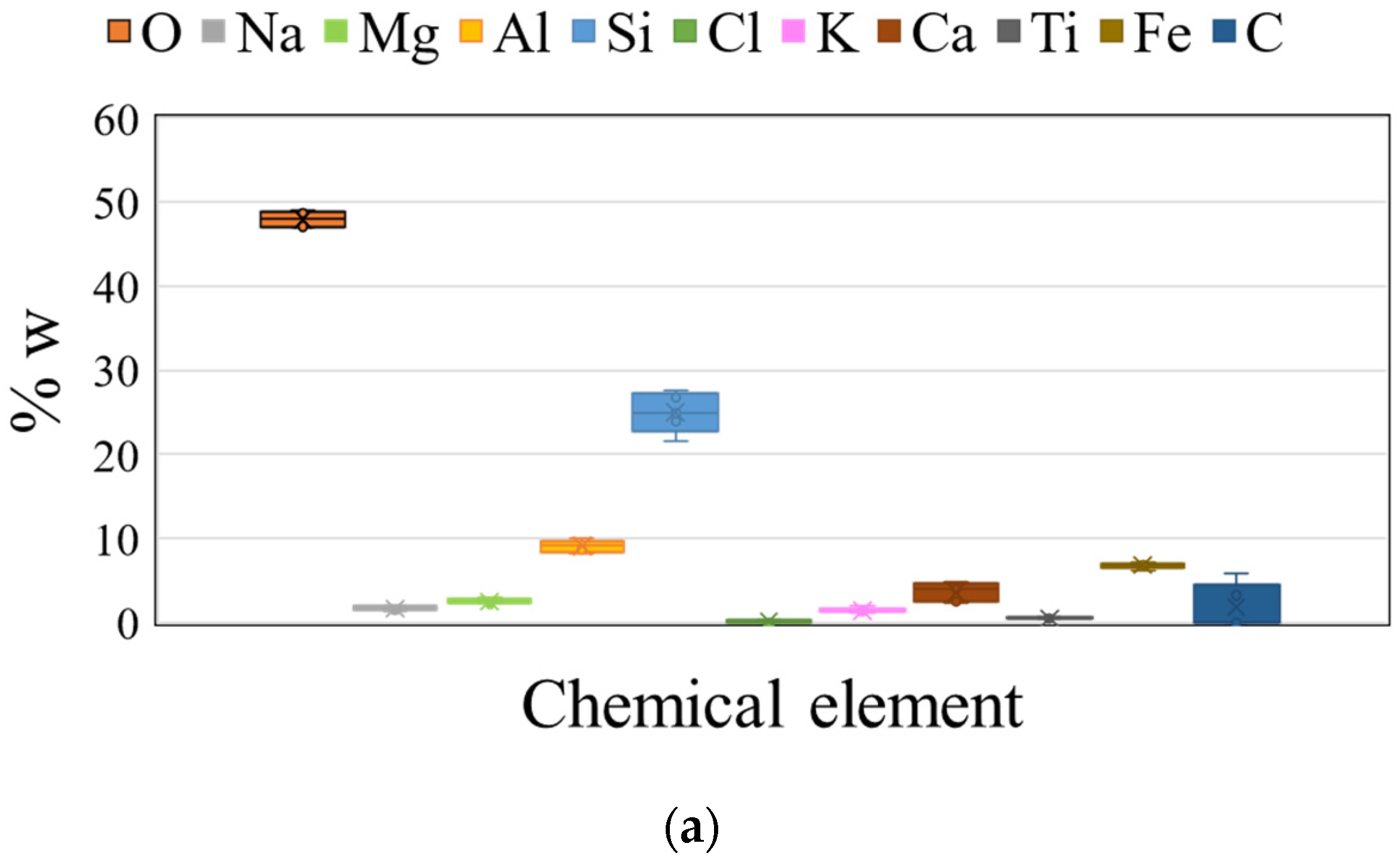

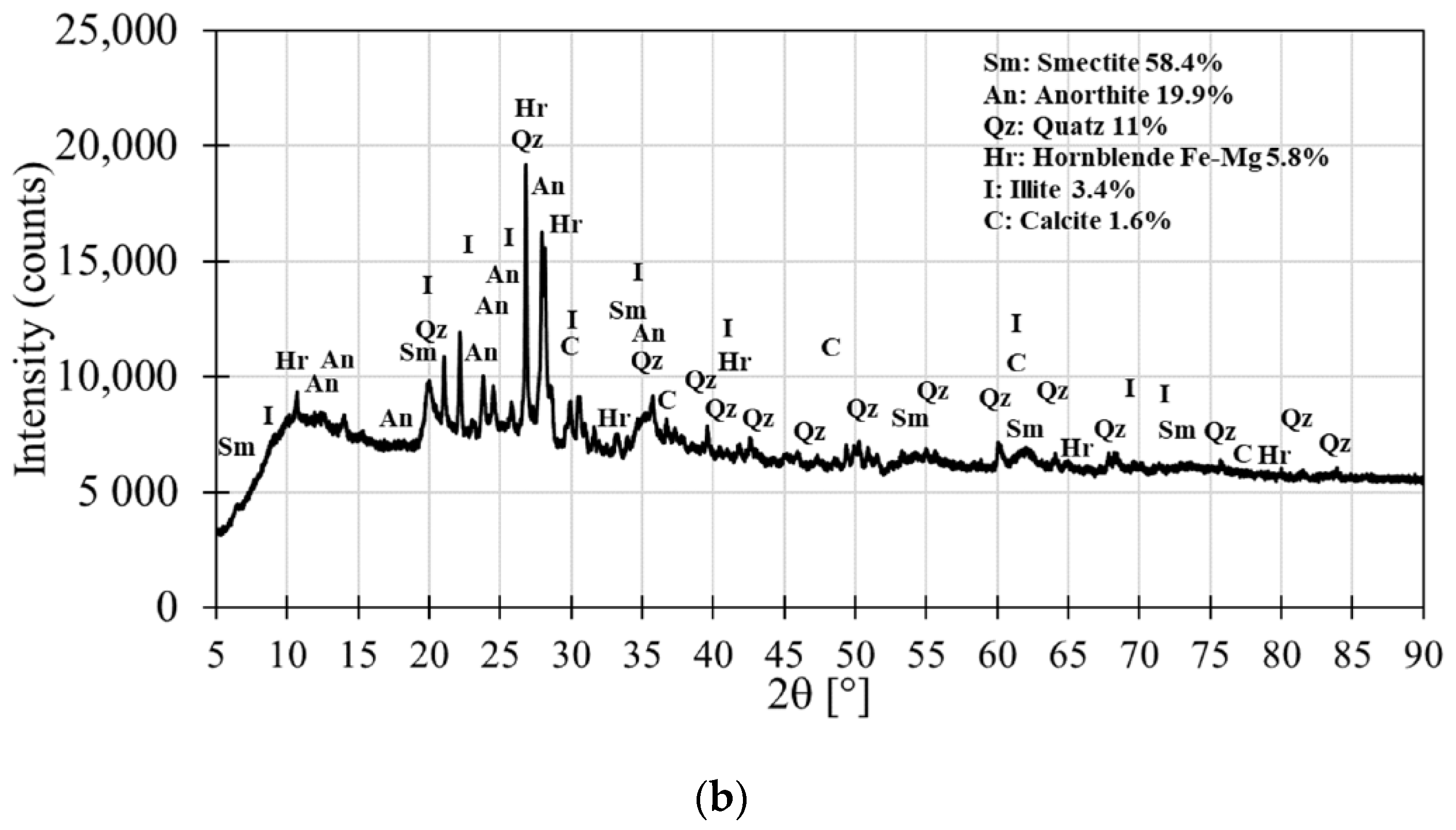

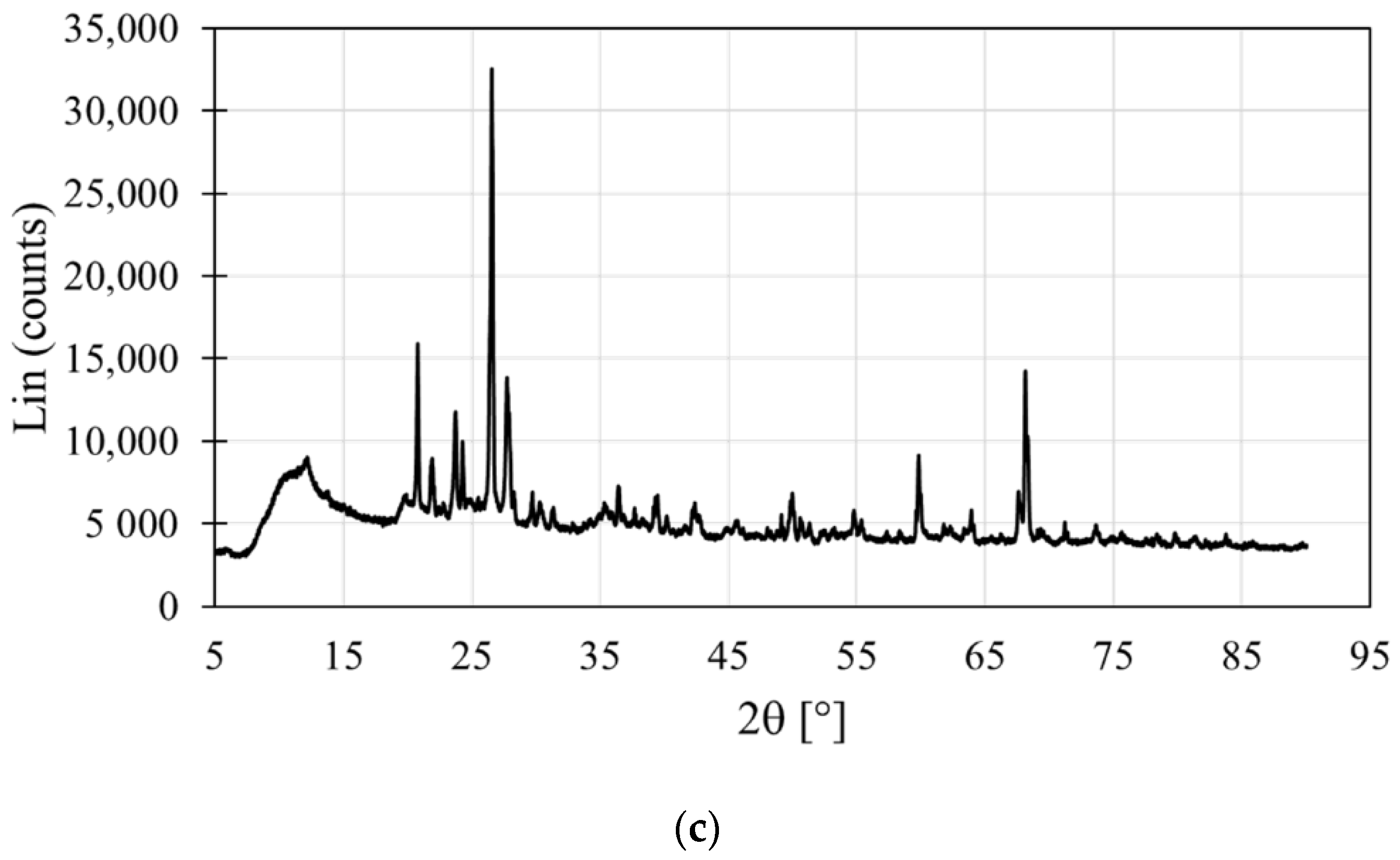

2.2.2. Maicillo Silty Sand

2.3. Application of MICP and Experimental Program

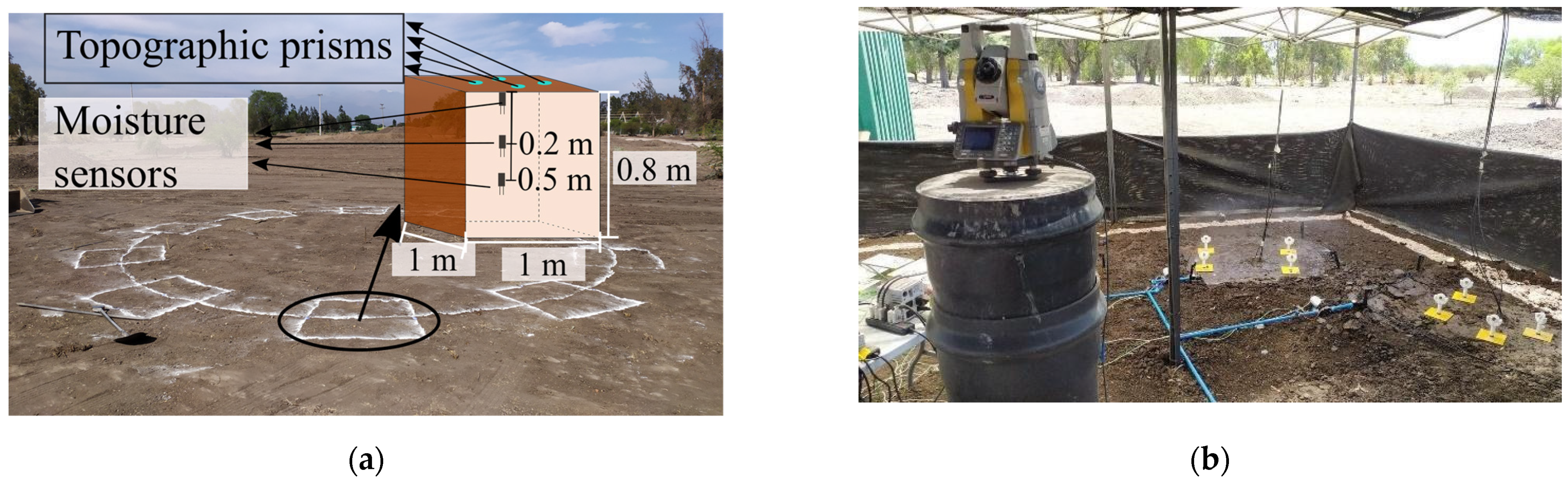

2.4. Field Test on Lampa Clay

3. Results and Discussions

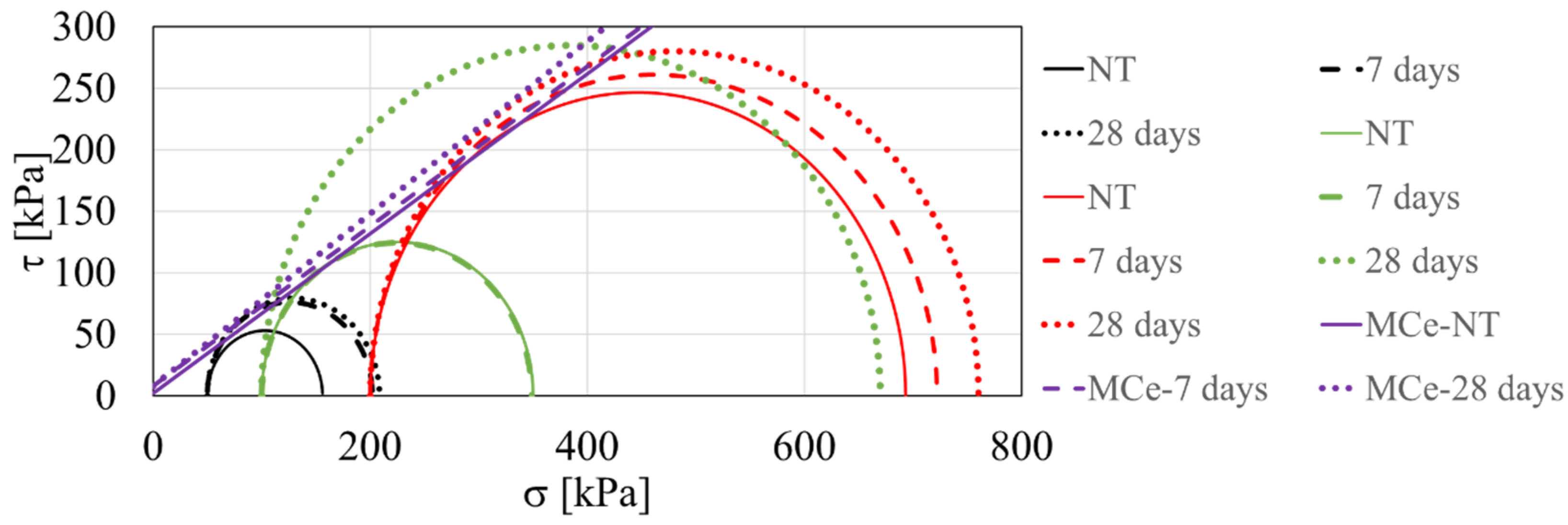

3.1. Maicillo

3.1.1. Maicillo Treated with CMICP Compacted at 80% of Proctor Density

3.1.2. Effect of LMICP on Small-Strain Stiffness

3.1.3. Maicillo Treated with LMICP Compacted at 90% of Proctor Density

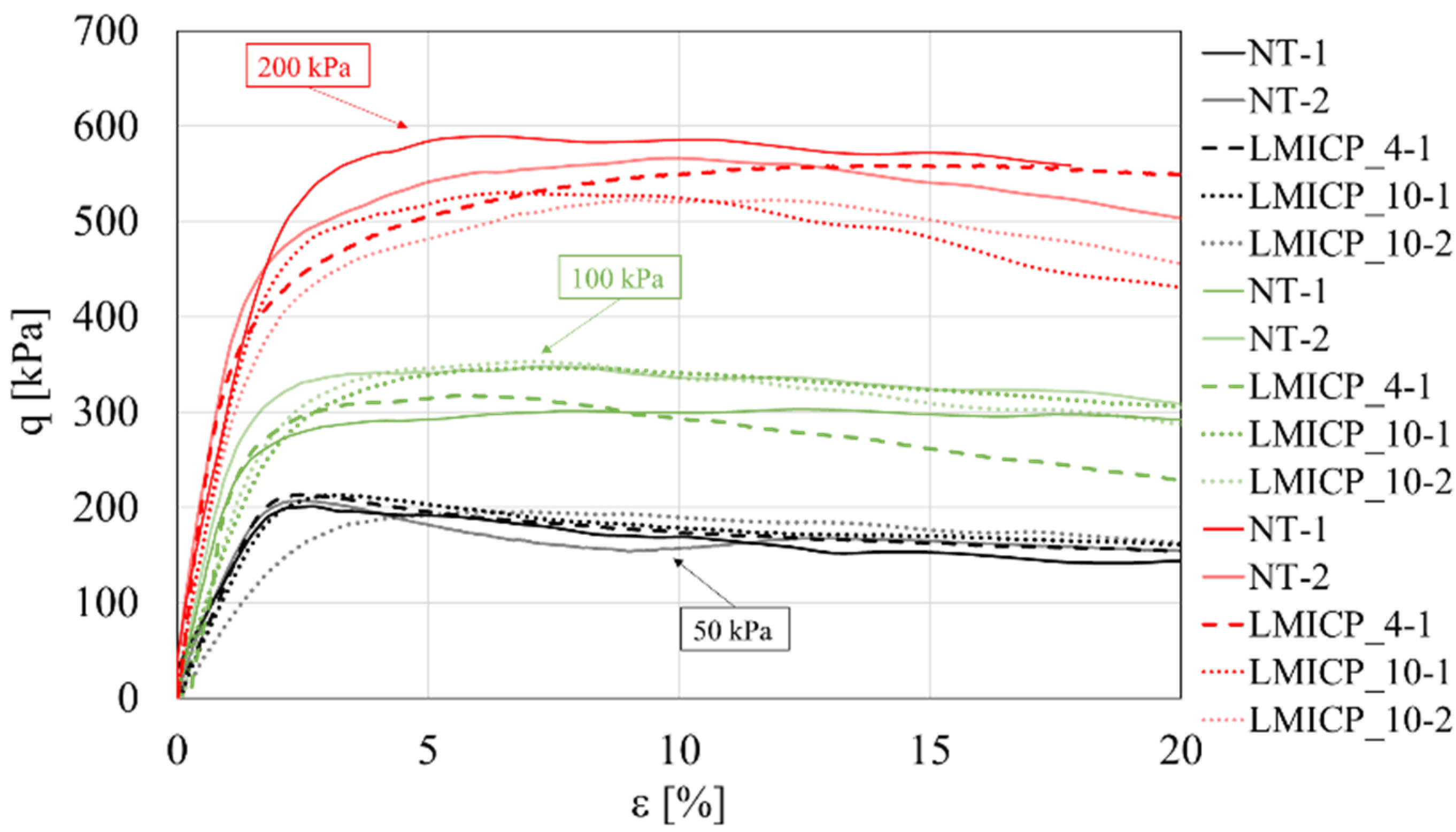

3.1.4. Discussion of Results in Maicillo Sandy Silt

3.2. Lampa Clay

3.2.1. Laboratory

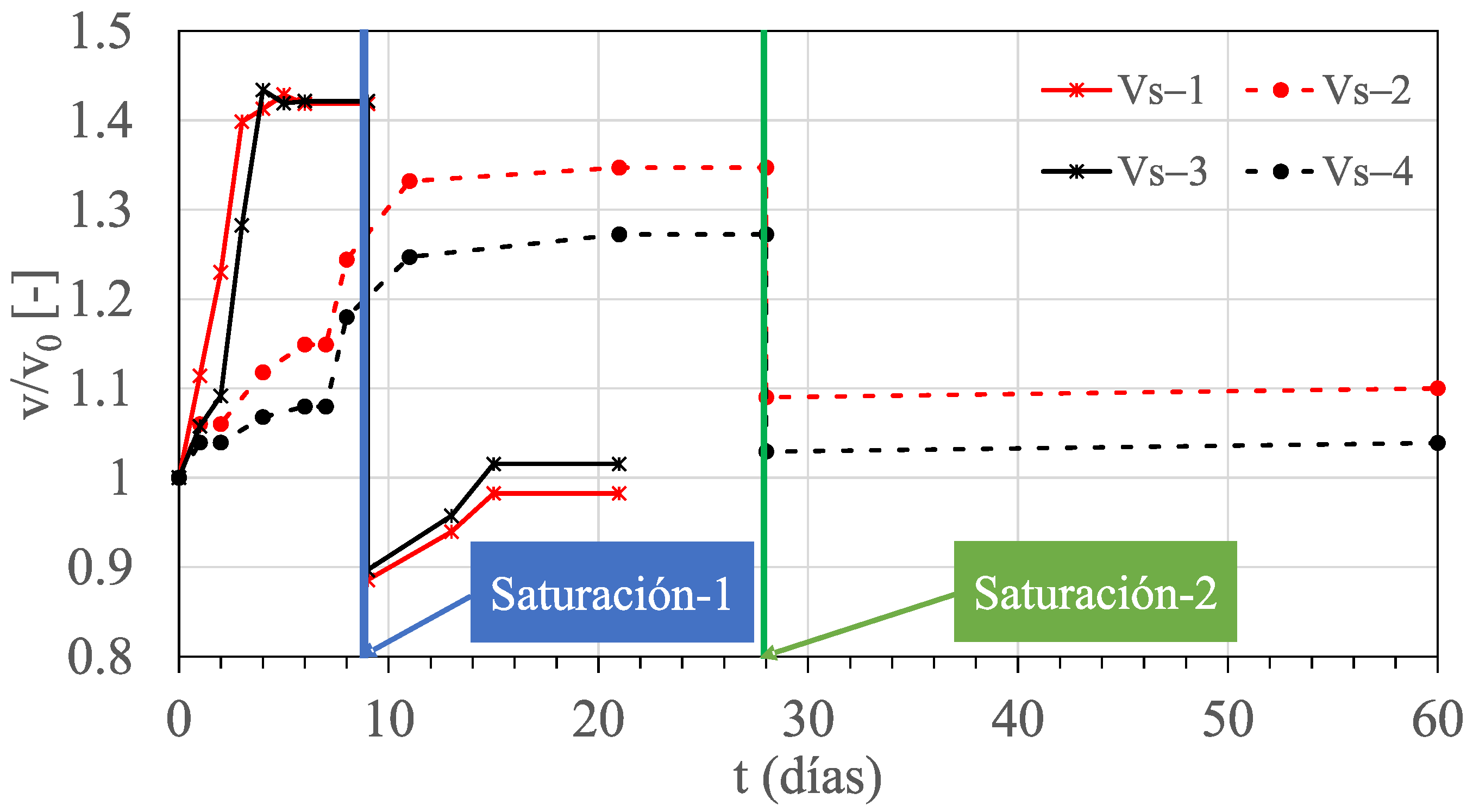

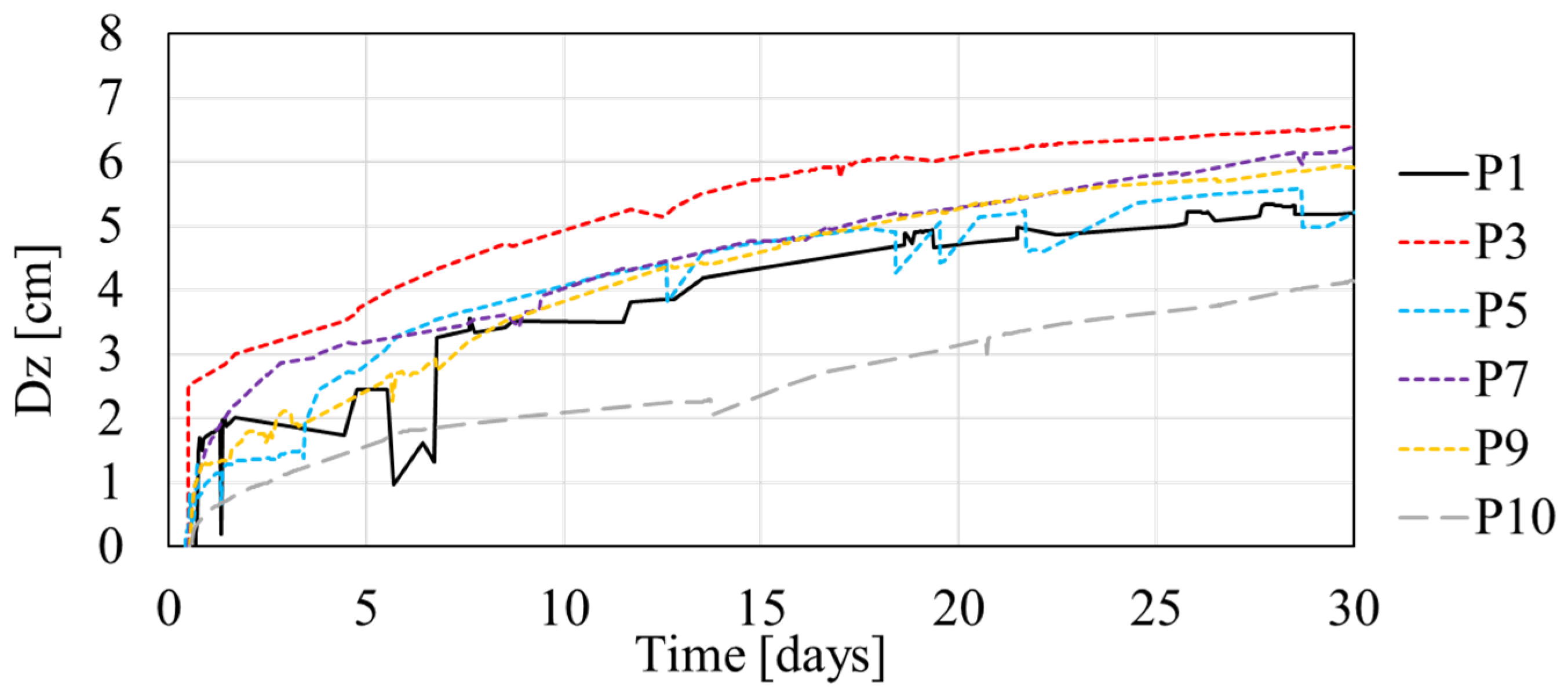

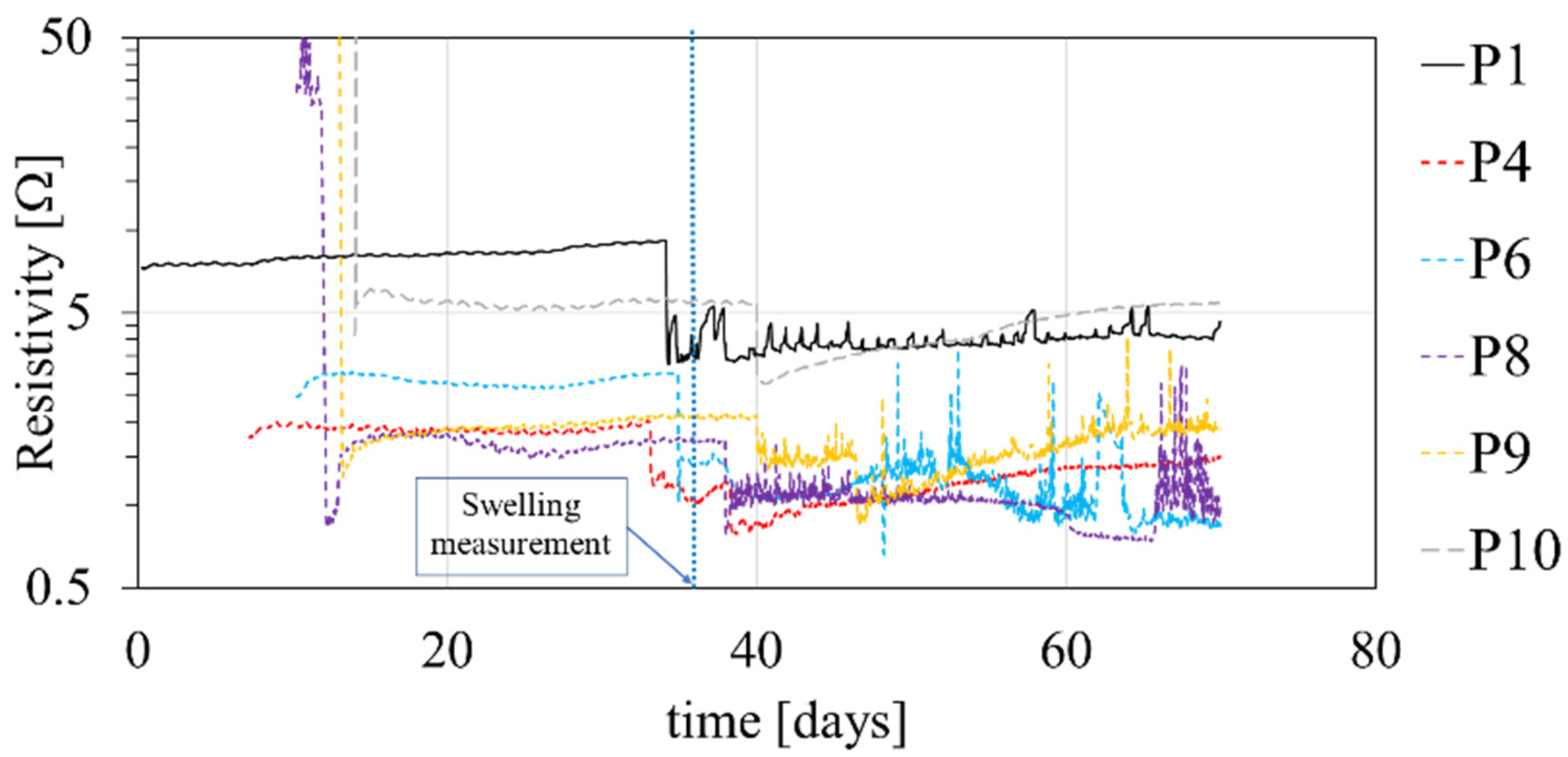

3.2.2. Field Test

3.2.3. Discussion of Results in Soil with Expansive Clay

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, B.M. Advanced Soil Mechanics, 5th ed.; CRC Press: New York, NY, USA, 2019; ISBN 9781351215183. [Google Scholar]

- Jiang, X.; Lu, Q.; Chen, S.; Dai, R.; Gao, J.; Li, P. Research progress of soft soil foundation treatment technology. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Changchun, China, 21–23 August 2020; Volume 455, p. 012081. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D. An Introduction to Geotechnical Engineering; Prentice-Hall: Englewood Cliffs, NJ, USA, 1981; ISBN 0134843940. [Google Scholar]

- Wise, J.R.; Hudson, W.R. An Examination of Expansive Clay Problems in Texas; Center for Highway Research, The University of Texas at Austin: Austin, TX, USA, 1971. [Google Scholar]

- Lu, S.; Sun, F.; Zong, Y. Effect of rice husk biochar and coal fly ash on some physical properties of expansive clayey soil (Vertisol). Catena 2014, 114, 37–44. [Google Scholar] [CrossRef]

- Jamsawang, P.; Nuansrithong, N.; Voottipruex, P.; Songpiriyakij, S.; Jongpradist, P. Laboratory investigations on the swelling behavior of composite expansive clays stabilized with shallow and deep clay-cement mixing methods. Appl. Clay Sci. 2017, 148, 83–94. [Google Scholar] [CrossRef]

- Dayioglu, M.; Cetin, B.; Nam, S. Stabilization of expansive Belle Fourche shale clay with different chemical additives. Appl. Clay Sci. 2017, 146, 56–69. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Santamarina, J.C. Biological Considerations in Geotechnical Engineering. J. Geotech. Geoenvironmental Eng. 2005, 131, 1222–1233. [Google Scholar] [CrossRef] [Green Version]

- Terzis, D.; Laloui, L. A decade of progress and turning points in the understanding of bio-improved soils: A review. Geomech. Energy Environ. 2019, 19, 100–116. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenvironmental Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Whiffin, V.S.; van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-art review of microbial-induced calcite precipitation and its sustainability in engineering applications. Sustainability 2020, 12, 6281. [Google Scholar] [CrossRef]

- Meldrum, F.C. Calcium carbonate in biomineralisation and biomimetic chemistry. Int. Mater. Rev. 2003, 48, 187–224. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, L.; Yan, H.; Zizak, I.; Zaslansky, P.; Li, Y.; Qi, L.; Ma, Y. Vaterite Microdisc Mesocrystals Exposing the (001) Facet Formed via Transformation from Proto-Vaterite Amorphous Calcium Carbonate. Cryst. Growth Des. 2020, 20, 3482–3492. [Google Scholar] [CrossRef]

- Enyedi, N.T.; Makk, J.; Kótai, L.; Berényi, B.; Klébert, S.; Sebestyén, Z.; Molnár, Z.; Borsodi, A.K.; Leél-Őssy, S.; Demény, A.; et al. Cave bacteria-induced amorphous calcium carbonate formation. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Cacchio, P.; Del Gallo, M. A novel approach to isolation and screening of calcifying bacteria for biotechnological applications. Geosci. 2019, 9, 479. [Google Scholar] [CrossRef] [Green Version]

- van Paassen, L. Biogrout: Ground Improvement by Microbially Induced Carbonate Precipitation. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2009. [Google Scholar]

- Tang, C.S.; Yin, L.-Y.; Jiang, N.-J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 1–23. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenvironmental Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef]

- Jiang, N.-J.; Soga, K. The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel–sand mixtures. Géotechnique 2017, 67, 42–53. [Google Scholar] [CrossRef] [Green Version]

- Cardoso, R.; Pires, I.; Duarte, S.O.D.; Monteiro, G.A. Effects of clay’s chemical interactions on biocementation. Appl. Clay Sci. 2018, 156, 96–103. [Google Scholar] [CrossRef]

- Li, M.; Fang, C.; Kawasaki, S.; Achal, V. Fly ash incorporated with biocement to improve strength of expansive soil. Sci. Rep. 2018, 8, 2565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, B.; Zhu, C.; Tang, C.S.; Xie, Y.H.; Yin, L.Y.; Cheng, Q.; Shi, B. Bio-remediation of desiccation cracking in clayey soils through microbially induced calcite precipitation (MICP). Eng. Geol. 2020, 264, 105389. [Google Scholar] [CrossRef]

- Chittoori, B.C.S.; Burbank, M.; Islam, M.T. Evaluating the Effectiveness of Soil-Native Bacteria in Precipitating Calcite to Stabilize Expansive Soils. In Proceedings of the IFCEE 2018: Innovations in Ground Improvements for Soils, Pavements, and Subgrades: Selected Papers from Sessions of the International Foundation Congress and Equipment, Orlando, FL, USA, 5–10 March 2018; pp. 59–68. [Google Scholar]

- Chittoori, B.C.S.; Rahman, T.; Burbank, M.; Ali, A.; Moghal, B. Evaluating shallow mixing protocols as application methods for microbial induced calcite precipitation targeting expansive soil treatment. In Proceedings of the Geo-Congress 2019: Soil Improvement, Philadelphia, PA, USA, 24–27 March 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 250–259. [Google Scholar]

- Morales, L.; Garzón, E.; Romero, E.; Sánchez-Soto, P.J. Microbiological induced carbonate (CaCO3) precipitation using clay phyllites to replace chemical stabilizers (cement or lime). Appl. Clay Sci. 2019, 174, 15–28. [Google Scholar] [CrossRef]

- Morales, L.; Romero, E.; Jommi, C.; Garzón, E.; Giménez, A. Feasibility of a soft biological improvement of natural soils used in compacted linear earth construction. Acta Geotech. 2015, 10, 157–171. [Google Scholar] [CrossRef]

- ASTM D4373-21. Standard Test Method for Rapid Determination of Carbonate Content of Soils; ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–5. [Google Scholar]

- Rodríguez, P.C.A. Un método simplificado de predicción de hinchamiento de arcillas expansivas debido a cambios de humedad. Obras y Proy. 2020, 3608, 35–44. [Google Scholar] [CrossRef]

- Doebelin, N.; Kleeberg, R. Profex: A graphical user interface for the Rietveld refinement program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bascuñán-Chaparro, S.; Moffat-Covarrubias, R. Relación Entre la Erosión Producida por un Flujo Superficial en Suelos Finos y Algunas Propiedades de Estos. Undergraduate Thesis, Universidad de Chile, Santiago, Chile, 2010. [Google Scholar]

- Rodriguez, P.; Poblete, M. Caracterizacion Geomecanica y Mineralogica del Maicillo en la Cordillera de Nahuelbuta. Undergraduate Thesis, Universidad Católica de la Santísima Concepción, Concepción, Chile, 2015. [Google Scholar]

- Toro, K. Influencia de las Características Geológicas en las Propieddes Geotécticas de Granitoides Jurásicos y Suelos Asociados en la ruta 68. Ph.D. Thesis, Universidad de Chile, Santiago, Chile, 2007. [Google Scholar]

- ASTM D6913/D6913M-17. Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis; ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–34. [Google Scholar]

- ASTM D4318-17. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–20. [Google Scholar]

- ASTM D1557-12. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)); ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–14. [Google Scholar]

- ASTM D4546-14. Standard Test Methods for One-Dimensional Swell or Collapse of Soils; ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–10. [Google Scholar]

- ASTM D7181—20. Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils; ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–12. [Google Scholar]

- Cui, M.J.; Zheng, J.J.; Zhang, R.J.; Lai, H.J.; Zhang, J. Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar] [CrossRef]

- Zehner, J.; Røyne, A.; Wentzel, A.; Sikorski, P. Microbial-induced calcium carbonate precipitation: An experimental toolbox for in-situ and real time investigation of micro-scale pH evolution. RSC Adv. 2020, 10, 20485–20493. [Google Scholar] [CrossRef]

| Bacteria | ID | BAC (g/L) | Ash (g/L) | REC (g/L) |

|---|---|---|---|---|

| Cultivated | CMICP | 16 | 0 | 24 |

| Lyophilized | LMCIP-1 | 16 | 6 | 24 |

| LMICP-2 | 32 | 12 | 48 | |

| LMICP-4 | 64 | 24 | 96 |

| Soil | Maicillo | Lampa Clay |

|---|---|---|

| Gravel | 0.5% | 0% |

| Sand | 87.5% | 13% |

| Fine content | 12% | 87% |

| Liquid limit, LL | 36% | 78% |

| Plastic index, IP | 11% | 49% |

| USCS | SP-SM | CH |

| Gs | 2.75 | 2.48 |

| Maximum Proctor density | 19.52 kN/m3 | 16.57 kN/m3 |

| Optimum water content | 10% | 20% |

| Soil | Treatment ID | Curing Time | % Maximum Proctor Dry Density | Test |

|---|---|---|---|---|

| Lampa clay | CMICP | 7 and 28 days | 100% | Free swelling/swelling pressure |

| LMICP-8 | 15 days | 80% | ||

| LMICP-20 | ||||

| Maicillo | CMICP | 7 and 28 days | 80% | CID triaxial test |

| LMICP-20 | 0 to 7 days | 90% | Bender Element test | |

| LMICP-4 | 0 to 28 days | |||

| LMICP-10 | 15 days | CID triaxial test | ||

| LMICP-10 | Triaxial compression test |

| Soil Parcel | ID | Concentrations | ||

|---|---|---|---|---|

| BAC (g/L) | Ash (g/L) | REC (g/L) | ||

| P1–P2 | UT | 0 | 0 | 0 |

| P3–P4 | LMICP-50 | 800 | 300 | 1200 |

| P5–P6 | LMICP-75 | 1200 | 450 | 1800 |

| P7–P8 | LMICP-100 | 1600 | 600 | 2400 |

| P9 | REC-100 | 0 | 0 | 2400 |

| P10 | BAC-100 | 1600 | 600 | 0 |

| Confinement (kPa) | Case | Esec (MPa) |

|---|---|---|

| 50 | NT | 4 |

| 7 | 6.7 | |

| 28 | 6.5 | |

| 100 | NT | 5.6 |

| 7 | 5.4 | |

| 28 | 22.2 | |

| 200 | NT | 11 |

| 7 | 7.9 | |

| 28 | 12.5 |

| Condition | εv (%) |

|---|---|

| NT_1 | 5% |

| NT_2 | 4.7% |

| CMICP_1 | 0% |

| CMICP_2 | 0% |

| Condition | εv (%) |

|---|---|

| NT_1 | 9.0% |

| NT_2 | 9.7% |

| LMICP-8_1 | 5.8% |

| LMICP-8_2 | 3.5% |

| LMICP-20_1 | 2.3% |

| LMICP-20_2 | 0% |

| REC-20_1 | 0.5% |

| REC-20_2 | 0% |

| Parcel | LL | IP |

|---|---|---|

| 1 | 56 | 26 |

| 4 | 56 | 27 |

| 6 | 54 | 27 |

| 8 | 55 | 31 |

| 9 | 55 | 27 |

| 10 | 60 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valencia-Galindo, M.; Sáez, E.; Ovalle, C.; Ruz, F. Evaluation of the Effectiveness of a Soil Treatment Using Calcium Carbonate Precipitation from Cultivated and Lyophilized Bacteria in Soil’s Compaction Water. Buildings 2021, 11, 545. https://doi.org/10.3390/buildings11110545

Valencia-Galindo M, Sáez E, Ovalle C, Ruz F. Evaluation of the Effectiveness of a Soil Treatment Using Calcium Carbonate Precipitation from Cultivated and Lyophilized Bacteria in Soil’s Compaction Water. Buildings. 2021; 11(11):545. https://doi.org/10.3390/buildings11110545

Chicago/Turabian StyleValencia-Galindo, Miguel, Esteban Sáez, Carlos Ovalle, and Francisco Ruz. 2021. "Evaluation of the Effectiveness of a Soil Treatment Using Calcium Carbonate Precipitation from Cultivated and Lyophilized Bacteria in Soil’s Compaction Water" Buildings 11, no. 11: 545. https://doi.org/10.3390/buildings11110545