State of the Art on Heat Pumps for Residential Buildings

Abstract

:1. Introduction Why Heat Pumps?

2. Method

- (1)

- Paper published only in the peer-reviewed journals or conferences,

- (2)

- Papers published after 2001,

- (3)

- Papers that evaluated the performance of heat pumps through simulations, or empirical analysis in residential buildings, and

- (4)

- Papers that performed techno-economic analysis and comparisons on heat pumps under different climates.

3. Heat Pump Basic Overview

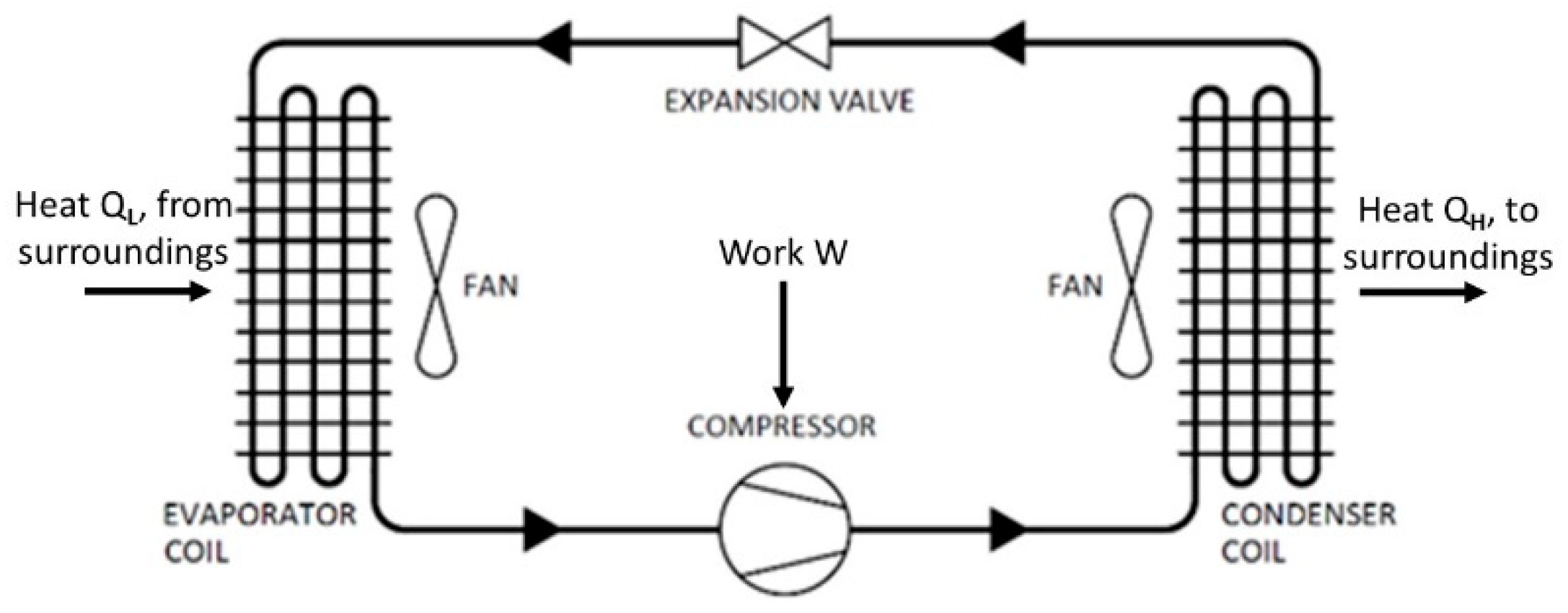

3.1. Basic Refrigeration Cycle

- (1)

- In the compression stage, the vapour state refrigerant is compressed, increasing its pressure and temperature.

- (2)

- In the condensation stage, the high-temperature vapour refrigerant flows to the condenser, where the heat flows to the sink. The refrigerant becomes a liquid but is still at high pressure and temperature.

- (3)

- The refrigerant pressure and temperature are reduced in the expansion stage as it flows into an expansion valve.

- (4)

- In the evaporation stage, the cold liquid refrigerant is vaporized into a cold vapour refrigerant by absorbing heat from the source. The refrigerant flows into the compressor for the next cycle.

- is the heat from the source;

- is the heat released to the sink;

- W is the work required.

- is the absolute temperature of the heat source of the engine;

- is the absolute temperature of the low temperature exhaust.

3.2. Heat Pump Components

3.2.1. Four-Way Valve

3.2.2. Heat Exchangers

3.2.3. Suction Line Heat Exchanger

4. Classification of Heat Pumps

4.1. Air Source Heat Pump (ASHP)

4.1.1. Air-to-Air Heat Pump

4.1.2. Air-to-Water Heat Pump

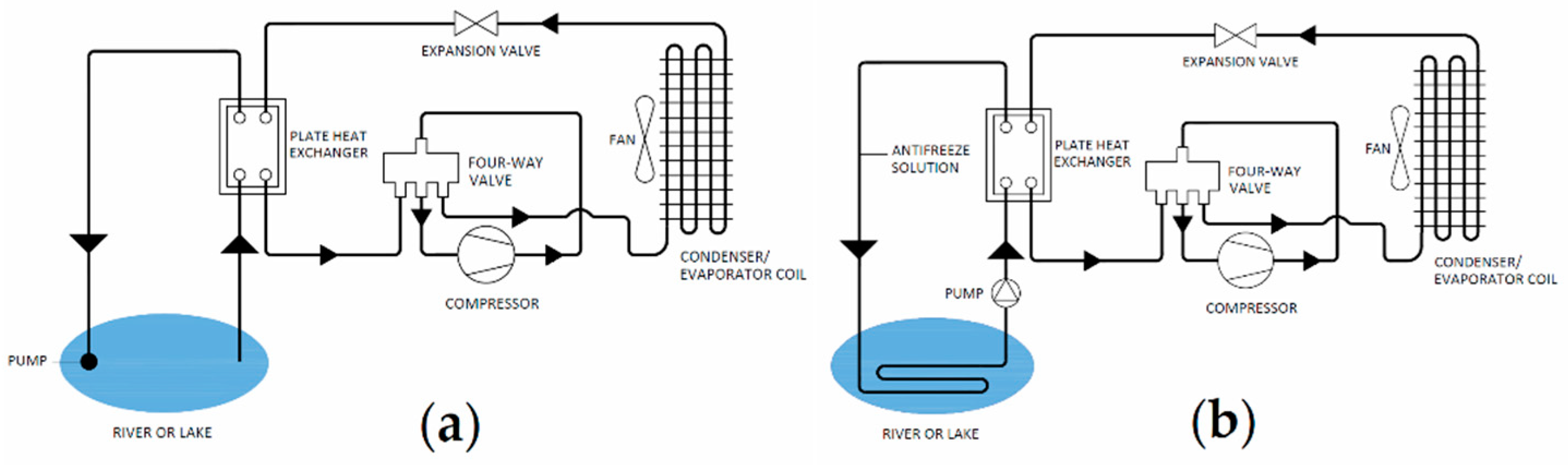

4.2. Water Source Heat Pump (WSHP)

4.2.1. Water-to-Water Heat Pump

4.2.2. Water-to-Air Heat Pump

4.3. Ground Source Heat Pump (GSHP)

4.3.1. Ground Coupled Heat Pump (GCHP)

4.3.2. Direct Expansion-Ground Source Heat Pump (DX-GSHP)

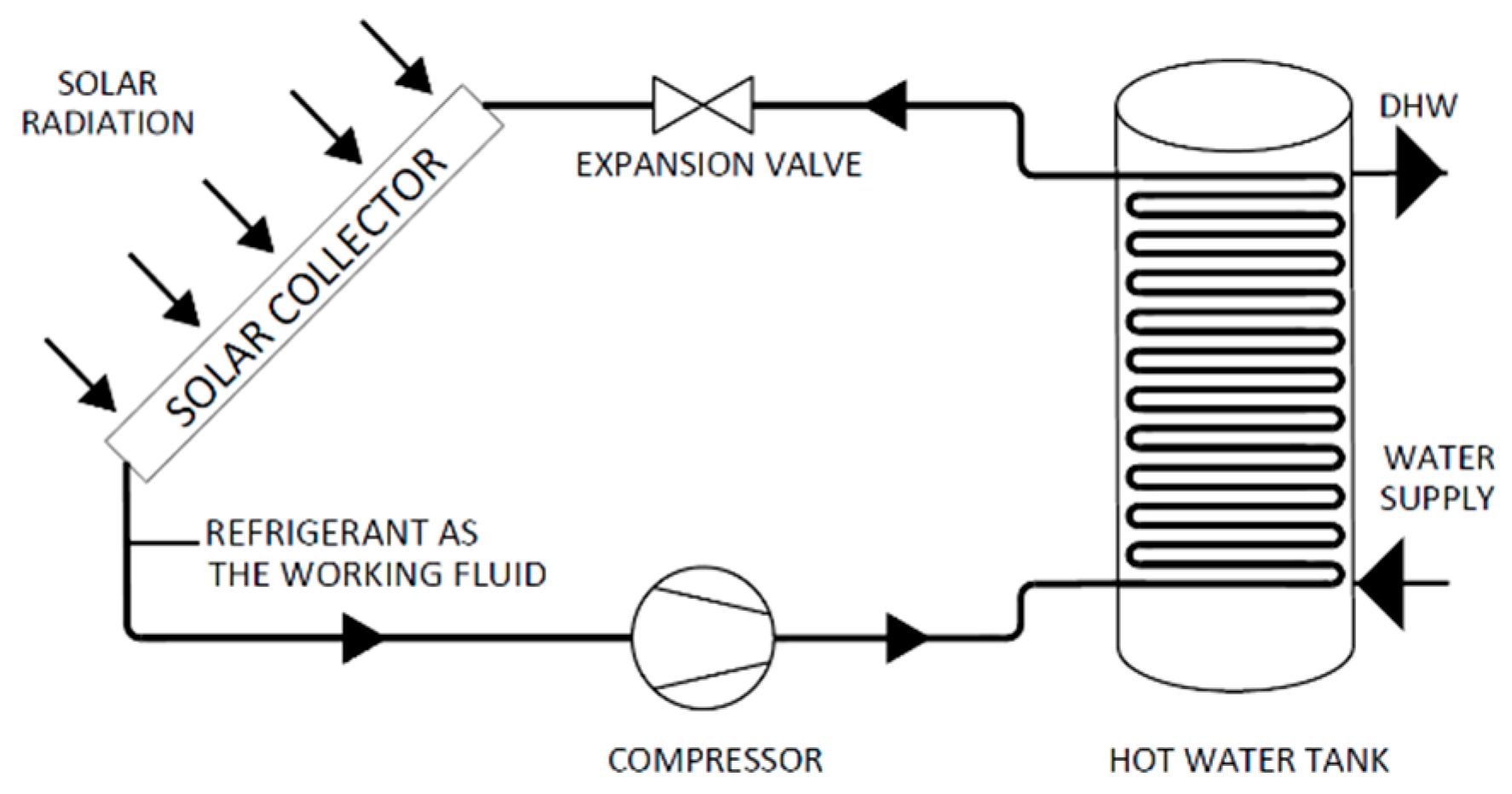

4.4. Solar Assisted Heat Pump (SAHP)

4.4.1. Direct Expansion-Solar Assisted Heat Pump (DX-SAHP)

4.4.2. Indirect Expansion-Solar Assisted Heat Pump (IX-SAHP)

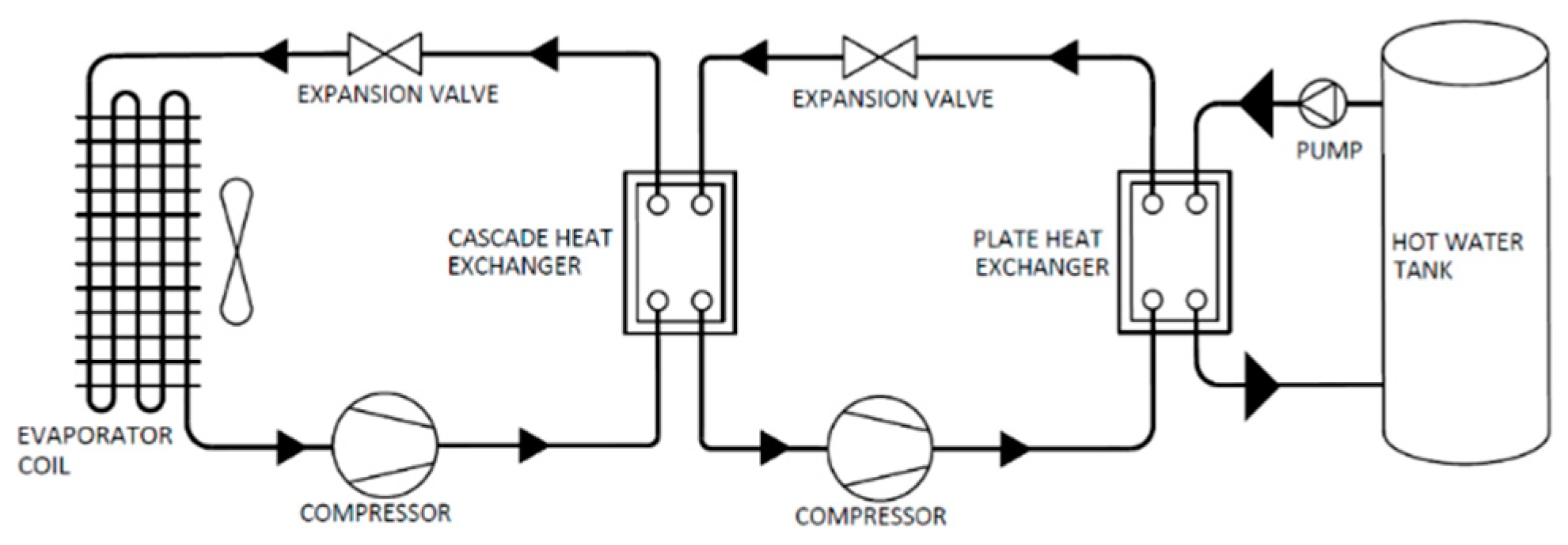

4.5. Cascade Heat Pump

4.6. Two-Stage Heat Pumps

4.7. Thermally Driven Heat Pumps

4.8. Comparison of Different Heat Pumps

5. Heat Pump End-Uses

5.1. Heat Pumps Coupled with Thermal Energy Storage

5.2. Heat Pumps with Solar PV Systems

5.2.1. The Increase of Self-Consumption

5.2.2. System Optimisation

5.2.3. Net Zero Energy Buildings

6. Environmental Aspects of Heat Pumps

6.1. Natural Refrigerants

6.2. Leakage

7. Economic Aspects of Heat Pumps

8. Conclusions: Overview and Suggestion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Acronym | Definition |

| ASHP | Air source heat pump |

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| CDH | Cooling degree hour |

| COP | Coefficient of performance |

| DC | Direct current |

| DHW | Domestic hot water |

| DSM | Demand side management |

| DX-GSHP | Direct expansion-ground source heat pump |

| DX-SAHP | Direct expansion-solar assisted heat pump |

| EER | Energy efficiency ratio |

| EU | European Union |

| FiTs | Feed-in tariffs |

| GCHP | Ground coupled heat pump |

| GHE | Ground heat exchanger |

| GHG | Greenhouse gas |

| GSHP | Ground source heat pump |

| GWP | Global warming potential |

| HDD | High degree day |

| HFCs | Hydrofluorocarbons |

| HVAC | Heating, ventilation, and air conditioning |

| IX-SAGSHP | Indirect expansion solar assisted ground source heat pump |

| IX-SAHP | Indirect expansion-solar assisted heat pump |

| NZEBs | Net zero energy buildings |

| ODP | Ozone depletion potential |

| PCM | Phase change material |

| PV | Photovoltaic |

| RAC | Room air conditioning |

| SAHP | Solar assisted heat pump |

| SCOP | Seasonal coefficient of performance |

| SWHP | Surface water heat pump |

| WSHP | Water source heat pump |

| Symbol | Description |

| QH | Heat from the source |

| QL | Heat released to the sink |

| R11 | Trichlorofluoromethane |

| R123 | 1,1-Dichloro-2,2,2-Trifluoroethane |

| R134a | 1,1,1,2-Tetrafluoroethane |

| R22 | Chlorodifluoromethane |

| R290 | Propane |

| R404A | R125/R143a/R134a (44/52/4 wt.%) |

| R410A | R32/R125 (50/50 wt.%) |

| R600a | Isobutane |

| R744 | Carbon dioxide |

| TH | Absolute temperature of the heat source of the engine |

| TL | Absolute temperature of the low temperature exhaust |

| W | Work |

| η | the Carnot, or ideal efficiency of a heat engine |

References

- Cavallini, A.; Cecchinato, L.; Corradi, M.; Fornasieri, E.; Zilio, C. Two-stage transcritical carbon dioxide cycle optimisation: A theoretical and experimental analysis. Int. J. Refrig. 2005, 28, 1274–1283. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.; Xu, Y.; Liu, C.; Luther, M. Vertical specialisation measurement of energy embodied in international trade of the construction industry. Energy 2018, 165, 689–700. [Google Scholar] [CrossRef]

- Kozarcanin, S.; Hanna, R.; Staffell, I.; Gross, R.; Andresen, G. Impact of climate change on the cost-optimal mix of decentralised heat pump and gas boiler technologies in Europe. Energy Policy 2020, 140, 111386. [Google Scholar] [CrossRef] [Green Version]

- Bee, E.; Prada, A.; Baggio, P. Demand-side management of air-source heat pump and photovoltaic systems for heating applications in the italian context. Environments 2018, 5, 132. [Google Scholar] [CrossRef] [Green Version]

- Rinaldi, A.; Soini, M.C.; Streicher, K.; Patel, M.K.; Parra, D. Decarbonising heat with optimal PV and storage investments: A detailed sector coupling modelling framework with flexible heat pump operation. Appl. Energy 2021, 282, 116110. [Google Scholar] [CrossRef]

- Australian Energy Update. Available online: https://www.energy.gov.au/sites/default/files/Australian%20Energy%20Statistics%202020%20Energy%20Update%20Report_0.pdf (accessed on 7 June 2021).

- Space Heating and Cooling. Available online: http://www.energyrating.gov.au/products/space-heating-and-cooling (accessed on 7 June 2021).

- Valancius, R.; Singh, R.M.; Jurelionis, A.; Vaiciunas, J. A review of heat pump systems and applications in cold climates: Evidence from Lithuania. Energies 2019, 12, 4331. [Google Scholar] [CrossRef] [Green Version]

- Bahadori, A.; Nwaoha, C.; Zendehboudi, S.; Zahedi, G. An overview of renewable energy potential and utilisation in Australia. Renew. Sustain. Energy Rev. 2013, 21, 582–589. [Google Scholar] [CrossRef]

- Battaglia, M.; Haberl, R.; Bamberger, E.; Haller, M. Increased self-consumption and grid flexibility of PV and heat pump systems with thermal and electrical storage. Energy Procedia 2017, 135, 358–366. [Google Scholar] [CrossRef]

- Fleuchaus, P.; Blum, P. Damage event analysis of vertical ground source heat pump systems in Germany. Geotherm. Energy 2017, 5, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Liu, C.; Yang, J.; Chen, J. Experimental study on R-22, R-427A, R-161 and R-290 in air-source heat pump for space heating at low ambient temperatures. Int. J. Refrig. 2018, 96, 147–154. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C.; Brown, J.S. Assessment of the low-GWP refrigerants R600a, R1234ze (Z) and R1233zd (E) for heat pump and organic Rankine cycle applications. Appl. Therm. Eng. 2020, 167, 114804. [Google Scholar] [CrossRef]

- Bolaji, B.; Huan, Z. Ozone depletion and global warming: Case for the use of natural refrigerant—A review. Renew. Sustain. Energy Rev. 2013, 18, 49–54. [Google Scholar] [CrossRef]

- Shrivastava, A.P.; Chandrakishor, C. Evaluation of refrigerant R290 as a replacement to R22. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 2, 739–747. [Google Scholar]

- Ma, Y.; Liu, Z.; Tian, H. A review of transcritical carbon dioxide heat pump and refrigeration cycles. Energy 2013, 55, 156–172. [Google Scholar] [CrossRef]

- Stauffer, Y.; Koch, N.; Hutter, A.; Pflugradt, N.D. Quantifying the potential of smart heat-pump control to increase the self-consumption of photovoltaic electricity in buildings. In Proceedings of the EuroSun 2018, Rapperswil, Switzerland, 10–13 September 2018. [Google Scholar]

- Zator, S.; Skomudek, W. Impact of DSM on energy management in a single-family house with a heat pump and photovoltaic installation. Energies 2020, 13, 5476. [Google Scholar] [CrossRef]

- Williams, C.J.; Binder, J.O.; Kelm, T. Demand side management through heat pumps, thermal storage and battery storage to increase local self-consumption and grid compatibility of PV systems. In Proceedings of the 2012 3rd IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Berlin, Germany, 14–17 October 2012; pp. 1–6. [Google Scholar]

- Heat Pumps. Available online: https://www.iea.org/reports/heat-pumps (accessed on 17 July 2021).

- Global Energy Transformation: The Remap Transition Pathway. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Apr/IRENA_GET_REmap_pathway_2019.pdf (accessed on 17 July 2021).

- Xiao, B.; He, L.; Zhang, S.; Kong, T.; Hu, B.; Wang, R. Comparison and analysis on air-to-air and air-to-water heat pump heating systems. Renew. Energy 2020, 146, 1888–1896. [Google Scholar] [CrossRef]

- Solar hot Water Rebate. Available online: https://www.solar.vic.gov.au/solar-hot-water-rebate (accessed on 17 July 2021).

- Verhelst, C.; Degrauwe, D.; Logist, F.; Van Impe, J.; Helsen, L. Multi-objective optimal control of an air-to-water heat pump for residential heating. Build. Simul. 2012, 5, 281–291. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, X.; Mondejar, M.E.; Haglind, F. A review of heat transfer enhancement techniques in plate heat exchangers. Renew. Sustain. Energy Rev. 2019, 101, 305–328. [Google Scholar] [CrossRef]

- Heat Exchanger. Available online: https://loluoch.digitalscholar.rochester.edu/portfolio/Heat%20Exchangers%20Van%20Gogh.pdf (accessed on 17 July 2021).

- Olaiya, K.A.; Alabi, I.O.; Okediji, A.P.; Alonge, O.I. Parametric and quantitative analysis on the development of shell and tube heat exchanger. IJAEMS 2018, 4, 451–459. [Google Scholar]

- Hermes, C.J. Heat transfer and pressure drop trade-offs in liquid-to-suction heat exchangers. Int. J. Refrig. 2019, 104, 496–500. [Google Scholar] [CrossRef]

- Nasution, D.M.; Idris, M.; Pambudi, N.A. Room air conditioning performance using liquid-suction heat exchanger retrofitted with R290. Case Stud. Therm. Eng. 2019, 13, 100350. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Q.; Li, B.; Fan, X.; Fu, Z. Application of an air source heat pump (ASHP) for heating in Harbin, the coldest provincial capital of China. Energy Build. 2017, 138, 96–103. [Google Scholar] [CrossRef]

- Renaldi, R.; Kiprakis, A.; Friedrich, D. An optimisation framework for thermal energy storage integration in a residential heat pump heating system. Appl. Energy 2017, 186, 520–529. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, P.; Szałański, P. Seasonal coefficient of performance of air-to-air heat pump and energy performance of a building in Poland. E3S Web Conf. 2019, 116, 00039. [Google Scholar] [CrossRef]

- Bee, E.; Prada, A.; Baggio, P.; Psimopoulos, E. Air-source heat pump and photovoltaic systems for residential heating and cooling: Potential of self-consumption in different European climates. Build. Simul. 2019, 12, 453–463. [Google Scholar] [CrossRef]

- Asaee, S.R.; Ugursal, V.I.; Beausoleil-Morrison, I. Techno-economic feasibility evaluation of air to water heat pump retrofit in the Canadian housing stock. Appl. Therm. Eng. 2017, 111, 936–949. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Zhang, L.; Nie, J.; Li, Y. Techno-economic analysis of air source heat pump applied for space heating in northern China. Appl. Energy 2017, 207, 533–542. [Google Scholar] [CrossRef]

- Pu, J.; Shen, C.; Zhang, C.; Liu, X. A semi-experimental method for evaluating frosting performance of air source heat pumps. Renew. Energy 2021, 173, 913–925. [Google Scholar] [CrossRef]

- Kim, J.; Choi, H.-J.; Kim, K.C. A combined dual hot-gas bypass defrosting method with accumulator heater for an air-to-air heat pump in cold region. Appl. Energy 2015, 147, 344–352. [Google Scholar] [CrossRef]

- Çakır, U.; Çomaklı, K.; Çomaklı, Ö.; Karslı, S. An experimental exergetic comparison of four different heat pump systems working at same conditions: As air to air, air to water, water to water and water to air. Energy 2013, 58, 210–219. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. General review of ground-source heat pump systems for heating and cooling of buildings. Energy Build. 2014, 70, 441–454. [Google Scholar] [CrossRef]

- Mitchell, M.S.; Spitler, J.D. Open-loop direct surface water cooling and surface water heat pump systems—A review. Heat. Vent. Air-Cond. Refrig. Res. 2013, 19, 125–140. [Google Scholar]

- Schibuola, L.; Scarpa, M. Experimental analysis of the performances of a surface water source heat pump. Energy Build. 2016, 113, 182–188. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, G.; Peng, J.; Lin, X.; Liu, T. The performance of an open-loop lake water heat pump system in south China. Appl. Therm. Eng. 2006, 26, 2255–2261. [Google Scholar] [CrossRef]

- Klotzbücher, T.; Kappler, A.; Straub, K.L.; Haderlein, S.B. Biodegradability and groundwater pollutant potential of organic anti-freeze liquids used in borehole heat exchangers. Geothermics 2007, 36, 348–361. [Google Scholar] [CrossRef]

- Dehghan, B. Experimental and computational investigation of the spiral ground heat exchangers for ground source heat pump applications. Appl. Therm. Eng. 2017, 121, 908–921. [Google Scholar] [CrossRef]

- Yin, P.; Pate, M.; Battaglia, F. In-field performance evaluation and economic analysis of residential ground source heat pumps in heating operation. J. Build. Eng. 2019, 26, 100932. [Google Scholar] [CrossRef]

- Han, C.; Ellett, K.M.; Naylor, S.; Yu, X.B. Influence of local geological data on the performance of horizontal ground-coupled heat pump system integrated with building thermal loads. Renew. Energy 2017, 113, 1046–1055. [Google Scholar] [CrossRef]

- Urchueguía, J.F.; Zacarés, M.; Corberán, J.M.; Montero, Á.; Martos, J.; Witte, H. Comparison between the energy performance of a ground coupled water to water heat pump system and an air to water heat pump system for heating and cooling in typical conditions of the European Mediterranean coast. Energy Convers. Manag. 2008, 49, 2917–2923. [Google Scholar] [CrossRef]

- Staffell, I.; Brett, D.; Brandon, N.; Hawkes, A. A review of domestic heat pumps. Energy Environ. Sci. 2012, 5, 9291–9306. [Google Scholar] [CrossRef]

- Bucci, A.; Prevot, A.B.; Buoso, S.; De Luca, D.A.; Lasagna, M.; Malandrino, M.; Maurino, V. Impacts of borehole heat exchangers (BHEs) on groundwater quality: The role of heat-carrier fluid and borehole grouting. Environ. Earth Sci. 2018, 77, 175. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Sadaghiani, M.S.; Ghazvini, M.; Shahriar, S.; Alhuyi Nazari, M. Ground source heat pump carbon emissions and ground-source heat pump systems for heating and cooling of buildings: A review. Environ. Prog. Sustain. Energy 2018, 37, 1241–1265. [Google Scholar] [CrossRef]

- Naili, N.; Hazami, M.; Attar, I.; Farhat, A. In-field performance analysis of ground source cooling system with horizontal ground heat exchanger in Tunisia. Energy 2013, 61, 319–331. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, G.; Zhou, J.; Wu, J.; Shen, W. A techno-economic comparison of a direct expansion ground-source and a secondary loop ground-coupled heat pump system for cooling in a residential building. Appl. Therm. Eng. 2012, 35, 29–39. [Google Scholar] [CrossRef]

- Boban, L.; Miše, D.; Herceg, S.; Soldo, V. Application and design aspects of ground heat exchangers. Energies 2021, 14, 2134. [Google Scholar] [CrossRef]

- Alshehri, F.; Beck, S.; Ingham, D.; Ma, L.; Pourkashanian, M. Techno-economic analysis of ground and air source heat pumps in hot dry climates. J. Build. Eng. 2019, 26, 100825. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Bigdelou, P.; Pourfayaz, F.; Yousefi, H. Numerical modeling and economic analysis of a ground source heat pump for supplying energy for a greenhouse in Alborz province, Iran. J. Clean. Prod. 2016, 131, 145–154. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Net-zero nation: HVAC and PV systems for residential net-zero energy buildings across the United States. Energy Convers. Manag. 2018, 177, 605–628. [Google Scholar] [CrossRef]

- Bockelmann, F.; Fisch, M.N. It works—Long-term performance measurement and optimization of six ground source heat pump systems in Germany. Energies 2019, 12, 4691. [Google Scholar] [CrossRef]

- Zhao, Z.; Shen, R.; Feng, W.; Zhang, Y.; Zhang, Y. Soil thermal balance analysis for a ground source heat pump system in a hot-summer and cold-winter region. Energies 2018, 11, 1206. [Google Scholar] [CrossRef] [Green Version]

- Nouri, G.; Noorollahi, Y.; Yousefi, H. Designing and optimization of solar assisted ground source heat pump system to supply heating, cooling and hot water demands. Geothermics 2019, 82, 212–231. [Google Scholar] [CrossRef]

- Sanz, A.; Fuente, R.; Martín, A.J. Solar hybrid PVT coupled heat pump systems towards cost-competitive NZEB. In Proceedings of the 12th International Conference on Solar Energy for Buildings and Industry, Rapperswil, Switzerland, 10–13 September 2018. [Google Scholar]

- Huan, C.; Wang, F.; Li, S.; Zhao, Y.; Liu, L.; Wang, Z.; Ji, C. A performance comparison of serial and parallel solar-assisted heat pump heating systems in Xi’an, China. Energy Sci. Eng. 2019, 7, 1379–1393. [Google Scholar] [CrossRef] [Green Version]

- Kong, X.; Sun, P.; Li, Y.; Jiang, K.; Dong, S. Experimental studies of a variable capacity direct-expansion solar-assisted heat pump water heater in autumn and winter conditions. Sol. Energy 2018, 170, 352–357. [Google Scholar] [CrossRef]

- Huang, W.; Ji, J.; Xu, N.; Li, G. Frosting characteristics and heating performance of a direct-expansion solar-assisted heat pump for space heating under frosting conditions. Appl. Energy 2016, 171, 656–666. [Google Scholar] [CrossRef]

- Kuang, Y.; Wang, R. Performance of a multi-functional direct-expansion solar assisted heat pump system. Sol. Energy 2006, 80, 795–803. [Google Scholar] [CrossRef]

- Li, Y.-H.; Kao, W.-C. Taguchi optimization of solar thermal and heat pump combisystems under five distinct climatic conditions. Appl. Therm. Eng. 2018, 133, 283–297. [Google Scholar] [CrossRef]

- Kamel, R.S.; Fung, A.S.; Dash, P.R. Solar systems and their integration with heat pumps: A review. Energy Build. 2015, 87, 395–412. [Google Scholar] [CrossRef]

- Wang, E.; Fung, A.S.; Qi, C.; Leong, W.H. Performance prediction of a hybrid solar ground-source heat pump system. Energy Build. 2012, 47, 600–611. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, B.; Zeng, Z.; He, W.; Liu, Y.; Xiangguo, X.; Chen, G. Development of a novel indirect-expansion solar-assisted multifunctional heat pump with four heat exchangers. Build. Serv. Eng. Res. Technol. 2015, 36, 469–481. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V. A method for the dynamic testing and evaluation of the performance of combined solar thermal heat pump hot water systems. Appl. Energy 2014, 114, 124–134. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V. Investigation of the performance of a combined solar thermal heat pump hot water system. Sol. Energy 2013, 93, 169–182. [Google Scholar] [CrossRef]

- Youssef, W.; Ge, Y.; Tassou, S.A. Indirect expansion solar assisted heat pump system for hot water production with latent heat storage and applicable control strategy. Energy Procedia 2017, 123, 180–187. [Google Scholar] [CrossRef]

- Bertsch, S.S.; Groll, E.A. Two-stage air-source heat pump for residential heating and cooling applications in northern US climates. Int. J. Refrig. 2008, 31, 1282–1292. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, H.S.; Kim, M.S. Optimal temperature between high and low stage cycles for R134a/R410A cascade heat pump based water heater system. Exp. Therm. Fluid Sci. 2013, 47, 172–179. [Google Scholar] [CrossRef]

- Le, K.X.; Huang, M.J.; Shah, N.N.; Wilson, C.; Mac Artain, P.; Byrne, R.; Hewitt, N.J. Techno-economic assessment of cascade air-to-water heat pump retrofitted into residential buildings using experimentally validated simulations. Appl. Energy 2019, 250, 633–652. [Google Scholar] [CrossRef]

- Xu, L.; Li, E.; Xu, Y.; Mao, N.; Shen, X.; Wang, X. An experimental energy performance investigation and economic analysis on a cascade heat pump for high-temperature water in cold region. Renew. Energy 2020, 152, 674–683. [Google Scholar] [CrossRef]

- Jung, H.W.; Kang, H.; Yoon, W.J.; Kim, Y. Performance comparison between a single-stage and a cascade multi-functional heat pump for both air heating and hot water supply. Int. J. Refrig. 2013, 36, 1431–1441. [Google Scholar] [CrossRef]

- Kwon, O.; Cha, D.; Park, C. Performance evaluation of a two-stage compression heat pump system for district heating using waste energy. Energy 2013, 57, 375–381. [Google Scholar] [CrossRef]

- Safa, A.A.; Fung, A.S.; Kumar, R. Performance of two-stage variable capacity air source heat pump: Field performance results and TRNSYS simulation. Energy Build. 2015, 94, 80–90. [Google Scholar] [CrossRef]

- Qu, M.; Abdelaziz, O.; Yin, H. New configurations of a heat recovery absorption heat pump integrated with a natural gas boiler for boiler efficiency improvement. Energy Convers. Manag. 2014, 87, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Fu, L.; Zhang, S. A review of working fluids of absorption cycles. Renew. Sustain. Energy Rev. 2012, 16, 1899–1906. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, Y.; Fu, L.; Zhang, S. Experimental and theoretical investigation of a novel full-open absorption heat pump applied to district heating by recovering waste heat of flue gas. Energy Build. 2018, 173, 45–57. [Google Scholar] [CrossRef]

- Boman, D.B. Adsorption Heat Pumps: Fundamentals and Applications; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Demir, H.; Mobedi, M.; Ülkü, S. A review on adsorption heat pump: Problems and solutions. Renew. Sustain. Energy Rev. 2008, 12, 2381–2403. [Google Scholar] [CrossRef] [Green Version]

- Núñez, T.; Mittelbach, W.; Henning, H.-M. Development of an adsorption chiller and heat pump for domestic heating and air-conditioning applications. Appl. Therm. Eng. 2007, 27, 2205–2212. [Google Scholar] [CrossRef]

- Pensini, A.; Rasmussen, C.N.; Kempton, W. Economic analysis of using excess renewable electricity to displace heating fuels. Appl. Energy 2014, 131, 530–543. [Google Scholar] [CrossRef] [Green Version]

- Moreno, P.; Castell, A.; Sole, C.; Zsembinszki, G.; Cabeza, L.F. PCM thermal energy storage tanks in heat pump system for space cooling. Energy Build. 2014, 82, 399–405. [Google Scholar] [CrossRef]

- Kelly, N.J.; Tuohy, P.G.; Hawkes, A.D. Performance assessment of tariff-based air source heat pump load shifting in a UK detached dwelling featuring phase change-enhanced buffering. Appl. Therm. Eng. 2014, 71, 809–820. [Google Scholar] [CrossRef] [Green Version]

- Psimopoulos, E.; Bee, E.; Luthander, R.; Bales, C. Smart control strategy for PV and heat pump system utilizing thermal and electrical storage and forecast services. In Proceedings of the ISES Solar World Congress 2017-IEA SHC International Conference on Solar Heating and Cooling for Buildings and Industry, Abu Dhabi, United Arab Emirates, 29 October–2 November 2017; pp. 2240–2251. [Google Scholar]

- Gelleschus, R.; Böttiger, M.; Bocklisch, T. Optimization-based control concept with feed-in and demand peak shaving for a PV battery heat pump heat storage system. Energies 2019, 12, 2098. [Google Scholar] [CrossRef] [Green Version]

- Sánchez, C.; Bloch, L.; Holweger, J.; Ballif, C.; Wyrsch, N. Optimised heat pump management for increasing photovoltaic penetration into the electricity grid. Energies 2019, 12, 1571. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Skye, H.M.; Domanski, P.A. Selecting HVAC systems to achieve comfortable and cost-effective residential net-zero energy buildings. Appl. Energy 2018, 212, 577–591. [Google Scholar] [CrossRef] [PubMed]

- Martin-Escudero, K.; Salazar-Herran, E.; Campos-Celador, A.; Diarce-Belloso, G.; Gomez-Arriaran, I. Solar energy system for heating and domestic hot water supply by means of a heat pump coupled to a photovoltaic ventilated façade. Sol. Energy 2019, 183, 453–462. [Google Scholar] [CrossRef]

- Jarre, M.; Noussan, M.; Simonetti, M. Primary energy consumption of heat pumps in high renewable share electricity mixes. Energy Convers. Manag. 2018, 171, 1339–1351. [Google Scholar] [CrossRef]

- Badache, M.; Ouzzane, M.; Eslami-Nejad, P.; Aidoun, Z. Experimental study of a carbon dioxide direct-expansion ground source heat pump (CO2-DX-GSHP). Appl. Therm. Eng. 2018, 130, 1480–1488. [Google Scholar] [CrossRef]

- American Society of Heating, R.; Air-Conditioning Engineers, I. 2017 ASHRAE® Handbook—Fundamentals (SI Edition); American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE): Atlanta, GA, USA, 2018. [Google Scholar]

| References | System Designs | Performance |

|---|---|---|

| [30] | Air-to-air heat pump Load: space heating Region: Harbin, China | COP: ranging from 1.04 to 2.44 with extremely cold climates (ambient temperatures of −20.9 °C to 10.4 °C) Frost formation: little frost formation on the outdoor evaporator due to low relative humidity |

| [32] | Air-to-water heat pump Load: space heating and DHW Region: the UK | The cost and GHG emission of an 8.5 kW heat pump with a 300 L thermal energy storage system operating on E10 electricity tariff are 37% less than a gas boiler system. |

| [34] | Air-to-water heat pump Load: space heating and DHW Region: the Canada | COP: ranging from 3.2 to 3.6 Approximately 36% of energy use and 23% of GHG emissions can be reduced by adopting air-to-water heat pumps in the Canadian housing stock. |

| [35] | Air-to-water heat pump Load: space heating Region: the northern region in China | COP: 3.1 in heating season Primary energy consumption: 68% less than direct electric heating, 48% less than regional coal-fired boiler heating Initial costs: ASHPs have the lowest initial costs compared to other devices after considering both heating and cooling. Running costs: 60% less that direct electric heating |

| [36] | Air-to-air heat pump Load: space heating Region: Not specified | COP: ranging from 1.5 to 3.0 At the ambient temperature of 2 °C, using a 1 kW electric heater heating evaporator coil can increase the heating capacity and the COP by 38% and 57% and reduce the power consumption by 11.7% than the conventional air-to-air heat pump. |

| References | System Designs | Performance |

|---|---|---|

| [38] | Water to-air, Water-to-water, Air-to-water, Air-to-air heat pump Load: heating, cooling and DHW, Region: Turkey | COP: 3.94 for water-to-air, 3.73 for water-to-water, 3.54 for air-to-air, 3.40 for air-to-water |

| [41] | Open-loop SWHP Load: space heating, space cooling and DHW Region: Venice, Italy | COP: The average COP of the SWHP is 3.66, which is 36% higher than ASHP in the heating season. Energy efficiency ratio (EER): The average EER of the SWHP is 4.13, which is 14% higher than ASHP in the cooling season. Primary energy consumption: 37% of annual energy savings can be achieved by SWHP compared to traditional systems. |

| [42] | Open-loop Lake water heat pump Load: district heating and cooling Region: Xiangtan, China | COP: 0.7–0.85 higher COP in cooling mode and around 0.46 higher in the heating season than the ASHP system Payback period: 5.6 years is obtained for this heat pump compared to the ASHP units. |

| References | System Designs | Performance |

|---|---|---|

| [44] | Vertical GCHP Load: space heating and space cooling Region: Tabriz, Iran | Suggestions: The distance between spiral GHEs needs to be at least 6 m for the system performance loss less than 20%. The length of spiral GHEs and the buried depth from ground surface should be at least 4 m and 2 m, respectively, for better system performance. |

| [45] | Vertical and horizontal GCHPs Load: space heating Region: Iowa, U.S. | Average COP: horizontal one ranging from 1.81 to 3.71, the vertical one ranging from 1.96 to 3.80. Costs: median savings of 70–7% in fuel cost for GCHPs compared to natural gas furnaces GHG emissions: 45% less emission for GCHPs than natural gas furnaces. |

| [47] | Vertical GCHP Load: space heating and space cooling Region: Valencia, Spain | Energy consumption: an average of 26–60% of energy savings in the heating season and 19 to 45% of energy savings in the cooling season than the conventional air-to-water heat pump. |

| [53] | Vertical and horizontal GCHPs Load: space heating Region: Elaziğ, Turkey | COP: 3.1–3.6 for horizontal GCHP, 3.2–3.8 for vertical GCHP The vertical GCHP is more efficient than the horizontal one, but its installation cost is higher. |

| [51] | Horizontal GCHP Load: space cooling Borj Cédria, northern Tunisia | COP: The COP of GCHP ranges from 3.8 to 4.5, and the COP of the overall cooling system ranges from 2.3 to 2.7. The exergy efficiency of GHE decreases from 36% to 12%, with the mass flow rate of circulating water increasing from 0.06 to 0.20 kg/s. |

| [52] | DX-GSHP and vertical GCHP Load: space heating and cooling Region: Changsha, China | Average COP: 6.03 for DX-GSHP, 5.64 for vertical GCHP Average power consumption: 1.39 kWh for DX-GSHP and 1.715 kWh for vertical GSHP Initial cost: The vertical GCHP is 1000 yuan less than the DX-GSHP system, but the DX-GSHP has the lower annual cost with a payback period of 2.13 years against the GCHP. |

| [54] | Vertical GCHP Load: space heating and cooling Region: Saudi Arabia | COP: 4.4 for the GCHP and 2.3 for the conventional ASHP Cost: 34.6% of the annual cost savings on power consumption than the ASHP Payback period: 15.6 years compared to the ASHP |

| [55] | Horizontal GCHP Load: space heating and cooling Region: Karaj, Iran | COP: 2.7 for the heating COP |

| References | System Designs | Performance |

|---|---|---|

| [61] | Parallel and series IX-SAHPs Load: DHW Region: Xi’an, China | COP: 4.34 for the parallel system and 3.23 for the series system Annual energy consumption: 894 GJ for the parallel system and 1200 GJ for the serial system |

| [62] | DX-SAHP Load: DHW Region: Qingdao, China | COP: ranging from 2.55 to 6.57, with the average value higher than 4.0 and 3.0 on sunny and overcast days of autumn. |

| [63] | DX-SAHP Load: space heating Region: Hefei, China | COP: ranging from 1.50 to 2.23 with different levels of solar irradiation, ambient temperature, and relative humidity Frost formation: Frost forming on the collector of DX-SAHP is slower than heat pumps with the fin-and-tube heat exchanger. |

| [64] | DX-SAHP Load: space heating, space cooling and DHW Region: Shanghai, China | System COP: ranging from 2.1 to 2.7 in the heating mode, 2.1 to 3.5 in the water heating mode, and 2.9 for average system COP in cooling mode Costs: relatively low running costs during the entire year |

| [69,70] | Parallel IX-SAHP Load: DHW Region: Athens, Greece | COP: 2.34 Energy consumption: 70% energy savings compared to conventional solar hot water system combined with electrical resistance or a direct-fired heater |

| [71] | Novel IX-SAHP Load: DHW Region: the UK | COP: maximum COP of 4.99 and 4.80 for the sunny day and cloudy day with PCM tank, maximum COP of 4.70 and 4.21 for the sunny day and cloudy day without PCM tank |

| References | System Designs | Performance |

|---|---|---|

| [74] | Cascade air-to-water heat pump Load: space heating and DHW Region: the UK | COP: almost below 2.5 Operating costs: higher than gas boiler and 90% efficiency oil boilers Carbon emissions: 14% and 57% less than gas and oil boilers, respectively |

| [75] | Cascade air-to-water heat pump Load: space heating Region: China | COP: ranging from 1.70 to 2.48 Operating costs: 17% and 46% lower than the gas boiler and direct electric heater, respectively at the ambient temperature of −10 °C Carbon emissions: 2.43 times more than the gas boiler and 41% less than the direct electric heater |

| [73] | Cascade air-to-water heat pump Load: space heating Region: Korea | COP: ranging from 1.95 to 3.4 |

| [76] | Cascade air-to-water heat pump Load: space heating and DHW Region: Korea | COP: ranging from 2.7 to 3.3 Heating capacity: The cascade heat pump has a higher and more stable heating capacity than the single-stage heat pump. |

| References | System Designs | Performance |

|---|---|---|

| [77] | Two-stage water-to-water heat pump Load: district heating | COP: ranging from 2.6 to 4.2. COP was increased by approximately 23% when increasing the heat source temperature by 20 °C from a temperature of 10 °C. Heating capacity: dropped by around 2% when the low stage compressor inlet superheat was increased by 9 °C from 2 °C. |

| [72] | Two-stage ASHP Load: space heating, space cooling and DHW | COP: ranging from 3.3 to 4.2 in cooling mode; ranging from 2.3 to 3.2 in heating mode. Installation costs: The cost of this two-stage ASHP is significantly higher than the single-stage ASHP, but lower than the GSHP. |

| [78] | Two-stage variable capacity ASHP Load: space heating and space cooling | COP: The cooling COP ranged from 4.7 to 5.7 with the ambient temperature of 34 °C to 15 °C. The heating COP ranged from 1.7 to 5.0 with the ambient temperature of −19 °C to 9 °C. |

| Heat Pumps | Pros | Cons |

|---|---|---|

| Air Source Heat Pump | Simple operation and low installation costs Less primary energy consumption and GHG emissions than conventional fossil-fuel-based systems | Frost formation on the outside evaporator at low ambient temperatures Heating capacity and COP may decrease under cold climates. |

| Water Source Heat Pump | Can utilize heat from abundant sources, such as rivers, ponds, and lakes Higher COP and energy efficiency ratio (EER) than ASHPs | Surface water temperature is affected by climate variations. Low water quality may cause the blockage, corrosion, and fouling of heat exchangers. Water availability can restrict the use of WSHPs. |

| Ground Source Heat Pump | Highly efficient systems Higher COP and greater energy savings than ASHPs More suitable to be applied in than ASHPs in cold climates Significant GHG emissions reductions compared to fossil-fuel-based systems. | High installation costs or land requirement Potential leaks of refrigerant and antifreeze solutions Metal corrosion of GHEs System performance may be affected by underground heat accumulation and depletion. |

| Solar Assisted Heat Pump | Significant environmental benefits 70% of energy savings can be achieved. Higher-temperature heat being delivered to heat pumps | Solar intermittency restricts the system performance Requires complex control system Relatively high installation costs |

| Cascade Heat pump | Higher heating capacity and COP than single-stage heat pumps Can operate efficiently under cold climates Great GHG emissions reduction compared to fossil-fuel-based systems | Higher installation cost, Higher operating costs than fossil-fuel-based systems Hard to add a four-way valve to achieve heating or cooling |

| Two Stage Heat Pump | Higher COP and heating capacity than conventional ASHPs Can operate efficiently under cold climates | Significantly higher costs than ASHPs Requires appropriate control logic |

| Heat Pumps | Capital Costs | Operational Costs | Comments | ||||

|---|---|---|---|---|---|---|---|

| High | Medium | Low | High | Medium | Low | ||

| Air Source Heat Pumps | √ | √ | AHSPs are selected as the reference case with the lowest capital costs due to their simple design and medium operational costs. | ||||

| Water Source Heat Pumps | √ | √ | The capital costs of WSHPs are higher than ASHPs due to additional costs for labour, heat exchangers, water coils, pumps, and so on. The operational costs are lower than ASHPs but higher than GSHPs. | ||||

| Ground Source Heat Pumps | √ | √ | GSHPs have the highest capital cost due to drilling boreholes, installing GHEs, and purchasing equipment, but their operational costs are significantly lower than ASHPs. | ||||

| Solar Assisted Heat Pumps | √ | √ | Based on different design configurations, the capital costs of SAHPs are higher than ASHPs and WSHPs due to the use of solar collectors, heat storage tanks, pumps, etc., but lower than GSHPs. | ||||

| Cascade Heat pumps | √ | √ | Cascade heat pumps have higher capital and operational costs than ASHPs because of more system components and power consumption. | ||||

| Two-Stage Heat Pumps | √ | √ | Similar to cascade heat pumps, the capital costs and operational costs of two-stage heat pumps are higher than ASHPs. | ||||

| Location | Annual Avg. Temp. | HDD 10.0 °C | CDH 23.3 °C |

|---|---|---|---|

| Sydney, Australia | 18.3 °C | 1 | 2566 |

| Chicago, IL, USA | 11 °C | 1639 | 2056 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Luther, M.B.; Amirkhani, M.; Liu, C.; Horan, P. State of the Art on Heat Pumps for Residential Buildings. Buildings 2021, 11, 350. https://doi.org/10.3390/buildings11080350

Wang Z, Luther MB, Amirkhani M, Liu C, Horan P. State of the Art on Heat Pumps for Residential Buildings. Buildings. 2021; 11(8):350. https://doi.org/10.3390/buildings11080350

Chicago/Turabian StyleWang, Zheng, Mark B. Luther, Mehdi Amirkhani, Chunlu Liu, and Peter Horan. 2021. "State of the Art on Heat Pumps for Residential Buildings" Buildings 11, no. 8: 350. https://doi.org/10.3390/buildings11080350