Assessment of Rotational Stiffness for Metallic Hinged Base Plates under Axial Loads and Moments

Abstract

:1. Introduction

2. Finite Element Simulation

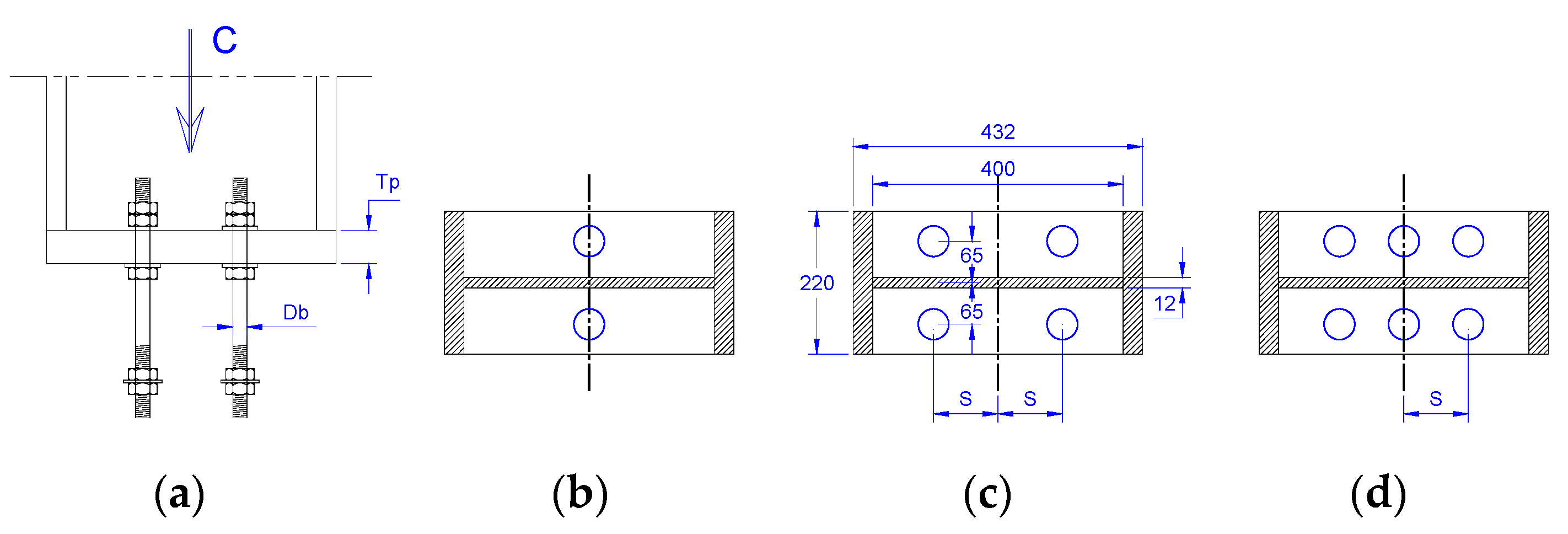

2.1. Geometry of Columns

2.2. Selection of Elements

2.3. Meshing and Convergence Study

2.4. Component Interaction and Contact

2.5. Material Definition

2.6. Boundary Condition and Loading Protocol

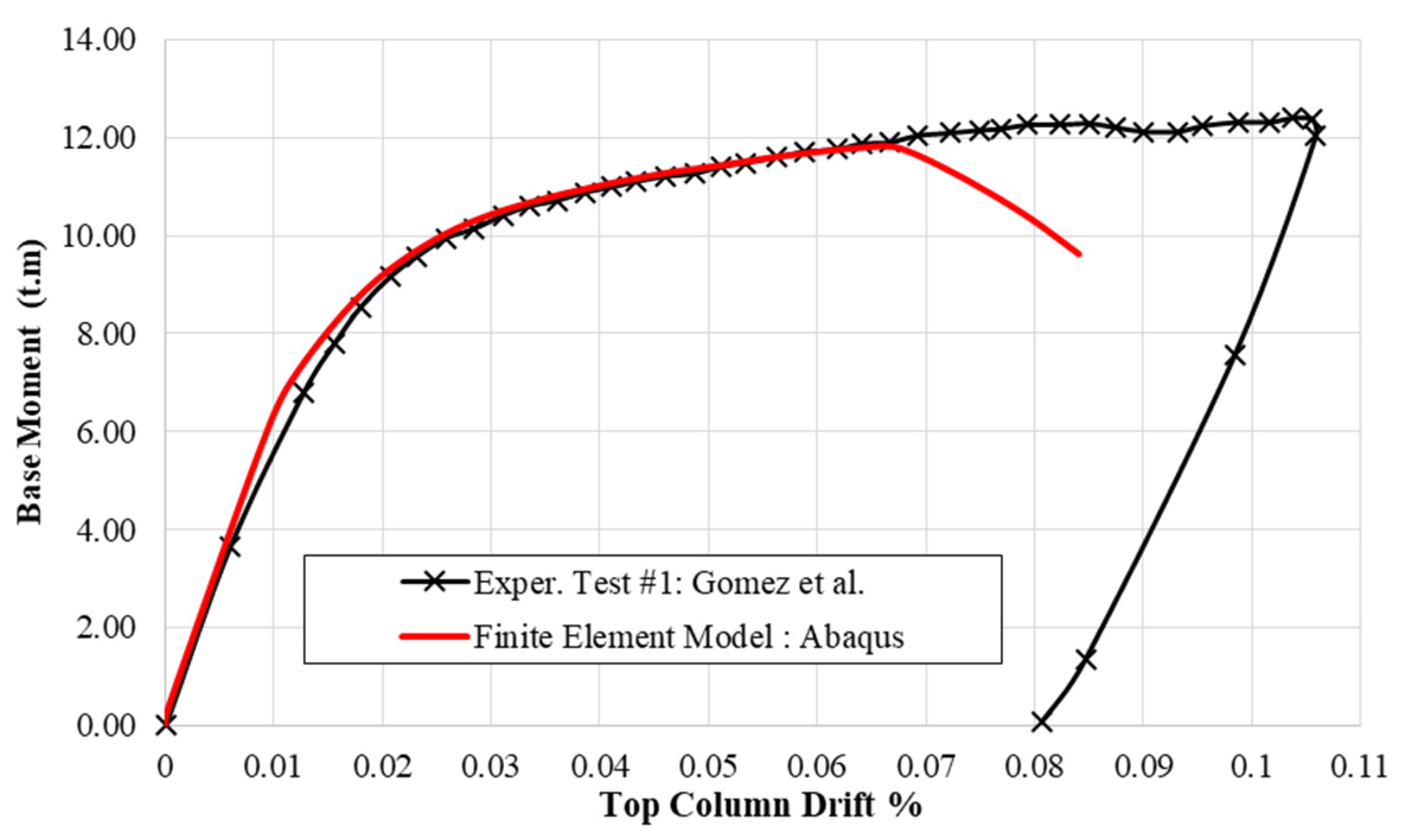

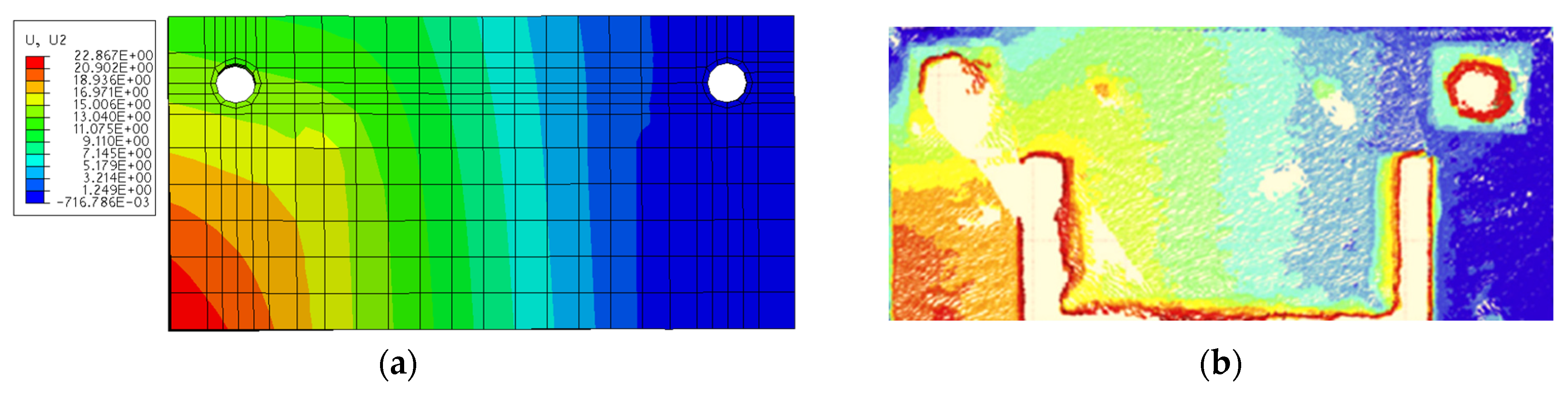

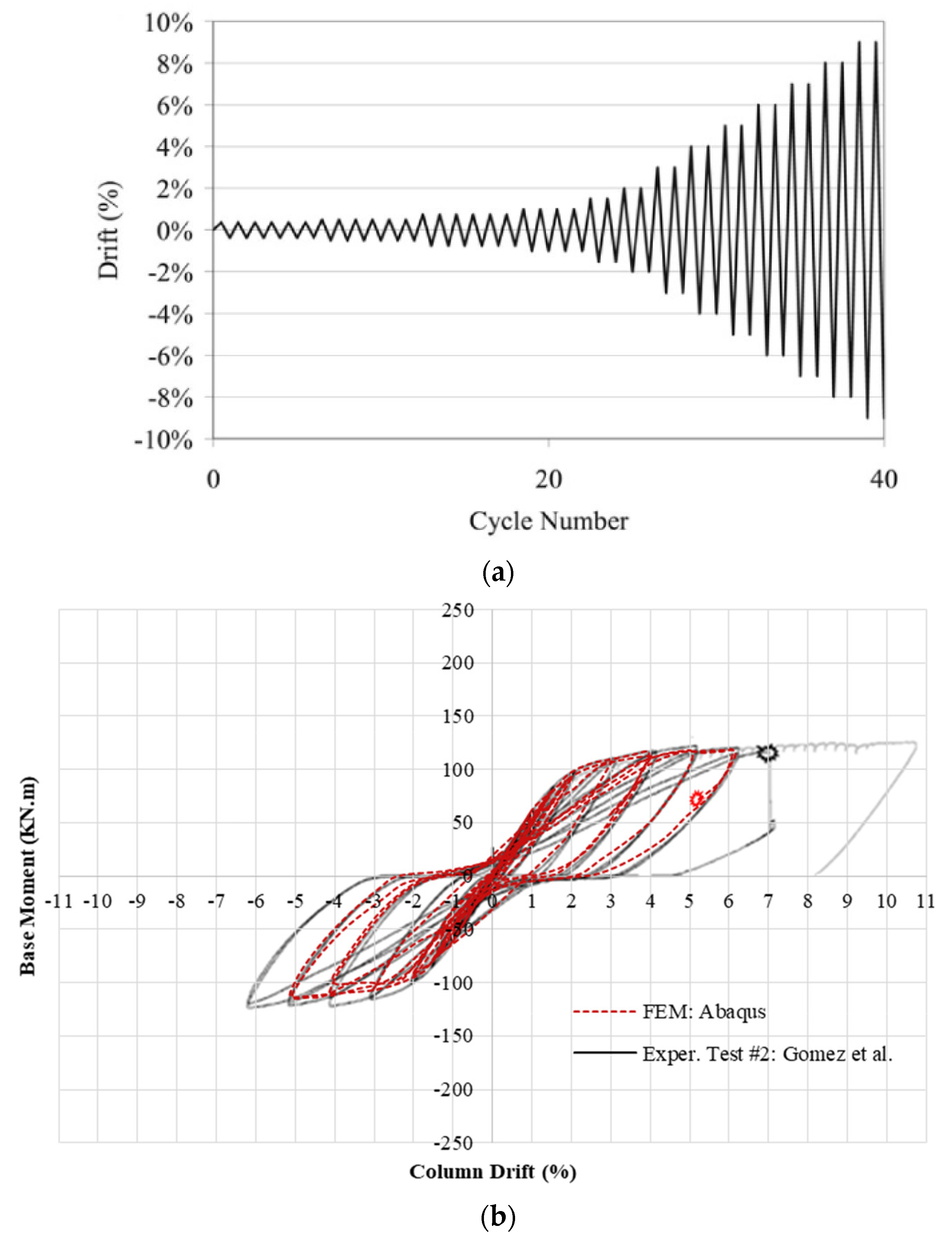

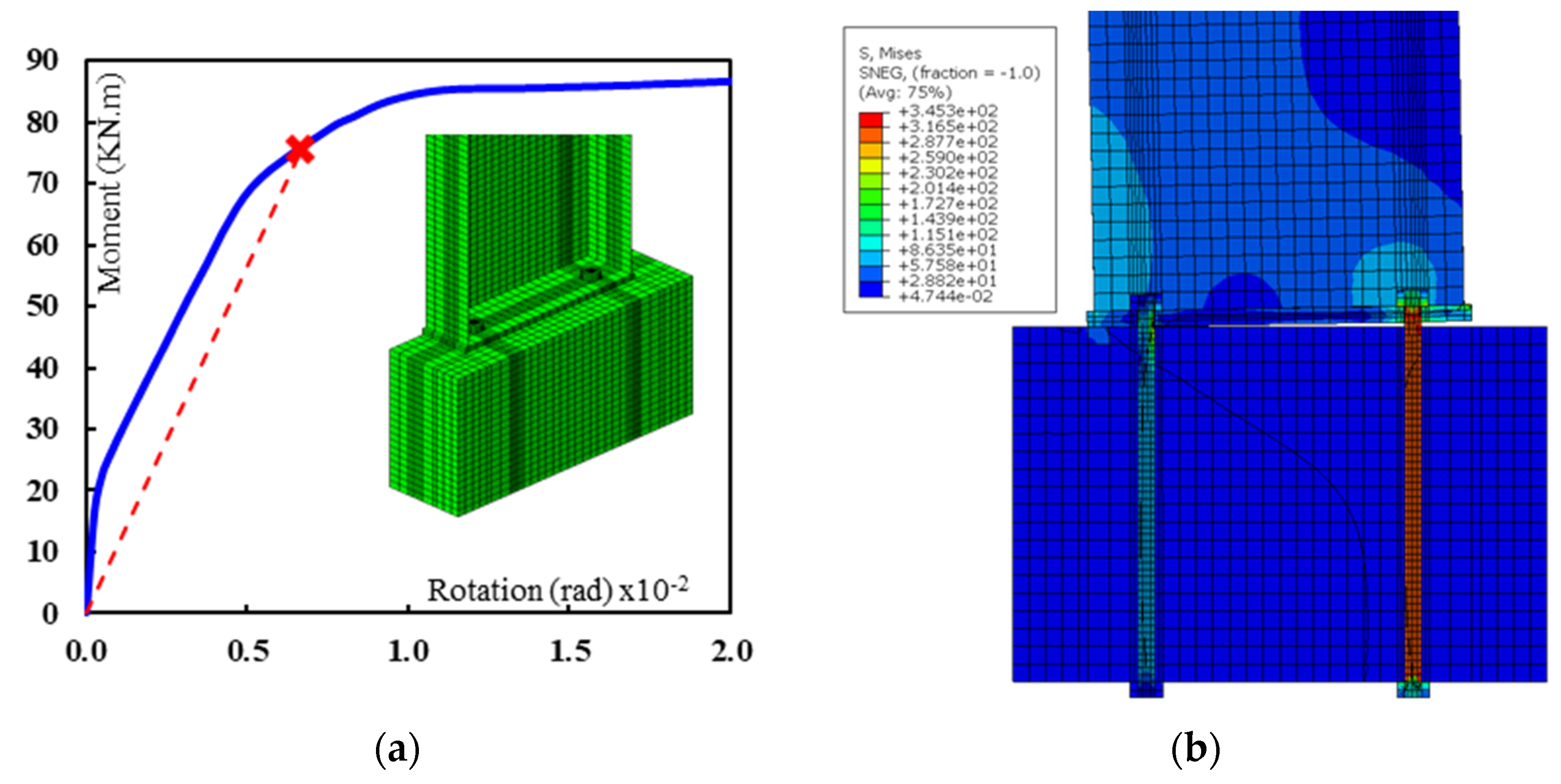

2.7. Validation of the FE Model

2.7.1. The First Specimen under Monotonic Loading

2.7.2. The Second Specimen under Cyclic Loading

3. Parametric Study

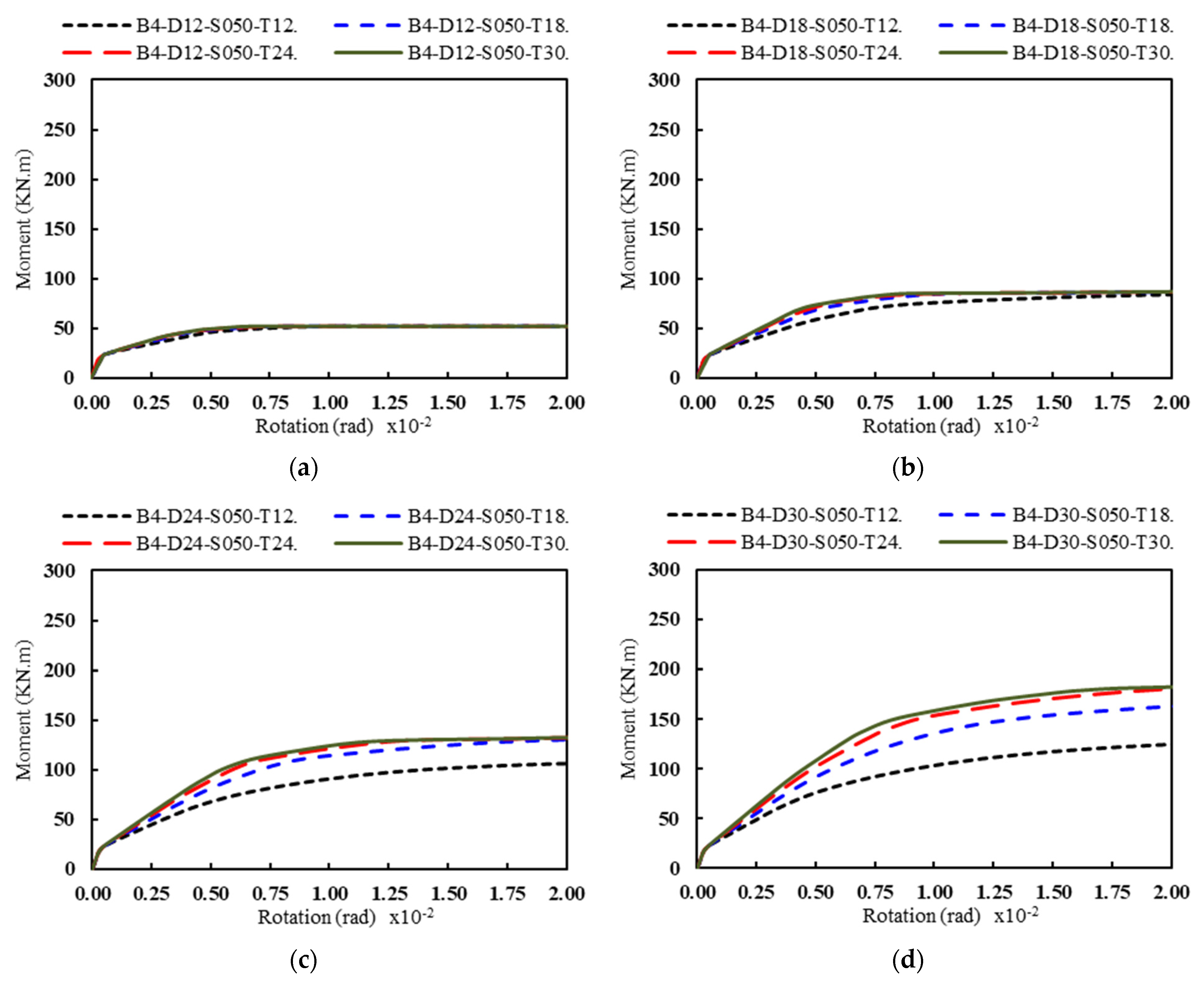

3.1. Effect of the Base Plate Thickness (T)

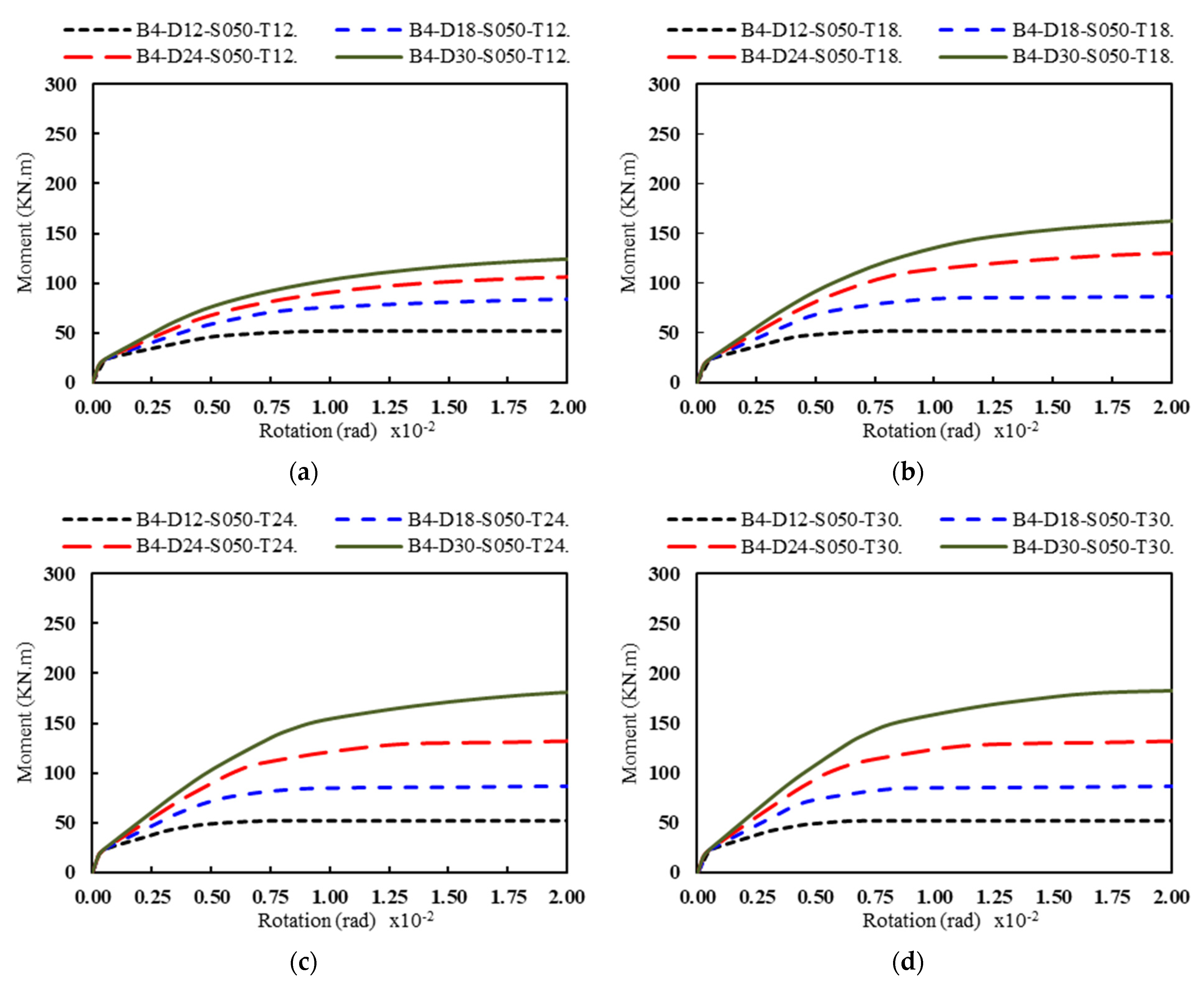

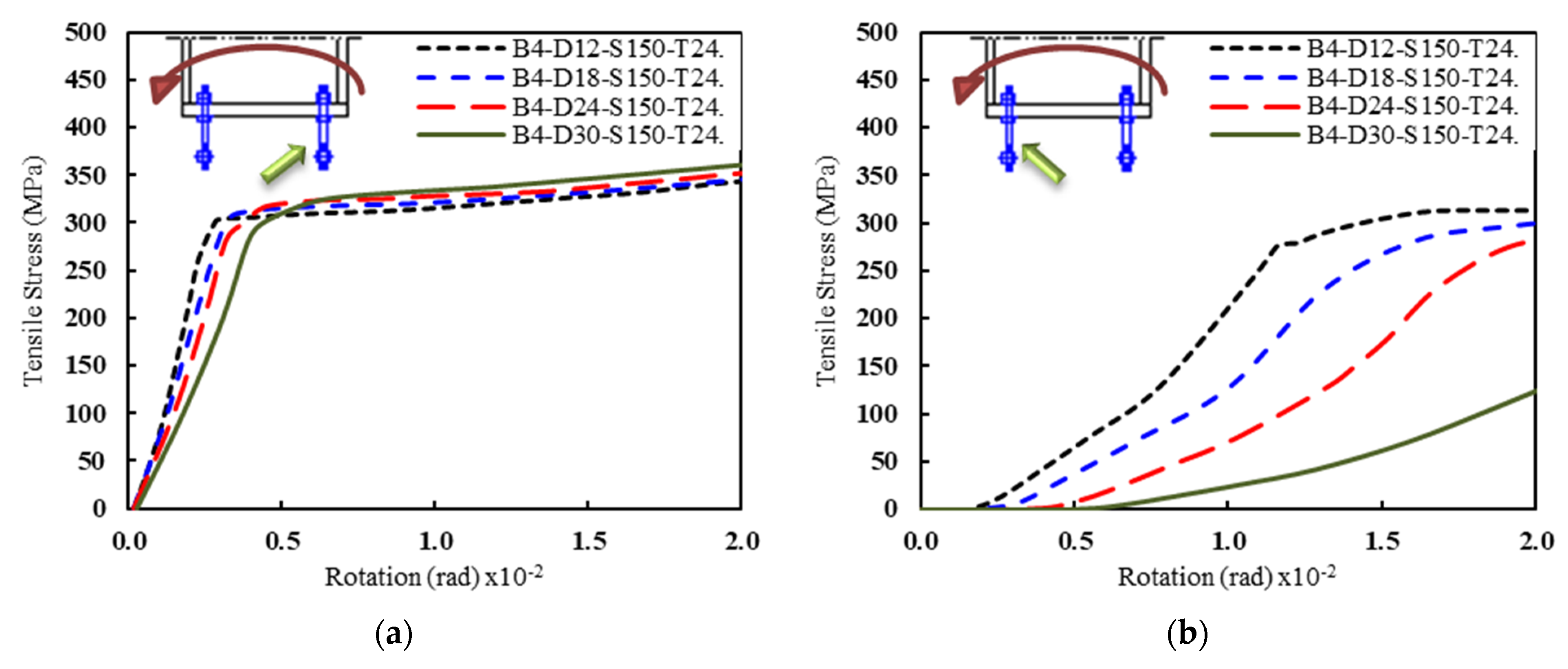

3.2. Effect of the Anchor Bolt Diameter (D)

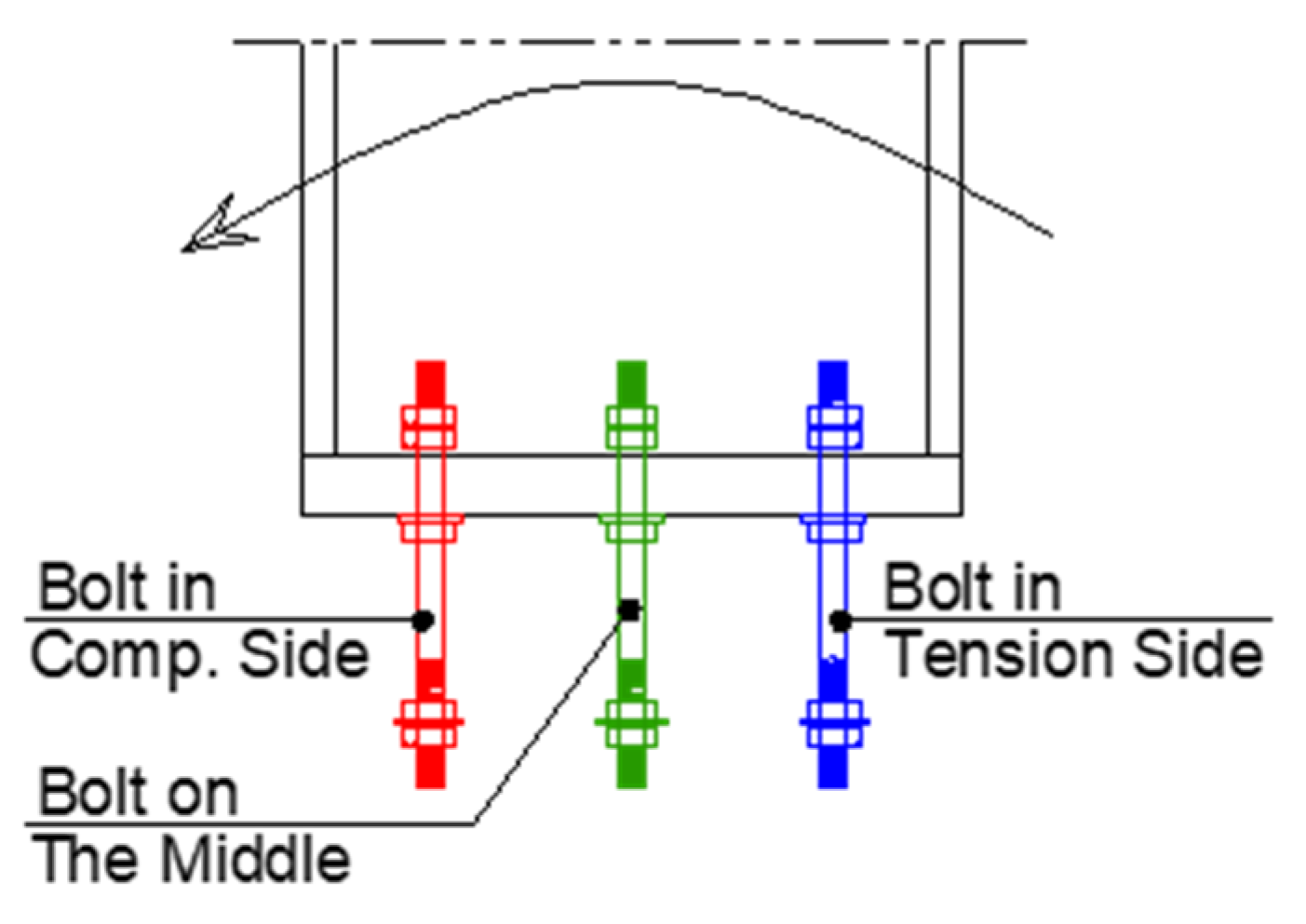

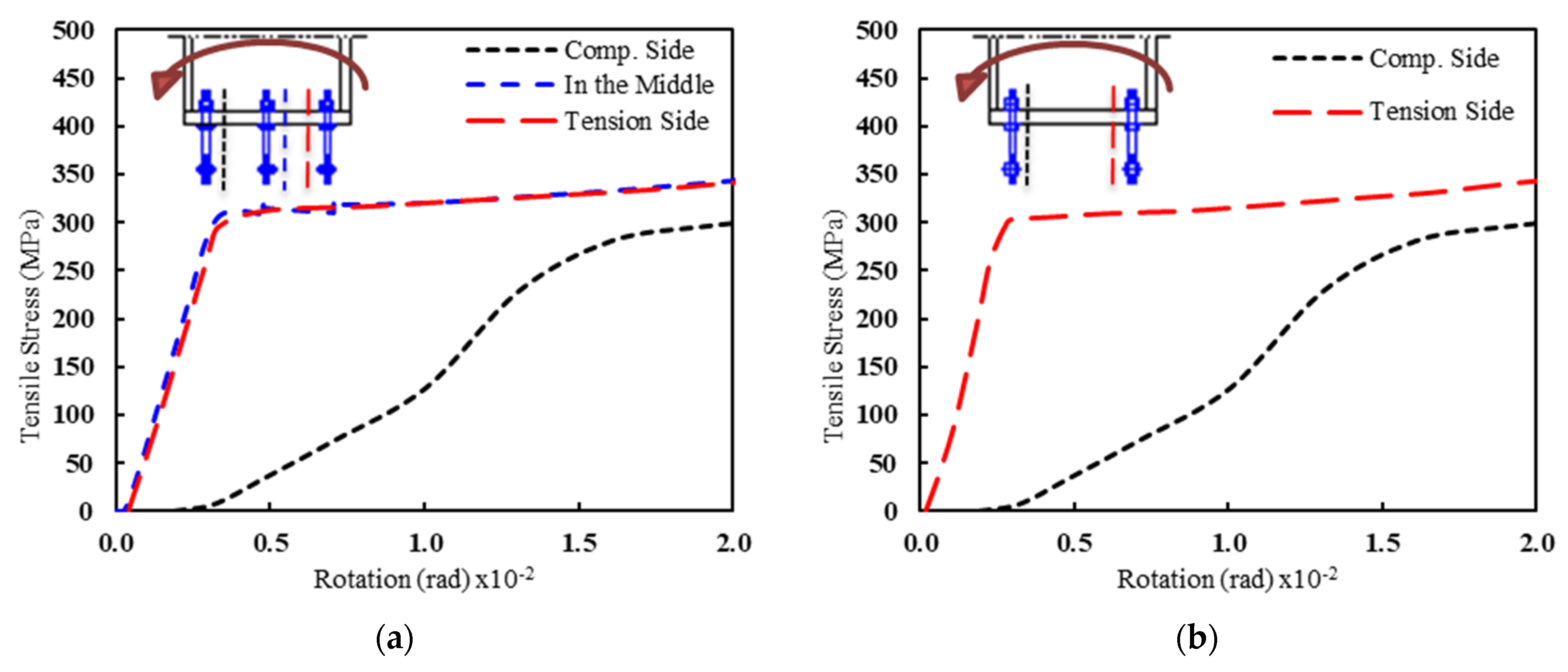

3.3. Effect of the Anchor Bolts Arrangement (Number and Spacing)

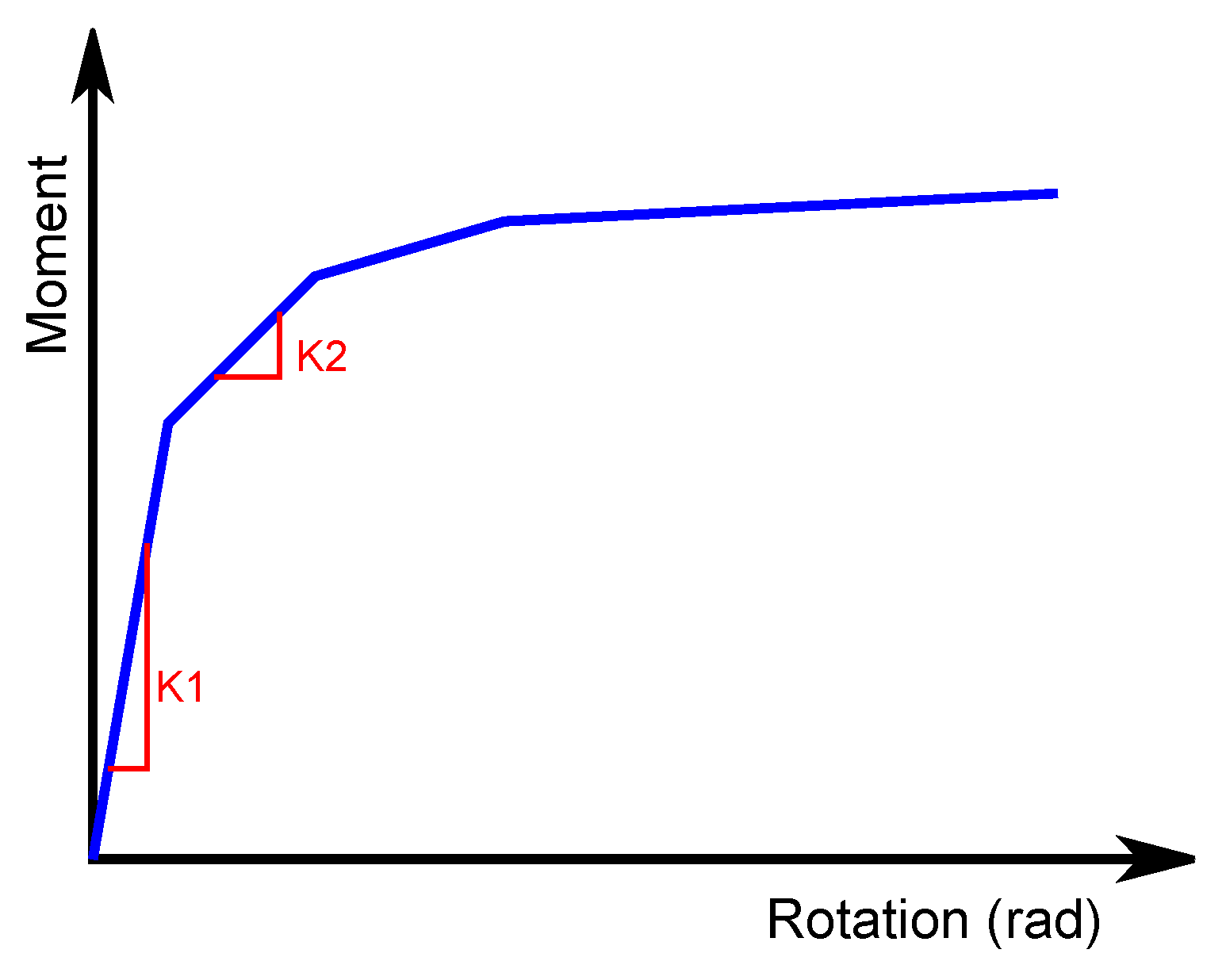

4. Discussions of the FE Results

5. Conclusions

- The most effective parameters that affect the elastic rotational stiffness and moment resistance of pinned base connections are the anchor bolt arrangement and diameter. The base plate thickness has a slight effect;

- The maximum increase in the rotational stiffness was 53% for the anchor bolt diameter of 30 mm when the base plate thickness increased from 12 mm to 30 mm;

- Based on the base plate thickness, the moment resistance improved by 150–260% when the bolt diameter increased from 12 mm to 30 mm;

- An increase in the elastic rotational stiffness by 50% was obtained for the four bolts arrangement, and the spacing increased from 50 mm to 150 mm. However, only a 37% increase was obtained for the six bolts arrangement, and the spacing increased from 100 mm to 150 mm;

- Increasing spacing between the anchor bolts leads to reductions in the effect of the base plate thickness on the rotational stiffness.

Author Contributions

Funding

Conflicts of Interest

References

- Kavoura, F.; Gencturk, B.; Dawood, M.; Gurbuz, M. Influence of base-plate connection stiffness on the design of low-rise metal buildings. J. Constr. Steel Res. 2015, 115, 169–178. [Google Scholar] [CrossRef]

- DeWolf, J.T.; Sarisley, E.F. Column Base Plates with Axial Loads and Moments. J. Struct. Div. 1980, 106, 2167–2184. [Google Scholar] [CrossRef]

- Burda, J.J.; Itani, A.M. Studies of Seismic Behavior of Steel Base Plates; 1999; Available online: http://hdl.handle.net/11714/7252 (accessed on 1 May 1999).

- Thambiratnam, D.; Paramasivam, P. Base Plates under Axial Loads and Moments. J. Struct. Eng. 1986, 112, 1166–1181. [Google Scholar] [CrossRef]

- Stamatopoulos, G.; Ermopoulos, J.C. Experimental and analytical investigation of steel column bases. J. Constr. Steel Res. 2011, 67, 1341–1357. [Google Scholar] [CrossRef]

- You, Y.-C.; Lee, D. Development of improved exposed column-base plate strong-axis joints of low-rise steel buildings. J. Constr. Steel Res. 2020, 169, 106062. [Google Scholar] [CrossRef]

- Picard, A.; Beaulieu, D. Behaviour of a simple column base connection. Can. J. Civ. Eng. 1985, 12, 126–136. [Google Scholar] [CrossRef]

- Lim, W.-Y.; Lee, D.; You, Y.-C. Exposed column-base plate strong-axis connections for small-size steel construction. J. Constr. Steel Res. 2017, 137, 286–296. [Google Scholar] [CrossRef]

- Picard, A.; Beaulieu, D.; Pérusse, B. Rotational restraint of a simple column base connection. Can. J. Civ. Eng. 1987, 14, 49–57. [Google Scholar] [CrossRef]

- Liu, T.C.-H. Investigation of rotational characteristics of column ‘PINNED’ bases of steel portal frames. Steel Compos. Struct. 2001, 1, 187–200. [Google Scholar] [CrossRef]

- Bajwa, S. Assessment of Analytical Procedures for Designing Metal Buildings for Wind Drift Serviceability; 2010; p. 204. Available online: http://hdl.handle.net/10919/34623 (accessed on 3 August 2010).

- Hong, J.K.; Uang, C.M. Cyclic Performance Evaluation of a Metal Building System with Web-Tapered Members; Report No. SSRP-06/23; Department of Structural Engineering, University of California: La Jolla, CA, USA, 2006. [Google Scholar]

- Kim, S.-E.; Lee, D.-H.; Ngo-Huu, C. Shaking table tests of a two-story unbraced steel frame. J. Constr. Steel Res. 2006, 63, 412–421. [Google Scholar] [CrossRef]

- Eröz, M.; White, D.W.; Desroches, R. Direct Analysis and Design of Steel Frames Accounting for Partially Restrained Column Base Conditions. J. Struct. Eng. 2008, 134, 1508–1517. [Google Scholar] [CrossRef]

- Watwood, V.B. Gable Frame Design Considerations. J. Struct. Eng. 1985, 111, 1543–1558. [Google Scholar] [CrossRef]

- Kavoura, F.; Gencturk, B.; Dawood, M. Reversed Cyclic Behavior of Column-to-Foundation Connections in Low-Rise Metal Buildings. J. Struct. Eng. 2017, 143, 04017095. [Google Scholar] [CrossRef]

- Kanvinde, A.; Jordan, S.; Cooke, R. Exposed column base plate connections in moment frames—Simulations and behavioral insights. J. Constr. Steel Res. 2013, 84, 82–93. [Google Scholar] [CrossRef]

- Da Silva, L.S.; Simões, R.; Gervásio, H. Design of Steel Structures: Eurocode 3: Design of Steel Structures, Part 1-1: General Rules and Rules for Buildings; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Kavoura, F.; Gencturk, B.; Dawood, M. Evaluation of existing provisions for design of “pinned” column base-plate connections. J. Constr. Steel Res. 2018, 148, 233–250. [Google Scholar] [CrossRef]

- Abaqus, Computer Software for Finite Element Analysis, Dassault Systems Simulia; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2016.

- Gomez, I.; Deierlein, G.; Kanvinde, A. Exposed Column Base Connections Subjected to Axial Compression and Flexure; 2010; Available online: https://datacenterhub.org/resources/1239 (accessed on 28 August 2010).

- Astaneh, A.; Bergsma, G.; Shen, J.H. Behavior and design of base plates for gravity, wind and seismic loads. In Proceedings of the National Steel Construction Conference, Chicago, IL, USA, 3–5 June 1992; pp. 209–214. [Google Scholar]

- Igor, S.; Grigoriev, E. Handbook of Physical Quantities, 1st ed.; Available online: https://www.routledge.com/Handbook-of-Physical-Quantities/Grigoriev-Meilikhov-Radzig/p/book/9780849328619 (accessed on 22 May 2021).

- FIB Bulletin 65: Model Code 2010—Final Draft, Volume 1; FIB—The International Federation for Structural Concrete: Lausanne, Switzerland, 2012.

- AISC. Steel Construction Manual, 14th ed.; AISC: Chicago, IL, USA, 2010. [Google Scholar]

| Steel Column | Steel Base Plate | Anchor Bolt | |

|---|---|---|---|

| fy (MPa) | 392 | 299 | 450 |

| fu (MPa) | 539 | 499 | 865 |

| Concrete | Grout | |

|---|---|---|

| fc (MPa) | 24.5 | 49.0 |

| Specimen | K1 | K2 | K * | M ** (KN.m) | E *** (N.m) | Tension Force in Anchor Bolt (KN) | ||

|---|---|---|---|---|---|---|---|---|

| (KN.m)/rad | Comp. Side | Middle | Tension Side | |||||

| B2-D12-S000-T12 | 44,671 | 2933 | 5702 | 38.01 | 204 | - | 35.2 | - |

| B4-D12-S050-T12 | 45,108 | 4788 | 7338 | 48.92 | 243 | 29.3 | - | 38.1 |

| B4-D12-S100-T12 | 66,828 | 6732 | 7321 | 48.81 | 259 | 20.5 | - | 36.8 |

| B4-D12-S150-T12 | 62,684 | 9489 | 7439 | 49.59 | 276 | 10.3 | - | 35.9 |

| B2-D18-S000-T12 | 65,421 | 4672 | 7462 | 49.74 | 239 | - | 75.3 | - |

| B4-D18-S050-T12 | 31,006 | 7213 | 10,078 | 67.18 | 300 | 50.4 | - | 85.9 |

| B4-D18-S100-T12 | 65,666 | 9692 | 11,352 | 75.68 | 345 | 28.9 | - | 85.6 |

| B4-D18-S150-T12 | 62,358 | 15,170 | 11,918 | 79.45 | 394 | 14.9 | - | 84.0 |

| B2-D24-S000-T12 | 48,080 | 5805 | 8386 | 55.91 | 262 | - | 140.9 | - |

| B4-D24-S050-T12 | 41,383 | 10,136 | 11,621 | 77.47 | 338 | 57.2 | - | 153.5 |

| B4-D24-S100-T12 | 63,887 | 12,146 | 13,762 | 91.75 | 396 | 32.8 | - | 159.2 |

| B4-D24-S150-T12 | 48,771 | 20,223 | 17,591 | 117.27 | 510 | 12.8 | - | 161.4 |

| B2-D30-S000-T12 | 31,258 | 7521 | 9349 | 62.32 | 283 | - | 199.0 | - |

| B4-D30-S050-T12 | 29,541 | 11,579 | 13,027 | 86.84 | 374 | 60.9 | - | 213.8 |

| B4-D30-S100-T12 | 30,570 | 16,363 | 15,538 | 103.58 | 441 | 36.6 | - | 243.9 |

| B4-D30-S150-T12 | 65,919 | 24,271 | 20,869 | 139.12 | 589 | 9.7 | - | 256.9 |

| B2-D12-S000-T18 | 44,881 | 3435 | 5716 | 38.11 | 212 | - | 35.8 | - |

| B4-D12-S050-T18 | 38,532 | 6005 | 7666 | 51.10 | 257 | 32.6 | - | 35.4 |

| B4-D12-S100-T18 | 67,251 | 8056 | 7439 | 49.59 | 266 | 23.8 | - | 36.3 |

| B4-D12-S150-T18 | 46,764 | 8987 | 7464 | 49.76 | 280 | 11.5 | - | 35.6 |

| B2-D18-S000-T18 | 20,369 | 5593 | 8061 | 53.74 | 254 | - | 82.3 | - |

| B4-D18-S050-T18 | 28,471 | 10,076 | 11,318 | 75.46 | 337 | 59.7 | - | 82.4 |

| B4-D18-S100-T18 | 67,272 | 12,984 | 11,577 | 77.18 | 372 | 37.4 | - | 82.3 |

| B4-D18-S150-T18 | 49,441 | 18,180 | 11,952 | 79.68 | 411 | 17.0 | - | 82.3 |

| B2-D24-S000-T18 | 38,163 | 7859 | 10,241 | 68.27 | 298 | - | 141.8 | - |

| B4-D24-S050-T18 | 49,381 | 11,121 | 14,360 | 95.73 | 395 | 57.9 | - | 146.9 |

| B4-D24-S100-T18 | 49,506 | 15,183 | 16,752 | 111.68 | 471 | 36.9 | - | 150.9 |

| B4-D24-S150-T18 | 48,717 | 23,417 | 18,054 | 120.36 | 563 | 12.9 | - | 149.0 |

| B2-D30-S000-T18 | 41,008 | 9375 | 11,772 | 78.48 | 331 | - | 219.9 | - |

| B4-D30-S050-T18 | 30,331 | 15,120 | 16,367 | 109.11 | 440 | 61.9 | - | 224.9 |

| B4-D30-S100-T18 | 29,662 | 17,059 | 20,167 | 134.45 | 537 | 34.1 | - | 238.1 |

| B4-D30-S150-T18 | 34,384 | 23,176 | 24,791 | 165.27 | 694 | 5.3 | - | 235.1 |

| B2-D12-S000-T24 | 38,796 | 3914 | 5716 | 38.11 | 213 | - | 34.8 | - |

| B4-D12-S050-T24 | 30,106 | 7455 | 7660 | 51.07 | 262 | 32.1 | - | 34.9 |

| B4-D12-S100-T24 | 41,994 | 8990 | 7482 | 49.88 | 269 | 24.4 | - | 35.1 |

| B4-D12-S150-T24 | 46,991 | 10,065 | 7469 | 49.79 | 282 | 11.7 | - | 35.2 |

| B2-D18-S000-T24 | 41,087 | 6657 | 8273 | 55.15 | 267 | - | 80.0 | - |

| B4-D18-S050-T24 | 29,253 | 10,496 | 11,757 | 78.38 | 352 | 56.9 | - | 79.6 |

| B4-D18-S100-T24 | 49,798 | 14,901 | 11,684 | 77.89 | 381 | 39.3 | - | 79.1 |

| B4-D18-S150-T24 | 49,732 | 19,195 | 11,958 | 79.72 | 417 | 16.9 | - | 79.3 |

| B2-D24-S000-T24 | 48,332 | 8768 | 11,016 | 73.44 | 320 | - | 140.4 | - |

| B4-D24-S050-T24 | 29,130 | 13,930 | 16,050 | 107.00 | 430 | 60.2 | - | 143.6 |

| B4-D24-S100-T24 | 48,427 | 17,907 | 16,928 | 112.85 | 498 | 42.0 | - | 145.6 |

| B4-D24-S150-T24 | 48,548 | 26,380 | 18,047 | 120.31 | 580 | 12.2 | - | 142.5 |

| B2-D30-S000-T24 | 49,366 | 10,939 | 13,212 | 88.08 | 362 | - | 210.6 | - |

| B4-D30-S050-T24 | 29,200 | 15,765 | 18,662 | 124.41 | 486 | 61.3 | - | 201.0 |

| B4-D30-S100-T24 | 65,577 | 24,066 | 22,488 | 149.92 | 594 | 34.1 | - | 232.7 |

| B4-D30-S150-T24 | 48,895 | 30,424 | 25,544 | 170.30 | 739 | 4.0 | - | 234.4 |

| B2-D12-S000-T30 | 41,191 | 3782 | 5717 | 38.12 | 213 | - | 34.9 | - |

| B4-D12-S050-T30 | 38,637 | 6220 | 7775 | 51.83 | 263 | 34.5 | - | 34.8 |

| B4-D12-S100-T30 | 46,811 | 10,576 | 7506 | 50.04 | 270 | 28.1 | - | 35.2 |

| B4-D12-S150-T30 | 42,979 | 11,118 | 7471 | 49.81 | 282 | 11.9 | - | 35.2 |

| B2-D18-S000-T30 | 28,033 | 6562 | 8258 | 55.05 | 272 | - | 78.1 | - |

| B4-D18-S050-T30 | 39,123 | 11,892 | 11,980 | 79.87 | 359 | 66.2 | - | 77.7 |

| B4-D18-S100-T30 | 50,070 | 15,120 | 11,736 | 78.24 | 385 | 41.0 | - | 79.6 |

| B4-D18-S150-T30 | 50,007 | 19,420 | 11,955 | 79.70 | 420 | 17.2 | - | 78.9 |

| B2-D24-S000-T30 | 38,346 | 9598 | 11,450 | 76.34 | 331 | - | 136.9 | - |

| B4-D24-S050-T30 | 41,972 | 15,508 | 16,498 | 109.99 | 448 | 68.1 | - | 141.9 |

| B4-D24-S100-T30 | 43,540 | 20,710 | 16,996 | 113.31 | 508 | 44.9 | - | 140.5 |

| B4-D24-S150-T30 | 47,432 | 28,155 | 18,036 | 120.24 | 586 | 12.0 | - | 141.5 |

| B2-D30-S000-T30 | 28,224 | 12,133 | 13,866 | 92.44 | 379 | - | 185.5 | - |

| B4-D30-S050-T30 | 49,865 | 17,980 | 20,104 | 134.03 | 514 | 66.3 | - | 213.8 |

| B4-D30-S100-T30 | 44,144 | 24,048 | 23,148 | 154.32 | 626 | 35.7 | - | 222.9 |

| B4-D30-S150-T30 | 47,114 | 32,522 | 25,531 | 170.20 | 758 | 3.8 | - | 224.4 |

| B6-D12-S100-T12 | 42,148 | 7753 | 8965 | 59.76 | 289 | 14.7 | 39.3 | 38.1 |

| B6-D18-S100-T12 | 42,164 | 11,908 | 13,085 | 87.24 | 375 | 20.3 | 72.8 | 88.0 |

| B6-D24-S100-T12 | 47,631 | 14,481 | 15,272 | 101.81 | 430 | 23.2 | 97.8 | 158.3 |

| B6-D30-S100-T12 | 54,834 | 17,071 | 17,294 | 115.29 | 479 | 25.0 | 86.9 | 238.5 |

| B6-D12-S100-T18 | 45,144 | 9264 | 9310 | 62.06 | 307 | 19.1 | 35.9 | 35.9 |

| B6-D18-S100-T18 | 46,322 | 14,473 | 14,619 | 97.46 | 424 | 21.8 | 74.0 | 83.6 |

| B6-D24-S100-T18 | 46,420 | 18,044 | 19,207 | 128.05 | 510 | 19.8 | 84.9 | 156.1 |

| B6-D30-S100-T18 | 40,430 | 18,345 | 21,825 | 145.50 | 571 | 18.4 | 89.3 | 236.8 |

| B6-D12-S100-T24 | 48,471 | 9807 | 9364 | 62.42 | 313 | 21.5 | 34.5 | 35.0 |

| B6-D18-S100-T24 | 46,471 | 17,144 | 14,978 | 99.85 | 442 | 23.9 | 71.0 | 79.8 |

| B6-D24-S100-T24 | 46,474 | 20,348 | 20,662 | 137.75 | 554 | 18.4 | 87.5 | 145.5 |

| B6-D30-S100-T24 | 36,858 | 20,730 | 24,764 | 165.09 | 631 | 9.9 | 83.0 | 217.8 |

| B6-D12-S100-T30 | 42,571 | 11,014 | 9401 | 62.67 | 316 | 22.2 | 34.8 | 35.0 |

| B6-D18-S100-T30 | 46,670 | 15,693 | 15,408 | 102.72 | 452 | 25.1 | 75.3 | 78.4 |

| B6-D24-S100-T30 | 39,637 | 22,244 | 21,065 | 140.43 | 574 | 19.3 | 101.9 | 140.2 |

| B6-D30-S100-T30 | 40,733 | 24,926 | 26,491 | 176.61 | 672 | 6.5 | 91.6 | 216.6 |

| B6-D12-S150-T12 | 62,885 | 11,170 | 9195 | 61.30 | 314 | 7.8 | 34.6 | 37.1 |

| B6-D18-S150-T12 | 45,776 | 16,291 | 14,769 | 98.46 | 446 | 8.9 | 74.1 | 85.0 |

| B6-D24-S150-T12 | 47,221 | 22,700 | 19,556 | 130.37 | 548 | 4.9 | 92.2 | 161.5 |

| B6-D30-S150-T12 | 45,205 | 26,739 | 22,904 | 152.69 | 632 | 2.6 | 89.2 | 254.4 |

| B6-D12-S150-T18 | 46,941 | 12,741 | 9438 | 62.92 | 328 | 8.7 | 35.3 | 35.5 |

| B6-D18-S150-T18 | 46,407 | 20,944 | 15,621 | 104.14 | 476 | 7.2 | 70.2 | 82.6 |

| B6-D24-S150-T18 | 45,227 | 24,733 | 21,996 | 146.64 | 623 | 0.8 | 93.2 | 149.7 |

| B6-D30-S150-T18 | 38,689 | 28,841 | 28,365 | 189.10 | 740 | 0.5 | 72.5 | 241.0 |

| B6-D12-S150-T24 | 48,487 | 13,606 | 9443 | 62.95 | 330 | 8.9 | 34.7 | 35.2 |

| B6-D18-S150-T24 | 59,220 | 22,115 | 15,840 | 105.60 | 490 | 4.9 | 74.2 | 79.2 |

| B6-D24-S150-T24 | 46,822 | 27,817 | 22,745 | 151.64 | 651 | 0.6 | 93.9 | 146.5 |

| B6-D30-S150-T24 | 42,561 | 31,725 | 29,327 | 195.51 | 789 | 0.3 | 89.3 | 229.5 |

| B6-D12-S150-T30 | 46,960 | 14,131 | 9433 | 62.89 | 331 | 9.2 | 35.1 | 35.3 |

| B6-D18-S150-T30 | 44,338 | 22,496 | 15,873 | 105.82 | 498 | 6.2 | 74.2 | 79.0 |

| B6-D24-S150-T30 | 48,078 | 29,511 | 23,254 | 155.03 | 670 | 0.4 | 104.8 | 141.4 |

| B6-D30-S150-T30 | 43,544 | 35,171 | 30,360 | 202.40 | 815 | 0.1 | 97.8 | 223.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawar, M.T.; Matar, E.B.; Maaly, H.M.; Alaaser, A.G.; El-Zohairy, A. Assessment of Rotational Stiffness for Metallic Hinged Base Plates under Axial Loads and Moments. Buildings 2021, 11, 368. https://doi.org/10.3390/buildings11080368

Nawar MT, Matar EB, Maaly HM, Alaaser AG, El-Zohairy A. Assessment of Rotational Stiffness for Metallic Hinged Base Plates under Axial Loads and Moments. Buildings. 2021; 11(8):368. https://doi.org/10.3390/buildings11080368

Chicago/Turabian StyleNawar, Mahmoud T., Ehab B. Matar, Hassan M. Maaly, Ahmed G. Alaaser, and Ayman El-Zohairy. 2021. "Assessment of Rotational Stiffness for Metallic Hinged Base Plates under Axial Loads and Moments" Buildings 11, no. 8: 368. https://doi.org/10.3390/buildings11080368