Effects of Shear Tabs and High-Strength Bolts in Seismic Performance of Steel Moment Connections

Abstract

:1. Introduction

2. Materials and Methods

2.1. FEM Simulation

2.2. Assumptions and Premises

- (1)

- The FEM simulation did not include (a) welding residual stress and thermal effects, or (b) tensile fracture of steel plates, bolt and weld materials.

- (2)

- Full-scale models were established for steel moment connections with BWWF details.

2.3. Boundary Conditions and Meshing

2.4. Sections and Materials

2.5. Stress–Strain Relation

2.6. Elements and Interfaces

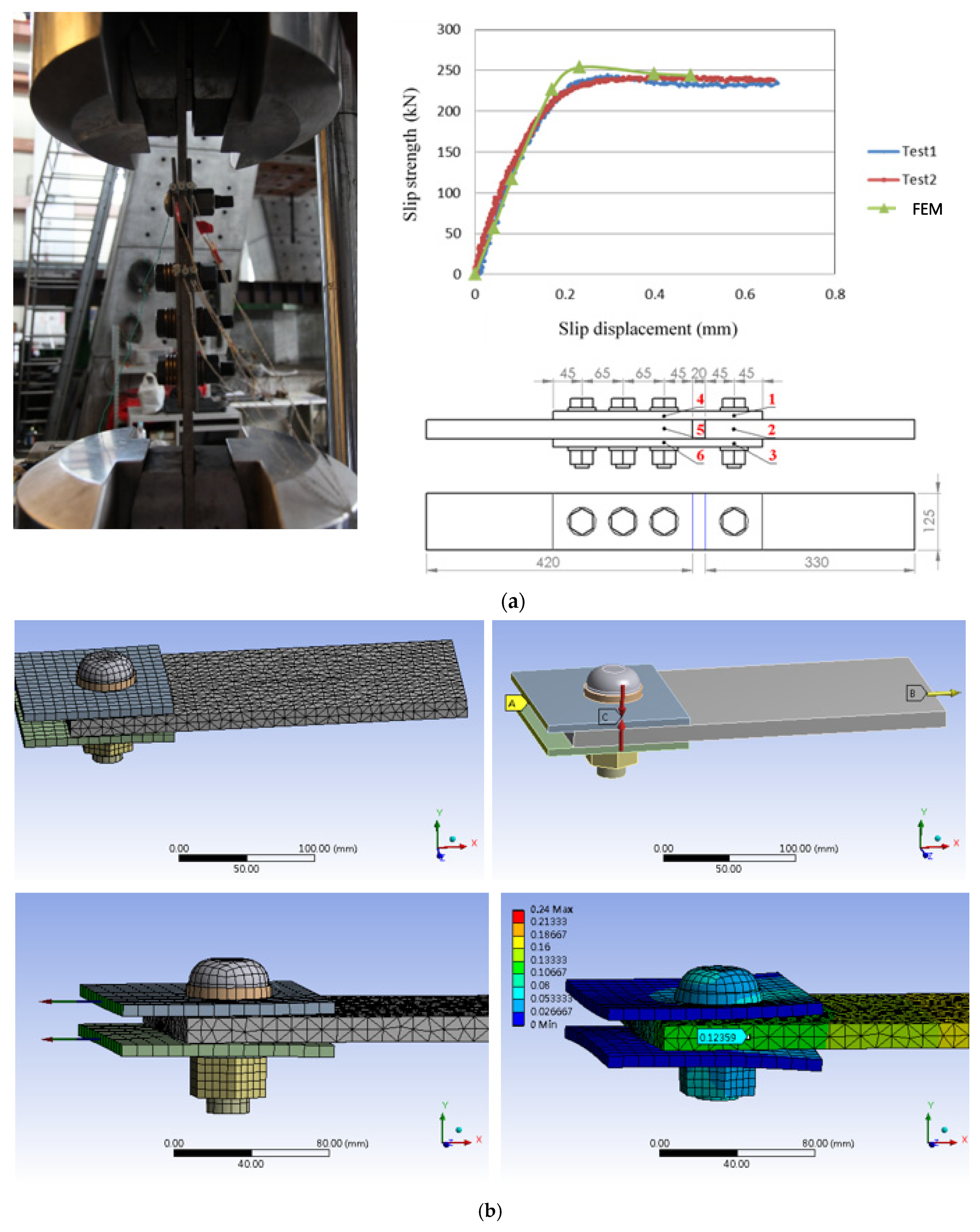

2.7. Modeling of Bolt Slippage

2.8. von Mises Stress and PEEQ Index

3. FEM Simulation of Connection Tests

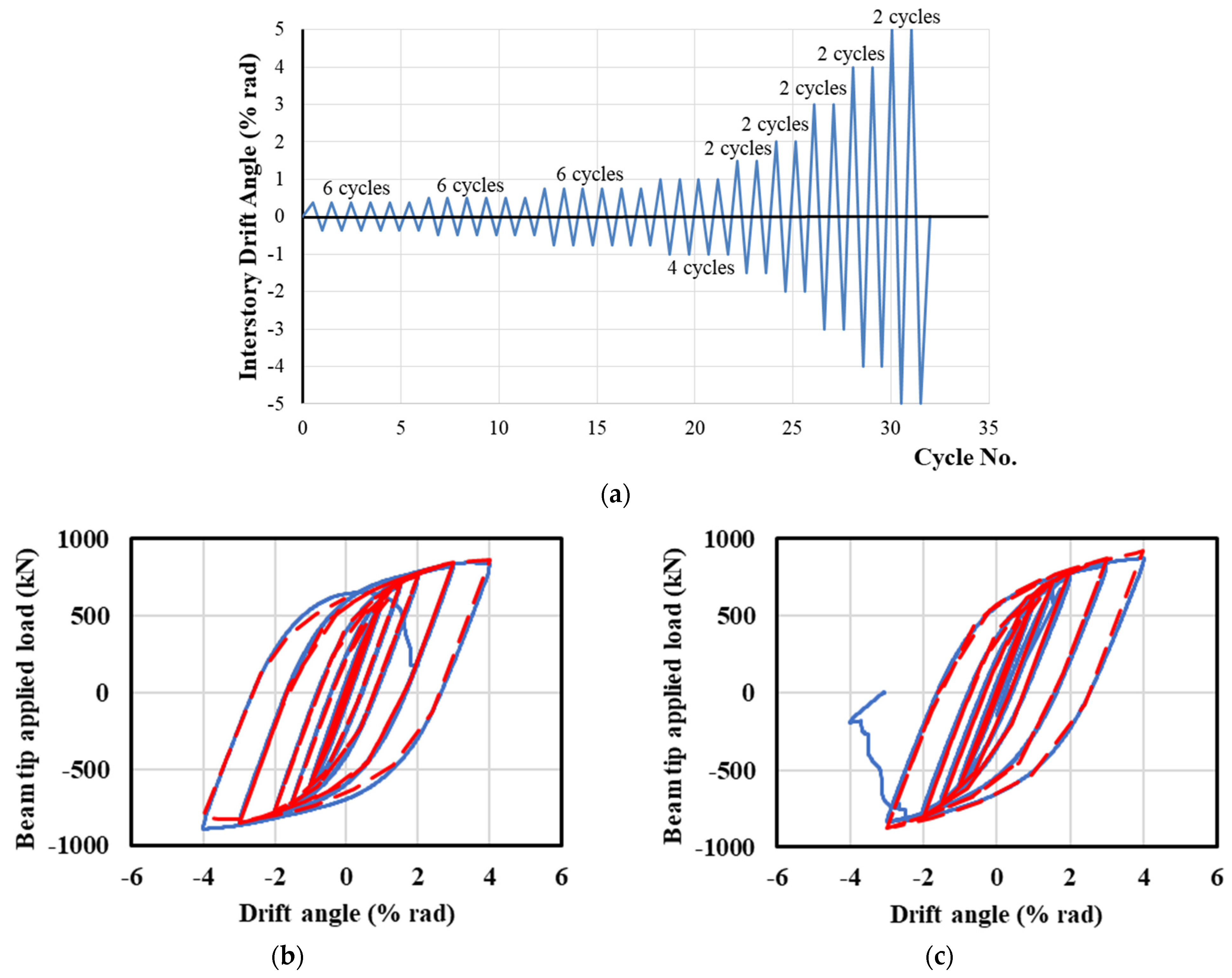

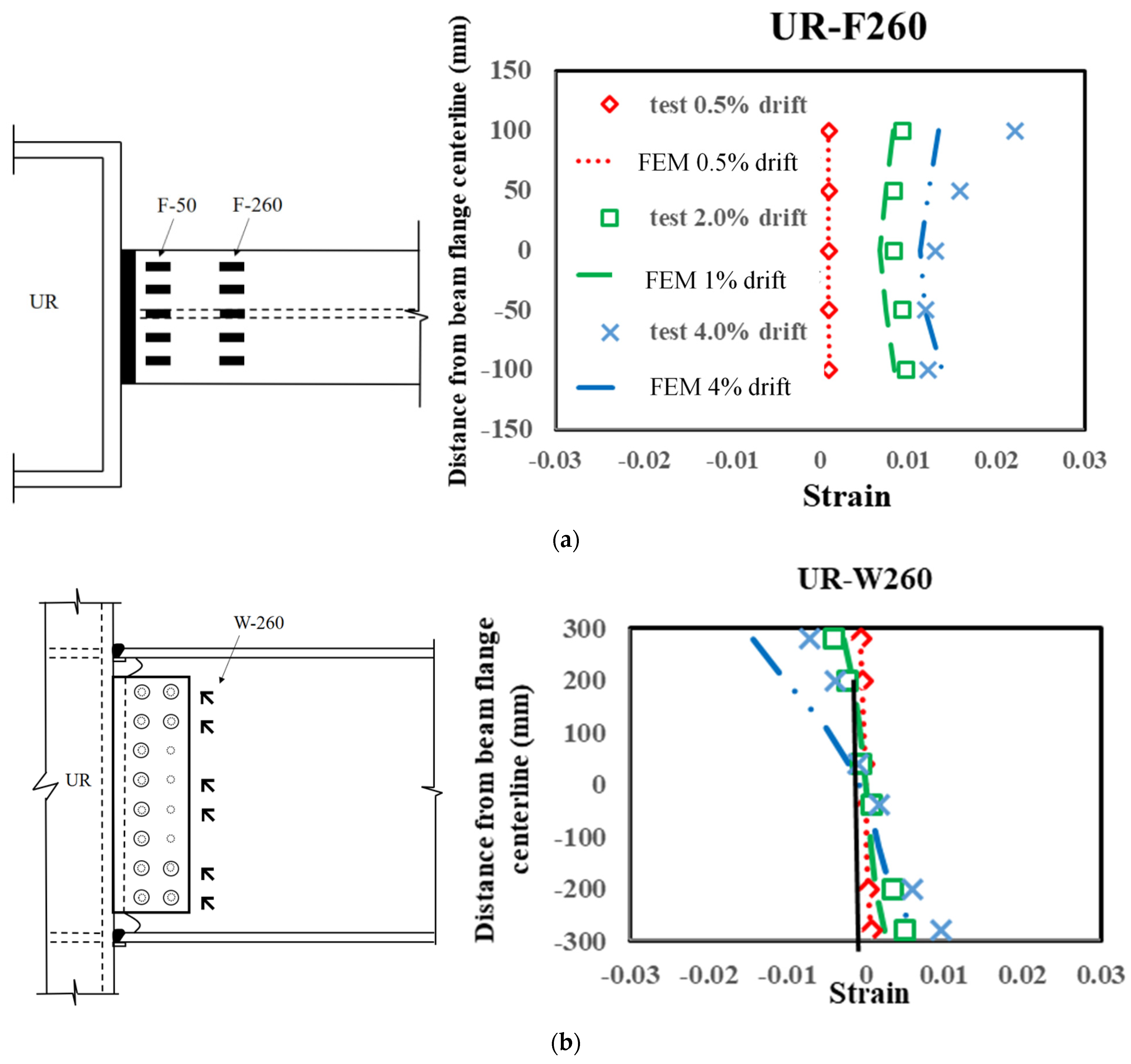

3.1. Validation by Connection Tests

Load-Displacement Responses

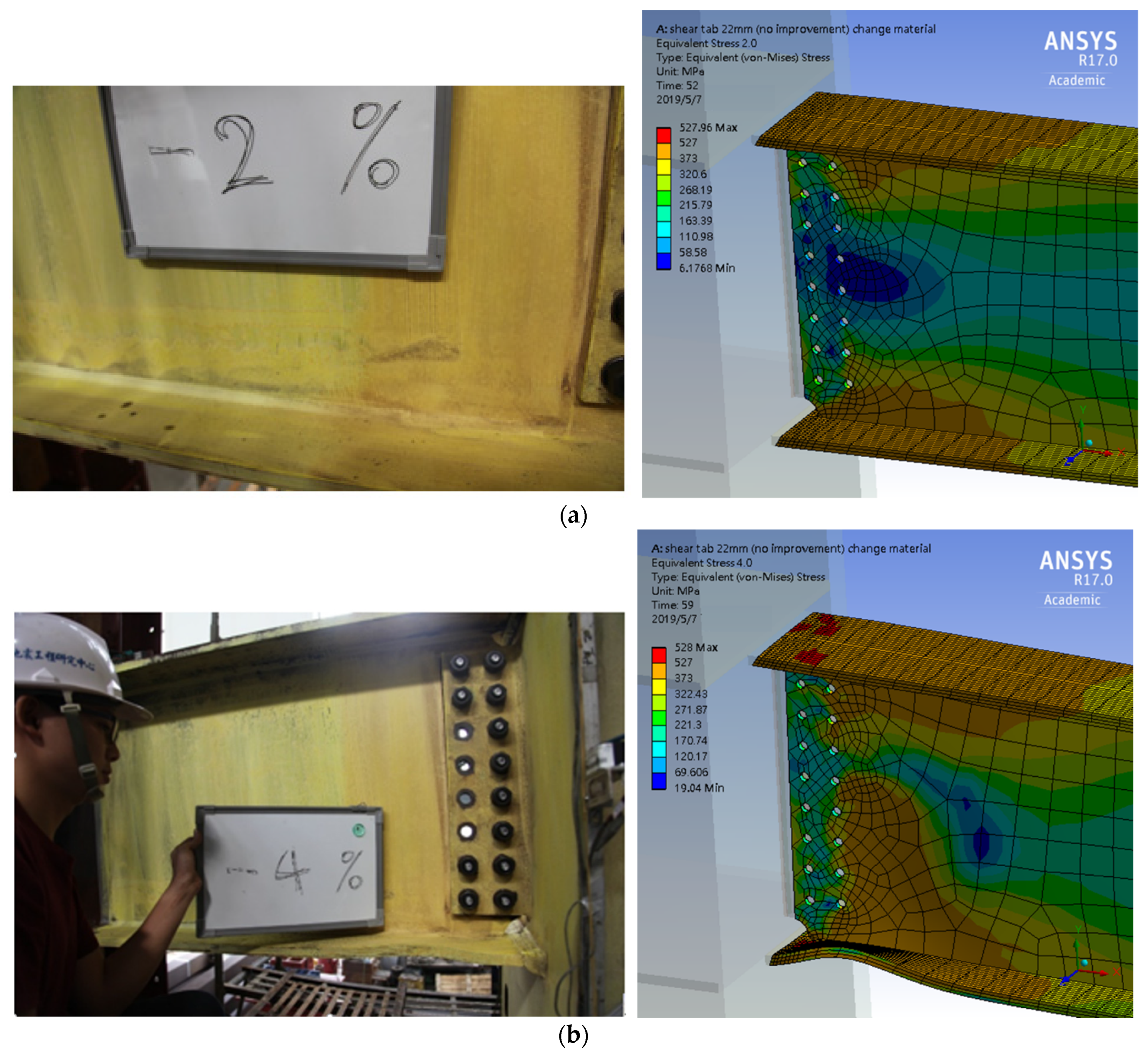

3.2. von Mises Stress and Connection Behavior

3.3. Strain Measurement

4. Parametric Analysis and Cases Study

4.1. Case Study

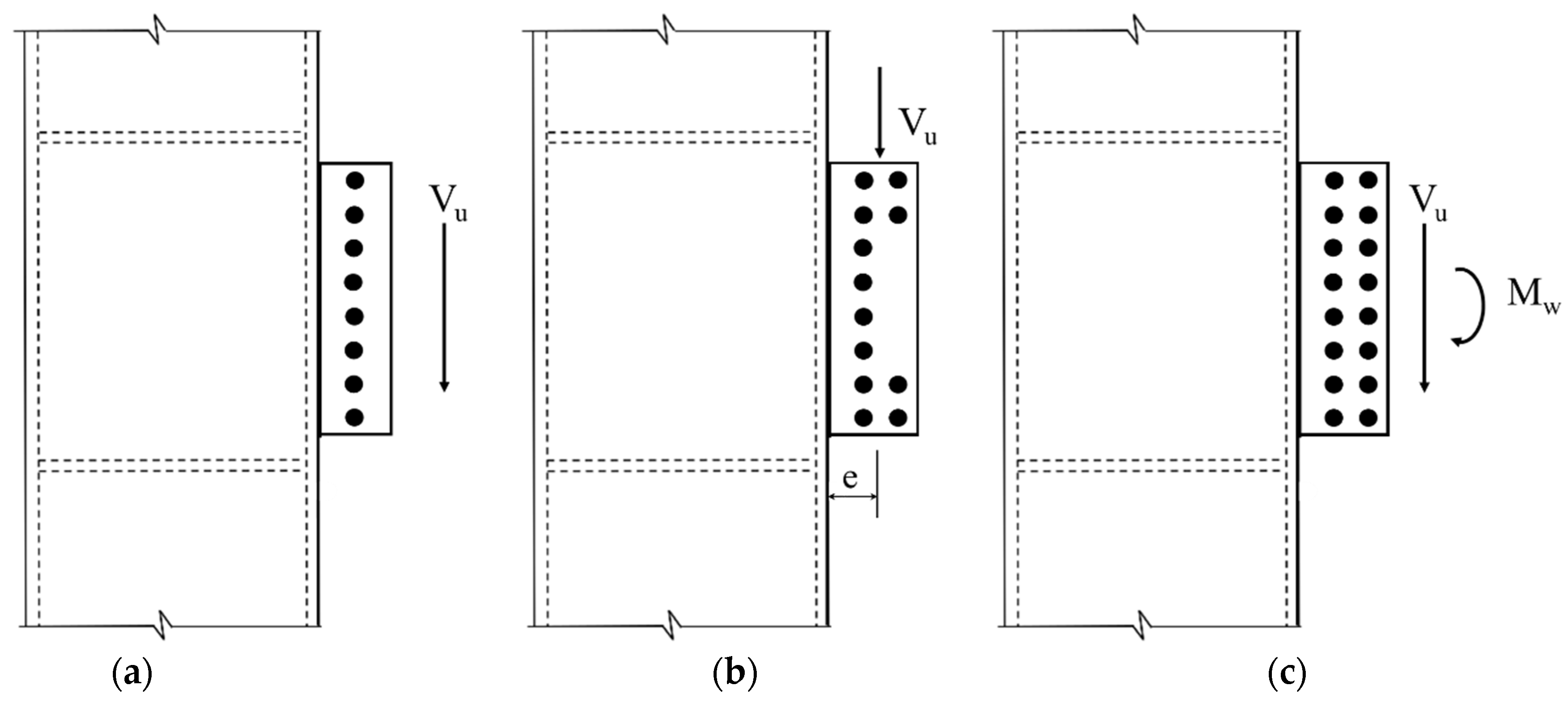

4.1.1. Design Consideration and Examples

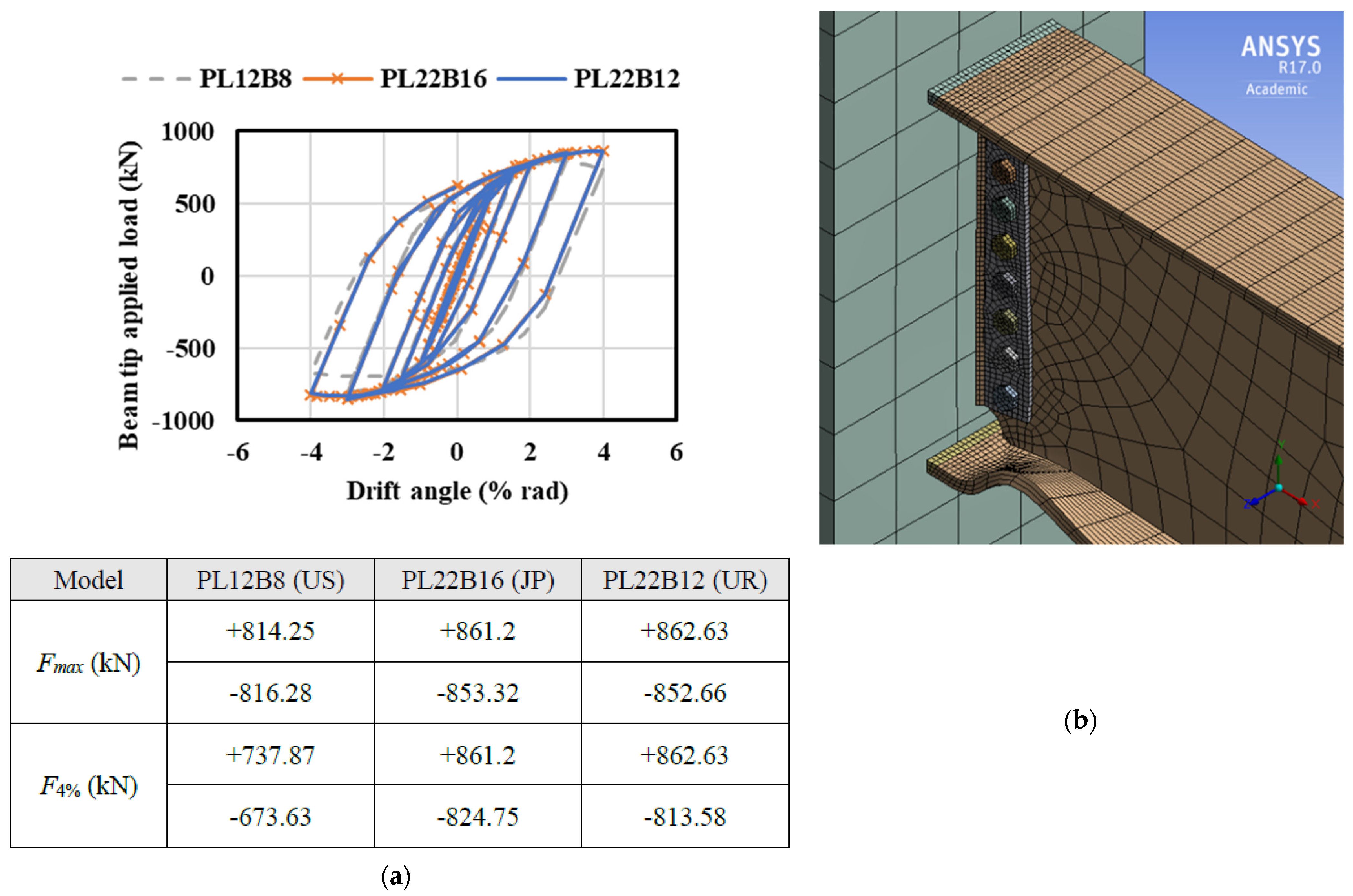

4.1.2. Evaluation of Connection Performance

4.2. Parametric Study

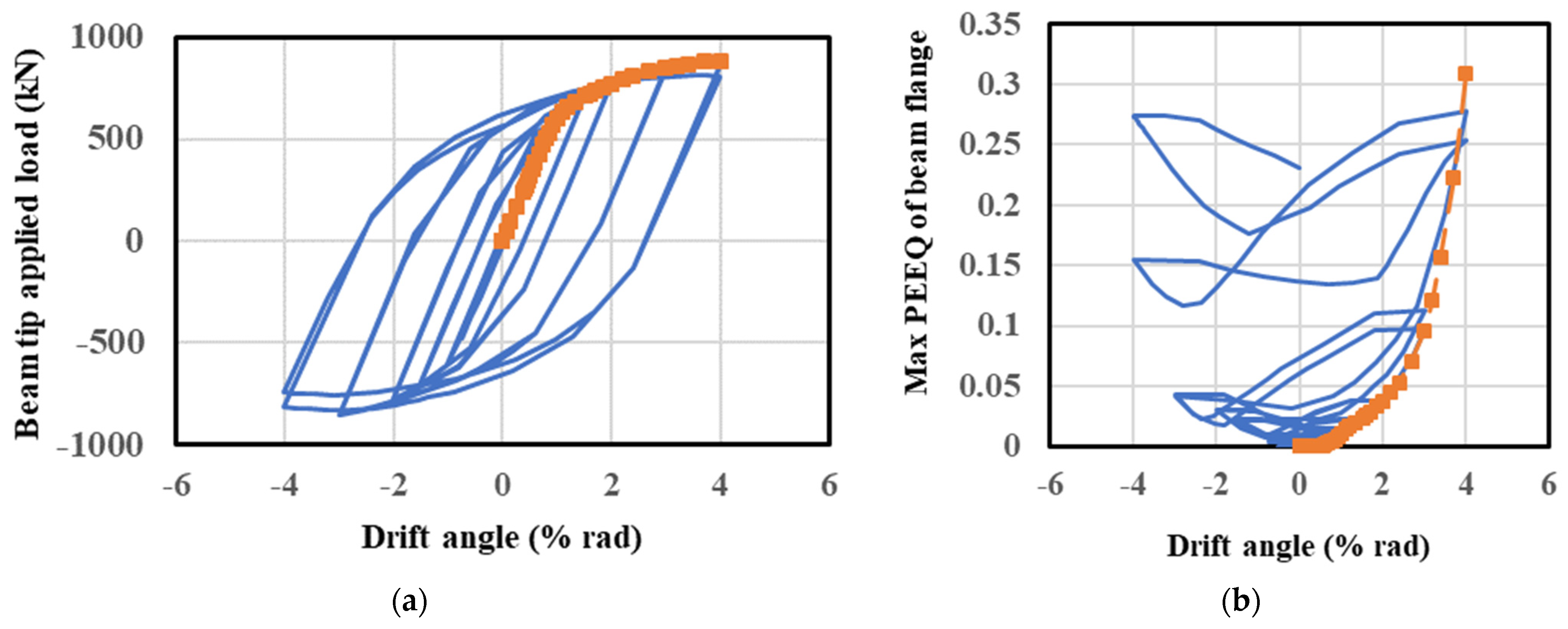

4.2.1. Response to Monotonic and Cyclic Loadings

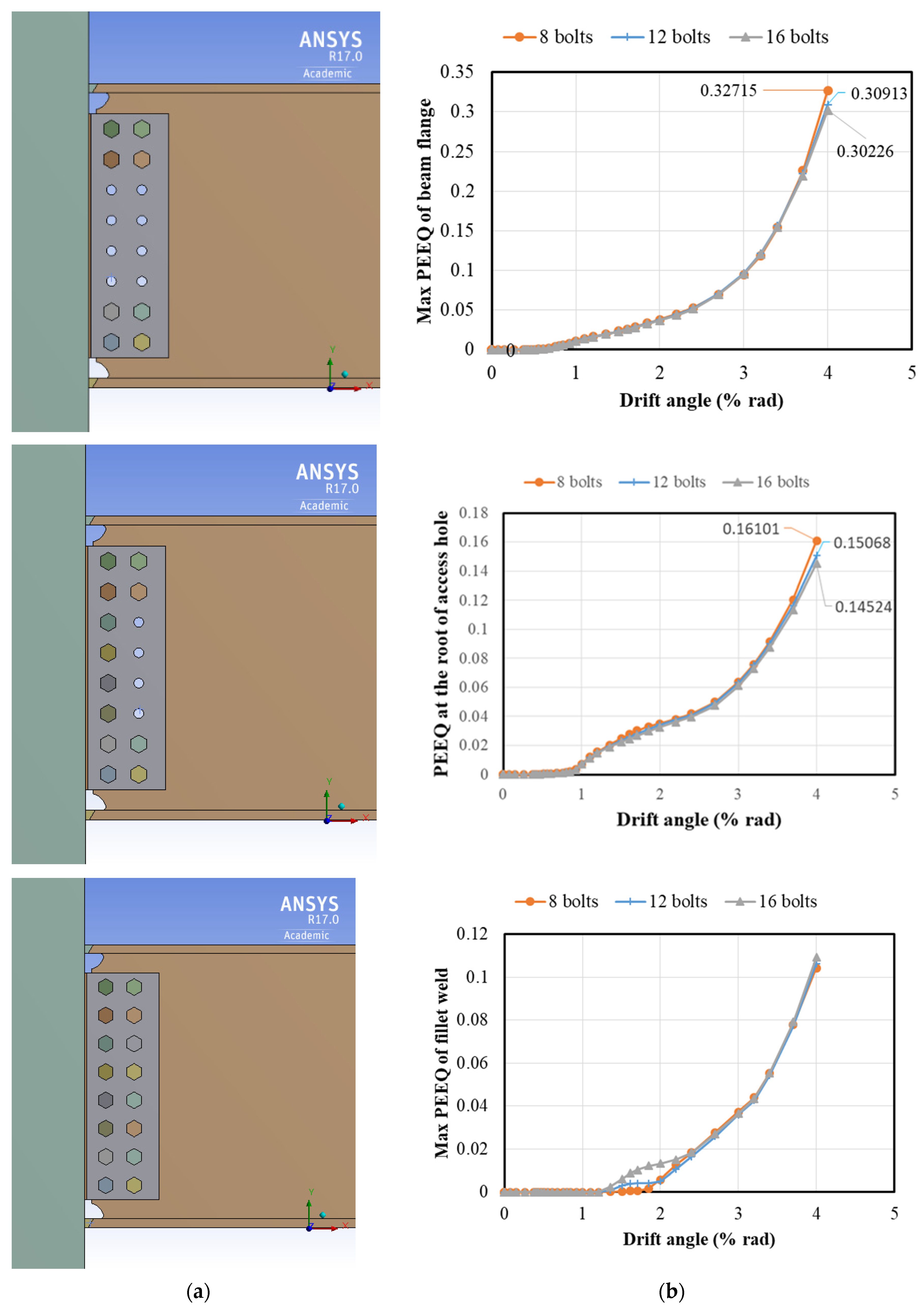

4.2.2. Effects of Bolt Arrangement and Strength

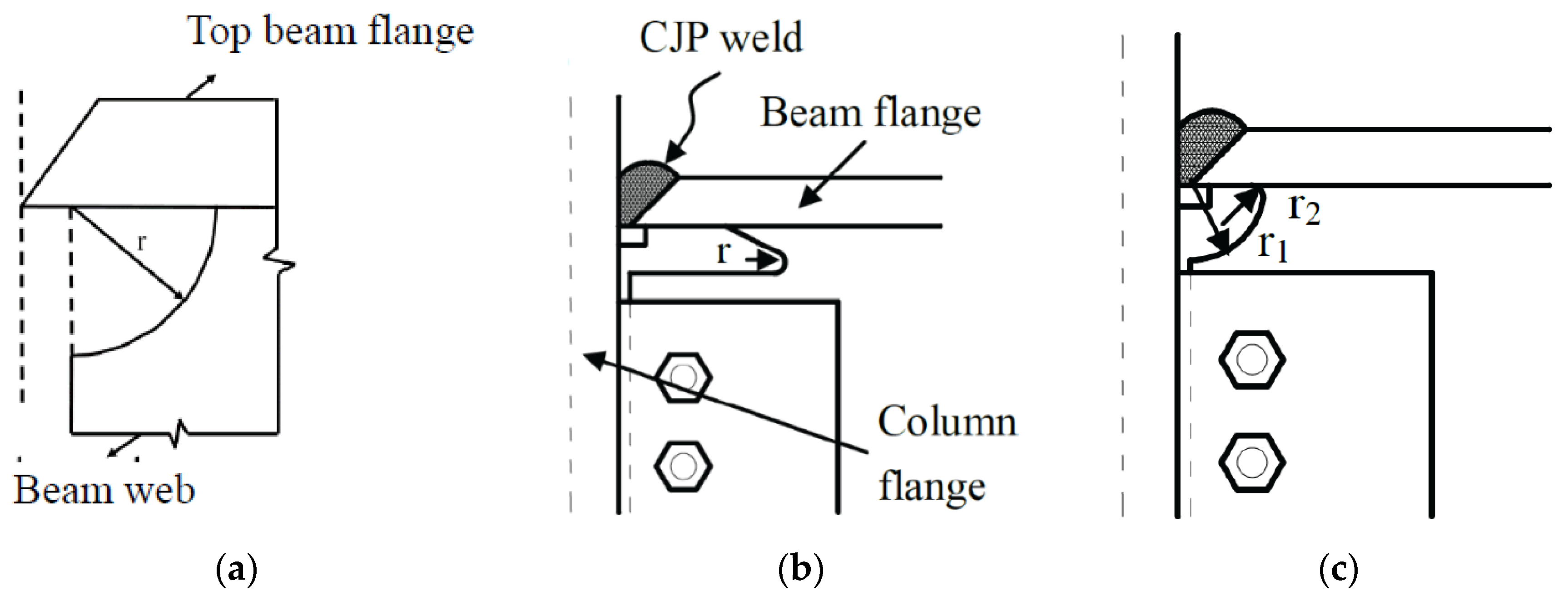

4.2.3. Shapes of Weld Access Holes and the Effects

4.2.4. Shear-Tab Thickness and the Effects

4.3. Discussion

5. Conclusions

- The design demands and capacity of bolted web connections were analyzed and compared. For the U.S. direct welded flange connection, the bolted web connection was designed to transfer the beam shear only. On the other hand, the perceptions about bolt slippage and the probably devastating effects caused Taiwan to improve the design practice. The slip strength of high-strength bolts was used instead, and consideration was taken of the eccentricity moment. In Japan, in contrast, the bolted web connection was designed to transfer the beam shear and to take the moment of the beam web.

- The design consideration and examples were studied with the aid of FEM simulation. The result indicates that there may be a small difference in the peak loads of the connections designed in accordance with the U.S., Taiwan and Japan standards. However, the U.S. direct welded flange connection can have flange buckling and strength degradation at a relatively smaller drift. The connection had a thinner shear tab and fewer high-strength bolts. On the other hand, the other two connections had very similar design results and loading responses.

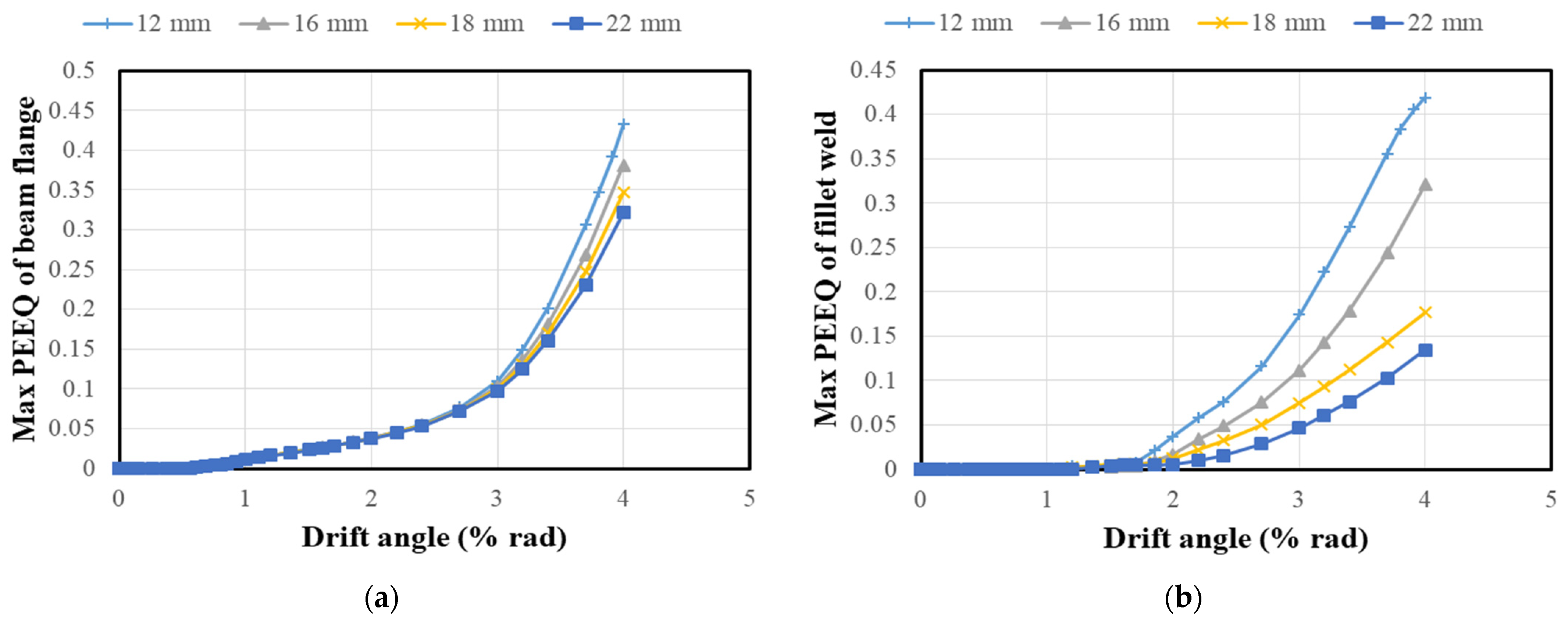

- The design parameters of steel moment connections were further studied with the aids of FEM simulation. It was found that shear-tab thickness may affect the seismic performance of the connections more than shapes of weld access holes, and bolt arrangements and strength. The greater the shear-tab thickness, the smaller the von Mises stress and PEEQ index. This means that the increase in shear-tab thickness can reduce the stress concentration and fracture potential of steel connections in an effective and efficient way.

- For a new steel moment connection, it is recommended to design a shear tab with shear strength and moment capacity greater than the beam web, and to use the slip strength of high-strength bolts in the evaluation of eccentric moment in the bolted web connection. For seismic upgrading of an existing connection, it is recommended to add another shear tab and to replace with higher strength bolts. Instead of yield strength, tensile strength of steel plates should be used to evaluate the strength demand of fillet welds between shear tabs and column faces.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notations

| E | Young’s modulus (GPa) |

| Esh | strain hardening rate |

| PEEQ | equivalent plastic strain |

| vector component of plastic strain in the direction of i and j | |

| von Mises stress (MPa) | |

| principal stresses (MPa) | |

| v | Poisson’s ratio |

References

- Sabol, T.S.; Engelhardt, M.D.; Aboutaha, R.S.; Frank, K.H. Overview of the AISC Northridge moment connection test program. In Proceedings of the 11th World Conference on Earthquake Engineering (WCEE11), Acapulco, Mexico, 23–28 June 1996; Paper No. 857. Available online: https://www.iitk.ac.in/nicee/wcee/article/11_857.PDF (accessed on 6 September 2021).

- Engelhardt, M.D.; Sabol, T.A. Seismic-resistant steel moment connections: Developments since the 1994 Northridge earthquake. Prog. Struct. Engng. Mater. 1997, 1, 68–77. [Google Scholar] [CrossRef]

- Stojadinović, B.; Goel, S.C.; Lee, K.-H.; Margarian, A.G.; Choi, J.-H. Parametric tests on unreinforced steel moment connections. ASCE J. Struct. Eng. 2000, 126, 40–49. [Google Scholar] [CrossRef]

- El-Tawil, S.; Mikesell, T.; Kunnath, S.K. Effect of local details and yield ratio on behavior of FR steel connections. ASCE J. Struct. Eng. 2000, 126, 79–87. [Google Scholar] [CrossRef]

- Ricles, J.M.; Mao, C.; Lu, L.-W.; Fisher, J.W. Ductile details for welded unreinforced moment connections subject to inelastic cyclic loading. Engrg. Struct. 2003, 25, 667–680. [Google Scholar] [CrossRef]

- Elkady, A.; Lignos, D.G. Analytical investigation of the cyclic behavior and plastic hinge formation in deep wide-flange steel beam-columns. Bull. Earthq. Eng. 2015, 13, 1097–1118. [Google Scholar] [CrossRef]

- Cravero, J.; Elkady, A.; Lignos, D.G. Experimental evaluation and numerical modeling of wide-flange steel columns subjected to constant and variable axial load coupled with lateral drift demands. ASCE J. Struct. Eng. 2020, 146, 04019222. [Google Scholar] [CrossRef] [Green Version]

- Sediek, O.A.; Wu, T.-Y.; McCormick, J.; El-Tawil, S. Collapse behavior of hollow structural section columns under combined axial and lateral loading. ASCE J. Struct. Eng. 2020, 146, 04020094. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, C.; Yan, Z.; Chen, X.; Cai, Y. Semi-rigidity connection model for unstiffened CHS X-type joints subjected out-of-plane bending. Intl. J. Steel Struct. 2018, 19, 834–849. [Google Scholar] [CrossRef]

- Zhao, B.; Sun, C.; Cai, Y.; Liu, C. An out-of-plane bending hysteretic model for multi-planar CHS X-connections. Structures 2020, 23, 335–350. [Google Scholar] [CrossRef]

- Zhao, B.; Ke, K.; Liu, C.; Hong, L. Computational Model for the Flexural Capacity and Stiffness of Eccentric RHS X-Connections under Brace Out-of-Plane Bending Moment. ASCE J. Struct. 2020, 146, 04019227. [Google Scholar] [CrossRef]

- Wu, T.-Y.; El-Tawil, S.; McCormick, J. Seismic collapse response of steel moment frames with deep columns. ASCE J. Struct. Eng. 2018, 144, 04018145. [Google Scholar] [CrossRef]

- Chen, C.C.; Lin, C.C.; Tsai, C.L. Evaluation of reinforced connections between steel beams and box columns. Eng. Struct. 2004, 26, 1889–1904. [Google Scholar] [CrossRef]

- Chen, C.C.; Chen, S.W.; Chung, M.D.; Lin, M.C. Cyclic behaviour of unreinforced and rib-reinforced moment connections. J. Constr. Steel. Res. 2005, 61, 1–21. [Google Scholar] [CrossRef]

- Chou, C.C.; Tsai, K.C.; Wang, Y.Y.; Jao, C.K. Seismic rehabilitation performance of steel side plate moment connections. Earth. Eng. Struct. Dyn. 2010, 39, 23–44. [Google Scholar] [CrossRef]

- Chung, Y.L.; Nagae, T.; Matsumiya, T.; Nakashima, M. Seismic resistance capacity of beam–column connections in high-rise buildings: E-Defense shaking table test. Earth. Eng. Struct. Dyn. 2010, 40, 605–622. [Google Scholar] [CrossRef]

- Chung, Y.L.; Nagae, T.; Matsumiya, T.; Nakashima, M. Seismic capacity of retrofitted beam–column connections in high-rise steel frames when subjected to long-period ground motions. Earth. Eng. Struct. Dyn. 2012, 41, 735–753. [Google Scholar] [CrossRef]

- Chang, H.Y.; Lai, C.M.; Yeh, C.Y.; Wang, T.Y. Evaluation of seismic performance for existing steel moment connections and the upgrading. In Proceedings of the International Conference in Commemoration of 20th Anniversary of the 1999 Chi-Chi Earthquake, Taipei, Taiwan, 15–19 September 2019. [Google Scholar]

- American Institute of Steel Construction (AISC). Seismic Provisions for Structural Steel Building; American Institute of Steel Construction (AISC): Chicago, IL, USA, 2016. [Google Scholar]

- Chen, C.Y.; Lai, C.M.; Chang, H.Y. Tests of slip-critical connections and the FEM simulation. In Proceedings of the 40th National Conference on Theoretical and Applied Mechanics, Hsinchu, Taiwan, 25–26 November 2016. (In Chinese). [Google Scholar]

- AANSYS. ANSYS 16.2 & 17.0 [Computer Software]; ANSYS: Canonsburg, PA, USA, 2015. [Google Scholar]

- Architectural Institute of Japan (AIJ). Recommendation for Design of Connections in Steel Structures; Architectural Institute of Japan (AIJ): Tokyo, Japan, 2012. [Google Scholar]

- Rahman, A.; Mahamid, M.; Amro, A.; Ghorbanpoor, A. The analyses of extended shear tab steel connections—Part I: The unstiffened connections. Eng. J. 2007, 44, 133–146. [Google Scholar]

- Morrison, M.L.; Schweizer, D.Q.; Hassan, T. Seismic enhancement of welded unreinforced flange-bolted web steel moment connections. ASCE J. Struct. Eng. 2016, 142, 04016102. [Google Scholar] [CrossRef]

- Boresi, A.P.; Schmidt, R.J.; Sidebottom, O.M. Advanced Mechanics of Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Geschwindner, L.F. Unified Design of Steel Structures, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Krawinkler, H.; Popov, P.E. Seismic behavior of moment connections and joints. ASCE J. Struct. Eng. 1982, 108, 372–391. [Google Scholar] [CrossRef]

- Recommended Seismic Design Criteria for New Steel Moment-Frame Buildings: FEMA 350; Federal Emergency Management Agency (FEMA): Washington DC, USA, 2000. Available online: https://www.nehrp.gov/pdf/fema350.pdf (accessed on 6 September 2021).

- Lee, C.-H.; Jeon, S.-W.; Kim, J.-H.; Uang, C.-M. Effects of panel zone strength and beam web connection method on seismic performance of reduced beam section steel moment connections. ASCE J. Struct. Eng. 2005, 131, 1854–1865. [Google Scholar] [CrossRef]

- Takatsuka, K.; Suita, K.; Manabe, Y.; Tanaka, T.; Tsukada, T. Effect of beam-to-column connection details on deformation capacity of cyclic loading. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008; Available online: https://www.iitk.ac.in/nicee/wcee/article/WCEE2012_3382.pdf (accessed on 6 September 2021).

| 1. Details of bolted web connections | ||||

|---|---|---|---|---|

| Shear tab(s) | High-strength bolts | |||

| UN-connection | SN490B steel, PL-640 × 130 × 22 | 12-M24 S10T | ||

| DB-connection | A572 Gr. 50 steel, 2PL-640 × 130 × 16 | 12-M22 F14T | ||

| 2. Mechanical properties of steel material | ||||

| Steel material | Fy (MPa) | Fu (MPa) | Elongation (%) | |

| SN490B steel | 325~445 | 490~610 | Flange ≥ 21Web ≥ 17 | |

| A572 Gr. 50 steel | ≥345 | ≥450 | ≥18 | |

| FE70 weld material | 555 | 592 | ≥26 | |

| JIS S10T bolt | 920 | 1000~1200 | ≥14 | |

| JIS F14T bolt | 1260 | 1400~1490 | ≥14 | |

| 3. Strength properties of high-strength bolts | ||||

| High-strength bolt | Pretension(kN) | Slip strength 1(kN) | Shear strength 2(kN) | |

| M24-S10T | 233 | 118 | 166 | |

| M22-F14T | 330 | 336 | 426 | |

| Steel Material | A572 Gr. 50 | SN490B | FE70 | S10T | F14T |

|---|---|---|---|---|---|

| Yield strength (MPa) | 350 | 373 | 555 | 920 | 1260 |

| Tensile strength (MPa) | 500 | 528 | 592 | 1000 | 1400 |

| Strain hardening exponent (Esh) | 0.04E | 0.04E | 0.0036E | 0.05E | 0.05E |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, C.-M.; Yeh, C.-Y.; Kang, S.-Y.; Chang, H.-Y. Effects of Shear Tabs and High-Strength Bolts in Seismic Performance of Steel Moment Connections. Buildings 2021, 11, 415. https://doi.org/10.3390/buildings11090415

Lai C-M, Yeh C-Y, Kang S-Y, Chang H-Y. Effects of Shear Tabs and High-Strength Bolts in Seismic Performance of Steel Moment Connections. Buildings. 2021; 11(9):415. https://doi.org/10.3390/buildings11090415

Chicago/Turabian StyleLai, Chi-Ming, Ching-Yu Yeh, Sin-Yu Kang, and Heui-Yung Chang. 2021. "Effects of Shear Tabs and High-Strength Bolts in Seismic Performance of Steel Moment Connections" Buildings 11, no. 9: 415. https://doi.org/10.3390/buildings11090415