Mechanical Characterization of Geopolymer Paste and Mortar Fabricated from Alum Sludge and Fly Ash

Abstract

:1. Introduction

2. Materials and Methods

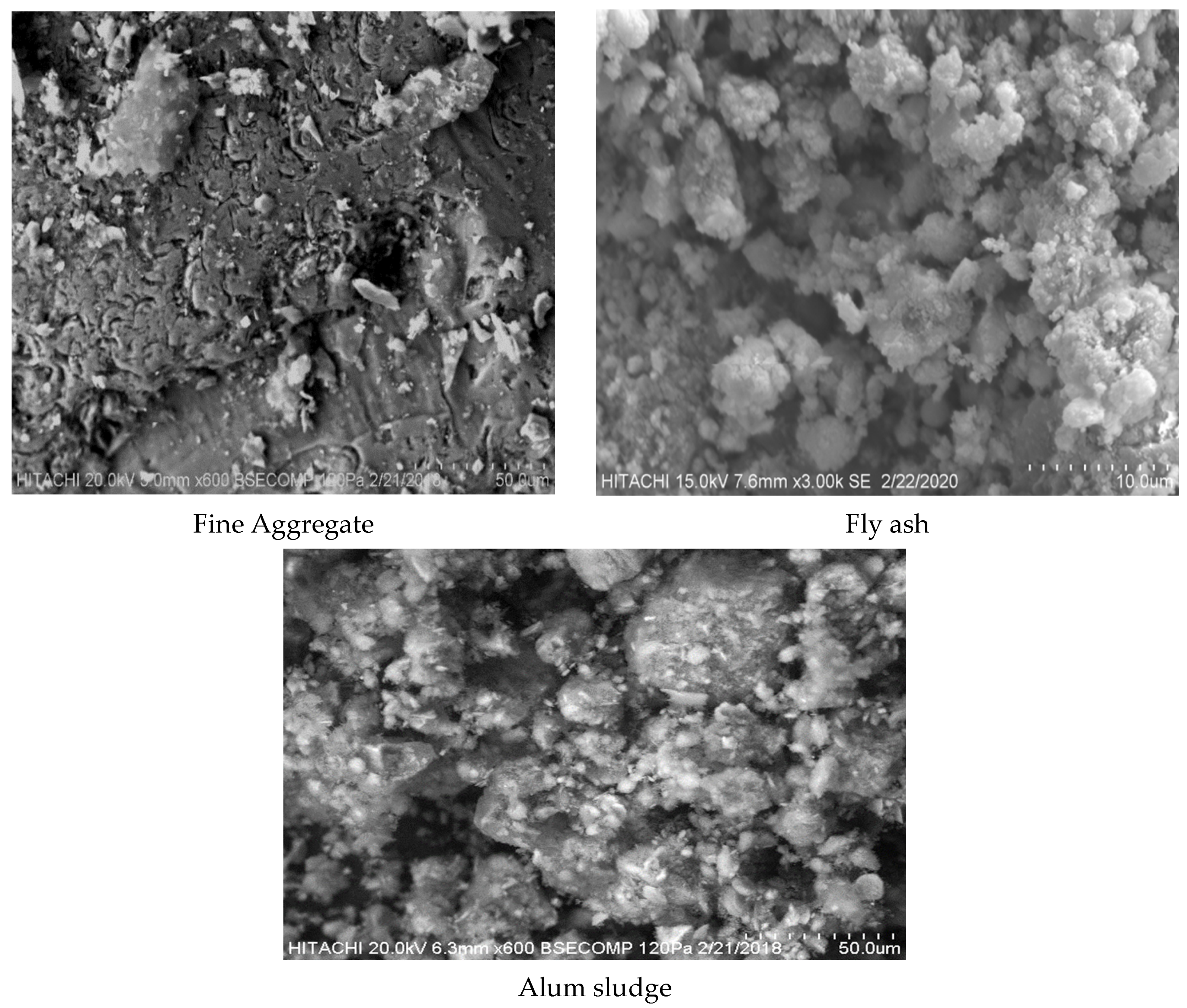

2.1. Materials

2.2. Methods

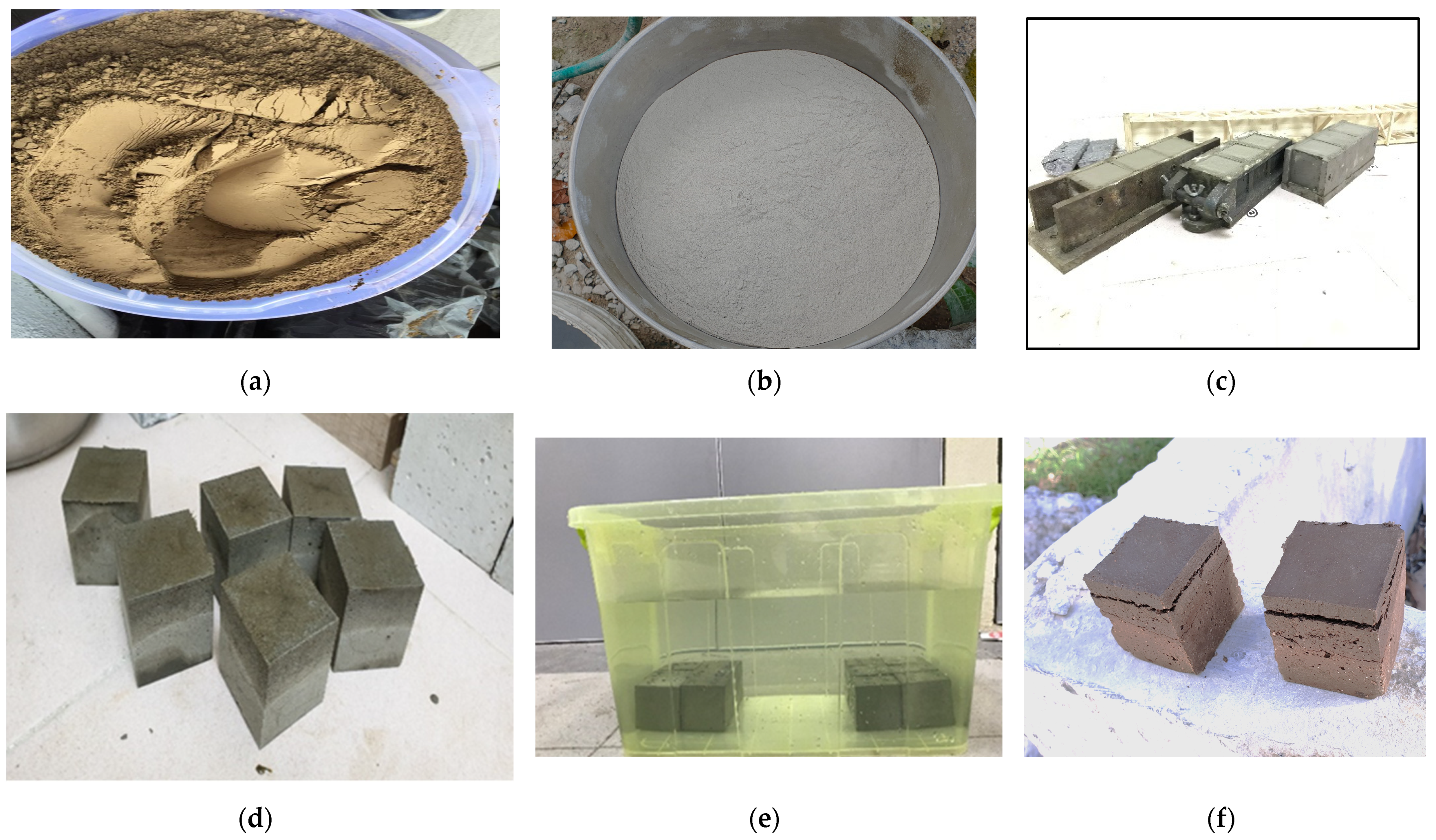

2.2.1. Preparation of Samples

2.2.2. Blending and Casting of Geopolymer Paste and Mortar

2.2.3. Properties of Materials

3. Results

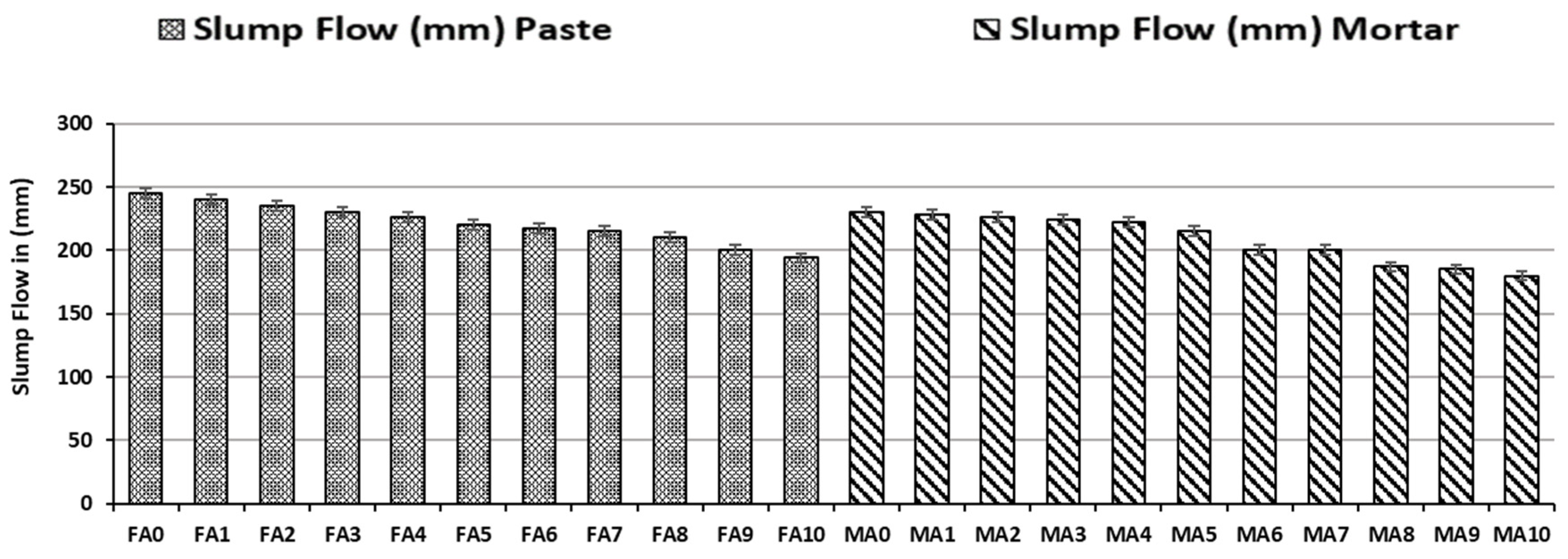

3.1. Geopolymer Paste/Mortar Workability

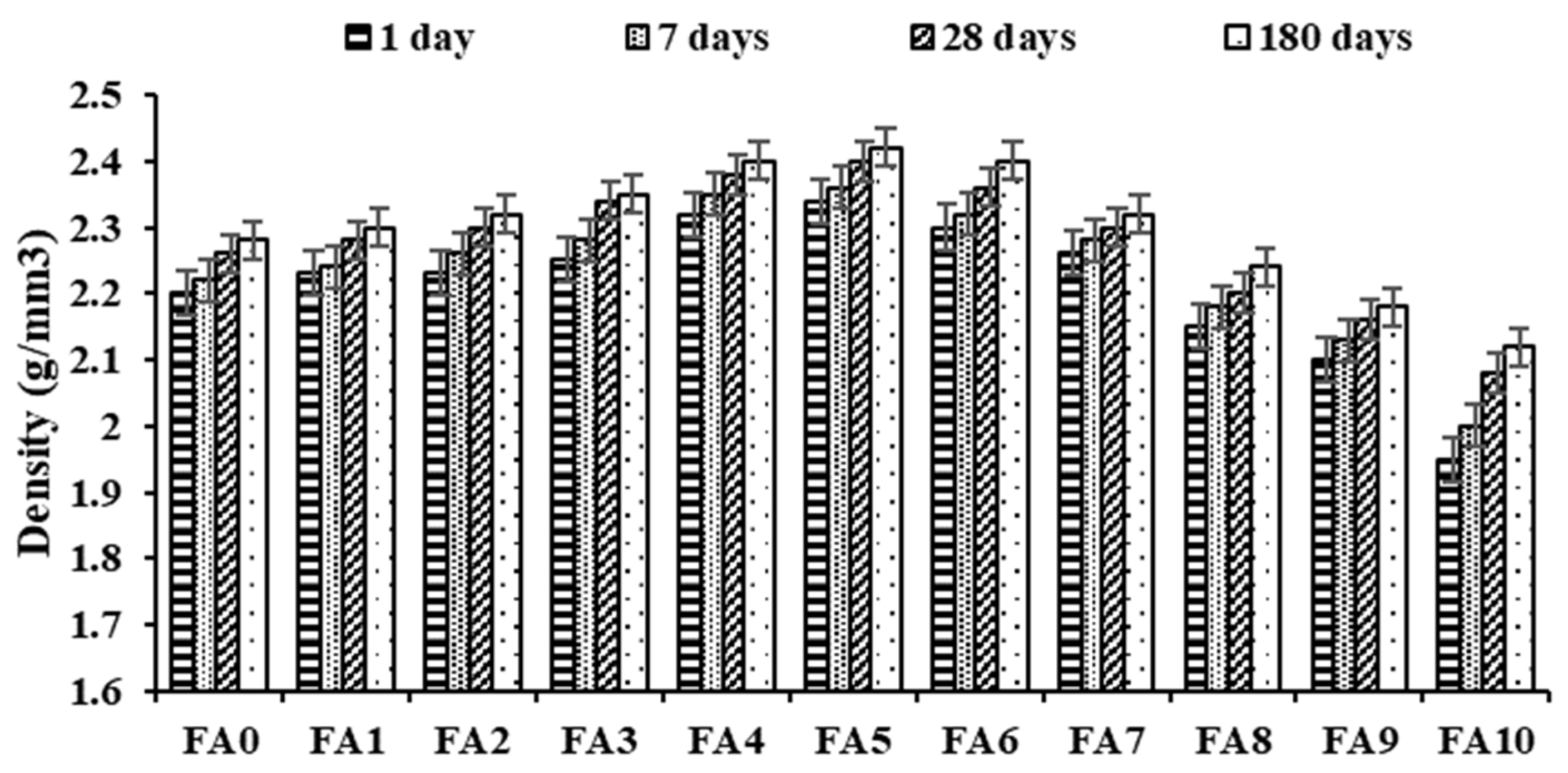

3.2. Density of Alum Sludge-Fly Ash Geopolymer Materials

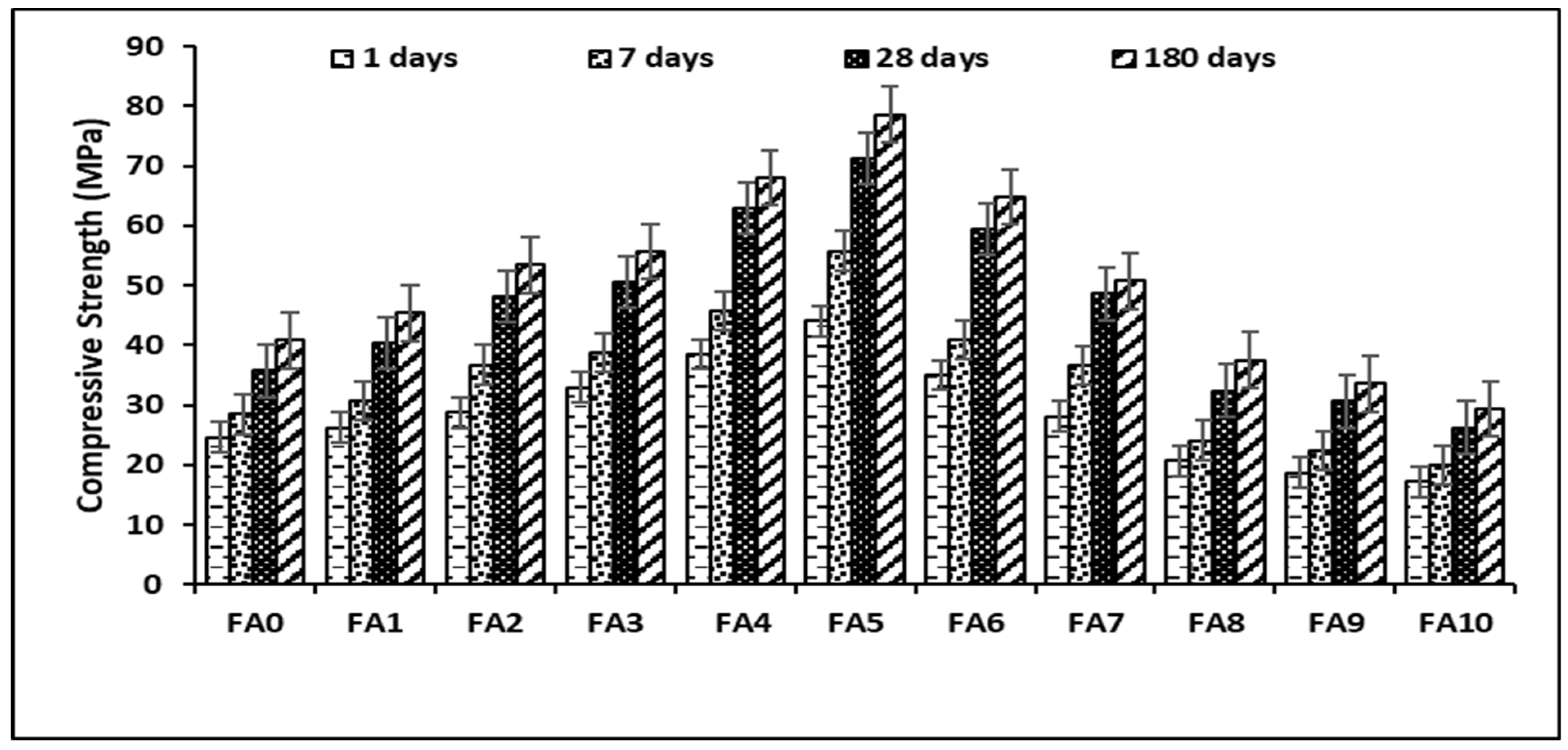

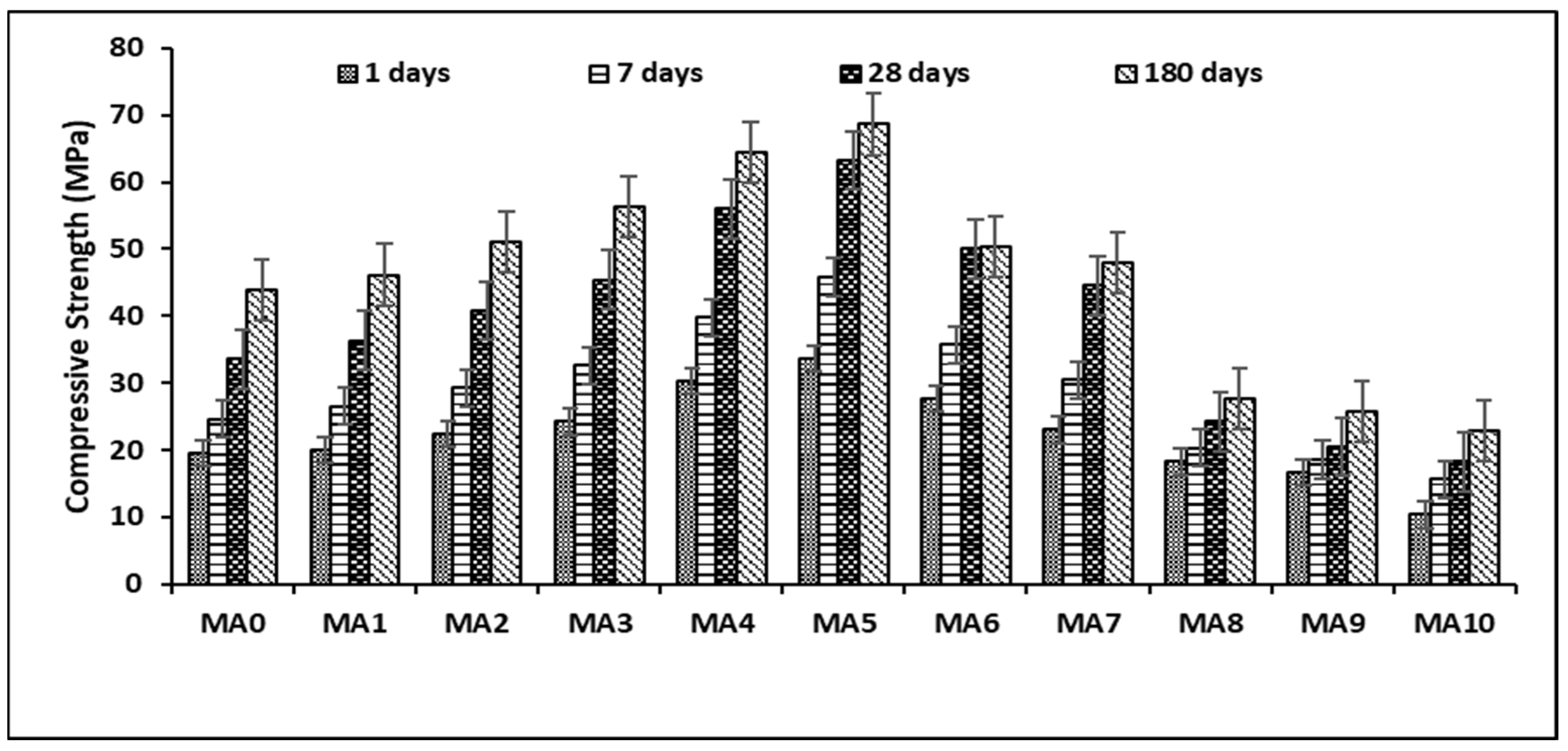

3.3. Behavior of Alum Sludge-Fly Ash Geopolymer Paste and Mortar on Compressive Strength

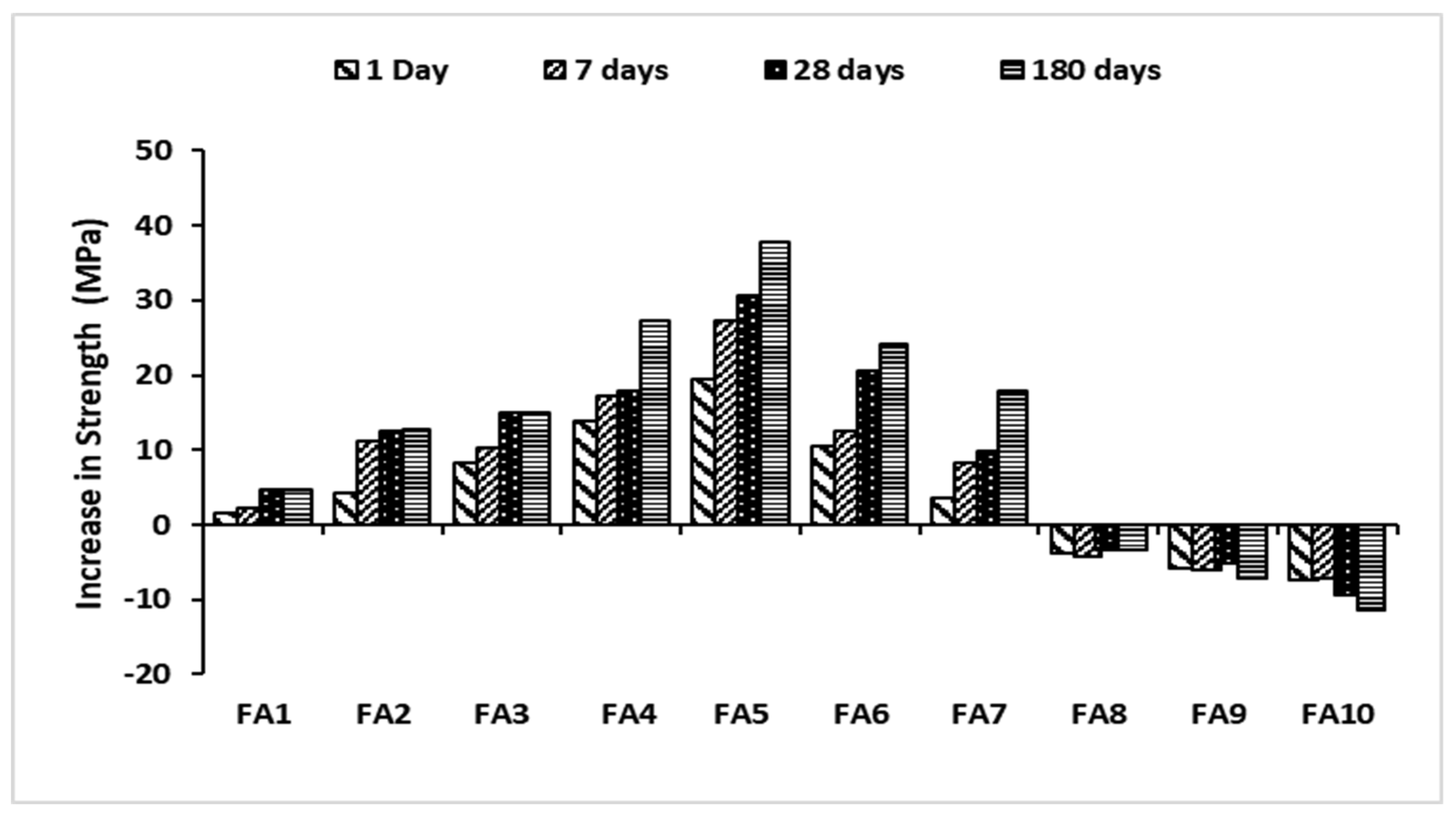

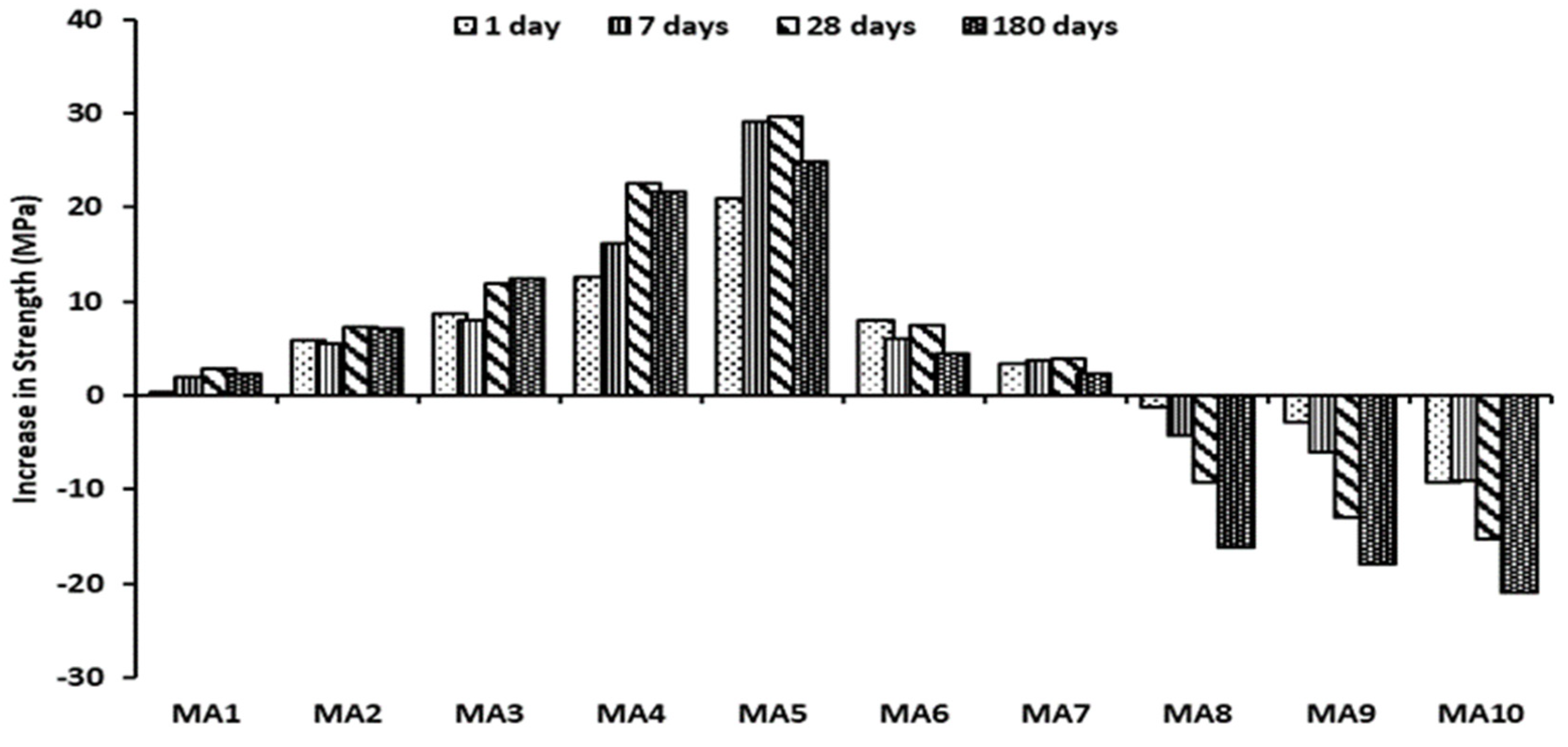

3.3.1. Increase in Compressive Strength due to Alum Sludge Content

3.3.2. Percentage Increase in Compressive Strength due to Alum Sludge Content

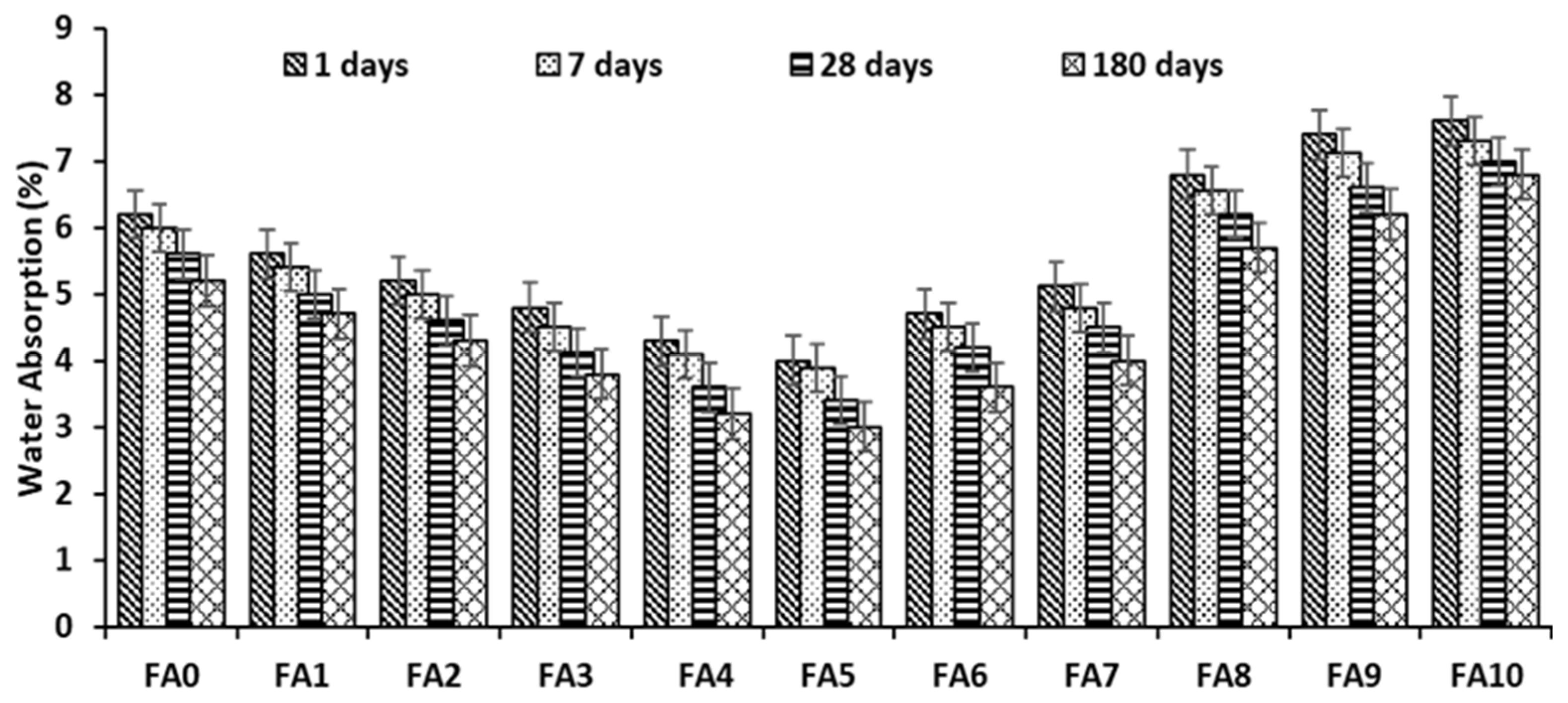

3.4. Water Absorption of Alum Sludge-Fly Ash Geopolymer Paste and Mortar

3.5. Behavior of Geopolymer Paste and Mortar due to Elevated Temperature

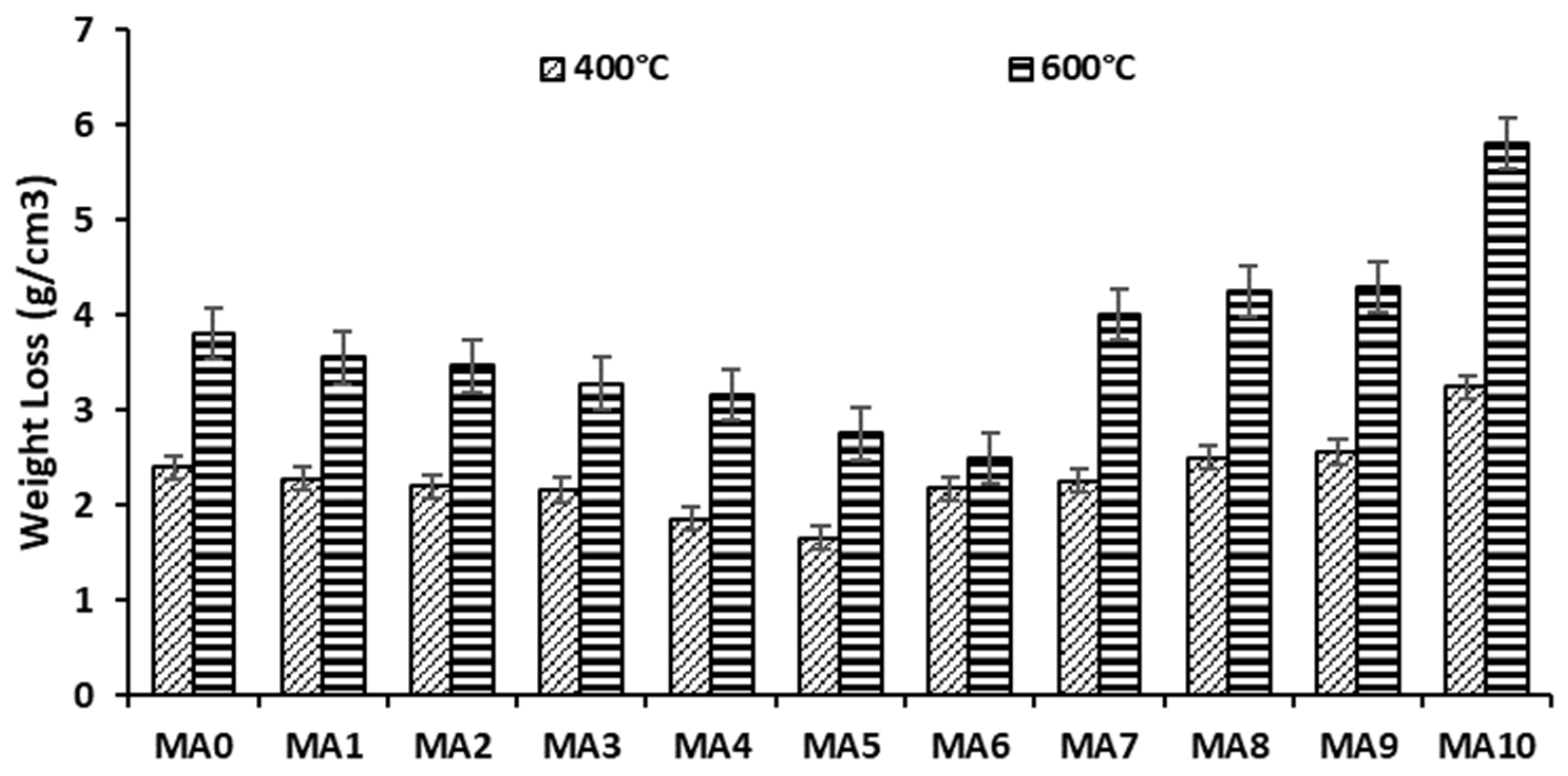

3.5.1. Weight Loss due to Elevated Temperature on Geopolymer Paste and Mortar

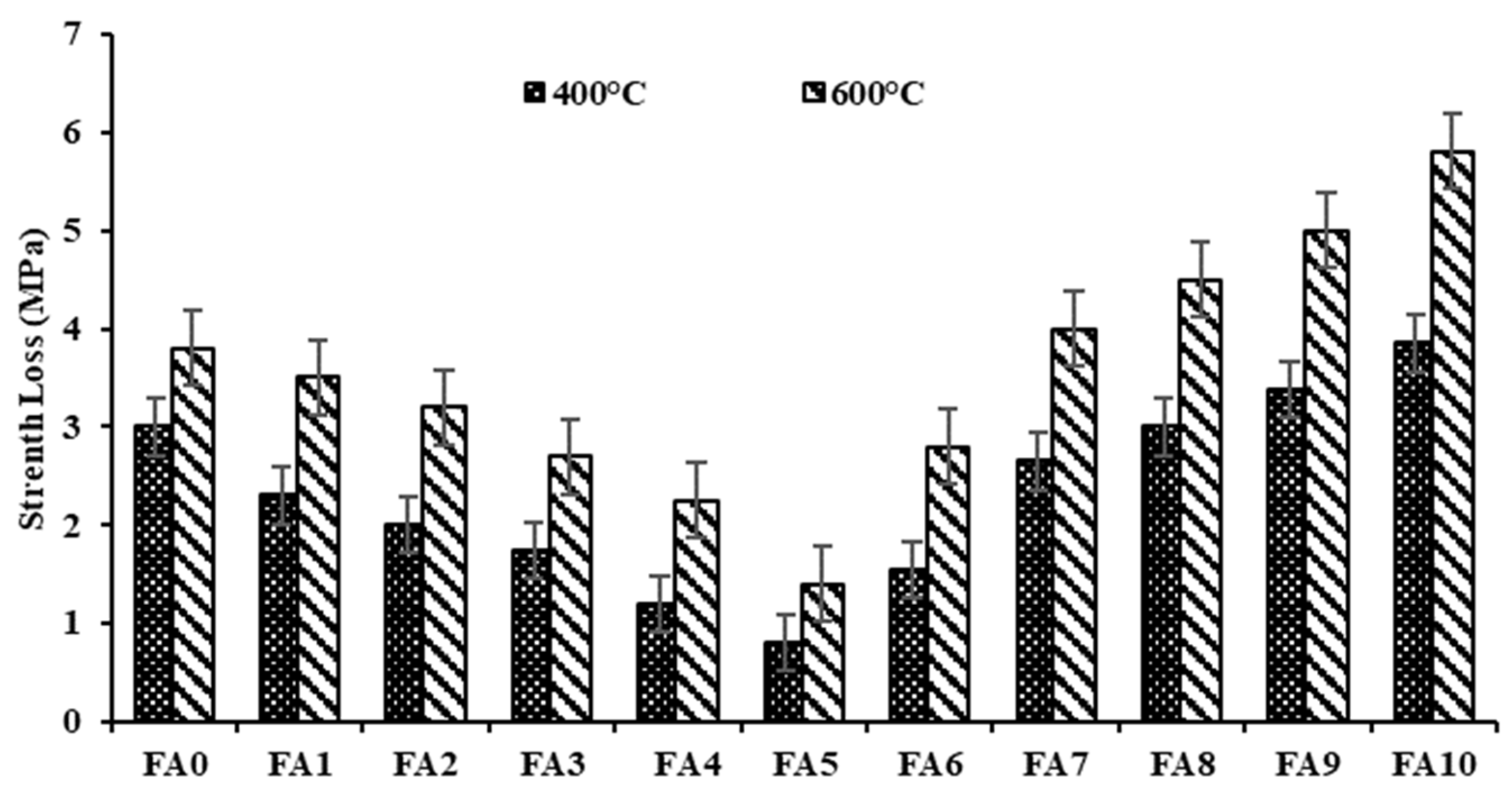

3.5.2. Strength Loss due to Elevated Temperature for Geopolymer Paste and Mortar

4. Conclusions

- Replacement of fly ash with alum sludge has proven to yield a flowable mix that can be used where flowability is needed, although the mix with only fly ash had the highest value of slump flow.

- From the performance of geopolymer paste and mortar based on density and strength properties, it was seen that the normal curing process adopted in this study did not affect the geopolymer samples negatively. The density of geopolymer paste and mortar increased with an increase in alum sludge as a substitute to fly ash. Alum sludge within optimum replacement content showed higher density compared to other samples in the study by forming a stronger and denser geopolymer structure.

- The compressive strength of geopolymer paste and mortar increased with an increase in alum sludge up to 50% and decreased with an increase in alum sludge above 50%. The optimum replacement content of fly ash with alum sludge was 50%, which gave the highest strength compared to other geopolymer mixes in this study.

- Both alum sludge and fly ash contributed immensely to improving the strength development of both geopolymer paste and mortar. This was due to the availability of SiO2 and Al2O3 from both alum sludge and fly ash that reacted with the alkalis to produce a stronger bond between the raw materials.

- The replacement of fly ash with alum sludge yielded a decrease in water absorption. Thus, the water absorption decreased with an increase in alum sludge content up to 50%, while the increase in alum sludge above 50% increased the rate of water absorption.

- The weight loss and strength loss due to elevated temperature decreased as alum sludge partially replaced fly ash up to 50% in both geopolymer paste and mortar. Meanwhile, alum sludge content above 50% yielded an increased weight loss and strength loss of geopolymer paste and mortar.

- The optimum replacement content of fly ash using alum sludge was shown to be 50% which gave the best improvement results for density, compressive strength, water absorption, and elevated temperature.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, Z.; Bouaissi, A.; Wang, X.; Huang, Y.; Li, L.-Y.; Abdullah, M.M.A.B.; Ramasamy, S. Dynamic Behaviors of Fly Ash–Ground-Granulated Blast-Furnace Slag–High-Magnesium Nickel Slag-Based Geopolymer Paste When Subjected to Impact Compressive Loadings. Adv. Eng. Mater. 2019, 21, 1900621. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F.; Sobrados, I.; Sanz, J. Structure of calcium silicate hydrates formed in alkaline-activated slag: Influence of the type of alkaline activator. J. Am. Ceram. Soc. 2003, 86, 1389–1394. [Google Scholar] [CrossRef]

- Xu, H.; Deventer, J.V. The Geopolymerisation of Alumino–Silicate Minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Odimegwu, T.C.; Zakaria, I.; Abood, M.M.; Nketsiah, C.K.; Ahmad, M. Review on Different Beneficial Ways of Applying Alum Sludge in a Sustainable Disposal Manner. Civ. Eng. J. 2018, 4, 2230. [Google Scholar] [CrossRef]

- Kaish, A.; Temple, C.O.; Ideris, Z.; Manal, M.A. Effects of different industrial waste materials as partial replacement of fine aggregate on strength and microstructure properties of concrete. J. Build. Eng. 2020, 35, 102092. [Google Scholar] [CrossRef]

- Kaish, A.M.; Temple, C.O.; Ideris, Z.; Manal, M.A.; Lutfun, N. Properties of concrete incorporating alum sludge in different conditions as partial replacement of fine aggregate. Constr. Build. Mater. 2021, 284, 122669. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H. Use of Heat-Treated Water Treatment Residuals in Fly Ash-Based Geopolymers. J. Am. Ceram. Soc. 2010, 93, 272–278. [Google Scholar] [CrossRef]

- Lee, W.-H.; Wang, J.-H.; Ding, Y.-C.; Cheng, T.-W. A study on the characteristics and microstructures of GGBS/FA based geopolymer paste and concrete. Constr. Build. Mater. 2019, 211, 807–813. [Google Scholar] [CrossRef]

- Aleem, A.M.; Arumairaj, P.D. Geopolymer Concrete—A Review. Int. J. Eng. Sci. Emerg. Technol. 2012, 1, 118–122. [Google Scholar] [CrossRef]

- Rickard, W.D.; Kealley, S.C.; Riessen, A. Thermally Induced Microstructural Changes in Fly Ash Geopolymers: Experimental Results and Proposed Model. J. Am. Ceram. Soc. 2014, 98, 929–939. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Influence of preheating of fly ash precursors to produce geopolymers. J. Am. Ceram. Soc. 2017, 100, 3165–3174. [Google Scholar] [CrossRef]

- Saludung, A.; Ogawa, Y.; Kawai1, K. Microstructure and mechanical properties of FA/GGBS-based geopolymer. In Proceedings of the MATEC Web of Conferences (ICRMCE 2018), Solo, Indonesia, 11–12 July 2018; EDP Sciences: Les Ulis, France, 2018; Volume 195, p. 01013. [Google Scholar] [CrossRef]

- Samantasinghar, S.; Suresh, P.S. Fresh and Hardened Properties of Fly Ash–Slag Blended Geopolymer Paste and Mortar. Int. J. Concr. Struct. Mater. 2019, 13, 47. [Google Scholar] [CrossRef]

- Srinivasan, K.; Sivakumar, A. Geopolymer Binders: A Need for Future Concrete Construction. ISRN Polym. Sci. 2013, 2013, 509185. [Google Scholar] [CrossRef]

- Saloma, A.; Hanafiah, S.; Mawar, A. Geopolymer Mortar with Fly Ash. Saloma, Anis Saggaff, Hanafiah, and Annisa Mawarni. MATEC Web Conf. 2016, 78, 01026. [Google Scholar] [CrossRef]

- Prabha, V.C.; Revathi, V. Geopolymer Mortar Incorporating Highcalcium Fly Ash And Silica Fume. Arch. Civ. Eng. 2019, 65, 3–16. [Google Scholar] [CrossRef]

- Shweta, M.; Jadhav, H.S. Investigation of Geopolymer Mortar and Concrete Under High Temperature. Int. J. Emerg. Technol. Adv. Eng. 2012, 5, 384–390. [Google Scholar]

- Hameed, A.M.; Rawdhan, R.R.; Al-Mishhadani, S.A. Effect of Various Factors on the Manufacturing of Geopolymer Mortar. Arch. Sci. 2017, 1, 111. [Google Scholar]

- Budh, C.D.; Warhade, N.R. Effect of Molarity on Compressive Strength of Geopolymer Mortar. Int. J. Civ. Eng. Res. 2014, 5, 83–86. [Google Scholar]

- Kaur, M.; Singh, J.; Kaur, M. Synthesis of Fly ash based Geopolymer Mortar considering different concentrations and combinations of Alkaline Activator Solution. Ceram. Int. 2017, 44, 1534–1537. [Google Scholar] [CrossRef]

- Chen-Tanw, N.; Riessen, A.; Chi, V.L.; Southam, D.C. Determining the Reactivity of a Fly Ash for Production of Geopolymer. J. Am. Ceram. Soc. 2009, 92, 881–887. [Google Scholar] [CrossRef]

- Rao, M.G.; Rao, G.T. Final Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and Mortar. Arab. J. Sci. Eng. 2015, 40, 3067–3074. [Google Scholar] [CrossRef]

- Sasui, S.; Kim, G.; Nam, J.; Koyama, T.; Chansomsak, S. Strength and Microstructure of Class-C Fly Ash and GGBS Blend Geopolymer Activated in NaOH & NaOH + Na2SiO3. Materials 2020, 13, 59. [Google Scholar] [CrossRef]

- Yahaya, M.A.; Odimegwu, T.C.; Kaish, A.M.; Breesem, K.M.; Zakaria, I.; Abood, M.M. Development of geopolymer mortar utilizing locally produced fly ash in Malaysia. In Proceedings of the 2nd International Conference on Materials Engineering & Science (IConMEAS 2019), Baghdad, Iraq, 25–9 September 2019; Volume 2213, p. 020248. [Google Scholar] [CrossRef]

- Hardjito, D. Studies of Fly Ash-Based Geopolymer Concrete. Ph.D. Thesis, Curtin University, Perth, Australia, 2005. [Google Scholar]

- Santosa, G.Z.; Filhoa, J.M.; Pinheirob, M.; Manzatoa, L. Synthesis of water treatment sludge ash-based geopolymers in an Amazonian context. J. Environ. Manag. 2019, 249, 109328. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.-L.; Lo, K.-W.; Cheng, T.-W.; Lin, W.-T.; Lin, Y.-W. Utilization of Silicon Carbide Sludge as Metakaolin-Based Geopolymer Materials. Sustainability 2020, 12, 7333. [Google Scholar] [CrossRef]

- Goncalves, A.; Esteves, A.M.; Carvalho, M. Incorporation of sludges from a water treatment plant in cement mortars. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8–11 November 2004. [Google Scholar]

- Owaid, H.M.; Roszilah, H.; Taha, M.R. Influence of Thermally Activated Alum Sludge Ash on the Near Surface Characteristics of Multiple-blended Binders Concretes. Appl. Mech. Mater. 2015, 754–755, 421–426. [Google Scholar] [CrossRef]

- Vaishali, S.; Niragi, D. Sustainable Use of Water Treatment Plant Sludge and Fly Ash in Civil Engineering Application. Int. J. Civ. Eng. Build. Mater. 2013, 3, 115–123. [Google Scholar]

- Njimou, J.R.; Pengou, M.; Tchakoute, H.K.; Tamwa, M.S.; Tizaoui, C.; Fannang, U.; Lemougna, P.N.; Njiki, C.P.N.; Ngameni, E. Removal of lead ions from aqueous solution using phosphate-based geopolymer cement composite. J. Chem. Technol. Biotechnol. 2021, 96, 1358–1369. [Google Scholar] [CrossRef]

- Quiatchon, P.R.J.; Dollente, I.J.R.; Abulencia, A.B.; Libre, R.G.D.G.; Villoria, M.B.D., Jr.; Guades, E.J.; Promentilla, M.A.B.; Ongpeng, J.M.C. Investigation on the Compressive Strength and Time of Setting of Low-Calcium Fly Ash Geopolymer Paste Using Response Surface Methodology. Polym. Polym. 2021, 13, 3461. [Google Scholar] [CrossRef]

- Acar, M.C.; Celik, A.I.; Kayabası, R.; Sener, A.; Ozdoner, N.; Ozkılıc, Y.O. Production of perlite-based-aerated geopolymer using hydrogen peroxide as eco-friendly material for energy-efficient buildings. J. Mater. Res. Technol. 2023, 24, 81–99. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O. Geopolymer concrete with high strength, workability and setting time using recycled steel wires and basalt powder. Steel Compos. Struct. 2023, 46, 689. [Google Scholar] [CrossRef]

- Kuri, J.C.; Hosan, A.; Shaikh, F.U.; Biswas, W.K. The Effect of RecycledWaste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. [Google Scholar] [CrossRef]

- Kuri, C.J.; Khan, N.M.; Sarker, K.P. Workability, strength and microstructural properties of ground ferronickel slag blended fly ash geopolymer mortar. J. Sustain. Cem. -Based Mater. 2020, 11, 75–87. [Google Scholar] [CrossRef]

- Breesem, K.M.; Abood, M.M.; Rahman, N.A. Influence of Magnesium Sulfate on Self-Compacting Alum Sludge Concrete Incorporating with Pozzolanic Materials. Mod. Appl. Sci. 2016, 10, 187–197. [Google Scholar] [CrossRef]

- Soleha, M.Y.; Ong, K.K.; Zin, W.Y. Characterization of raw and thermally treated alum sludge. Key Eng. Mater. 2016, 701, 138–142. [Google Scholar] [CrossRef]

- Coutand, M.; Cyr, M.; Clastres, P. Use of sewage sludge ash as mineral admixture in mortar. Proc. Inst. Civil Eng. Constr. Mater. 2006, 159, 153–163. [Google Scholar] [CrossRef]

| Sample No. | Molarity | Sand (gm) | Fly Ash (%) | Alum Sludge (%) | NaOH Solution (gm) | SiO₂/Na₂O (gm) |

|---|---|---|---|---|---|---|

| Geopolymer paste | ||||||

| FA0 | 14 | 0 | 100 | 0 | 71.5 | 178.5 |

| FA1 | 14 | 0 | 90 | 10 | 71.5 | 178.5 |

| FA2 | 14 | 0 | 80 | 20 | 71.5 | 178.5 |

| FA3 | 14 | 0 | 70 | 30 | 71.5 | 178.5 |

| FA4 | 14 | 0 | 60 | 40 | 71.5 | 178.5 |

| FA5 | 14 | 0 | 50 | 50 | 71.5 | 178.5 |

| FA6 | 14 | 0 | 40 | 60 | 71.5 | 178.5 |

| FA7 | 14 | 0 | 30 | 70 | 71.5 | 178.5 |

| FA8 | 14 | 0 | 20 | 80 | 71.5 | 178.5 |

| FA9 | 14 | 0 | 10 | 90 | 71.5 | 178.5 |

| FA10 | 14 | 0 | 0 | 100 | 71.5 | 178.5 |

| Geopolymer mortar | ||||||

| MA0 | 14 | 250 | 100 | 0 | 71.5 | 178.5 |

| MA1 | 14 | 250 | 90 | 10 | 71.5 | 178.5 |

| MA2 | 14 | 250 | 80 | 20 | 71.5 | 178.5 |

| MA3 | 14 | 250 | 70 | 30 | 71.5 | 178.5 |

| MA4 | 14 | 250 | 60 | 40 | 71.5 | 178.5 |

| MA5 | 14 | 250 | 50 | 50 | 71.5 | 178.5 |

| MA6 | 14 | 250 | 40 | 60 | 71.5 | 178.5 |

| MA7 | 14 | 250 | 30 | 70 | 71.5 | 178.5 |

| MA8 | 14 | 250 | 20 | 80 | 71.5 | 178.5 |

| MA9 | 14 | 250 | 10 | 90 | 71.5 | 178.5 |

| MA10 | 12.5 | 250 | 0 | 100 | 71.5 | 178.5 |

| Test | FAG | ALS | FLD |

|---|---|---|---|

| Specific gravity | 2.63 | 2.37 | 2.54 |

| Blain’s fineness (cm2/g) | 5369 | 5283 | |

| Passing 45 µ sieve (%) | 68 | 100 | 98 |

| Color | Off-white | Light brown | Grayish |

| Samples | SiO2 % | Al2O3 % | CaO % | Fe2O3 % | Na2O % | K2O % | MgO % | MnO % | TiO2 % |

|---|---|---|---|---|---|---|---|---|---|

| FAG | 86.76 | 11.64 | 3.58 | 1.78 | 1.43 | 1.21 | 0.77 | 0.05 | - |

| ALS | 46.54 | 38.75 | 0.43 | 4.91 | - | 1.88 | 0.32 | 0.02 | 0.6 |

| FLD | 59.18 | 22.82 | 10.54 | 14.13 | 1.09 | 1.77 | 3.2 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Odimegwu, T.C.; Kaish, A.B.M.A.; Jamil, M.; Zain, M.F.M.; Turlanbekov, A.; Al Zand, A.W. Mechanical Characterization of Geopolymer Paste and Mortar Fabricated from Alum Sludge and Fly Ash. Buildings 2023, 13, 2118. https://doi.org/10.3390/buildings13082118

Odimegwu TC, Kaish ABMA, Jamil M, Zain MFM, Turlanbekov A, Al Zand AW. Mechanical Characterization of Geopolymer Paste and Mortar Fabricated from Alum Sludge and Fly Ash. Buildings. 2023; 13(8):2118. https://doi.org/10.3390/buildings13082118

Chicago/Turabian StyleOdimegwu, Temple Chimuanya, A. B. M. A. Kaish, Maslina Jamil, M. F. M. Zain, Asset Turlanbekov, and Ahmed W. Al Zand. 2023. "Mechanical Characterization of Geopolymer Paste and Mortar Fabricated from Alum Sludge and Fly Ash" Buildings 13, no. 8: 2118. https://doi.org/10.3390/buildings13082118