Summer Thermal Challenges in Emergency Tents: Insights into Thermal Characteristics of Tents with Air Conditioning

Abstract

:1. Introduction

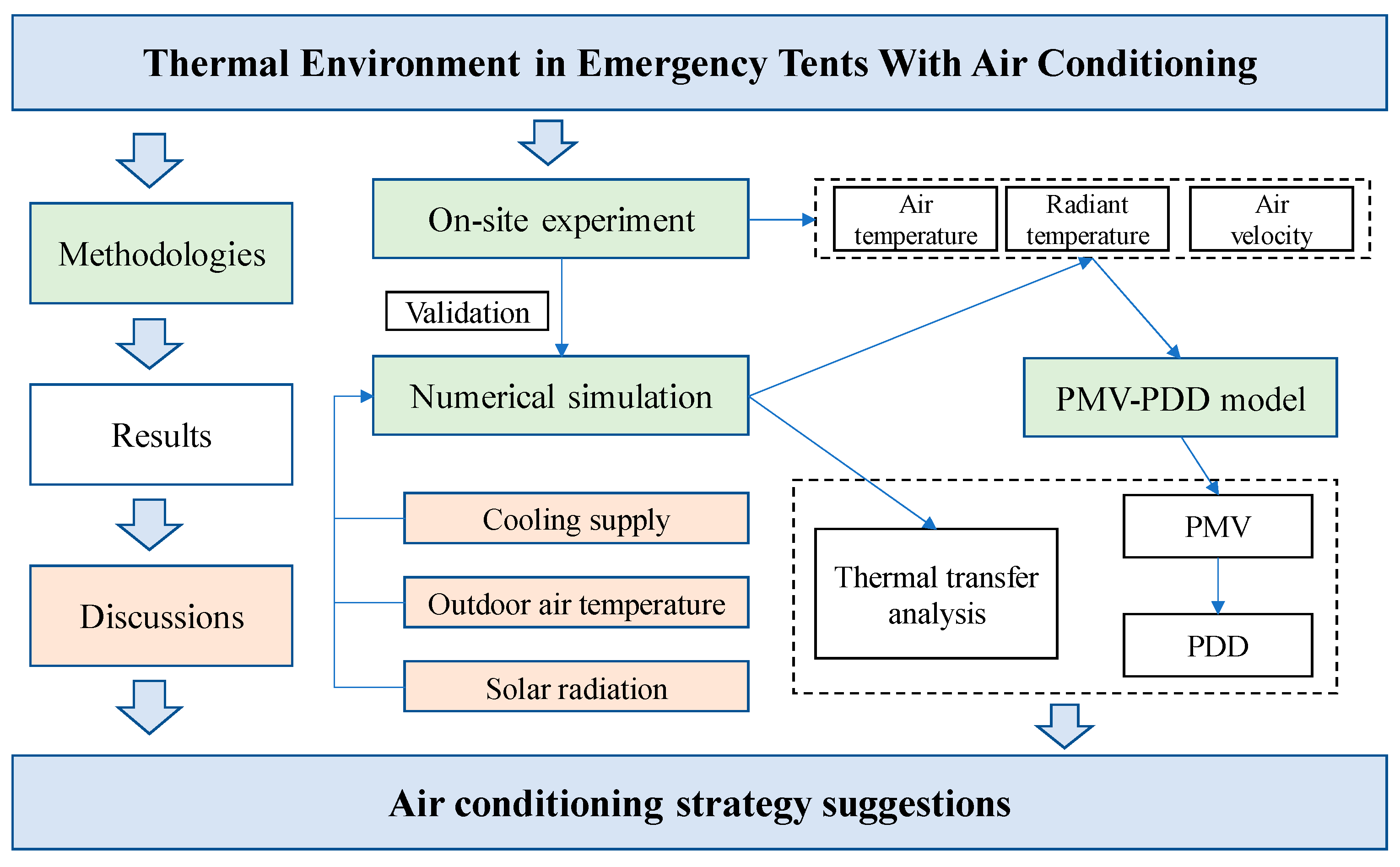

2. Materials and Methods

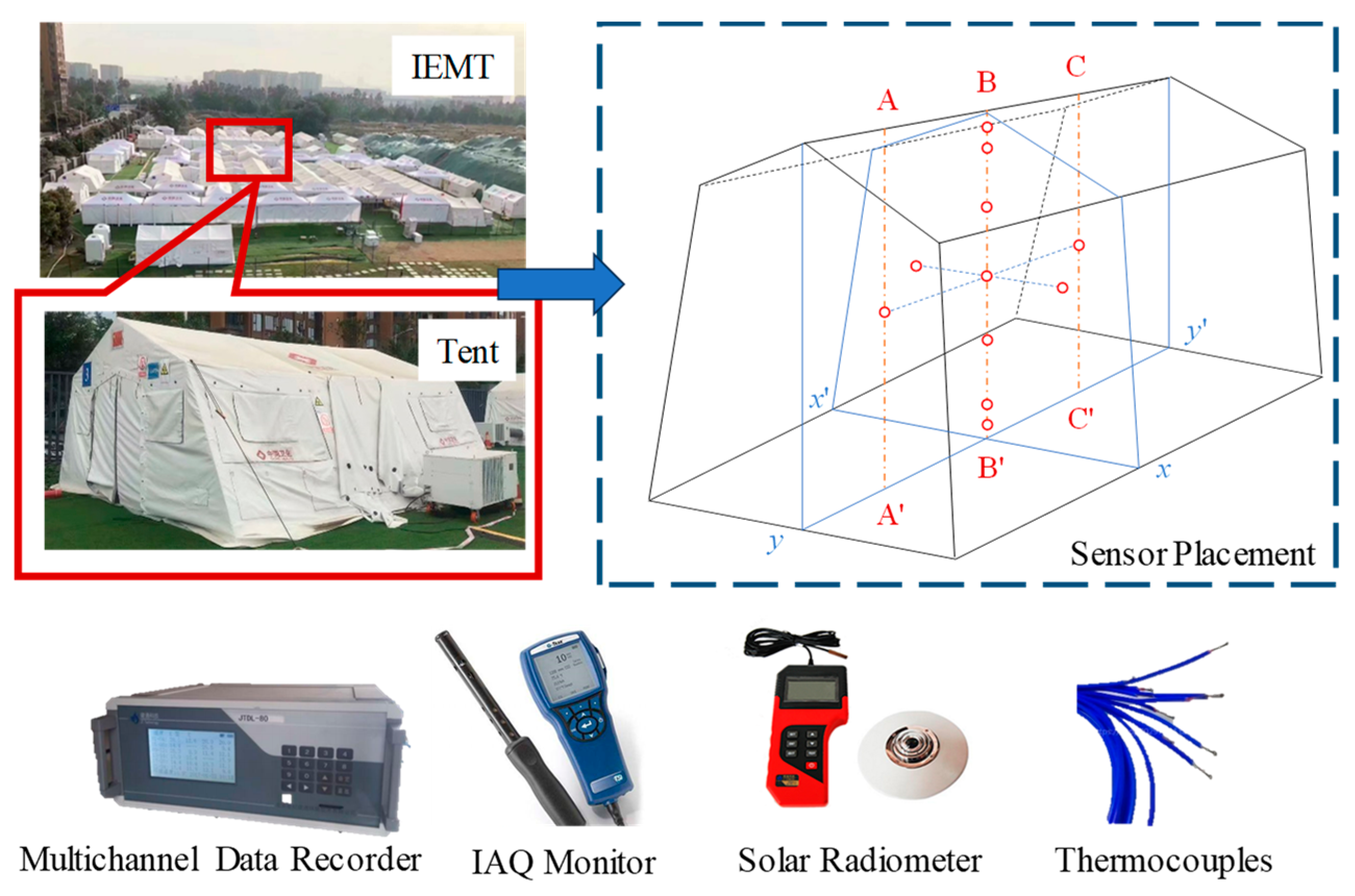

2.1. Experimental Setup

2.2. Numerical Simulation Model

2.3. PMV-PPD Model

3. Results

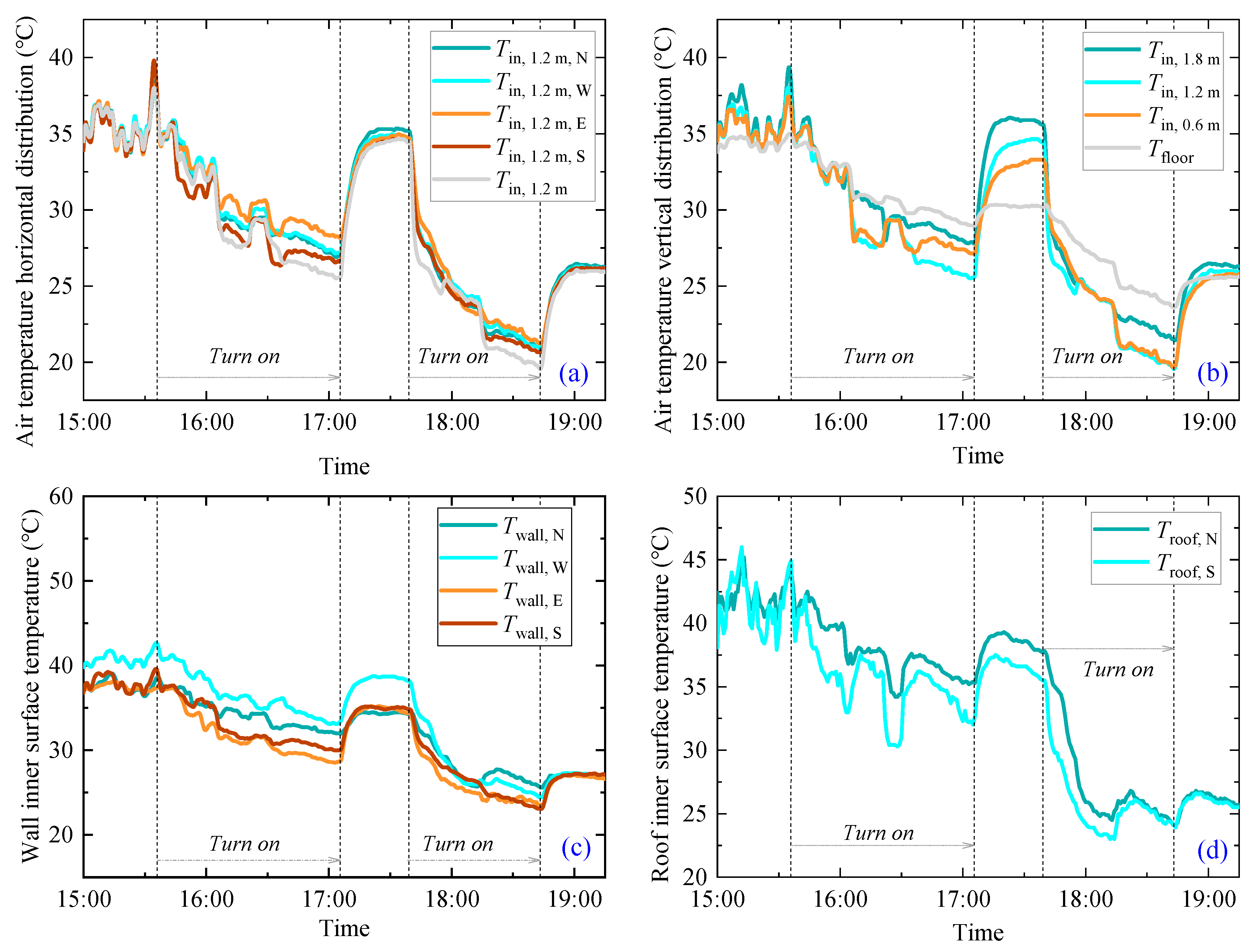

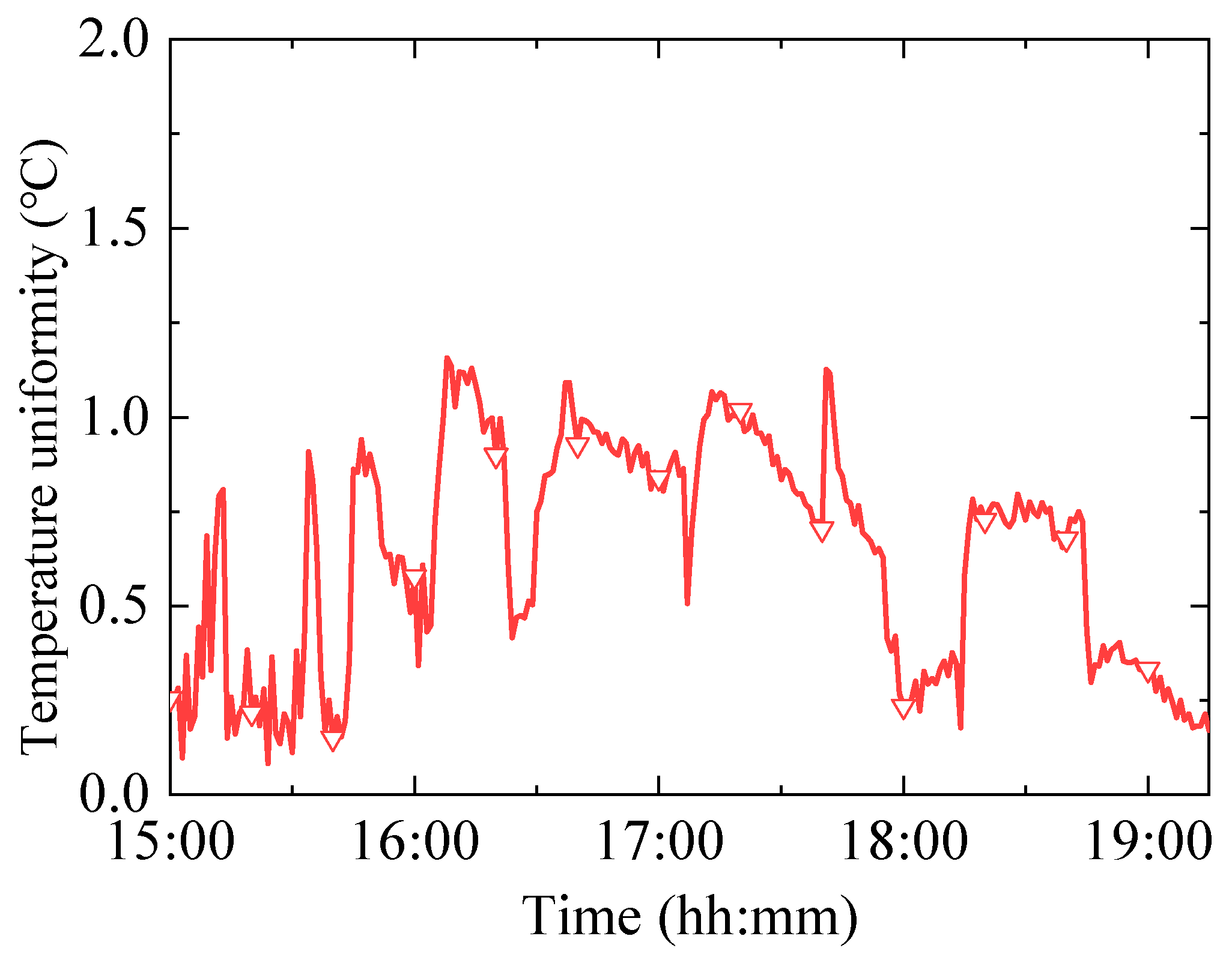

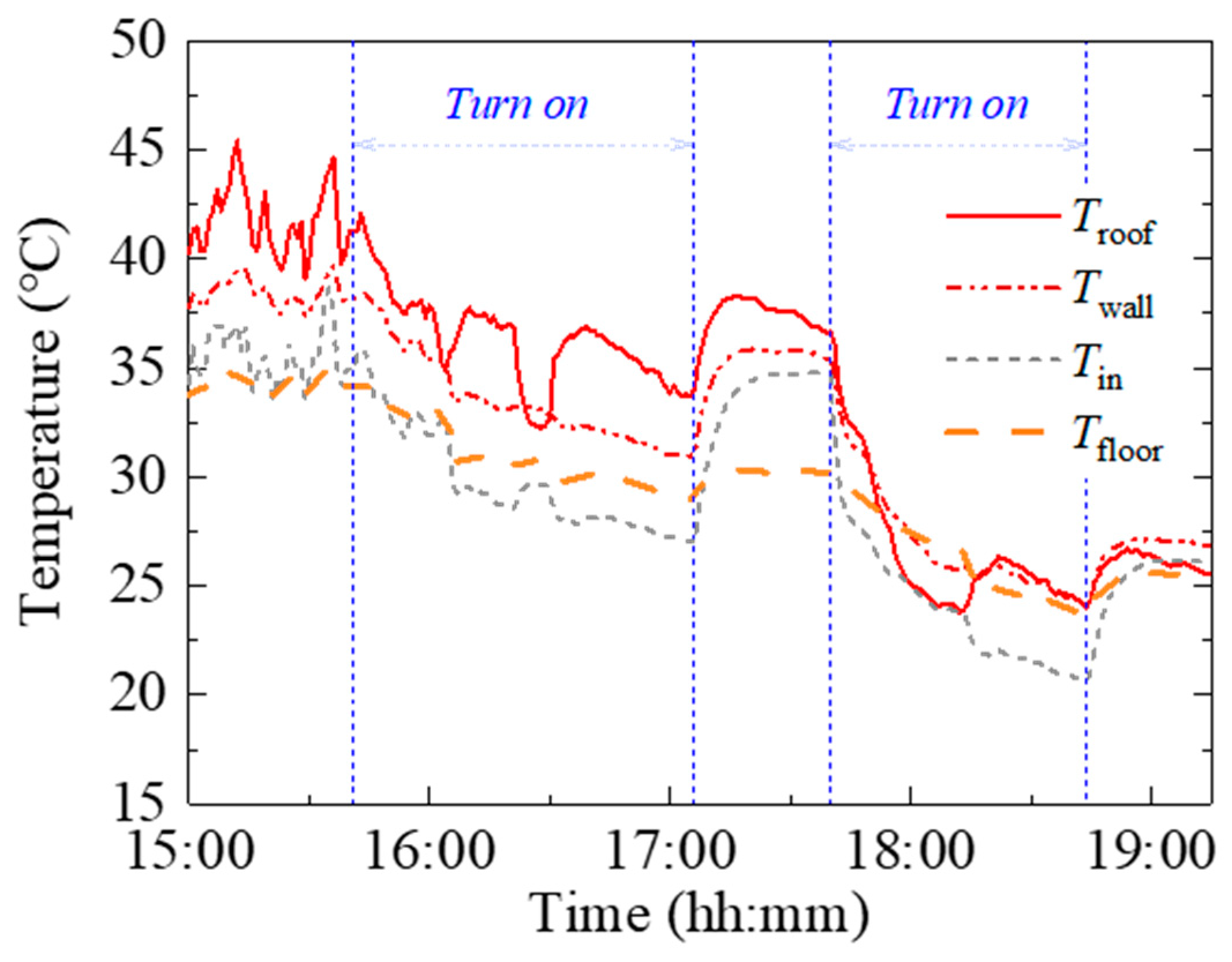

3.1. Experimental Results

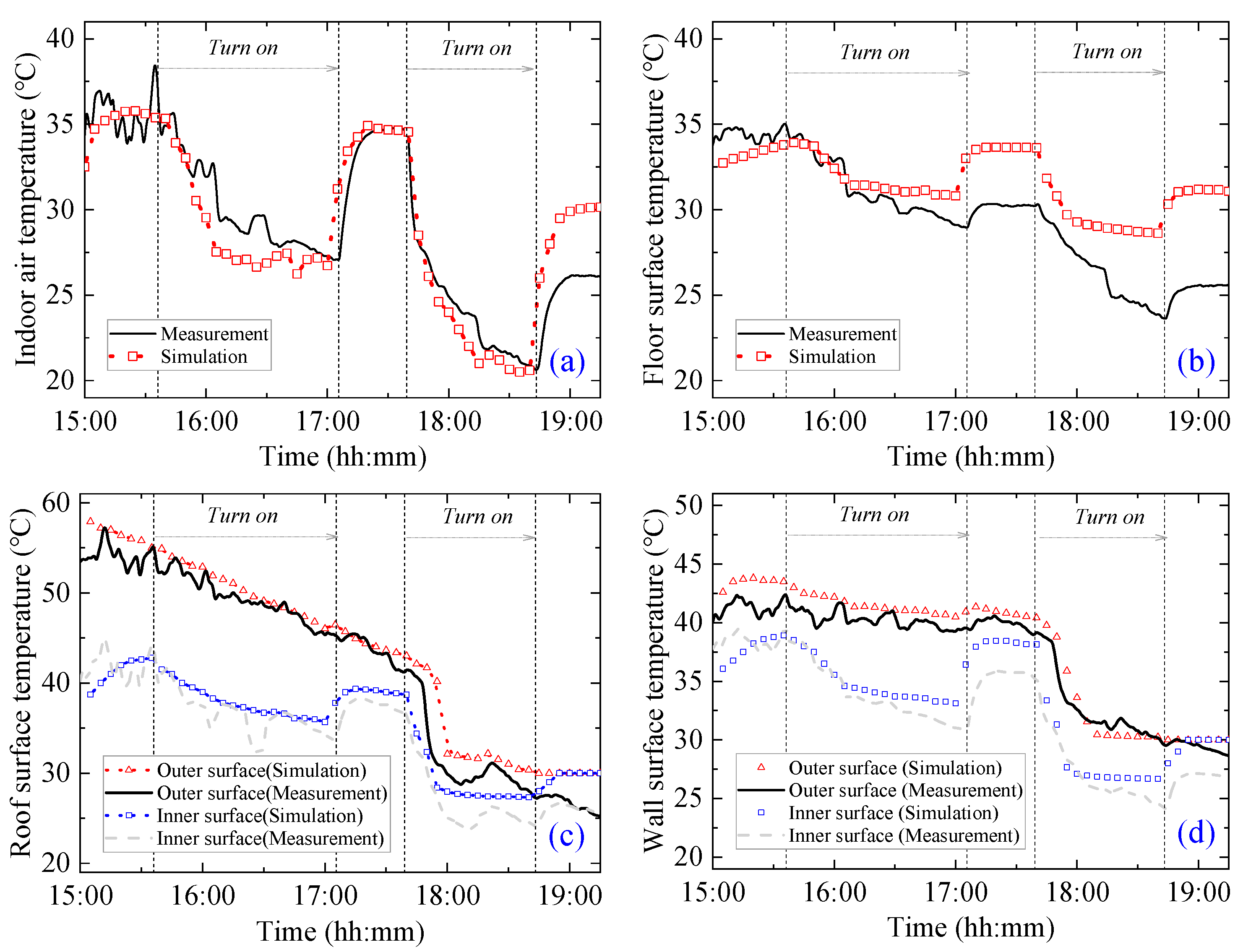

3.2. Validation

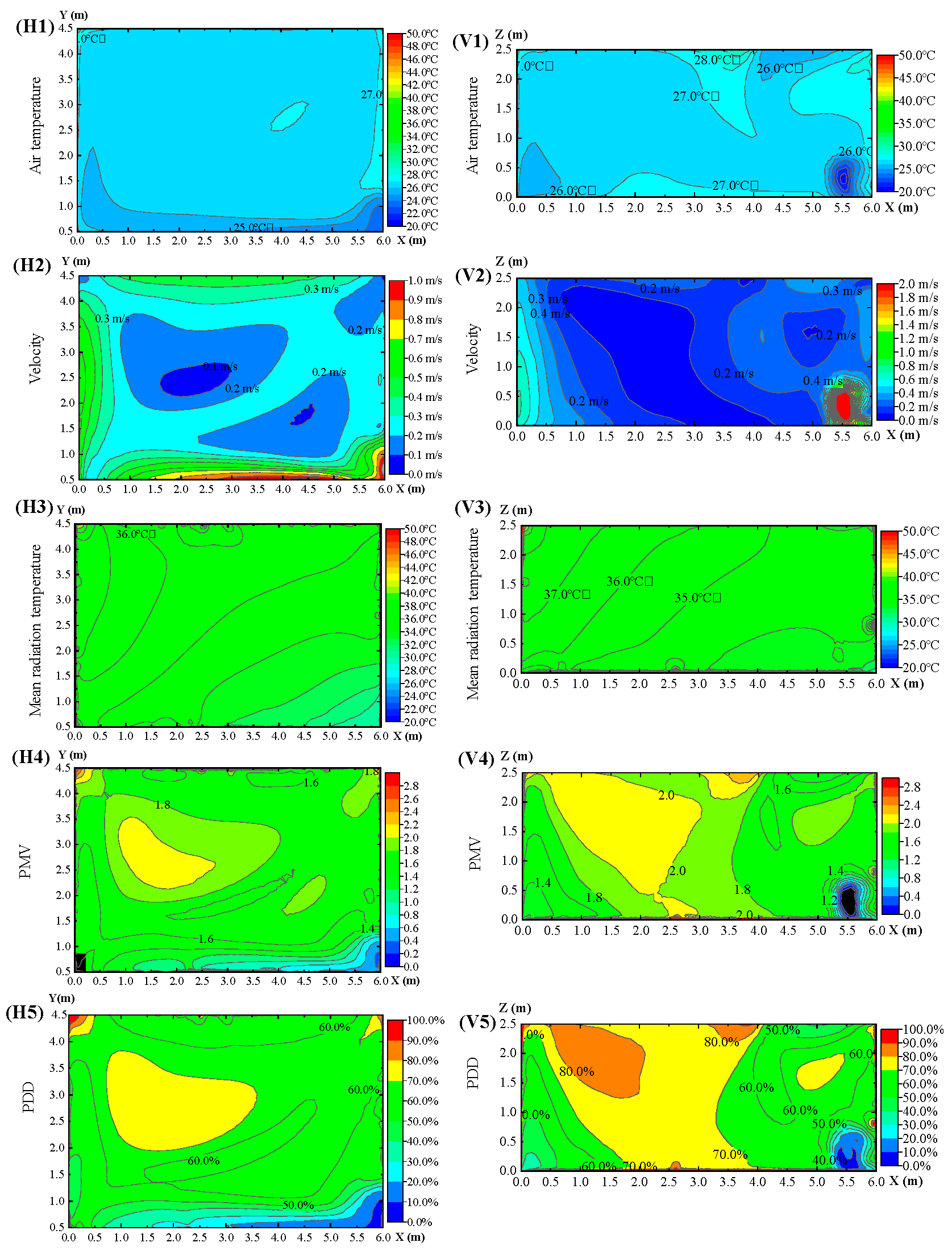

3.3. PMV-PPD Analysis

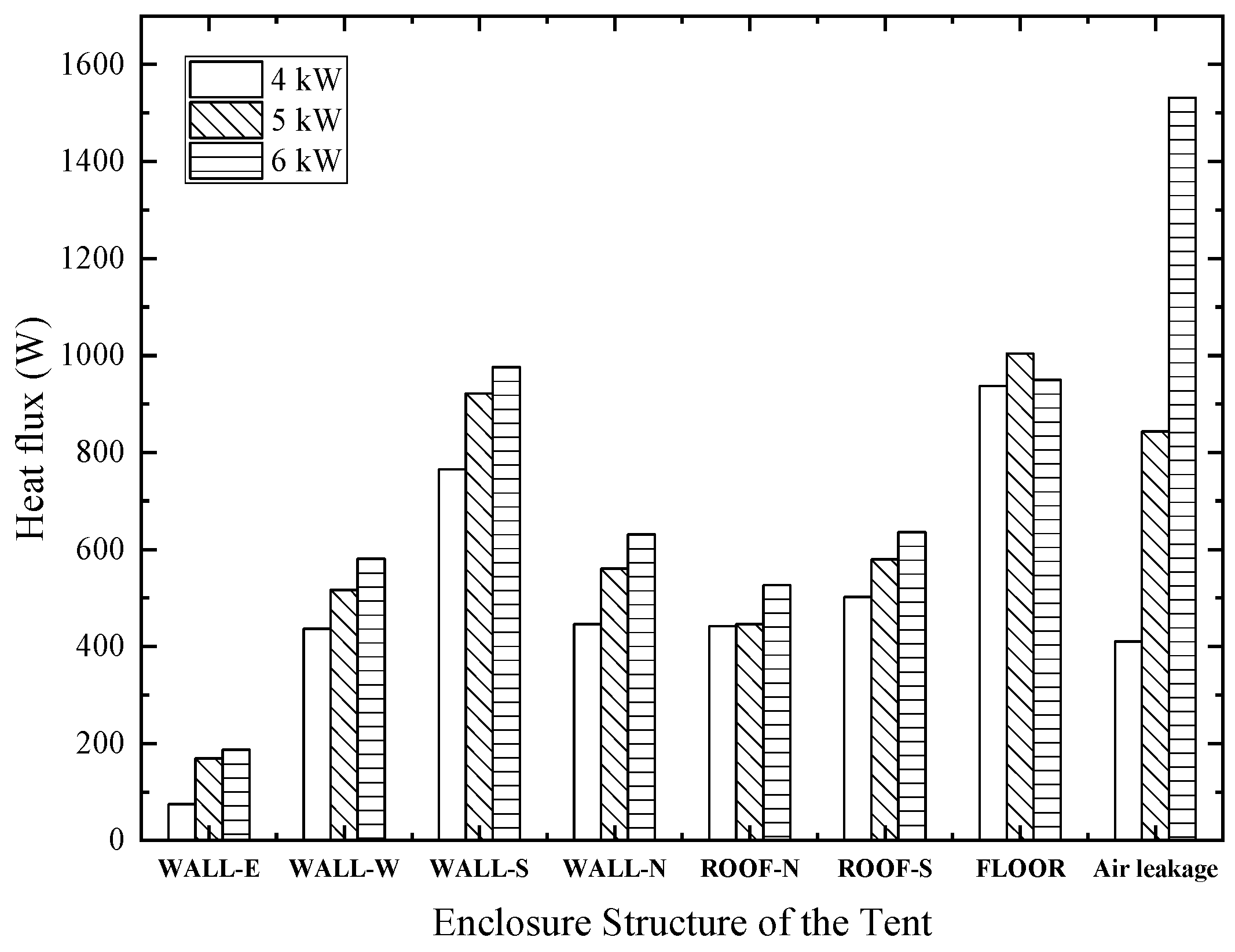

3.4. Heat Transfer Analysis

4. Discussions

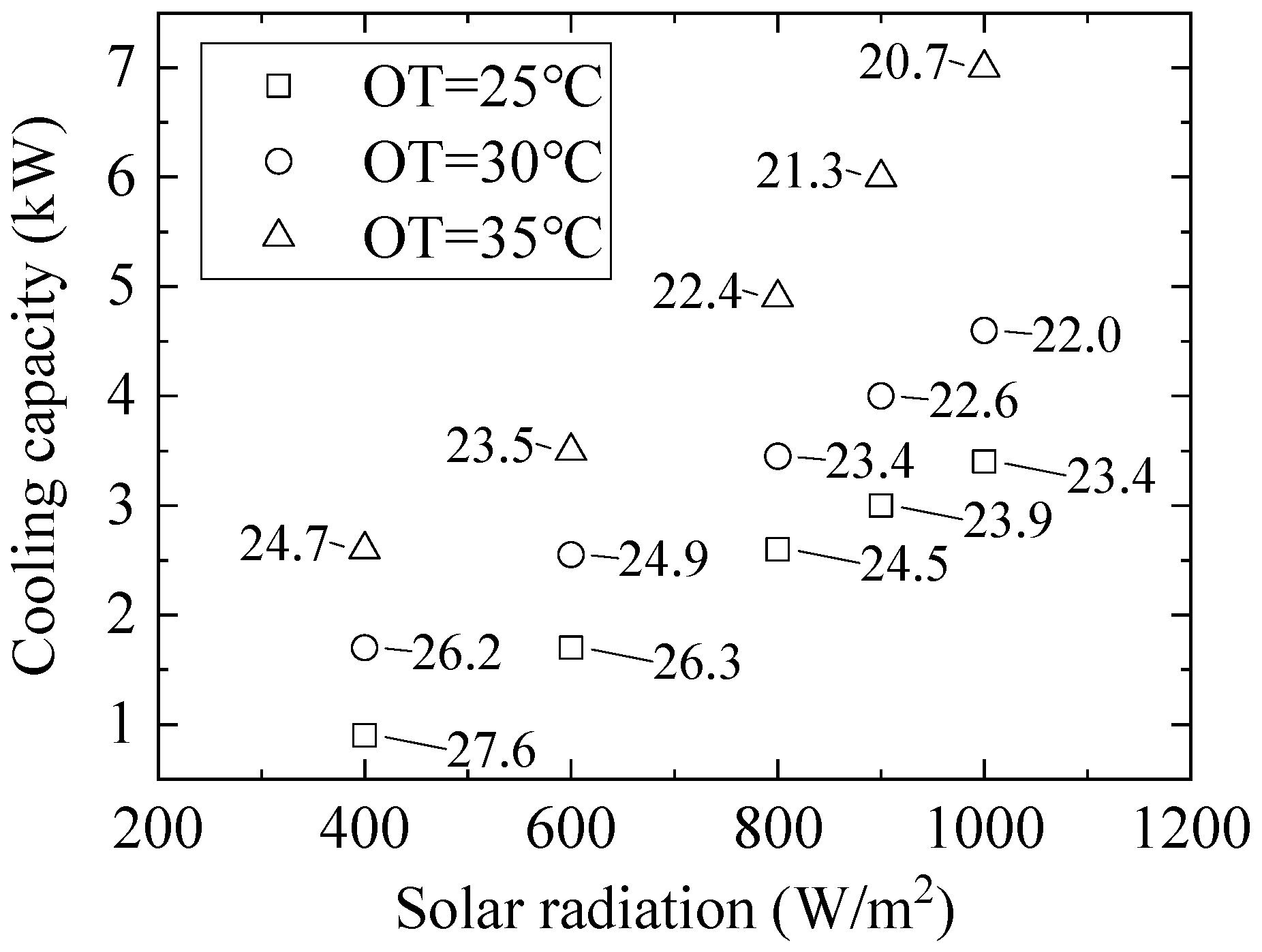

4.1. Thermal Comfort Analysis under Different Cooling Supply Conditions

4.2. Heat Transfer Analysis under Different Cooling Supply Conditions

4.3. Air-Conditioning Strategies for Emergency Tents

4.4. Limitation and Future Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Ruan, X.; Shi, P. Selection of emergency shelter sites for seismic disasters in mountainous regions: Lessons from the 2008 Wenchuan Ms 8.0 Earthquake, China. J. Asian Earth Sci. 2011, 40, 926–934. [Google Scholar] [CrossRef]

- Nappi, M.M.L.; Souza, J.C. Disaster management: Hierarchical structuring criteria for selection and location of temporary shelters. Nat. Hazards 2015, 75, 2421–2436. [Google Scholar] [CrossRef]

- Manoochehry, S.; Hoseinzadeh, E.; Taha, P.; Rasouli, H.R.; Hoseinzadeh, S.J.T.M. Field Hospital in Disasters: A Systematic Review. Trauma Mon. 2018, 24, e65126. [Google Scholar] [CrossRef]

- Obyn, S.; van Moeseke, G.; Virgo, V. Thermal performance of shelter modelling: Improvement of temporary structures. Energy Build. 2015, 89, 170–182. [Google Scholar] [CrossRef]

- Poschl, R.A. Modelling the Thermal Comfort Performance of Tents Used in Humanitarian Relief; Loughborough University: Loughborough, UK, 2017. [Google Scholar]

- Wang, Y.; Long, E.; Deng, S. Applying passive cooling measures to a temporary disaster-relief prefabricated house to improve its indoor thermal environment in summer in the subtropics. Energy Build. 2017, 139, 456–464. [Google Scholar] [CrossRef]

- Jegodka, Y.; Lagally, L.; Mertes, H.; Deering, K.; Schoierer, J.; Buchberger, B.; Bose-O’Reilly, S. Hot days and COVID-19: Online survey of nurses and nursing assistants to assess occupational heat stress in Germany during summer 2020. J. Clim. Change Health 2021, 3, 100031. [Google Scholar] [CrossRef] [PubMed]

- Pilsworth, M.N. The Calculation of Heat Loss from Tents; Defense Technical Information Center: Fort Belvoir, VA, USA, 1978. [Google Scholar]

- Cornaro, C.; Sapori, D.; Bucci, F.; Pierro, M.; Giammanco, C. Thermal performance analysis of an emergency shelter using dynamic building simulation. Energy Build. 2015, 88, 122–134. [Google Scholar] [CrossRef]

- Salvalai, G.; Imperadori, M.; Scaccabarozzi, D.; Pusceddu, C. Thermal performance measurement and application of a multilayer insulator for emergency architecture. Appl. Therm. Eng. 2015, 82, 110–119. [Google Scholar] [CrossRef]

- Crawford, C.; Manfield, P.; McRobie, A. Assessing the thermal performance of an emergency shelter system. Energy Build. 2005, 37, 471–483. [Google Scholar] [CrossRef]

- Hu, S.; Meng, Q.; Wang, C. Experimental Research of Improvement on Thermal Environment of Tents’ by Passive Cooling. J. Logist. Eng. Univ. 2007, 23, 81–83. [Google Scholar]

- Zhang, L.; Meng, X.; Liu, F.; Xu, L.; Long, E. Effect of retro-reflective materials on temperature environment in tents. Case Stud. Therm. Eng. 2017, 9, 122–127. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, Y.; Gong, Z.; Yang, H. Experiment Research on Shading to Improve the Thermal Environment of Tents. MATEC Web Conf. 2016, 61, 01009. [Google Scholar] [CrossRef]

- Wang, J.; Long, E.; Liao, X.; Xu, L. Effectiveness of improving tent envelope thermal performance based on PCM. Huagong Xuebao/CIESC J. 2014, 65, 107–113. [Google Scholar] [CrossRef]

- Borge-Diez, D.; Colmenar-Santos, A.; Pérez-Molina, C.; Castro-Gil, M. Passive climatization using a cool roof and natural ventilation for internally displaced persons in hot climates: Case study for Haiti. Build. Environ. 2013, 59, 116–126. [Google Scholar] [CrossRef]

- Borge-Diez, D.; Colmenar-Santos, A.; Mur-Pérez, F.; Castro-Gil, M. Impact of passive techniques and clean conditioning systems on comfort and economic feasibility in low-cost shelters. Energy Build. 2013, 62, 414–426. [Google Scholar] [CrossRef]

- Susanti, L. Thermal Comfort Evaluation of Emergency Tent Using PMV and PPD Model. In Proceedings of the International MultiConference of Engineers and Computer Scientists, Hong Kong, China, 18–20 March 2015. [Google Scholar]

- Maracchini, G.; D’Orazio, M. Improving the livability of lightweight emergency architectures: A numerical investigation on a novel reinforced-EPS based construction system. Build. Environ. 2022, 208, 108601. [Google Scholar] [CrossRef]

- Tao, G.L.X.; Duan, D.; Li, H.; Chen, E.; Zhang, Z. Experimental study on warming and cooling in medical tent. Chin. Med. Equip. J. 2021, 42, 6. [Google Scholar]

- ANSI/ASHRAE Standard 55; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2023.

- Badache, M.; Eslami-Nejad, P.; Ouzzane, M.; Aidoun, Z.; Lamarche, L. A new modeling approach for improved ground temperature profile determination. Renew. Energy 2016, 85, 436–444. [Google Scholar] [CrossRef]

- Becker, S.; Potchter, O.; Yaakov, Y. Calculated and observed human thermal sensation in an extremely hot and dry climate. Energy Build. 2003, 35, 747–756. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, H.; Li, Y.; Qu, K.; Zhao, L.; Kong, G.; Jia, W. Building a satisfactory indoor environment for healthcare facility occupants: A literature review. Build. Environ. 2023, 228, 109861. [Google Scholar] [CrossRef]

- Cao, K.; Lan, M.; Wang, H.; Li, Y.; Liu, X. The thermal environment and thermal comfort of disaster relief tents in high-temperature composite environment. Case Stud. Therm. Eng. 2023, 50, 103453. [Google Scholar] [CrossRef]

- La Gennusa, M.; Nucara, A.; Pietrafesa, M.; Rizzo, G.; Scaccianoce, G. Angle Factors and Projected Area Factors for Comfort Analysis of Subjects in Complex Confined Enclosures: Analytical Relations and Experimental Results. Indoor Built Environ. 2008, 17, 346–360. [Google Scholar] [CrossRef]

- GB/T 33658-2017; Thermal Comfort Requirements and Evaluation for Indoor Environment. Standardization Administration of China: Beijing, China, 2017.

| Instrument Name | Model | Measuring Range | Accuracy |

|---|---|---|---|

| Solar Radiometer | JTR05 | 0~2000 W/m2 | ±2% |

| Indoor Air Quality (IAQ) Monitor | TrakPro-64 | 0~30 m/s | ±(0.1 m/s + 5%) |

| Thermocouple Sensor | T-type | −200~350 °C | ±0.5 °C |

| Multichannel Data Recorder | JTDL-80 | −20~100 °C | ±(0.5 °C + 5%) |

| Time | 15:00–15:37 | 15:37–17:05 | 17:05–17:37 | 17:37–18:40 | 18:40–19:15 |

|---|---|---|---|---|---|

| Operation | off | on | off | on | off |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, M.; Liao, Y.; Jia, Y.; Zhang, W.; Long, E. Summer Thermal Challenges in Emergency Tents: Insights into Thermal Characteristics of Tents with Air Conditioning. Buildings 2024, 14, 710. https://doi.org/10.3390/buildings14030710

Xiang M, Liao Y, Jia Y, Zhang W, Long E. Summer Thermal Challenges in Emergency Tents: Insights into Thermal Characteristics of Tents with Air Conditioning. Buildings. 2024; 14(3):710. https://doi.org/10.3390/buildings14030710

Chicago/Turabian StyleXiang, Mingli, Yuxuan Liao, Yonghong Jia, Wentao Zhang, and Enshen Long. 2024. "Summer Thermal Challenges in Emergency Tents: Insights into Thermal Characteristics of Tents with Air Conditioning" Buildings 14, no. 3: 710. https://doi.org/10.3390/buildings14030710