Sustainability Evaluation of Residential Buildings Based on the Footprint Family: Application to Case Studies in Andalusia

Abstract

:1. Introduction

1.1. Carbon Footprint

1.2. Ecological Footprint

1.3. Water Footprint

1.4. Construction and Demolition Waste (CDW)

1.5. Sustainability Assessment Methods

2. Methodology

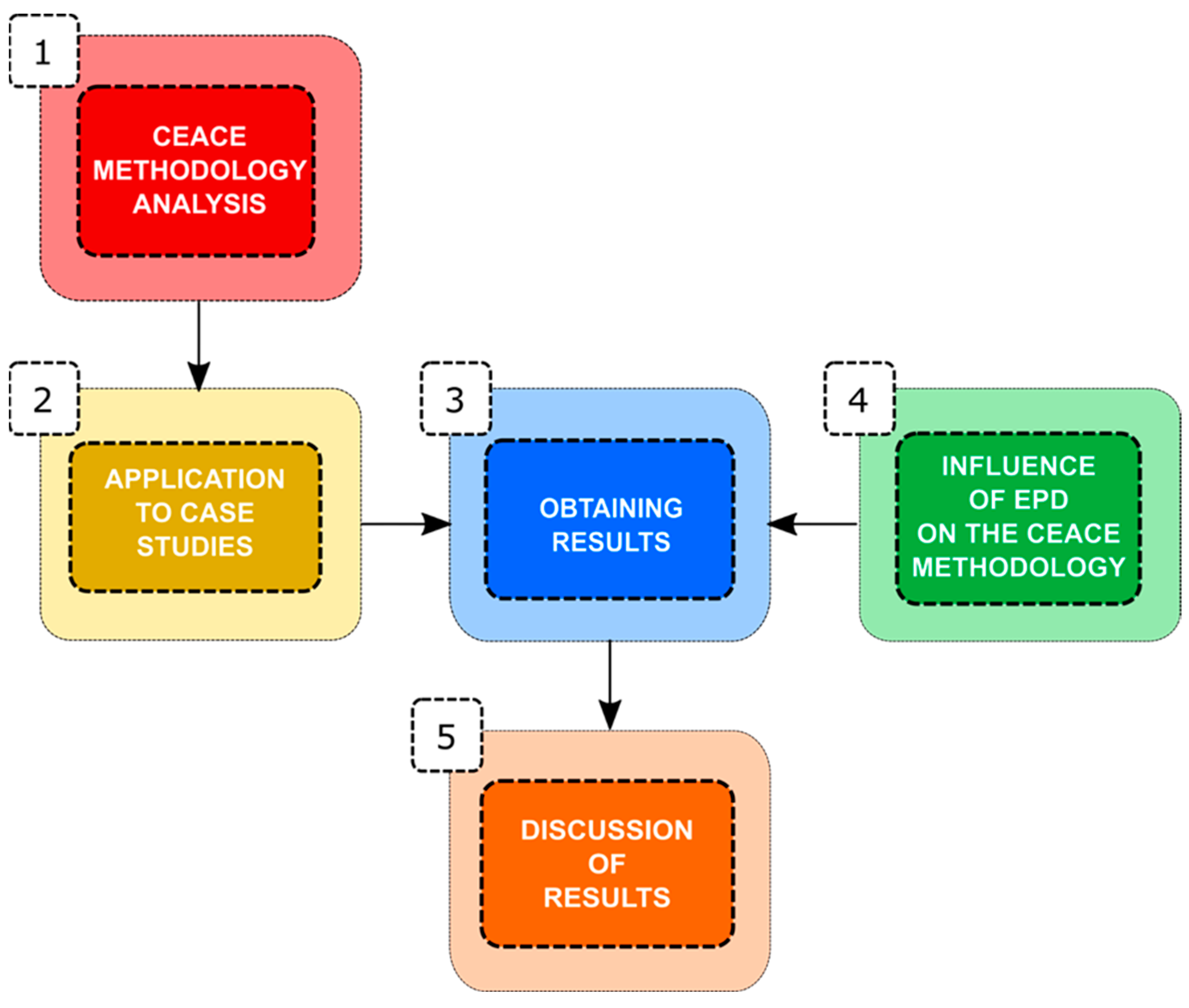

- The analysis of the methodological development towards obtaining the CEACE method (Certificado Ecológico Andaluz de Construcción de Edificios: Andalusian Ecological Certificate for the Construction of Buildings). The input data consists of the project budget, its quantity surveying, and cost assessment, while the output data involves the project footprints, CDW, and social aspects mentioned above;

- The CEACE method will be applied and validated through the analysis of 15 projects defined as combinations of residential projects with different constructive solutions. A sample of 200 housing projects is used for the standardisation of indicators that lead to global, economic, environmental, and social value;

- Obtaining results: Values of the following parameters will be obtained for each of the 15 projects: Costs, CF, EF, WF, and CDW (normalised by GFA). Subsequently, an aggregate indicator (I_CEACE) will be obtained, based on a standardisation6 and weighting process analysed in Section 3.3, for each of the 15 projects, which will contain environmental, economic, and social information on them. The percentage of influence of each of the work chapters in relation to the costs, CF, EF, WF, and CDW parameters will also be determined;

- Study of the influence of the use of Environmental Product Declarations (EPD) in the CEACE method: The project of the 15 that has generated the highest value of the I_CEACE indicator will be analyzed. Based on the analysis obtained from the CEACE method, it will be possible to determine the construction unit that generates the greatest impact, subsequently selecting the materials that compose it. Alternatives to these materials that have EPD will be sought in the market [86]. Finally, different scenarios will be evaluated to analyse the influence of the use of materials with EPD on the I_CEACE indicator;

- Discussion of results. A critical analysis of the results will be carried out. From this discussion, it will be demonstrated that the results are sensitive to changes in the foundation and typology of the building.

3. Development of the CEACE Method

- The economic and environmental budget (according to the indicators of the footprint family and CDW) of the project is assessed using CEACE software (https://personal.us.es/jaimesolis/, accessed on 14 March 2024) [87];

- The environmental and economic calculations are exported to an Excel spreadsheet. The social data is then incorporated (information regarding local materials, health and safety on the construction site, and local labour);

- The aggregate indicator (economic, environmental, and social) and the qualification of the project are determined.

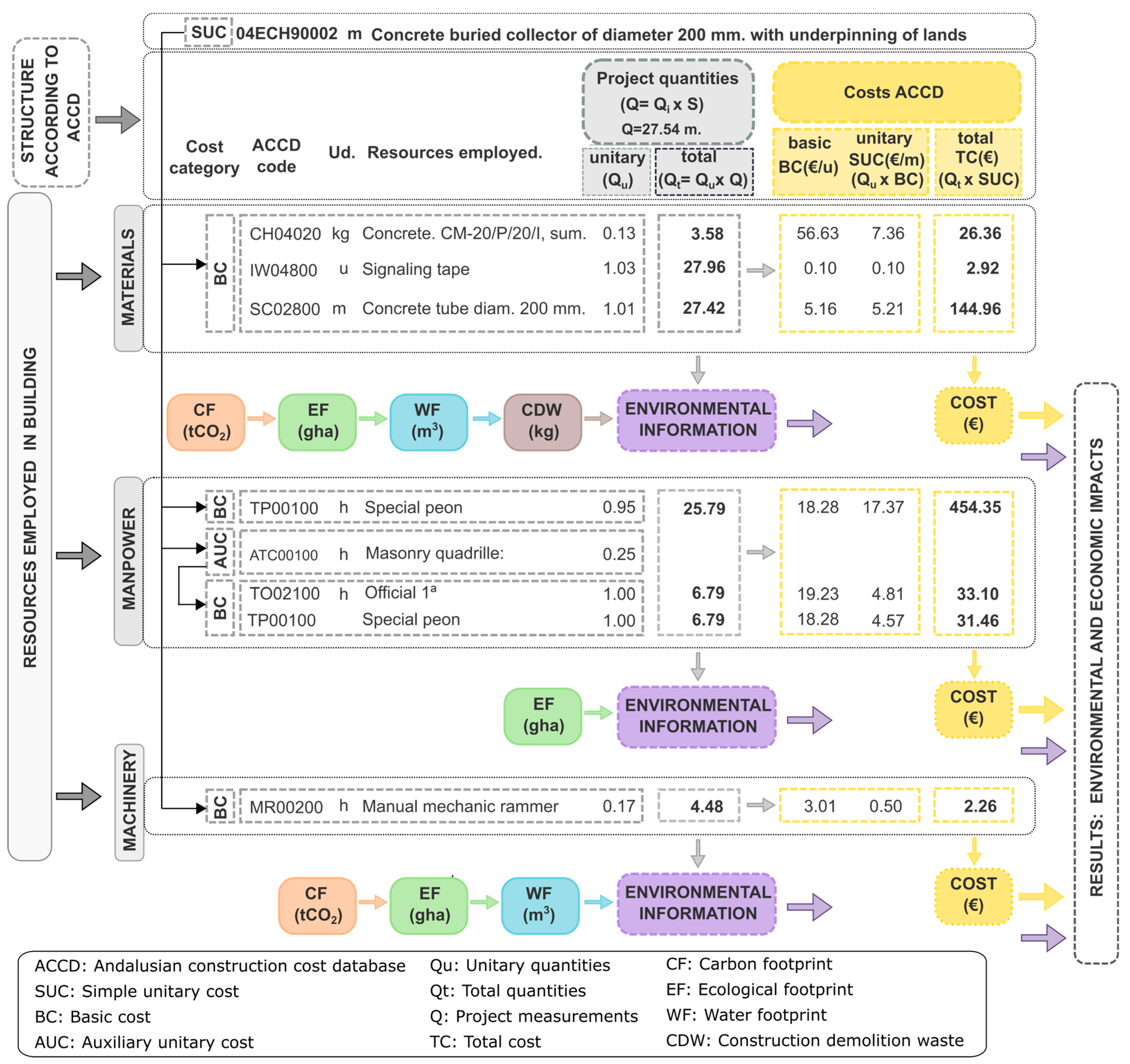

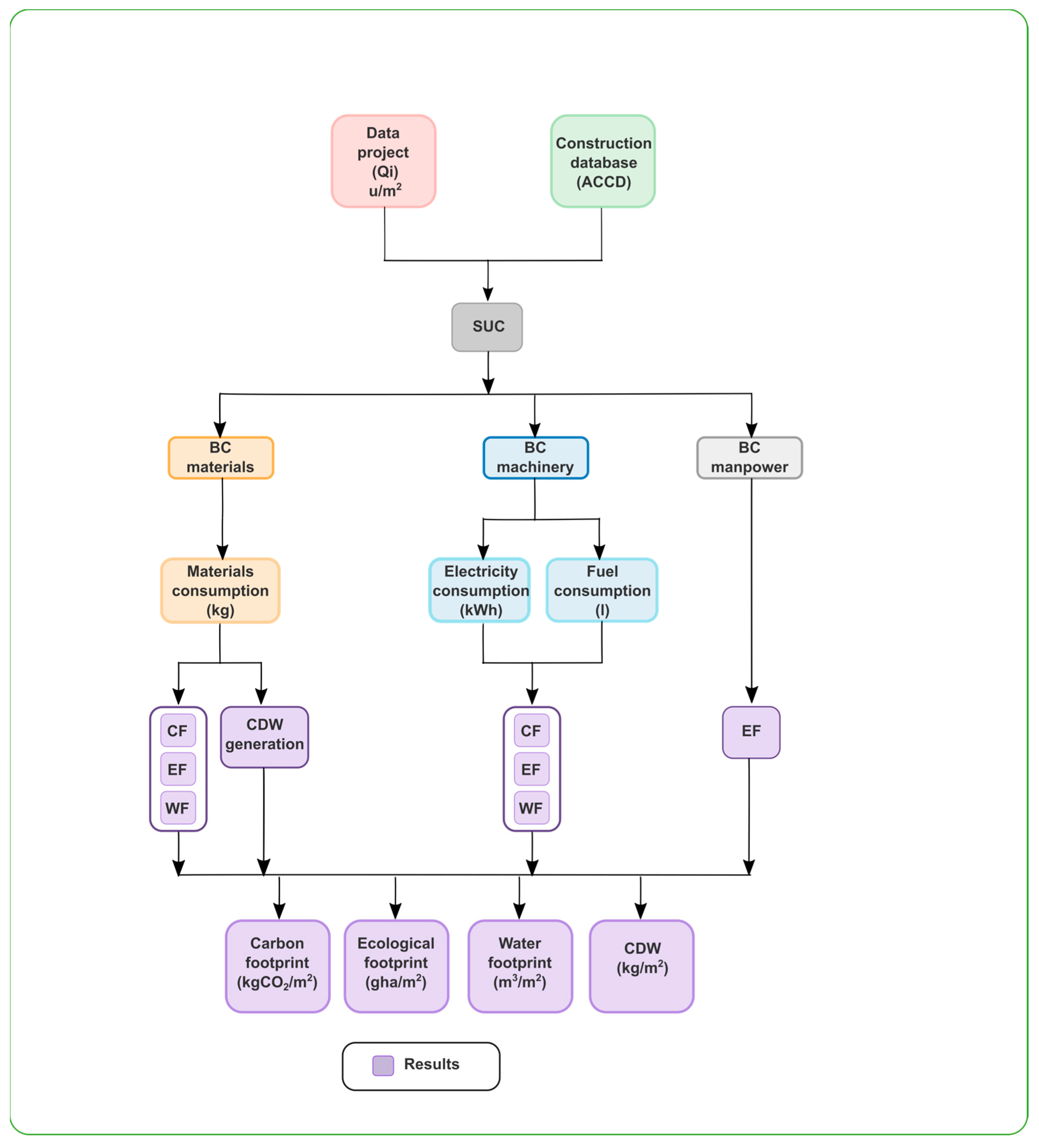

3.1. Project Budget

3.2. Environmental Information

3.3. Characteristics of the Construction Projects

- zi: i normalized value from the data

- xi: i actual value from the data

- min (x): minimum value in the data

- max (x): maximum value in the data

4. Case Studies

5. Results

6. Study of the Influence of the Use of Environmental Product Declarations (EPD) in the CEACE Method

- TO00600, 0.046 h, official first-class rebar placing;

- TO02100 0.053 h official first class;

- TP00100 0.356 h special peon;

- CA00320 2 kg steel B 500 S;

- CA00620 0.99 kg electro welded steel mesh, B 500 T;

- CB00600 4.86 U cement mortar vault;

- CH80040 0.115 m3 fresh concrete HA-35/p/20/IIa;

- CM00300 0.001m3 pine wood in plank;

- CV00100 2.338 m rigid armour self-resistant beam;

- MV00100 0.07 h vibrator.

- Scenario of the original project. It has an elevator, and the environmental data comes from the CEACE database;

- Similar to the stage, although it does not have an elevator. I_CEACE decreases slightly;

- Starting from Scenario 2, the units with the greatest impact are selected. Similar materials with EPD are sought: steel rebars, concrete HA-35, and self-resistant joists. Once the information has been obtained as explained above, then the budget is assessed again with the CEACE tool;

- Starting from Scenario 3, a new EPD is added, in this case corresponding to cement mortar vaults. Once the information has been obtained as explained above, then the budget is assessed again with the CEACE method.

7. Discussion of Results

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACCD | Andalusia Construction Cost Data Base |

| BC | Basic Cost |

| CAM | Compulsory minimum environmental criteria |

| CDW | Construction and demolition waste |

| CEACE | Certificado Ecológico Andaluz de Construcción de Edificios (Andalusian Ecological Certificate for the Construction of Buildings) |

| CF | Carbon footprint |

| EF | Ecological footprint |

| EPD | Environmental Product Declarations |

| EU | European Union |

| FF | Footprint family |

| GFA | Ground floor area |

| GHG | Greenhouse gas |

| GPP | Green Public Procurement |

| LCA | Life Cycle Assessment |

| SUC | Simple Unit Cost |

| WF | Water footprint |

Appendix A

| Code | Unit | Concept | Total Quantity (ud.ref) | Cost (EUR) | CF (tCO2) | EF (hag) | WF (m3) | CDW (kg) |

|---|---|---|---|---|---|---|---|---|

| Chapter | ||||||||

| 02. Earth Works | ||||||||

| 02ACC00001 | m3 | Hole excavation for the foundation footing in soil of medium consistency | 5291.01 | 4285.72 | 11.29 | 5.69 | 40.81 | 0.00 |

| 02RRM00001 | m3 | Earth filling carried out mechanically | 122.11 | 102.57 | 0.49 | 0.24 | 42.27 | 0.00 |

| 02TMM00002 | m3 | Soil transport, MAX. distance 5 km, loaded mechanically | 6614.68 | 20,108.63 | 94.83 | 47.04 | 342.62 | 0.00 |

| Total Chapter 02. Earthworks | 24,496.92 | 106.61 | 52.98 | 425.70 | 0.00 | |||

| 03. Foundation | ||||||||

| 03ACC00011 | kg | Rebar for the foundation B500S | 81,325.00 | 105,722.50 | 129.21 | 58.82 | 2395.93 | 2649.57 |

| 03ERT80060 | m2 | Metal formwork 2 cm, in retaining wall | 1587.43 | 56,083.90 | 11.87 | 5.16 | 6802.01 | 434.89 |

| 03HRZ80030 | m3 | Reinforced concrete, HA-25/P/40/IIa with B400S steel, in footings and pile caps, poared with crane | 1098.99 | 126405.83 | 394.69 | 187.46 | 6148.20 | 145,714.62 |

| 03HMM00002 | m3 | Mass concrete HM-20/P/40/I in foundations | 122.11 | 8244.87 | 30.28 | 14.51 | 452.34 | 13,447.68 |

| Total Chapter 03. Foundation | 296,457.10 | 566.05 | 265.94 | 15,798.49 | 162,246.76 | |||

| 04. Sewerage | ||||||||

| 04VBP00002 | m | Reinforced PVC downpipe, 110 mm diameter | 1221.10 | 24495.27 | 5.22 | 2.51 | 887.24 | 92.89 |

| 04CCP00031 | m | Hung PVC mainfold, 315 mm diameter | 244.22 | 12963.20 | 2.89 | 1.37 | 505.92 | 52.80 |

| 04EAP90002 | u | Sewerage passage box, 63 × 63 cm, 1 m deep, executed in soil | 122.11 | 26584.57 | 27.46 | 13.33 | 297.35 | 6861.88 |

| Total Chapter 04. Sewerage | 64,043.03 | 35.57 | 17.20 | 1690.50 | 7007.57 | |||

| 05. Structure | ||||||||

| 05FUA00118 | m2 | Slab formed by autoresist beams and concrete vaults (HA-35) | 12,088.90 | 396,395.03 | 835.93 | 400.10 | 15126.04 | 330,368.44 |

| 05HAC00015 | kg | Rebar B500S | 147,875.00 | 192,237.50 | 234.95 | 106.95 | 4356.57 | 4817.77 |

| 05HET00201 | m2 | Metal formwork with phenolic board cladding | 9280.34 | 181,245.04 | 41.38 | 19.86 | 5922.41 | 419.77 |

| 05HHJ00003 | m3 | Concrete for reinforcement in beams HA-25/P/20/Iia | 1221.10 | 95,038.21 | 360.97 | 173.09 | 5393.56 | 160,313.79 |

| Total Chapter 05. Structure | 864,915.78 | 1473.23 | 700.00 | 30,798.59 | 495,919.76 | |||

| 06. Masonry | ||||||||

| 06LHC00001 | m2 | Wall with ceramic breaks of 7 cm thick | 4029.62 | 73,862.93 | 147.86 | 70.38 | 947.21 | 36048.22 |

| 06LPM00001 | m2 | Brick wall with 1 foot drilled bricks | 10623.50 | 375,009.55 | 844.11 | 401.04 | 5278.41 | 207,113.81 |

| 06DTD00001 | m2 | Brick partition wall with ceramic brick of 9 cm thick | 9890.88 | 133,922.52 | 295.50 | 140.53 | 1832.40 | 72,663.03 |

| 06DSS00001 | m2 | Brick partition wall with ceramic brick with mortar | 8914.01 | 94,755.93 | 121.53 | 58.22 | 787.10 | 29542.06 |

| Total Chapter 06. Masonry | 677,550.93 | 1409.01 | 670.16 | 8845.12 | 345,367.11 | |||

| 07. Roof | ||||||||

| 07HTF00002 | m2 | Walkable roof | 1343.21 | 102,836.16 | 62.53 | 29.54 | 706.40 | 11,666.56 |

| Total Chapter 07. Roof | 102,836.16 | 62.53 | 29.54 | 706.40 | 11,666.56 | |||

| 08. Instalations | ||||||||

| 08FFC90100 | m | Copper ducting, recessed, 12 mm diameter | 5617.05 | 58,361.15 | 13.15 | 6.15 | 594.17 | 160.27 |

| 08FGL00004 | u | Mixer washbasin faucet equipment. Premium quality | 732.66 | 74,753.30 | 73.15 | 33.27 | 2707.56 | 480.82 |

| 08FSI00001 | u | Low tank toilet, white vitrified porcelain | 305.27 | 45,372.28 | 39.36 | 18.13 | 1434.33 | 303.01 |

| 08FSL00091 | u | Pedestal washbasin white vitrified porcelain | 305.27 | 52,732.34 | 38.94 | 17.93 | 672.94 | 296.78 |

| 08NAA90101 | u | Solar interstorage unit with fixed coil capacity 150 litres, DHW | 123.00 | 47,715.39 | 11.70 | 5.38 | 245.48 | 44.34 |

| 08NEE90011 | u | Inclined structure to support solar pannel of DHW | 76.00 | 16,282.24 | 0.01 | 0.04 | 0.25 | 0.05 |

| 08NOC90001 | u | Flat solar collector, absorber surface is 1.8 m2 | 76.00 | 28,622.36 | 1.61 | 0.83 | 39.13 | 39.89 |

| 08NPP90001 | m | Heat-insulated annealed cupper ducting 15 mm diameter | 2820.00 | 97,628.40 | 3.95 | 1.96 | 181.89 | 41.93 |

| 08FDP00011 | u | PVC siphon canister 125 mm with PVC tube 20 mm diameter, 1.9 thick | 976.88 | 40,687.05 | 45.25 | 20.83 | 5899.88 | 405.17 |

| 08FCC00055 | m | Heat-insulated copper ducting, 36 mm, recessed | 2320.08 | 48,744.88 | 16.79 | 7.52 | 751.15 | 206.62 |

| 08CAF00102 | u | Heat pump condenser 17,700 frig/h and 19,500 kcal/h | 120.00 | 94,3603.20 | 112.65 | 52.18 | 2363.03 | 426.85 |

| 08MAA90011 | u | Elevator without motor, 400 kg and 5 persons capacity | 3.00 | 71,114.70 | 22.92 | 15.36 | 1139.25 | 199.99 |

| 08CCE00000 | m2 | Radiator with single panel sheet of steel and 2-way wrench | 185.76 | 33,934.64 | 15.47 | 7.21 | 326.79 | 62.30 |

| 08CAW00001 | m | Two conductor circuits, 1.5 mm2 | 8303.46 | 29,062.11 | 9.12 | 4.37 | 1565.59 | 103.48 |

| 08ERR00246 | m | General power supply line 3 × 95 + 2 × 50 mm2 inside PVC tube | 2564.30 | 348,411.44 | 55.23 | 25.23 | 4995.41 | 626.47 |

| 08ELL00002 | u | Recessed switch for light | 1587.43 | 70,053.29 | 19.39 | 9.13 | 2566.69 | 211.33 |

| 08ETT00002 | u | Recessed power outlet 1/16 A with 1.5 mm2 | 2686.41 | 90,021.60 | 18.17 | 8.80 | 2648.87 | 203.20 |

| 08EPP00152 | m | Ground electric connection with bare popper wire of 35 mm2 | 2197.97 | 25,342.59 | 2.85 | 1.58 | 116.50 | 20.44 |

| Total Chapter 08. Instalations | 2,122,442.96 | 499.72 | 235.90 | 28,248.89 | 3832.94 | |||

| 09. Isolation | ||||||||

| 09TPP00030 | m2 | Sprayed polyurethane wall insulation 20 mm | 8914.01 | 32,179.58 | 29.07 | 12.25 | 2172.88 | 267.42 |

| Total Chapter 09. Isolation | 32,179.58 | 29.07 | 12.25 | 2172.88 | 267.42 | |||

| 10. Finishes | ||||||||

| 10WRC00001 | m | Ceramic tile 14 × 28 cm | 1098.99 | 14,122.02 | 2.84 | 1.48 | 47.14 | 229.87 |

| 10TET00005 | m2 | Continuos ceiling with smooth plater pates, metal frame | 976.88 | 16,577.65 | 6.07 | 2.98 | 97.73 | 1029.20 |

| 10SSS00010 | m2 | Concrete screed with HM-20, 15 cm thickness | 1221.10 | 26,033.85 | 49.27 | 23.70 | 1107.15 | 23,454.67 |

| 10SCS00001 | m2 | Flooring ceramic tile 14 × 28 cm | 9768.78 | 190,686.59 | 223.99 | 105.38 | 3983.03 | 20,928.36 |

| 10CGG00028 | m2 | Trimmed and plastered on walls, includes plaster mortar | 33,458.10 | 424,917.87 | 9.54 | 8.42 | 655.38 | 28947.95 |

| 10CEE00006 | m2 | Plastering and striped for tiling | 21,002.90 | 288,579.85 | 31.77 | 18.65 | 536.03 | 4506.93 |

| 10AAL00003 | m2 | White tile 15 × 15 cm with adhesive | 5250.72 | 102,914.11 | 116.53 | 53.95 | 2187.94 | 8218.58 |

| Total Chapter 10. Finishes | 1,063,831.94 | 439.99 | 214.55 | 8614.40 | 87,315.56 | |||

| 11. Carpentry, safety and security elements | ||||||||

| 11SRM00001 | m2 | Rolled steel security mesh with plates and square bars | 122.11 | 6506.02 | 5.30 | 2.43 | 150.31 | 0.22 |

| 11SPP00001 | m2 | Manually activated roller shutter with slats of 1.0 mm thick | 854.77 | 41,823.90 | 45.44 | 21.02 | 1658.77 | 257.82 |

| 11SBA00001 | m | Stell railing with 14 mm diamter bars | 732.66 | 45,131.86 | 36.32 | 16.64 | 1030.83 | 1.32 |

| 11MPB00151 | m2 | Main door, with frame | 1587.43 | 189,475.64 | −11.61 | -6.61 | 1623.95 | 1036.59 |

| 11LVA00127 | m2 | Aluminum casement window type II (1.5 to 3 m wide) | 732.66 | 78,130.86 | 17.48 | 7.08 | 457.35 | 49.94 |

| 11LPA00125 | m2 | Aluminum hinged door | 732.66 | 76,394.46 | 123.96 | 48.86 | 3162.50 | 316.20 |

| Total Chapter 11. Carpentry, safety and security elements | 437,462.74 | 216.89 | 89.41 | 8083.71 | 1662.08 | |||

| 12. Glazing and synthetic products | ||||||||

| 12NNI80001 | m2 | Window glass, 8 mm thick | 1343.21 | 32,035.56 | 10.60 | 4.78 | 579.53 | 149.34 |

| Total Chapter 12. Glazing and synthetic products | 32,035.56 | 10.60 | 4.78 | 579.53 | 149.34 | |||

| 13. Paints | ||||||||

| 13EAA00001 | m2 | Acrylic elastomer paint | 14,836.30 | 54,449.22 | 23.92 | 10.00 | 728.55 | 445.09 |

| 13EEE00001 | m2 | Greasy enamel paint | 1648.48 | 11,737.18 | 1.85 | 0.86 | 200.60 | 40.16 |

| 13IPP00001 | m2 | Plastic paint on bricks, gypsum or cement | 34,837.90 | 142,487.01 | 124.24 | 53.60 | 6111.60 | 1397.70 |

| 13IEE00002 | m2 | Grasy enamel painting on wood carpentry | 3870.87 | 35,960.38 | 14.44 | 6.38 | 1201.09 | 150.35 |

| Total Chapter 13.Paints | 244,633.79 | 164.46 | 70.83 | 8241.84 | 2033.29 | |||

| TOTAL | 5,962,886.48 | 5013.73 | 2363.56 | 114,206.04 | 1,117,468.40 | |||

References

- European Comission. LEVEL(S) Taking Action on the TOTAL Impact of the Construction Sector; European Comission: Brussels, Belgium, 2019. [Google Scholar]

- European Comission. A New Circular Economy Action Plan; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- Jang, H.J.; Wang, S.J.; Tae, S.H.; Zheng, P.F. Establishment of an Environmental Impact Factor Database for Building Materials to Support Building Life Cycle Assessments in China. Buildings 2024, 14, 228. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of Construction Materials: Methodologies, Applications and Future Directions for Sustainable Decision-Making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Warrier, G.A.; Palaniappan, S.; Habert, G. Classification of Sources of Uncertainty in Building LCA. Energy Build. 2024, 305, 113892. [Google Scholar] [CrossRef]

- Wackernagel, M.; Rees, W. Our Ecological Footprint: Reducing Human Impact on the Earth; New Society: Gabriola Island, BC, Canada, 1996. [Google Scholar]

- Galli, A.; Antonelli, M.; Wambersie, L.; Bach-Faig, A.; Bartolini, F.; Caro, D.; Iha, K.; Lin, D.; Mancini, M.S.; Sonnino, R.; et al. EU-27 Ecological Footprint Was Primarily Driven by Food Consumption and Exceeded Regional Biocapacity from 2004 to 2014. Nat. Food 2023, 4, 810–822. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.I.; Farghali, M.; Dong, Y.; Kong, J.; Yousry, M.; Rashwan, A.K.; Chen, Z.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.-S. Reducing the Carbon Footprint of Buildings Using Biochar-Based Bricks and Insulating Materials: A Review. Environ. Chem. Lett. 2024, 22, 71–104. [Google Scholar] [CrossRef]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Lokke, S. Carbon Footprint: A Catalyst for Life Cycle Assessment? J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Chapagain, A.K.; Hoekstra, A.Y. Water Footprints of Nations (Value of Water Research Report Series/Unesco-IHE No. 16); UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2004. [Google Scholar]

- Sunitha, S.; Akash, A.U.; Sheela, M.N.; Kumar, J.S. The Water Footprint of Root and Tuber Crops. Environ. Dev. Sustain. 2024, 26, 3021–3043. [Google Scholar] [CrossRef]

- Fang, K.; Song, S.; Heijungs, R.; de Groot, S.; Dong, L.; Song, J.; Wiloso, E.I. The Footprint’s Fingerprint: On the Classification of the Footprint Family. Curr. Opin. Environ. Sustain. 2016, 23, 54–62. [Google Scholar] [CrossRef]

- Galli, A. Footprints—Environmental Science—Oxford Bibliographies. Available online: https://www.oxfordbibliographies.com/view/document/obo-9780199363445/obo-9780199363445-0046.xml (accessed on 11 November 2022).

- Hoekstra, A.Y.; Wiedmann, T.O. Humanity’s Unsustainable Environmental Footprint. Science 2014, 344, 1114–1117. [Google Scholar] [CrossRef] [PubMed]

- Matuštík, J.; Kočí, V. What Is a Footprint? A Conceptual Analysis of Environmental Footprint Indicators. J. Clean. Prod. 2021, 285, 124833. [Google Scholar] [CrossRef]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; Haes, H.A.U. Midpoints versus Endpoints: The Sacrifices and Benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef]

- European Comission. Public Procurement for a Circular Economy; European Comission: Brussels, Belgium, 2017. [Google Scholar]

- Giljum, S.; Burger, E.; Hinterberger, F.; Lutter, S.; Bruckner, M. A Comprehensive Set of Resource Use Indicators from the Micro to the Macro Level. Resour. Conserv. Recycl. 2011, 55, 300–308. [Google Scholar] [CrossRef]

- Stoeglehner, G.; Narodoslawsky, M. Implementing Ecological Footprinting in Decision-Making Processes. Land Use Policy 2008, 25, 421–431. [Google Scholar] [CrossRef]

- Fang, K.; Heijungs, R.; De Snoo, G.R. Theoretical Exploration for the Combination of the Ecological, Energy, Carbon, and Water Footprints: Overview of a Footprint Family. Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating Ecological, Carbon and Water Footprint into a Footprint Family of Indicators: Definition and Role in Tracking Human Pressure on the Planet. Ecol. Ind. 2012, 16, 100–112. [Google Scholar] [CrossRef]

- Laurent, A.; Owsianiak, M. Potentials and Limitations of Footprints for Gauging Environmental Sustainability. Curr. Opin. Environ. Sustain. 2017, 25, 20–27. [Google Scholar] [CrossRef]

- Vanham, D.; Leip, A.; Galli, A.; Kastner, T.; Bruckner, M.; Uwizeye, A.; van Dijk, K.; Ercin, E.; Dalin, C.; Brandão, M.; et al. Environmental Footprint Family to Address Local to Planetary Sustainability and Deliver on the SDGs. Sci. Total Environ. 2019, 693, 133642. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Solís, J. Evaluación de La Footprint Family En Edificación (Footprint Family Evaluation in Buildings). Master’s Thesis, Universidad de Sevilla, Seville, Spain, 2014. [Google Scholar]

- Rivero-Camacho, C.; Ferreira-Sánchez, A. Application of the “Footprint Family” for the Environmental Evaluation of Public Buildings in Spain. Case Study: Educational Center. Rev. Habitat Sustentable 2021, 11, 72–85. [Google Scholar] [CrossRef]

- Rivero-Camacho, C.; Martín-del-Río, J.J.; Marrero-Meléndez, M. Evolution of the Life Cycle of Residential Buildings in Andalusia: Economic and Environmental Evaluation of Their Direct and Indirect Impacts. Sustain. Cities Soc. 2023, 93, 104507. [Google Scholar] [CrossRef]

- Marrero, M.; Rivero-Camacho, C.; Alba-Rodríguez, M.D. What Are We Discarding during the Life Cycle of a Building? Case Studies of Social Housing in Andalusia, Spain. Waste Manag. 2020, 102, 391–403. [Google Scholar] [CrossRef]

- Lopes, R.; Silva, D.; Rivero-Camacho, C.; Rusu, D.; Marrero, M. Methodology for Improving the Sustainability of Industrial Buildings via Matrix of Combinations Water and Carbon Footprint Assessment. Sustainability 2022, 14, 15297. [Google Scholar] [CrossRef]

- Alvarez, S.; Carballo-Penela, A.; Mateo-Mantecón, I.; Rubio, A. Strengths-Weaknesses-Opportunities-Threats Analysis of Carbon Footprint Indicator and Derived Recommendations. J. Clean. Prod. 2016, 121, 238–247. [Google Scholar] [CrossRef]

- Schwartz, Y.; Raslan, R.; Mumovic, D. The Life Cycle Carbon Footprint of Refurbished and New Buildings—A Systematic Review of Case Studies. Renew. Sustain. Energy Rev. 2018, 81, 231–241. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Kontoleon, K.J.; Bikas, D. Normalising and Assessing Carbon Emissions in the Building Sector: A Review on the Embodied CO2 emissions of Residential Buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- UNE-EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. AENOR: Madrid, Spain, 2012.

- De Wolf, C. Material Quantities in Building Structures and Their Environmental Impact; MIT: Boston, MA, USA, 2014. [Google Scholar]

- Solís-Guzmán, J.; Rivero-Camacho, C.; Alba-Rodríguez, D.; Martínez-Rocamora, A. Carbon Footprint Estimation Tool for Residential Buildings for Non-Specialized Users: OERCO2 Project. Sustainability 2018, 10, 1359. [Google Scholar] [CrossRef]

- Amiri, A.; Emami, N.; Ottelin, J.; Sorvari, J.; Marteinsson, B.; Heinonen, J.; Junnila, S. Embodied Emissions of Buildings—A Forgotten Factor in Green Building Certificates. Energy Build. 2021, 241, 110962. [Google Scholar] [CrossRef]

- Le Den, X.; Steinmann, J.; Röck, M.; Birgisdottir, H.; Horup, L.H.; Tozan, B.; Sørensen, A. Towards Embodied Carbon Benchmarks for Buildings in Europe—Summary Report; Rambøll: London, UK, 2022. [Google Scholar] [CrossRef]

- Radhi, H.; Sharples, S. Global Warming Implications of Facade Parameters: A Life Cycle Assessment of Residential Buildings in Bahrain. Environ. Impact Assess. Rev. 2013, 38, 99–108. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG Emissions of Buildings—The Hidden Challenge for Effective Climate Change Mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Cellura, M.; Guarino, F.; Longo, S.; Mistretta, M. Energy Life-Cycle Approach in Net Zero Energy Buildings Balance: Operation and Embodied Energy of an Italian Case Study. Energy Build. 2014, 72, 371–381. [Google Scholar] [CrossRef]

- Samad, P.P.; Faryadi, S.H. Determination of Ecological Footprints of Dense and High-Rise Districts, Case Study of Elahie Neighborhood, Tehran. J. Environ. Stud. 2008, 34, 63–72. [Google Scholar]

- Zhao, X.Y.; Mao, X.W. Comparison Environmental Impact of the Peasant Household in Han, Zang and Hui Nationality Region: Case of Zhangye, Gannan and Linxia in Gansu Province. Acta Ecol. Sin. 2013, 33, 5397–5406. [Google Scholar] [CrossRef]

- Li, B.; Cheng, D.-J. Hotel Ecological Footprint Model: Its Construction and Application. Chin. J. Ecol. 2010, 7, 31. [Google Scholar]

- Bin, G.; Parker, P. Measuring Buildings for Sustainability: Comparing the Initial and Retrofit Ecological Footprint of a Century Home—The REEP House. Appl. Energy 2012, 93, 24–32. [Google Scholar] [CrossRef]

- Li, D.Z.; Hui, E.C.M.; Leung, B.Y.P.; Li, Q.M.; Xu, X. A Methodology for Eco-Efficiency Evaluation of Residential Development at City Level. Build. Environ. 2010, 45, 566–573. [Google Scholar] [CrossRef]

- Rivero-Camacho, C.; Martín-Del-Río, J.J.; Solís-Guzmán, J.; Marrero, M. Ecological Footprint of the Life Cycle of Buildings. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Singapore, 2021; pp. 1–39. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Ramírez-de-Arellano, A. Methodology for Determining the Ecological Footprint of the Construction of Residential Buildings in Andalusia (Spain). Ecol. Indic. 2013, 25, 239–249. [Google Scholar] [CrossRef]

- González-Vallejo, P.; Marrero, M.; Solís-Guzmán, J. The Ecological Footprint of Dwelling Construction in Spain. Ecol. Indic. 2015, 52, 75–84. [Google Scholar] [CrossRef]

- Marrero, M.; Puerto, M.; Rivero-Camacho, C.; Freire-Guerrero, A.; Solís-Guzmán, J. Assessing the Economic Impact and Ecological Footprint of Construction and Demolition Waste during the Urbanization of Rural Land. Resour. Conserv. Recycl. 2017, 117, 160–174. [Google Scholar] [CrossRef]

- United Nations Environment Program (UNEP). Eco-Housing Guidelines for Tropical Regions; UNEP Regional Resource Centre for Asia and the Pacific: Bangkok, Thailand, 2006. [Google Scholar]

- GBC Australia. Building the Business Case for Green Buildings in Australia; GBC Australia: Sidney, Australia, 2008. [Google Scholar]

- ISO 14046:2014; Environmental Management—Water Footprint—Principles, Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/43263.html (accessed on 22 September 2022).

- Hoekstra, A.Y. Water Footprint Assessment: Evolvement of a New Research Field. Water Resour. Manag. 2017, 31, 3061–3081. [Google Scholar] [CrossRef]

- McCormack, M.; Treloar, G.J.; Palmowski, L.; Crawford, R. Modelling Direct and Indirect Water Requirements of Construction. Build. Res. Inf. 2007, 35, 156–162. [Google Scholar] [CrossRef]

- Crawford, R.H.; Pullen, S. Life Cycle Water Analysis of a Residential Building and Its Occupants. Build. Res. Inf. 2011, 39, 589–602. [Google Scholar] [CrossRef]

- Bardhan, S. Assessment of Water Resource Consumption in Building Construction in India. Ecosyst. Sustain. Dev. 2011, 144, 1743–3541. [Google Scholar] [CrossRef]

- Heravi, G.; Abdolvand, M.M. Assessment of Water Consumption during Production of Material and Construction Phases of Residential Building Projects. Sustain. Cities Soc. 2019, 51, 101785. [Google Scholar] [CrossRef]

- Han, M.Y.; Chen, G.Q.; Meng, J.; Wu, X.D.; Alsaedi, A.; Ahmad, B. Virtual Water Accounting for a Building Construction Engineering Project with Nine Sub-Projects: A Case in E-Town, Beijing. J. Clean. Prod. 2016, 112, 4691–4700. [Google Scholar] [CrossRef]

- Meng, J.; Chen, G.Q.; Shao, L.; Li, J.S.; Tang, H.S.; Hayat, T.; Alsaedi, A.; Alsaadi, F. Virtual Water Accounting for Building: Case Study for E-Town, Beijing. J. Clean. Prod. 2014, 68, 7–15. [Google Scholar] [CrossRef]

- Rivero-Camacho, C.; Marrero, M. Water Footprint of the Life Cycle of Buildings: Case Study in Andalusia, Spain. In Green Energy Technol; Ren, J., Ed.; Springer Nature: Cham, Switzerland, 2022; pp. 135–165. [Google Scholar] [CrossRef]

- Ruiz-Pérez, M.R.; Alba-Rodríguez, M.D.; Marrero, M. Evaluation of Water Footprint of Urban Renewal Projects. Case Study in Seville, Andalusia. Water Res. 2022, 221, 118715. [Google Scholar] [CrossRef] [PubMed]

- European Commission 2016 Eurostat—Data Explorer. Available online: https://ec.europa.eu/eurostat (accessed on 15 February 2024).

- Donatello, S.; Dodd, N. Level(s) Indicator 2.2: Construction and Demolition Waste and Materials User Manual: Introductory Briefing, Instructions and Guidance (Publication Version 1.1); European Commision: Brussels, Belgium, 2021. [Google Scholar]

- Wu, Z.; Yu, A.T.W.; Shen, L.; Liu, G. Quantifying Construction and Demolition Waste: An Analytical Review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef] [PubMed]

- Cochran, K.M.; Townsend, T.G. Estimating Construction and Demolition Debris Generation Using a Materials Flow Analysis Approach. Waste Manag. 2010, 30, 2247–2254. [Google Scholar] [CrossRef] [PubMed]

- Yost, P.A.; Halstead, J.M. A Methodology for Quantifying the Volume of Construction Waste. Waste Manag. Res. 1996, 14, 453–461. [Google Scholar] [CrossRef]

- Aguirre, C.; Latorre, M.V.; Burboa, R.; Montecinos, P. Diagnóstico de La Generación de Residuos Sólidos de Construcción de Edificación En Obras de Edificación En Altura En La Región Metropolitana. Rev. Construcción 2005, 4, 38–46. [Google Scholar]

- Mokhtar, S.N.; Mahmood, N.Z.; Hassan, C.R.C.; Masudi, A.F.; Sulaiman, N.M. Factors That Contribute to the Generation of Construction Waste at Sites. Adv. Mat. Res. 2011, 163, 4501–4507. [Google Scholar] [CrossRef]

- Wimalasena, B.A.D.S.; Ruwanpura, J.Y.; Hettiaratchi, J.P.A. Modeling Construction Waste Generation towards Sustainability. In Proceedings of the Construction Research Congress 2010: Innovation for Reshaping Construction Practice—Proceedings of the 2010 Construction Research Congress, Banff, Alta, Canada, 8–10 May 2010; pp. 1498–1507. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Economic Analysis of Conventional versus Selective Demolition—A Case Study. Resour. Conserv. Recycl. 2011, 55, 382–392. [Google Scholar] [CrossRef]

- Llatas, C. A Model for Quantifying Construction Waste in Projects According to the European Waste List. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef] [PubMed]

- Mercader-Moyano, P.; Ramírez-De-Arellano-Agudo, A. Selective Classification and Quantification Model of C&D Waste from Material Resources Consumed in Residential Building Construction. Waste Manag Res. 2013, 31, 458–474. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish Model for Quantification and Management of Construction Waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Level(s). Available online: https://environment.ec.europa.eu/topics/circular-economy/levels_en (accessed on 23 September 2022).

- A European Green Deal|European Commission. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 23 September 2022).

- Positive-Energy and Low Carbon Buildings. Available online: http://www.batiment-energiecarbone.fr/en/ (accessed on 23 September 2022).

- Italian Government. Criteri Ambientali Minimi per l’Edilizia (Minimum Environmental Criteria for construction); Ministry of Environment: Rome, Italy, 2017.

- Itaca. Available online: https://www.itaca.org/valutazione_sostenibilita.asp# (accessed on 23 September 2022).

- GBC Spain HADES Herramienta de Ayuda al Diseño Para Una Edificación Más Sostenible. Available online: http://www.gbce.es/ (accessed on 5 February 2024).

- GBC Spain VERDE. Available online: https://gbce.es/certificacion-verde/herramientas_verde/verde_edificios_2022/ (accessed on 7 February 2023).

- SpainGBC LEED Certificate. Available online: http://www.spaingbc.org/web/leed-4.php (accessed on 30 November 2023).

- BREEAM ES Website. Available online: http://www.breeam.es/ (accessed on 30 December 2023).

- Asociación Ecómetro Ecometro LCA Tool Website. Available online: http://acv.ecometro.org/ (accessed on 30 December 2018).

- Ruiz-Pérez, M.R.; Alba-Rodríguez, M.D.; Castaño-Rosa, R.; Solís-Guzmán, J.; Marrero, M. HEREVEA Tool for Economic and Environmental Impact Evaluation for Sustainable Planning Policy in Housing Renovation. Sustainability 2019, 11, 2852. [Google Scholar] [CrossRef]

- OERCO2. Construction Material Life Cycle Website. Available online: http://oerco2.eu/ (accessed on 1 January 2023).

- ACCD. Andalusian Construction Cost Database (ACCD). Consejería de Obras Pública y Vivienda de La Junta de Andalucía. Available online: https://www.juntadeandalucia.es/organismos/fomentoarticulaciondelterritorioyvivienda/areas/vivienda-rehabilitacion/planes-instrumentos/paginas/bcca-jul-2023.html (accessed on 1 February 2024).

- UNE-EN-15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. AENOR: Madrid, Spain, 2020.

- Ceace Project CEACE. Available online: https://personal.us.es/jaimesolis/ (accessed on 23 September 2022).

- ITeC BEDEC Website. Available online: https://metabase.itec.cat/vide/es/bedec (accessed on 31 December 2023).

- Cype Ingenieros, S.A. Cypetherm HE PLus. Available online: https://bimserver.center/bim_store.asp (accessed on 30 December 2023).

- Freire-Guerrero, A.; Alba-Rodríguez, M.D.; Marrero, M. A Budget for the Ecological Footprint of Buildings Is Possible: A Case Study Using the Dwelling Construction Cost Database of Andalusia. Sustain. Cities Soc. 2019, 51, 101737. [Google Scholar] [CrossRef]

- Rivero-Camacho, C. Estudio de Huellas En El Ciclo de Vida Del Edificio Residencial (Study of Footprints in the Life Cycle of the Residential Building); University of Seville: Seville, Spain, 2020. [Google Scholar]

- Ecoinvent Centre. Ecoinvent Database. Available online: https://ecoinvent.org/database/ (accessed on 5 February 2024).

- SimaPro. Available online: https://simapro.com/ (accessed on 17 May 2023).

- Marrero, M.; Ramirez-De-Arellano, A. The Building Cost System in Andalusia: Application to Construction and Demolition Waste Management. Constr. Manag. Econ. 2010, 28, 495–507. [Google Scholar] [CrossRef]

- Marrero, M.; Rivero-Camacho, C.; Martínez-Rocamora, A.; Alba-Rodríguez, D.; Lucas-Ruiz, V. Holistic Assessment of the Economic, Environmental, and Social Impact of Building Construction. Application to Housing Construction in Andalusia. J. Clean. Prod. 2024, 434, 140170. [Google Scholar] [CrossRef]

- AzariJafari, H.; Guest, G.; Kirchain, R.; Gregory, J.; Amor, B. Towards Comparable Environmental Product Declarations of Construction Materials: Insights from a Probabilistic Comparative LCA Approach. Build. Environ. 2021, 190, 107542. [Google Scholar] [CrossRef]

- Cardoso, V.E.M.; Sanhudo, L.; Silvestre, J.D.; Almeida, M.; Costa, A.A. Challenges in the Harmonisation and Digitalisation of Environmental Product Declarations for Construction Products in the European Context. Int. J. Life Cycle Assess. 2024. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Palumbo, E.; Llatas, C.; Velasco Acevedo, Á.; Fernández Galvéz, M.D.; Hoxha, E.; Passer, A. The Use of Environmental Product Declarations of Construction Products as a Data Source to Conduct a Building Life-Cycle Assessment in Spain. Sustainability 2023, 15, 1284. [Google Scholar] [CrossRef]

- AENOR Global EPD AENOR—Declaraciones GlobalEPD En Vigor. Available online: https://www.aenor.com/certificacion/certificacion-de-producto/declaraciones-ambientales-de-producto/declaraciones-globalepd-en-vigor (accessed on 13 February 2023).

- ANDECE DAP Spain Declaraciones Ambientales ANDECE—ANDECE. Available online: https://www.andece.org/declaraciones-ambientales-andece/ (accessed on 14 February 2023).

- Clark, D. What Colour Is Your Building? Measuring and Reducing the Energy and Carbon Footprint of Buildings; RIBA Publishing: London, UK, 2012; ISBN 978-1859464472. [Google Scholar]

- Granados, H.; Fernández-Castillo, J.; Lçopez-Asiaín, J. Ratios Nacionales de Generación de RCD (Spanish Ratio of CDW Generation); CGATE and CSCAE: Madrid, Spain, 2020. [Google Scholar]

| Project | Floors above Ground | Floors below Ground | Gross Floor Area (GFA) | Number of Dwellings | Ground Floor Use | Foundation |

|---|---|---|---|---|---|---|

| 1 | 10 | 1 | 11,100.88 | 120 | Dwellings | Reinforced concrete slab |

| 2 | 10 | 2 | 11,100.88 | 120 | Premises | Reinforced concrete slab |

| 3 | 5 | 1 | 5550.50 | 60 | Dwellings | Isolated concrete pad |

| 4 | 5 | 2 | 5550.50 | 60 | Dwellings | Reinforced concrete slab |

| 5 | 5 | 1 | 5550.50 | 60 | Dwellings | Piles |

| 6 | 4 | 2 | 4440.40 | 48 | Premises | Reinforced concrete slab |

| 7 | 4 | 1 | 4440.40 | 48 | Dwellings | Reinforced concrete slab |

| 8 | 4 | 1 | 4440.40 | 48 | Premises | Piles |

| 9 | 4 | 1 | 4440.40 | 48 | Dwellings | Isolated concrete pad |

| 10 | 3 | 1 | 3330.25 | 36 | Dwellings | Isolated concrete pad |

| 11 | 3 | 1 | 3330.25 | 36 | Premises | Piles |

| 12 | 3 | 1 | 3330.25 | 36 | Dwellings | Reinforced concrete slab |

| 13 | 2 | 0 | 3836.17 | 24 | Dwellings | Isolated concrete pad |

| 14 | 2 | 1 | 3836.17 | 40 | Dwellings | Isolated concrete pad |

| 15 | 1 | 0 | 2696.57 | 13 | Dwellings | Concrete trenches |

| Total per GFA in m2 | |||||

|---|---|---|---|---|---|

| Project | Cost (EUR/m2) | CF (t CO2/m2) | EF (hag/m2) | WF (m3/m2) | CDW (kg/m2) |

| 1 | 537.15 | 0.452 | 0.213 | 10.29 | 100.66 |

| 2 | 534.07 | 0.499 | 0.235 | 11.14 | 109.28 |

| 3 | 474.12 | 0.432 | 0.204 | 10.02 | 102.87 |

| 4 | 570.36 | 0.568 | 0.267 | 12.58 | 120.69 |

| 5 | 541.78 | 0.486 | 0.235 | 10.81 | 118.08 |

| 6 | 593.03 | 0.601 | 0.286 | 13.11 | 138.27 |

| 7 | 519.93 | 0.485 | 0.229 | 11.49 | 102.43 |

| 8 | 497.45 | 0.464 | 0.228 | 11.69 | 115.81 |

| 9 | 510.64 | 0.459 | 0.216 | 11.31 | 106.10 |

| 10 | 539.37 | 0.508 | 0.240 | 12.03 | 126.57 |

| 11 | 477.27 | 0.516 | 0.253 | 11.80 | 127.61 |

| 12 | 570.64 | 0.535 | 0.253 | 12.15 | 123.03 |

| 13 | 665.06 | 0.556 | 0.272 | 13.51 | 126.50 |

| 14 | 699.64 | 0.657 | 0.312 | 16.54 | 159.93 |

| 15 | 550.90 | 0.655 | 0.309 | 15.14 | 169.27 |

| Unitary Values | Coefficients | I_CEACE | I_norm_CEACE | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Project | CFu | EFu | WFu | CDWu | Au | Eu | Su | ||

| 1 | 0.394 | 0.402 | 0.286 | 0.379 | 0.365 | 0.25 | 0.35 | 0.345 | −0.499 |

| 2 | 0.534 | 0.537 | 0.384 | 0.457 | 0.478 | 0.24 | 0.35 | 0.423 | −0.250 |

| 3 | 0.335 | 0.349 | 0.255 | 0.399 | 0.334 | 0.12 | 0.35 | 0.305 | −0.626 |

| 4 | 0.739 | 0.731 | 0.547 | 0.560 | 0.644 | 0.32 | 0.35 | 0.551 | 0.157 |

| 5 | 0.495 | 0.538 | 0.345 | 0.536 | 0.479 | 0.26 | 0.35 | 0.426 | −0.241 |

| 6 | 0.835 | 0.841 | 0.608 | 0.719 | 0.751 | 0.36 | 0.35 | 0.632 | 0.415 |

| 7 | 0.492 | 0.497 | 0.424 | 0.395 | 0.452 | 0.21 | 0.35 | 0.401 | −0.320 |

| 8 | 0.432 | 0.495 | 0.445 | 0.516 | 0.472 | 0.17 | 0.35 | 0.408 | −0.298 |

| 9 | 0.415 | 0.421 | 0.403 | 0.428 | 0.417 | 0.20 | 0.35 | 0.373 | −0.410 |

| 10 | 0.559 | 0.567 | 0.484 | 0.613 | 0.556 | 0.25 | 0.35 | 0.480 | −0.069 |

| 11 | 0.585 | 0.644 | 0.459 | 0.623 | 0.578 | 0.13 | 0.35 | 0.476 | −0.082 |

| 12 | 0.639 | 0.642 | 0.498 | 0.581 | 0.590 | 0.32 | 0.35 | 0.513 | 0.036 |

| 13 | 0.702 | 0.756 | 0.653 | 0.613 | 0.681 | 0.50 | 0.35 | 0.605 | 0.330 |

| 14 | 1.000 | 1.000 | 1.000 | 0.915 | 0.979 | 0.57 | 0.35 | 0.824 | 1.028 |

| 15 | 0.996 | 0.981 | 0.840 | 1.000 | 0.954 | 0.28 | 0.35 | 0.762 | 0.830 |

| Normalization scale: | |||||||||

| −2 to −3 | −1 to −2 | 0 to −1 | 0 to 1 | 1 to 2 | 2 to 3 | s | 0.313 | ||

| −3 s | −2 s | −s | s | +1 s | +2 s | x | 0.501 | ||

| Material | CF (t CO2) | EF (hag) | WF (m3) | |||

|---|---|---|---|---|---|---|

| CEACE | EPD | CEACE | EPD | CEACE | EPD | |

| Steel rebars (kg) | 1.460 × 10−3 | 0.563 × 10−3 | 0.659 × 10−3 | 0.275 × 10−3 | 2.700 × 10−2 | 2.980 × 10−3 |

| Cement mortar vaults (u) | 1.480 × 10−3 | 0.564 × 10−3 | 0. 709 × 10−3 | 0.275 × 10−3 | 1.468 × 10−2 | 0.840 |

| Reinforced concrete HA-35 (m3) | 4.020 × 10−1 | 2.850 × 10−1 | 1.920 × 10−1 | 1.389 × 10−1 | 6.000 | 6.260 |

| Self-resistant joists (m) | 5.010 × 10−3 | 6.351 × 10−3 | 2.400 × 10−3 | 3.095 × 10−3 | 7.070 × 10−2 | 1.127 |

| Project 14 Scenarios | CF (t CO2/m2) | EF (hag/m2) | WF (hag/m2) | I_CEACE |

|---|---|---|---|---|

| 1 | 0.657 | 0.312 | 16.545 | 0.720 |

| 2 | 0.647 | 0.305 | 16.050 | 0.695 |

| 3 | 0.628 | 0.297 | 19.655 | 0.748 |

| 4 | 0.621 | 0.294 | 25.612 | 0.741 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solís-Guzmán, J.; Garzón-González, P.; González-Vallejo, P.; Marrero, M. Sustainability Evaluation of Residential Buildings Based on the Footprint Family: Application to Case Studies in Andalusia. Buildings 2024, 14, 1131. https://doi.org/10.3390/buildings14041131

Solís-Guzmán J, Garzón-González P, González-Vallejo P, Marrero M. Sustainability Evaluation of Residential Buildings Based on the Footprint Family: Application to Case Studies in Andalusia. Buildings. 2024; 14(4):1131. https://doi.org/10.3390/buildings14041131

Chicago/Turabian StyleSolís-Guzmán, Jaime, Paula Garzón-González, Patricia González-Vallejo, and Madelyn Marrero. 2024. "Sustainability Evaluation of Residential Buildings Based on the Footprint Family: Application to Case Studies in Andalusia" Buildings 14, no. 4: 1131. https://doi.org/10.3390/buildings14041131