Investigation of Waste Paper Cellulosic Fibers Utilization into Cement Based Building Materials

Abstract

:1. Introduction

2. Materials and Methods

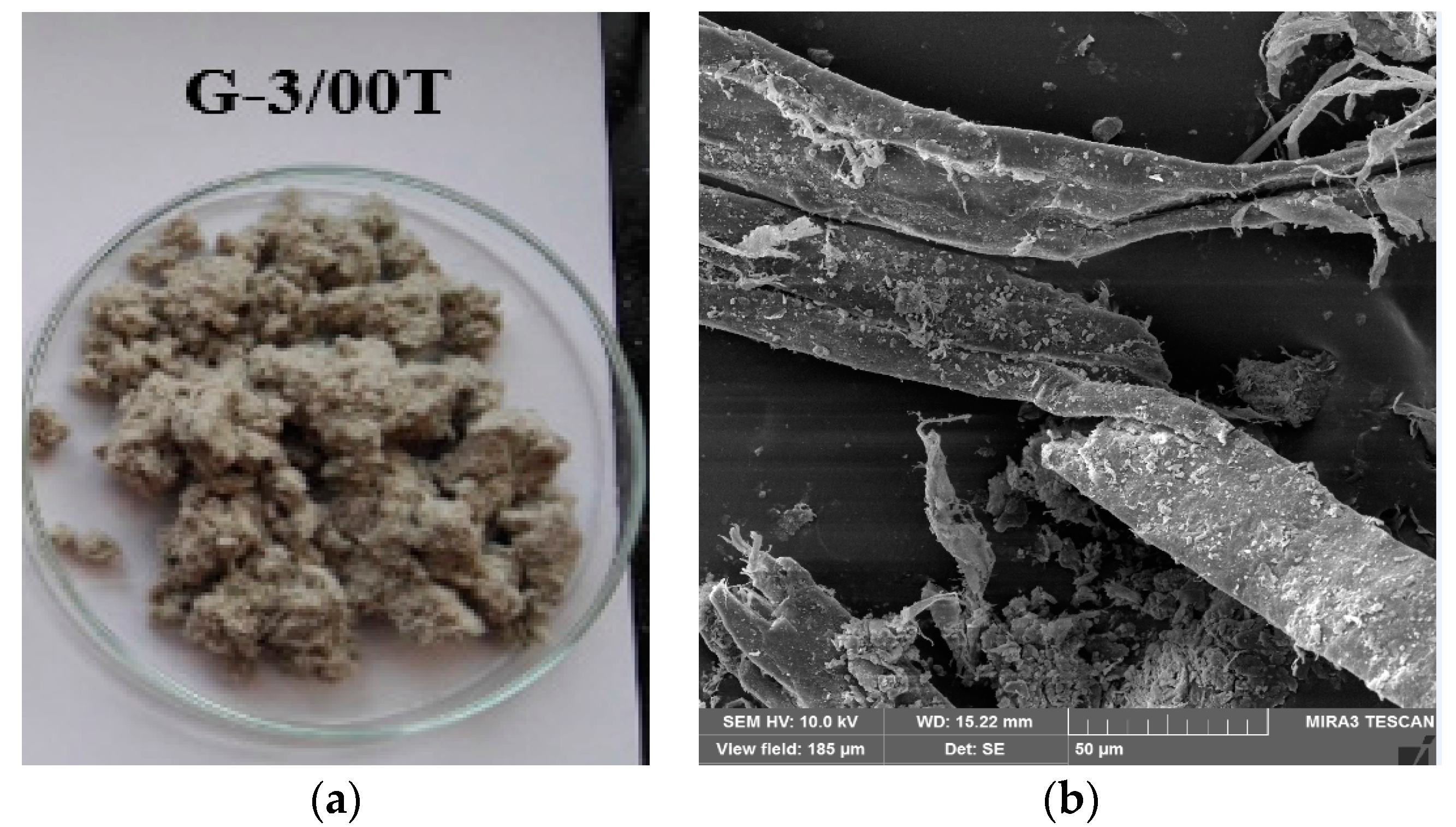

2.1. Materials

2.2. Preparation of Fiber-Reinforced Cement Mortar

2.3. Methods of Testing Prepared Fiber Cement Composite Specimens

3. Results and Discussion

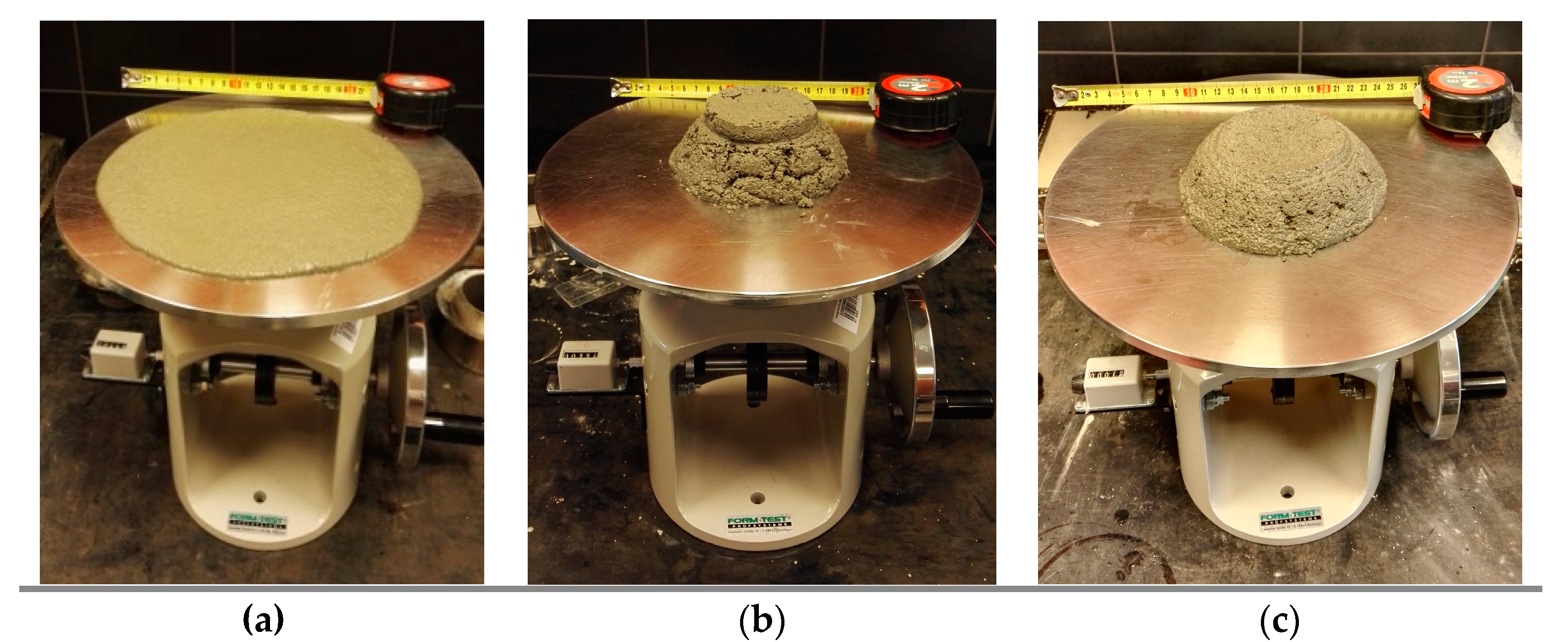

3.1. Flow Behavior of Fiber-Reinforced Cement Mortar

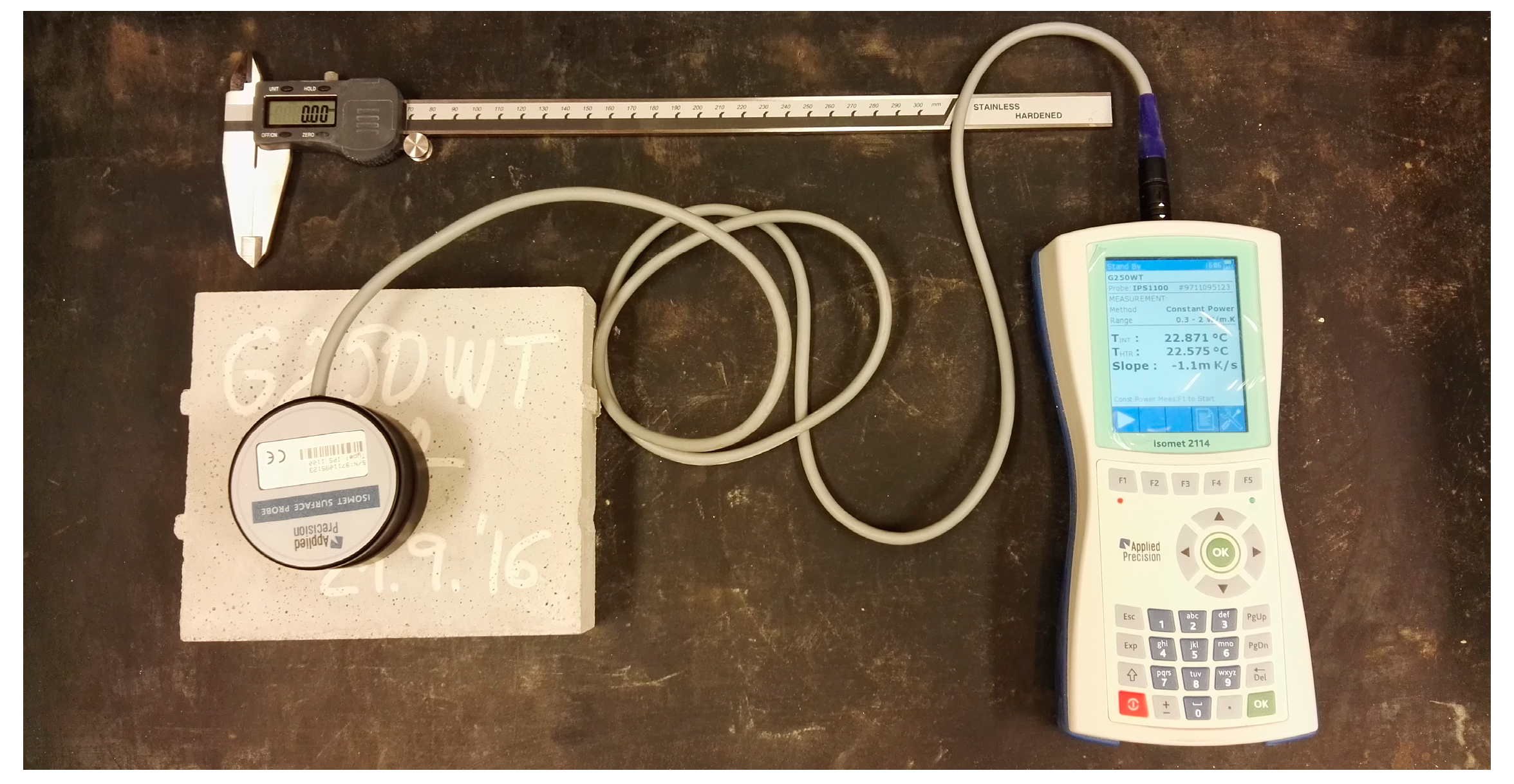

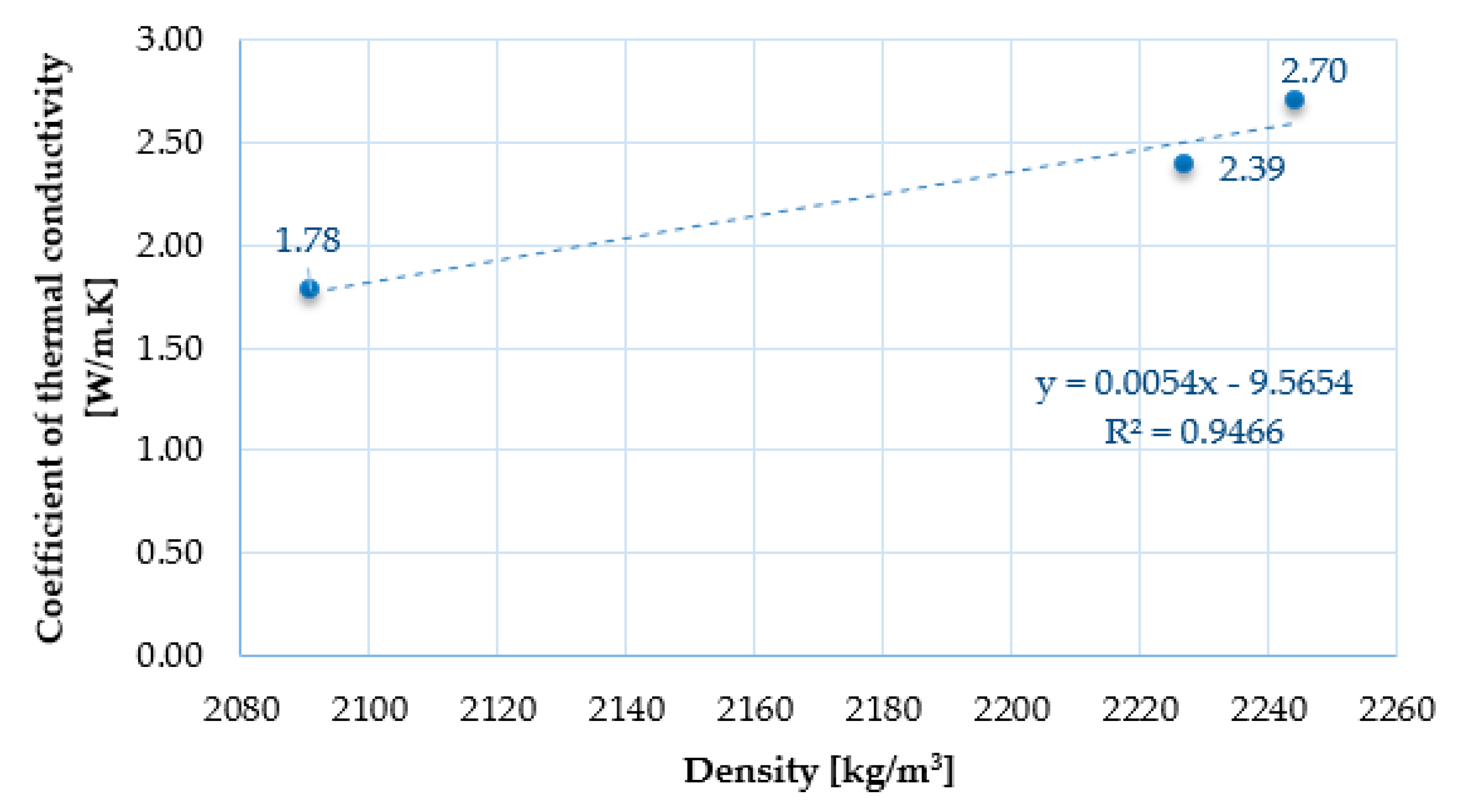

3.2. Density and Thermal Conductivity of Fiber-Reinforced Cement Mortar

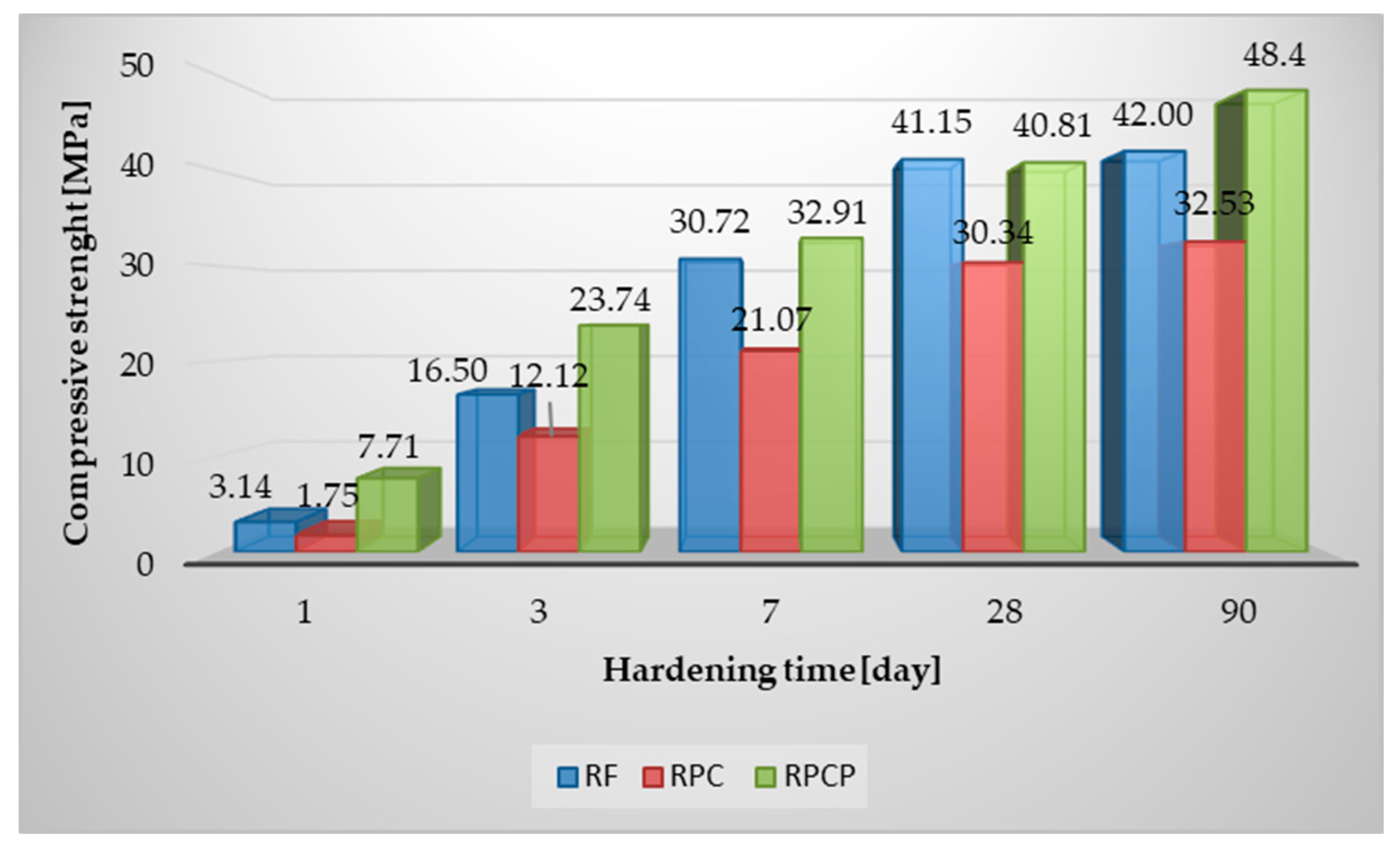

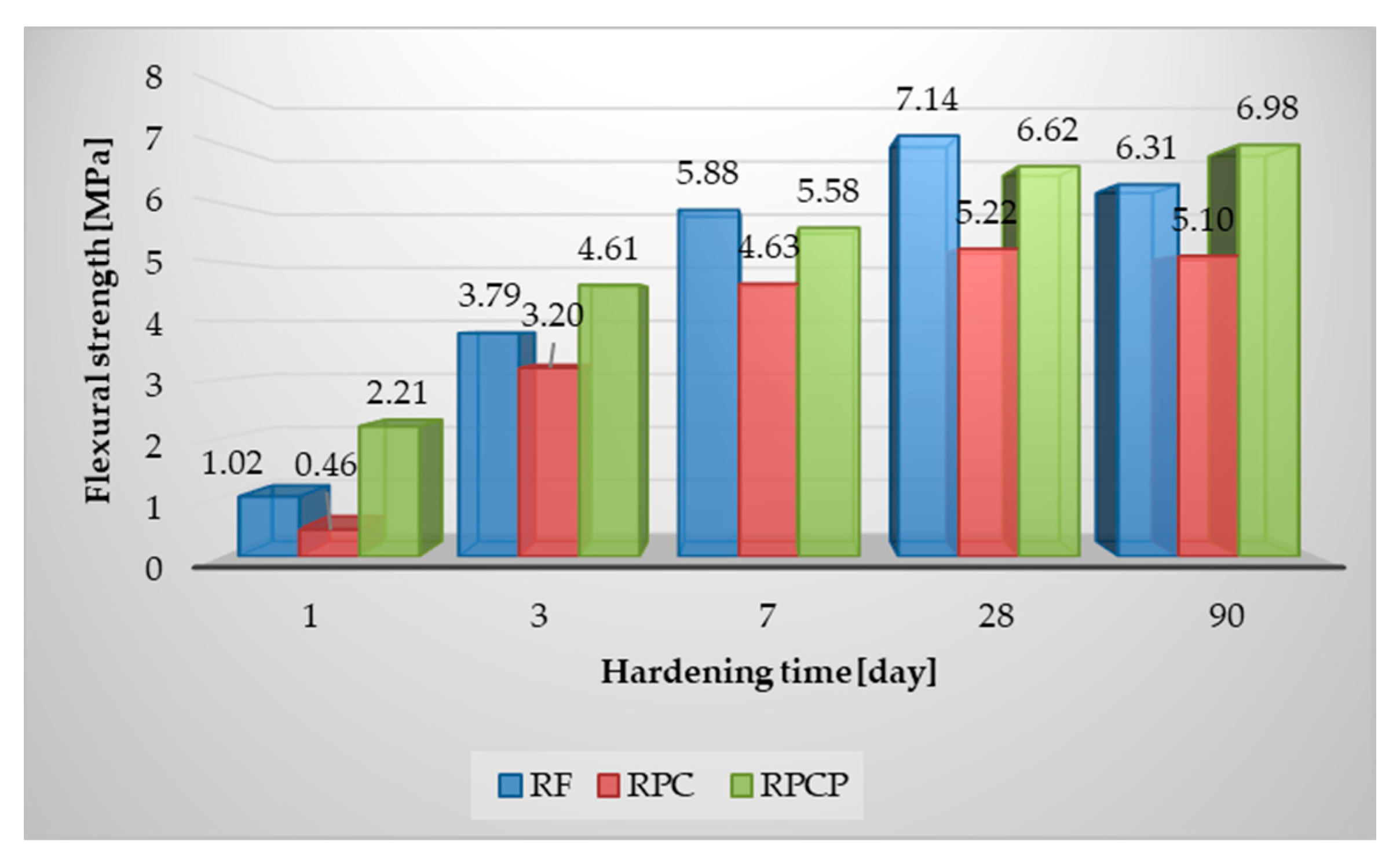

3.3. Mechanical Properties of Fiber-Reinforced Cement Mortar

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gola, L.; Václavík, V.; Valíček, J.; Harničárová, M.; Kušnerová, M.; Dvorský, T. Drainage concrete based on cement composite and industrial waste. Adv. Struct. Mater. 2015, 70, 155–165. [Google Scholar] [CrossRef]

- Václavík, V.; Dvorský, T.; Dirner, V.; Daxner, J.; Šťastný, M. Polyurethane foam as aggregate for thermal insulating mortars and lightweight concrete. Teh. Vjesn. 2012, 19, 665–672. [Google Scholar]

- Vaclavik, V.; Valicek, J.; Novosad, M.; Stankova, H.; Bendova, M.; Daxner, J. Monitoring of deformation of thermal insulating plaster with fillers from recycled polyurethane foam using conventional geodetic methods. In Proceedings of the International Multidisciplinary Scientific GeoConference: SGEM: Surveying Geology & Mining Ecology Management, Albena, Bulgaria, 17–23 June 2012; Volume 4, p. 719. [Google Scholar]

- Stevulova, N.; Vaclavik, V.; Junak, J.; Grul, R.; Bacikova, M. Utilization possibilities of selected waste kinds in building materials preparing. In Proceedings of the 8th International Scientific Conference-SGEM2008, Sofia, Bulgaria, 16–20 June 2008. [Google Scholar]

- Wei, J.A.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Constr. Build. Mater. 2012, 34, 451–456. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Res. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793–803. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Rodrigues Filho, U.P.; Savastano, H.; Bras, J.; Belgacem, M.N.; Lahr, F.R. Cellulose modified fibres in cement based composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- Mármol, G.; Santos, S.F.; Savastano, H.; Borrachero, M.V.; Monzó, J.; Payá, J. Mechanical and physical performance of low alkalinity cementitious composites reinforced with recycled cellulosic fibres pulp from cement kraft bags. Ind. Crop. Prod. 2013, 49, 422–427. [Google Scholar] [CrossRef]

- Anju, T.R.; Ramamurthy, K.; Dhamodharan, R. Surface modified microcrystalline cellulose from cotton as a potential mineral admixture in cement mortar composite. Cem. Concr. Compos. 2016, 74, 147–153. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber-cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Ghavami, K. Bamboo as reinforcement in structural concrete elements. Cem. Concr. Compos. 2005, 27, 637–649. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I.; Hospodarova, V.; Junak, J. Implementation of waste cellulosic fibres into building materials. Chem. Eng. Trans. 2016, 50, 367–372. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Pundienė, I.; Lekūnaitė-Lukošiūnė, L.; Vėjelis, S.; Korjakins, A. Impact of hemp shives aggregate mineralization on physical–mechanical properties and structure of composite with cementitious binding material. Ind. Crop. Prod. 2015, 77, 724–734. [Google Scholar] [CrossRef]

- Cigasova, J.; Stevulova, N.; Schwarzova, I. Innovative Use of Plant Wastes-Hemp Hurds Slices. Chem. Eng. Trans. 2016, 50, 373–378. [Google Scholar] [CrossRef]

- Andiç-Çakir, O.; Sarikanat, M.; Tüfekçi, H.B.; Demirci, C.; Erdogan, Ü.H. Physical and mechanical properties of randomly oriented coir fiber-cementitious composites. Compos. Part B Eng. 2014, 61, 49–54. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Soydan, A.M.; Sari, A.K.; Duymaz, B.; Akdeniz, R.; Tunaboylu, B. Air-cured fiber-cement composite mixtures with different types of cellulose fibers. Adv. Mater. Sci. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Pepe, M.; Martinelli, E.; de Andrade Silva, F.; Toledo Filho, R.D. Influence of natural fibers characteristics on the interface mechanics with cement based matrices. Compos. Part B Eng. 2018, 140, 183–196. [Google Scholar] [CrossRef]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of cellulose fibre on the thermal and mechanical properties of cement paste. In Proceedings of the International RILEM Conference on the use of recycled materials in buildings and structures, Barcelona, Spain, 8–11 November 2004; Volume 2. [Google Scholar]

- De Andrade Silva, F.; Toledo Filho, R.D.; de Almeida Melo Filho, J.; Fairbairn, E.D.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Aciu, C.; Iluţiu–Varvara, D.A.; Cobirzan, N.; Balog, A. Recycling of paper waste in the composition of plastering mortars. Procedia Technol. 2014, 12, 295–300. [Google Scholar] [CrossRef]

- Gomes, L.M.; Aroche, A.; Schafer, M.; Erhart, R.; Moraes, C.A.M.; de Campos Rocha, T.L.A.; Brehm, F.A. Influence of cellulose pulp waste in plastering mortar. Key Eng. Mater. 2015, 634, 222–234. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; D’Shawn, G.T. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber. Cem. Concr. Res. 2016, 81, 94–111. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B.; Al-Kutti, W.A.; Ahmad, S.; Maslehuddin, M. Correlation between compressive strength and certain durability indices of plain and blended cement concretes. Cem. Concr. Compos. 2009, 31, 672–676. [Google Scholar] [CrossRef]

- Silva, F.A.; Melo Filho, J.A.; Toledo Filho, R.D.; Fairbairn, E.M.R. Mechanical behavior and durability of compression moulded sisal fiber cement mortar laminates (SFCML). In Proceedings of the 1st International RILEM Conference on Textile Reinforced Concrete (ICTRC), Aachen, Germany, 5–7 September 2006; RILEM Publications SARL: Paris, France, 2006; pp. 171–180. [Google Scholar]

- Tonoli, G.H.D.; Belgacem, M.N.; Siqueira, G.; Bras, J.; Savastano, H.; Lahr, F.R. Processing and dimensional changes of cement based composites reinforced with surface-treated cellulose fibres. Cem. Concr. Compos. 2013, 37, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Neithalath, N.; Weiss, J.; Olek, J. Acoustic performance and damping behavior of cellulose-cement composites. Cem. Concr. Compos. 2004, 26, 359–370. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Constr. Build. Mater. 2011, 25, 3661–3667. [Google Scholar] [CrossRef]

- STN EN 196-1: 2016. Methods of Testing Cement. Part 1: Determination of Strength; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2016. [Google Scholar]

- STN EN 1008: 2003. Mixing Water Concrete. Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2003. [Google Scholar]

- STN EN 934-2+A1: 2013. Admixtures for Concrete, Mortar and Grout. Part 2: Concrete Admixtures Definitions, Requirements, Conformity, Marking and Labeling; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2013. [Google Scholar]

- STN EN 1015-3/A2: 2007. Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2007. [Google Scholar]

- STN EN 1015-10/A1: 2007. Methods of Test for Mortar for Masonry. Part 10: Determination of Dry Bulk Density of Hardened Mortar; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2007. [Google Scholar]

- STN EN 1015-11/A1: 2007. Methods of Test for Mortar for Masonry. Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2007. [Google Scholar]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Basak, R.K.; Adhikari, B.; Majumder, S.B. Improvement of the mechanical properties of jute fiber reinforced cement mortar: A statistical approach. Constr. Build. Mater. 2013, 38, 776–784. [Google Scholar] [CrossRef]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Onésippe, C.; Passe-Coutrin, N.; Toro, F.; Delvasto, S.; Bilba, K.; Arsène, M.A. Sugar cane bagasse fibres reinforced cement composites: Thermal considerations. Compos. Part A Appl. Sci. Manuf. 2010, 41, 549–556. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Shin, U.C. Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Khedari, J.; Suttisonk, B.; Pratinthong, N.; Hirunlabh, J. New lightweight composite construction materials with low thermal conductivity. Cem. Concr. Compos. 2001, 23, 65–70. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Thermal and mechanical performance of oil palm fiber reinforced mortar utilizing palm oil fly ash as a complementary binder. Constr. Build. Mater. 2016, 126, 476–483. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Effect of superplasticizer on the rheological properties of coir fibre reinforced cement mortar. In Proceedings of the 27th conference on our world in concrete & structures, Singapore, 29–30 August 2002; Singapore Concrete Institute: Singapore, 2002; pp. 489–492. [Google Scholar]

- Shuldyakov, K.; Kramar, L.; Trofimov, B.; Ivanov, I. Superplasticizer effect on cement paste structure and concrete freeze-thaw resistance. AIP Conf. Proc. 2016, 1698, 070011. [Google Scholar] [CrossRef]

- Mohan, R.; Jadhav, V.; Ahmed, A.; Rivas, J.; Kelkar, A. Effect of Plasticizer Additives on the Mechanical Properties of Cement Composite—A Molecular Dynamics Analysis. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2014, 8, 84–88. [Google Scholar]

- Puertas, F.; Santos, H.; Palacios, M.; Martínez-Ramírez, S. Polycarboxylate superplasticiser admixtures: Effect on hydration, microstructure and rheological behaviour in cement pastes. Adv. Cem. Res. 2005, 17, 77–89. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, N.P.; Singh, S.K.; Singh, N.B. Combined effect of sodium sulphate and superplasticizer on the hydration of fly ash blended Portland (R) cement. Mater. Res. 2010, 13, 177–183. [Google Scholar] [CrossRef]

| Characteristic of Cellulosic Fiber | Max. Length (µm) | Bulk Density (kg/m3) | Dry Matter (%) | Ash (%) | Thermal Conductivity λ (W/m∙K) | Volume Heat Capacity × 10−6 (J/m3∙K) | Thermal Diffusivity × 106 (m2/s) |

|---|---|---|---|---|---|---|---|

| G-3/00T | 1200 | 30–50 | 93 | 20 | 0.0595 | 0.1709 | 0.3478 |

| Tested Samples | Flow Diameter Value (mm) |

|---|---|

| RF | 239 |

| RPC | 124 |

| RPCP | 135 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hospodarova, V.; Stevulova, N.; Briancin, J.; Kostelanska, K. Investigation of Waste Paper Cellulosic Fibers Utilization into Cement Based Building Materials. Buildings 2018, 8, 43. https://doi.org/10.3390/buildings8030043

Hospodarova V, Stevulova N, Briancin J, Kostelanska K. Investigation of Waste Paper Cellulosic Fibers Utilization into Cement Based Building Materials. Buildings. 2018; 8(3):43. https://doi.org/10.3390/buildings8030043

Chicago/Turabian StyleHospodarova, Viola, Nadezda Stevulova, Jaroslav Briancin, and Katarina Kostelanska. 2018. "Investigation of Waste Paper Cellulosic Fibers Utilization into Cement Based Building Materials" Buildings 8, no. 3: 43. https://doi.org/10.3390/buildings8030043

APA StyleHospodarova, V., Stevulova, N., Briancin, J., & Kostelanska, K. (2018). Investigation of Waste Paper Cellulosic Fibers Utilization into Cement Based Building Materials. Buildings, 8(3), 43. https://doi.org/10.3390/buildings8030043