Promoting the Circular Economy on an Island: Anaerobic Co-Digestion of Local Organic Substrates as a Possible Renewable Energy Source

Abstract

:1. Introduction

2. Material and Methods

2.1. Local Organic Wastes

- Waste from dairies collected in a dairy farm. Two different dairy wastes were collected: from outdoors places–cow manure 1 (C1)- and from coverage places–cow manure 2 (C2).

- Solid waste from a kitchen of canteens military–air base of Lajes (K).

- Waste from pig farms–pig slurry (P).

- Waste from aviaries industries –bird manure (B). Poultry manure (chickens, geese, turkeys and ducks).

- Sewage sludge from a local wastewater treatment plant –WWTP- (S).

- Waste from a treatment plant of lacteous products, called Pronicol. It was oily lacteous waste from the flotation tank- (O).

2.2. Analytical Determinations

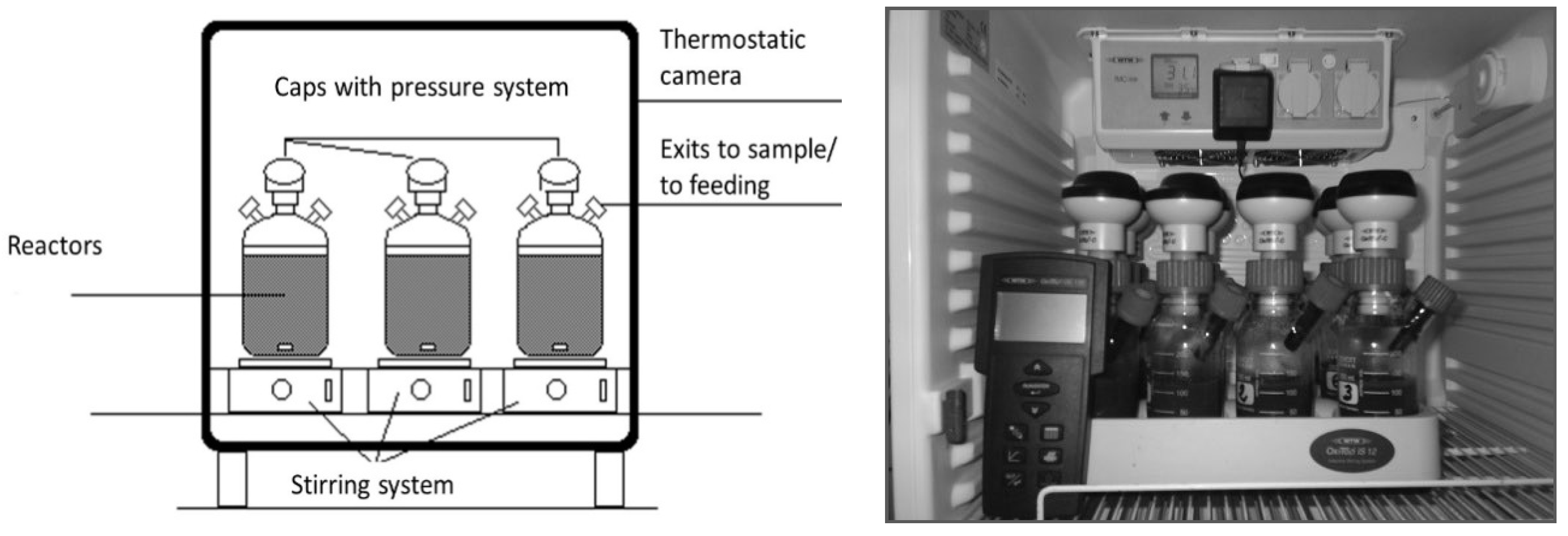

2.3. Experimental Setup

2.3.1. Activity Tests: Specific Methanogenic Activity (SMA)

- (Ac) CH4 is the methanogenic activity (gCOD(mLCH4).g-1VSS.d-1);

- V CH4 is the amount of methane produced (mL);

- t is the reaction time (days);

- X0 is the inoculum concentration (g/mL);

- Vr is the effective volume in the reactors (mL);

- f is the conversion factor that represents the amount of COD in grams per mL.

2.3.2. Biochemical Methane Production (BMP) Tests

2.4. Kinetic Analysis: Modified Gompertz Model

3. Results and Discussion

3.1. Waste Characterisation and Analysis

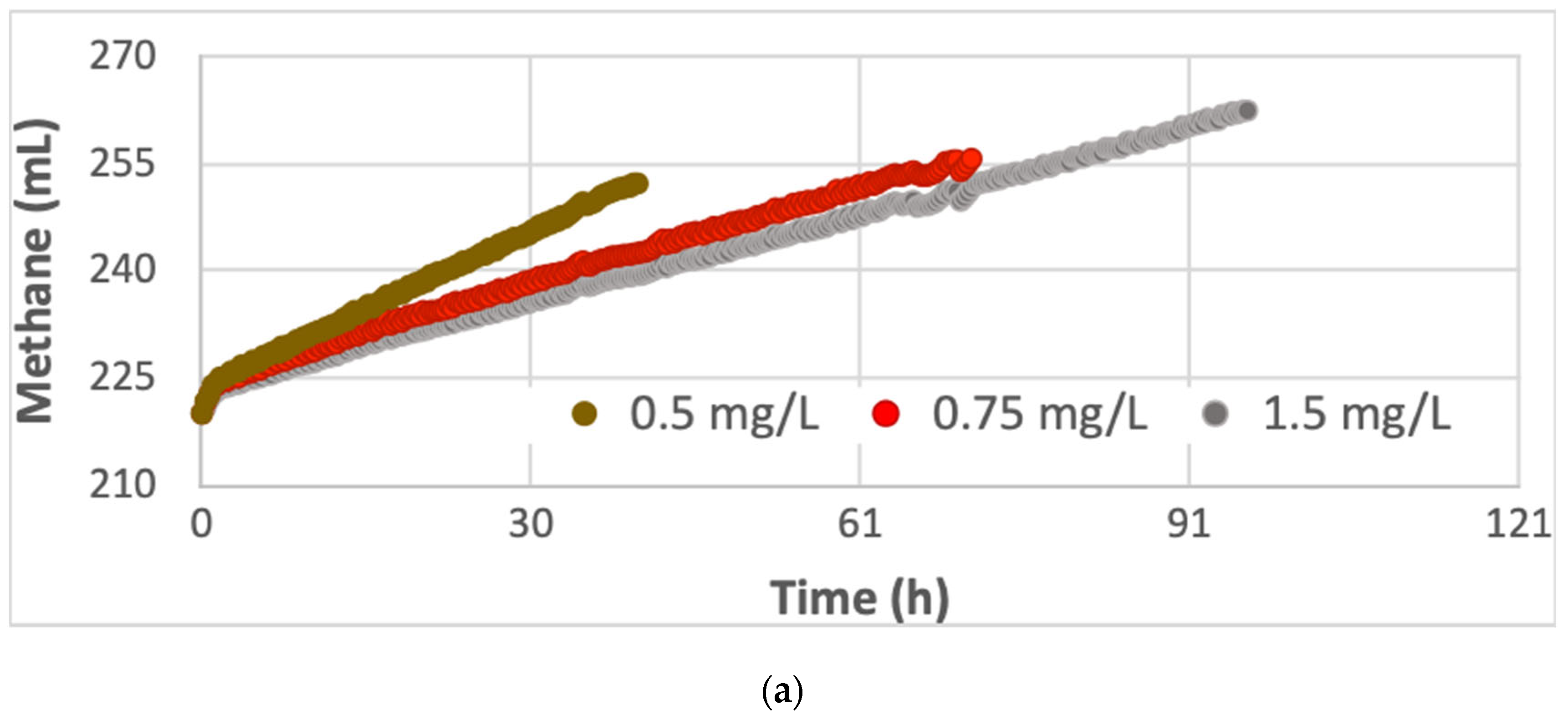

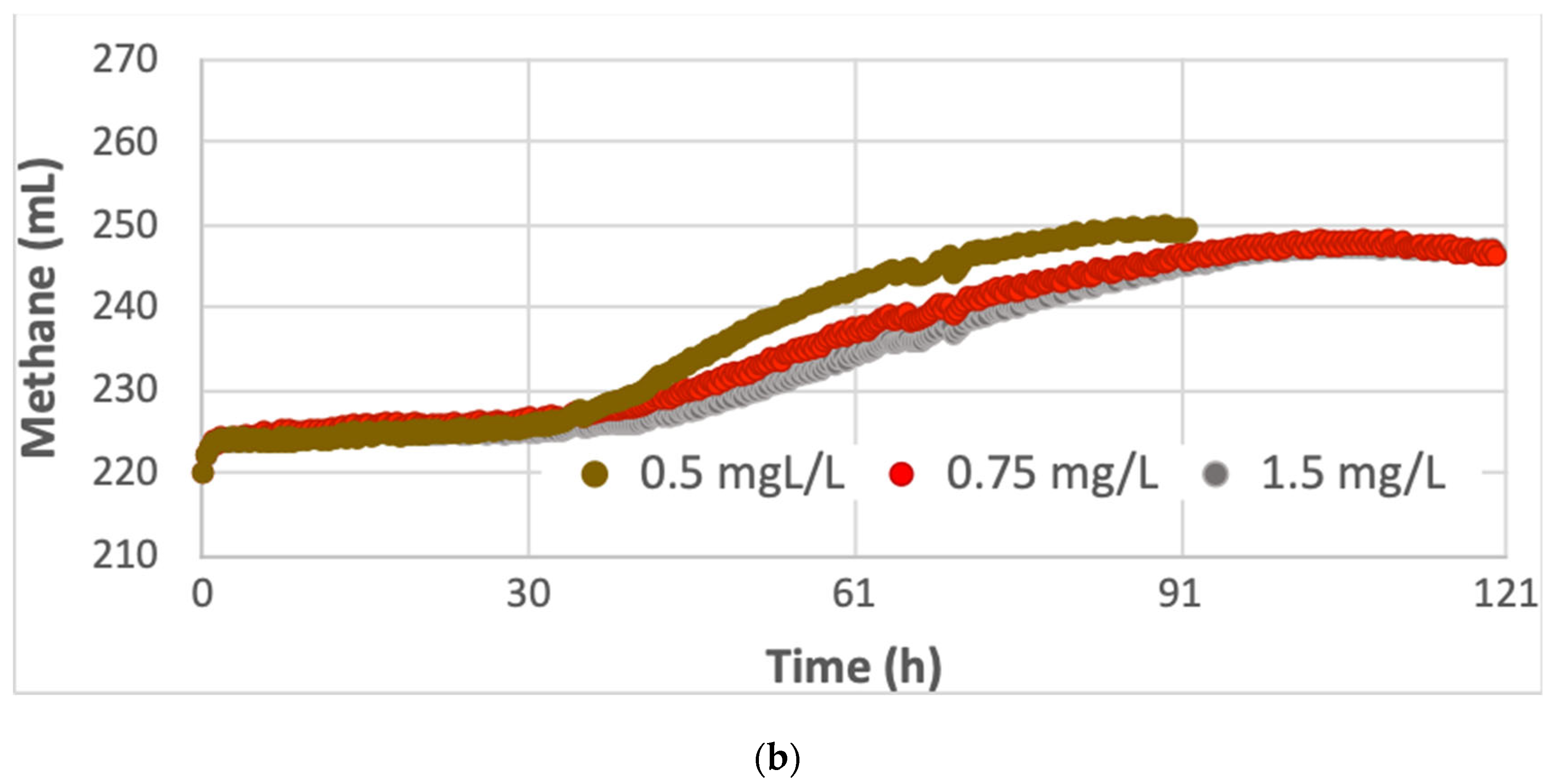

3.2. Specific Methanogenic Activity (SMA)

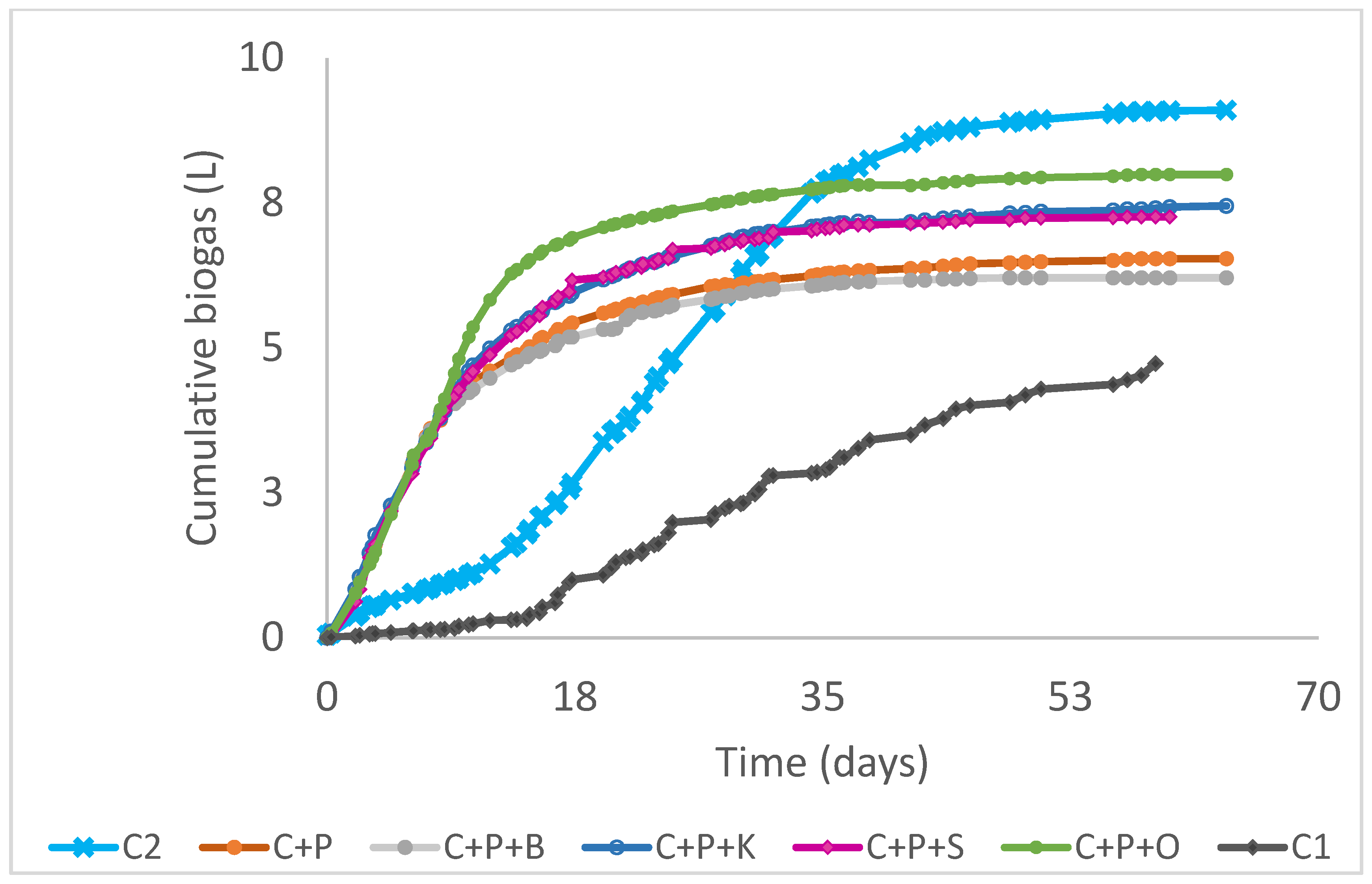

3.3. BMP Tests

3.3.1. Effects on the Digestate: Removal of Organic Material from AcoD of Local Waste

3.3.2. Generation of Biogas from AcoD of Local Wastes

3.3.3. Kinetic and Yield Analysis from AcoD of Local Waste

3.4. Evaluation of Methane Potential on the Island

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tavares, T.; Leon, F.; Vaswani, J.; Peñate, B.; Ramos-Martín, A. Study for Recycling Water Treatment Membranes and Components towards a Circular Economy—Case of Macaronesia Area. Membranes 2022, 12, 970. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wang, C.; Huang, Y.; Lu, H.; Chen, J.; Shi, J.; Jin, H. Heat, Electricity, and Fuel Gas Ploy-Generation System on an Island based on Plastic Waste Gasification in Supercritical Water. ACS Sustain. Chem. Eng. 2022, 10, 13786–13791. [Google Scholar] [CrossRef]

- EU Commission Decision 2011/753/EU of 18 November 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32011D0753 (accessed on 17 January 2023).

- COM 2017. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: The Role of Waste -to -Energy in the Circular Economy. Brussels. 26 enero 2017. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2017:0034:FIN:EN:PDF (accessed on 17 January 2023).

- Zhao, D.; Yan, B.; Liu, C.; Yao, B.; Luo, L.; Yang, Y.; Liu, L.; Wu, F.; Zhou, Y. Mitigation of acidogenic product inhibition and elevated mass transfer by biochar during anaerobic digestion of food waste. Bioresour. Technol. 2021, 338, 125531. [Google Scholar] [CrossRef] [PubMed]

- Mulu, E.; M’Arimi, M.M.; Ramkat, R.C. A review of recent developments in application of low cost natural materials in purification and upgrade of biogas. Renew. Sustain. Energy Rev. 2021, 145, 111081. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Akbar, D.; Rasul, M.G.; Narayanan, R.; Mofijur, M. A review of recent developments in application of low cost natural materials in purification and upgrade of biogas. Fuel 2022, 310, 122346. [Google Scholar] [CrossRef]

- Liew, C.S.; Yunus, N.M.; Chidi, B.S.; Lam, M.K.; Goh, P.S.; Mohamad, M.; Sin, J.C.; Lam, S.M.; Lim, J.W.; Lam, S.S. A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. J. Hazard. Mater. 2022, 423, 126995. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, J.; Lorea, B.; González-Gaitano, G. Biological Solubilisation of Leather Industry Waste in Anaerobic Conditions: Effect of Chromium (III) Presence, Pre-Treatments and Temperature Strategies. Int. J. Mol. Sci. 2022, 23, 13647. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, J.; Perez, M.; Romero, L.I. Comparison of Mesophilic and Thermophilic Dry Anaerobic Digestion of OFMSW: Kinetic Analysis. Chem. Eng. J. 2013, 232, 59–64. [Google Scholar] [CrossRef]

- Kumar, P.; Hussain, A.; Dubey, S.K. Methane formation from food waste by anaerobic digestion. Biomass Convers. Biorefinery 2016, 6, 271–280. [Google Scholar] [CrossRef]

- Ji, C.; Kong, C.X.; Mei, Z.-L.; Li, J. A Review of the Anaerobic Digestion of Fruit and Vegetable Waste. Appl. Biochem. Biotechnol. 2017, 183, 906–922. [Google Scholar] [CrossRef]

- Ofon, U.A.; Ndubuisi-Nnaji, U.U.; Shaibu, S.E.; Fatunla, O.K.; Offiong, N.A.O. Recycling anaerobic digestate enhances the co-digestion potential of agro-industrial residues: Influence of different digestates as sources of microbial inoculum. Environ. Technol. 2021, 43, 4472–4483. [Google Scholar] [CrossRef] [PubMed]

- Ziganshina, E.E.; Ziganshin, A.M. Anaerobic Digestion of Chicken Manure in the Presence of Magnetite, Granular Activated Carbon, and Biochar: Operation of Anaerobic Reactors and Microbial Community Structure. Microorganisms 2022, 10, 1422. [Google Scholar] [CrossRef] [PubMed]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Sung, S.W.; Raskin, L.; Khanal, S.K. Anaerobic co-digestion of various organic wastes: Kinetic modeling and synergistic impact evaluation. Bioresour. Technol. 2022, 343, 126063. [Google Scholar] [CrossRef] [PubMed]

- Benabdallah El Hadj, T.; Astals, S.; Gali, A.; Mace, S.; Mata-Alvarez, J. Ammonia influence in anaerobic digestion of OFMSW. Water Sci. Technol. 2009, 59, 1153. [Google Scholar] [CrossRef]

- Sosnowski, P.; Wieczorek, A.; Ledakowicz, S. Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv. Environ. Res. 2003, 7, 609–616. [Google Scholar] [CrossRef]

- Vedrenne, F.; Béline, F.; Dabert, P.; Bernet, N. The effect of incubation conditions on the laboratory measurement of the methane producing capacity of livestock wastes. Bioresour. Technol. 2008, 99, 146–155. [Google Scholar] [CrossRef]

- De Diego-Díaz, B.; Fernández-Rodríguez, J.; Vitas, A.I.; Peñas, F.J. Biomethanization of solid wastes from the alcoholic beverage industry: Malt and sloe. Kinetic and microbiological analysis. Chem. Eng. J. 2018, 334, 650–656. [Google Scholar] [CrossRef]

- Odejobi, O.J.; Ajala, O.O.; Osuolale, F.N. Anaerobic co-digestion of kitchen waste and animal manure: A review of operating parameters, inhibiting factors, and pretreatment with their impact on process performance. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, M.S.; Romero-Güiza, X.; Fonoll, M.; Peces, S.; Astals. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef]

- Azores Regional Statistical Service. 2022. Available online: https://srea.azores.gov.pt/default.aspx?lang_id=1 (accessed on 1 December 2022).

- Adebayo, A.O.; Jekayinfa, S.O.; Ahmed, N.A.; Ogunkunle, O. Effect of organic loading rate on biogas yields of pig slurry in a continuously stirred tank reactor at mesophilic temperature. Procedia Manuf. 2019, 35, 337–342. [Google Scholar] [CrossRef]

- Bhatnagar, N.; Ryan, D.; Murphy, R.; Enright, A.M. A comprehensive review of green policy, anaerobic digestion of animal manure and chicken litter feedstock potential—Global and Irish perspective. Renew. Sustain. Energy Rev. 2022, 154, 111884. [Google Scholar] [CrossRef]

- APHA; AWWA; WPCF. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Field, J.A.; Leyendeckers, M.J.H.; Sierra-Alvarez, R.; Lettinga, G.; Habets, L.H.A. The methanogenic toxicity of bark tannins and the anaerobic biodegradability of water soluble bark matter. Water Sci. Technol. 1988, 20, 219–240. [Google Scholar] [CrossRef]

- Hussain, A.; Dubey, S.K. Specific methanogenic activity test for anaerobic degradation of influents. Appl. Water Sci. 2017, 7, 535–542. [Google Scholar] [CrossRef]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef] [PubMed]

- de Quadros, T.C.F.; Sicchieri, I.M.; Perin JK, H.; Challiol, A.Z.; Bortoloti, M.A.; Fernandes, F.; Kuroda, E.K. Valorization of Fruit and Vegetable Waste by Anaerobic Digestion: Definition of Co-substrates and Inoculum. Waste Biomass Valor. 2022. [Google Scholar] [CrossRef]

- Ismail, A.; Kakar, F.L.; Elbeshbishy, E.; Nakhla, G. Combined thermal hydrolysis pretreatment and anaerobic co-digestion of waste activated sludge and food waste. Renew. Energy 2022, 195, 528–539. [Google Scholar] [CrossRef]

- Sedighi, A.; Karrabi, M.; Shahnavaz, B.; Mostafavinezhad, M. Bioenergy Production from the Organic Fraction of Municipal Solid Waste and Sewage Sludge Using Mesophilic Anaerobic Co-Digestion: An Experimental and Kinetic Modeling Study. Renew. Sustain. Energy Rev. 2022, 153, 111797. [Google Scholar] [CrossRef]

- Renggaman, A.; Choi, H.L.; Sudiarto, S.I.A.; Febrisiantosa, A.; Ahn, D.H.; Choung, Y.W.; Suresh, A. Biochemical Methane Potential of Swine Slaughter Waste, Swine Slurry, and Its Codigestion Effect. Energies 2021, 14, 7103. [Google Scholar] [CrossRef]

- Rasit, N.; Idris, A.; Harun, R.; Wan, W.A.; Ghani, K. Effects of lipid inhibition on biogas production of anaerobic digestion from oily effluents and sludges: An overview. Renew. Sustain. Energy Rev. 2015, 45, 351–358. [Google Scholar] [CrossRef]

- Akyol, Ç. In search of the optimal inoculum to substrate ratio during anaerobic co-digestion of spent coffee grounds and cow manure. Waste Manag. Res. 2020, 38, 1278–1283. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Cao, X.; Xiao, Y.; Wei, X.; Wu, S.; Zhu, J. Start-up of co-digestion of poultry litter and wheat straw in anaerobic sequencing batch reactor by gradually increasing organic loading rate: Methane production and microbial community analysis. Bioresour. Technol. 2022, 354, 127232. [Google Scholar] [CrossRef] [PubMed]

- Xing, B.-S.; Tang, X.-F.; Wang, R.; Cao, S.; Wen, J.; Zhang, Y.; Chang, X.-L.; Wang, X.C.; Chen, R. Comparative study of the effect of loading increments on the mesophilic codigestion of waste activated sludge and food waste: Reactor performance, stability analysis, and microbial community. Chemosphere 2022, 308 Pt 1, 136308. [Google Scholar] [CrossRef] [PubMed]

- Zhong, M.; Yang, D.; Liu, R.; Ding, Y.; Dai, X. Effects of hydrothermal treatment on organic compositions, structural properties, dewatering and biogas production of raw and digested sludge. Sci. Total Environ. 2022, 848, 157618. [Google Scholar] [CrossRef]

- Agabo-García, C.; Pérez, M.; Solera, R. Adaptation of thermophilic sludge-inoculum to co-digestion with Sherry-wine distillery wastewater. Biomass Bioenergy 2020, 139, 105628. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, Y.; Song, A.; Wang, L.; Shen, C.; Gui, Z.; Zhang, Q.; Cao, J. Efficient short-chain fatty acids recovery from anaerobic fermentation of wine vinasse and waste activated sludge and the underlying mechanisms. Biochem. Eng. J. 2019, 145, 18–26. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, P.; Zhang, G.; Wang, Y.; Yang, A. Degradation properties of protein and carbohydrate during sludge anaerobic digestion. Bioresour. Technol. 2015, 192, 126–130. [Google Scholar] [CrossRef]

- Awais, M.; Alvarado-Morales, M.; Tsapekos, P.; Gulfraz, M.; Angelidaki, I. Methane production and kinetic modeling for co-digestion of manure with lignocellulosic residues. Energy Fuels 2016, 30, 10516–10523. [Google Scholar] [CrossRef]

- Moller, H.B.; Sommer, S.G.; Ahring, B.K. Methane productivity of manure, straw and solid fractions of manure. Biomass Bioenergy 2004, 26, 485–495. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Tyagi, B.; Vijay, V.K.; Vijay, V.; Thakur, I.S.; Kamyab, H.; Nguyen, D.D.; Kumar, A. Advances in biogas valorization and utilization systems: A comprehensive review. J. Clean. Prod. 2020, 273, 123052. [Google Scholar] [CrossRef]

- Vijay, V.; Subbarao, P.M.V.; Chandra, R. Identification of potential waste seeds of wildly growing tree species for the production of biogas. Environ. Sci. Pollut. Res. 2020, 27, 14515–14528. [Google Scholar] [CrossRef] [PubMed]

| Reactors | Name | Vwater (mL) | Vwaste (mL) | Vcow manure 1 (mL) (C1) | Vcow manure 2 (mL) (C2) * | Vpig slurry (mL) (P) * | Vbird manure (mL) (B) * | Vkitchen waste (mL) (K) | Vsewage sludge (mL) (S) | Voily lacteous waste (mL) (O) | TS (%) | VS (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | C2 | 200 | 600 | - | 600 | - | - | - | - | 5.01 | 4.32 | |

| 3/4 | C+P | 200 | 600 | - | 330 | 270 | - | - | - | 4.35 | 3.73 | |

| 5/6 | C+P+B | 150 | 650 | - | 330 | 270 | 50 | - | - | 5.16 | 4.99 | |

| 7/8 | C+P+K | 150 | 650 | - | 330 | 270 | - | 50 | - | - | 4.82 | 4.26 |

| 9/10 | C+P+S | 150 | 650 | - | 330 | 270 | - | 50 | 4.65 | 3.74 | ||

| 11/12 | C+P+O | 150 | 650 | - | 330 | 270 | - | - | 50 | 4.85 | 4.16 | |

| 13/14 | C1 | 200 | 600 | 600 | - | - | - | - | - | 4.89 | 4.64 |

| Cow Manure 1 (C1) * | Cow Manure 2 (C2) | Pig Slurry (P) * | Bird Manure (B) | Sewage Sludge (S) | Oily Lacteous Waste (O) | Kitchen Waste (K) | |

|---|---|---|---|---|---|---|---|

| COD (g/L) | 162 ± 9 | 101 ± 6 | 47 ± 4 | 215 ± 14 | 138 ± 8 | 335 ± 19 | 228 ± 12 |

| TOCs(g/L) | 14.12 ± 1.9 | 8.18 ± 1.2 | 4.26 ± 0.9 | 12.59 ± 2.1 | 22.16 ± 2.9 | 27.51 ± 2.4 | 20.35 ± 1.5 |

| TKN (mg/L) | 90 ± 4 | 78 ± 5 | 78 ± 4 | 179 ± 10 | 213 ± 13 | 123 ± 9 | 790 ± 44 |

| Proteins (mg/L) | 560 ± 29 | 409 ± 20 | 490 ± 29 | 1120 ± 53 | 1330 ± 69 | 770 ± 36 | 4935 ± 249 |

| Phosphorous (mg/L) | 908 ± 48 | 606 ± 35 | 1282 ± 76 | 310 ± 17 | 1741 ± 89 | 2190 ± 115 | 2743 ± 133 |

| TS (%) | 15.2 ± 0.8 | 11.1 ± 0.7 | 7.2 ± 0.4 | 66.1 ± 3.6 | 10.0 ± 0.9 | 8.9 ± 0.6 | 27.3 ± 1.8 |

| VS (%) | 12.1 ± 0.6 | 8.8 ± 0.3 | 5.0 ± 0.4 | 51.5 ± 2.3 | 9.0 ± 0.8 | 8.1 ± 0.4 | 26.3 ± 1.7 |

| Moisture (%) | 84.8 ± 4.5 | 88.9 ± 4.31 | 92.8 ± 4.0 | 33.9 ± 1.8 | 90.0 ± 4.6 | 91.1 ± 4.8 | 72.7 ± 3.4 |

| Substrate Concentration (g/L Acetate) | Cow Manure | Pig Slurry | ||

|---|---|---|---|---|

| Specific Metanogenic Activity –SMA-(g-COD(CH4)/(g-VSS.d)) | Slope Linear Regression (mL/h) | Specific Metanogenic Activity –SMA-(g-COD(CH4)/(g-VSS.d)) | Slope Linear Regression (mL/h) | |

| 0.5 | 0.109 ± 0.004 | 0.7294 | 0.080 ± 0.008 | 0.4314 |

| 0.75 | 0.112 ± 0.013 | 0.4513 | 0.089 ± 0.007 | 0.3310 |

| 1.5 | 0.111 ± 0.072 | 0.4056 | 0.087 ± 0.004 | 0.3626 |

| Cow Manure 2 | Cow Manure+Pig slurry | Cow Manure+Pig slurry+Bird manure | Cow Manure+Pig Slurry+Kitchen Waste | Cow Manure+Pig Slurry+Sewage Sludge | Cow Manure+Pig Slurry+Oily Lacteous Waste | Cow Manure 1 | |

|---|---|---|---|---|---|---|---|

| C2 | C+P | C+P+B | C+P+K | C+P+S | C+P+O | C1 | |

| Initial Characterisation | |||||||

| TOCs(g/L) | 4.09 ± 0.56 | 2.95 ± 0.21 | 3.91 ± 0.68 | 2.99 ± 0.59 | 3.03 ± 0.50 | 4.89 ± 0.71 | 2.98 ± 0.16 |

| TKN (mg/L) | 34 ± 5 | 39 ± 4 | 34 ± 3 | 39 ± 4 | 39 ± 4 | 39 ± 4 | 31 ± 3 |

| Proteins (mg/L) | 210 ± 15 | 245 ± 25 | 210 ± 21 | 245 ± 20 | 245 ± 15 | 245 ± 25 | 193 ± 18 |

| Phosphorous (mg/L) | 227.3 ± 28.2 | 341.3 ± 16.3 | 360.7 ± 25.3 | 512.8 ± 18.9 | 450.1 ± 21.2 | 478.2 ± 38.0 | 337.5 ± 25.9 |

| COD (g/L) | 40.00 ± 6.20 | 34.55 ± 7.50 | 37.27 ± 5.90 | 34.55 ± 3.60 | 45.45 ± 4.50 | 48.45 ± 7.90 | 56.52 ± 8.90 |

| TS (%) | 5.01 ± 1.10 | 4.35 ± 0.90 | 5.16 ± 1.20 | 4.91 ± 0.95 | 4.65 ± 1.05 | 4.85 ± 0.95 | 4.89 ± 1.25 |

| VS (%) | 4.32 ± 0.85 | 3.73 ± 0.99 | 4.99 ± 1.11 | 4.26 ± 1.06 | 3.74 ± 0.60 | 4.16 ± 0.51 | 4.64 ± 0.39 |

| Organic Removal | |||||||

| CODfinal (g/L) | 12.73 | 11.27 | 12.18 | 11.67 | 10.18 | 15.09 | 16.55 |

| Removal COD (%) | 68.18 | 67.37 | 67.32 | 67.37 | 77.60 | 66.80 | 70.88 |

| TSfinal (%) | 3.64 | 2.74 | 3.34 | 3.28 | 3.76 | 3.04 | 3.16 |

| Removal TS (%) | 27.35 | 37.01 | 35.27 | 27.62 | 19.14 | 37.32 | 35.38 |

| VSfinal (%) | 3.14 | 2.35 | 3.23 | 2.89 | 3.03 | 2.61 | 3.00 |

| Removal VS (%) | 27.31 | 37.00 | 35.27 | 32.16 | 18.98 | 37.26 | 35.34 |

| Cow Manure 2 | Cow Manure+Pig Slurry | Cow Manure+Pig Slurry+Bird Manure | Cow Manure+Pig Slurry+Kitchen Waste | Cow Manure+Pig Slurry+Sewage Sludge | Cow Manure+Pig Slurry+Oily Lacteous Waste | Cow Manure 1 | |

|---|---|---|---|---|---|---|---|

| C2 | C+P | C+P+B | C+P+K | C+P+S | C+P+O | C1 | |

| Biogas Production (L) | 9.10 ± 0.80 | 6.54 ± 0.61 | 6.21 ± 0.57 | 7.45 ± 0.39 | 7.26 ± 0.72 | 7.99 ± 0.63 | 4.73 ± 0.41 |

| CH4Production (L) | 6.44 ± 0.49 | 4.70 ± 0.56 | 4.44 ± 0.38 | 5.22 ± 0.60 | 4.99 ± 0.51 | 5.86 ± 0.62 | 3.40 ± 0.240 |

| CH4(%) | 70.8 | 71.9 | 71.5 | 70.1 | 68.7 | 73.3 | 71.9 |

| Specific Methane Yield (L/g CODrem) | 0.236 | 0.202 | 0.177 | 0.224 | 0.141 | 0.193 | 0.084 |

| Specific Methane Yield (L/g VSadd) | 0.184 | 0.132 | 0.126 | 0.151 | 0.147 | 0.162 | 0.096 |

| Kinetic Parameters | |||||||

| C2 | C+P | C+P+B | C+P+K | C+P+S | C+P+O | C1 | |

| Rmax((L-Biogas/g-VSadded day) | 0.009 ± 0.00019 | 0.014 ± 0.00046 | 0.010 ± 0.00036 | 0.012 ± 0.00032 | 0.014 ± 0.00038 | 0.017 ± 0.00034 | 0.003 ± 0.00004 |

| L (days) | 8.31 ± 0.29 | −0.73 ± 0.28 | −0.83 ± 0.30 | −0.69 ± 0.25 | −0.23 ± 0.23 | 0.9 ± 0.14 | 11.84 ± 0.247 |

| P (L-Biogas/g-Vsadded) | 0.281 ± 0.0031 | 0.210 ± 0.0013 | 0.151 ± 0.0010 | 0.205 ± 0.0011 | 0.236 ± 0.0012 | 0.233 ± 0.00079 | 0.132 ± 0.0014 |

| R2 | 0.9942 | 0.9850 | 0.9822 | 0.9899 | 0.9896 | 0.9954 | 0.9979 |

| Units | Biogas Production 70% CH4 (L/unit.day) | Total Biogas 70% CH4 (m3/day) | Energy (kWh/day) | ||

|---|---|---|---|---|---|

| Cow Manure | Cows | 550 | 7700 | ||

| Pig Slurry | Pigs | 1500 | 100 | 150 | 889 |

| Bird Manure | Birds | 1000 | 2.5 | 3 | 15 |

| Municipal Solid Waste (MSW) | People | 35 | 1921 | ||

| Total | --- | --- | --- | 9773 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Rodríguez, J.; Di Berardino, M.; Di Berardino, S. Promoting the Circular Economy on an Island: Anaerobic Co-Digestion of Local Organic Substrates as a Possible Renewable Energy Source. Microorganisms 2023, 11, 285. https://doi.org/10.3390/microorganisms11020285

Fernández-Rodríguez J, Di Berardino M, Di Berardino S. Promoting the Circular Economy on an Island: Anaerobic Co-Digestion of Local Organic Substrates as a Possible Renewable Energy Source. Microorganisms. 2023; 11(2):285. https://doi.org/10.3390/microorganisms11020285

Chicago/Turabian StyleFernández-Rodríguez, Juana, Mónica Di Berardino, and Santino Di Berardino. 2023. "Promoting the Circular Economy on an Island: Anaerobic Co-Digestion of Local Organic Substrates as a Possible Renewable Energy Source" Microorganisms 11, no. 2: 285. https://doi.org/10.3390/microorganisms11020285