Organic Wastes as Feedstocks for Non-Conventional Yeast-Based Bioprocesses

Abstract

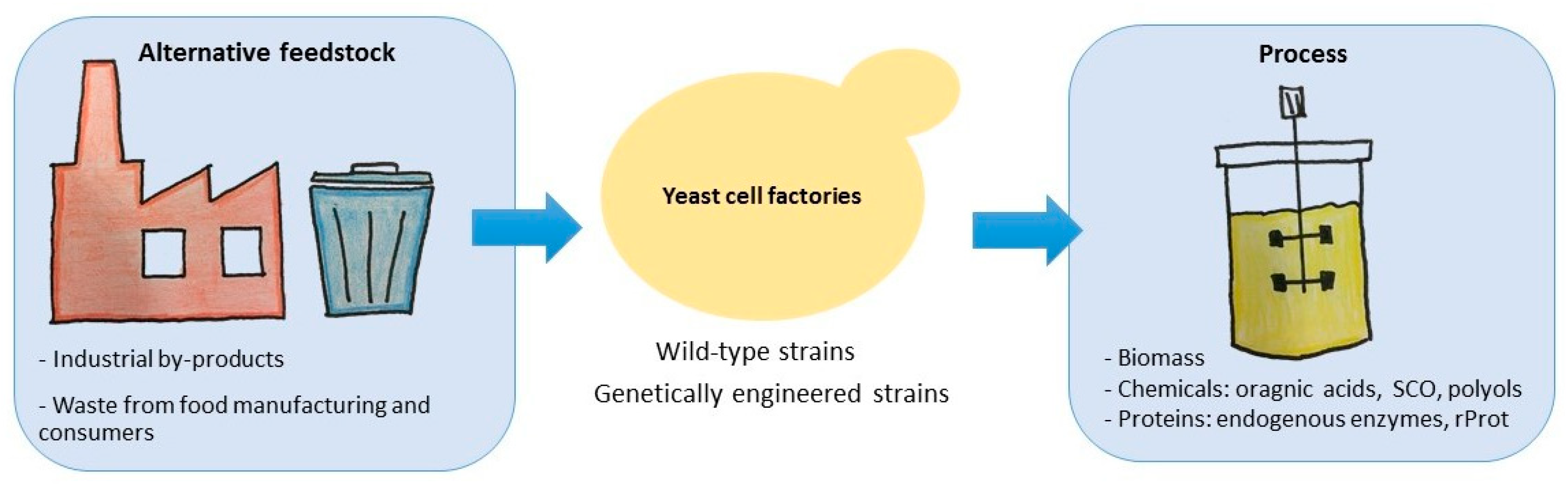

:1. Introduction

2. Hydrophobic Substrates

2.1. Pure Oil

2.2. Used Oil and Industrial Fats

2.3. Oily Wastewater

3. Crude Glycerol

4. Alternative Saccharides

4.1. Monosaccharides: Xylose and Galactose

4.2. Disaccharides and Polysaccharides

4.2.1. Inulin

4.2.2. Molasses (Sucrose)

4.2.3. Recalcitrant Plant Components

5. Food Wastes

6. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent Trends in the Pretreatment of Lignocellulosic Biomass for Value-Added Products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Takai, H.; Iwama, R.; Kobayashi, S.; Horiuchi, H.; Fukuda, R.; Ohta, A. Construction and characterization of a Yarrowia lipolytica mutant lacking genes encoding cytochromes P450 subfamily 52. Fungal Genet. Biol. 2012, 49, 58–64. [Google Scholar] [CrossRef]

- Fickers, P.; Benetti, P.H.; Waché, Y.; Marty, A.; Mauersberger, S.; Smit, M.S.; Nicaud, J.M. Hydrophobic substrate utilisation by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res. 2005, 5, 527–543. [Google Scholar] [CrossRef] [PubMed]

- Haddouche, R.; Delessert, S.; Sabirova, J.; Neuvéglise, C.; Poirier, Y.; Nicaud, J.-M. Roles of multiple acyl-CoA oxidases in the routing of carbon flow towards β-oxidation and polyhydroxyalkanoate biosynthesis in Yarrowia lipolytica. FEMS Yeast Res. 2010, 10, 917–927. [Google Scholar] [CrossRef]

- Ledesma-Amaro, R.; Lazar, Z.; Rakicka, M.; Guo, Z.; Fouchard, F.; Coq, A.-M.C.-L.; Nicaud, J.-M. Metabolic engineering of Yarrowia lipolytica to produce chemicals and fuels from xylose. Metab. Eng. 2016, 38, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, G.M.; Hussain, M.S.; Gambill, L.; Gao, D.; Yaguchi, A.; Blenner, M. Engineering xylose utilization in Yarrowia lipolytica by understanding its cryptic xylose pathway. Biotechnol. Biofuels 2016, 9, 149. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Mawgoud, A.M.; Markham, K.A.; Palmer, C.M.; Liu, N.; Stephanopoulos, G.; Alper, H.S. Metabolic engineering in the host Yarrowia lipolytica. Metab. Eng. 2018, 50, 192–208. [Google Scholar] [CrossRef]

- Markham, K.A.; Alper, H.S. Synthetic Biology Expands the Industrial Potential of Yarrowia lipolytica. Trends Biotechnol. 2018, 36, 1085–1095. [Google Scholar] [CrossRef]

- Cybulski, K.; Tomaszewska-Hetman, L.; Rakicka, M.; Juszczyk, P.; Rywińska, A. Production of pyruvic acid from glycerol by Yarrowia lipolytica. Folia Microbiol. Praha 2019, 1–12. [Google Scholar] [CrossRef]

- Market Research and Global Citric Acid Markets Report. 2011–2018 & 2019–2024. Available online: https://www.prnewswire.com/news-releases/global-citric-acid-markets-report-2011-2018--2019-2024-300814817.html (accessed on 24 July 2019).

- Kamzolova, S.V.; Dedyukhina, E.G.; Samoilenko, V.A.; Lunina, J.N.; Puntus, I.F.; Allayarov, R.L.; Chiglintseva, M.N.; Mironov, A.A.; Morgunov, I.G. Isocitric acid production from rapeseed oil by Yarrowia lipolytica yeast. Appl. Microbiol. Biotechnol. 2013, 97, 9133–9144. [Google Scholar] [CrossRef] [PubMed]

- Darvishi, F.; Nahvi, I.; Zarkesh-Esfahani, H.; Momenbeik, F. Effect of plant oils upon lipase and citric acid production in Yarrowia lipolytica yeast. J. Biomed. Biotechnol. 2009, 2009, 562943. [Google Scholar] [CrossRef] [PubMed]

- Venter, T.; Kock, J.L.F.; Botes, P.J.; Smit, M.S.; Hugo, A.; Joseph, M. Acetate Enhances Citric Acid Production by Yarrowia lipolytica When Grown on Sunflower Oil. Syst. Appl. Microbiol. 2004, 27, 135–138. [Google Scholar] [CrossRef] [PubMed]

- Kamzolova, S.V.; Allayarov, R.K.; Lunina, J.N.; Morgunov, I.G. The effect of oxalic and itaconic acids on threo-Ds-isocitric acid production from rapeseed oil by Yarrowia lipolytica. Bioresour. Technol. 2016, 206, 128–133. [Google Scholar] [CrossRef] [PubMed]

- Holz, M.; Förster, A.; Mauersberger, S.; Barth, G. Aconitase overexpression changes the product ratio of citric acid production by Yarrowia lipolytica. Appl. Microbiol. Biotechnol. 2009, 81, 1087–1096. [Google Scholar] [CrossRef] [PubMed]

- Kamzolova, S.V.; Morgunov, I.G. α-Ketoglutaric acid production from rapeseed oil by Yarrowia lipolytica yeast. Appl. Microbiol. Biotechnol. 2013, 97, 5517–5525. [Google Scholar] [CrossRef]

- Grzesiak, P.; Słupecka-Ziemilska, M.; Woliński, J. The biological role of a-ketoglutaric acid in physiological processes and its therapeutic potential. Dev. Period. Med. 2016, 20, 61–67. [Google Scholar] [PubMed]

- Kamzolova, S.V.; Vinokurova, N.G.; Dedyukhina, E.G.; Samoilenko, V.A.; Lunina, J.N.; Mironov, A.A.; Allayarov, R.K.; Morgunov, I.G. The peculiarities of succinic acid production from rapeseed oil by Yarrowia lipolytica yeast. Appl. Microbiol. Biotechnol. 2014, 98, 4149–4157. [Google Scholar] [CrossRef]

- Fickers, P.; Marty, A.; Nicaud, J.M. The lipases from Yarrowia lipolytica: Genetics, production, regulation, biochemical characterization and biotechnological applications. Biotechnol. Adv. 2011, 29, 632–644. [Google Scholar] [CrossRef]

- Fickers, P.; Le Dall, M.T.; Gaillardin, C.; Thonart, P.H.; Nicaud, J.M. New disruption cassettes for rapid gene disruption and marker rescue in the yeast Yarrowia lipolytica. J. Microbiol. Methods 2003, 55, 727–737. [Google Scholar] [CrossRef]

- Fickers, P.; Destain, J.; Thonart, P. Improvement of Yarrowia lipolytica lipase production by fed-batch fermentation. J. Basic Microbiol. 2008, 48, 1–4. [Google Scholar]

- Destain, J.; Fickers, P.; Weekers, F.; Moreau, B.; Thonart, P. Utilisation of methyloleate in production of microbial lipase. Appl. Biochem. Biotechnol. 2005, 121–124, 269–278. [Google Scholar] [CrossRef]

- Krzyczkowska, J.; Kozłowska, M. Effect of Oils Extracted from Plant Seeds on the Growth and Lipolytic Activity of Yarrowia lipolytica Yeast. J. Am. Oil Chem. Soc. 2017, 94, 661–671. [Google Scholar] [CrossRef] [PubMed]

- Du, H.-X.; Xiao, W.-H.; Wang, Y.; Zhou, X.; Zhang, Y.; Liu, D.; Yuan, Y.-J. Engineering Yarrowia lipolytica for Campesterol Overproduction. PLoS ONE 2016, 11, e0146773. [Google Scholar] [CrossRef] [PubMed]

- Papanikolaou, S.; Aggelis, G. Modeling lipid accumulation and degradation in Yarrowia lipolytica cultivated on industrial fats. Curr. Microbiol. 2003, 46, 398–402. [Google Scholar] [CrossRef] [PubMed]

- Blazeck, J.; Liu, L.; Knight, R.; Alper, H.S. Heterologous production of pentane in the oleaginous yeast Yarrowia lipolytica. J. Biotechnol. 2013, 165, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lv, J.; Xu, J.; Zhang, T.; Deng, Y.; He, J. Citric Acid Production in Yarrowia lipolytica SWJ-1b Yeast When Grown on Waste Cooking Oil. Appl. Biochem. Biotechnol. 2015, 175, 2347–2356. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, L.; Zhou, P.; Hou, J.; Qiu, Y. Subsidy modes, waste cooking oil and biofuel: Policy effectiveness and sustainable supply chains in China. Energy Policy 2014, 65, 270–274. [Google Scholar] [CrossRef]

- Katre, G.; Joshi, C.; Khot, M.; Zinjarde, S.; RaviKumar, A. Evaluation of single cell oil (SCO) from a tropical marine yeast Yarrowia lipolytica NCIM 3589 as a potential feedstock for biodiesel. AMB Express 2012, 2, 36. [Google Scholar] [CrossRef]

- Katre, G.; Ajmera, N.; Zinjarde, S.; RaviKumar, A. Mutants of Yarrowia lipolytica NCIM 3589 grown on waste cooking oil as a biofactory for biodiesel production. Microb. Cell Factories 2017, 16, 176. [Google Scholar] [CrossRef]

- Carly, F.; Vandermies, M.; Telek, S.; Steels, S.; Thomas, S.; Nicaud, J.-M.; Fickers, P. Enhancing erythritol productivity in Yarrowia lipolytica using metabolic engineering. Metab. Eng. 2017, 42, 19–24. [Google Scholar] [CrossRef]

- Xiaoyan, L.; Yu, X.; Lv, J.; Xu, J.; Xia, J.; Wu, Z.; Zhang, T.; Deng, Y. A cost-effective process for the coproduction of erythritol and lipase with Yarrowia lipolytica M53 from waste cooking oil. Food Bioprod. Process. 2017, 103, 86–94. [Google Scholar] [CrossRef]

- Lopes, M.; Miranda, S.M.; Alves, J.M.; Pereira, A.S.; Belo, I. Waste Cooking Oils as Feedstock for Lipase and Lipid-Rich Biomass Production. Eur. J. Lipid Sci. Technol. 2019, 121, 1800188. [Google Scholar] [CrossRef]

- Dominguez, A.E.; Deive, F.J.; Ángeles Sanromán, M.; Longo, M.A.; Sanromán Braga, M.Á. Biodegradation and utilization of waste cooking oil by Yarrowia lipolytica CECT 1240. Eur. J. Lipid Sci. Technol. 2010, 112, 1200–1208. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Chevalot, I.; Komaitis, M.; Marc, I.; Aggelis, G. Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl. Microbiol. Biotechnol. 2002, 58, 308–312. [Google Scholar] [CrossRef] [PubMed]

- Lopes, M.; Gomes, A.S.; Silva, C.M.; Belo, I. Microbial lipids and added value metabolites production by Yarrowia lipolytica from pork lard. J. Biotechnol. 2018, 265, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Ruiz, E.; HamediRad, M.; Zhao, H. Pathway Design, Engineering, and Optimization. In Synthetic Biology–Metabolic Engineering; Advances in Biochemical Engineering/Biotechnology; Springer: Berlin/Heidelberg, Germany, 2016; pp. 77–116. ISBN 978-3-319-55317-7. [Google Scholar]

- Waché, Y.; Aguedo, M.; Nicaud, J.-M.; Belin, J.-M. Catabolism of hydroxyacids and biotechnological production of lactones by Yarrowia lipolytica. Appl. Microbiol. Biotechnol. 2003, 61, 393–404. [Google Scholar] [CrossRef] [PubMed]

- Braga, A.; Belo, I. Immobilization of Yarrowia lipolytica for Aroma Production from Castor Oil. Appl. Biochem. Biotechnol. 2013, 169, 2202–2211. [Google Scholar] [CrossRef]

- Pereira de Andrade, D.; Carvalho, B.F.; Schwan, R.F.; Dias, D.R. Production of γ-Decalactone by Yeast Strains under Different Conditions. Food Technol. Biotechnol. 2017, 55, 225–230. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Galiotou-Panayotou, M.; Fakas, S.; Komaitis, M.; Aggelis, G. Citric acid production by Yarrowia lipolytica cultivated on olive-mill wastewater-based media. Bioresour. Technol. 2008, 99, 2419–2428. [Google Scholar] [CrossRef]

- Sarris, D.; Rapti, A.; Papafotis, N.; Koutinas, A.A.; Papanikolaou, S. Production of Added-Value Chemical Compounds through Bioconversions of Olive-Mill Wastewaters Blended with Crude Glycerol by a Yarrowia lipolytica Strain. Molecules 2019, 24, 222. [Google Scholar] [CrossRef]

- Goncalves, A.M.; Pedro, A.; Maia, C.; Sousa, F.; Queiroz, J.; Passarinha, L. Pichia pastoris: A recombinant microfactory for antibodies and human membrane proteins. J. Microbiol. Biotechnol. 2013, 23, 587–601. [Google Scholar] [CrossRef] [PubMed]

- Lanciotti, R.; Gianotti, A.; Baldi, D.; Angrisani, R.; Suzzi, G.; Mastrocola, D.; Guerzoni, M.E. Use of Yarrowia lipolytica strains for the treatment of olive mill wastewater. Bioresour. Technol. 2005, 96, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Veluturla, S.; Archna, N.; Rao, D.S.; Hezil, N.; Indraja, I.S.; Spoorthi, S. Catalytic valorization of raw glycerol derived from biodiesel: A review. Biofuels 2018, 9, 305–314. [Google Scholar] [CrossRef]

- Bagnato, G.; Iulianelli, A.; Sanna, A.; Basile, A. Glycerol Production and Transformation: A Critical Review with Particular Emphasis on Glycerol Reforming Reaction for Producing Hydrogen in Conventional and Membrane Reactors. Membranes 2017, 7, 17. [Google Scholar] [CrossRef] [PubMed]

- Workman, M.; Holt, P.; Thykaer, J. Comparing cellular performance of Yarrowia lipolytica during growth on glucose and glycerol in submerged cultivations. AMB Express 2013, 3, 58. [Google Scholar] [CrossRef] [PubMed]

- Rywińska, A.; Juszczyk, P.; Wojtatowicz, M.; Robak, M.; Lazar, Z.; Tomaszewska, L.; Rymowicz, W. Glycerol as a promising substrate for Yarrowia lipolytica biotechnological applications. Biomass Bioenergy 2013, 48, 148–166. [Google Scholar] [CrossRef]

- Zheng, D.-Q.; Jin, X.-N.; Zhang, K.; Fang, Y.-H.; Wu, X.-C. Novel strategy to improve vanillin tolerance and ethanol fermentation performances of Saccharomycere cerevisiae strains. Bioresour. Technol. 2017, 231, 53–58. [Google Scholar] [CrossRef]

- Yovkova, V.; Otto, C.; Aurich, A.; Mauersberger, S.; Barth, G. Engineering the α-ketoglutarate overproduction from raw glycerol by overexpression of the genes encoding NADP+-dependent isocitrate dehydrogenase and pyruvate carboxylase in Yarrowia lipolytica. Appl. Microbiol. Biotechnol. 2014, 98, 2003–2013. [Google Scholar] [CrossRef]

- Rzechonek, D.A.; Dobrowolski, A.; Rymowicz, W.; Mirończuk, A.M. Aseptic production of citric and isocitric acid from crude glycerol by genetically modified Yarrowia lipolytica. Bioresour. Technol. 2019, 271, 340–344. [Google Scholar] [CrossRef]

- Kamzolova, S.V.; Vinokurova, N.G.; Lunina, J.N.; Zelenkova, N.F.; Morgunov, I.G. Production of technical-grade sodium citrate from glycerol-containing biodiesel waste by Yarrowia lipolytica. Bioresour. Technol. 2015, 193, 250–255. [Google Scholar] [CrossRef]

- Kamzolova, S.V.; Morgunov, I.G. Biosynthesis of pyruvic acid from glycerol-containing substrates and its regulation in the yeast Yarrowia lipolytica. Bioresour. Technol. 2018, 266, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, Y.-Q.; Zhao, X.-F.; Gao, X.-D. Roles of the three Ras proteins in the regulation of dimorphic transition in the yeast Yarrowia lipolytica. FEMS Yeast Res. 2014, 14, 451–463. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Yang, X.; Gao, S.; Wang, H.; Lin, C.S.K. High efficiency succinic acid production from glycerol via in situ fibrous bed bioreactor with an engineered Yarrowia lipolytica. Bioresour. Technol. 2017, 225, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Gao, S.; Li, X.; Yang, X.; Lin, C.S.K. Efficient metabolic evolution of engineered Yarrowia lipolytica for succinic acid production using a glucose-based medium in an in situ fibrous bioreactor under low-pH condition. Biotechnol. Biofuels 2018, 11, 236. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Gao, S.; Yang, X.; Lin, C.S.K. Green and sustainable succinic acid production from crude glycerol by engineered Yarrowia lipolytica via agricultural residue based in situ fibrous bed bioreactor. Bioresour. Technol. 2018, 249, 612–619. [Google Scholar] [CrossRef] [PubMed]

- Tomaszewska, L.; Rywińska, A.; Gładkowski, W. Production of erythritol and mannitol by Yarrowia lipolytica yeast in media containing glycerol. J. Ind. Microbiol. Biotechnol. 2012, 39, 1333–1343. [Google Scholar] [CrossRef] [PubMed]

- Mirończuk, A.M.; Furgała, J.; Rakicka, M.; Rymowicz, W. Enhanced production of erythritol by Yarrowia lipolytica on glycerol in repeated batch cultures. J. Ind. Microbiol. Biotechnol. 2014, 41, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Rakicka, M.; Biegalska, A.; Rymowicz, W.; Dobrowolski, A.; Mirończuk, A.M. Polyol production from waste materials by genetically modified Yarrowia lipolytica. Bioresour. Technol. 2017, 243, 393–399. [Google Scholar] [CrossRef] [PubMed]

- Rakicka, M.; Mirończuk, A.M.; Tomaszewska-Hetman, L.; Rywińska, A.; Rymowicz, W. An Effective Method of Continuous Production of Erythritol from Glycerol by Yarrowia lipolytica MK1. Food Technol. Biotechnol. 2017, 55, 125–130. [Google Scholar] [CrossRef]

- Carly, F.; Niu, H.; Delvigne, F.; Fickers, P. Influence of methanol/sorbitol co-feeding rate on pAOX1 induction in a Pichia pastoris Mut+ strain in bioreactor with limited oxygen transfer rate. J. Ind. Microbiol. Biotechnol. 2016, 43, 517–523. [Google Scholar] [CrossRef]

- Silva Teixeira Souza, K.; Schwan, R.; Dias, D. Lipid and Citric Acid Production by Wild Yeasts Grown in Glycerol. J. Microbiol. Biotechnol. 2014, 24, 497–506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dobrowolski, A.; Mituła, P.; Rymowicz, W.; Mirończuk, A.M. Efficient conversion of crude glycerol from various industrial wastes into single cell oil by yeast Yarrowia lipolytica. Bioresour. Technol. 2016, 207, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Soares, G.P.A.; Souza, K.S.T.; Vilela, L.F.; Schwan, R.F.; Dias, D.R. γ-decalactone production by Yarrowia lipolytica and Lindnera saturnus in crude glycerol. Prep. Biochem. Biotechnol. 2017, 47, 633–637. [Google Scholar] [CrossRef] [PubMed]

- Anastácio, G.S.; Santos, K.O.; Suarez, P.A.Z.; Torres, F.A.G.; De Marco, J.L.; Parachin, N.S. Utilization of glycerin byproduct derived from soybean oil biodiesel as a carbon source for heterologous protein production in Pichia pastoris. Bioresour. Technol. 2014, 152, 505–510. [Google Scholar] [CrossRef] [PubMed]

- Noseda, D.G.; Recúpero, M.; Blasco, M.; Bozzo, J.; Galvagno, M.Á. Production in stirred-tank bioreactor of recombinant bovine chymosin B by a high-level expression transformant clone of Pichia pastoris. Protein Expr. Purif. 2016, 123, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Miao, J.; Luo, W.; Li, G.; Du, Y.; Yu, X. Crude glycerol from biodiesel as a carbon source for production of a recombinant highly thermostable β-mannanase by Pichia pastoris. Biotechnol. Lett. 2018, 40, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Semkiv, M.V.; Kata, I.; Ternavska, O.; Sibirny, W.; Dmytruk, K.V.; Sibirny, A.A. Overexpression of the genes of glycerol catabolism and glycerol facilitator improves glycerol conversion to ethanol in the methylotrophic thermotolerant yeast Ogataea polymorpha. Yeast Chichester Engl. 2019, 36, 329–339. [Google Scholar] [CrossRef] [PubMed]

- Gírio, F.M.; Fonseca, C.; Carvalheiro, F.; Duarte, L.C.; Marques, S.; Bogel-Łukasik, R. Hemicelluloses for fuel ethanol: A review. Bioresour. Technol. 2010, 101, 4775–4800. [Google Scholar] [CrossRef]

- Liu, X.; Lin, Q.; Yan, Y.; Peng, F.; Sun, R.; Ren, J. Hemicellulose from Plant Biomass in Medical and Pharmaceutical Application: A Critical Review. Curr. Med. Chem. 2017, 24. [Google Scholar] [CrossRef]

- Li, P.; Sun, H.; Chen, Z.; Li, Y.; Zhu, T. Construction of efficient xylose utilizing Pichia pastoris for industrial enzyme production. Microb. Cell Factories 2015, 14, 22. [Google Scholar] [CrossRef]

- Ryu, S.; Hipp, J.; Trinh, C.T. Activating and Elucidating Metabolism of Complex Sugars in Yarrowia lipolytica. Appl. Environ. Microbiol. 2016, 82, 1334–1345. [Google Scholar] [CrossRef] [PubMed]

- Tsigie, Y.A.; Wang, C.-Y.; Truong, C.-T.; Ju, Y.-H. Lipid production from Yarrowia lipolytica Po1g grown in sugarcane bagasse hydrolysate. Bioresour. Technol. 2011, 102, 9216–9222. [Google Scholar] [CrossRef] [PubMed]

- Tsigie, Y.A.; Wang, C.-Y.; Kasim, N.S.; Diem, Q.-D.; Huynh, L.-H.; Ho, Q.-P.; Truong, C.-T.; Ju, Y.-H. Oil Production from Yarrowia lipolytica Po1g Using Rice Bran Hydrolysate. J. Biomed. Biotechnol. 2012. [Google Scholar] [CrossRef] [PubMed]

- Niehus, X.; Crutz-Le Coq, A.-M.; Sandoval, G.; Nicaud, J.-M.; Ledesma-Amaro, R. Engineering Yarrowia lipolytica to enhance lipid production from lignocellulosic materials. Biotechnol. Biofuels 2018, 11, 11. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Alper, H.S. Enabling xylose utilization in Yarrowia lipolytica for lipid production. Biotechnol. J. 2016, 11, 1230–1240. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Lin, Y.; He, P.; Li, L.; Wang, Q.; Ma, Y. Characterization of the sugar alcohol-producing yeast Pichia anomala. J. Ind. Microbiol. Biotechnol. 2014, 41, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Sarks, C.; Jin, M.; Sato, T.K.; Balan, V.; Dale, B.E. Studying the rapid bioconversion of lignocellulosic sugars into ethanol using high cell density fermentations with cell recycle. Biotechnol. Biofuels 2014, 7, 73. [Google Scholar] [CrossRef]

- Okonkwo, C.C.; Azam, M.M.; Ezeji, T.C.; Qureshi, N. Enhancing ethanol production from cellulosic sugars using Scheffersomyces (Pichia) stipitis. Bioprocess. Biosyst. Eng. 2016, 39, 1023–1032. [Google Scholar] [CrossRef]

- Kashid, M.; Ghosalkar, A. Evaluation of fermentation kinetics of acid-treated corn cob hydrolysate for xylose fermentation in the presence of acetic acid by Pichia stipitis. 3 Biotechnol. 2017, 7, 240. [Google Scholar] [CrossRef]

- Nitiyon, S.; Keo-oudone, C.; Murata, M.; Lertwattanasakul, N.; Limtong, S.; Kosaka, T.; Yamada, M. Efficient conversion of xylose to ethanol by stress-tolerant Kluyveromyces marxianus BUNL-21. SpringerPlus 2016, 5, 185. [Google Scholar] [CrossRef]

- Lazar, Z.; Gamboa-Meléndez, H.; Le Coq, A.M.C.; Neuvéglise, C.; Nicaud, J.-M. Awakening the endogenous Leloir pathway for efficient galactose utilization by Yarrowia lipolytica. Biotechnol. Biofuels 2015, 8, 185. [Google Scholar] [CrossRef] [PubMed]

- Chi, Z.-M.; Zhang, T.; Cao, T.-S.; Liu, X.-Y.; Cui, W.; Zhao, C.-H. Biotechnological potential of inulin for bioprocesses. Bioresour. Technol. 2011, 102, 4295–4303. [Google Scholar] [CrossRef] [PubMed]

- Gupta, N.; Jangid, A.K.; Pooja, D.; Kulhari, H. Inulin: A novel and stretchy polysaccharide tool for biomedical and nutritional applications. Int. J. Biol. Macromol. 2019, 132, 852–863. [Google Scholar] [CrossRef]

- Hughes, S.R.; Qureshi, N.; López-Núñez, J.C.; Jones, M.A.; Jarodsky, J.M.; Galindo-Leva, L.Á.; Lindquist, M.R. Utilization of inulin-containing waste in industrial fermentations to produce biofuels and bio-based chemicals. World J. Microbiol. Biotechnol. 2017, 33, 78. [Google Scholar] [CrossRef] [PubMed]

- Rakicka, M.; Wolniak, J.; Lazar, Z.; Rymowicz, W. Production of high titer of citric acid from inulin. BMC Biotechnol. 2019, 19, 11. [Google Scholar] [CrossRef] [PubMed]

- Gong, F.; Sheng, J.; Chi, Z.; Li, J. Inulinase production by a marine yeast Pichia guilliermondii and inulin hydrolysis by the crude inulinase. J. Ind. Microbiol. Biotechnol. 2007, 34, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Chi, Z.; Sheng, J.; Wang, L.; Li, J.; Gong, F. Inulinase-producing Marine Yeasts: Evaluation of their Diversity and Inulin Hydrolysis by Their Crude Enzymes. Microb. Ecol. 2007, 54, 722–729. [Google Scholar] [CrossRef]

- Wang, X.; Sun, Y.; Shen, X.; Ke, F.; Zhao, H.; Liu, Y.; Xu, L.; Yan, Y. Intracellular expression of Vitreoscilla hemoglobin improves production of Yarrowia lipolytica lipase LIP2 in a recombinant Pichia pastoris. Enzyme Microb. Technol. 2012, 50, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Chautard, P.; Guiraud, J.; Galzy, P. Inulinase activity of Pichia polymorpha. Acta Microbiol. Acad. Sci. Hung. 1981, 28, 245–255. [Google Scholar]

- Bajon, A.M.; Guiraud, J.P.; Galzy, P. Isolation of an inulinase derepressed mutant of Pichia polymorpha for the production of fructose. Biotechnol. Bioeng. 1984, 26, 128–133. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chi, Z.; Liu, G.L.; Wang, F.; Madzak, C.; Chi, Z.-M. Inulin hydrolysis and citric acid production from inulin using the surface-engineered Yarrowia lipolytica displaying inulinase. Metab. Eng. 2010, 12, 469–476. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Y.; Chi, Z.; Liu, G.-L.; Madzak, C.; Chi, Z.-M. Both Decrease in ACL1 Gene Expression and Increase in ICL1 Gene Expression in Marine-Derived Yeast Yarrowia lipolytica Expressing INU1 Gene Enhance Citric Acid Production from Inulin. Mar. Biotechnol. 2013, 15, 26–36. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.-L.; Chi, Z.; Chi, Z.-M. Molecular characterization and expression of microbial inulinase genes. Crit. Rev. Microbiol. 2013, 39, 152–165. [Google Scholar] [CrossRef] [PubMed]

- Rakicka, M.; Lazar, Z.; Rywińska, A.; Rymowicz, W. Efficient utilization of inulin and glycerol as fermentation substrates in erythritol and citric acid production using Yarrowia lipolytica expressing inulinase. Chem. Pap. 2016, 70, 1452–1459. [Google Scholar] [CrossRef]

- Adrio, J.L. Oleaginous yeasts: Promising platforms for the production of oleochemicals and biofuels. Biotechnol. Bioeng. 2017, 114, 1915–1920. [Google Scholar] [CrossRef]

- Zhao, C.H.; Cui, W.; Liu, X.Y.; Chi, Z.M.; Madzak, C. Expression of inulinase gene in the oleaginous yeast Yarrowia lipolytica and single cell oil production from inulin-containing materials. Metab. Eng. 2010, 12, 510–517. [Google Scholar] [CrossRef]

- Shi, N.; Mao, W.; He, X.; Chi, Z.; Chi, Z.; Liu, G. Co-expression of Exo-inulinase and Endo-inulinase Genes in the Oleaginous Yeast Yarrowia lipolytica for Efficient Single Cell Oil Production from Inulin. Appl. Biochem. Biotechnol. 2018, 185, 334–346. [Google Scholar] [CrossRef]

- Wang, G.-Y.; Chi, Z.; Song, B.; Wang, Z.-P.; Chi, Z.-M. High level lipid production by a novel inulinase-producing yeast Pichia guilliermondii Pcla22. Bioresour. Technol. 2012, 124, 77–82. [Google Scholar] [CrossRef]

- Yu, X.; Guo, N.; Chi, Z.; Gong, F.; Sheng, J.; Chi, Z. Inulinase overproduction by a mutant of the marine yeast Pichia guilliermondii using surface response methodology and inulin hydrolysis. Biochem. Eng. J. 2009, 43, 266–271. [Google Scholar] [CrossRef]

- Zhao, C.-H.; Chi, Z.; Zhang, F.; Guo, F.-J.; Li, M.; Song, W.-B.; Chi, Z.-M. Direct conversion of inulin and extract of tubers of Jerusalem artichoke into single cell oil by co-cultures of Rhodotorula mucilaginosa TJY15a and immobilized inulinase-producing yeast cells. Bioresour. Technol. 2011, 102, 6128–6133. [Google Scholar] [CrossRef]

- Yan, D.; Lu, Y.; Chen, Y.-F.; Wu, Q. Waste molasses alone displaces glucose-based medium for microalgal fermentation towards cost-saving biodiesel production. Bioresour. Technol. 2011, 102, 6487–6493. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.-P.; Wang, Q.-Q.; Liu, S.; Liu, X.-F.; Yu, X.-J.; Jiang, Y.-L. Efficient Conversion of Cane Molasses towards High-Purity Isomaltulose and Cellular Lipid Using an Engineered Yarrowia lipolytica Strain in Fed-Batch Fermentation. Molecules 2019, 24, 1228. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Han, B.; Gui, X.; Wang, G.; Xu, L.; Yan, Y.; Madzak, C.; Pan, D.; Wang, Y.; Zha, G.; et al. Engineering Yarrowia lipolytica to Simultaneously Produce Lipase and Single Cell Protein from Agro-industrial Wastes for Feed. Sci. Rep. 2018, 8, 758. [Google Scholar] [CrossRef] [PubMed]

- Darvishi, F.; Moradi, M.; Madzak, C.; Jolivalt, C. Production of Laccase by Recombinant Yarrowia lipolytica from Molasses: Bioprocess Development Using Statistical Modeling and Increase Productivity in Shake-Flask and Bioreactor Cultures. Appl. Biochem. Biotechnol. 2017, 181, 1228–1239. [Google Scholar] [CrossRef] [PubMed]

- Lazar, Z.; Dulermo, T.; Neuvéglise, C.; Crutz-Le Coq, A.-M.; Nicaud, J.-M. Hexokinase—A limiting factor in lipid production from fructose in Yarrowia lipolytica. Metab. Eng. 2014, 26, 89–99. [Google Scholar] [CrossRef] [PubMed]

- Rakicka, M.; Lazar, Z.; Dulermo, T.; Fickers, P.; Nicaud, J.M. Lipid production by the oleaginous yeast Yarrowia lipolytica using industrial by-products under different culture conditions. Biotechnol. Biofuels 2015, 8, 104. [Google Scholar] [CrossRef] [PubMed]

- Gajdoš, P.; Nicaud, J.M.; Rossignol, T.; Čertík, M. Single cell oil production on molasses by Yarrowia lipolytica strains overexpressing DGA2 in multicopy. Appl. Microbiol. Biotechnol. 2015, 99, 8065–8074. [Google Scholar] [CrossRef]

- Mirończuk, A.M.; Rakicka, M.; Biegalska, A.; Rymowicz, W.; Dobrowolski, A. A two-stage fermentation process of erythritol production by yeast Y. lipolytica from molasses and glycerol. Bioresour. Technol. 2015, 198, 445–455. [Google Scholar] [CrossRef]

- Kingston, D.; Novelli, G.F.; Cerrutti, P.; Recupero, M.N.; Blasco, M.; Galvagno, M.A. Use of grape pomaces to produce biomass of a Komagataella pastoris strain expressing a bovine chymosin activity. Food Sci. Nutr. 2014, 2, 734–743. [Google Scholar] [CrossRef]

- Parekh, S.R.; Pandey, N.K. Production of glycerol by Hansenula anomala. Biotechnol. Bioeng. 1985, 27, 1089–1091. [Google Scholar] [CrossRef]

- Hamouda, H.I.; Nassar, H.N.; Madian, H.R.; Abu Amr, S.S.; El-Gendy, N.Sh. Response Surface Optimization of Bioethanol Production from Sugarcane Molasses by Pichia veronae Strain HSC-22. Biotechnol. Res. Int. 2015, 2015, 10. [Google Scholar] [CrossRef] [PubMed]

- Lane, S.; Zhang, S.; Wei, N.; Rao, C.; Jin, Y.-S. Development and physiological characterization of cellobiose-consuming Yarrowia lipolytica. Biotechnol. Bioeng. 2015, 112, 1012–1022. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Duquesne, S.; Bozonnet, S.; Cioci, G.; Nicaud, J.-M.; Marty, A.; O’Donohue, M.J. Development of cellobiose-degrading ability in Yarrowia lipolytica strain by overexpression of endogenous genes. Biotechnol. Biofuels 2015, 8, 109. [Google Scholar] [CrossRef] [PubMed]

- Boonvitthya, N.; Bozonnet, S.; Burapatana, V.; O’Donohue, M.J.; Chulalaksananukul, W. Comparison of the Heterologous Expression of Trichoderma reesei Endoglucanase II and Cellobiohydrolase II in the Yeasts Pichia pastoris and Yarrowia lipolytica. Mol. Biotechnol. 2013, 54, 158–169. [Google Scholar] [CrossRef] [PubMed]

- Duquesne, S.; Bozonnet, S.; Bordes, F.; Dumon, C.; Nicaud, J.-M.; Marty, A. Construction of a Highly Active Xylanase Displaying Oleaginous Yeast: Comparison of Anchoring Systems. PLoS ONE 2014, 9, e95128. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wei, H.; Alahuhta, M.; Chen, X.; Hyman, D.; Johnson, D.K.; Zhang, M.; Himmel, M.E. Heterologous Expression of Xylanase Enzymes in Lipogenic Yeast Yarrowia lipolytica. PLoS ONE 2014, e111443. [Google Scholar] [CrossRef]

- Kickenweiz, T.; Glieder, A.; Wu, J.C. Construction of a cellulose-metabolizing Komagataella phaffii (Pichia pastoris) by co-expressing glucanases and β-glucosidase. Appl. Microbiol. Biotechnol. 2018, 102, 1297–1306. [Google Scholar] [CrossRef]

- Ledesma-Amaro, R.; Dulermo, T.; Nicaud, J.M. Engineering Yarrowia lipolytica to produce biodiesel from raw starch. Biotechnol. Biofuels 2015, 8, 148. [Google Scholar] [CrossRef]

- Yang, C.H.; Huang, Y.C.; Chen, C.Y.; Wen, C.Y. Expression of Thermobifida fusca thermostable raw starch digesting alpha-amylase in Pichia pastoris and its application in raw sago starch hydrolysis. J. Ind. Microbiol. Biotechnol. 2010, 37, 401–406. [Google Scholar] [CrossRef]

- Key Facts on Food Loss and Watse You Should Know. Available online: http://www.fao.org/save-food/resources/keyfindings/en/ (accessed on 24 July 2019).

- Koutinas, M.; Patsalou, M.; Stavrinou, S.; Vyrides, I. High temperature alcoholic fermentation of orange peel by the newly isolated thermotolerant Pichia kudriavzevii KVMP10. Lett. Appl. Microbiol. 2016, 62, 75–83. [Google Scholar] [CrossRef]

- Wilkins, M.R.; Suryawati, L.; Maness, N.O.; Chrz, D. Ethanol production by Saccharomyces cerevisiae and Kluyveromyces marxianus in the presence of orange-peel oil. World J. Microbiol. Biotechnol. 2007, 23, 1161–1168. [Google Scholar] [CrossRef]

- Johnravindar, D.; Karthikeyan, O.P.; Selvam, A.; Murugesan, K.; Wong, J.W.C. Lipid accumulation potential of oleaginous yeasts: A comparative evaluation using food waste leachate as a substrate. Bioresour. Technol. 2018, 248, 221–228. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, L.; Johri, S. Biovalorization potential of peels of Ananas cosmosus (L.) Merr. for ethanol production by Pichia stipitis NCIM 3498 & Pachysolen tannophilus MTCC 1077. Indian J. Exp. Biol. 2015, 53, 9. [Google Scholar]

- Brabender, M.; Hussain, M.S.; Rodriguez, G.; Blenner, M.A. Urea and urine are a viable and cost-effective nitrogen source for Yarrowia lipolytica biomass and lipid accumulation. Appl. Microbiol. Biotechnol. 2018, 102, 2313–2322. [Google Scholar] [CrossRef] [PubMed]

- García, E.E.; Belin, J.-M.; Waché, Y. Use of a Doehlert factorial design to investigate the effects of pH and aeration on the accumulation of lactones by Yarrowia lipolytica. J. Appl. Microbiol. 2007, 103, 1508–1515. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, C.; Lopes, M.; Ferreira, J.P.; Belo, I. Biological treatment of olive mill wastewater by non-conventional yeasts. Bioresour. Technol. 2009, 100, 3759–3763. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Source of Feedstocks | Yeast | Products | Process Mode | Yield-/titer (maximal value) | References |

|---|---|---|---|---|---|

| Hydrophobic Substrates | |||||

| Olive and Sweet Almond Oil | Y.l. DSM3286 | CA | SF | 0.006 g/gDCW.h-0.36 g/g | [13] |

| Sunflower (3%) | Y.l. UOFSY-1701 | CA | SF | 0.5 → 18.7 g/L | [13] |

| Rapeseed oil (2%–6%) | Y.l. VKMY-2373 | ICA/CA | 10L FB | 70 g/L (ICA/CA = 1:0.32) 0.97 g/h-0.95 g/g | [11] |

| Sunflower oil 10% | Y.l. H222 | ICA/CA | SF | 56.8 g/L (ICA/CA = 1:0.42) | [15] |

| Rapeseed oil (2%–6%) | Y.l. VKMY-2412 | KGA | 10L FB | 102 g/L-0.8 g/L.h-0.95 g/g, | [16] |

| Rapessed oil | Y.l. VKMY-2412 | SA | 10L FB | 69 g/L | [18] |

| Oleic acid 0.5% (v/v) | Y.l. LgX64.81 | Lip2p | SF | 9.9 U/ml.h.A600 | [20] |

| Olive oil/ethyl-oleate | Y.l. LgX64.82 | Lip2p | FB | 3044 U/ml | [20,21] |

| Oleic acid/glucose | Y.l. JMY1105 | Lip2p | SF | 158.246 U/ml | [3] |

| Seed oils | Y.l. WT29 | Lip2p | SF | 2.33 U/ml | [23] |

| Seed oils | Y.l. C-22 | Campesterol | SF, 5L FB | 453 mg/L-0.008 g/g | [24] |

| Linoleic acid | Y.l. PO1f | pentane | SF | 4.98 mg/L | [26] |

| Castor oil/ricinoleic acid | Y.l. wild-type | γ-decalactone | SF | 400 mg/L-10 g/L | [38,39,40,128], |

| Corn oil | Y.l. 1094 | SCO | 1.5L Batch | 0.37 g/g | [35] |

| Used Oil and Industrial Fats | |||||

| Used cooking oil / single cell oil | Y.l. SWJ-1b | CA/ICA | 10L Batch | 31.7 g/L CA-6.5 g/L ICA | [27] |

| UCO | Y.l. NCIM 3450 | SCO - | SF | 0.45 g/g-2.45 g/L | [29] |

| UCO 3% | Y.l. M53 | Lip2p | 5L Batch | 12.7 U/ml-0.74 g/g | [32] |

| UCO-arabic gum | Y.l. W29 | Lip2p | Batch | 12000 U/ml | [33] |

| Glucose-UCO | Y.l. CECT | Lip2p | SF | 2500 U/ml | [34] |

| Waste motor oil (WMO) | Y.l. NCIM 3450 | SCO | SF | 0.55 g/g-0.32 g/L | [29] |

| Animal fat | Y.l. ACA-DC50109 | SCO | 1.5L Batch | 0.54 g/g | [35] |

| Pork lard | Y.l. | SCO-Lip2p-CA | 2L Batch | 0.57 g/gCDW-560 U/L-9.2 g/L | [36] |

| OMW | Y.l. ACA-DC 50109 | CA | SF | 37 g/L and 0.55 g/g | [41] |

| OMW | Y.l. (W29, CBS 2073, IMUFRJ50682) | Lip2p | 2L Batch | 1041 U/ml | [129] [44] |

| Fish waste | Y.l. NCIM3589 | SCO | SF | 0.14 g/g | [29] |

| Crude Glycerol | |||||

| Glycerol (2%–3%) | Y.l. WSH-Z06 | KGA/PYR | 3L FB | 64.7 g/L-39.1 g/L | [49] |

| Crude glycerol 5% (w/v) | Y.l. GUT1-GUT2 | CA/ICA | 5L Batch | 0.25 g/g-0.38 g/L.h, | [51] |

| Raw glycerol | Y.l. VKM Y-2373 | CA | 5L Batch | 82 g/L | [52] |

| Raw glycerol | Y.l. VKM Y-2378 | PYR | 10L FB | 41 g/L-0.82 g/g | [53] |

| Raw glycerol | Y.l. SKO6 | PYR | FB | 124.4 g/L-0.62 g/g | [9] |

| Raw glycerol | Y.l. PGC1003 | SA | isFBB FB | 51.9 g/L-1.46 g/L.h 0.42 g/g-209.7 g/L | [55,57] |

| Glycerol | Y.l. Wratislavia K1 | Man/Ery | 5L Batch | 80 g/L-0.49 g/g | [58] |

| Sucrose and glycerol | Y.l. Wratislavia K1 | Ery | rBatch | 220 g/L-0.54 g/l.h | [59] |

| Glycerol | Y.l. MK1 | Ery | Chem | 113.1 g/L-1.1 g/L.h-0.57 g/g | [60] |

| Raw glycerol and castor oil | Y.l. CCMA0357 | γ-decalactone | SF | 3.5 g/L | [65] |

| Crude glycerol and methanol-inducer | P.p. | Recombinant bovine chymosin | 6L FB | 192 IMCU/ml | [67] |

| Pure glycerol | P.p. | Mannanase | 5 L Batch | 2385 U/ml | [68] |

| Crude glycerol 15% | O.p. | Ethanol | SF | 3.55 g/L 11.6 mg/gDCW.h-72.3 mg/g | [69] |

| Inulin | |||||

| Inulin | Y.l. SWJ-1b | CA | Batch | 68.9g/L CA-4.1 g/L ICA | [93] |

| Inulin 10% | Y.l. | CA | 5L Batch | 84 g/L-0.89 g/g | [95] |

| Pure inulin 200 g/L | Y.l. Wratislavia K1 | CA | 5L Batch | 105.2 g/L | [96] |

| Pure inulin | Y.l. AWG7 INU8 | CA | rBatch | 200 g/L-0.85 g/g | [87] |

| Inulin | Y.l. ACA-DC50109 | SCO | 2L Batch | 0.50 g/g | [98] |

| Inulin 5% (w/v) | Y.l. ACA-DC 50109 | SCO | SF | 0.48 g/g-6.56 g/L | [99] |

| Inulin 7% | P.g. Pcla22 | SCO | 2L batch | 0.19 g/g | [100] |

| Inulin | P.g. M-30 mutant | inulinase | SF | 128 U/mL | [101] |

| Inulin | R.m. TJY15a | SCO | 2L Batch | 0.55 g/g | [98] |

| Inulin and glycerol | Y.l. K1 INU6 | Ery | 5L Batch | 121 g/L-0.6 g/g | [96] |

| Molasses (Sucroses) | |||||

| Molasses-corn steep liquor | Y.l.S47 | isomaltulose | SF | 102 g/L | [104] |

| Molasses | Y.l.S47 | isomaltulose | FB | 161.2 g/L-0.96 g/g | [104] |

| Molasses | Y. lipo YLY5 (SUC2, LIP2) and extracellular lipase (LIP2) | Lip2p | 10 L Batch | 2175 U/ml | [105] |

| Molasses | Y.l. Po1g (Suc+) | laccase | 5 L Batch | 0.093 U/h-0.03 U/g | [106] |

| Sugar beet-molasses-glycerol | Y.l. JMY4086 | SCA/CA | Chem | 0.31 g/gCDW-0.43 g/l.h 80 g/L | [107,108] |

| Molasses (8% v/v) | Y.l. Q4 strain | SCO | SF | 0. 30 g/g | [109] |

| Sugar beet-molasses-crude glycerol | Y.l. A101 | Ery | TS Batch | 114 g/L-0.57 g/g | [110] |

| Sugar beet molasses blended with crude glycerol | Y.l. Wratislavia K1 | polyol | TS Batch | 100.5 g/L-0.67 g/g | [60] |

| Sugarcane molasses-grape pomace extract | P.p (GS115 derivative) | bovine chymosin | 5 L Batch | 8.5 U/ml | [111] |

| Molasses-corn steep liquor-based | P.a. anomala | Glycerol | SF | 65 g/L-0.33 g/g | [112] |

| Sugarcane molasses | P.v. HSC-22 | Bioethanol | 10 L Batch | 32 g/L-0.44 g/g | [113] |

| Xylose and Galactose | |||||

| Sugarcane bagasse hydrolysate | Y.l. PO1g | SCO | SF | 58%, 6.68 g/L per day | [74] |

| Rice branch hydrolysate | Y.l. PO1g | SCO | SF | 48%-5.16 g/L | [75] |

| Agave bagasse hydrolysate | Y.l.ylXYL + Obese | 3L FB | 67%-16.5 g/l | [76] | |

| Xylose 150 g/l | Y.l.E26 | lipid | 1.5L Batch | 15 g/l-0.19 g/L.h | [77] |

| Xylose (100 g/L) | P.a. TIB-x229 | polyols such as D-arabitol, xylitol, ribitol | SF | 0.77 g/g | [78] |

| Waste xylose mother liquor | P.a. TIB-x230 | Polyols | SF | Arabitol (28.7 g/L), Ribitol (15.3 g/L) and Xylitol (15,7 g/L) | [78] |

| Corn stover hydrolysat xylose concentration of 60 g/L | P.s. FLP-061 | ethanol | RaBIT | 44.8 g/l-0.39 g/l.h-0.37 g/l.h | [79] |

| Corn hydrolysate | P.s. ATCC58784 | ethanol | RaBIT | 0.5 g/L.h-0.43 g/g | [79] |

| Galactose | Y.l. | CA/SCO | 5L Batch | CA= 29.2 g/L-0.51 g/g; SCO 3.2 g/l-0.056 g/g | [83] |

| Recalcitrant Plant Components | |||||

| Cellobiose | Y.l. | CA | SF | 0.37 g/g | [114] |

| Cellobiose | Y.l. | FAME | 1.5L Batch | 0.8 g/L | [115] |

| Starch | Y.l. | SCO | SF | 27% of DCW | [120] |

| Defatted rice bran | Y.l. PO1g | SCO | SF | 48%-5 g/L | [75] |

| Sugarcane bagasse hydrolysate | Y.l. PO1g | SCO | SF | 58.5%-1.76 g/L-day | [74] |

| Food Wastes | |||||

| Mixed food waste hydrolysates | Y.l.PSA02004 | SA | isFBB | 18.9 g/L-0.38 g/g | [56] |

| Orange peel | P.k. KVMP10 | ethanol | SF | 54 g/L | [123] |

| Orange peel | K.m. | ethanol | SF | 37 g/L | [124] |

| Food waste leachates | Y.l. | SCO | SF | 49% of DCW | [125] |

| Peels of Ananas cosmosus | P.s. NCIM3498 | ethanol | SF | 10.9 g/L | [126] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, D.T.H.; Theron, C.W.; Fickers, P. Organic Wastes as Feedstocks for Non-Conventional Yeast-Based Bioprocesses. Microorganisms 2019, 7, 229. https://doi.org/10.3390/microorganisms7080229

Do DTH, Theron CW, Fickers P. Organic Wastes as Feedstocks for Non-Conventional Yeast-Based Bioprocesses. Microorganisms. 2019; 7(8):229. https://doi.org/10.3390/microorganisms7080229

Chicago/Turabian StyleDo, Diem T. Hoang, Chrispian W. Theron, and Patrick Fickers. 2019. "Organic Wastes as Feedstocks for Non-Conventional Yeast-Based Bioprocesses" Microorganisms 7, no. 8: 229. https://doi.org/10.3390/microorganisms7080229

APA StyleDo, D. T. H., Theron, C. W., & Fickers, P. (2019). Organic Wastes as Feedstocks for Non-Conventional Yeast-Based Bioprocesses. Microorganisms, 7(8), 229. https://doi.org/10.3390/microorganisms7080229