1. Introduction

Use of fossil fuels produces several negative effects on public health, climate change, and the environment. In order to sustain the worldwide economic growth and reduce the negative impacts on the environment, green energy solutions are promoted worldwide. Biodiesel highlights as such a strong alternative solution to diesel, as its wide usage confirmed its potentiality to reduce the serious environmental concerns, as well as oil dependency. Current biodiesel research is mainly focused on the production of third-generation feedstocks (e.g., engineered crops), after years of experimentation and tests on the second (e.g., non-edible food crops and vegetable oil, waste oils and fats) and first (e.g., food crops and edible vegetable oils) generation feedstocks [

1]. The negative publicity of the early stages based on “food versus fuel” dilemma belongs to history, as today biodiesel has gained worldwide acceptance, as a clean, biodegradable and biocompatible green product, which is in harmony with the political and environmental awareness and in line with future strategies on renewable fossil fuels. However, the high cost of biodiesel production remains the main disadvantage to its wide spread use.

Lately, the use of waste cooking (frying) oils has gained much attention as an alternative green, abundant, and sustainable feedstock for the production of biodiesel, due to its lower production cost in relation to other feedstocks and the elimination of the negative harmful environmental effects of throwing household and industrial waste oils into drains. Towards this, a number of review studies exist in the literature; these are focused on the production techniques and the relevant processes [

2,

3,

4], as well as on the available analytical methods (e.g., gas chromatography (GC), thin-layer chromatography (TLC), high-performance liquid chromatography (HPLC), gel permeation chromatography (GPC), and thermogravimetric analysis (TGA)) for measuring the biodiesel quality and the fuel properties [

5]. Yaakob et al. [

6] highlighted a number of important parameters for the production of biodiesel reviewing the applied methods, the different types of reactors, the types and amounts of alcohol, as well as the catalysts. A number of other researchers worked towards studying the optimum parameters for biodiesel production from frying oils. In such a study, Felizardo et al. [

7] examined the conditions of time, catalysts, and methanol/oil molar ratio for optimum biodiesel production in a laboratory scale. Similarly, Uzun et al. [

8] investigated the best reaction conditions (i.e., catalyst concentration, reaction time, methanol/oil molar ratio, reaction temperature, catalyst type (hydroxides, methoxides and ethoxides), and purification type (washing with hot water, purification with silica gel and dowex) on the biodiesel yields and measured the fuel properties using the respective ASTM International and EN (European Norms) biodiesel standards. In the same context, Predojevic [

9] applied a two-step alkali transesterification process and tested three purification methods (silica gel, 5% phosphoric acid and hot distilled water) to examine the best yields for the produced biodiesel; the two first methods were finally recommended. Furthermore, optimization of biodiesel production from waste cooking oil was investigated using waste eggshell as a base catalyst [

10], and by utilization of lipase as a biocatalyst [

11].

A step ahead, is the employ of artificial neural networks (ANN) for predicting the engine performance and the gas emissions, after using blends of waste frying palm oil biodiesel [

12].

Nowadays, another green energy trend is that of circular economy, especially on industrial and homemade levels which implies, among others, the minimization and re-usage of waste. Towards this, biodiesel is now produced from spent coffee grounds (SCG), a popular food waste previously ending up unprocessed in landfills [

13,

14].

Biodiesel is a methyl ester product (a mixture of FAMEs: fatty acid methyl esters) derived from the transesterification of vegetable oils with methanol. The transesterification includes the splitting of vegetable oil molecules (triglycerides) in three chains of fatty acids and one glycerol molecule, separately. These alkyl chains are called biodiesel. Many raw materials are used in the production of biodiesels (e.g., vegetable oils, animal fats, and algae oil); the most known in Europe are rapeseed oil (rape methyl ester, RME) [

15] and in USA soybean oil (soybean oil methyl esters, SME), whereas many other oils that can be converted to biodiesel exist, such as sunflower, palm oil, canola oil biodiesel (COB), etc. [

16,

17]. Initially, diesel engine was designed to run on vegetable oil, but because of weakness in the operation, a modification of vegetable oils was performed by transesterification, so that vegetable oils become compatible with existing diesel engines [

18,

19,

20]. The data about the biodiesel production cost vary depending on the feedstock used and the production process. Biodiesel can be used in engines, either pure (B100, when the manufacturer accepts such usage), or as a blend with diesel. However, biodiesel has lower energy content than diesel and, as a result, the performance and fuel consumption can be influenced. Moreover, it shows the highest NO

x emission levels, lowers the oxidation stability of diesel [

21] and potentially favors bacteria growth. Furthermore, unsaturated fatty acids react with oxygen to form peroxides; this leads to degradation yielding by-products that can cause sludge and varnish in the fuel system [

22]. Also, FAMEs can cause corrosion of the fuel injector, block the low-pressure fuel system, increase dilution and polymerization of the oil sump, clogging the pump due to high fuel viscosity at low temperature, increase injection pressure, elastomeric gaskets failures and blockage of the fuel injection [

20,

23,

24].

Nevertheless, biodiesel usage shows a growing trend worldwide [

25]. Biodiesel is highly biodegradable [

26], presents low toxicity, better lubricity and can replace diesel fuel; it is an established alternative fuel for diesel engines. The use of biodiesel as fuel results in the reduction of major exhaust pollutants (SO

x, CO, Particulate Matter-PM, Volatile Organic Compounds-VOCs). Therefore, the negative environmental and health effects of diesel use are reduced [

23,

24,

27]. In the study of Ozsezen and Canakci [

12], where different blends of biodiesel (waste frying palm oil) were tested, a reduction in CO, unburned hydrocarbons and smoke opacity was observed, whereas NO

x and CO

2 emissions showed the opposite behavior, especially in high engine speeds. NO

x emissions remain a major problem when using biodiesel. Therefore, Agarwal et al. [

28], suggested the use of exhaust gas recirculation (EGR) with biodiesel in order to reduce NO

x emissions. This is achieved as flame temperature is lower along with oxygen concentration in the combustion chamber; thus, less NO

x are produced.

Similarities between diesel fuel and heating oil (middle distillates) enable the blending of heating oil with biodiesel. Such a product already exists on the market of Germany (heating oil blended with 10% biodiesel for domestic heating) [

29]. Towards this, storage stability of home heating oil was improved using 10−20% soybean-derived fuel (Soygold), along with the combustion properties [

30].

The aim of the present work was to examine the potential re-usage of a biodiesel product that could not fulfil the export specifications legislation and therefore remained out of the market. As biodiesel is typically blended with diesel at different concentration levels, its addition to heating oil at various volumes (2.5%, 5%, 7%, 10%, 20%, and 50%

v/

v) was examined. Towards this, three main parameters were initially measured (cetane index (CI) after distillation, oxidation stability, and cold filter plugging point (CFPP)) and discussed [

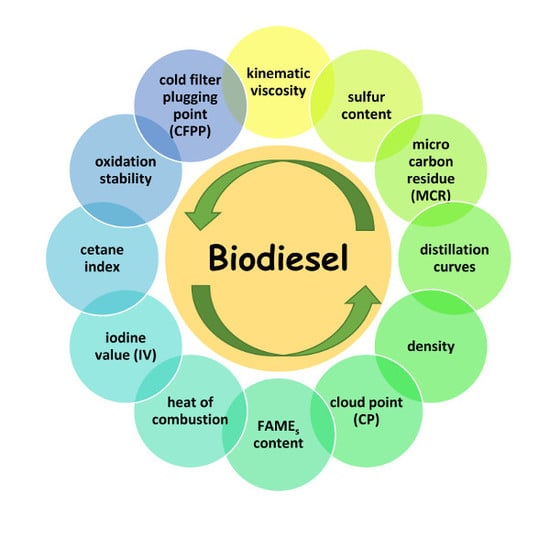

31]. In the same way, nine key points parameters were additionally measured (kinematic viscosity, sulfur content, micro carbon residue (MCR), distillation curves, density, cloud point (CP), FAMEs content, heat of combustion, iodine value (IV)), next to the three latter values, in order to provide a more comprehensive knowledge for the produced mixture.

4. Conclusions

The present paper assesses the possibility of using a biodiesel residual product that was characterized as unsuitable for export purposes (basic properties out of the specifications), as a feedstock to heating oil in order to improve its specifications. Twelve key parameters of the produced mixture were measured following EN and ASTM standards. Blends of biodiesel and heating oils were prepared at different ratios (2.5%, 7%, 10%, 20%, and 50% FAMEs). FAMEs addition from 2.5 to 50% resulted in raised values for a number of fuel properties (e.g., kinematic viscosity, MCR, distillation temperature up to 80% distillate, and density), and decreased values for sulfur content, heat of combustion and oxidation stability. Fuel parameters of IV, CP, CN, CFPP showed a mixed trend. Subsequently, some properties were improved such as oxidation stability, CFPP, cetane index (for Sample 2), sulfur content, while some others were not; albeit, were within specifications (e.g., viscosity and MCR). Nevertheless, further studies on fuel blending are necessary to estimate the potential limitations and advantages of the product mixture, before the wide use of biodiesel and heating oil as a fuel source to replace fossil diesel. Finally, further research and statistical analysis on the domestic residual biodiesel production ought to be performed, prior to a potential new industrial plant taking advantage of the current byproduct and using it as feedstock.