Preparation of Asphalt Concretes by Gyratory Compactor: A Case of Study with Rheological and Mechanical Aspects

Abstract

:1. Introduction

2. Experimental Part

2.1. Neat and RTFOT-Aged Bitumens

2.2. Aggregates Materials: Gradation and Main Properties

2.3. Preparation of Asphalt Concretes Specimens: Volumetric Analysis by Gyratory Compactor (GC) and Indirect Tensile Strength (ITS)

3. Results and Discussion

3.1. Activation Energy (Ea) and Pre-Exponential Factor (ln As)

- (1)

- the filler-containing samples have higher viscosities than the corresponding neat samples, as expected for such kind of samples;

- (2)

- the RTFOT ageing causes an increase in viscosity: this increase is of 17.5 kJ mol−1 for the neat bitumen, and of about 14.3 kJ mol−1 for the bitumen + filler.

3.2. Correlation between Ea and ln As

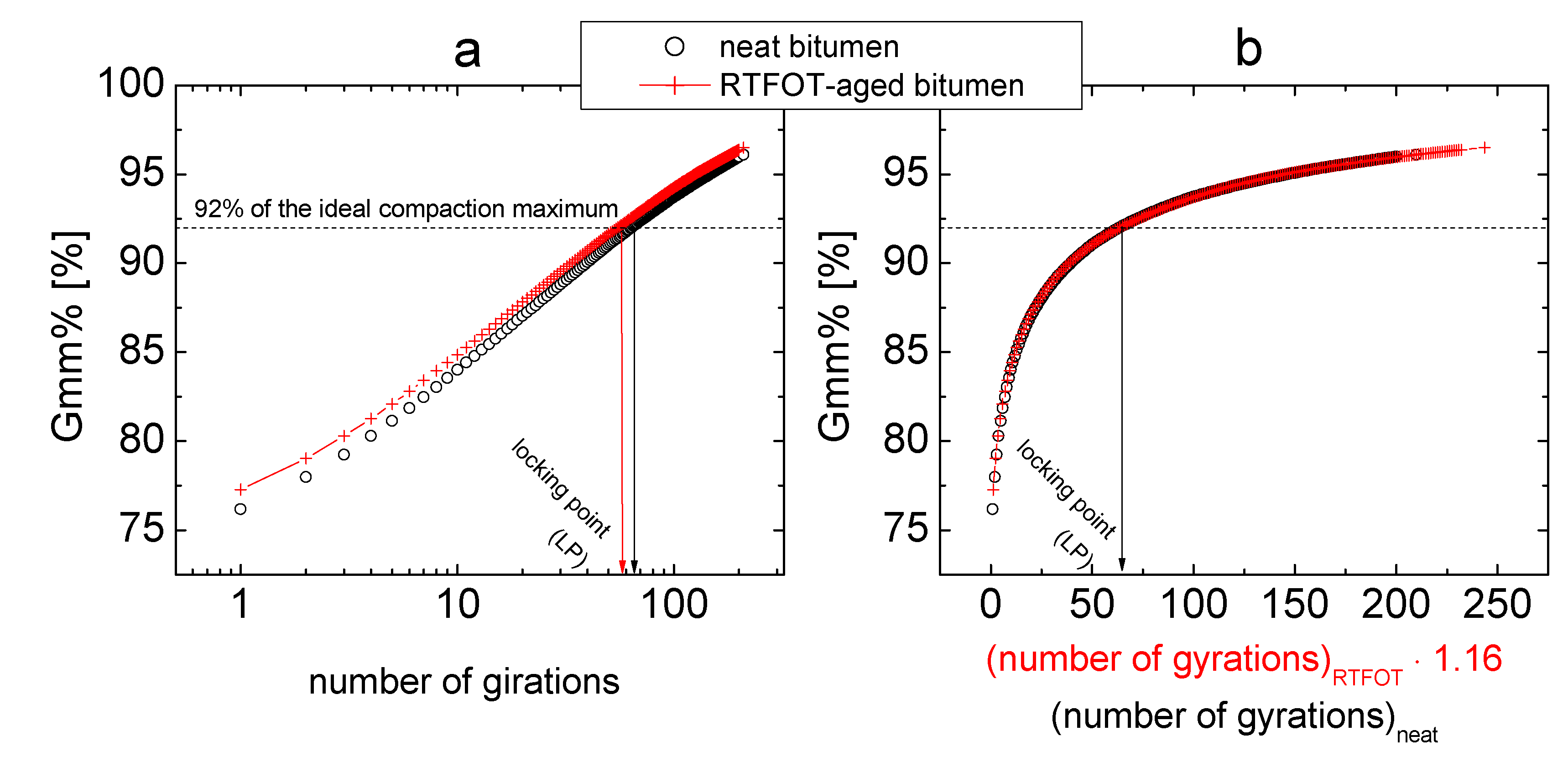

3.3. Volumetric Analysis by Gyratory Compactor

- -

- Density variation (%Gmm);

- -

- Air voids content (%Va);

- -

- Voids in mineral aggregate (%VMA);

- -

- Voids filled with asphalt (%VFA).

- -

- being CDI for the neat bitumen = 5,528 and CDI for the RTFOT-aged bitumen = 4,747, their ratio is 5,528/4,747 = 1.16;

- -

- being LP for the neat bitumen = 63 and LP for the RTFOT-aged bitumen = 54, their ratio is 63/54 = 1.16.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Shin-Che Huang, S.C.; Di Benedetto, H. Advances in Asphalt Materials 1st Edition Road and Pavement Construction; Elsevier Science: Amsterdam, The Netherlands, 2015; Hardcover ISBN 9780081002698, eBook ISBN 9780081002711. [Google Scholar]

- Caputo, P.; Loise, V.; Ashimova, S.; Teltayev, B.; Vaiana, R.; Oliviero Rossi, C. Inverse Laplace Transform (ILT) NMR: A powerful tool to differentiate a real rejuvenator and a softener of aged bitumen. Colloids Surf. A 2019, 574, 154–161. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Sasol Wax Sasobit REDUX Factsheet. 2016. Available online: https://www.sasolwax.com/fileadmin/sasolwax/documents/Asphalt%20Additives/Asphalt_Additive_Sasobit_REDUX.pdf (accessed on 11 April 2020).

- Rowe, G.M.; Baumgardner, G.L.; Reinke, G.; D’Angelo, J.; Anderson, D.A. Evaluation of the BBR test with mixtures containing waxes. In Proceedings of the Binder Expert Task Group Meeting, San Antonio, TX, USA, 14–15 September 2009. [Google Scholar]

- Lu, X.; Redelius, P. Effect of bitumen wax on asphalt mixture performance. Constr. Build. Mater. 2007, 21, 70. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M.C. Study of Surfactant Additives for the Manufacture of Warm Mix Asphalt: From Laboratory Design to Asphalt Plant Manufacture. Appl. Sci. 2017, 7, 745. [Google Scholar] [CrossRef] [Green Version]

- Caputo, P.; Abe, A.A.; Loise, V.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero Rossi, C. The Role of Additives in Warm Mix Asphalt Technology: An Insight into their Mechanisms of Improving an Emerging Technology. Nanomaterials 2020, 10, 1202. [Google Scholar] [CrossRef] [PubMed]

- Prowell, B.D.; Hurley, G.C.; Frank, B. Warm-Mix Asphalt: Best Practices, 2nd ed.; Quality Improvement Publication: Lanham, MD, USA, 2011. [Google Scholar]

- Srikanth, G.; Kumar, R.; Vasudeva, R. A Review on Warm Mix Asphalt. In Proceedings of the National Conference: Advanced Structures, Materials and Methodology in Civil Engineering (ASMMCE–2018), NIT Jalandhar, India, 3–4 November 2018. [Google Scholar]

- Caputo, P.; Ranieri, G.A.; Godbert, N.; Aiello, I.; Tagarelli, A.; Oliviero Rossi, C. Investigation of new additives to reduce the fume emission of bitumen during Asphalt Concrete Processing. Mediterr. J. Chem. 2018, 7, 259–266. [Google Scholar] [CrossRef]

- EAPA. The Use of Warm Mix Asphalt—EAPA Position Paper; European Asphalt Pavement Association: Brussels, Belgium, 2014. [Google Scholar]

- Oliviero Rossi, C.; Caputo, P.; Baldino, N.; Lupi, F.R.; Miriello, D.; Angelico, R. Effects of adhesion promoters on the contact angle of bitumen-aggregate interface. Int. J. Adhes. Adhes. 2016, 70, 297–303. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Oliviero Rossi, C.; Seta, L.; Lupi, F.R.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Caputo, P.; Porto, M.; Calandra, P.; De Santo, M.P.; Oliviero Rossi, C. Effect of epoxidized soybean oil on mechanical properties of bitumen and aged bitumen. Mol. Cryst. Liq. Cryst. 2018, 675, 68–74. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; Ashimova, S.; Fabozzi, A.; D’Errico, G.; Angelico, R. Effects of Natural Antioxidant Agents on the Bitumen Aging Process: An EPR and Rheological Investigation. Appl. Sci. 2018, 8, 1405. [Google Scholar] [CrossRef] [Green Version]

- Porto, M.; Caputo, P.; Loise, V.; De Filpo, G.; Oliviero Rossi, C.; Calandra, P. Polysaccharides-Reinforced Bitumens: Specificities and Universality of Rheological Behavior. Appl. Sci. 2019, 9, 5564. [Google Scholar] [CrossRef] [Green Version]

- Vaiana, R.; Iuele, T.; Gallelli, V.; Tighe, S. Warm mix asphalt by water-containing methodology: A laboratory study on workability properties versus micro-foaming time. Can. J. Civ. Eng. 2014, 41, 183–190. [Google Scholar] [CrossRef]

- Vaiana, R.; Iuele, T.; Gallelli, V. Warm mix asphalt with synthetic zeolite: A laboratory study on mixes workability. Int. J. Pavement Res. Technol. 2013, 6, 562–569. [Google Scholar] [CrossRef]

- Dessouky, S.; Pothuganti, A.; Walubita, L.F.; Rand, D. Laboratory Evaluation of the Workability and Compactability of Asphaltic Materials prior to Road Construction. J. Mater. Civ. Eng. 2013, 25, 810–818. [Google Scholar] [CrossRef]

- Hesami, E.; Jelagin, D.; Kringos, N.; Birgisson, B. An empirical framework for determining asphalt mastic viscosity as a function of mineral filler concentration. Constr. Build. Mater. 2012, 35, 23–29. [Google Scholar] [CrossRef]

- Gudimettla, J.M.; Cooley, L.A., Jr.; Brown, E.R. Workability of Hot-Mix Asphalt. Transp. Res. Rec. 2004, 1891, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Hunter, A.E.; Airey, G.D.; Collop, A.C. Aggregate Orientation and Segregation in Laboratory-Compacted Asphalt Samples. Transp. Res. Rec. 2004, 1891, 8–15. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Dong, Z.; Tan, Z.; Guo, F.; Yan, J. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Miró, R.; Martínez, A.H.; Pérez-Jiménez, F.E.; Botella, R.; Álvarez, A. Effect of filler and content on the bituminous mastic behaviour under cyclic loads. Constr. Build. Mater. 2017, 132, 33–42. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, J.; Jiao, Y.; Tan, G.; Guo, Q.; Wang, S.; Ni, P. Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr. Build. Mater. 2016, 118, 268–275. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Influence of the geometrical and physical properties of filler in the filler–bitumen interaction. Constr. Build. Mater. 2015, 76, 322–329. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Effect of the chemical composition of fillers in the filler–bitumen interaction. Constr. Build. Mater. 2016, 104, 85–91. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Chen, X. Effects of mineral fillers on hot-mix asphalt laboratory-measured properties. Int. J. Pavement Eng. 2007, 8, 1–9. [Google Scholar] [CrossRef]

- Khan, Z.A.; Al-Abdul Wahab, H.I.; Asi, I.; Ramadhan, R. Comparative study of asphalt concrete laboratory compaction methods to simulate field compaction. Constr. Build. Mater. 1998, 12, 373–384. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R.; Moro, A. Dependence of Volumetric Parameters of Hot Mix Asphalts on Testing Methods. J. Mater. Civ. Eng. 2014, 26, 45–53. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R. A study on volumetric versus surface properties of wearing courses. Constr. Build. Mater. 2013, 38, 766–775. [Google Scholar] [CrossRef]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structure and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Okan, S.; Dalim, K.P.; Emad, K. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 2018, 3428961. [Google Scholar] [CrossRef] [Green Version]

- Oliviero Rossi, C.; Caputo, P.; Loise, V.; Miriello, D.; Teltayev, B.; Angelico, R. Role of food grade additive in the high temperature performance of modified bitumens. Colloids Surf. A Phys. Eng. Asp. 2017, 592, 618–624. [Google Scholar] [CrossRef]

- Ashimova, S.; Teltayev, B.; Oliviero Rossi, C.; Caputo, P.; Eskandarsefat, S. Organic-based recycling agents for road paving applications in cold-climate regions. Int. J. Pavement Eng. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; De Luca, G.; Maiuolo, L.; Eskandarsefat, S.; Sangiorgi, C. 1H-NMR Spectroscopy: A Possible Approach to Advanced Bitumen Characterization for Industrial and Paving Applications. Appl. Sci. 2018, 8, 229. [Google Scholar] [CrossRef] [Green Version]

- Caputo, P.; Loise, V.; Crispini, A.; Sangiorgi, C.; Scarpelli, F.; Oliviero Rossi, R. The efficiency of bitumen rejuvenator investigated through Powder X-ray Diffraction (PXRD) analysis and T2-NMR spectroscopy. Colloids Surf. A 2019, 571, 50–54. [Google Scholar] [CrossRef]

- Yen, T.F.; Chilingarian, G.V. Asphalthenes and Asphalts; Elsevier: New York, NY, USA, 1994. [Google Scholar]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Turco Liveri, V.; Oliviero Rossi, C. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Petersen, J.C. Chemical Composition of Asphalt as Related to Asphalt Durability: State of the Art. Transp. Res. Rec. 1984, 999, 13–30. [Google Scholar]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Hunter, R.N., Ed.; Thomas Telford Publishing: London, UK, 2003. [Google Scholar]

- Sheu, E.Y.; Storm, D.A. Colloidal properties of asphaltenes in organic solvents. In Asphaltenes: Fundamentals and Applications; Sheu, E.Y., Mullins, O.C., Eds.; Plenum Press: New York, NY, USA, 1995; Chapter 1. [Google Scholar]

- Yoon, S.; Durgashanker Bhatt, S.; Lee, W.; Lee, H.Y.; Jeong, S.Y.; Baeg, J.-O.; Wee Lee, C. Separation and characterization of bitumen from Athabasca oil sand. Korean. J. Chem. Eng. 2009, 26, 64–71. [Google Scholar]

- ANAS. Special Tender Specifications. In Road Paving; Technical Standards: Rome, Italy, 2009. [Google Scholar]

- Kennedy, T.W.; Huber, G.A.; Harrigan, E.T.; Cominsky, R.J.; Hughes, C.S.; Von Quintus, H.; Moulthrop, J.S. Superior Performing Asphalt Pavements (Superpave): The Product of the SHRP Asphalt Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Kuang, X.; Liu, G.; Dong, X.; Wang, D. Correlation between stress relaxation dynamics and thermochemistry for covalent adaptive networks polymers. Mater. Chem. Front. 2017, 1, 111–118. [Google Scholar] [CrossRef]

- Calandra, P.; Nicotera, I.; Oliviero Rossi, C.; Turco Liveri, V. Dynamical properties of self-assembled surfactant-based mixtures: Triggering of 1D anomalous diffusion in bis(2-ethylhexyl) phosphoric acid/n-octylamine systems. Langmuir 2013, 29, 14848–14854. [Google Scholar] [CrossRef]

- Calandra, P.; Turco Liveri, V.; Monia Ruggirello, A.; Licciardi, M.; Lombardo, D.; Mandanici, A. Anti-Arrhenian behaviour of conductivity in octanoic acid–bis(2-ethylhexyl)amine systems: A physico-chemical study. J. Mater. Chem. C 2015, 3, 3198–3210. [Google Scholar] [CrossRef]

- Petrowsky, M.; Frech, R. Application of the compensated arrhenius formalism to dielectric relaxation. J. Phys. Chem. B 2009, 113, 16118–16123. [Google Scholar] [CrossRef]

- Loise, V.; Caputo, P.; Porto, M.; Teltayev, B.; Angelico, R.; Oliviero Rossi, C. Unravelling the role of a green rejuvenator agent in contrasting the aging effect on bitumen: A dynamics rheology, nuclear magnetic relaxometry and self-diffusion study. Colloids Surf. A 2020, 603, 125182. [Google Scholar] [CrossRef]

- Cummings, P.T.; Evans, D.J. Nonequilibrium molecular dynamics approaches to transport properties and non-Newtonian fluid rheology. Ind. Eng. Chem. Res. 1992, 31, 1237–1252. [Google Scholar] [CrossRef]

- Carvalho-Silva, V.H.; Coutinho, N.D.; Aquilanti, V. Temperature Dependence of Rate Processes Beyond Arrhenius and Eyring: Activation and Transitivity. Front. Chem. 2019, 7, 380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scherer, G.W. Use of the Adam-Gibbs Equation in the Analysis of Structural Relaxation. J. Am. Ceram. Soc. 1984, 67, 504–511. [Google Scholar] [CrossRef]

- Eyring, H. The activated complex in chemical reactions. J. Chem. Phys. 1935, 3, 107–115. [Google Scholar] [CrossRef]

- Tyrrell, H.J.V.; Harris, K.R. Diffusion in Liquids; Butterworths: London, UK, 1984. [Google Scholar]

- El Asjadi, S.; Nederpel, Q.A.; Cotiuga, I.M.; Picken, S.J.; Besseling, N.A.M.; Mendes, E.; Lommerts, B.J. Biopolymer scleroglucan as an emulsion stabilizer. Colloids Surf. A Physicochem. Eng. Asp. 2018, 546, 326–333. [Google Scholar] [CrossRef]

- Byran, J.; Kantzas, A.; Bellehumer, C. Oil-viscosity predictions from low-field NMR measurements. SPE Reserv. Eval. Eng. 2005, 8, 44–52. [Google Scholar] [CrossRef]

- Messaâdi, A.; Dhouibi, N.; Hamda, H.; Belgacem, F.B.M.; Adbelkader, Y.H.; Ouerfelli, N.; Hamzaoui, A.H. A New Equation Relating the Viscosity Arrhenius Temperature and the Activation Energy for Some Newtonian Classical Solvents. J. Chem. 2015, 2015, 163262. [Google Scholar] [CrossRef] [Green Version]

- Polaczyk, P.; Huang, B.; Shu, X.; Gong, H. Investigation into Locking Point of Asphalt Mixtures Utilizing Superpave and Marshall Compactors. J. Mater. Civ. Eng. 2019, 31, 04019188. [Google Scholar] [CrossRef]

- Bahia, H.U.; Friemel, T.P.; Peterson, P.A.; Russell, J.S.; Poehnelt, B. Optimization of constructibility and resistance to traffic: A new design approach for HMA using the superpave compactor. J. Assoc. Asph. Paving Technol. 1998, 67, 189–232. [Google Scholar]

- Caputo, P.; Porto, M.; Loise, V.; Teltayev, B.; Oliviero Rossi, C. Analysis of mechanical performance of bitumen modified with waste plastic and rubber (SBR) additives by rheology and PGSE NMR experiments. Eurasian Chem. Technol. J. 2019, 21, 235–239. [Google Scholar] [CrossRef]

- Caputo, P.; Shaikhah, D.; Porto, M.; Loise, V.; De Santo, M.P.; Oliviero Rossi, C. NMR Di_usiometry Spectroscopy, a Novel Technique for Monitoring the Micro-Modifications in Bitumen Ageing. Appl. Sci. 2020, 10, 5409. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; Loise, V.; Ashimova, S.; Teltayev, B.; Sangiorgi, C. A New Green Rejuvenator: Evaluation of Structural Changes of Aged and Recycled Bitumens by Means of Rheology and NMR; Springer: Cham, Switzerland, 2019; pp. 177–182. [Google Scholar] [CrossRef]

- Błażejowski, K.; Olszacki, J.; Peciakowski, H.; Wójcik-Wiśniewska, M. Testing of bitumen-aggregate affinity by various methods. In Proceedings of the 16th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Farcas, F. Étude d’une Méthode de Simulation du Vieillissement des Bitumes sur Route; LCPC Research Report CR21; LCPC: Paris, France, 1998. [Google Scholar]

- Abdo, A.A.; Bayomy, F.; Masad, E.; Santi, M. Evaluation of Aggregate Structure Stability Using the Superpave Gyratory Compactor. In Proceedings of the Transportation Research Board 85th Annual Meeting, Washington, DC, USA, 22–26 January 2006. [Google Scholar]

- Sanchez-Alonso, E.; Vega-Zamanillo, A.; Castro-Fresno, D.; Del Rio-Prat, M. Evaluation of compactibility and mechanical properties of bituminous mixes with warm additives. Constr. Build. Mater. 2011, 25, 2304–2311. [Google Scholar] [CrossRef]

- Mo, L.; Li, X.; Fang, X.; Huurman, M.; Wu, S. Laboratory investigation of compaction characteristics and performance of warm mix asphalt containing chemical additives. Constr. Build. Mater. 2012, 37, 239–247. [Google Scholar] [CrossRef]

- Kanitpong, K.; Sonthong, S.; Nam, K.; Martono, W.; Bahia, H.U. Laboratory Study on Warm Mix Asphalt Additives. In Proceedings of the Transportation Research Board 86th Annual Meeting, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- Faheem, A.; Bahia, H.U. Using the Gyratory Compactor to Measure Mechanical Stability of Asphalt Mixtures; Wisconsin Highway Research Program Report, N. WHRP 05-02; Wisconsin Department of Transportation: Madison, WI, USA, 2004.

- Sadasivam, S. Evaluation of the Effects of Compaction Methods on the Predicted Performance of Superpave Mixtures. Master’s Thesis, Graduate Faculty of North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

| BITUMEN | Penetration (dmm) (±1) | Ring and Ball (°C) (±1) |

|---|---|---|

| Neat | 66 | 48 |

| RTFOT-Aged | 27 | 59 |

| Aggregate Type | Test/Index | Value | Standard |

|---|---|---|---|

| Coarse Aggregate | Aggregate nature | Limestone | - |

| Los Angeles Abrasion Test [%] | 21 | EN 1097–2 (2010) | |

| Shape Index [%] | 26 | EN 933-4 (2008) | |

| Aggregate density [g/cm3] | 2.772 | EN 15326 (2009) | |

| Fine Aggregate | Aggregate nature | Limestone | - |

| Sand Equivalent Test [%] | 94 | EN 933-8 (2012) | |

| Fine Aggregate Angularity Index [%] | 46 | ASTM C1252 (2006) | |

| Filler Stiffness Power (filler/binder = 1.5) | 8 °C (°) | EN 13179-1 (2013) | |

| (°) ΔR&B = Delta ring and ball test (EN 1427:2015) | |||

| Neat Bitumen Mix | RTFOT-Aged Bitumen Mix | Acceptance Thresholds [45] | |

|---|---|---|---|

| bulk density (g/cm3) | 2.481 ± 0.005 | 2.465 ± 0.005 | - |

| Marshall Stability (KN) | 11.9 ≈± 0.4 | 13.0 ± 0.4 | >11 |

| Flow (mm) | 2.5 ± 0.2 | 1.9 ± 0.2 | - |

| Marshall Quotient (KN/mm) | 4.8 ± 0.5 | 6.8 ± 0.5 | >3 |

| Neat Bitumen | |||||

|---|---|---|---|---|---|

| Number of Gyrations | %Gmm | %VMA | %VFA | %Va | %Va Acceptance Thresholds [45] |

| Nini = 10 | 84.0 | 26 | 38 | 16 | 11–15 |

| NLP = 63 | 92.0 | 19 | 57 | 8 | - |

| Ndes = 120 | 94.3 | 17 | 66 | 6 | 3–6 |

| Nmax = 210 | 96.1 | 15 | 74 | 4 | ≥2 |

| RTFOT-Aged Bitumen | |||||

|---|---|---|---|---|---|

| Number of Gyrations | %Gmm | %VMA | %VFA | %Va | %Va Acceptance Thresholds [45] |

| Nini = 10 | 84.9 | 25 | 39 | 15 | 11–15 |

| NLP = 54 | 92.0 | 19 | 57 | 8 | - |

| Ndes = 120 | 94.9 | 16 | 68 | 5 | 3–6 |

| Nmax = 210 | 96.5 | 15 | 76 | 3 | ≥2 |

| Index | Neat Bitumen Mix | RTFOT-Aged Bitumen Mix | Ratio |

|---|---|---|---|

| Locking point (LP) | 63 | 54 | 1.16 |

| CDI | 5528 | 4747 | 1.16 |

| TDI | 378 | 451 | 0.84 |

| CFI [kN m−2] | 24,930 | 21,540 | 1.16 |

| TFI [kN m−2] | 65,370 | 70,590 | 0.93 |

| Standard Deviation | Neat Bitumen Mix | RTFOT-Aged Bitumen Mix | Acceptance Thresholds [45] | |

|---|---|---|---|---|

| Indirect Tensile Strength [N/mm2] | (0.05) | 1.03 | 1.72 | >0.7 |

| ITS Coefficient [N/mm2] | (25) | 177 | 390 | >65 |

| Compression deformation [mm] | (0.1) | 1.0 | 0.7 | - |

| Tensile deformation [mm] | (0.02) | 0.28 | 0.25 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caputo, P.; Calandra, P.; Vaiana, R.; Gallelli, V.; De Filpo, G.; Oliviero Rossi, C. Preparation of Asphalt Concretes by Gyratory Compactor: A Case of Study with Rheological and Mechanical Aspects. Appl. Sci. 2020, 10, 8567. https://doi.org/10.3390/app10238567

Caputo P, Calandra P, Vaiana R, Gallelli V, De Filpo G, Oliviero Rossi C. Preparation of Asphalt Concretes by Gyratory Compactor: A Case of Study with Rheological and Mechanical Aspects. Applied Sciences. 2020; 10(23):8567. https://doi.org/10.3390/app10238567

Chicago/Turabian StyleCaputo, Paolino, Pietro Calandra, Rosolino Vaiana, Vincenzo Gallelli, Giovanni De Filpo, and Cesare Oliviero Rossi. 2020. "Preparation of Asphalt Concretes by Gyratory Compactor: A Case of Study with Rheological and Mechanical Aspects" Applied Sciences 10, no. 23: 8567. https://doi.org/10.3390/app10238567