Review on Application of Quaternary Ammonium Salts for Gas Hydrate Inhibition

Abstract

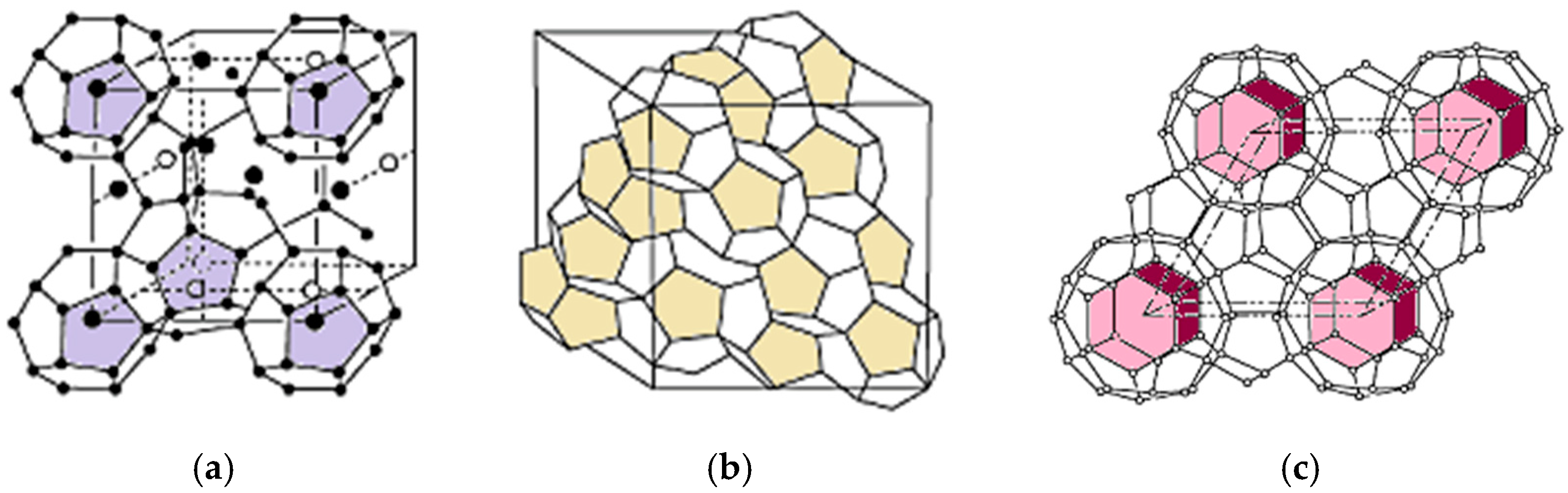

:1. Introduction

2. Flow Assurance Issues Related to Natural Gas

3. Gas Hydrate Inhibition

3.1. Thermodynamic Hydrate Inhibitors (THIs) and Low Dosage Hydrate Inhibitors (LDHIs)

3.2. Quaternary Ammonium Salts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, W.; Li, X.; Hu, J.; Wu, K.; Sun, F.; Sun, Z.; Chu, H.; Qi, X. Research on flow assurance of deepwater submarine natural gas pipelines: Hydrate prediction and prevention. J. Loss Prev. Process Ind. 2019, 61, 130–146. [Google Scholar] [CrossRef]

- Fang, H.; Duan, M. Chapter 4—Special problems of deep-sea oil and gas engineering. Offshore Oper. Facil. 2014, 537–686. [Google Scholar] [CrossRef]

- Hong, S.Y.; Lim, J.I.; Kim, J.H.; Lee, J.D. Kinetic studies on methane hydrate formation in the presence of kinetic inhibitor via in situ Raman spectroscopy. Energy Fuels 2012, 26, 7045–7050. [Google Scholar] [CrossRef]

- Abbasi, A.; Hashim, F.M. A review on the Application of Empirical Models to Hydrate Formation Prediction. MATEC Web Conf. 2014, 13, 02035. [Google Scholar] [CrossRef]

- Ke, W.; Svartaas, T.M.; Chen, D. A review of gas hydrate nucleation theories and growth models. J. Nat. Gas Sci. Eng. 2019, 61, 169–196. [Google Scholar] [CrossRef]

- Glew, D.N. Some Stoicheiometric Gas Hydrates. Nature 1959, 184, 545–546. [Google Scholar] [CrossRef]

- Davidson, D. The motion of guest molecules in clathrate hydrates. Can. J. Chem. 1971, 49, 1224–1242. [Google Scholar] [CrossRef]

- Krishna, L.; Koh, C.A. Inorganic and methane clathrates: Versatility of guest-host compounds for energy harvesting. MRS Energy Sustain. 2015, 2, E8. [Google Scholar] [CrossRef] [Green Version]

- Ke, W.; Kelland, M.A. Kinetic hydrate inhibitor studies for gas hydrate systems: A review of experimental equipment and test methods. Energy Fuels 2016, 30, 10015–10028. [Google Scholar] [CrossRef]

- Tariq, M.; Rooney, D.; Othman, E.; Aparicio, S.; Atilhan, M.; Khraisheh, M. Gas Hydrate Inhibition: A Review of the Role of Ionic Liquids. Ind. Eng. Chem. Res. 2014, 53, 17855–17868. [Google Scholar] [CrossRef]

- De Menezes, D.É.S.; Filho, P.D.P.; Fuentes, M.D.R. Use of 1-Butyl-3-methylimidazolium-based ionic liquids as methane hydrate inhibitors at high pressure conditions. Chem. Eng. Sci. 2019, 115323. [Google Scholar] [CrossRef]

- Lederhos, J.; Long, J.; Sum, A.; Christiansen, R.; Sloan, E., Jr. Effective kinetic inhibitors for natural gas hydrates. Chem. Eng. Sci. 1996, 51, 1221–1229. [Google Scholar] [CrossRef]

- Del Villano, L.; Kommedal, R.; Kelland, M.A. Class of kinetic hydrate inhibitors with good biodegradability. Energy Fuels 2008, 22, 3143–3149. [Google Scholar] [CrossRef]

- Kelland, M.A. History of the Development of Low Dosage Hydrate Inhibitors. Energy Fuels 2006, 20, 825–847. [Google Scholar] [CrossRef]

- Sum, A.K.; Sandler, S.I. Ab initio calculations of cooperativity effects on clusters of methanol, ethanol, 1-propanol, and methanethiol. J. Phys. Chem. A 2000, 104, 1121–1129. [Google Scholar] [CrossRef]

- Masoudi, R.; Tohidi, B.; Anderson, R.; Burgass, R.W.; Yang, J. Experimental measurement and thermodynamic modelling of clathrate hydrate equilibria and salt solubility in aqueous ethylene glycol and electrolyte solutions. Fluid Phase Equilib. 2004, 219, 157–163. [Google Scholar] [CrossRef]

- Cha, M.; Shin, K.; Kim, J.; Chang, D.; Seo, Y.; Lee, H.; Kang, S.-P. Thermodynamic and kinetic hydrate inhibition performance of aqueous ethylene glycol solutions for natural gas. Chem. Eng. Sci. 2013, 99, 184–190. [Google Scholar] [CrossRef]

- Ahmed, T. Equations of State and PVT Analysis; Gulf Publishing Company: Houston, TX, USA, 2007. [Google Scholar]

- Mokhatab, S.; Poe, W.A. Handbook of Natural Gas Transmission and Processing; Gulf Professional Publishing: Houston, TX, USA, 2012. [Google Scholar]

- Khan, M.S.; Lal, B.; Shariff, A.M.; Mukhtar, H. Ammonium hydroxide ILs as dual-functional gas hydrate inhibitors for binary mixed gas (carbon dioxide and methane) hydrates. J. Mol. Liquids 2019, 274, 33–44. [Google Scholar] [CrossRef]

- Wang, Y.; Koh, C.A.; White, J.; Patel, Z.; Zerpa, L.E. Hydrate formation management simulations with anti-agglomerants and thermodynamic inhibitors in a subsea tieback. Fuel 2019, 252, 458–468. [Google Scholar] [CrossRef]

- Guo, Y.; Meng, X.; Meng, T.; Wang, D.; Liu, S. A novel method of risk assessment based on cloud inference for natural gas pipelines. J. Nat. Gas Sci. Eng. 2016, 30, 421–429. [Google Scholar] [CrossRef]

- Wasden, F.K. Flow Assurance in Deepwater Flowlines and Pipelines—Challenges Met, Challenges Remaining. Presented at the Presented at the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2003. [Google Scholar]

- Yu, W.; Song, S.; Li, Y.; Min, Y.; Huang, W.; Wen, K.; Gong, J. Gas supply reliability assessment of natural gas transmission pipeline systems. Energy 2018, 162, 853–870. [Google Scholar] [CrossRef]

- Yu, W.; Wen, K.; Min, Y.; He, L.; Huang, W.; Gong, J. A methodology to quantify the gas supply capacity of natural gas transmission pipeline system using reliability theory. Reliab. Eng. Syst. Saf. 2018, 175, 128–141. [Google Scholar] [CrossRef]

- Sloan, E.D. Natural Gas Hydrates in Flow Assurance; Gulf Professional Publishing: Houston, TX, USA, 2010. [Google Scholar]

- Chaudhari, P.; Zerpa, L.E.; Sum, A.K. A correlation to quantify hydrate plugging risk in oil and gas production pipelines based on hydrate transportability parameters. J. Nat. Gas Sci. Eng. 2018, 58, 152–161. [Google Scholar] [CrossRef]

- Trummer, S.A.; Mohallem, R.; Franco, E.; de Assis, J.V. Hydrate Remediation During Well Testing Operations in the Deepwater Campos Basin, Brazil. Presented at the Presented at the SPE/ICoTA Coiled Tubing & Well Intervention Conference & Exhibition, The Woodlands, TX, USA, 26–27 March 2013. [Google Scholar]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Gulf Professional Publishing: Houston, TX, USA, 2012. [Google Scholar]

- Tang, C.; Liang, D. Inhibitory effects of novel green inhibitors on gas hydrate formation. Chin. J. Chem. Eng. 2019, 27, 2107–2117. [Google Scholar] [CrossRef]

- Khan, M.S.; Lal, B.; Bustam, M.A. Gas Hydrate Inhibitors. In Chemical Additives for Gas Hydrates; Springer: Berlin/Heidelberg, Germany, 2020; pp. 27–46. [Google Scholar]

- Sloan, E.D., Jr.; Koh, C.A. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Ke, W.; Chen, D. A short review on natural gas hydrate, kinetic hydrate inhibitors and inhibitor synergists. Chin. J. Chem. Eng. 2019, 27, 2049–2061. [Google Scholar] [CrossRef]

- Cha, J.-H.; Kang, S.-P.; Han, S.; Kang, J.W.; Kim, K.-S. Phase equilibria of CH4 and CO2 hydrates formed from aqueous solutions of glutaric acid and malonic acid. Fluid Phase Equilib. 2016, 413, 71–74. [Google Scholar] [CrossRef]

- Kakati, H.; Mandal, A.; Laik, S. Synergistic effect of Polyvinylpyrrolidone (PVP) and L-tyrosine on kinetic inhibition of CH4+C2H4+C3H8 hydrate formation. J. Nat. Gas Sci. Eng. 2016, 34, 1361–1368. [Google Scholar] [CrossRef]

- Khan, M.S.; Lal, B.; Keong, L.K.; Ahmed, I. Tetramethyl ammonium chloride as dual functional inhibitor for methane and carbon dioxide hydrates. Fuel 2019, 236, 251–263. [Google Scholar] [CrossRef]

- Lee, D.; Go, W.; Seo, Y. Experimental and computational investigation of methane hydrate inhibition in the presence of amino acids and ionic liquids. Energy 2019, 182, 632–640. [Google Scholar] [CrossRef]

- Sa, J.H.; Kwak, G.H.; Han, K.; Ahn, D.; Cho, S.J.; Lee, J.D.; Lee, K.H. Inhibition of methane and natural gas hydrate formation by altering the structure of water with amino acids. Sci. Rep. 2016, 6, 31582. [Google Scholar] [CrossRef] [PubMed]

- Sa, J.-H.; Kwak, G.-H.; Lee, B.R.; Park, D.-H.; Han, K.; Lee, K.-H. Hydrophobic amino acids as a new class of kinetic inhibitors for gas hydrate formation. Sci. Rep. 2013, 3, 2428. [Google Scholar] [CrossRef] [PubMed]

- Sa, J.-H.; Lee, B.R.; Park, D.-H.; Han, K.; Chun, H.D.; Lee, K.-H. Amino Acids as Natural Inhibitors for Hydrate Formation in CO2 Sequestration. Environ. Sci. Technol. 2011, 45, 5885–5891. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-S.; Kang, J.W.; Kang, S.-P. Tuning ionic liquids for hydrate inhibition. Chem. Commun. 2011, 47, 6341–6343. [Google Scholar] [CrossRef]

- Xiao, C.; Wibisono, N.; Adidharma, H. Dialkylimidazolium halide ionic liquids as dual function inhibitors for methane hydrate. Chem. Eng. Sci. 2010, 65, 3080–3087. [Google Scholar] [CrossRef]

- Xiao, C.; Adidharma, H. Dual function inhibitors for methane hydrate. Chem. Eng. Sci. 2009, 64, 1522–1527. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Ionic liquids:“designer” solvents for green chemistry. Methods Reag. Green Chem. 2007, 105–130. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Applications of ionic liquids in the chemical industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef] [PubMed]

- Marsh, K.N.; Deev, A.; Wu, A.C.; Tran, E.; Klamt, A. Room temperature ionic liquids as replacements for conventional solvents—A review. Korean J. Chem. Eng. 2002, 19, 357–362. [Google Scholar] [CrossRef]

- Stojanovic, A.; Morgenbesser, C.; Kogelnig, D.; Krachler, R.; Keppler, B.K. Quaternary ammonium and phosphonium ionic liquids in chemical and environmental engineering. In Ionic Liquids: Theory, Properties, New Approaches; IntechOpen: London, UK, 2011. [Google Scholar]

- Boethling, R.S.; Lynch, D.G. Quaternary ammonium surfactants. In Detergents; Springer: Berlin/Heidelberg, Germany, 1992; pp. 145–177. [Google Scholar]

- Juergensen, L.; Busnarda, J.; Caux, P.Y.; Kent, R.A. Fate, behavior, and aquatic toxicity of the fungicide DDAC in the Canadian environment. Environ. Toxicol. 2000, 15, 174–200. [Google Scholar] [CrossRef]

- Wasserscheid, P.; Welton, T. Ionic Liquids in Synthesis; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Chowdhury, S.; Mohan, R.S.; Scott, J.L. Reactivity of ionic liquids. Tetrahedron 2007, 63, 2363–2389. [Google Scholar] [CrossRef] [Green Version]

- Rogers, R.D.; Seddon, K.R.; Volkov, S. Green Industrial Applications of Ionic Liquids; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Leyma, R.; Platzer, S.; Jirsa, F.; Kandioller, W.; Krachler, R.; Keppler, B.K. Novel thiosalicylate-based ionic liquids for heavy metal extractions. J. Hazard. Mater. 2016, 314, 164–171. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, M.S.; Lal, B.; Bavoh, C.B.; Keong, L.K.; Bustam, A.; Mellon, N.B. Influence of Ammonium based Compounds for Gas Hydrate Mitigation: A Short Review. Indian J. Sci. Technol. 2017, 10, 1–6. [Google Scholar] [CrossRef]

- Gupta, P.; Nair, V.C.; Sangwai, J.S. Phase Equilibrium of Methane Hydrate in the Presence of Aqueous Solutions of Quaternary Ammonium Salts. J. Chem. Eng. Data 2018, 63, 2410–2419. [Google Scholar] [CrossRef]

- Kazemi, F.; Javanmardi, J.; Aftab, S.; Mohammadi, A.H. Experimental study and thermodynamic modeling of the stability conditions of methane clathrate hydrate in the presence of TEACl and/or BMIM-BF4 in aqueous solution. J. Chem. Thermodyn. 2019, 130, 95–103. [Google Scholar] [CrossRef]

- Qasim, A.; Khan, M.S.; Lal, B.; Ismail, M.C.; Rostani, K. Quaternary ammonium salts as thermodynamic hydrate inhibitors in the presence and absence of monoethylene glycol for methane hydrates. Fuel 2020, 259, 116219. [Google Scholar] [CrossRef]

- Qasim, A.; Khan, M.S.; Lal, B.; Shariff, A.M. Phase equilibrium measurement and modeling approach to quaternary ammonium salts with and without monoethylene glycol for carbon dioxide hydrates. J. Mol. Liquids 2019, 282, 106–114. [Google Scholar] [CrossRef]

- Rasoolzadeh, A.; Javanmardi, J.; Mohammadi, A.H. An experimental study of the synergistic effects of BMIM-BF4, BMIM-DCA and TEACl aqueous solutions on methane hydrate formation. Pet. Sci. 2019, 16, 409–416. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Bernardi, S.; Searles, D.J.; Wang, L. Effect of Carbon Chain Length of Organic Salts on the Thermodynamic Stability of Methane Hydrate. J. Chem. Eng. Data 2016, 61, 1952–1960. [Google Scholar] [CrossRef]

- Su, Y.; Bernardi, S.; Searles, D.J.; Wang, L. Phase equilibria and gas storage capacity of clathrate hydrates of methane+ quaternary ammonium salts. In Proceedings of the Chemeca 2016: Chemical Engineering—Regeneration, Recovery and Reinvention, Adelaide, Australia, 25–28 September 2016; p. 418. [Google Scholar]

- Peng, B.-Z.; Chen, J.; Sun, C.-Y.; Dandekar, A.; Guo, S.-H.; Liu, B.; Mu, L.; Yang, L.-Y.; Li, W.-Z.; Chen, G.-J. Flow characteristics and morphology of hydrate slurry formed from (natural gas+ diesel oil/condensate oil+ water) system containing anti-agglomerant. Chem. Eng. Sci. 2012, 84, 333–344. [Google Scholar] [CrossRef]

- Nashed, O.; Dadebayev, D.; Khan, M.S.; Bavoh, C.B.; Lal, B.; Shariff, A.M. Experimental and modelling studies on thermodynamic methane hydrate inhibition in the presence of ionic liquids. J. Mol. Liquids 2018, 249, 886–891. [Google Scholar] [CrossRef]

- Kelland, M.A.; Hartanti, A.R.D.; Ruysschaert, W.G.Z.; Thorsen, H.B. Tetrahydrofuran Hydrate Crystal Growth Inhibition with Synergistic Mixtures: Insight into Gas Hydrate Inhibition Mechanisms. Energy Fuels 2017, 31, 8109–8115. [Google Scholar] [CrossRef]

- Dickens, G.R.; Quinby-Hunt, M.S. Methane hydrate stability in pore water: A simple theoretical approach for geophysical applications. J. Geophys. Res. Solid Earth 1997, 102, 773–783. [Google Scholar] [CrossRef]

- Bavoh, C.B.; Nashed, O.; Khan, M.S.; Partoon, B.; Lal, B.; Sharif, A.M. The impact of amino acids on methane hydrate phase boundary and formation kinetics. J. Chem. Thermodyn. 2018, 117, 48–53. [Google Scholar] [CrossRef]

- Partoon, B.; Wong, N.M.S.; Sabil, K.M.; Nasrifar, K.; Ahmad, M.R. A study on thermodynamics effect of [EMIM]-Cl and [OH-C2MIM]-Cl on methane hydrate equilibrium line. Fluid Phase Equilib. 2013, 337, 26–31. [Google Scholar] [CrossRef]

- Bavoh, C.B.; Partoon, B.; Lal, B.; Gonfa, G.; Khor, S.F.; Sharif, A.M. Inhibition effect of amino acids on carbon dioxide hydrate. Chem. Eng. Sci. 2017, 171, 331–339. [Google Scholar] [CrossRef]

- Khan, M.S.; Bavoh, C.B.; Partoon, B.; Nashed, O.; Lal, B.; Mellon, N.B. Impacts of ammonium based ionic liquids alkyl chain on thermodynamic hydrate inhibition for carbon dioxide rich binary gas. J. Mol. Liquids 2018, 261, 283–290. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Gulf Professional Publishing: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Peng, X.; Hu, Y.; Liu, Y.; Jin, C.; Lin, H. Separation of ionic liquids from dilute aqueous solutions using the method based on CO2 hydrates. J. Nat. Gas Chem. 2010, 19, 81–85. [Google Scholar] [CrossRef]

- Cha, J.-H.; Kim, K.-S.; Lee, H. Size-selective Pd nanoparticles stabilized by dialkylmorpholinium ionic liquids. Korean J. Chem. Eng. 2009, 26, 760–764. [Google Scholar] [CrossRef]

- Li, X.-S.; Liu, Y.-J.; Zeng, Z.-Y.; Chen, Z.-Y.; Li, G.; Wu, H.-J. Equilibrium hydrate formation conditions for the mixtures of methane+ ionic liquids+ water. J. Chem. Eng. Data 2010, 56, 119–123. [Google Scholar] [CrossRef]

- Koh, C.A.; Sloan, E.D.; Sum, A.K.; Wu, D.T. Fundamentals and Applications of Gas Hydrates. Annu. Rev. Chem. Biomol. Eng. 2011, 2, 237–257. [Google Scholar] [CrossRef] [PubMed]

- Holder, G.D.; Mokka, L.P.; Warzinski, R.P. Formation of gas hydrates from single-phase aqueous solutions. Chem. Eng. Sci. 2001, 56, 6897–6903. [Google Scholar] [CrossRef]

- Peng, D.-Y.; Robinson, D.B. A New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Shen, X.-D.; Zhou, X.-B.; Liang, D.-Q. Kinetic Effects of Ionic Liquids on Methane Hydrate. Energy Fuels 2019, 33, 1422–1432. [Google Scholar] [CrossRef]

- Renon, H.; Prausnitz, J.M. Liquid-Liquid and Vapor-Liquid Equilibria for Binary and Ternary Systems with Dibutyl Ketone, Dimethyl Sulfoxide, n-Hexane, and 1-Hexene. Ind. Eng. Chem. Fundam. Process Des. Dev. 1968, 7, 220–225. [Google Scholar] [CrossRef]

- Renon, H.; Prausnitz, J.M. Local compositions in thermodynamic excess functions for liquid mixtures. AIChE J. 1968, 14, 135–144. [Google Scholar] [CrossRef]

- Sabil, K.M.; Nashed, O.; Lal, B.; Ismail, L.; Japper-Jaafar, A. Experimental investigation on the dissociation conditions of methane hydrate in the presence of imidazolium-based ionic liquids. J. Chem. Thermodyn. 2015, 84, 7–13. [Google Scholar] [CrossRef]

| Chemicals | Chemical Formula | Conc. | Operating Condition | Method & Type of Gas | Application as | Main Findings | Year/Ref. |

|---|---|---|---|---|---|---|---|

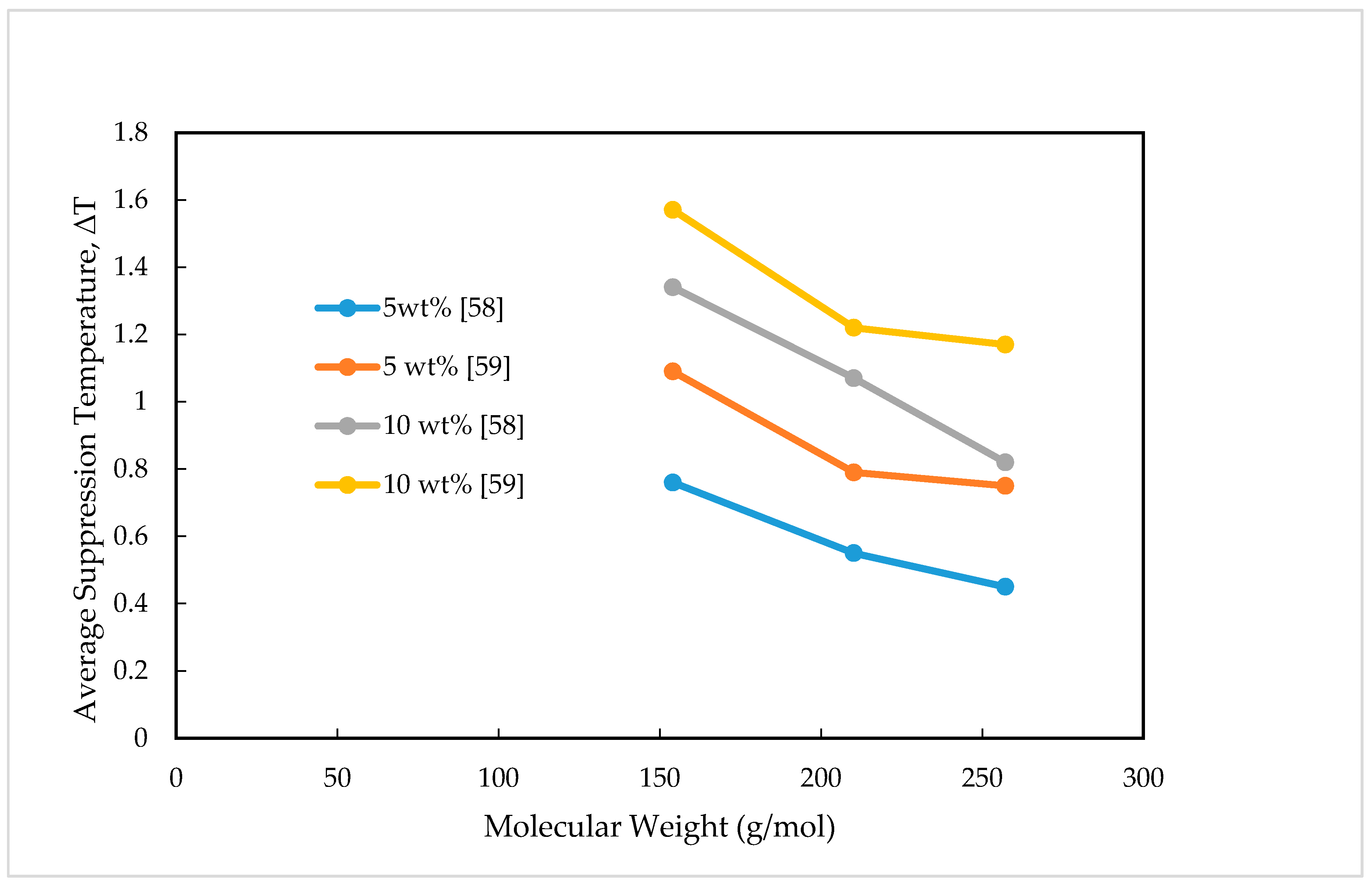

| Tetraethylammonium iodide (TEAI) | C8H20IN | 1 wt% 5 wt% 10 wt% | 274–284.6 K 3.45–8.3 MPa | T-cycle method CH4 | THI | The suppression temperature of TMAB, TEAB, and TEAI at 10 wt% is 1.34 K, 1.07 K, and 0.82 K, respectively. TMAB performed better than TEAB and TEAI, individually and in combination with MEG. | 2020 [58] |

| Tetramethylammonium bromide (TMAB) | C4H12BrN | ||||||

| Tetraethylammonium bromide (TEAB) | C8H20NBr | ||||||

| Tetramethyl ammonium chloride (TMACl) | C4H12NCl | 1 wt% 5 wt% 10 wt% | 285.0 K and 8.00 MPa for CH4 283.0 K and 3.50 MPa for CO2 | T-cycle method CO2 & CH4 | THI & KHI | TMACl performed efficiently as a potential dual functional hydrate inhibitor for both CO2 and CH4 gases. The average suppression temperatures for TMACl at 1, 5, and 10 wt% are 0.70 K, 0.96 K, and 1.42 K, respectively. | 2019 [37] |

| Tetraethyl ammonium iodide (TEAI) | C8H20IN | 5 wt% 10 wt% | 275.0–283.0 K 2.0–3.50 MPa | T-cycle method CO2 | THI | The suppression temperature of TEAI, TEAB, and TMAB at 10 wt% is 1.17 K, 1.22 K, and 1.57 K, respectively. TMAB performed better than TEAB and TEAI individually and in mixture with MEG. | 2019 [59] |

| Tetraethyl ammonium bromide (TEAB) | C8H20NBr | ||||||

| Tetramethyl ammonium bromide (TMAB) | C4H12BrN | ||||||

| Tetraethyl ammonium chloride (TEACl) | C8H20ClN | 10 wt% | 272.65–298.15 K 4.1–7.1 MPa | Isochoric pressure search CH4 | THI & KHI | TEACl enhances methane hydrate storage capacity and reduce methane hydrate stability. | 2019 [60] |

| Tetraethylammonium chloride (TEACl) | C8H20ClN | 4.77 wt% 9.15 wt% 11.82 wt% | 274.6–283.4 K 3.18–7.93 MPa | Isochoric pressure search CH4 | THI | Addition of 11.82 wt% TEACl and 11.82 wt% of BMIM-BF4 mixture results in more reduction in methane hydrate equilibrium temperature (average temperature depression of 2.7 K), compared to the other two studied mixtures. The inhibition effect is also enhanced when the system pressure is increased. | 2019 [57] |

| Tetramethyl ammonium bromide (TMAB) | C4H12BrN | 0.05 and 0.1 mass fraction | 282.4–276.8 K 4.2–7.6 MPa | Isochoric pressure search CH4 | THI | TMAB and TEAB show hydrate formation inhibition effects thermodynamically. However, TBAB has shown methane hydrate promotion effect. | 2018 [56] |

| Tetraethyl ammonium bromide (TEAB) | C8H20NBr | ||||||

| Tetrabutyl ammonium bromide (TBAB) | C16H36BrN | ||||||

| Tetraethylammonium iodide (TEAI) | C8H20IN | 0.1 mass fraction | 5.1–11.1 MPa | HighPressure Micro DSC CH4 | THI | The presence of TEAI alters the HLVE boundary to a higher pressure and lower temperature. | 2018 [64] |

| Tetra-n-butylammonium bromide (TBAB) | C16H36BrN | 15,000 ppm | −0.5 °C | Isothermal test and maximum subcooling test THF | THI & KHI | Crystal growth inhibition is the dominant inhibition mechanism in the gas hydrate system operating in these mixtures. Although THAB demonstrated poor inhibition effect with PVCap in the THF hydrate tests, it shows synergy with the gas hydrate system. | 2017 [65] |

| Tetra-n-butylphosphonium bromide (TBPB) | C16H36P·Br | 4500 ppm | |||||

| Tetramethyl ammonium bromide (TMAB) | C4H12BrN | 10 wt% | 278.94–291.85 K 4.79–14.32 MPa | Isochoric pressure search CH4 | THI | TMAB, TEAB, or TPrAB slightly alters the phase equilibrium conditions to a lower temperature and higher pressure region, which is comparable to NaCl. In contrast, the addition of TBAB and TPeAB promotes hydrate formation. | 2016 [61] |

| Tetraethyl ammonium bromide (TEAB) | C8H20NBr | 10 wt% | |||||

| Tetrapropyl ammonium bromide (TPrAB) | C12H28BrN | 10 wt% | |||||

| Tetrabutyl ammonium bromide (TBAB) | C16H36BrN | 10 wt% 5 wt% | |||||

| Tetramethylammonium bromide (TMAB) | C4H12BrN | 0.62 mol% | 279.41–291.85 K 4.79–14.32 MPa | Step-heating pressure search method CH4 | THI & KHI | TBAB or TPeAB shows semiclathrate hydrate promotion effect. TMAB, TEAB or TPrAB shows slight inhibition effect. | 2016 [62] |

| Tetraethylammonium bromide (TEAB) | C8H20NBr | 0.62 mol% | |||||

| Tetrapropylammonium bromide (TPrAB) | C12H28BrN | 0.62 mol% | |||||

| Tetrabutylammonium bromide (TBAB) | C16H36BrN | 0.62 mol% | |||||

| Tetrapentylammonium bromide (TPeAB) | C20H44BrN | 0.62 mol% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, H.H.; Husin, H. Review on Application of Quaternary Ammonium Salts for Gas Hydrate Inhibition. Appl. Sci. 2020, 10, 1011. https://doi.org/10.3390/app10031011

Hussain HH, Husin H. Review on Application of Quaternary Ammonium Salts for Gas Hydrate Inhibition. Applied Sciences. 2020; 10(3):1011. https://doi.org/10.3390/app10031011

Chicago/Turabian StyleHussain, Haizatul Hafizah, and Hazlina Husin. 2020. "Review on Application of Quaternary Ammonium Salts for Gas Hydrate Inhibition" Applied Sciences 10, no. 3: 1011. https://doi.org/10.3390/app10031011