Strong and Thermostable Boron-Containing Phenolic Resin-Derived Carbon Modified Three-Dimensional Needled Carbon Fiber Reinforced Silicon Oxycarbide Composites with Tunable High-Performance Microwave Absorption Properties

Abstract

:1. Introduction

2. Experimental Section

2.1. Preparation of BPR-Derived Carbon Modified 3D Needled Carbon Fiber Reinforced SiOC Composites

2.2. Characterization and Measurement

3. Results and Discussion

3.1. Effect of Pyrolysis Temperature on the Composition and Microstructure of the Composites

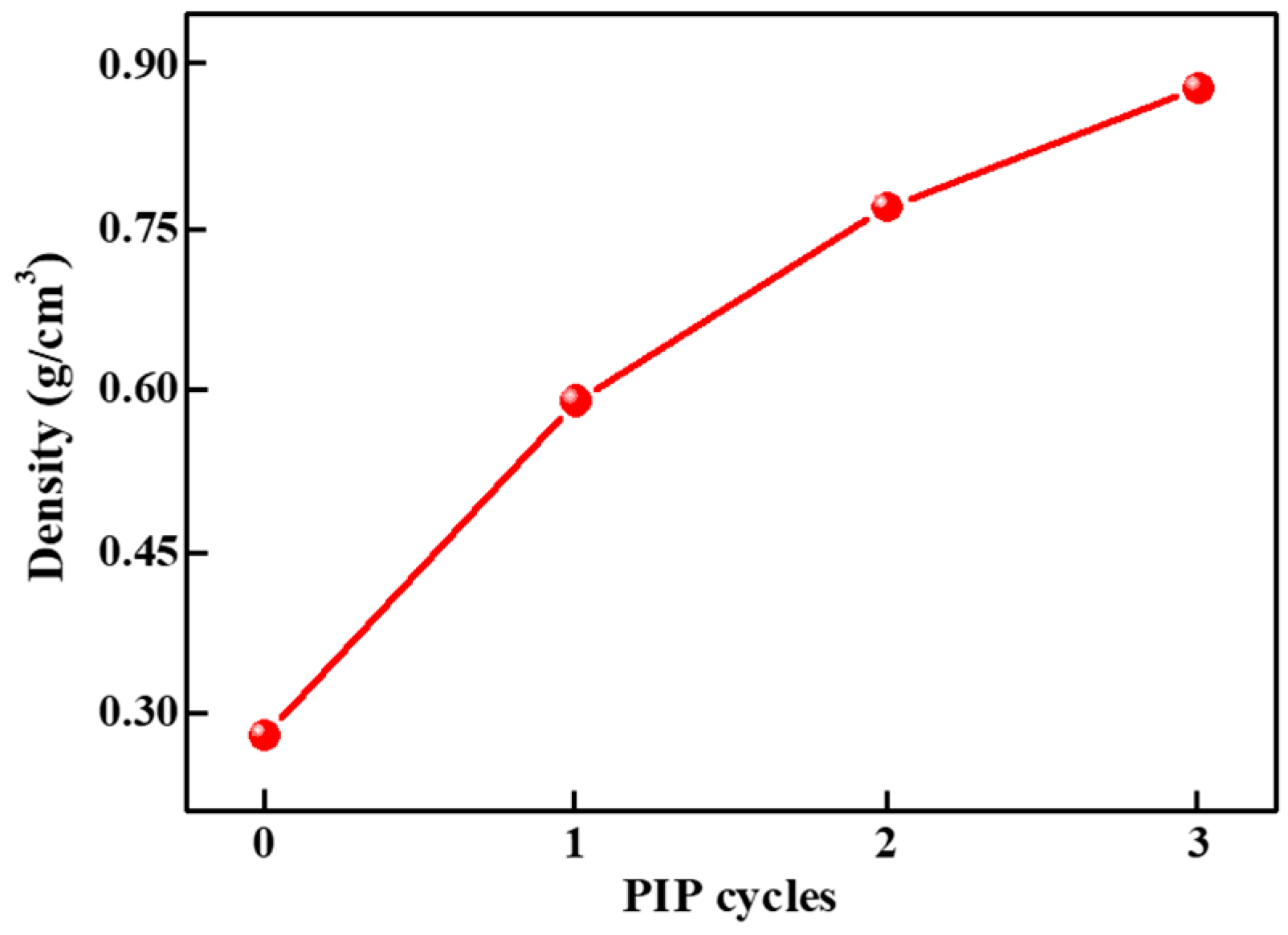

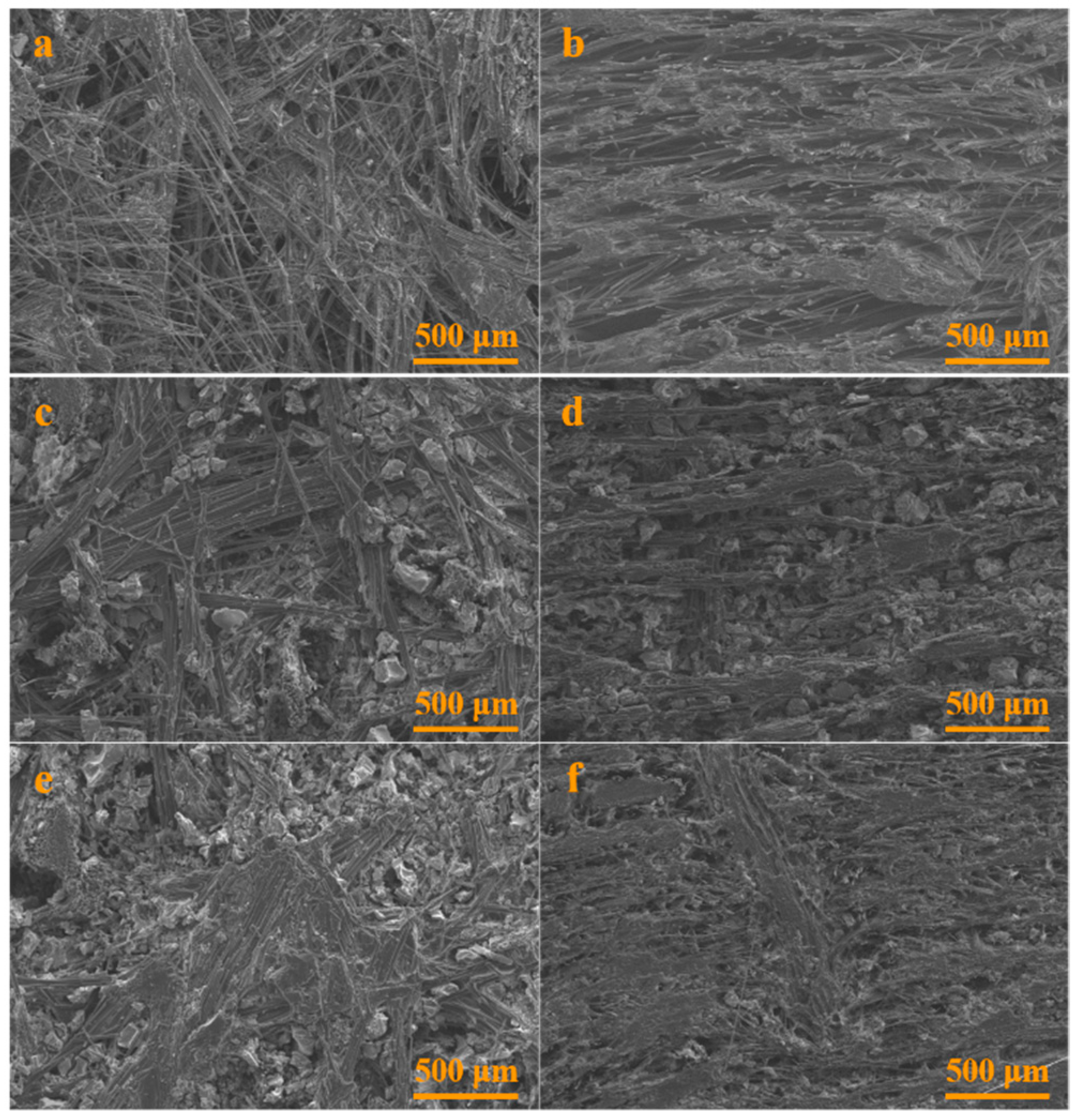

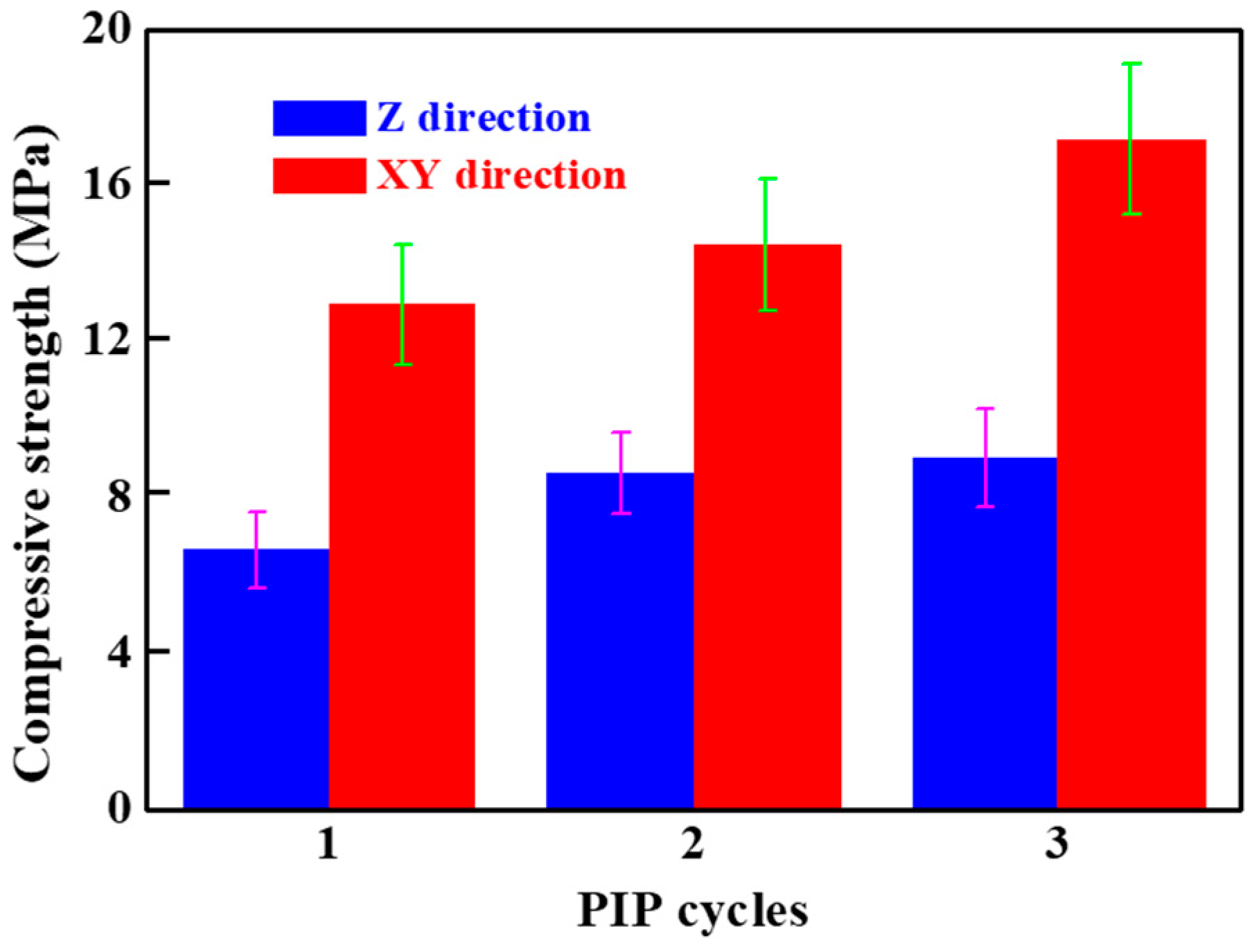

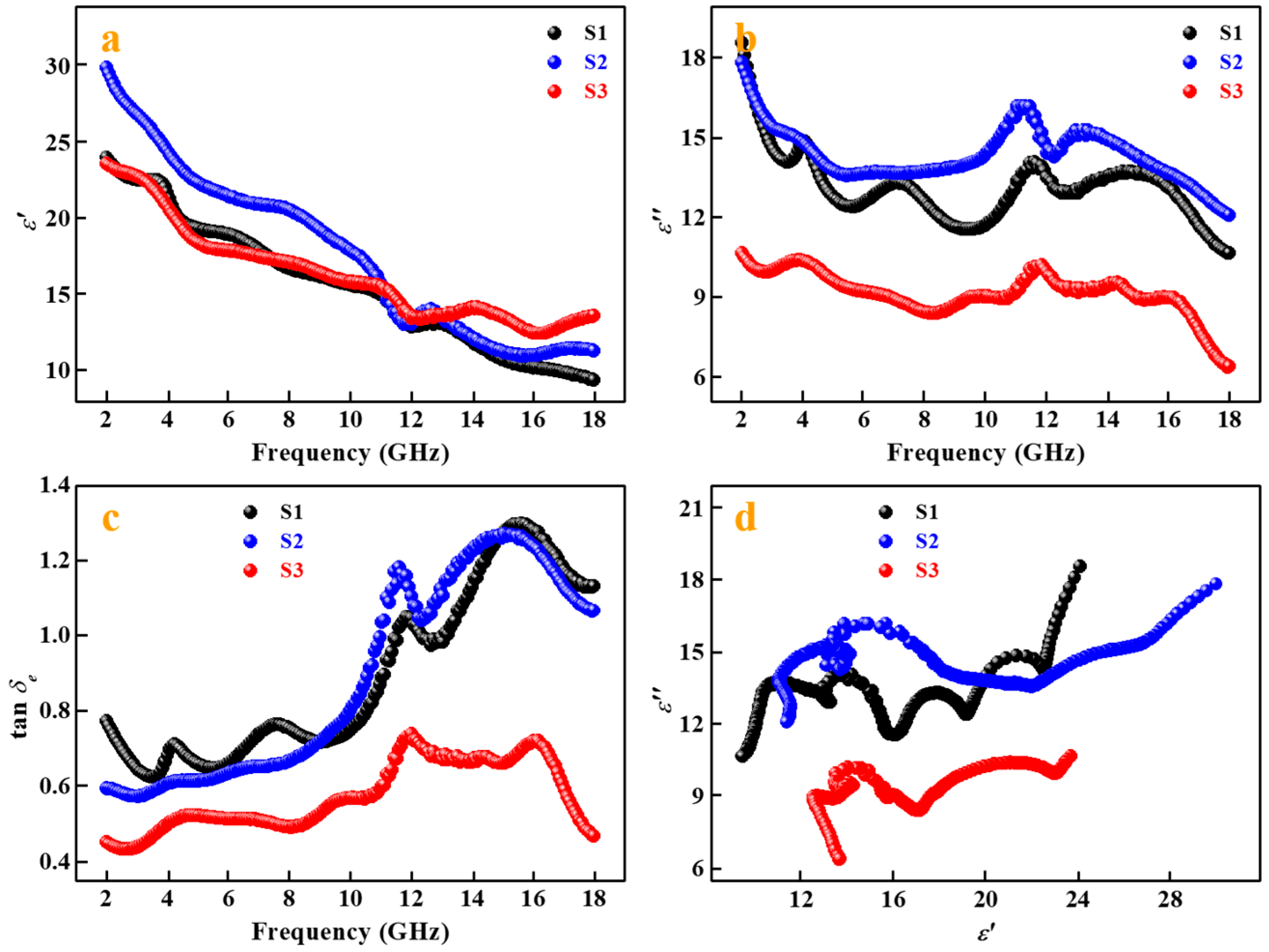

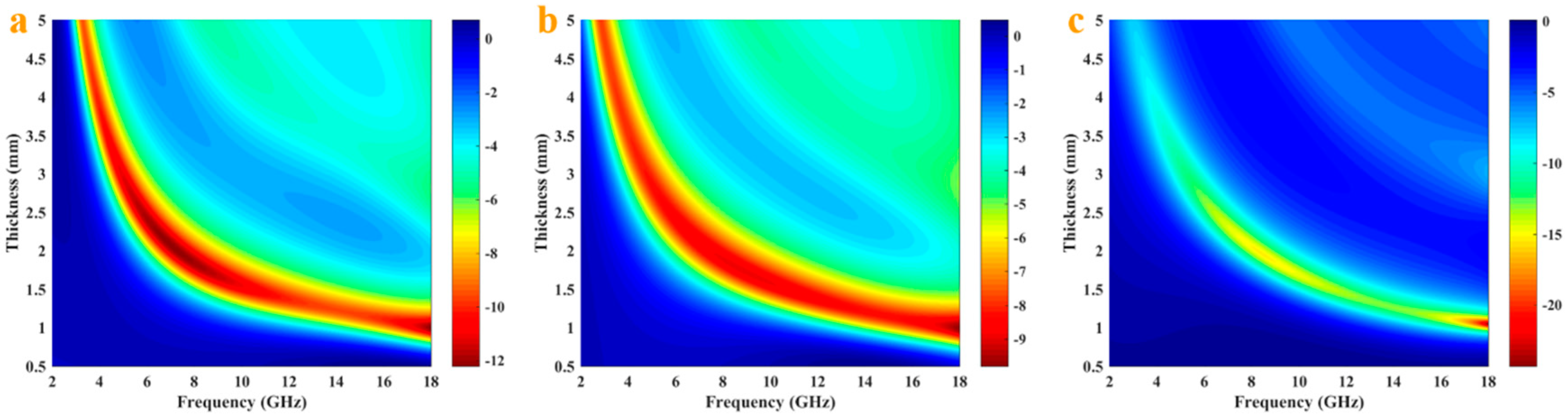

3.2. Influence of PIP Cycle Numbers on the Microstructure and Properties of the Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Natali, M.; Kenny, J.M.; Torre, L. Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: A review. Prog. Mater. Sci. 2016, 84, 192–275. [Google Scholar] [CrossRef]

- Yin, R.; Cheng, H.; Hong, C.; Zhang, X. Synthesis and characterization of novel phenolic resin/silicone hybrid aerogel composites with enhanced thermal, mechanical and ablative properties. Compos. Part A—Appl. S. 2017, 101, 500–510. [Google Scholar] [CrossRef]

- Xu, B.; Hong, C.; Zhou, S.; Han, J.; Zhang, X. High-temperature erosion resistance of ZrB2-based ceramic coating for lightweight carbon/carbon composites under simulated atmospheric re-entry conditions by high frequency plasma wind tunnel test. Ceram. Int. 2016, 42, 9511–9518. [Google Scholar] [CrossRef]

- Sun, Y.; Hong, C.; Zhang, X.; Han, J.; Qu, Q. Preparation and properties of SiOC ceramic modified carbon fiber needled felt preform composites. Ceram. Int. 2020, 46, 1743–1749. [Google Scholar] [CrossRef]

- Ma, Q.S.; Chen, Z.H.; Zheng, W.W.; Hu, H.F. Effects of pyrolysis processes on microstructure and mechanical properties of Cf/SiOC composites fabricated by preceramic polymer pyrolysis. Ceram. Int. 2005, 31, 305–314. [Google Scholar] [CrossRef]

- Yan, L.; Hong, C.; Sun, B.; Zhao, G.; Cheng, Y.; Dong, S.; Zhang, X. In situ growth of core–sheath heterostructural SiC nanowire arrays on carbon fibers and enhanced electromagnetic wave absorption performance. ACS Appl. Mater. Inter. 2017, 9, 6320–6331. [Google Scholar] [CrossRef]

- Han, W.; Zhao, G.; Zhang, X.; Zhou, S.; Wang, P.; An, Y.; Xu, B. Graphene oxide grafted carbon fiber reinforced siliconborocarbonitride ceramics with enhanced thermal stability. Carbon 2015, 95, 157–165. [Google Scholar] [CrossRef]

- Deng, P.; Shi, Y.; Liu, Y.; Liu, Y.; Wang, Q. Solidifying process and flame retardancy of epoxy resin cured with boron-containing phenolic resin. Appl. Surf. Sci. 2018, 427, 894–904. [Google Scholar] [CrossRef]

- Song, C.; Cheng, L.; Liu, Y.; Zhao, M.; Ye, F. Microstructure and electromagnetic wave absorption properties of RGO-SiBCN composites via PDC technology. Ceram. Int. 2018, 44, 18759–18769. [Google Scholar] [CrossRef]

- Duan, W.; Yin, X.; Li, Q.; Liu, X.; Cheng, L.; Zhang, L. Synthesis and microwave absorption properties of SiC nanowires reinforced SiOC ceramic. J. Eur. Ceram. Soc. 2014, 34, 257–266. [Google Scholar] [CrossRef]

- Du, B.; He, C.; Shui, A.; Zhang, X.; Hong, C. Microwave-absorption properties of heterostructural SiC nanowires/SiOC ceramic derived from polysiloxane. Ceram. Int. 2019, 45, 1208–1214. [Google Scholar] [CrossRef]

- Du, B.; Qian, J.; Hu, P.; He, C.; Cai, M.; Wang, X.; Shui, A. Enhanced electromagnetic wave absorption of Fe-doped silicon oxycarbide nanocomposites. J. Am. Ceram. Soc. 2020, 103, 1732–1743. [Google Scholar] [CrossRef]

- Du, B.; He, C.; Qian, J.; Cai, M.; Wang, X.; Shui, A. Electromagnetic wave absorbing properties of glucose-derived carbon-rich SiOC ceramics annealed at different temperatures. J. Am. Ceram. Soc. 2019, 102, 7015–7025. [Google Scholar] [CrossRef]

- Niu, M.; Wang, H.; Su, L.; Zhang, D.; Shi, J. Fabrication and properties of lightweight SiOC modified carbon-bonded carbon fiber composites. Ceram. Int. 2016, 42, 10614–10618. [Google Scholar] [CrossRef]

- Qin, H.; Liu, Y.; Ye, F.; Cheng, Z.; Chen, C.; Cheng, L.; Zhang, L. Dielectric and microwave absorption properties of SiCnw-SiBCN composite ceramics deposited via chemical vapor infiltration. J. Alloy. Compd. 2019, 771, 747–754. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Gong, W.; Chen, P.; Zhu, Y.; Zhu, B. Construction of multiple heterogeneous interface and its effect on microwave absorption of SiBCN ceramics. Ceram. Int. 2019. [Google Scholar] [CrossRef]

- Ren, F.; Yin, X.; Mo, R.; Ye, F.; Zhang, L.; Cheng, L. Hierarchical carbon nanowires network modified PDCs-SiCN with improved microwave absorption performance. Ceram. Int. 2019, 45, 14238–14248. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.; Ye, F.; Kong, L. Effects of multi-walled carbon nanotubes on the crystallization behavior of PDCs-SiBCN and their improved dielectric and EM absorbing properties. J. Eur. Ceram. Soc. 2014, 34, 1053–1061. [Google Scholar] [CrossRef]

- Li, Q.; Yin, X.; Duan, W.; Kong, L.; Hao, B.; Ye, F. Electrical, dielectric and microwave-absorption properties of polymer derived SiC ceramics in X band. J. Alloy. Compd. 2013, 565, 66–72. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, L.; Yin, X.; Zhang, Y.; Kong, L.; Liu, Y.; Cheng, L. Dielectric and microwave-absorption properties of SiC nanoparticle/SiBCN composite ceramics. J. Eur. Ceram. Soc. 2014, 34, 205–215. [Google Scholar] [CrossRef]

- Hong, W.; Dong, S.; Hu, P.; Luo, X.; Du, S. In situ growth of one-dimensional nanowires on porous PDC-SiC/Si3N4 ceramics with excellent microwave absorption properties. Ceram. Int. 2017, 43, 14301–14308. [Google Scholar] [CrossRef]

- Duan, W.; Yin, X.; Ye, F.; Li, Q.; Han, M.; Liu, X.; Cai, Y. Synthesis and EMW absorbing properties of nano SiC modified PDC–SiOC. J. Mater. Chem. C 2016, 4, 5962–5969. [Google Scholar] [CrossRef]

- Luo, C.; Tang, Y.; Jiao, T.; Kong, J. High-temperature stable and metal-free electromagnetic wave-absorbing SiBCN ceramics derived from carbon-rich hyperbranched polyborosilazanes. ACS Appl. Mater. Inter. 2018, 10, 28051–28061. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.; Chen, Z.; Ai, S.; Hou, B.; Zhang, J.; Liang, X.; Cui, S. Effects of SiC coating on microwave absorption of novel three-dimensional reticulated SiC/porous carbon foam. Ceram. Int. 2019, 45, 8660–8668. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, J.; Wang, L.; Peng, F.; Liu, H.; Zhang, J.; Guo, Z. In-situ pyrolyzed polymethylsilsesquioxane multi-walled carbon nanotubes derived ceramic nanocomposites for electromagnetic wave absorption. Ceram. Int. 2019, 45, 11756–11764. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Ai, S.; Hou, B.; Zhang, J.; Liang, X.; Cui, S. Porous SiC/melamine-derived carbon foam frameworks with excellent electromagnetic wave absorbing capacity. J. Adv. Ceram. 2019, 8, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Meng, X.; Zhang, X.; Hong, C.; Han, J.; Han, W.; Du, S. High temperature structure evolution of macroporous SiOC ceramics prepared by a sol–gel method. Ceram. Int. 2015, 41, 11091–11096. [Google Scholar] [CrossRef]

- Dong, S.; Hu, P.; Zhang, X.; Han, J.; Zhang, Y.; Luo, X. Carbon foams modified with in-situ formation of Si3N4 and SiC for enhanced electromagnetic microwave absorption property and thermostability. Ceram. Int. 2018, 44, 7141–7150. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, W.; Zhang, X.; Hu, P.; Han, J. Designable synthesis of core-shell SiCw@ C heterostructures with thickness-dependent electromagnetic wave absorption between the whole X-band and Ku-band. Chem. Eng. J. 2018, 354, 767–776. [Google Scholar] [CrossRef]

- Dong, S.; Song, J.; Zhang, X.; Hu, P.; Sun, B.; Zhou, S.; Luo, X. Strong contribution of in situ grown nanowires to enhance the thermostabilities and microwave absorption properties of porous graphene foams under different atmospheres. J. Mater. Chem. C 2017, 5, 11837–11846. [Google Scholar] [CrossRef]

- Pena-Alonso, R.; Mariotto, G.; Gervais, C.; Babonneau, F.; Soraru, G.D. New insights on the high-temperature nanostructure evolution of SiOC and B-doped SiBOC polymer-derived glasses. Chem. Mater. 2007, 19, 5694–5702. [Google Scholar] [CrossRef]

- Gao, Y.; Li, L.; Tan, P.; Liu, L.; Zhang, Z. Application of Raman spectroscopy in carbon nanotube-based polymer composites. Chinese Sci. Bull. 2010, 55, 3978–3988. [Google Scholar] [CrossRef]

- Sasaki, K.I.; Wakabayashi, K.; Enoki, T. Polarization dependence of Raman spectra in strained graphene. Phys. Revi. B 2010, 82, 205407. [Google Scholar] [CrossRef] [Green Version]

- Hu, P.; Dong, S.; Zhang, X.; Gui, K.; Chen, G.; Hu, Z. Synthesis and characterization of ultralong SiC nanowires with unique optical properties, excellent thermal stability and flexible nanomechanical properties. Sci. Rep-UK 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, X.; Zhang, D.; Sun, B.; Yan, L.; Luo, X. Strong effect of atmosphere on the microstructure and microwave absorption properties of porous SiC ceramics. J. Eur. Ceram. Soc. 2018, 38, 29–39. [Google Scholar] [CrossRef]

- Bi, S.; Su, X.; Hou, G.; Liu, C.; Song, W.L.; Cao, M.S. Electrical conductivity and microwave absorption of shortened multi-walled carbon nanotube/alumina ceramic composites. Ceram. Int. 2013, 39, 5979–5983. [Google Scholar] [CrossRef]

- Song, W.L.; Cao, M.S.; Hou, Z.L.; Yuan, J.; Fang, X.Y. High-temperature microwave absorption and evolutionary behavior of multiwalled carbon nanotube nanocomposite. Scripta Mater. 2009, 61, 201–204. [Google Scholar] [CrossRef]

- Dong, S.; Lyu, Y.; Li, X.; Chen, J.; Zhang, X.; Han, J.; Hu, P. Construction of MnO nanoparticles anchored on SiC whiskers for superior electromagnetic wave absorption. J. Colloid Interf. Sci. 2020, 559, 186–196. [Google Scholar] [CrossRef]

- Xie, S.; Guo, X.N.; Jin, G.Q.; Guo, X.Y. Carbon coated Co–SiC nanocomposite with high-performance microwave absorption. Phys. Chem. Chem. Phys. 2013, 15, 16104–16110. [Google Scholar] [CrossRef]

- Seïd, K.A.; Badot, J.C.; Dubrunfaut, O.; Levasseur, S.; Guyomard, D.; Lestriez, B. Multiscale electronic transport mechanism and true conductivities in amorphous carbon–LiFePO4 nanocomposites. J. Mater. Chem. 2012, 22, 2641–2649. [Google Scholar] [CrossRef]

- Ding, D.; Wang, Y.; Li, X.; Qiang, R.; Xu, P.; Chu, W.; Du, Y. Rational design of core-shell Co@C microspheres for high-performance microwave absorption. Carbon 2017, 111, 722–732. [Google Scholar] [CrossRef]

- Qiao, M.; Lei, X.; Ma, Y.; Tian, L.; He, X.; Su, K.; Zhang, Q. Application of yolk–shell Fe3O4@ N-doped carbon nanochains as highly effective microwave-absorption material. Nano Res. 2018, 11, 1500–1519. [Google Scholar] [CrossRef]

- Wang, P.; Cheng, L.; Zhang, Y.; Wu, H.; Hou, Y.; Yuan, W.; Zheng, L. Flexible, hydrophobic SiC ceramic nanofibers used as high frequency electromagnetic wave absorbers. Ceram. Int. 2017, 43, 7424–7435. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Sun, Y. Strong and Thermostable Boron-Containing Phenolic Resin-Derived Carbon Modified Three-Dimensional Needled Carbon Fiber Reinforced Silicon Oxycarbide Composites with Tunable High-Performance Microwave Absorption Properties. Appl. Sci. 2020, 10, 1924. https://doi.org/10.3390/app10061924

Sun Y, Sun Y. Strong and Thermostable Boron-Containing Phenolic Resin-Derived Carbon Modified Three-Dimensional Needled Carbon Fiber Reinforced Silicon Oxycarbide Composites with Tunable High-Performance Microwave Absorption Properties. Applied Sciences. 2020; 10(6):1924. https://doi.org/10.3390/app10061924

Chicago/Turabian StyleSun, Yu, and Yuguo Sun. 2020. "Strong and Thermostable Boron-Containing Phenolic Resin-Derived Carbon Modified Three-Dimensional Needled Carbon Fiber Reinforced Silicon Oxycarbide Composites with Tunable High-Performance Microwave Absorption Properties" Applied Sciences 10, no. 6: 1924. https://doi.org/10.3390/app10061924