A Study on Shock Absorption Characteristics of Honeycomb-Inserted Bollards

Abstract

1. Introduction

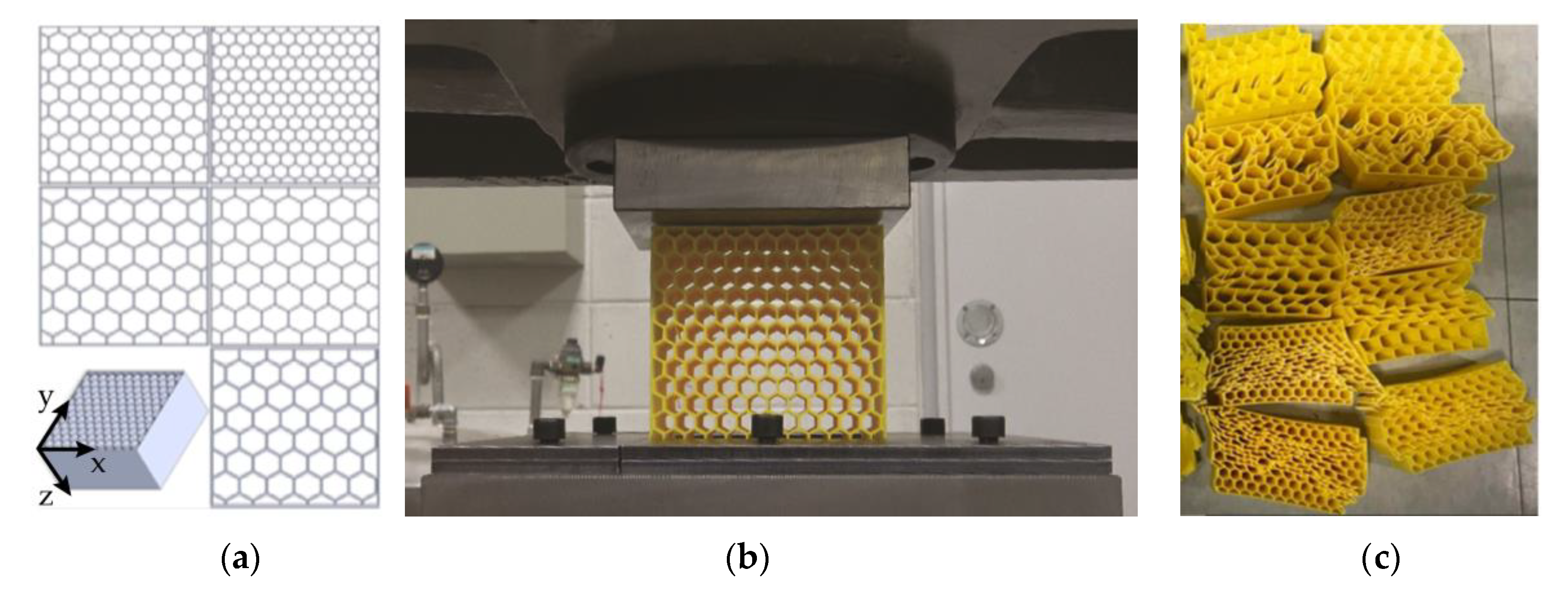

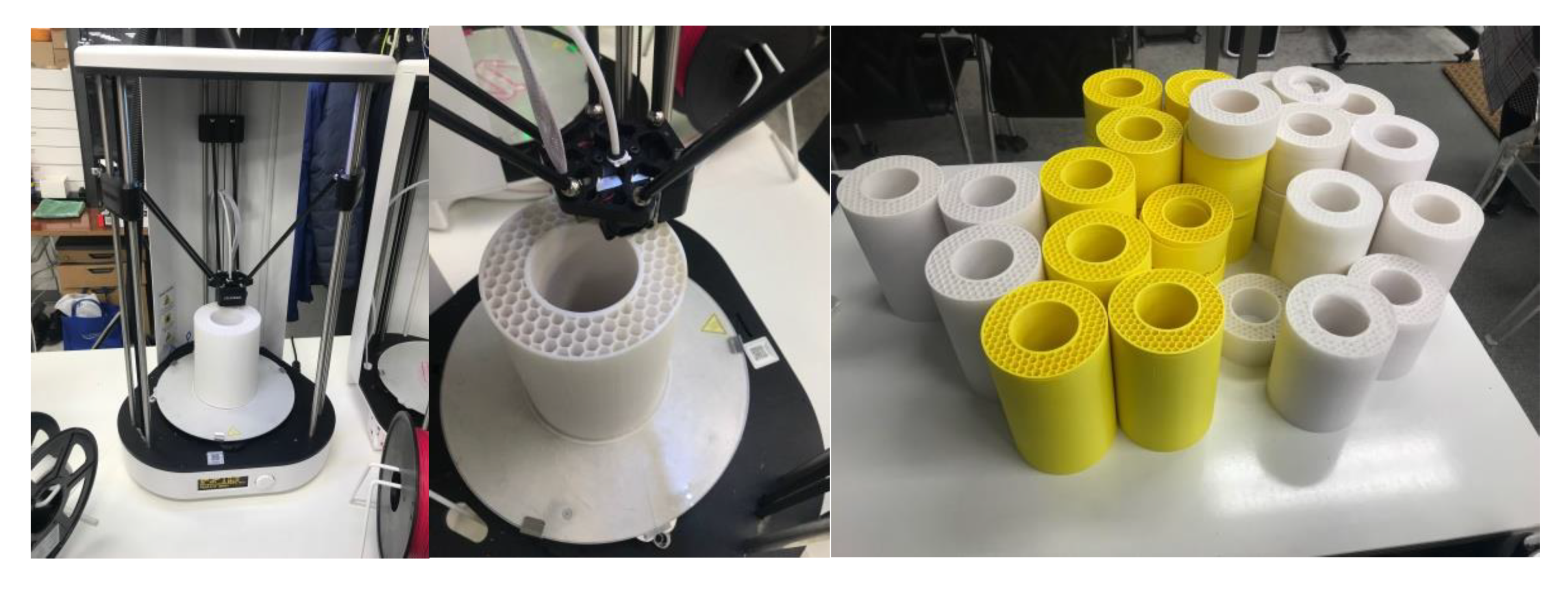

2. Design and Tests of In-Plane Honeycomb

2.1. Theoretical Background

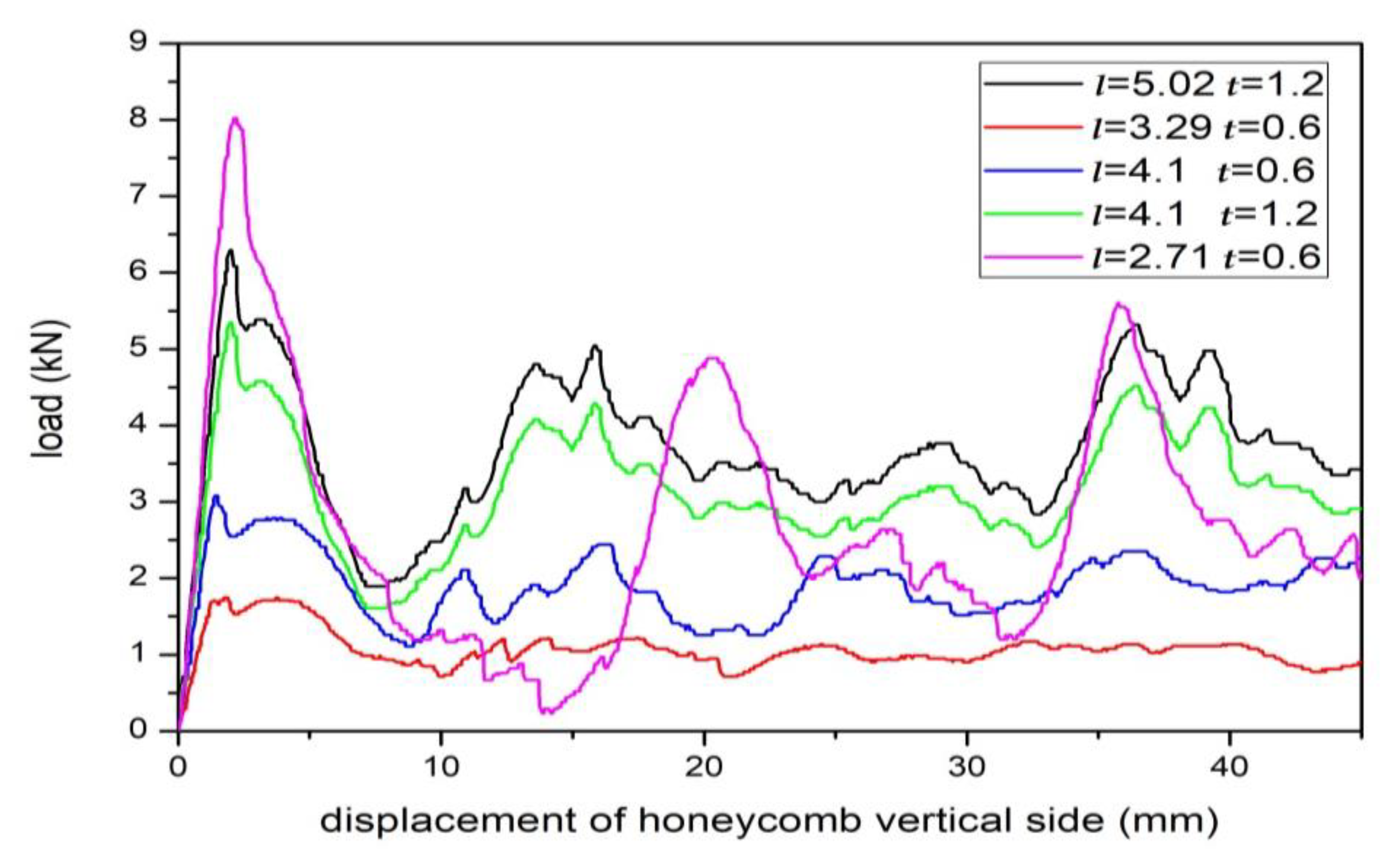

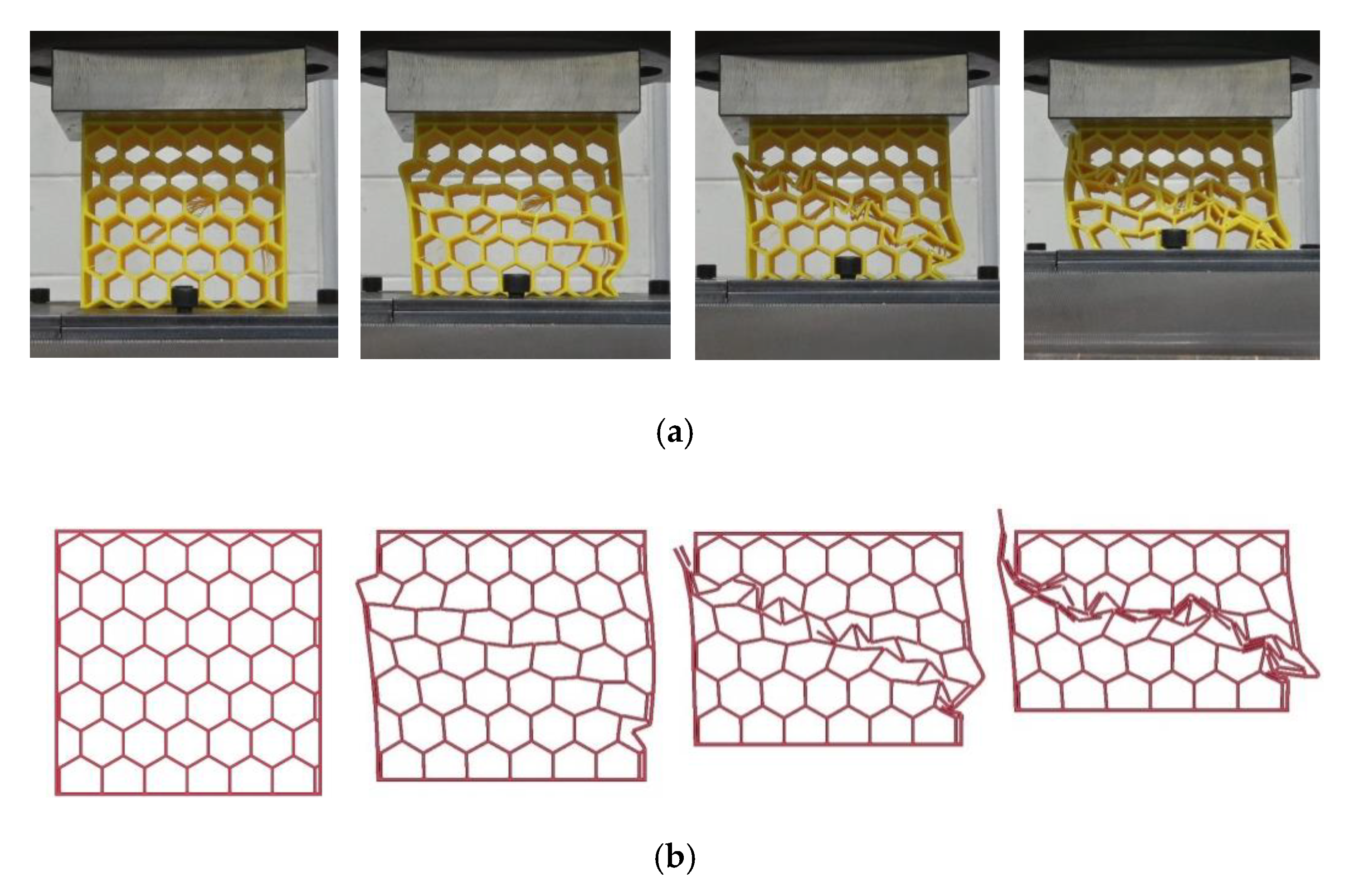

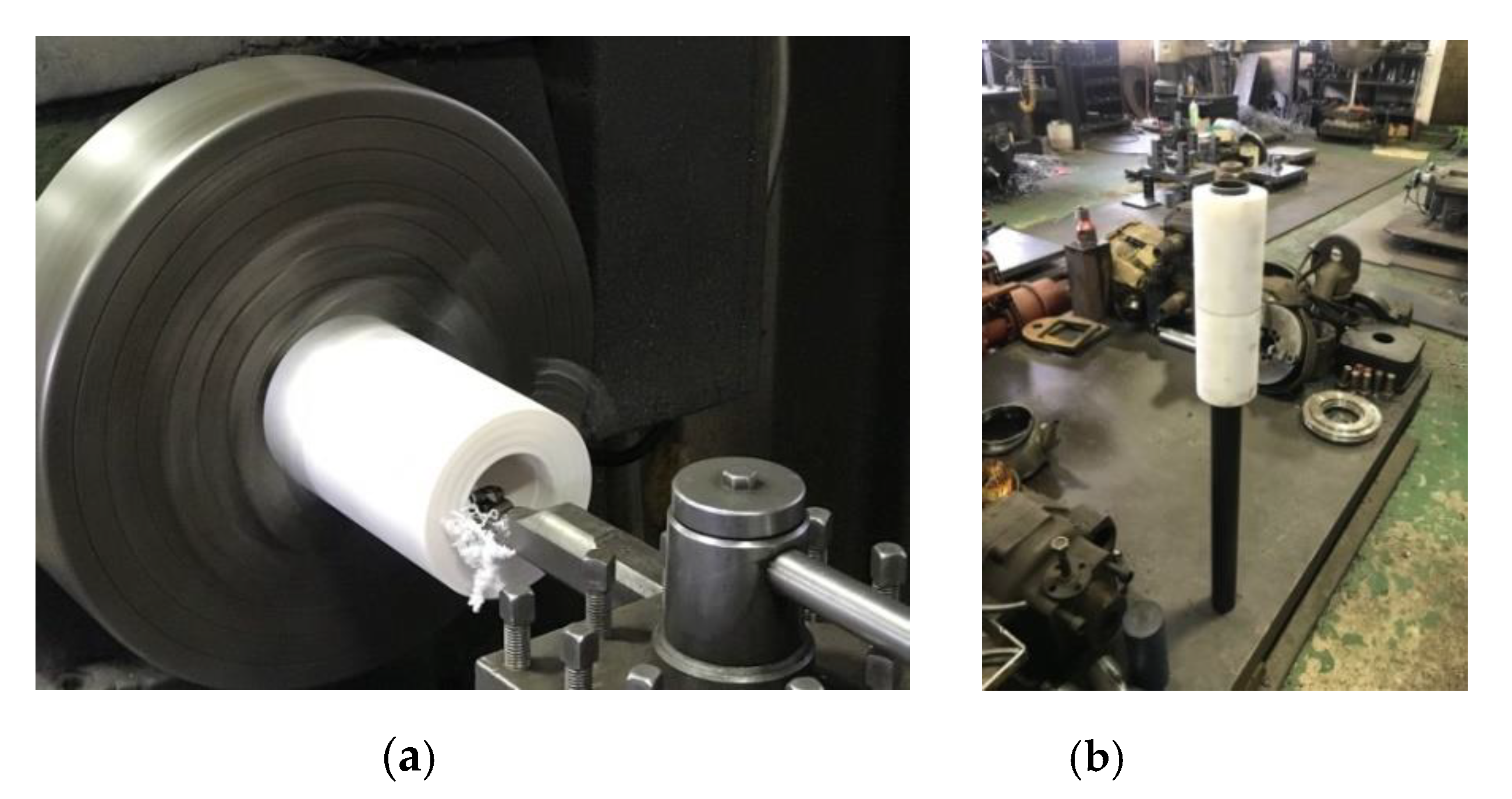

2.2. In-Plane Honeycomb Compression Test

3. Numerical Simulations

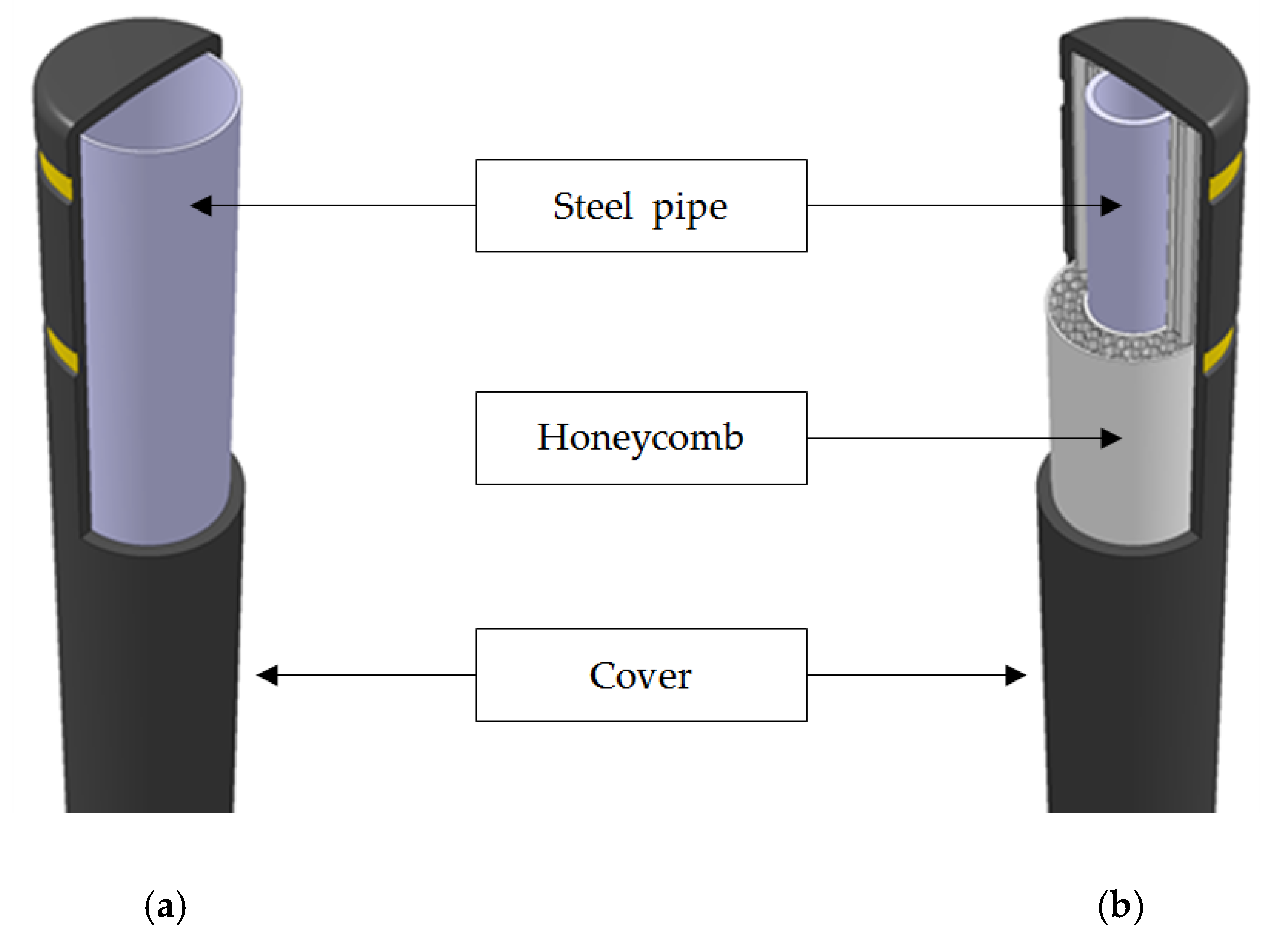

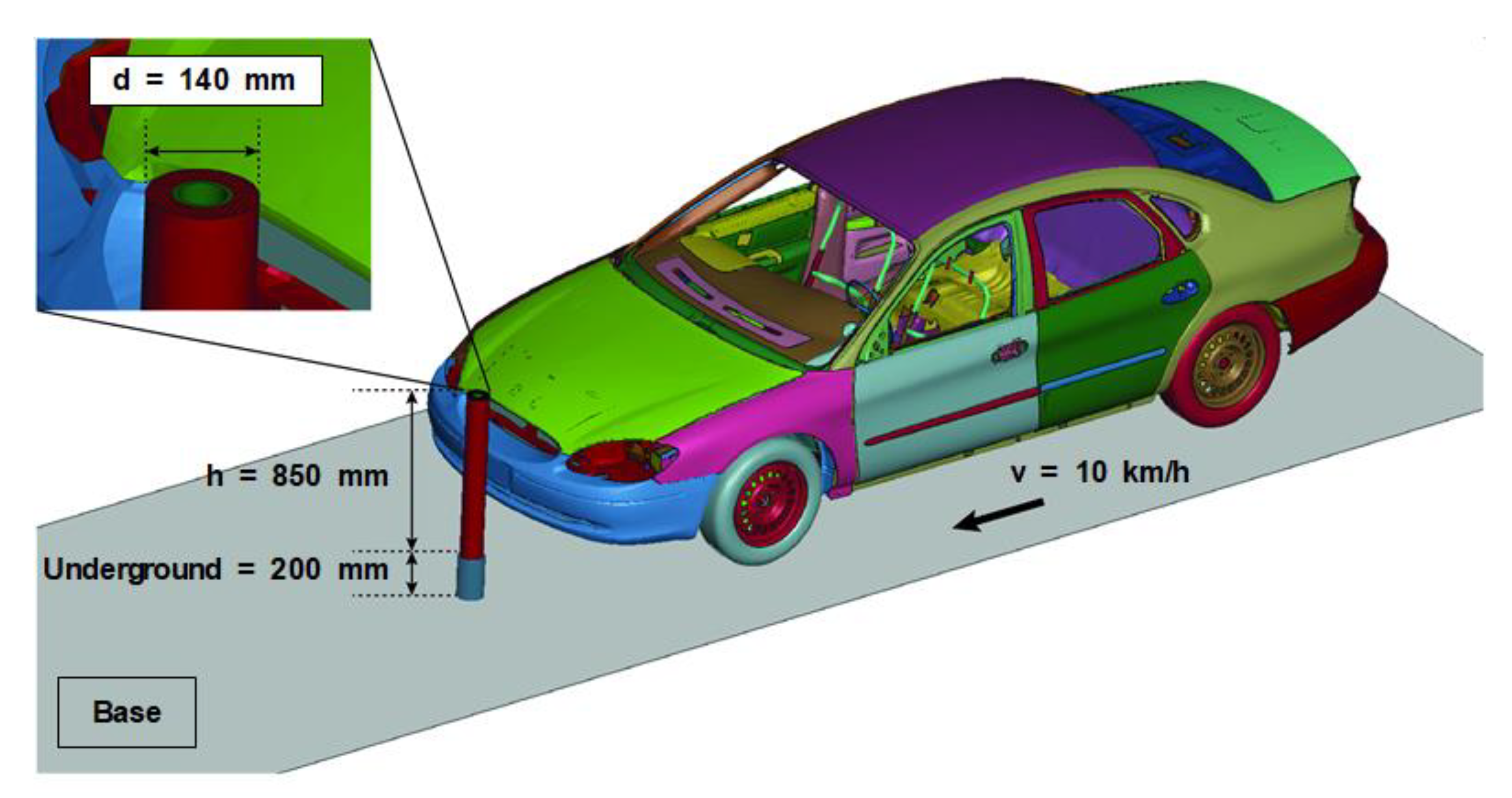

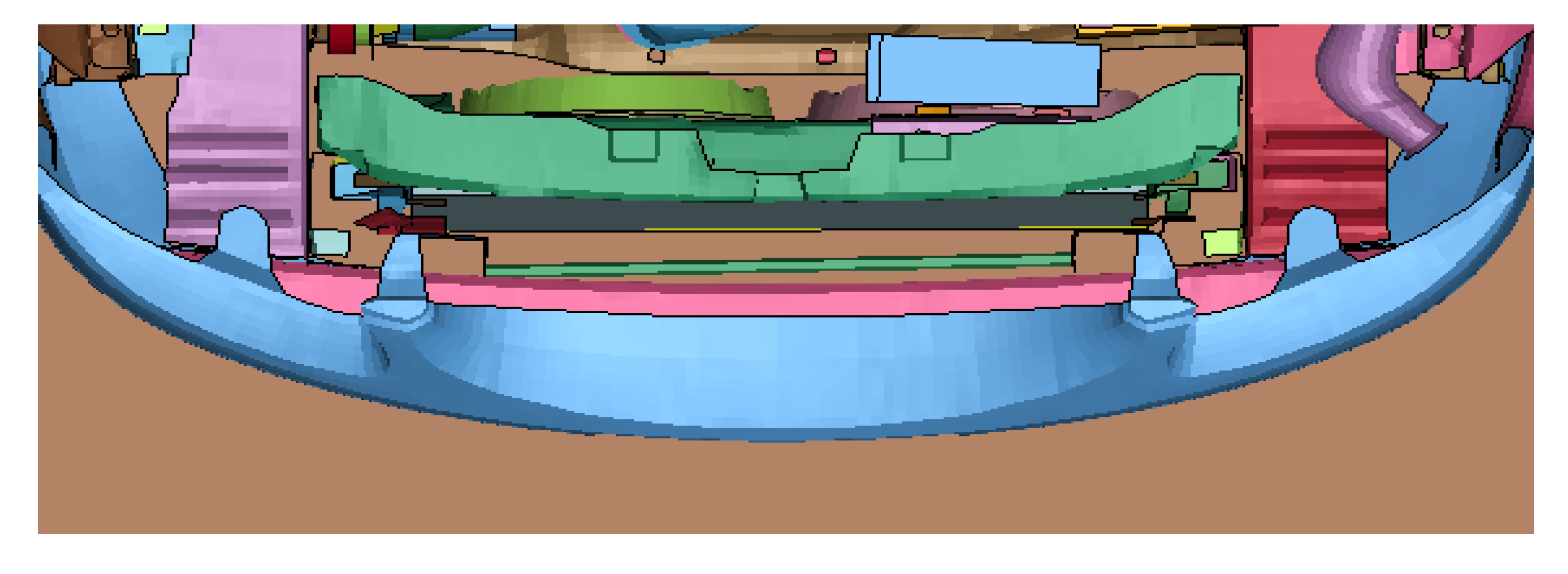

3.1. Bollard Design

3.2. Numerical Simulations

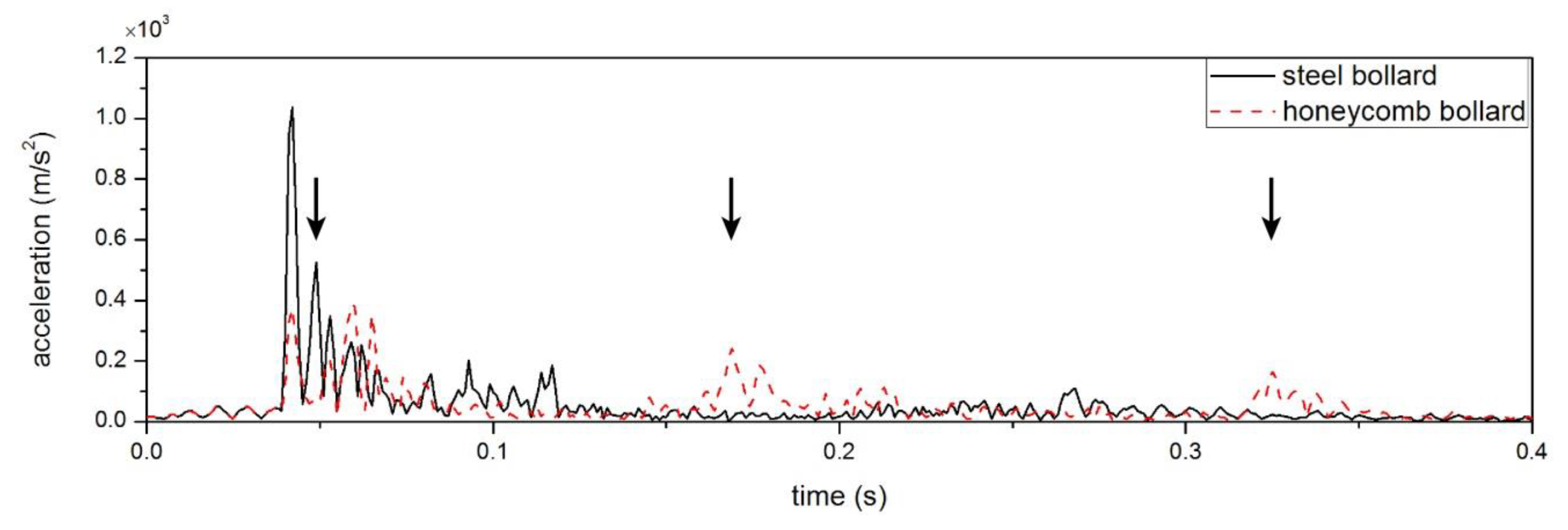

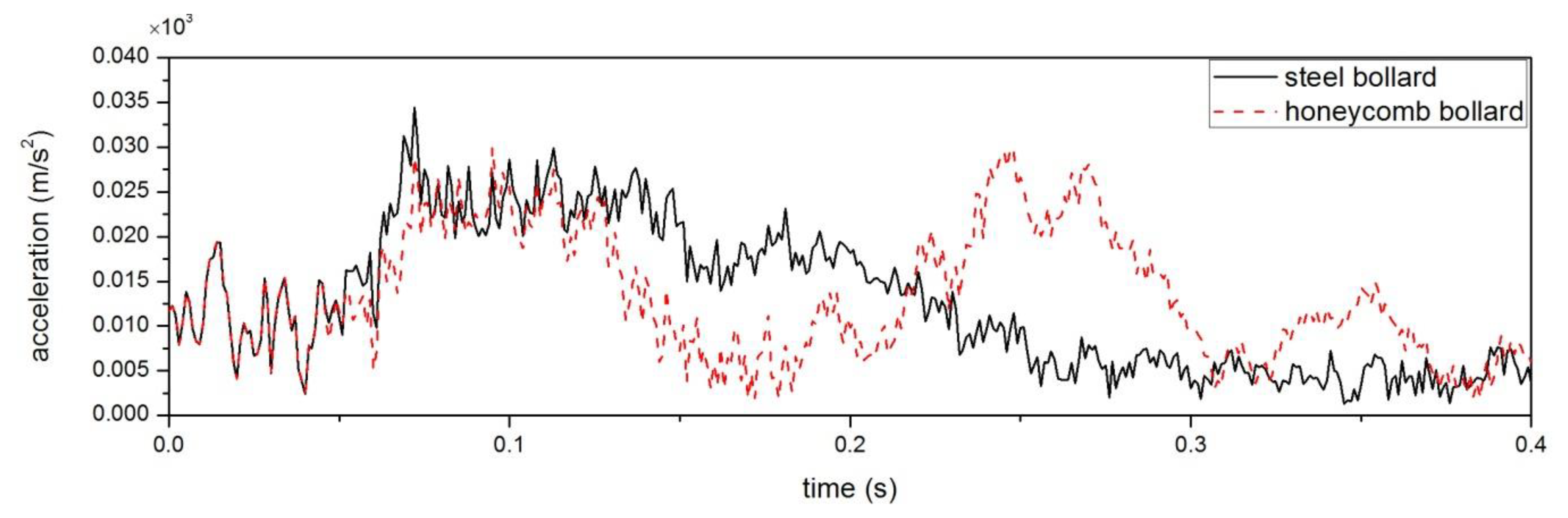

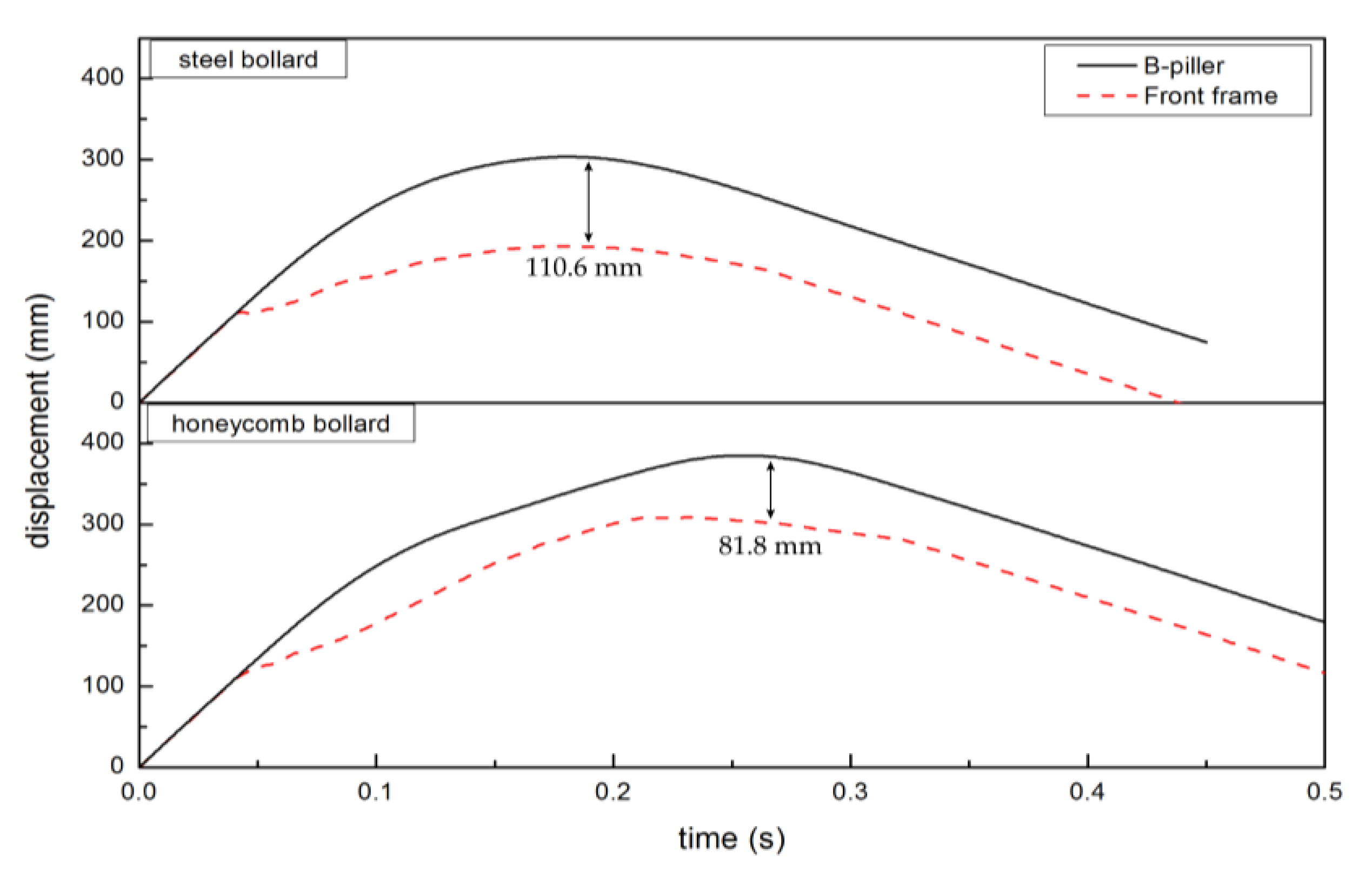

3.3. Simulation Result

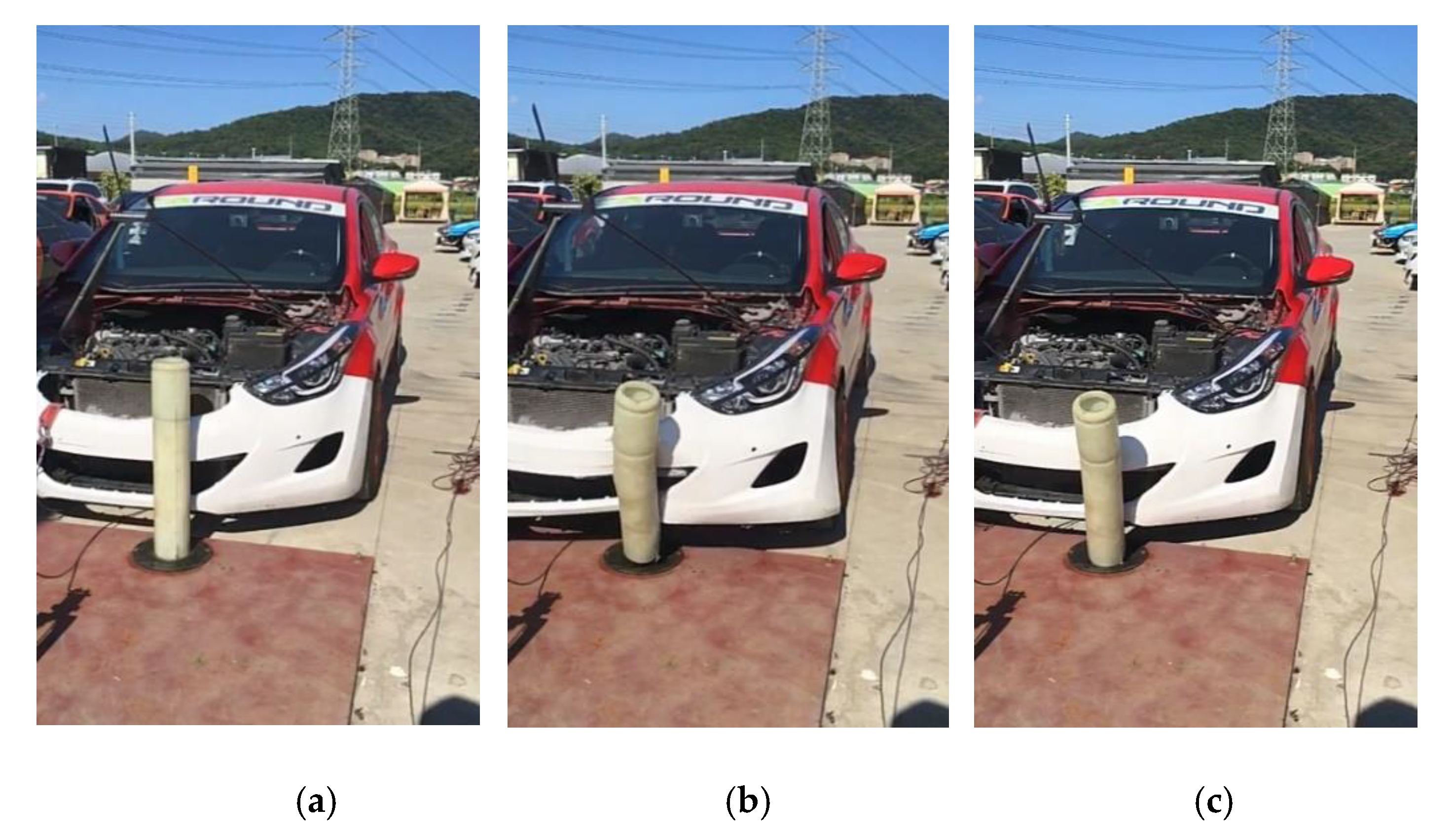

4. Vehicle-Bollard Collision Experiments

4.1. Experimental Setup

4.2. Experimental Results

5. Summary and Conclusions

- Honeycomb unit specimen with varying honeycomb cell wall length (l) and thickness (t) were manufactured with PLA materials for compression tests, which confirmed that the honeycomb strength is inversely proportional to l2 and proportional to t2, as reported in the literature.

- Maximum accelerations at the vehicle front bumper frame and the B-pillar were simulated with various yield strengths. Compared to steel bollard, simulations with 20 MPa in-plane honeycomb bollard, when impacted by the vehicle at 10 km/h, showed the maximum acceleration time being delayed by 0.017 s, the peak acceleration value decreased to 37.4% of the steel bollard’s peak, and maximum deformation time increased by 0.083 s. The maximum acceleration of the B-pillar decreased by 13% when compared to that of steel bollard.

- From the analysis of the vehicle-bollard collision experiment videos, the maximum acceleration occurrence time at the bumper cover has increased by 0.783 s.

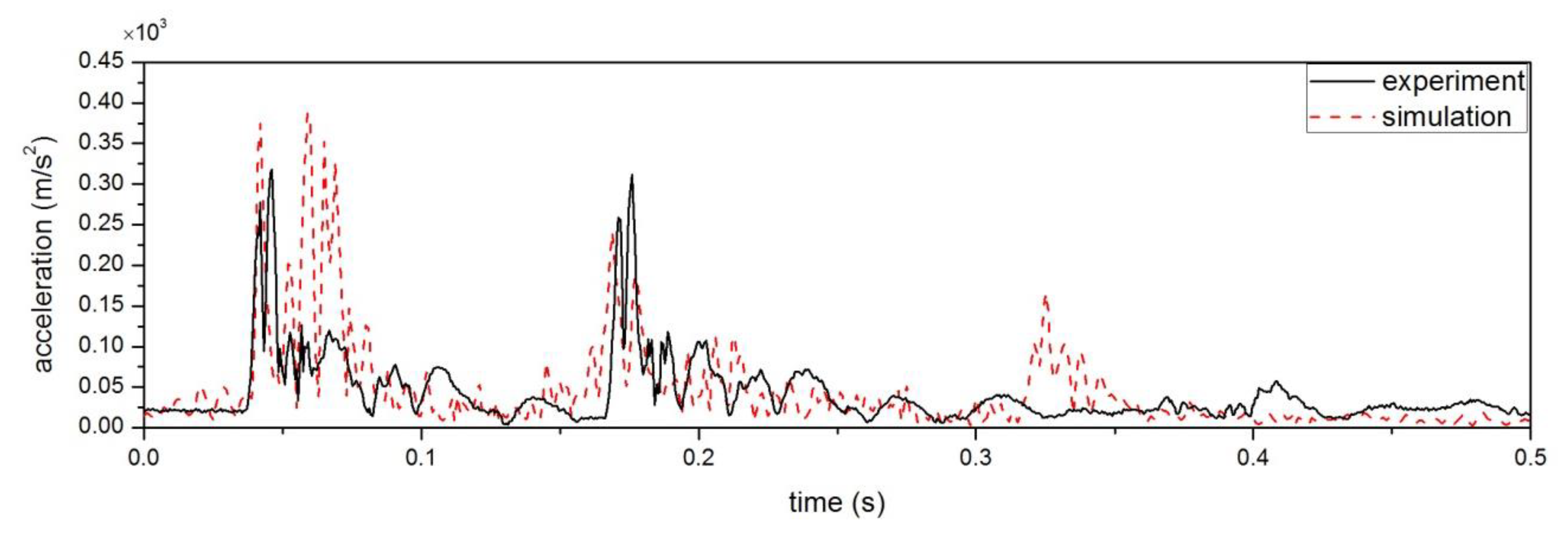

- The maximum accelerations, measured during the experiment and calculated from the simulation, were 0.35 × 103 m/s2 and 0.388 × 103 m/s2, respectively. This proves the similarity in the acceleration and damage characteristics between the experiment and the simulation.

- From the vehicle-bollard collision experiments, it was observed that the steel bollard not only caused damage to the test vehicle front bumper frame as in the simulation but also to its radiator. With only minor bumper frame deformation for the test against honeycomb bollard, this research proves the improved shock absorption characteristics of the proposed in-plane honeycomb bollards.

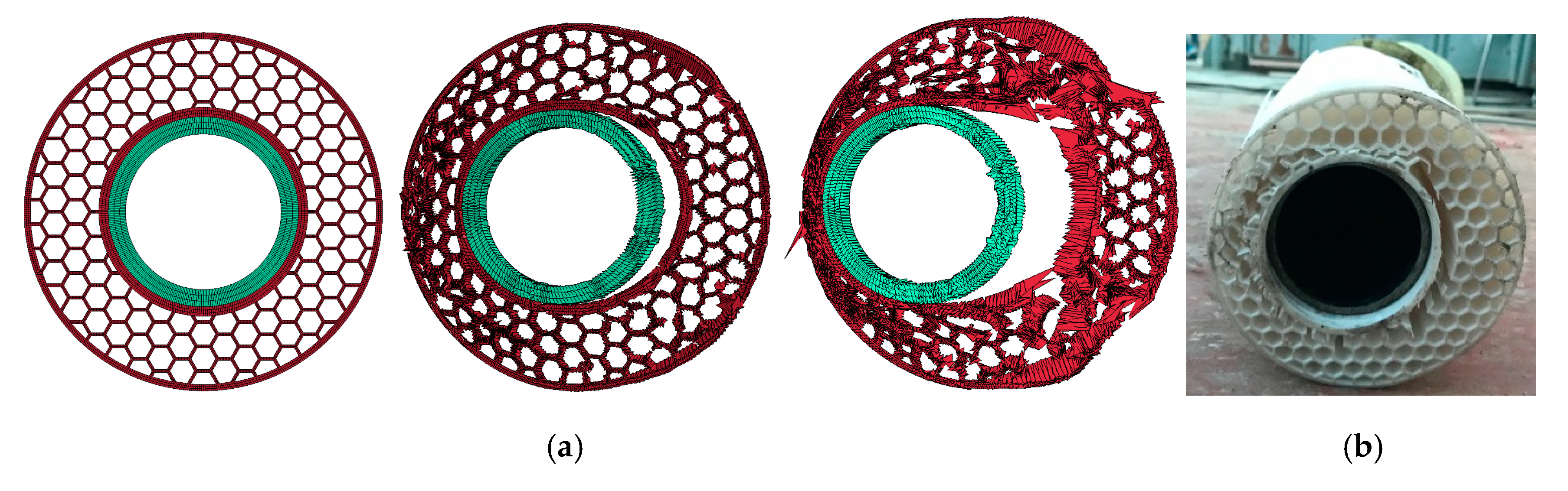

- Vehicle-bollard collision tests against in-plane honeycomb bollards showed damages concentrated to three locations along the bollard—the front bumper contact point, base and support interfacing point, and the bollard bottom end. This coincides with the simulation results to further prove the consistency and reliability of the research results.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Seon, S.W.; Yun, I.S.; Park, H.D.; Seon, B.S.; Lee, W. A Study on Shock Absorption Bollard using Honeycomb Geometry. Korean Soc. Precis. Eng. 2018, 2018, 537. [Google Scholar]

- Cha, E.H.; Jeon, D.J.; Han, S.E. Performance Evaluation and Proposal on Standard Establishment of the Bollard through Impact Analysis. J. Korean Assoc. Spat. Struct. 2016, 16, 59–66. [Google Scholar] [CrossRef]

- Ahn, J.S.; Oh, C.W. A Study on the Implementation of the Auditory Map for Blind People. Geogr. J. Korea 2014, 48, 573–584. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Act on Promotion of the Transportation Convenience of Mobility Disadvantaged Persons; Ministry of Land, Infrastructure and Transport: Sejong, Korea, 2019. [Google Scholar]

- Chen, L.; Xiao, Y.; Xiao, G.; Liu, C.; Agrawal, A. Test and numerical simulation of truck collision with anti-ram bollards. Int. J. Impact Eng. 2014, 75, 30–39. [Google Scholar] [CrossRef]

- National Counterterrorism Center. 2010 NCTC Report on Terrorism; National Counterterrorism Center: Washington, DC, USA, 2011. [Google Scholar]

- Kim, G.H.; Lee, O.S.; Park, I.S.; Kim, J.W.; Chung, T.Y.; Heo, S.J. Damageability, Repairability and Safety of Automobile at Low Speed Frontal and Rear Crash Test. Korean Soc. Automot. Eng. 1998, 5, 789–794. [Google Scholar]

- Deptula, L.; Noah, A. Assessing the Costs & Benefits of Effective Lightweighting Technologies. Cent. Automot. Res. 2015. Available online: http://www.cargroup.org/wp-content/uploads/2017/02/Assessing-the-Costs-Benefits-of-Effective-Lightweighting-Technologies.pdf (accessed on 30 March 2020).

- Mun, N. Activation of Automotive Replacement Auto-Parts. Auto J. 2019, 44–46. Available online: https://www.sae.org/standards/content/j1555_201910/ (accessed on 30 March 2020).

- Recommended Practice for Optimizing Automobile Damageability and Repairability. 2019. J1555_201910. Available online: https://www.sae.org/standards/content/j1555_201910/ (accessed on 30 March 2020).

- Lee, C.J.; Lee, S.B.; Ko, D.C.; Kim, B.M. Effect of Bead Shape in Aluminum Crash Box for Effective Impact Energy Absorption Under Low-Velocity Impact Condition. Trans. Korean Soc. Mech. Eng. 2012, 36, 1155–1162. [Google Scholar] [CrossRef]

- Yin, H.; Huang, X.; Scarpa, F.; Wen, G.; Chen, Y.; Zhang, C. In-plane crashworthiness of bio-inspired hierarchical honeycombs. Compos. Struct. 2018, 192, 516–527. [Google Scholar] [CrossRef]

- Tiwaria, G.; Thomasa, T.; Khandelwalb, R.P. Influence of reinforcement in the honeycomb structures under axial compressive load. Thin-Walled Struct. 2017, 126, 238–245. [Google Scholar] [CrossRef]

- Chawla, A.; Mukherjee, S.; Kumar, D.; Nakatani, T.; Ueno, M. Prediction of crushing behaviour of honeycomb structures. Int. J. Crashworthiness 2003, 8, 229–235. [Google Scholar] [CrossRef]

- Wang, H.; Lu, Z.; Yang, Z.; Li, X. A novel re-entrant auxetic honeycomb with enhanced in-plane impact resistance. Compos. Struct. 2019, 208, 758–770. [Google Scholar] [CrossRef]

- Kim, H.D.; Lee, H.H.; Park, J.S. Prediction to shock absorption energy of an aluminum honeycomb. J. Aeronaut. Space Sci. 2011, 39, 391–399. [Google Scholar] [CrossRef][Green Version]

- Geng, X.; Liu, Y.; Zheng, W.; Wang, Y.; Li, M. Prediction of Crushing Response for Metal Hexagonal Honeycomb under Quasi-Static Loading. Shock Vib. 2018, 2018, 8043410. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Bonanno, A.; Crupi, V.; Epasto, G.; Guglielmino, E.; Palomba, G. Aluminum honeycomb sandwich for protective structures of earth moving machines. Procedia Struct. Integr. 2018, 8, 332–344. [Google Scholar] [CrossRef]

- Said, M.R.; Reddy, T. Quasi-static response of laterally simple compressed hexagonal rings. Int. J. Crashworthiness 2002, 7, 345–364. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, J.-S.; Lee, S.-J.; Cheon, S.-K. A Study on the Impact Characteristics of honeycomb Sandwich Panels for the Hybrid Composite Train Bodyshell. Korean Soc. Mech. Eng. 2006, 2635–2639. [Google Scholar]

- Rebelo, H.; Lecompte, D.; Cismasiu, C.; Jonet, A.; Belkassem, B.; Maazoun, A. Experimental and numerical investigation on 3D printed PLA sacrificial honeycomb cladding. Int. J. Impact Eng. 2019, 131, 162–173. [Google Scholar] [CrossRef]

- Tran, J.P.; Linforth, S.; Ngo, T.; Lumantarna, R.; Nguyen, K. Design Analysis of Hybrid Composite Anti-ram Bollard Subjected to Impulsive Loadings. Compos. Struct. 2018, 189, 568–613. [Google Scholar] [CrossRef]

- Khan, J.G.; Dalu, R.S.; Gadekar, S.S. Defects in Extrusion Process and Their Impact on Product Quality. Int. J. Mech. Eng. Robot. Res. 2014, 3, 187–194. [Google Scholar]

- NIIR Board of Consultants & Engineers. The Complete Technology Book on Plastic Extrusion, Moulding and Mould Designs; NIIR: Moscow, Russia, 2017. [Google Scholar]

- Du Bois, J.H.; Du Bois, P. A Study in Mass Scaling for Sheet Metal Forming with LS-DYNA. In Proceedings of the 15th International LS-DYNA Users Conference, Detroit, MI, USA, 10–12 June 2018. [Google Scholar]

- Heimbs, S. Virtual testing of sandwich core structures with LS-Dyna. In Proceedings of the 26th CADFEM Users’ Meeting, Darmstadt, Germany, 22–24 October 2008. [Google Scholar]

- Chunke, L.; Xinping, S.; Jiao, W. Simulation Analysis of Car Front Collision Based on LS-DYNA and Hyper Works. J. Trans. Technol. 2014, 4, 337–342. [Google Scholar] [CrossRef][Green Version]

| Item | Unit | PLA | Steel |

|---|---|---|---|

| Density | kg/m3 | 1252 | 7830 |

| Young’s Modulus | Pa | 3.5 × 10+09 | 2.07 × 10+11 |

| Poisson’s Ratio | - | 0.36 | 0.33 |

| Bulk Modulus | Pa | 4.17 × 10+09 | - |

| Shear Modulus | Pa | 1.287 × 10+09 | - |

| Yield Stress (MPa) | Front Bumper Frame Maximum Acceleration (m/s2) | B-Pillar Maximum Acceleration (m/s2) | |

|---|---|---|---|

| Steel Bollard | 215 | 1.037 × 10+3 | 3.44 × 10+1 |

| Honeycomb Bollard | 10 | 0.701 × 10+3 | 3.16 × 10+1 |

| 20 | 0.388 × 10+3 | 2.99 × 10+1 | |

| 30 | 0.481 × 10+3 | 3.19 × 10+1 | |

| 40 | 0.550 × 10+3 | 3.25 × 10+1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seon, S.; Kim, K.; Bae, C.; Yi, W. A Study on Shock Absorption Characteristics of Honeycomb-Inserted Bollards. Appl. Sci. 2020, 10, 3014. https://doi.org/10.3390/app10093014

Seon S, Kim K, Bae C, Yi W. A Study on Shock Absorption Characteristics of Honeycomb-Inserted Bollards. Applied Sciences. 2020; 10(9):3014. https://doi.org/10.3390/app10093014

Chicago/Turabian StyleSeon, Sangwon, Kyungwuk Kim, Cheonho Bae, and Won Yi. 2020. "A Study on Shock Absorption Characteristics of Honeycomb-Inserted Bollards" Applied Sciences 10, no. 9: 3014. https://doi.org/10.3390/app10093014

APA StyleSeon, S., Kim, K., Bae, C., & Yi, W. (2020). A Study on Shock Absorption Characteristics of Honeycomb-Inserted Bollards. Applied Sciences, 10(9), 3014. https://doi.org/10.3390/app10093014