Fatigue Design of Steel Bridge Deck Asphalt Pavement Based on Nonlinear Damage Accumulation Theory

Abstract

:1. Introduction

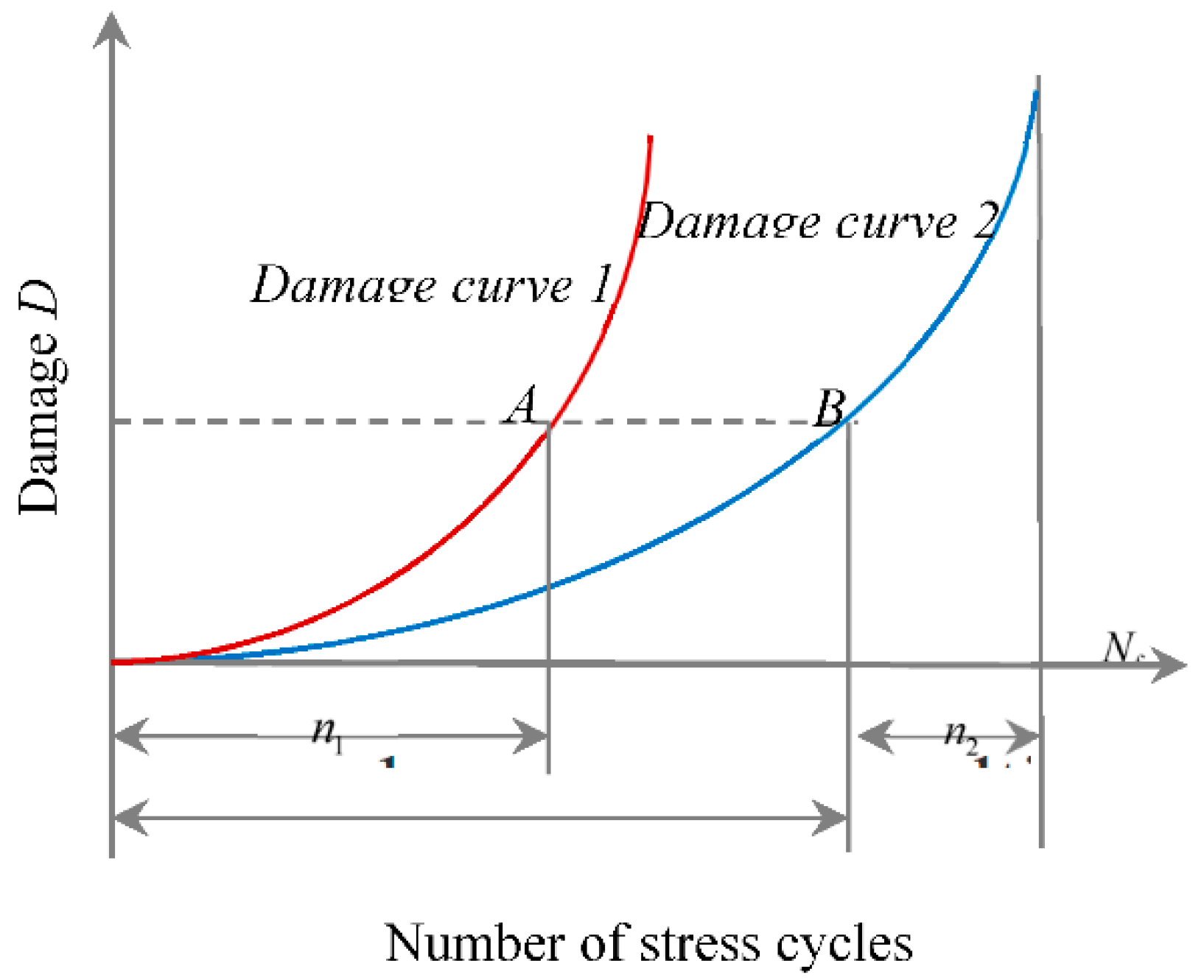

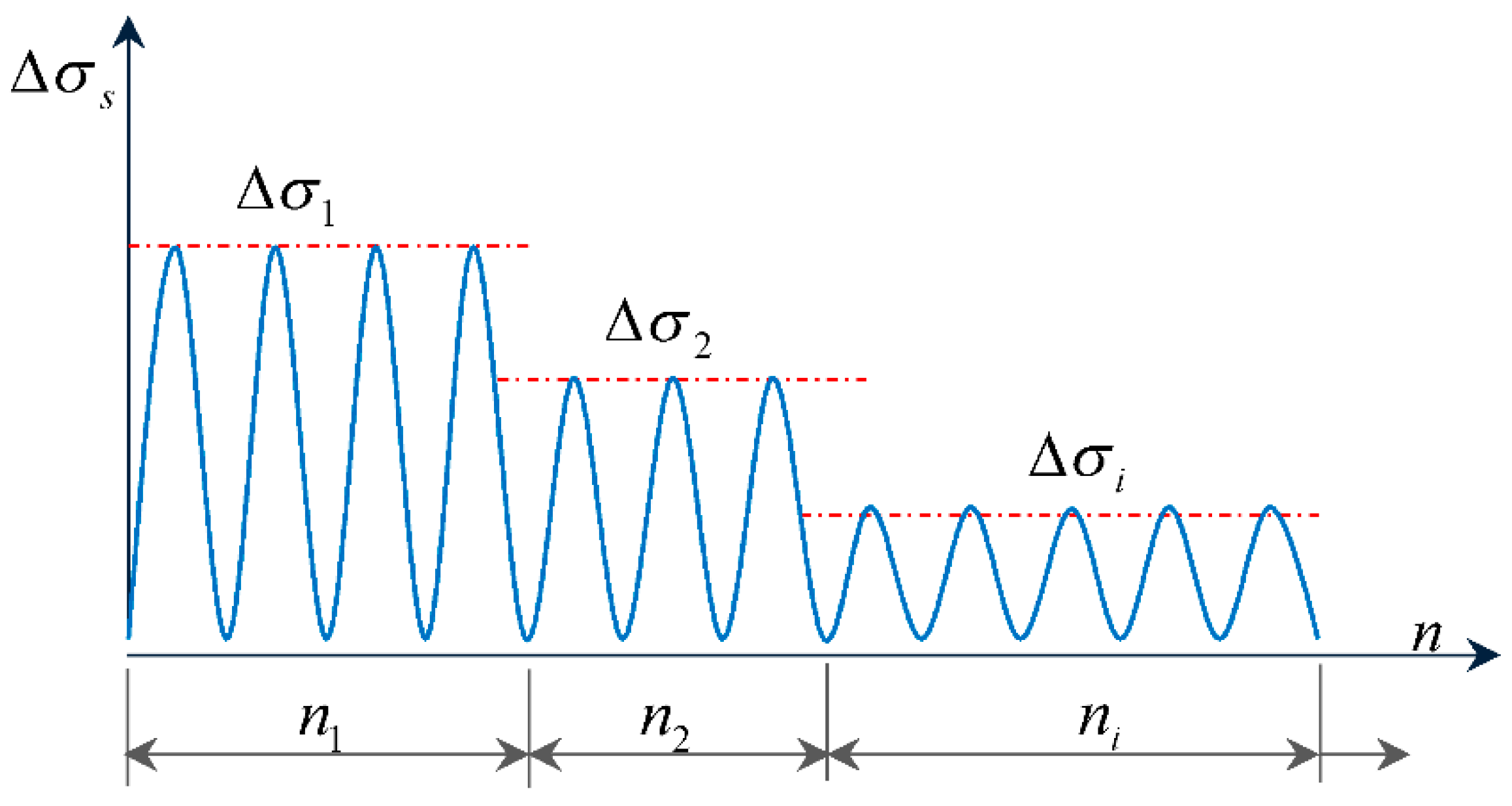

2. Nonlinear Damage Theory

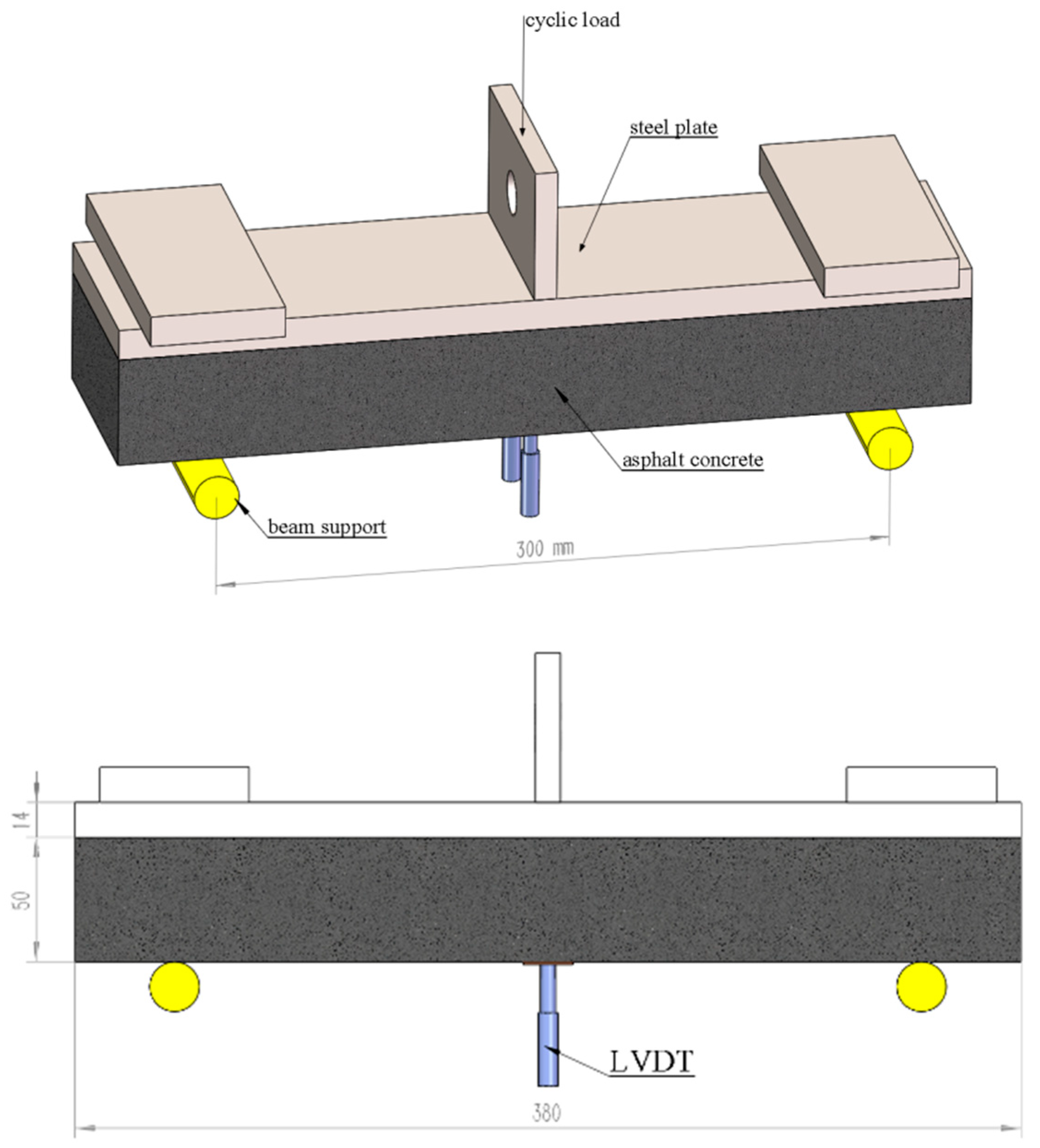

3. Calculation of Equivalent Stress

4. Fatigue Performance Estimation

- (1)

- (2)

- Calculate the actual stress variation range under fatigue load, namely, the equivalent stress variation range

- (3)

- Check the strength based on the fatigue strength value and the equivalent stress range

- (4)

- Calculate the stress ratio of asphalt pavement structure from the fatigue strength value and the equivalent stress variation range

- (5)

- Determine the grade of stress states according to the stress ratio.

5. Engineering Application Examples

5.1. Design Scheme 1

5.2. Design Scheme 2

- (1)

- When using the Miner model to design, the stress ratio is greater than 0.9, and the design results of fatigue life are independent of the loading sequence, which is consistent with Miner’s theory.

- (2)

- When using the M–H model to design, the design results of fatigue life are closely related to loading sequence, and the more the load levels are, the more obvious the influence. For the third-level load, when the loading sequence is from high to low, the stress ratio is 1.2863, which is higher than the design for the linear Miner model. However, when the loading sequence changed from low to high, the stress ratio is 0.8467, which is lower than the design results of the linear Miner model. For the fourth-level load, the change of stress ratio is more obvious when the loading sequence changes. When the loading sequence is from high to low, the stress ratio is 1.3271, which is higher than the design for the linear Miner model. However, when the loading sequence changes from low to high, the stress ratio is 0.7616, which is lower than the design results of the linear Miner model.

- (3)

- When using the modified M–H model to design, the design results of fatigue life are closely related to the loading sequence. The more the load levels are, the more obvious the influence on the stress ratio. According to the results, the modified model can avoid the insufficient accuracy of prediction caused by simply considering the loading sequence effects to a certain extent, which is a modification of its analysis results to ensure the effectiveness of analysis and design.

- (4)

- According to different design theories, the results of design parameters for the stress ratio are obviously different, which can be chosen according to different working conditions and its design theory to design. For the multistage load actions, the design model based on the M–H model can take the loading sequence effects into account well, while the modified M–H model can consider loading sequence effects and load interactions at the same time, giving more reliable analysis results.

6. Conclusions

- (1)

- Based on the Manson–Halford model and the nonlinear damage accumulation theory, a new fatigue design model of steel bridge deck asphalt pavement structure under multistage load was established, which could effectively carry out structural fatigue design with certain accuracy.

- (2)

- The more the load levels are, the more obvious effects on the stress ratio. The fatigue design of the model can well consider multistage loading sequence effects and load interactions. To a certain extent, to avoid only considering the loading sequence effects due to the resulting insufficient accuracy of reason analysis, more reliable analysis results are given to ensure the effectiveness of fatigue analysis and design of asphalt pavement structure.

- (3)

- The parameters involved in the established fatigue design model can be realized according to the calculation and analysis of multilevel load stress levels so as to avoid the influence of artificially introduced parameters, and relatively few parameters can be directly applied to the practical problems of steel bridge deck pavement engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, W. Integrated Design Procedure for Epoxy Asphalt Concrete–Based Wearing Surface on Long-Span Orthotropic Steel Deck Bridges. J. Mater. Civ. Eng. 2015, 28, 04015189. [Google Scholar] [CrossRef]

- Chavel, B. Steel Bridge Design Handbook: Bridge Deck Design; Rep. No. FHWA-IF-12-052; Federal Highway Administration: Washington, DC, USA, 2012; Volume 17. [Google Scholar]

- Wolchuk, R. Orthotrope Fahrbahnplatte—Entwicklungen und Möglichkeiten für die Zukunft. Stahlbau 2007, 76, 478–494. [Google Scholar] [CrossRef]

- Xu, X.; Yang, X.; Huang, W.; Xiang, H.; Yang, W. New damage evolution law for steel–asphalt concrete composite pavement considering wheel load and temperature variation. Materials 2019, 12, 3723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, C.; Zhang, H.; Pan, Y. Cracking mechanism and repair techniques of epoxy asphalt on steel bridge deck surfacing. Transp. Res. Rec. 2016, 2550, 123–130. [Google Scholar] [CrossRef]

- Losa, M.; Di Natale, A. Evaluation of representative loading frequency for linear elastic analysis of asphalt surfacing. Transp. Res. Rec. 2012, 2305, 150–161. [Google Scholar] [CrossRef]

- Liu, H.L.; Yang, D.X. IGS-SIMP Method Based Stress-constrained Topology Optimization of Continuous Structrues. Chin. J. Comput. Mech. 2018, 35, 144–151. [Google Scholar]

- Kim, T.W.; Baek, J.; Lee, H.J.; Lee, S.Y. Effect of surfacing design parameters on the behavior of orthotropic steel bridge deck surfacings under traffic loading. Int. J. Surf. Eng. 2014, 15, 471–482. [Google Scholar]

- Zhang, L.; Wang, W.; Lu, Q.; Chen, X. An innovative approach to determine deck surfacing modulus and interfacial slip stiffness based on a composite beam model. Constr. Build. Mater. 2013, 40, 411–418. [Google Scholar] [CrossRef]

- Bocci, E.; Graziani, A.; Canestrari, F. Mechanical 3D characterization of epoxy asphalt concrete for surfacing layers of orthotropic steel decks. Constr. Build. Mater. 2015, 79, 145–152. [Google Scholar] [CrossRef]

- Kainuma, S.; Jeong, Y.S.; Ahn, J.-H.; Yamagami, T.; Tsukamoto, S. Behavior and stress of orthotropic deck with bulb rib by surface corrosion. J. Constr. Steel Res. 2015, 113, 135–145. [Google Scholar] [CrossRef]

- Hornyak, N.; Crovetti, J.A. Analysis of load pulse durations for Marquette interchange instrumentation project. Transp. Res. Rec. 2009, 2094, 53–61. [Google Scholar] [CrossRef]

- Kozy, B.M.; Connor, R.J.; Paterson, D.; Mertz, D.R. Proposed revisions to AASHTO-LRFD bridge design specifications for orthotropic steel deck bridges. J. Bridge Eng. 2010, 16, 759–767. [Google Scholar] [CrossRef]

- Medani, T.O.; Liu, X.; Huurman, M.; Scarpas, A.; Molenaar, A.A.A. Characterisation of surfacing materials for orthotropic steel deck bridges. Part 1: Experimental work. Int. J. Surf. Eng. 2010, 11, 237–253. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Kolstein, H.; Bijlaard, F. Fatigue assessment of full-scale retrofitted orthotropic bridge decks. J. Bridge Eng. 2017, 22, 04017092. [Google Scholar] [CrossRef] [Green Version]

- Campbell, F.C. Fatigue and Fracture: Understanding the Basics; ASM International: Materials Park, OH, USA, 2012. [Google Scholar]

- Liu, W.; Xu, S.; Li, Q. Experimental study on fracture performance of ultra-high toughness cementitious composites with J-integral. Eng. Fract. Mech. 2012, 96, 656–666. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, P. Optimum blending requirements for EVA modified binder. Int. J. Surf. Res. Technol. 2015, 8, 172–178. [Google Scholar] [CrossRef]

- Bayat, A.; Knight, M. Field evaluation and analysis of flexible surfacing structural responses under dynamic loads. Road Mater. Surf. Des. 2012, 13, 26–37. [Google Scholar]

- Delgadillo, R.; Bahia, H.U.; Lakes, R. A nonlinear constitutive relationship for asphalt binders. Mater. Struct. 2012, 45, 457–473. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, G.; Tighe, S.; Chen, M.; Wu, S.; Adhikari, S.; Gao, Y. Quantitative comparison of surface and interface adhesive properties of fine aggregate asphalt mixtures composed of basalt, steel slag, and andesite. Constr. Build. Mater. 2020, 246, 118507. [Google Scholar] [CrossRef]

- Ameri, M.; Nowbakht, S.; Molayem, M.; Mirabimoghaddam, M.H. A study on fatigue modeling of hot mix asphalt mixtures based on the viscoelastic continuum damage properties of asphalt binder. Constr. Build. Mater. 2016, 106, 243–252. [Google Scholar] [CrossRef]

- Golos, K.; Ellyin, F. A total strain energy density theory for cumulative fatigue damage. J. Press. Vessel Technol. 1988, 110, 36–41. [Google Scholar] [CrossRef]

- Manson, S.; Halford, G. Practical implementation of the double linear damage rule and damage curve approach for treating cumulative fatigue damage. Int. J. Fatigue 1981, 17, 169–192. [Google Scholar]

- Marco, S.; Starkey, W. A concept of fatigue damage. Trans. ASME 1954, 76, 627–632. [Google Scholar]

- Alencar, G.; de Jesus, A.M.P.; Alencar, G.; de Jesus, A.M.P.; Calçada, R.A.B.; da Silva, J.G.S. Fatigue life evaluation of a composite steel-concrete roadway bridge through the hot-spot stress method considering progressive surfacing deterioration. Eng. Struct. 2018, 166, 46–61. [Google Scholar] [CrossRef]

- Pokorski, P.; Radziszewski, P.; Sarnowski, M. Fatigue life of asphalt surfacings on bridge decks. Procedia Eng. 2016, 153, 556–562. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.; Liu, X.; Zhang, Y.; Lin, P.; Apostolidis, P.; Erkens, S.; Li, M.; Xu, J. Multi-scale characterization of lignin modified bitumen using experimental and molecular dynamics simulation methods. Mater. Struct. 2021, 287, 123058. [Google Scholar]

- Cho, J.G.; Koo, J.S.; Jung, H.S. A Lightweight Design Approach for an EMU Carbody Using a Material Selection Method and Size Optimization. J. Mech. Sci. Technol. 2016, 30, 673–681. [Google Scholar] [CrossRef]

- Talatahari, S. Optimum Design of Skeletal Structures Using Ant Lion Optimizer. Int. J. Optim. Civ. Eng. 2016, 6, 13–25. [Google Scholar]

- Xu, X.; Yang, X.; Yang, W.; Guo, X.; Xiang, H. New damage evolution law for modeling fatigue life of asphalt concrete surfacing of long-span steel bridge. Constr. Build. Mater. 2020, 259, 119795. [Google Scholar] [CrossRef]

- China Communications Press. Specifications for Design of Highway Asphalt Surfacing, CN-JT; JTG D50-2017; China Communications Press: Beijing, China, 2017. [Google Scholar]

- China Communications Press. Standard Test Material of Bitumen and Bituminous Mixtures for Highway Engineering, CN-JT; JTG E20-2011; China Communications Press: Beijing, China, 2011. [Google Scholar]

- Yan, C.L.; Hao, Y.X.; Liu, K. Fatigue Life Prediction of Materials Based on BP Neural Networks Optimized by Genetic Algorithm. J. Jilin Univ. 2014, 44, 1710–1715. [Google Scholar]

- Cheng, H.; Liu, L.; Sun, L. Field measurements of dynamic strain responses of asphalt surfacing on steel deck bridge. China Civ. Eng. J. 2019, 52, 100–108. [Google Scholar]

| Three Levels | Four Levels | ||||

|---|---|---|---|---|---|

| 1 | 0.85 | 0.3 | 0.85 | 0.2 | 1.0 |

| 2 | 0.70 | 0.3 | 0.70 | 0.2 | |

| 3 | 0.55 | 0.4 | 0.65 | 0.2 | |

| 4 | - | - | 0.55 | 0.4 | |

| 1 | 0.85 | 0.3 | 0.51429 | 0.2267 | 0.0812 | 0.0804 | ||

| 2 | 0.70 | 0.3 | 0.65687 | 0.3886 | 0.1698 | 0.1521 | ||

| 3 | 0.55 | 0.4 | 3.27326 | 0.4512 | 0.3967 | 0.3484 | ||

| Total | - | 1.0 | - | 0.4512 | 0.3967 | 0.3484 | ||

| Miner model | ||||||||

| M–H model | ||||||||

| Modified M–H model | ||||||||

| 1 | 0.85 | 0.2 | 0.51429 | 0.15472 | 0.05423 | 0.05017 | ||

| 2 | 0.70 | 0.2 | 0.65687 | 0.12801 | 0.12136 | 0.11845 | ||

| 3 | 0.65 | 0.2 | 1.74563 | 0.30117 | 0.19652 | 0.17143 | ||

| 4 | 0.55 | 0.4 | 3.27326 | 0.36542 | 0.30147 | 0.26406 | ||

| Total | - | 1.0 | - | 0.36542 | 0.30147 | 0.26406 | ||

| Miner model | ||||||||

| M–H model | ||||||||

| Modified M–H model | ||||||||

| 1 | 0.55 | 0.4 | 3.27326 | 0.0612 | 0.0219 | 0.0212 | ||

| 2 | 0.70 | 0.3 | 0.65687 | 0.1986 | 0.0594 | 0.0637 | ||

| 3 | 0.85 | 0.3 | 0.51429 | 0.4512 | 0.1236 | 0.1214 | ||

| Total | - | 1.0 | - | 0.4512 | 0.1236 | 0.1214 | ||

| Miner model | ||||||||

| M–H model | ||||||||

| Modified M–H model | ||||||||

| 1 | 0.55 | 0.4 | 3.27326 | 0.05643 | 0.01947 | 0.01979 | ||

| 2 | 0.65 | 0.2 | 1.74563 | 0.10747 | 0.02541 | 0.02753 | ||

| 3 | 0.70 | 0.2 | 0.65687 | 0.20198 | 0.04409 | 0.04715 | ||

| 4 | 0.85 | 0.2 | 0.51429 | 0.36542 | 0.07803 | 0.08091 | ||

| Total | - | 1.0 | - | 0.36542 | 0.07803 | 0.08091 | ||

| Miner model | ||||||||

| M–H model | ||||||||

| Modified M–H model | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Li, Y.; Huang, W.; Chen, D.; Zhang, C.; Shi, W. Fatigue Design of Steel Bridge Deck Asphalt Pavement Based on Nonlinear Damage Accumulation Theory. Appl. Sci. 2021, 11, 5668. https://doi.org/10.3390/app11125668

Xu X, Li Y, Huang W, Chen D, Zhang C, Shi W. Fatigue Design of Steel Bridge Deck Asphalt Pavement Based on Nonlinear Damage Accumulation Theory. Applied Sciences. 2021; 11(12):5668. https://doi.org/10.3390/app11125668

Chicago/Turabian StyleXu, Xunqian, Yu Li, Wei Huang, Dakai Chen, Chen Zhang, and Wenkang Shi. 2021. "Fatigue Design of Steel Bridge Deck Asphalt Pavement Based on Nonlinear Damage Accumulation Theory" Applied Sciences 11, no. 12: 5668. https://doi.org/10.3390/app11125668