Study on Microstructure, Mechanical Properties and Erosion Characteristics of Al-Si Alloy Manufactured by Continuous Casting Direct Rolling Process

Abstract

:1. Introduction

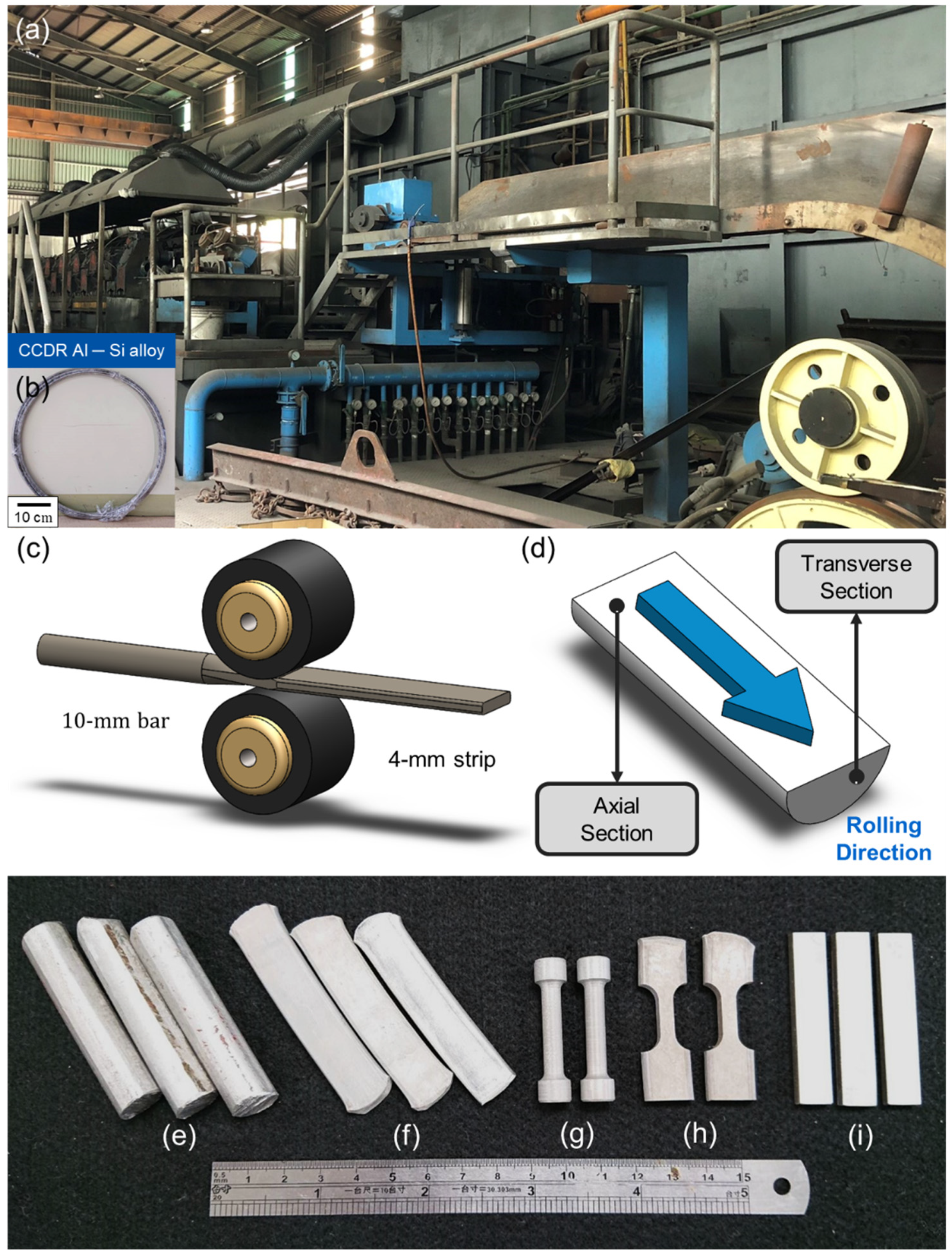

2. Materials and Methods

3. Results and Discussion

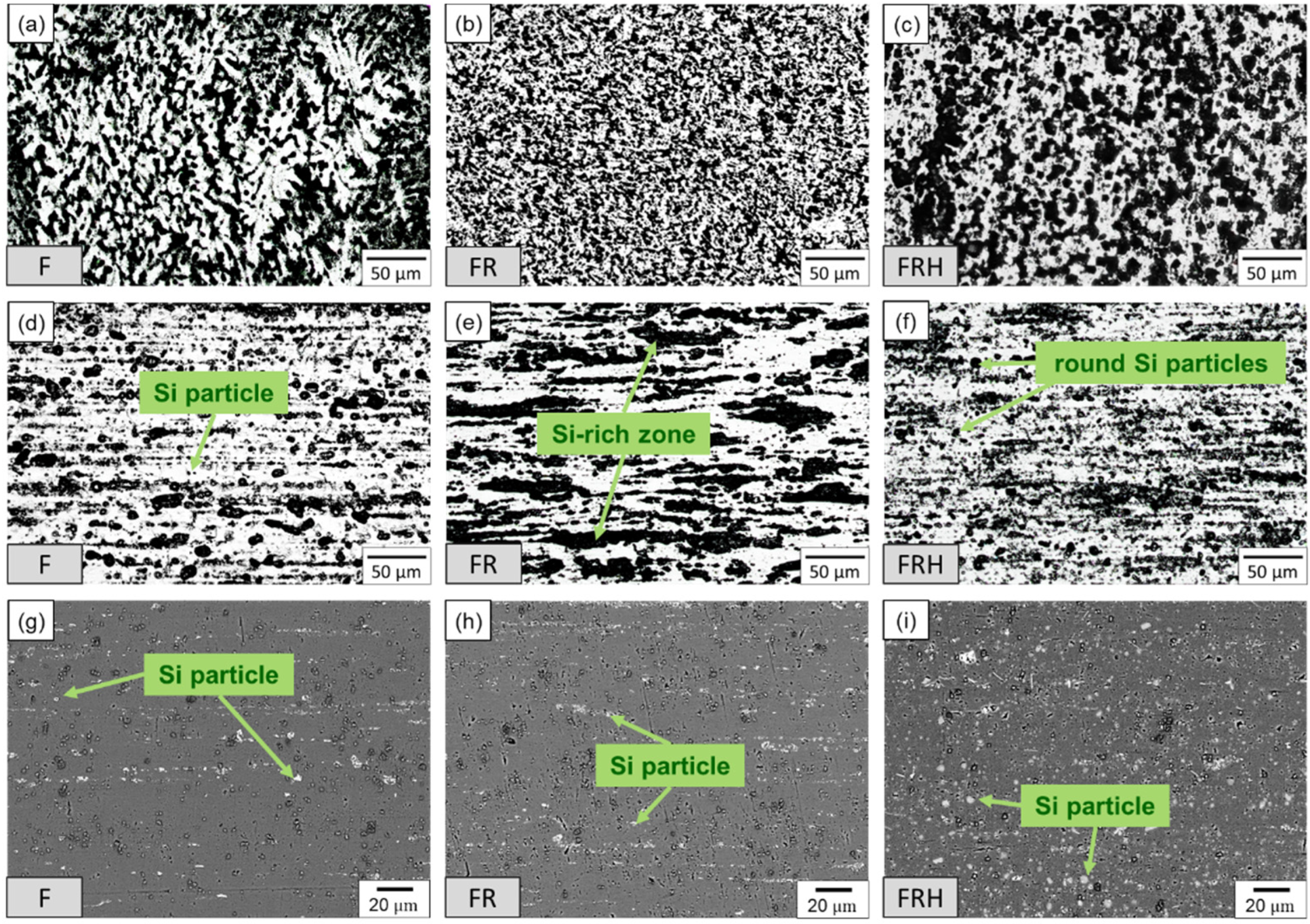

3.1. Microstructural Characteristics

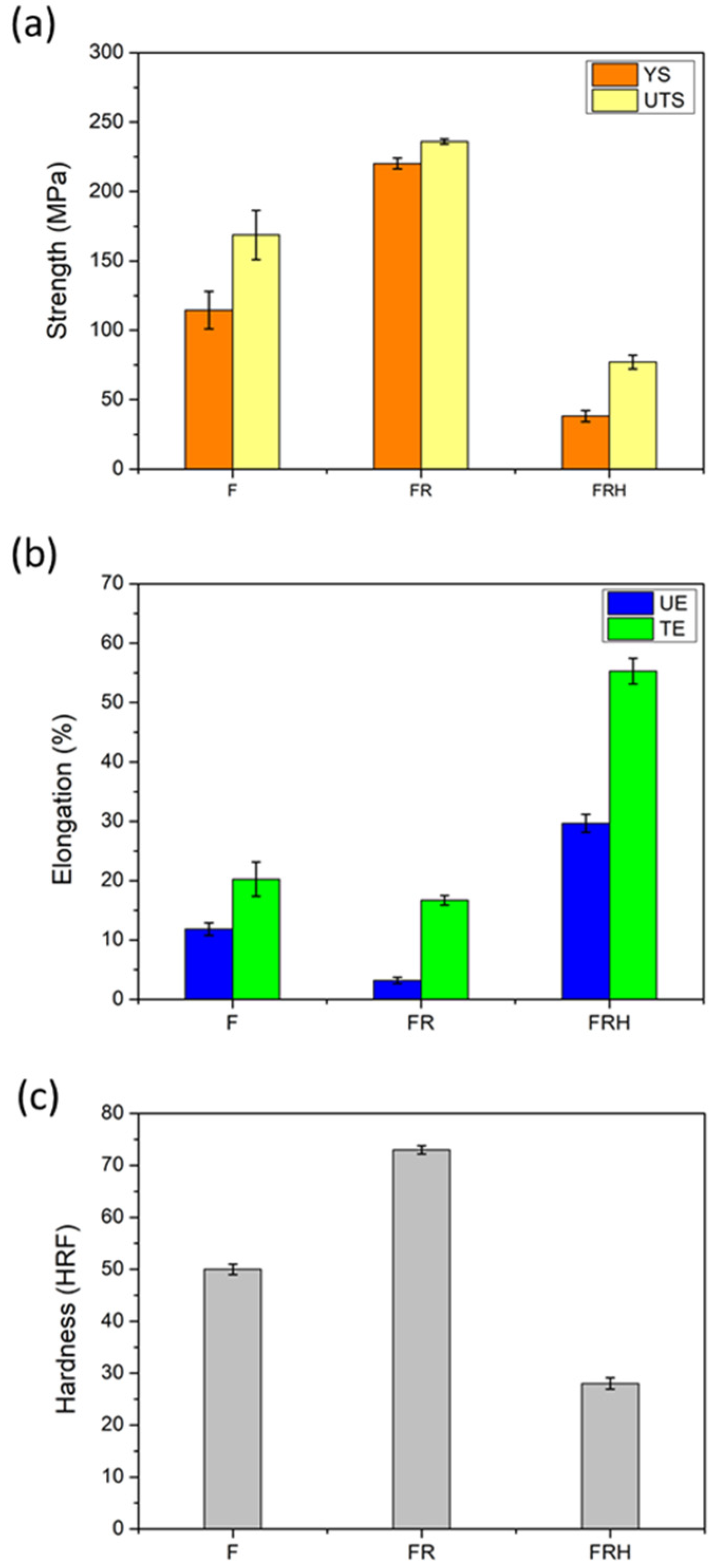

3.2. Tensile Mechanical Properties and Hardness

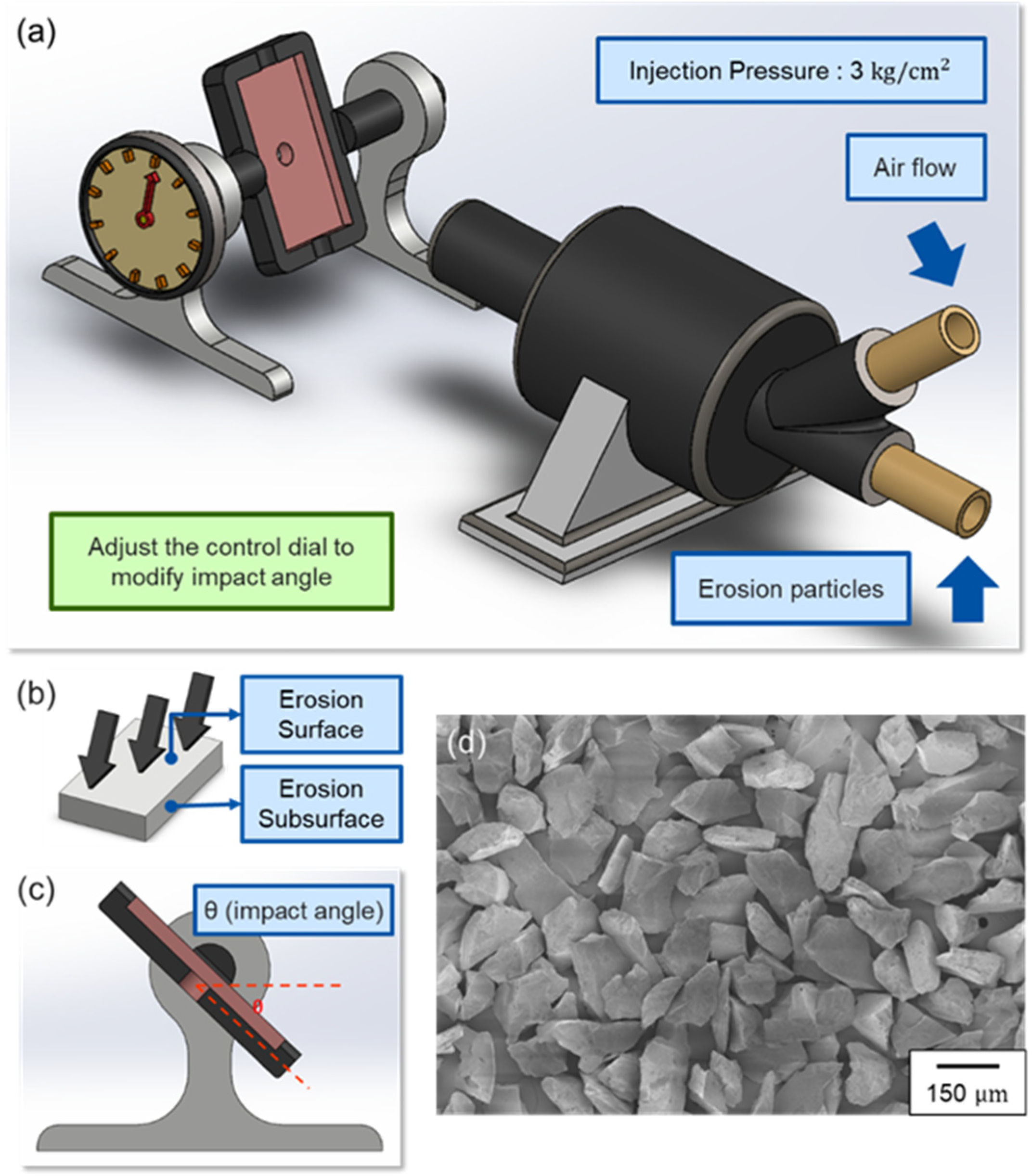

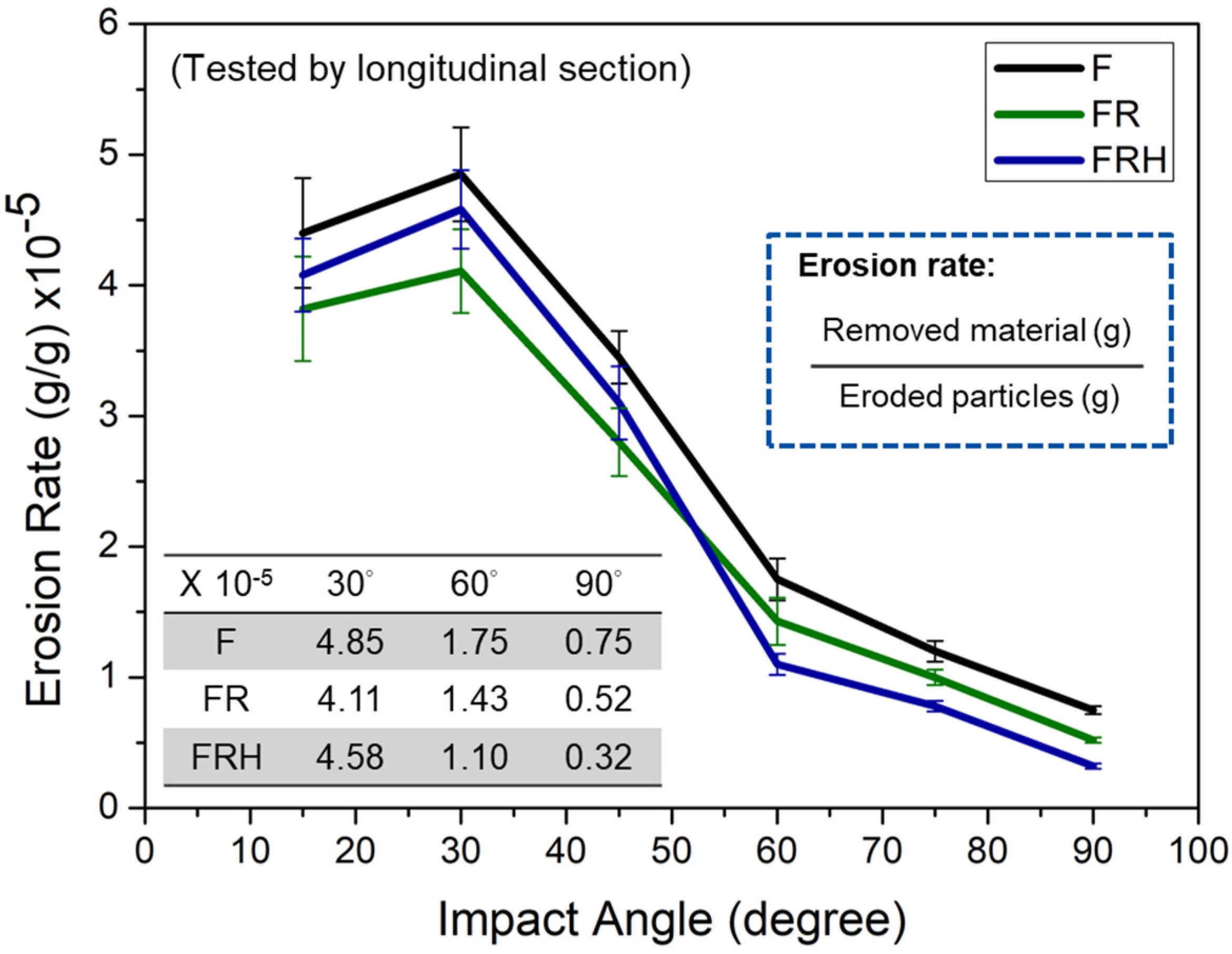

3.3. Characteristics and Mechanism of Erosion

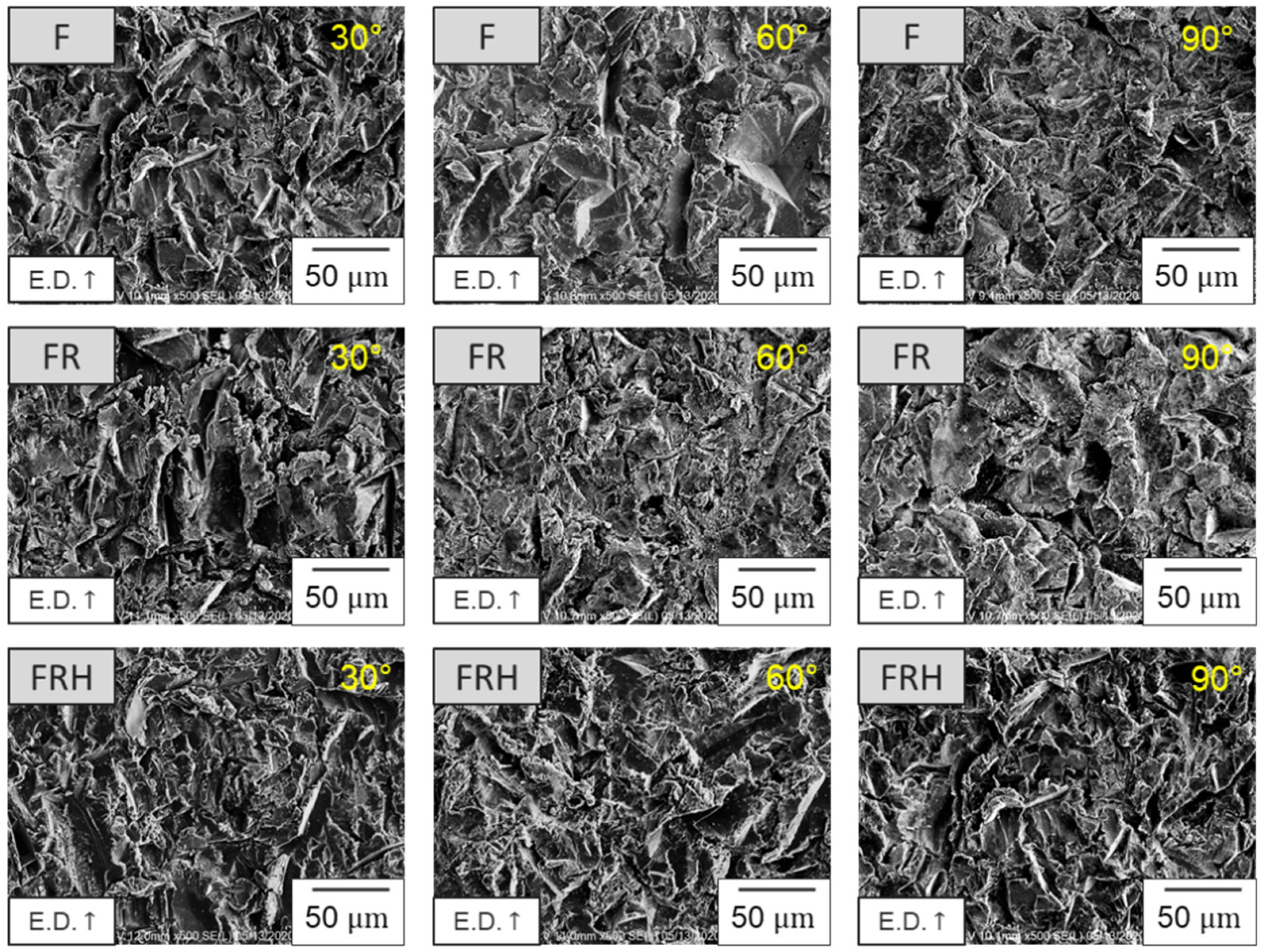

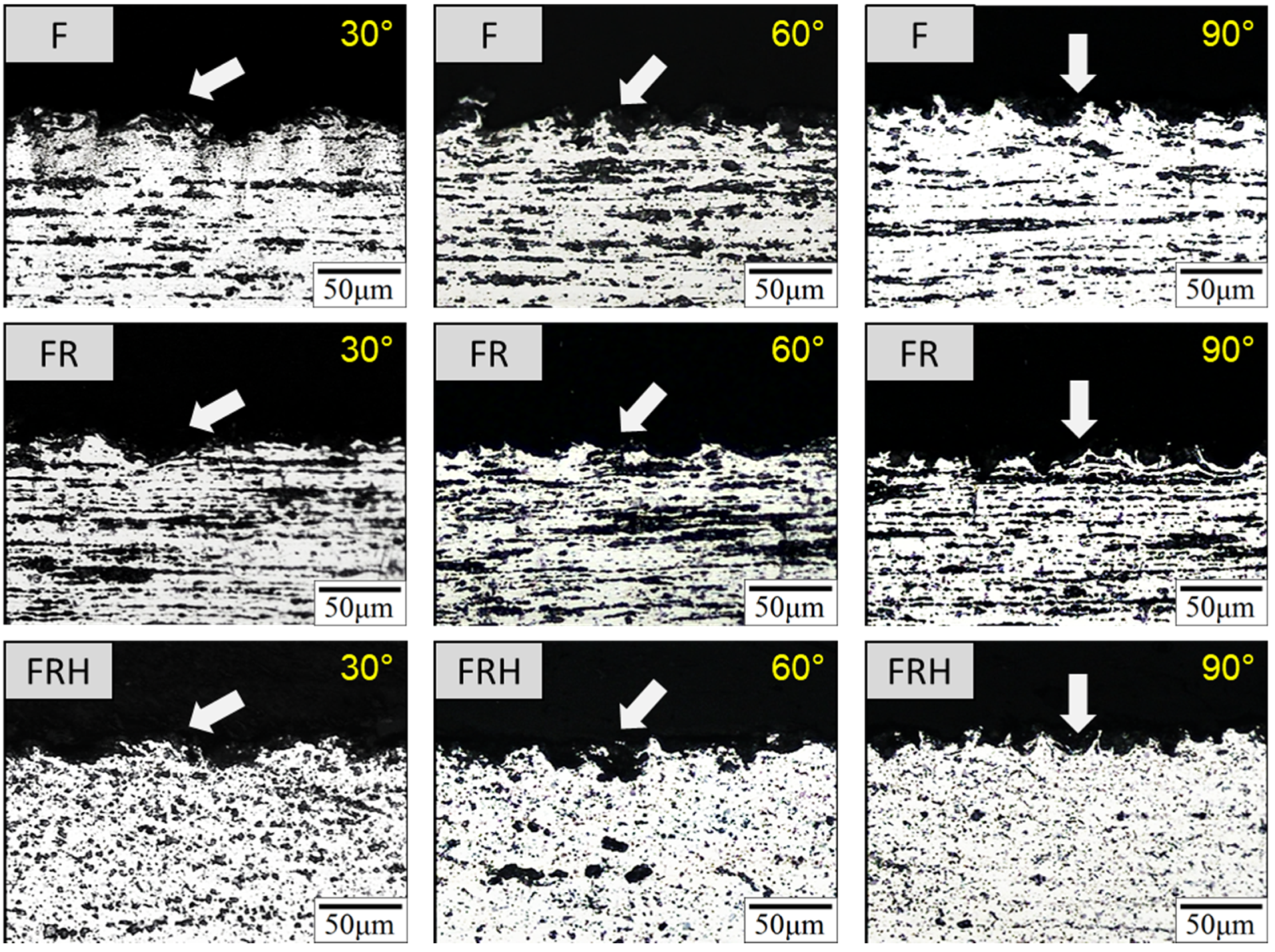

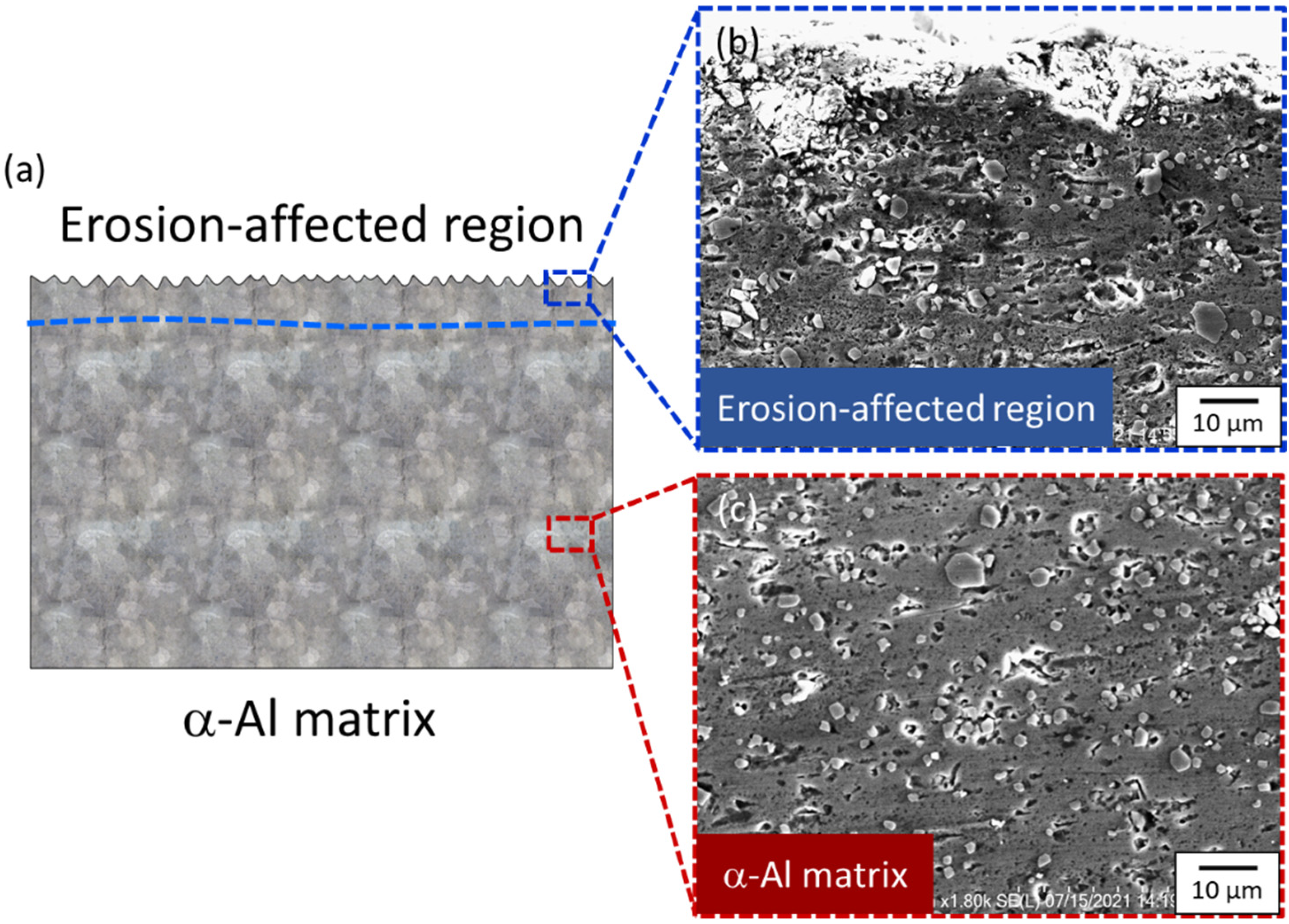

3.4. Surface Characteristics of Erosion

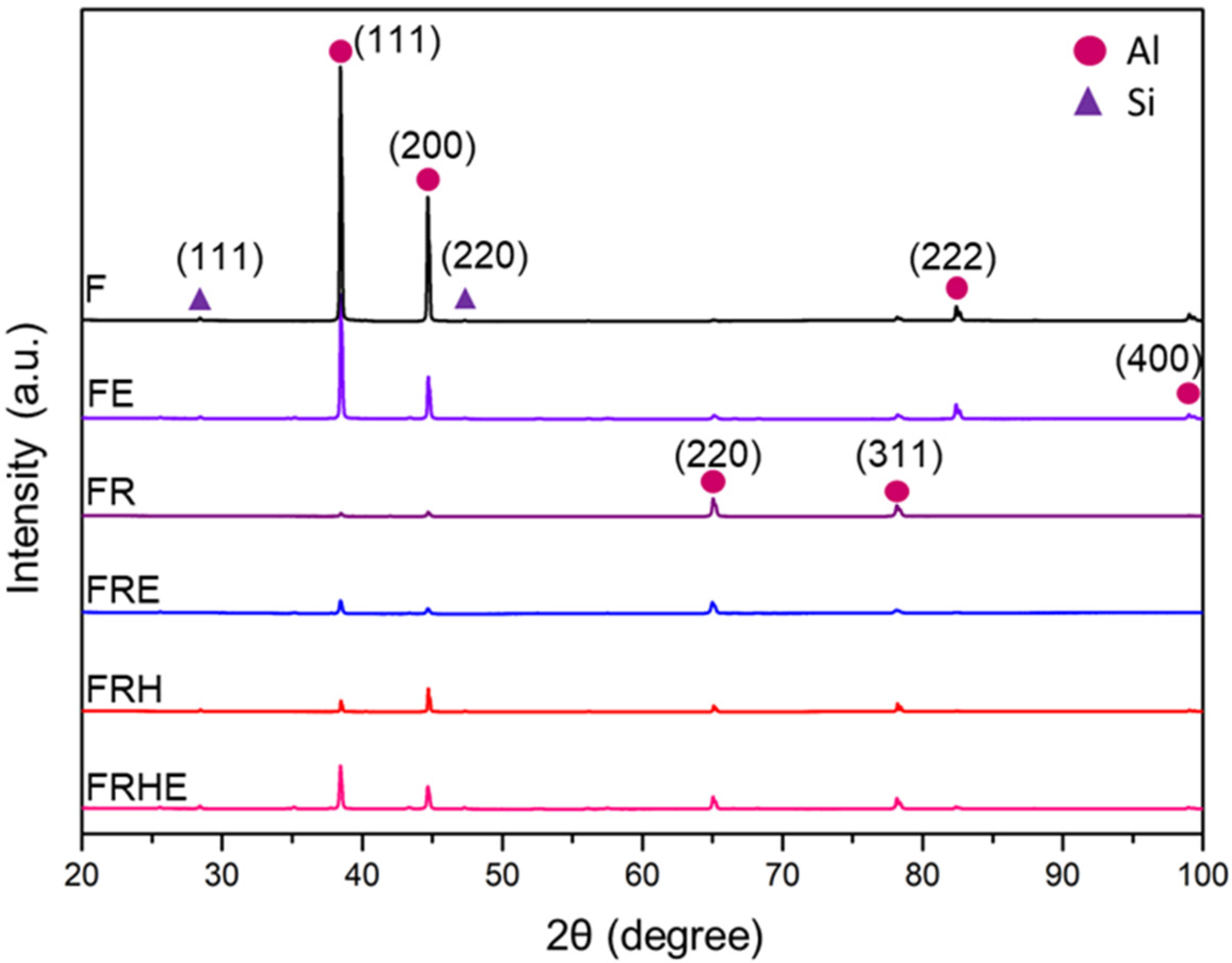

3.5. Surface Phase Composition after Erosion

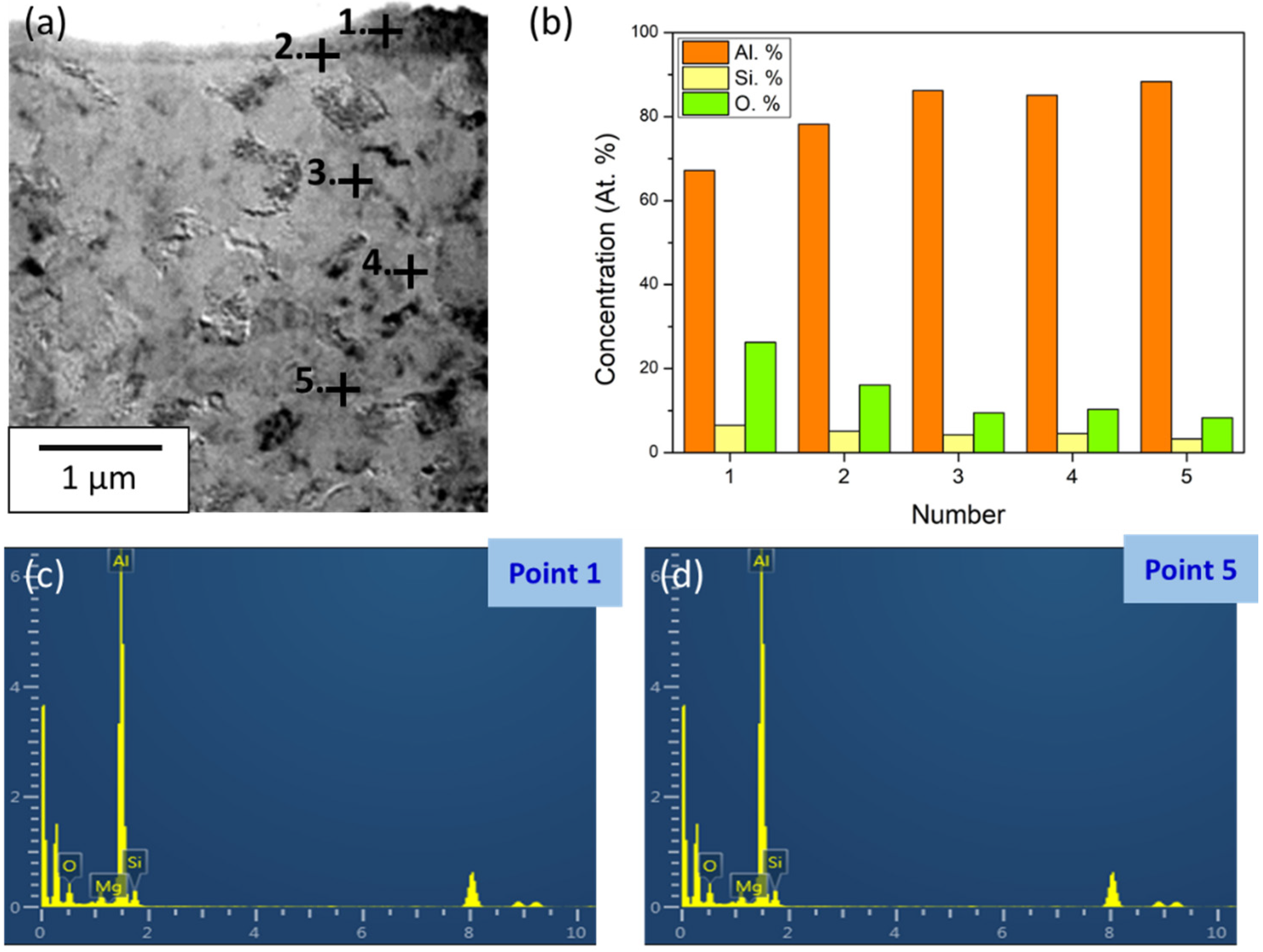

3.6. Erosion Induces Phase Transformation

4. Conclusions

- The strength of the CCDR Al-Si alloy can be significantly improved through cold rolling; ductility is not suitable for further processing. The two-stage heat treatment increase the ductility but decreases the strength, in comparison to the former, though it can satisfy the requirements for secondary cold working.

- The CCDR Al-Si alloy under different conditions exhibited a ductile-dominated erosion mechanism. Cold rolling alone or in combination with a heat treatment both improved the wear resistance. The FR specimen showed the best wear resistance at a lower angle, but the FRH specimen was at a higher impact angle.

- The CCDR Al-Si alloy had a stable phase structure; no new phase appeared, and both the peak intensity and preferred orientation changed after erosion wear. Erosion induced fine grains, and a Si solid solution effect improved the erosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kase, M.; Matsuzuka, K.; Takahashi, H.; Oba, H.; Hirata, O. Continuous casting direct rolling technology at Nippon Steel’s Sakai Works. Steel Times 1985, 213, 268. [Google Scholar]

- Echigo, R.; Yoshida, H.; Mochizuki, T. Temperature Equalization by the Radiative Converter for a Slab in Continuous Casting Direct Rolling. JSME Int. J. Ser. 2 Fluids Eng. Heat Transf. Power Combust. Thermophys. Prop. 1988, 31, 545–552. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.-R.; Hung, F.-Y.; Chen, B.-J. Effects of heat treatment on a novel continuous casting direct rolling 6056 aluminum alloy: Cold rolling characteristics and tensile fracture properties. J. Mater. Res. Technol. 2021, 11, 535–547. [Google Scholar] [CrossRef]

- Muntin, A.V. Advanced Technology of Combined Thin Slab Continuous Casting and Steel Strip Hot Rolling. Metallurgist 2019, 62, 900–910. [Google Scholar] [CrossRef]

- Amiri, M.M.; Fereshteh-Saniee, F. An Experimental Investigation on the Effect of Cooling Rate During Combined Continuous Casting and Rolling Process on Mechanical Properties of 7075 Aluminum Alloy. Trans. Indian Inst. Met. 2019, 73, 441–448. [Google Scholar] [CrossRef]

- Maehara, Y.; Nakai, K.; Yasumoto, K.; Mishima, T. Hot Cracking of Low Alloy Steels in Simulated Continuous Casting-Direct Rolling Process. Trans. Iron Steel Inst. Jpn. 1988, 28, 1021–1027. [Google Scholar] [CrossRef]

- Kim, M.G.; Lee, G.C.; Park, J.P. Materials Science Forum; Trans Tech Publications Ltd.: Kapellweg, Switzerland, 2010; Volume 638, pp. 255–260. [Google Scholar]

- Zhang, X.Y.; Zhang, H.; Kong, X.X.; Fu, D.F. Microstructure and properties of Al–0.70 Fe–0.24 Cu alloy conductor prepared by horizontal continuous casting and subsequent continuous extrusion forming. Trans. Nonferrous Met. Soc. China 2015, 25, 1763–1769. [Google Scholar] [CrossRef]

- Hernandez, F.C.R.; Ramírez, J.M.H.; Mackay, R. Al-Si Alloys: Automotive, Aeronautical, and Aerospace Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Casalegno, V.; Salvo, M.; Rizzo, S.; Goglio, L.; Damiano, O.; Ferraris, M. Joining of carbon fibre reinforced polymer to Al-Si alloy for space applications. Int. J. Adhes. Adhes. 2018, 82, 146–152. [Google Scholar] [CrossRef]

- Heusler, L.; Schneider, W. Influence of alloying elements on the thermal analysis results of Al-Si cast alloys. J. Light Met. 2002, 2, 17–26. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, K.; Li, Y.; Zhao, D.; Liu, X. Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions. Mater. Des. 2012, 33, 220–225. [Google Scholar] [CrossRef]

- Ye, H. An Overview of the Development of Al-Si-Alloy Based Material for Engine Applications. J. Mater. Eng. Perform. 2003, 12, 288–297. [Google Scholar] [CrossRef]

- Dahle, A.K.; Tøndel, P.A.; Paradies, C.J.; Arnberg, L. Effect of grain refinement on the fluidity of two commercial Al-Si foundry alloys. Met. Mater. Trans. A 1996, 27, 2305–2313. [Google Scholar] [CrossRef]

- Ravi, K.; Pillai, R.; Amaranathan, K.; Pai, B.; Chakraborty, M. Fluidity of aluminum alloys and composites: A review. J. Alloy. Compd. 2008, 456, 201–210. [Google Scholar] [CrossRef]

- El-Gamal, S.; Mohammed, G. Effects of γ-irradiation and strain rate on the tensile and the electrical properties of Al-4043 alloy. Radiat. Phys. Chem. 2014, 99, 68–73. [Google Scholar] [CrossRef]

- Li, J.; Feng, Q.; Liu, F.; Wu, W. Experimental studies of the tooth wear resistance with different profiles in single screw compressor. Tribol. Int. 2013, 57, 210–215. [Google Scholar] [CrossRef]

- Stošic, N.; Milutinović, L.; Hanjalić, K.; Kovačević, A. Investigation of the influence of oil injection upon the screw compressor working process. Int. J. Refrig. 1992, 15, 206–220. [Google Scholar] [CrossRef]

- Fastykovskii, A.; Chinokalov, E.; Prudnikov, A.; Oskolkova, T. IOP Conference Series: Materials Science and Engineering; IOP Publishing: Novokuznetsk, Russia, 2020; Volume 866, p. 012016. [Google Scholar]

- Fastykovskii, A.R.; Chinokalov, E.V.; Milovanov, A.G.; Myskova, N.V.; Shumkin, A.A. Cold-Drawn Reinforcing Wire with Screw Profile. Metallurgist 2014, 58, 540–544. [Google Scholar] [CrossRef]

- Gupta, M.; Lavernia, E.J. Effect of processing on the microstructural variation and heat-treatment response of a hypercutectic Al-Si alloy. J. Mater. Process. Technol. 1995, 54, 261–270. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, Z.; Han, D.; Chen, Q.; Li, Z. Effects of Si Content and Aging Temperature on Wear Resistance of Surfacing Layers Welded with 4043 Aluminum Welding Wires. Rare Met. Mater. Eng. 2016, 45, 71–74. [Google Scholar]

- Singh, R.K.; Telang, A.; Das, S. Microstructure and mechanical properties of Al-Si alloy in as-cast and heat treated condition. Am. J. Eng. Res. 2016, 5, 133–137. [Google Scholar]

- El-Khalek, A.A.; El-Salam, F.A. Effect of irradiation and pre-ageing temperature on the mechanical properties of Al-Si alloy. Radiat. Eff. Defects Solids 2008, 163, 835–842. [Google Scholar] [CrossRef]

- Hung, F.-Y.; Chen, L.-H.; Lui, T.-S. Phase Transformation of an Austempered Ductile Iron during an Erosion Process. Mater. Trans. 2004, 45, 2981–2986. [Google Scholar] [CrossRef]

- Liou, J.; Lui, T.; Chen, L. SiO2 particle erosion of A356.2 aluminum alloy and the related microstructural changes. Wear 1997, 211, 169–176. [Google Scholar] [CrossRef]

- Zhao, J.-R.; Hung, F.-Y.; Lui, T.-S. Particle Erosion Induced Phase Transformation of Different Matrix Microstructures of Powder Bed Fusion Ti-6Al-4V Alloy Flakes. Metals 2019, 9, 730. [Google Scholar] [CrossRef] [Green Version]

- Chuang, H.C.; Lui, T.S.; Chen, L.H. Characteristics and Effects of Particle Morphology and Tensile Ductility Resulting from FSP of Al-Si-Cu-Ni Casting and Forging Piston. Mater. Trans. 2013, 54, 1373–1380. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.-R.; Hung, F.-Y.; Lui, T.-S. Erosion Resistance and Particle Erosion-Induced Tensile Embrittlement of 3D-Selective Laser Melting Inconel 718 Superalloy. Metals 2019, 10, 21. [Google Scholar] [CrossRef] [Green Version]

- Wood, R.; Walker, J.; Harvey, T.; Wang, S.; Rajahram, S. Influence of microstructure on the erosion and erosion–corrosion characteristics of 316 stainless steel. Wear 2013, 306, 254–262. [Google Scholar] [CrossRef]

- Chintapalli, R.K.; Marro, F.G.; Jimenez-Pique, E.; Anglada, M. Phase transformation and subsurface damage in 3Y-TZP after sandblasting. Dent. Mater. 2013, 29, 566–572. [Google Scholar] [CrossRef]

- Ye, Y.; Li, J.; Lv, X.; Liu, L. Study on Failure Mechanism and Phase Transformation of 304 Stainless Steel during Erosion Wear. Metals 2020, 10, 1427. [Google Scholar] [CrossRef]

- Chang, K.C.; Zhao, J.R.; Hung, F.Y. Effects of Hyper-High-Temperature Solid-Solution Treatment on Microstructure Evolution and Nanoprecipitation of the Al-Ni-Cu-Fe-Zr-Sc Alloy Manufactured by Selective Laser Melting. J. Alloy. Compd. 2021, 883, 160781. [Google Scholar] [CrossRef]

- Saad, G.; Fayek, S.; Fawzy, A.; Soliman, H.; Mohammed, G. Deformation characteristics of Al-4043 alloy. Mater. Sci. Eng. A 2010, 527, 904–910. [Google Scholar] [CrossRef]

- Farkoosh, A.; Javidani, M.; Hoseini, M.; Larouche, D.; Pekguleryuz, M. Phase formation in as-solidified and heat-treated Al-Si-Cu-Mg-Ni alloys: Thermodynamic assessment and experimental investigation for alloy design. J. Alloy. Compd. 2013, 551, 596–606. [Google Scholar] [CrossRef]

- Huang, B.C.; Hung, F.Y. Al2O3 Particle Erosion Induced Phase Transformation: Structure, Mechanical Property, and Impact Toughness of an SLM Al-10Si-Mg Alloy. Nanomaterials 2021, 11, 2131. [Google Scholar] [CrossRef]

- Chen, K.-J.; Hung, F.-Y.; Lui, T.-S.; Tsai, C.-L. Improving the applicability of wear-resistant Al–10Si–0.5 Mg alloy obtained through selective laser melting with T6 treatment in high-temperature, and high-wear environments. J. Mater. Res. Technol. 2020, 9, 9242–9252. [Google Scholar] [CrossRef]

- Hovis, S.; Talia, J.; Scattergood, R. Erosion mechanisms in aluminum and Al-Si alloys. Wear 1986, 107, 175–181. [Google Scholar] [CrossRef]

- Magnee, A. Generalized law of erosion: Application to various alloys and intermetallics. Wear 1995, 181, 500–510. [Google Scholar] [CrossRef]

- Daoud, A.; El-Khair, M.T.A.; Abdel-Azim, A.N. Effect of Al2O3 Particles on the Microstructure and Sliding Wear of 7075 Al Alloy Manufactured by Squeeze Casting Method. J. Mater. Eng. Perform. 2004, 13, 135–143. [Google Scholar] [CrossRef]

- Das, S.; Mondal, D.P.; Sawla, S. Solid particle erosion of Al alloy and Al-alloy composites: Effect of heat treatment and angle of impingement. Met. Mater. Trans. A 2004, 35, 1369–1379. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.W. Engineering Tribology; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Bellman, R.; Levy, A. Erosion mechanism in ductile metals. Wear 1981, 70, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Sheldon, G.L. Effects of Surface Hardness and Other Material Properties on Erosive Wear of Metals by Solid Particles. J. Eng. Mater. Technol. 1977, 99, 133–137. [Google Scholar] [CrossRef]

- Das, S.; Mondal, D.; Sawla, S.; Ramakrishnan, N. Synergic effect of reinforcement and heat treatment on the two body abrasive wear of an Al-Si alloy under varying loads and abrasive sizes. Wear 2008, 264, 47–59. [Google Scholar] [CrossRef]

- Kasprzak, W.; Chen, L.D.; Shaha, S. Heat treatment development for a rapidly solidified heat resistant cast Al-Si alloy. J. Mater. Eng. Perform. 2013, 22, 1839–1847. [Google Scholar] [CrossRef]

- Cai, F.; Huang, X.; Yang, Q.; Nagy, D. Effect of Microstructure on the Solid Particle Erosion Properties of Ni Plating. J. Mater. Eng. Perform. 2009, 18, 305–311. [Google Scholar] [CrossRef]

| Elements | Al | Si | Fe | Cu | Mn | Mg | Zn | Ti |

| Composition | Bal. | 4.86 | 0.23 | 0.079 | 0.003 | 0.002 | 0.017 | 0.02 |

| Group | Treatment Conditions | Motivations |

|---|---|---|

| F | As-manufactured | fundamental material properties evaluation |

| FR | as-manufactured + rolling | strain hardening |

| FRH | As-manufactured + rolling + heat treatment | secondary cold working |

| Group | YS (MPa) | UTS (MPa) | UE (%) | TE (%) | HRF |

|---|---|---|---|---|---|

| F | 115 | 169 | 11.8 | 20.2 | 50 |

| FR | 220 | 240 | 3.2 | 16.7 | 73 |

| FRH | 38 | 77 | 29.7 | 55.3 | 28 |

| SD of YS (MPa) | SD of UTS (MPa) | SD of UE (%) | SD of TE (%) | SD of HRF | |

| F | 13.60 | 17.64 | 1.07 | 2.88 | 1.00 |

| FR | 3.87 | 1.75 | 0.53 | 0.80 | 0.80 |

| FRH | 4.12 | 4.97 | 1.52 | 2.16 | 1.10 |

| Continuous Production | Save Energy, and Process Costs | Workability | Erosion Wear Resistance | Stable Phase Structure | |

|---|---|---|---|---|---|

| CCDR process | ● | ● | ● | ● | ● |

| Traditional Process | ● | ● |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.-C.; Chang, K.-C.; Hung, F.-Y. Study on Microstructure, Mechanical Properties and Erosion Characteristics of Al-Si Alloy Manufactured by Continuous Casting Direct Rolling Process. Appl. Sci. 2021, 11, 8351. https://doi.org/10.3390/app11188351

Huang B-C, Chang K-C, Hung F-Y. Study on Microstructure, Mechanical Properties and Erosion Characteristics of Al-Si Alloy Manufactured by Continuous Casting Direct Rolling Process. Applied Sciences. 2021; 11(18):8351. https://doi.org/10.3390/app11188351

Chicago/Turabian StyleHuang, Bo-Chin, Kai-Chieh Chang, and Fei-Yi Hung. 2021. "Study on Microstructure, Mechanical Properties and Erosion Characteristics of Al-Si Alloy Manufactured by Continuous Casting Direct Rolling Process" Applied Sciences 11, no. 18: 8351. https://doi.org/10.3390/app11188351