Assessment of the Effect of Phase Change Material (PCM) Glazing on the Energy Consumption and Indoor Comfort of an Office in a Semiarid Climate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Facilities

- WWR was equal to 56%.

- The east-oriented wall was the only façade exposed to outdoor conditions. This façade consisted of glazes and opaque envelopes.

- The opaque part of the east-oriented façade was a heavy-concrete wall of 0.20 m without insulation.

- An upper window consisted of double-clear glazing filled with air to provide daylight.

- Interior walls, ceilings, and floors are adiabatic because each office is adjacent to other occupied spaces on the same level and the above and underneath floors.

- The glazed façade of the PCM room was double-glazed with a cavity filled with PCM. This window was 5 + 4 mm laminated glass, 11.5 mm PCM and 4 + 5 mm laminated glass. Table 1 shows the thermophysical properties of the glazed façade (heat transfer coefficient U-value, visible transmittance Tvis and solar transmittance Tsol) calculated using WINDOW 8.0 [28] and, the experimental data of Goia [29], that used the same paraffin wax and the window properties as our experiment. Figure 2a shows the cross-section of the PCM window, and Figure 2b shows the partial enthalpy of the PCM paraffin according to the manufacturer datasheet [30]. A total of 20.8 kg of paraffin wax was used.

- The glazed façade of the AIR room was double-glazed with a cavity filled with air. This window was 5 + 4 mm laminated glass, 11.5 mm air and 4 + 5 mm laminated glass. Table 1 shows the thermophysical properties of the glazed façade (heat transfer coefficient U-value, visible transmittance Tvis and solar transmittance Tsol).

- Internal gain sources in both rooms were the HVAC system and the measurement equipment (laptop, datalogger, UPS, and sensors). There were no internal gains related to people, artificial lighting, or typical office equipment.

- A wall-mounted heating and cooling HVAC of 18,000 Btu/h (approximately 5.3 kW) was installed in each office to control the indoor air temperature. The thermostats were set at 25 °C for heating and cooling. HVAC can work only in heating or cooling mode. The heating and cooling modes were set according to the weather conditions in each season.

2.2. Experimental Campaign and Data Selection

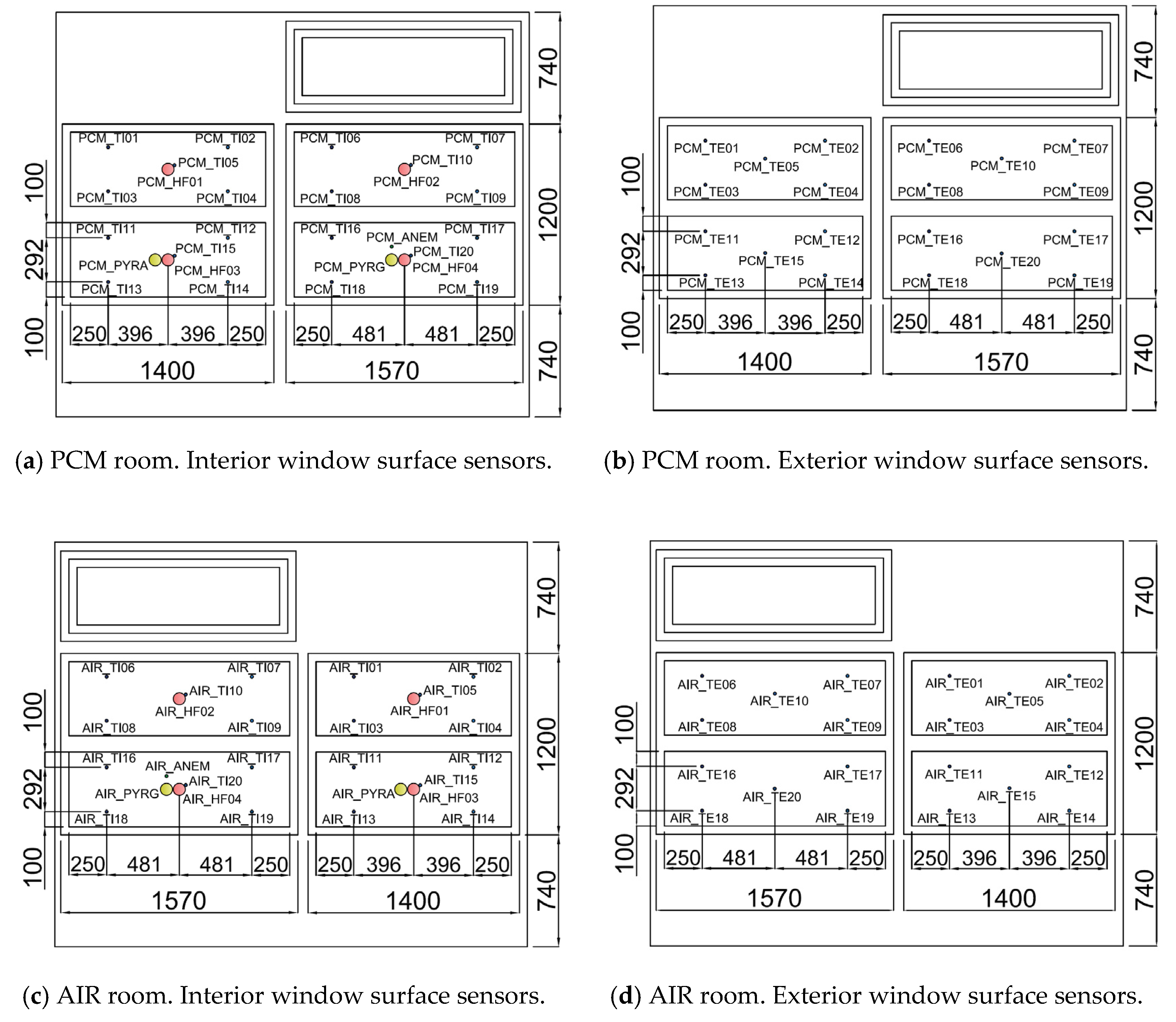

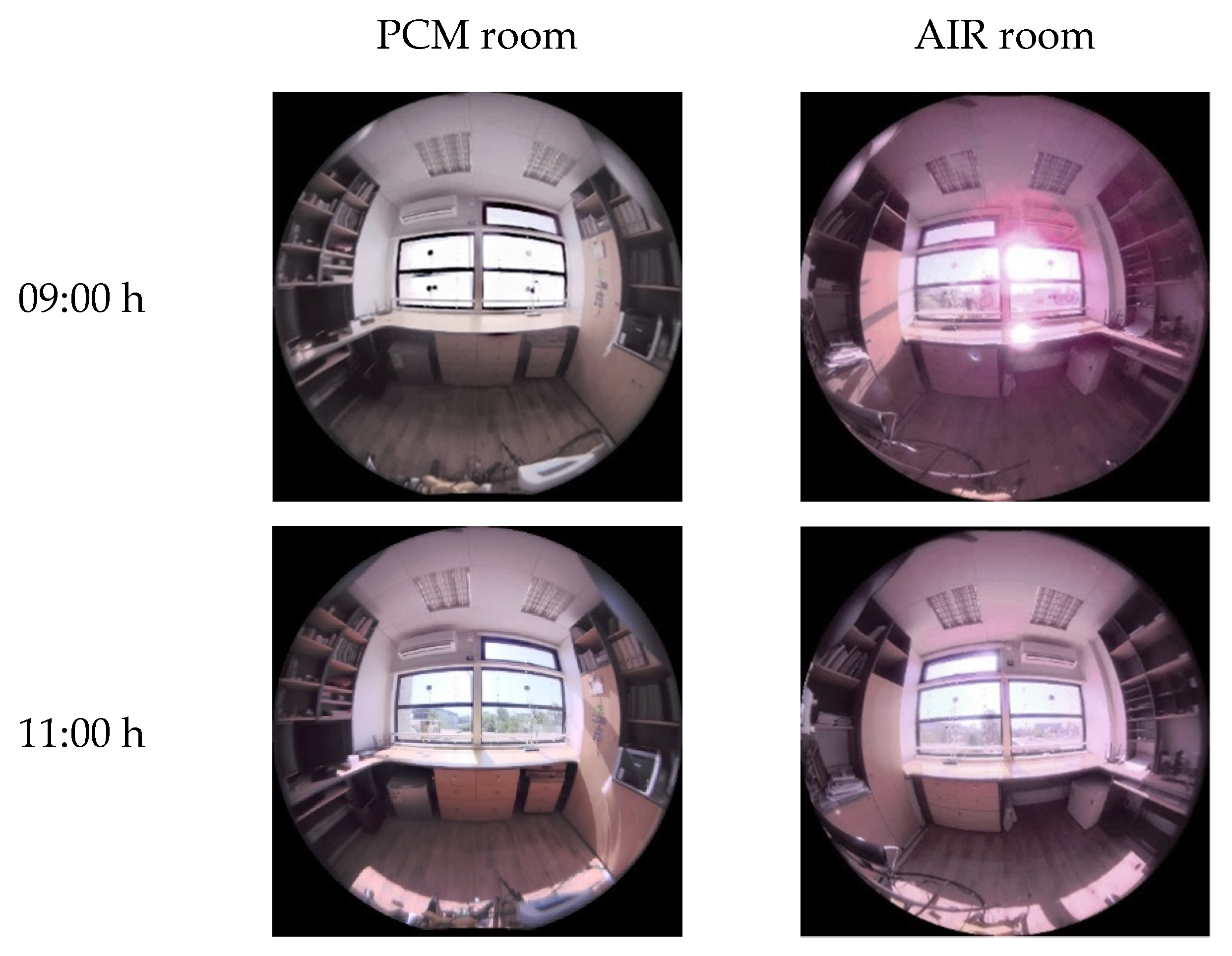

2.3. Experimental Setup

2.4. Procedure for the Evaluation of Energy Consumption, Thermal Comfort, and Visual Comfort

2.4.1. Energy Consumption

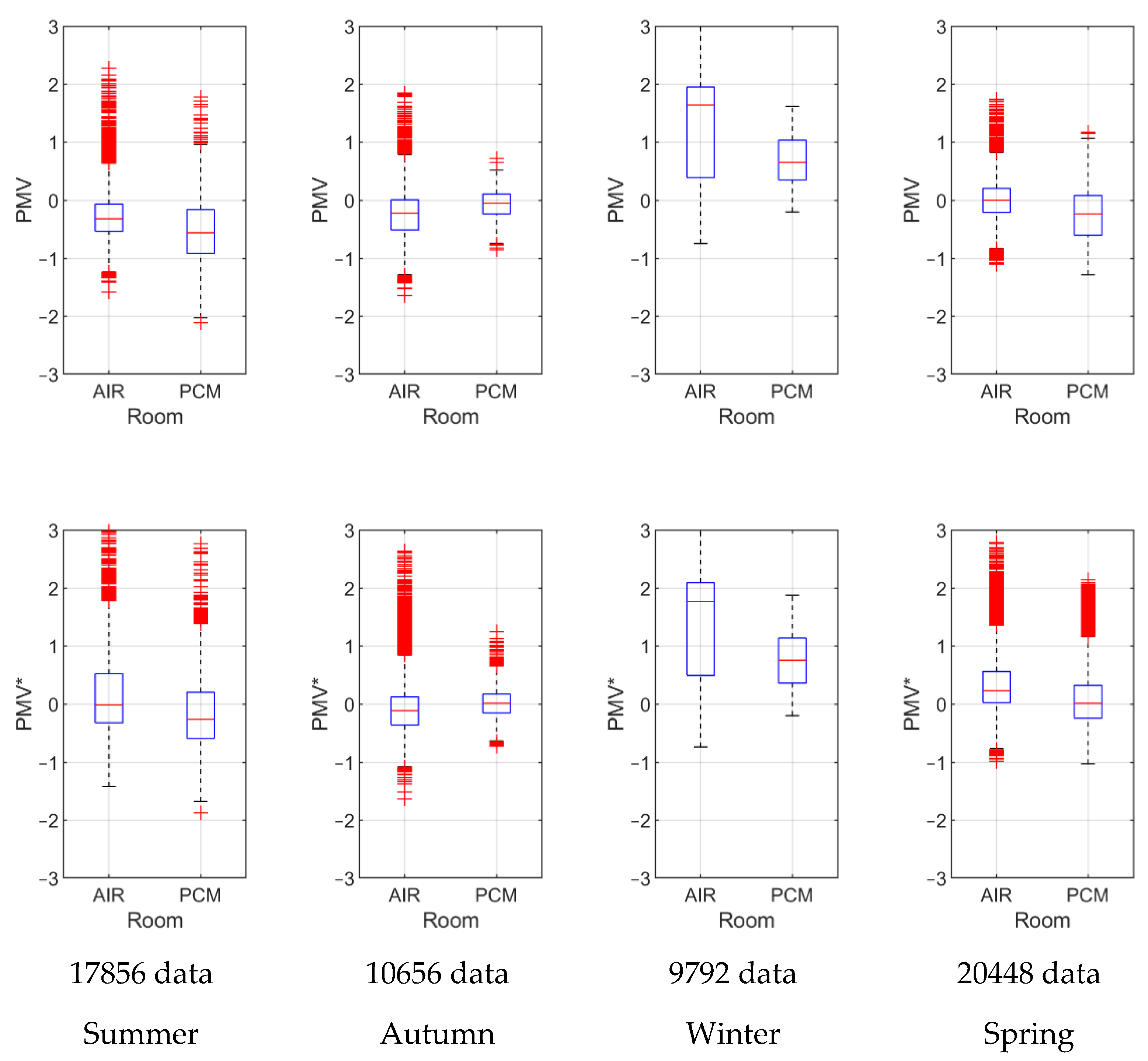

2.4.2. Thermal Comfort

2.4.3. Visual Comfort

3. Results

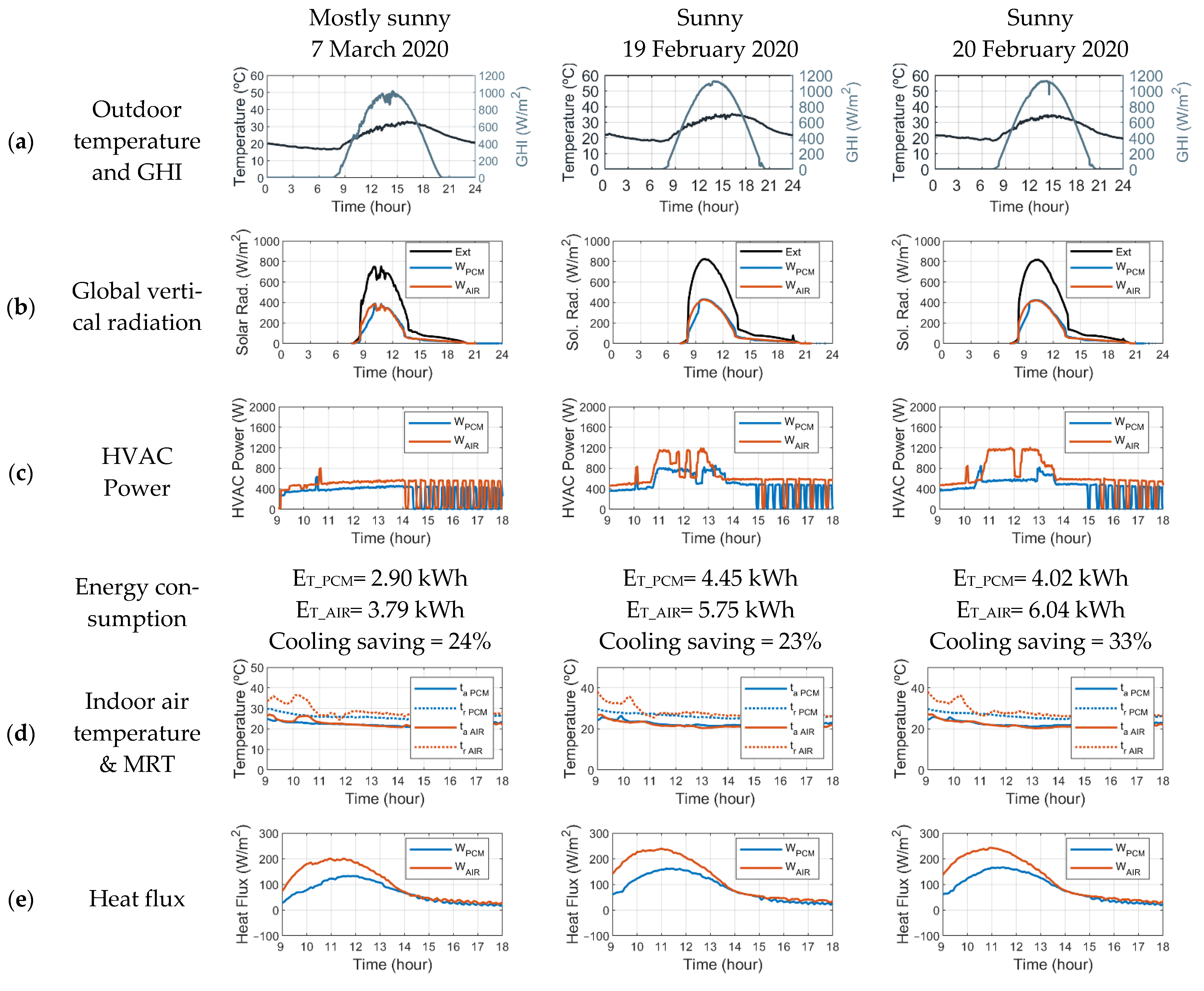

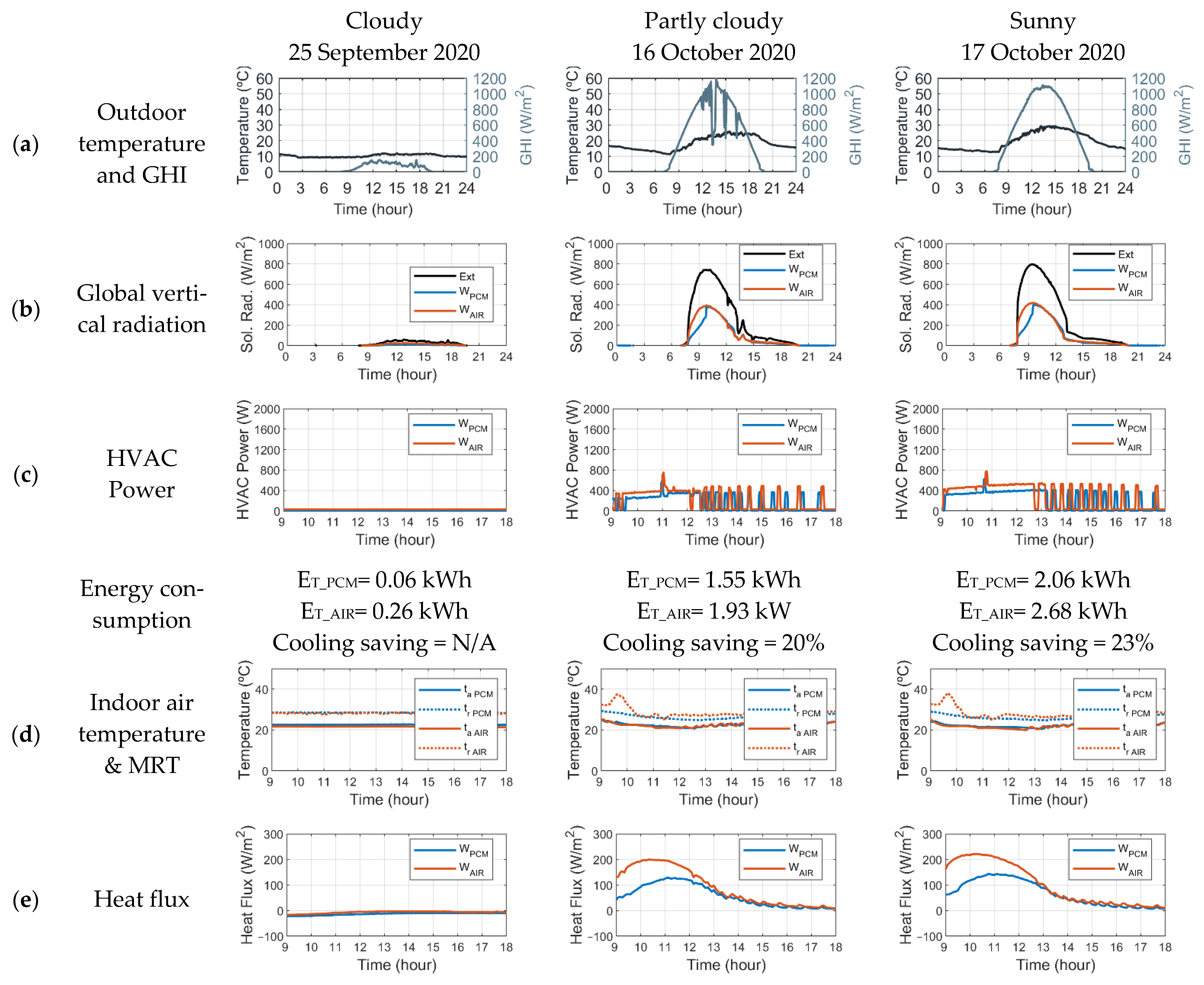

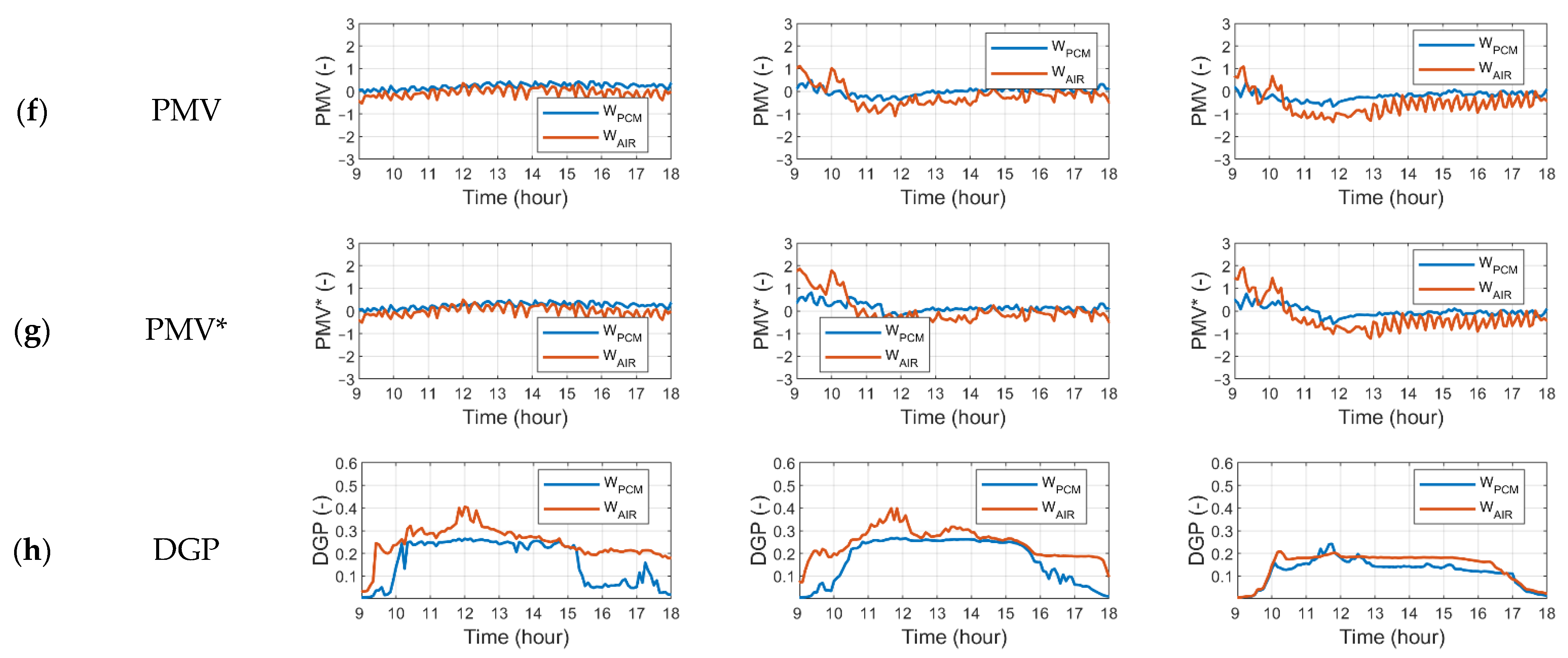

- Daily results for energy consumption, thermal comfort, and visual comfort are presented as hourly profiles for representative days (Figure 9, Figure 10, Figure 11 and Figure 12). These figures plot daily outdoor temperature and global horizontal irradiance (GHI), daily global vertical radiation on the building façade, transmitted radiation through the window, HVAC power, HVAC energy consumption and energy savings, indoor air temperature and mean radiant temperature (MRT), PMV, PMV*, and DGP.

3.1. Summer Season

3.2. Mid-Season Warm

3.3. Mid-Season Cold

3.4. Winter Season

3.5. Relation between Energy Savings and Climate Conditions

4. Conclusions

- Regarding energy consumption, the best PCM window performance was in summer when cooling needs and the peak loads of the PCM room were significantly decreased compared to the AIR room. Furthermore, in mid-seasons, PCM helped to reduce the cooling needs slightly for sunny and partly cloudy days and lower the heating needs at the end of working hours. In contrast, no relevant impact of the PCM window on the office energy performance was found in winter due to the lack of enough solar radiation and low outdoor air temperature to activate the phase change, even on sunny days. It is expected that a PCM with a higher melting temperature would show better results in summer, further decreasing the cooling energy use and the peak load. Nevertheless, the benefits of the PCM window would be lost during the mid-seasons.

- PCM glazing considerably improves thermal comfort in terms of PMV and PMV* compared to the reference window. This improvement is because the PCM phase change occurs mainly during the first hours of the day when direct solar radiation is incident on the east-oriented façade. Therefore, the mean radiant temperature remains close to the melting temperature of 25 °C. Moreover, PCM in the solid-state prevented most solar radiation transmission into the indoor environment, maintaining a PMV* close to zero.

- PCM glazing helps to control luminance distribution and prevent glare during sunny and partly cloudy days of winter and mid-season cold, keeping the DGP values below 0.25. Otherwise, PCM glazing did not present improvements in visual comfort regarding the reference window during summer and mid-season warm because both windows had similar luminance distributions during the whole day. Thus, DGP values are similar in both offices. Under direct solar radiation in the field of view and with the PCM in the solid-state, high luminance values were observed on the window. Interreflections of the direct radiation in the PCM layer might produce a significant fraction of the direct radiation that would be transmitted to the indoor environment. Then, there is glare risk in the PCM room as well as in the AIR room.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- IEA. Energy Efficiency: Buildings. The Global Exchange for Energy Efficiency Policies, Data and Analysis. Available online: https://www.iea.org/topics/energyefficiency/buildings/ (accessed on 5 July 2021).

- GABC. Global Roadmap towards Low-GHG and Resilient Buildings; Global Alliance for Buildings and Construction, International Energy Agency, UN Environment: Paris, France, 2016. [Google Scholar]

- IEA. Technology Roadmap: Energy Efficient Building Envelopes; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F. Literature review on the use of phase change materials in glazing and shading solutions. Renew. Sustain. Energy Rev. 2016, 53, 515–535. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Kylili, A.; Kalogirou, S.A. Phase change materials (PCMs) integrated into transparent building elements: A review. Mater. Renew. Sustain. Energy 2015, 4, 6. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Zinzi, M.; Carnielo, E.; Serra, V. Spectral and angular solar properties of a PCM-filled double glazing unit. Energy Build. 2015, 87, 302–312. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Bian, J.; Zhang, G.; Li, D.; Liu, X. Influence of optical parameters on thermal and optical performance of multi-layer glazed roof filled with PCM. Appl. Therm. Eng. 2018, 134, 615–625. [Google Scholar] [CrossRef]

- Heim, D.; Krempski-Smejda, M.; Dellicompagni, P.R.; Knera, D.; Wieprzkowicz, A.; Franco, J. Dynamics of Melting Process in Phase Change Material Windows Determined Based on Direct Light Transmission. Energies 2021, 14, 721. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Bian, J.; Li, D.; Liu, X. Influence of PCM design parameters on thermal and optical performance of multi-layer glazed roof. Appl. Energy 2018, 212, 151–161. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- Grynning, S.; Goia, F.; Rognvik, E.; Time, B. Possibilities for characterization of a PCM window system using large scale measurements. Int. J. Sustain. Built Environ. 2013, 2, 56–64. [Google Scholar] [CrossRef] [Green Version]

- Grynning, S.; Goia, F.; Time, B. Dynamic Thermal Performance of a PCM Window System: Characterization Using Large Scale Measurements. Energy Procedia 2015, 78, 85–90. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Perino, M.; Serra, V. Experimental analysis of the energy performance of a full-scale PCM glazing prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- Li, S.; Sun, G.; Zou, K.; Zhang, X. Experimental research on the dynamic thermal performance of a novel triple-pane building window filled with PCM. Sustain. Cities Soc. 2016, 27, 15–22. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Wang, B.; Liu, C.; Arıcı, M. Optical and thermal performance of glazing units containing PCM in buildings: A review. Constr. Build. Mater. 2020, 233, 117327. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Zhang, Y. Review of thermal energy storage technologies based on PCM application in buildings. Energy Build. 2013, 67, 56–69. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L.; Goia, F.; Serra, V. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (SWOT) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Perino, M.; Serra, V. Improving thermal comfort conditions by means of PCM glazing systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Sullivan, R. Thermal Comfort Issues in the LRI Study; Internal Memorandum/Report; Windows and Daylighting Group, Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1986. [Google Scholar]

- Giovannini, L.; Goia, F.; Verso, V.R.M.L.; Serra, V. Phase Change Materials in Glazing: Implications on Light Distribution and Visual Comfort. Preliminary Results. Energy Procedia 2017, 111, 357–366. [Google Scholar] [CrossRef] [Green Version]

- Giovannini, L.; Goia, F.; Lo Verso, V.R.M.; Serra, V. A Comparative Analysis of the Visual Comfort Performance between a PCM Glazing and a Conventional Selective Double Glazed Unit. Sustainability 2018, 10, 3579. [Google Scholar] [CrossRef] [Green Version]

- Radiance. Available online: https://www.radiance-online.org (accessed on 27 July 2021).

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Rubel, F.; Brugger, K.; Haslinger, K.; Auer, I. The climate of the European Alps: Shift of very high resolution Köppen-Geiger climate zones 1800-2100. Meteorol. Z. 2017, 26, 115–125. [Google Scholar] [CrossRef]

- ANSI/ASHRAE/IES. Energy-Efficient Design of Low-Rise Residential Buildings (ANSI/ASHRAE/IES Standard 90.2-2018). American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2018. Available online: https://ashrae.library.site/resource/list/12 (accessed on 11 October 2021).

- WINDOW 8.0. Available online: https://windows.lbl.gov/software/window (accessed on 11 October 2021).

- Goia, F. Thermo-physical behaviour and energy performance assessment of PCM glazing system configurations: A numerical analysis. Front. Archit. Res. 2012, 1, 341–347. [Google Scholar] [CrossRef] [Green Version]

- Rubitherm. Data Sheet RT25; 2018. Available online: https://www.rubitherm.eu/en/index.php/productcategory/organische-pcm-rt (accessed on 11 October 2021).

- Kruisselbrink, T.; Aries, M.; Rosemann, A. A Practical Device for Measuring the Luminance Distribution. Int. J. Sustain. Lighting 2017, 19, 75–90. [Google Scholar] [CrossRef] [Green Version]

- Kruisselbrink, T.W.; Dangol, R.; van Loenen, E.J. Recommendations for long-term luminance distribution measurements: The spatial resolution. Build. Environ. 2020, 169, 106538. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- ISO. Ergonomics of the thermal environment—Analytical determination and interpretation of thermal comfort using calculation of the PMV and PPD indices and local thermal comfort criteria (ISO 7730:2005). International Organization for Standardization. 2005. Available online: https://www.iso.org/standard/39155.html (accessed on 11 October 2021).

- Wienold, J.; Christoffersen, J. Evaluation methods and development of a new glare prediction model for daylight environments with the use of CCD cameras. Energy Build. 2006, 38, 743–757. [Google Scholar] [CrossRef]

- Wienold, J. Dynamic Daylight Glare Evaluation. In Proceedings of the 11th International IBPSA Conference, Glasgow, UK, 27–30 July 2009. [Google Scholar]

- Ward, G. HDRgen. Available online: http://www.anyhere.com/ (accessed on 17 June 2021).

- Pierson, C.; Cauwerts, C.; Bodart, M.; Wienold, J. Tutorial: Luminance Maps for Daylighting Studies from High Dynamic Range Photography. LEUKOS 2021, 17, 140–169. [Google Scholar] [CrossRef] [Green Version]

| PCM Window (Liquid) | PCM Window (Solid) | Double-Glazed Window | |

|---|---|---|---|

| U-value (W/m2K) | 4.07 | 4.07 | 2.96 |

| Tvis (-) | 0.70 | 0.50 | 0.78 |

| Tsol (-) | 0.68 | 0.41 | 0.69 |

| Season | Energy Consumption | Thermal Comfort | Visual Comfort |

|---|---|---|---|

| Summer | 73 | 62 | 55 |

| Autumn | 32 | 37 | 33 |

| Spring | 63 | 71 | 68 |

| Winter | 6 | 34 | 45 |

| Season | Day | Type | Tmin (°C) | Tmax (°C) | Tavg (°C) | It (Wh/m2day) |

|---|---|---|---|---|---|---|

| Summer | 19 February 2020 | Sunny | 17.8 | 35.4 | 25.9 | 8749 |

| 20 February 2020 | Sunny | 18.3 | 34.6 | 25.3 | 8651 | |

| 7 March 2020 | Mostly sunny | 16.6 | 33.0 | 23.6 | 7370 | |

| Mid-season warm | 17 October 2020 | Sunny | 12.7 | 29.4 | 19.7 | 8330 |

| 16 October 2020 | Partly cloudy | 4.6 | 25.9 | 18.2 | 7683 | |

| 25 September 2020 | Cloudy | 9.0 | 11.9 | 10.4 | 954 | |

| Mid-season cold | 16 May 2020 | Sunny | 11.2 | 28.5 | 19.0 | 4145 |

| 11 May 2020 | Partly cloudy | 7.7 | 22.0 | 13.9 | 4274 | |

| 19 May 2020 | Cloudy | 7.4 | 12.6 | 10.0 | 1312 | |

| Winter | 13 July 2020 | Sunny | 7.3 | 25.6 | 14.7 | 3752 |

| 9 July 2020 | Partly cloudy | 7.3 | 18.8 | 11.3 | 3069 | |

| 10 July 2020 | Cloudy | 8.4 | 14.5 | 10.7 | 1233 |

| Sensor | Measurement | Model | Company | Quantity | Accuracy |

|---|---|---|---|---|---|

| Pyrheliometer | Direct solar radiation | CHP1 | Kipp & Zonen | 1 | ±3% |

| Sun trucker | - | SOLYS 2 | Kipp & Zonen | 1 | - |

| Pyranometer | Diffuse solar radiation | CMP11 | Kipp & Zonen | 2 | ±1.35% |

| Pyranometer | Global horizontal solar radiation | CMP11 | Kipp & Zonen | 1 | ±1.35% |

| Humidity and temperature probe | Relative humidity and temperature | HMP60 | Vaisala | 1 | ±3% (temp) & ±5% (RH) |

| Thermocouple | Solar-air temperature | Type T | Pelican Wire | 1 | ±5% |

| Pyranometer | Global vertical solar radiation | CMP11 | Kipp & Zonen | 1 | ±1.35% |

| Sensor | Measurement | Model | Company | Quantity | Accuracy |

|---|---|---|---|---|---|

| Current/voltage sensor | HVAC power | Multivoies | OmégaWatt | 1 | ±2% |

| Thermocouples | Surface temperature | Type T | Pelican Wire Company | 20 | ±5% |

| Heat flux sensor | Heat flux | HFP01 | Hukseflux | 4 | ±5% |

| Pyranometer | Transmitted solar radiation | CMP11 | Kipp & Zonen | 1 | ±1.35% |

| Pyrgeometer | Longwave radiation | CGR3 | Kipp & Zonen | 1 | ±5.7% |

| Humidity and temperature probe | Relative humidity and temperature | HMP60 | Vaisala | 1 | ±3% (temp) & ±5% (RH) |

| Anemometer | Air velocity | SensoData 5500 Anemo | Sensor Electronic | 1 | ±0.02 m/s |

| Thermal comfort sensor | PMV | SensoData 5500 MK | Sensor Electronic | 1 | - 1 |

| Globe thermometer | Mean radiant temperature | Testo 0602 0743 | Testo | 1 | ±1% |

| CMOS sensor | Luminance distribution | IMX 219 | Sony | 1 | ±3% to ±17.5% |

| Raspberry Pi 3 | Data acquisition | Model B | Raspberry Foundation | 1 | - |

| Data Acquisition System | Data acquisition | 34972A | Keysight | 1 | - |

| Season | M (met) | Icl (clo) |

|---|---|---|

| Summer | 1.2 | 0.5 |

| Mid-seasons | 1.2 | 0.7 |

| Winter | 1.2 | 1.0 |

| Sensation | Value |

|---|---|

| Cold | −3 |

| Cool | −2 |

| Slightly cool | −1 |

| Neutral | 0 |

| Slightly warm | +1 |

| Warm | +2 |

| Hot | +3 |

| Sensation | Range |

|---|---|

| Imperceptible | <0.35 |

| Perceptible | 0.35–0.40 |

| Disturbing | 0.40–0.45 |

| Intolerable | >0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uribe, D.; Vera, S. Assessment of the Effect of Phase Change Material (PCM) Glazing on the Energy Consumption and Indoor Comfort of an Office in a Semiarid Climate. Appl. Sci. 2021, 11, 9597. https://doi.org/10.3390/app11209597

Uribe D, Vera S. Assessment of the Effect of Phase Change Material (PCM) Glazing on the Energy Consumption and Indoor Comfort of an Office in a Semiarid Climate. Applied Sciences. 2021; 11(20):9597. https://doi.org/10.3390/app11209597

Chicago/Turabian StyleUribe, Daniel, and Sergio Vera. 2021. "Assessment of the Effect of Phase Change Material (PCM) Glazing on the Energy Consumption and Indoor Comfort of an Office in a Semiarid Climate" Applied Sciences 11, no. 20: 9597. https://doi.org/10.3390/app11209597