Hardware Development and Safety Control Strategy Design for a Mobile Rehabilitation Robot

Abstract

:1. Introduction

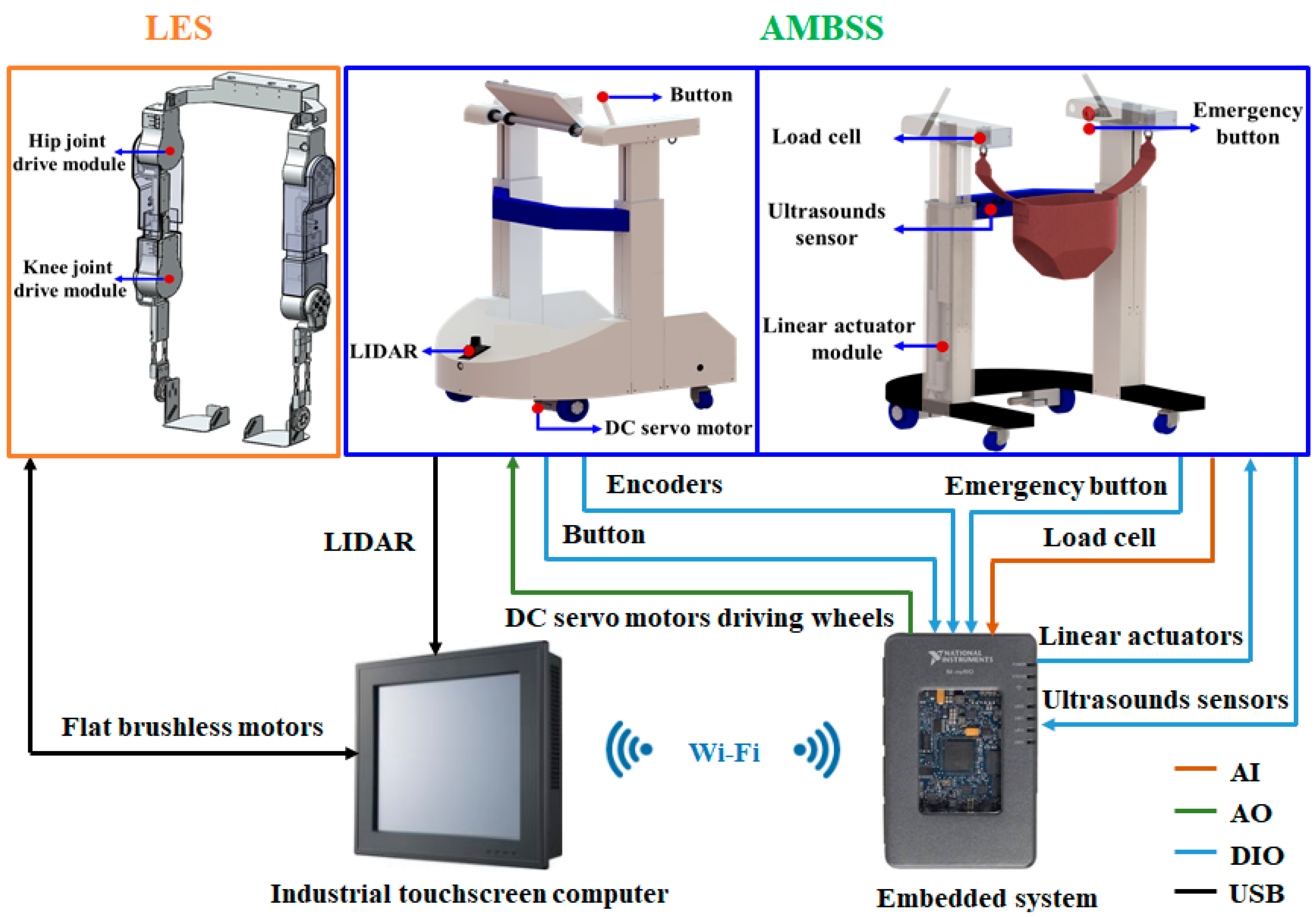

2. System Design for Mobile Rehabilitation Robot (MRR)

3. Dynamic Models

3.1. The Dynamic Model of the Lower-Limb Exoskeleton

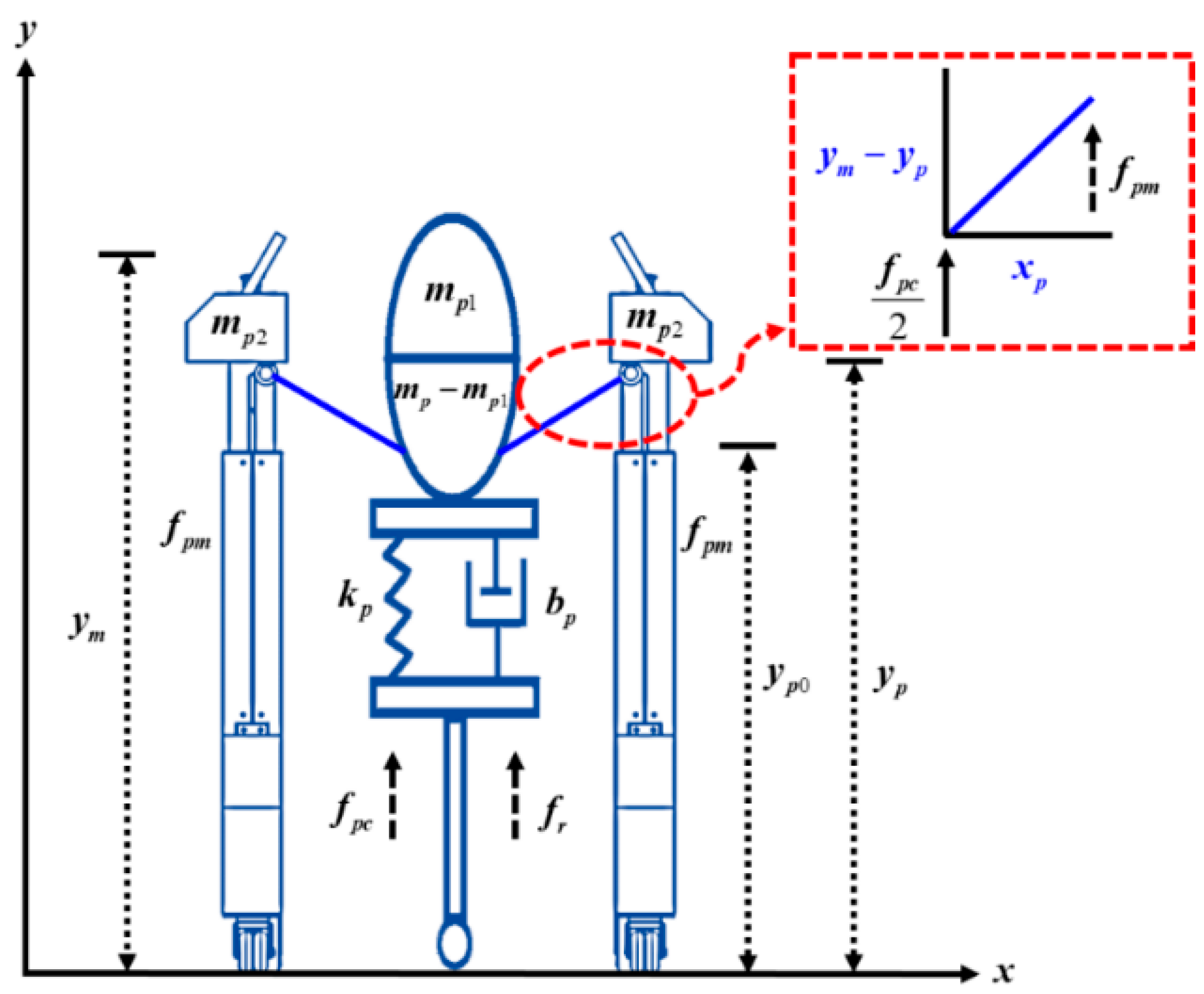

3.2. The Dynamic Model of AMBSS

4. Dynamic Models

4.1. Linear Extended State Observer Design

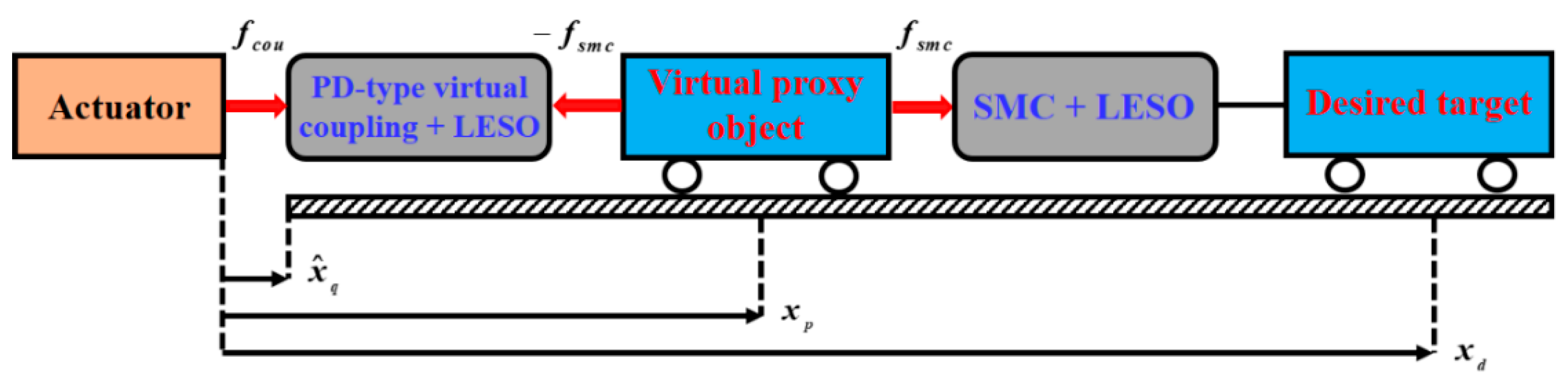

4.2. Integration of LESO within PSMC

4.3. Stability Analysis

5. Experimental Validation

5.1. Experiment Setup

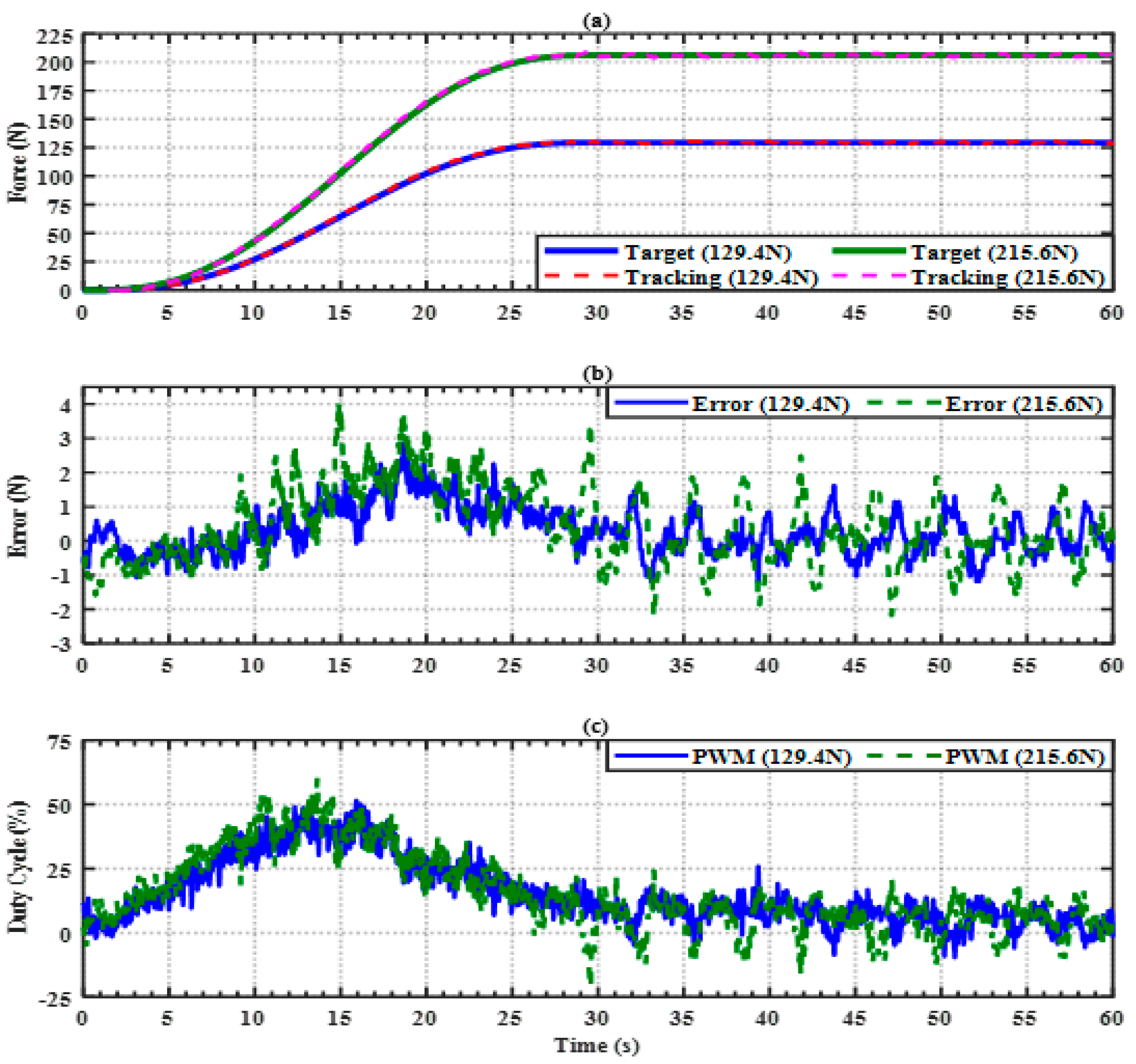

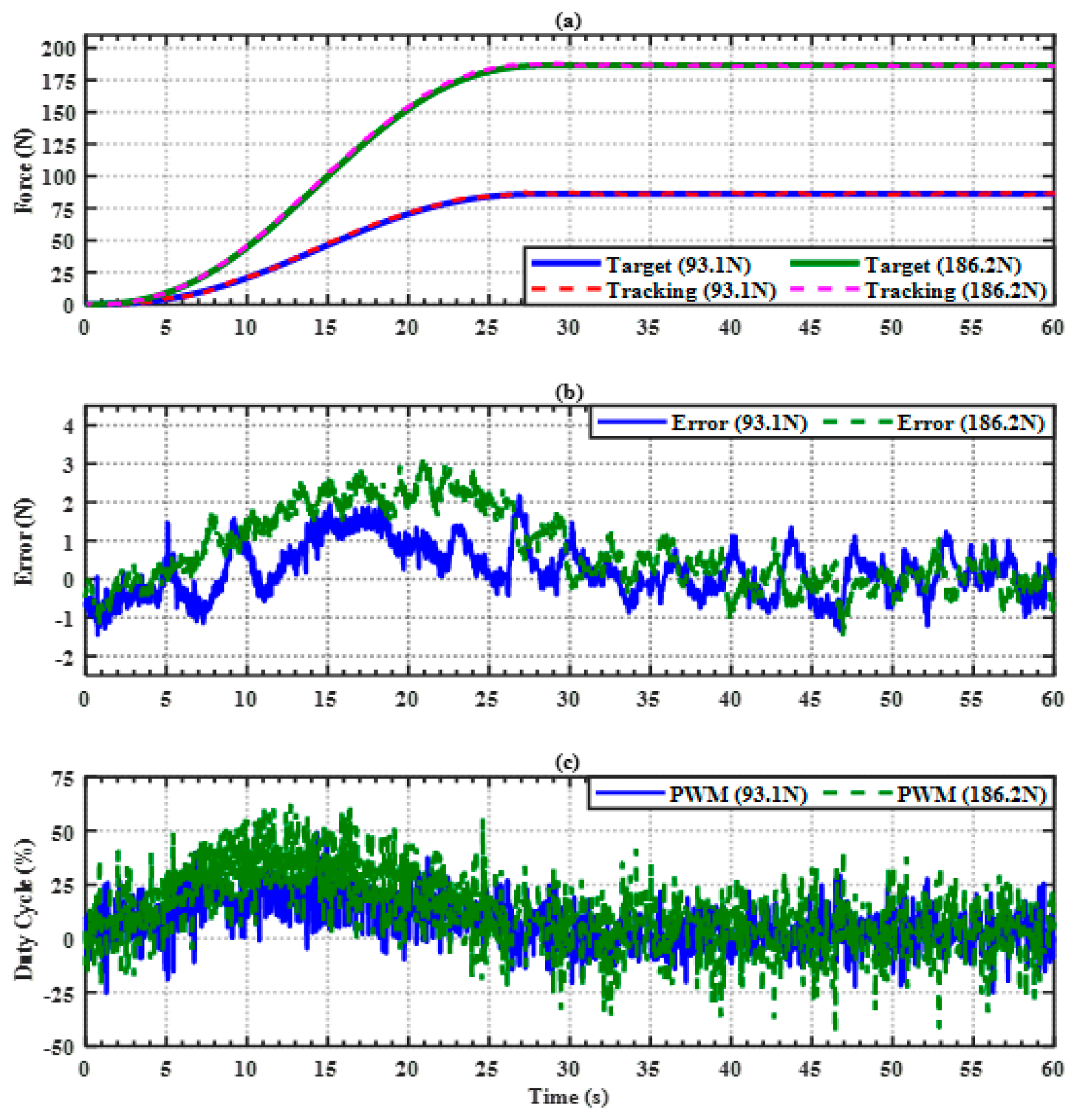

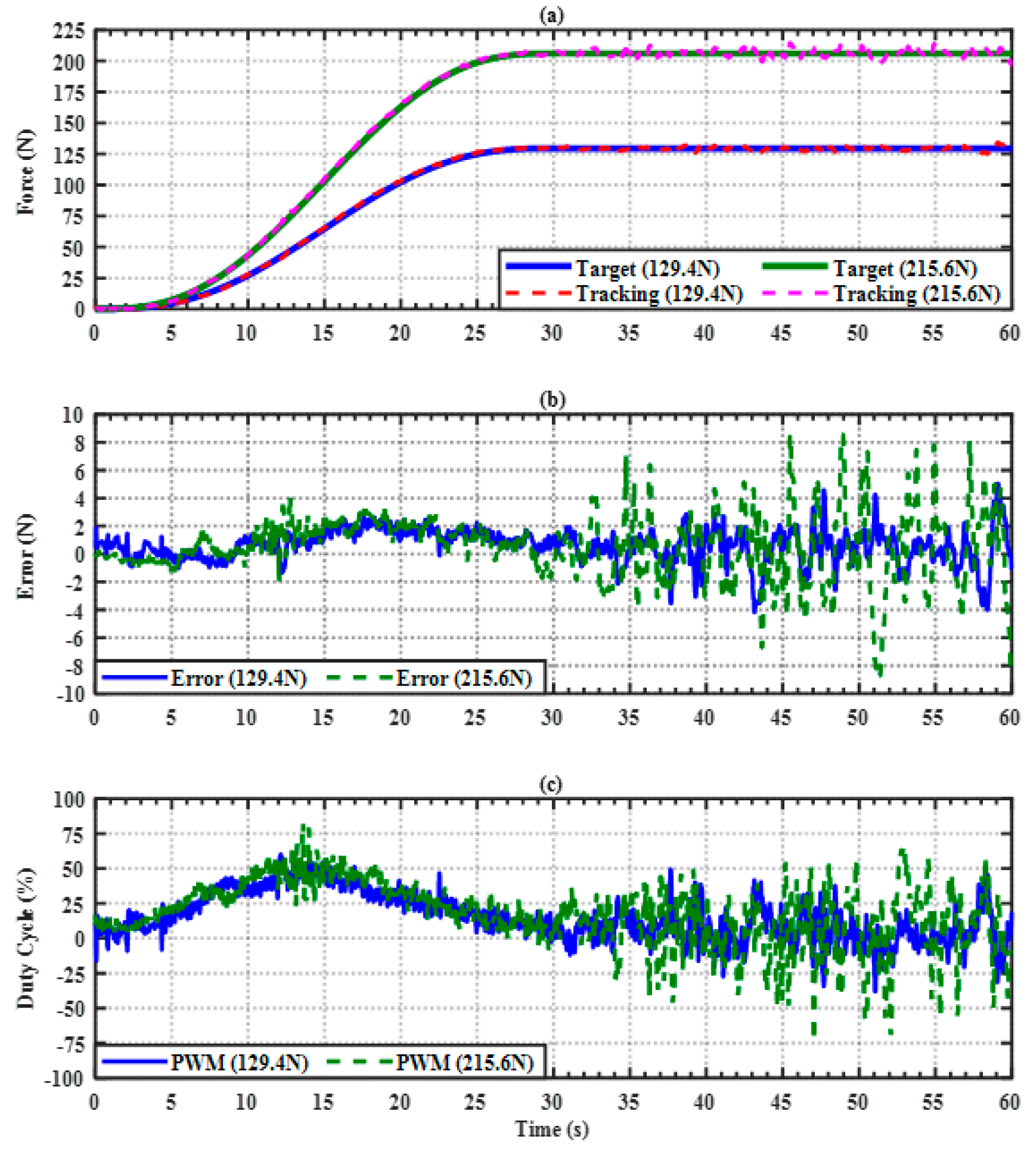

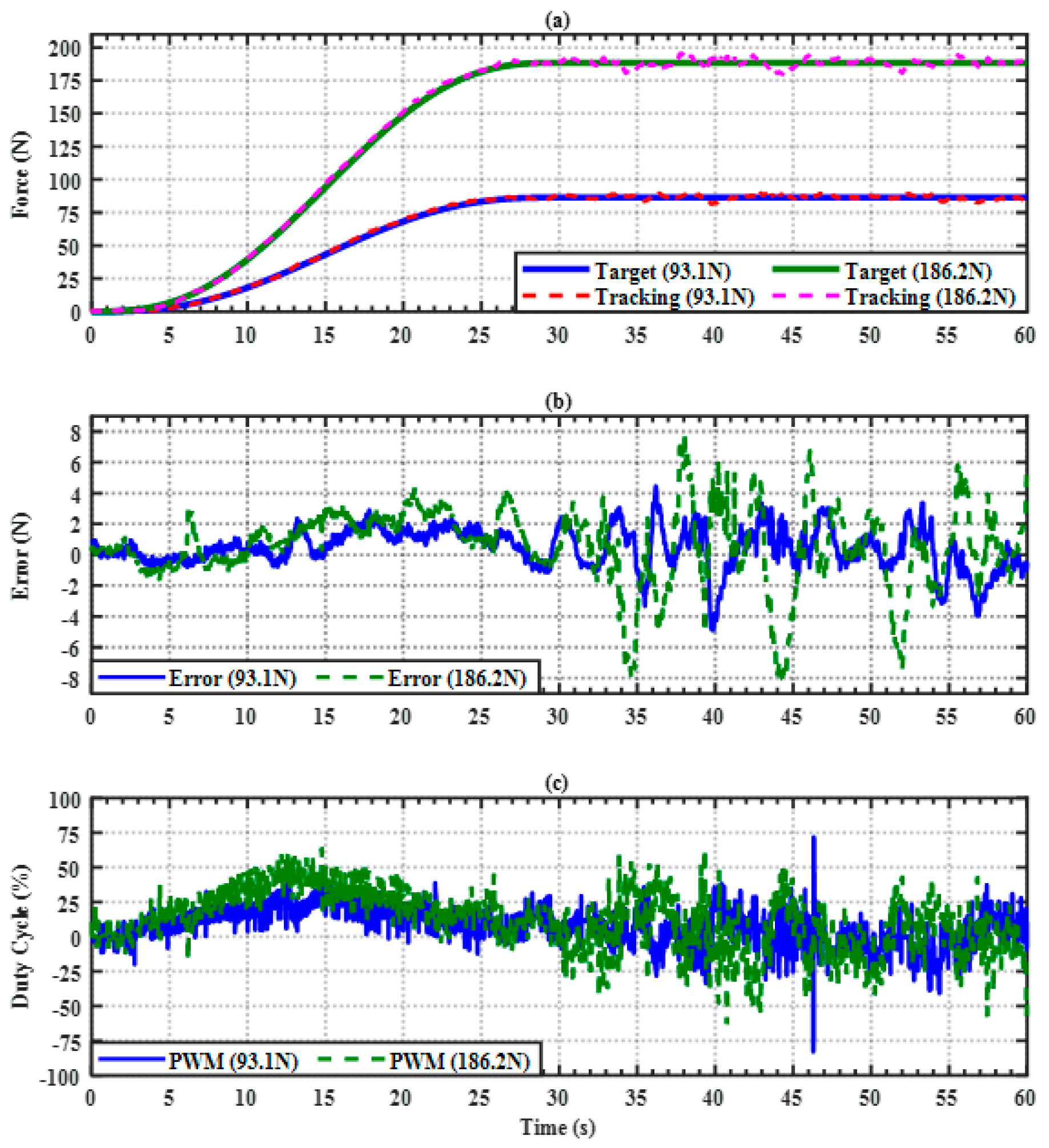

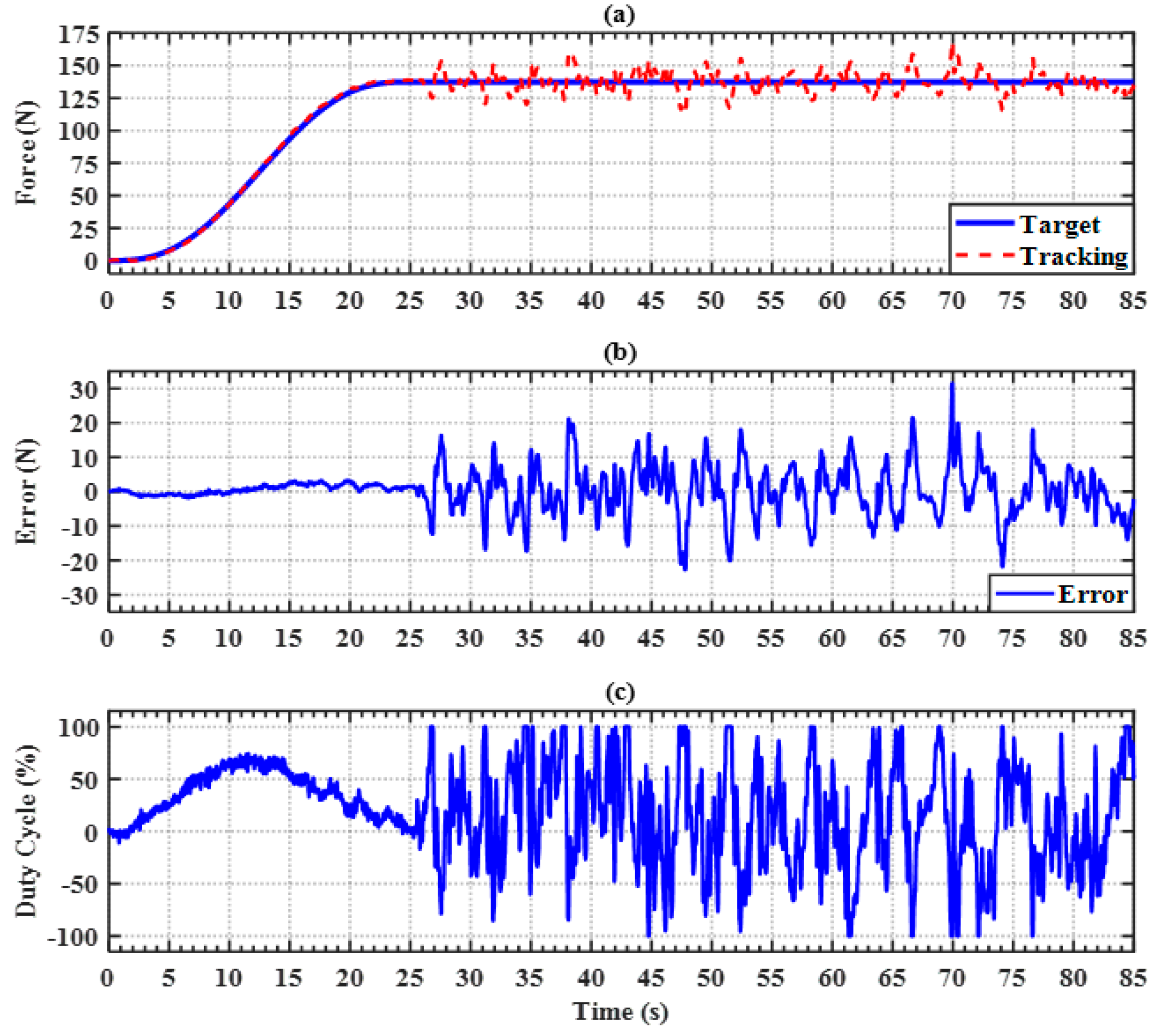

5.2. Unloading Force Control of AMBSS

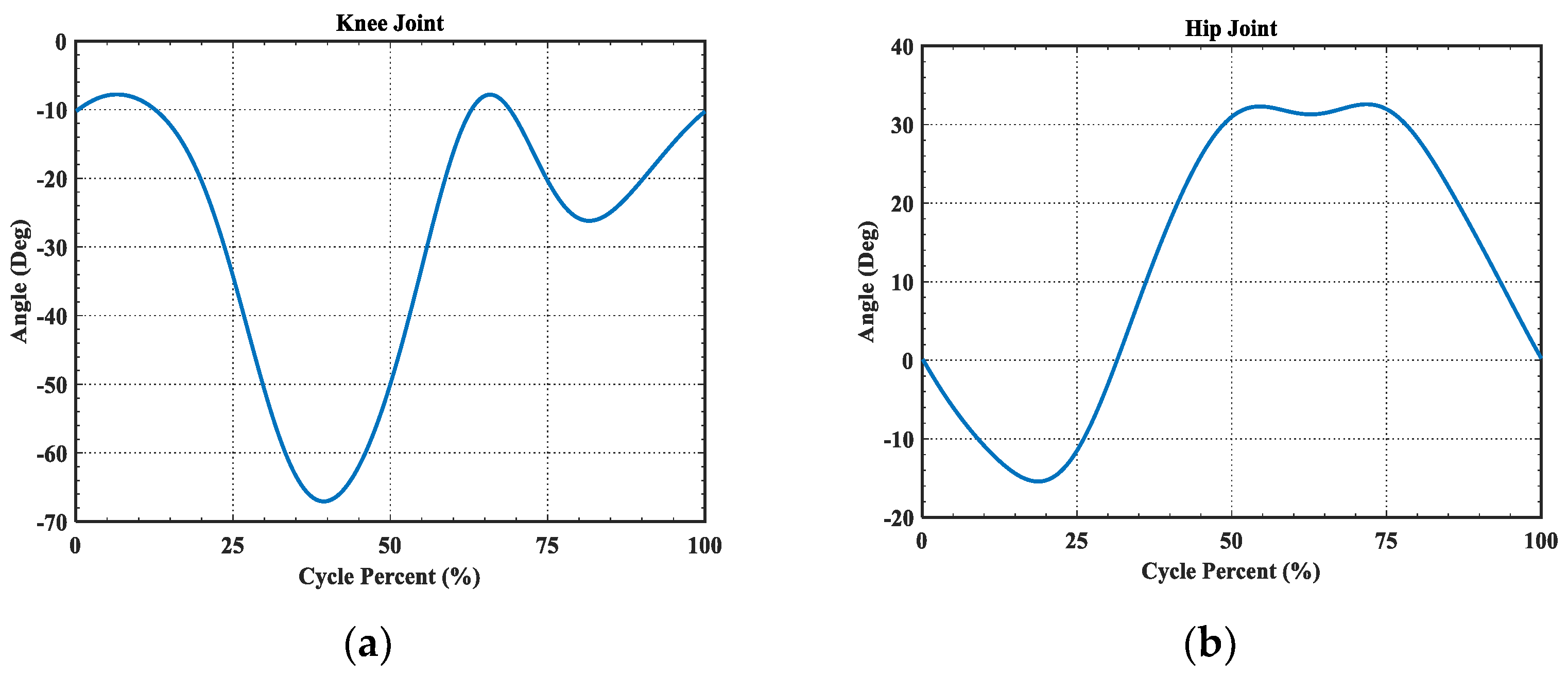

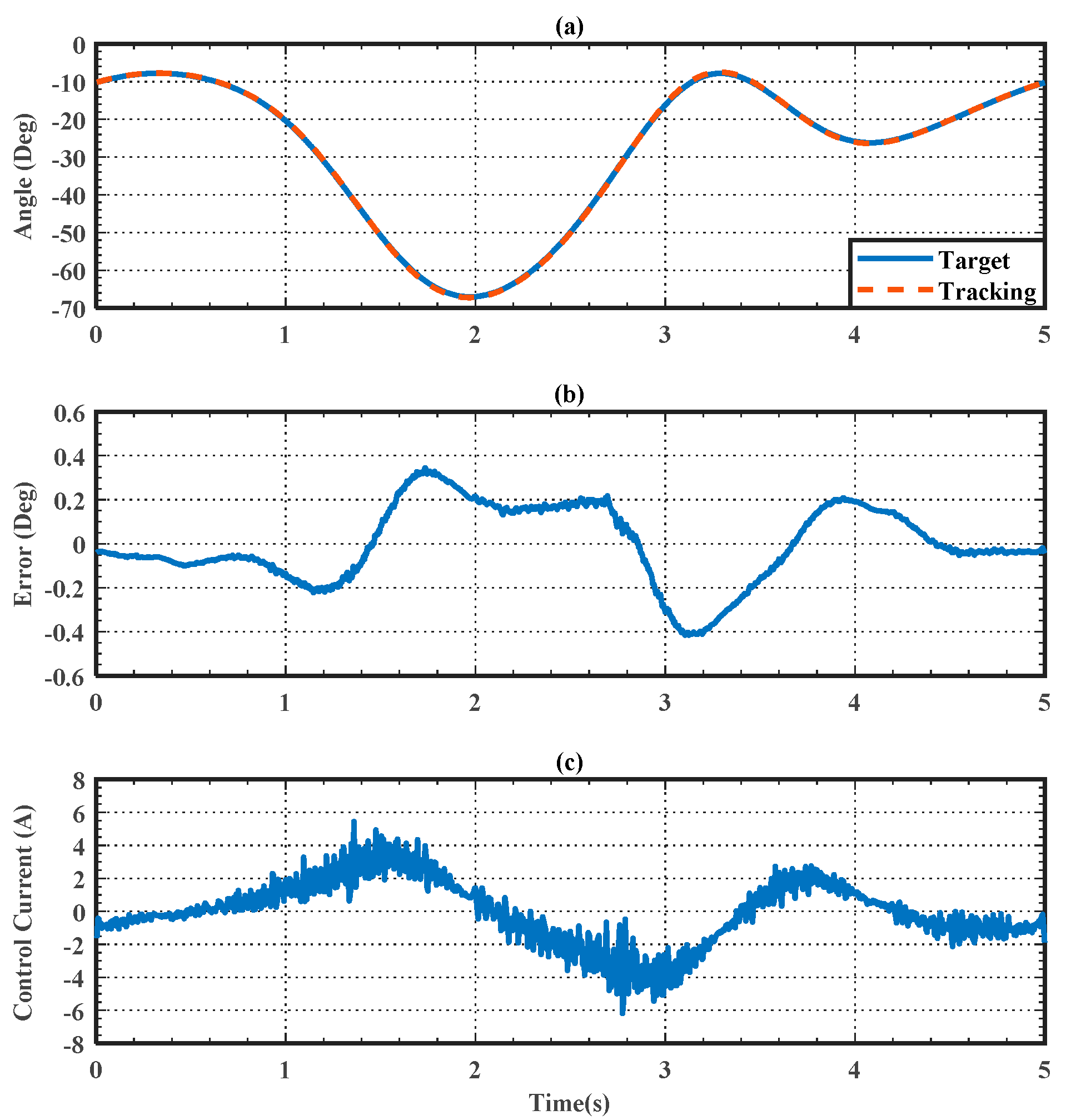

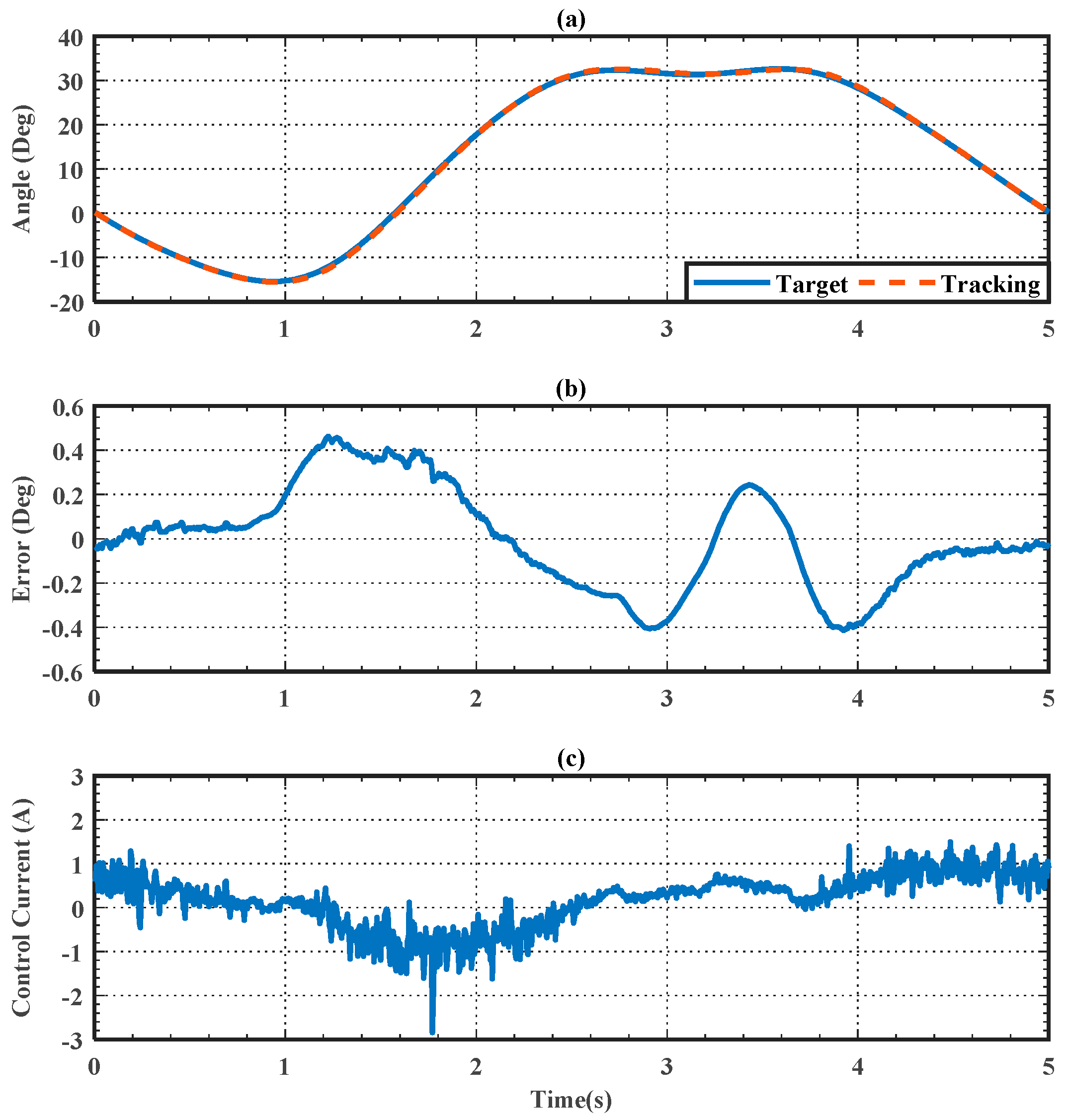

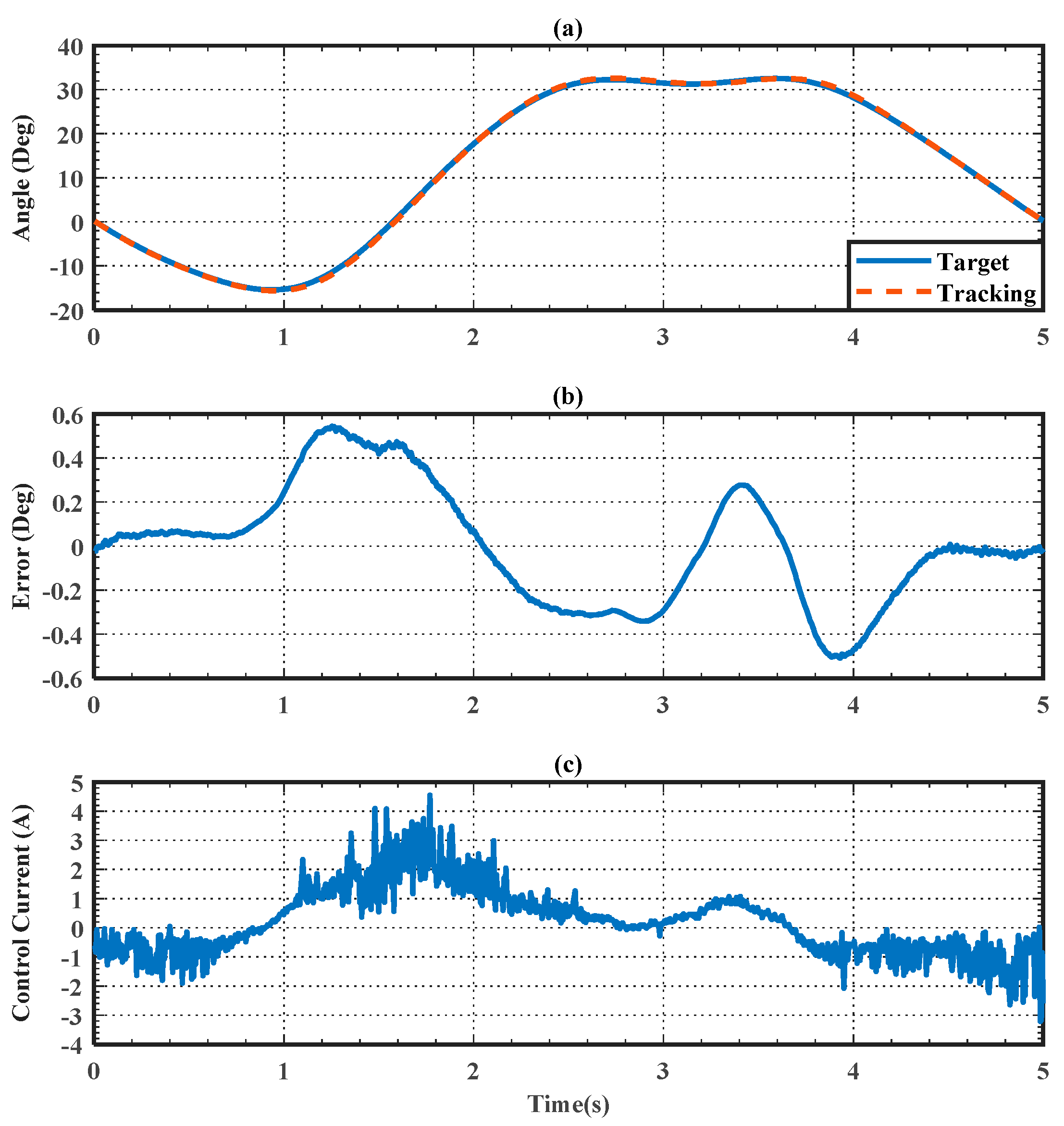

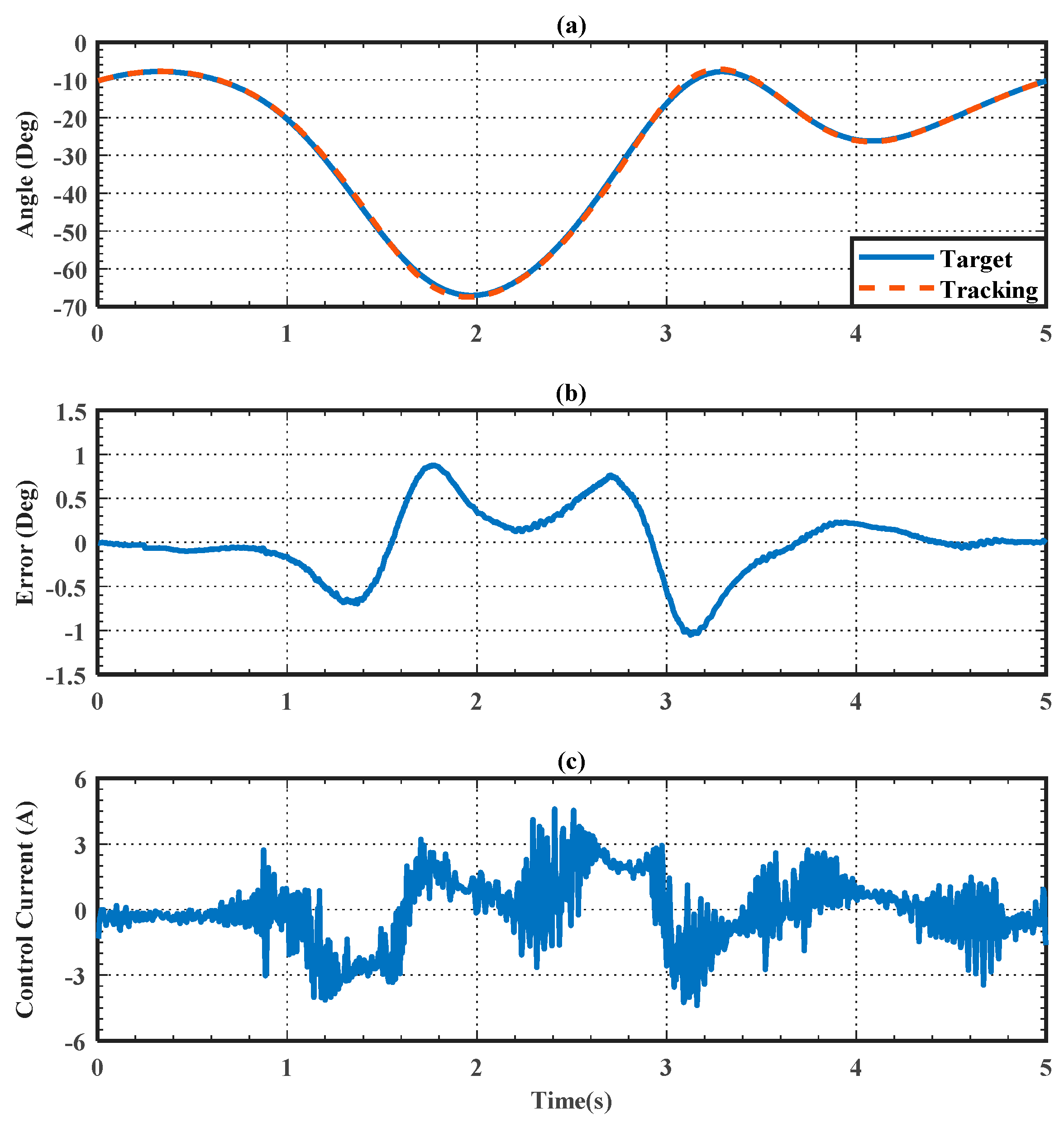

5.3. Lower Limb Exoskeleton Gait Trajectory Tracking Control

5.4. Using the MRR for Over-Ground Gait Training

5.5. Discontinuity Recovery Safety Performance Test

6. Conclusions

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Alias, N.A.; Huq, M.S.; Ibrahim, B.S.K.K.; Omar, R. The Efficacy of State of the Art Overground Gait Rehabilitation Robotics: A Bird’s Eye View. Procedia Comput. Sci. 2017, 105, 365–370. [Google Scholar] [CrossRef]

- Srivastava, S.P.; Kao, C.S.; Kim, H.; Stegall, P.; Zanotto, D.; Higginson, J.S.; Agrawal, S.K.; Scholz, J.P. Assist-as-needed robot-aided gait training improves walking function in individuals following stroke. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 956–963. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, Z.; Vanderborght, B.; Wang, N.; Wang, Q. Proxy-based sliding mode control of a robotic ankle-foot system for post-stroke rehabilitation. Adv. Robot. 2016, 30, 992–1003. [Google Scholar] [CrossRef]

- Kang, C.J.; Chum, M.H.; Lee, J.; Lee, J.Y. Effects of robot (SUBAR)-assisted gait training in patients with chronic stroke. Medicine 2021, 100, e27974. [Google Scholar] [CrossRef]

- Steven, L.; Pattawong, P.; Ash, R.; James, M.T.; Sri, K.; Mircea, T. A Soft Exosuit for Flexible Upper-Extremity Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 1604–1617. [Google Scholar]

- Alan, F.P.V.; Jesse, Y.R.M.; Gerardo, O.T.; Felipe, J.S.V.; Alan, C.R.; Jorge, A.B.M.; Julio, C.R.C. Soft Exoskeletons: Development, Requirements, and Challenges of the Last Decade. Actuators 2021, 10, 166. [Google Scholar]

- Nedergård, H.; Arumugam, A.; Sandlund, M.; Bråndal, A.; Häger, C.K. Effect of robotic-assisted gait training on objective biomechanical measures of gait in persons post-stroke: A systematic review and meta-analysis. J. Neuroeng. Rehabil. 2021, 18, 64. [Google Scholar] [CrossRef]

- Pamungkas, D.S.; Caesarendra, W.; Soebakti, H.; Analia, R.; Susanto, S. Overview: Types of Lower Limb Exoskeletons. Electronics 2019, 8, 1283. [Google Scholar] [CrossRef]

- Banala, S.K.; Agrawal, S.K.; Kim, S.H.; Scholz, J.P. Novel Gait Adaptation and Neuromotor Training Results Using an Active Leg Exoskeleton. IEEE/ASME Trans. Mechatron. 2010, 15, 216–225. [Google Scholar] [CrossRef]

- Nam, K.Y.; Kim, H.J.; Kwon, B.S.; Park, J.W.; Lee, H.J.; Yoo, A. Robot-assisted gait training (Lokomat) improves walking function and activity in people with spinal cord injury: A systematic review. J. Neuroeng. Rehabil. 2017, 14, 24. [Google Scholar] [CrossRef]

- Hobbs, B.; Artemiadis, P. A Review of Robot-Assisted Lower-Limb Stroke Therapy: Unexplored Paths and Future Directions in Gait Rehabilitation. Front. Neurorobot. 2020, 14, 19. [Google Scholar] [CrossRef]

- Kim, S.K.; Park, D.; Yoo, B.; Shim, D.; Choi, J.O.; Choi, T.Y.; Park, E.S. Overground Robot-Assisted Gait Training for Pediatric Cerebral Palsy. Sensors 2021, 21, 2087. [Google Scholar] [CrossRef]

- Eloy, U.; Guillermo, A.P.; Ramón, C.; Rodrigo, G.C.; Rafael, R.; José, L.P. HYBRID: Ambulatory Robotic Gait Trainer with Movement Induction and Partial Weight Support. Sensors 2019, 19, 4773. [Google Scholar]

- Elena, M.; Simona, C.; Andrea, P.; Luca, B.; Ugo, F.; Zach, M.; Raffaello, M.L.; Lorenza, P.; Nicola, V. Gait training using a robotic hip exoskeleton improves metabolic gait efciency in the elderly. Sci. Rep. 2019, 9, 7157. [Google Scholar]

- Kim, H.Y.; Shin, J.H.; Yang, S.P.; Shin, M.A.; Lee, S.H. Robot-assisted gait training for balance and lower extremity function in patients with infratentorial stroke: A single-blinded randomized controlled trial. J. Neuroeng. Rehabil. 2019, 16, 99. [Google Scholar] [CrossRef]

- Knaepen, K.; Beyl, P.; Duerinck, S.; Hagman, F.; Lefeber, D.; Meeusen, R. Human-robot interaction: Kinematics and muscle activity inside a powered compliant knee exoskeleton. IEEE Trans. Neural Syst. Rehabil. Eng. 2014, 22, 1128–1137. [Google Scholar] [CrossRef]

- Lee, L.W.; Li, I.H.; Liang, T.W. A Proof of Concept Study for the Design, Manufacturing, and Control of a Mobile Overground Gait-Training System. Int. J. Fuzzy Syst. 2021, 23, 2396–2416. [Google Scholar] [CrossRef]

- Liu, T.P.; Low, K.H.; Qu, X.; Lim, H.B.; Hoon, K.H. Hardware development and locomotion control strategy for an over-ground gait trainer: NaTUre-Gaits. IEEE J. Transl. Eng. Health Med. 2014, 2, 1–9. [Google Scholar] [CrossRef]

- Marks, D.; Schweinfurther, R.; Dewor, A.; Huster, T.; Paredes, L.P.; Zutter, D.; Möller, J.C. The Andago for overground gait training in patients with gait disorders after stroke—GaitTrainer ults from a usability study. Physiother. Res. Rep. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Seo, K.H.; Lee, J.J. The development of two mobile gait rehabilitation systems. IEEE Trans. Neural Syst. Rehabil. Eng. 2009, 17, 156–166. [Google Scholar] [CrossRef]

- Stauffer, Y.; Allemand, Y.; Bouri, M.; Fournier, J.; Clavel, R.; Metrailler, P.; Brodard, R.; Reynard, F. The walktrainer-a new generation of walking reeducation device combining orthoses and muscle stimulation. IEEE Trans. Neural Syst. Rehabil. Eng. 2009, 17, 38–45. [Google Scholar] [CrossRef]

- Benamor, A.; Messaoud, H. Robust adaptive sliding mode control for uncertain systems with unknown time-varying delay input. ISA Trans. 2018, 79, 1–12. [Google Scholar] [CrossRef]

- Pan, Y.; Yang, C.; Pan, L.; Yu, H. Integral sliding mode control: Performance, modification, and improvement. IEEE Trans. Ind. Inform. 2018, 14, 3087–3096. [Google Scholar] [CrossRef]

- Ryo, K.; Satoshi, Y.; Hideo, F.; Motoji, Y. Proxy-based sliding mode control: A safer extension of PID position control. IEEE Trans. Robot. 2010, 26, 670–683. [Google Scholar]

- Gu, G.Y.; Zhu, L.M.; Su, C.Y.; Ding, H.; Fatikow, S. Proxy-based sliding-mode tracking control of piezoelectric-actuated nanopositioning stages. IEEE/ASME Trans. Mechatron. 2015, 20, 1956–1965. [Google Scholar] [CrossRef]

- Huo, W.; Paniagua, V.A.; Ding, G.; Amirat, Y.; Mohammed, S. Adaptive proxy-based controller of an active ankle foot orthosis to assist lower limb movements of paretic patients. Robotica 2019, 37, 2147–2164. [Google Scholar] [CrossRef]

- Kashiri, N.; Lee, J.; Tsagarakis, N.G.; Damme, M.V.; Vanderborght, B.; Caldwell, D.G. Proxy-based position control of manipulators with passive compliant actuators: Stability analysis and experiments. Robot. Auton. Syst. 2016, 75, 398–408. [Google Scholar] [CrossRef]

- Lee, L.W.; Lu, C.Y.; Li, I.H.; Lee, C.W.; Su, T.J. Design and control of a 6-DOF robotic manipulator driven by pneumatic muscles and motor. Sens. Mater. 2021, 33, 3081–3100. [Google Scholar] [CrossRef]

- Prieto, P.J.; Rubio, E.; Hernandez, L.; Orlando, U. Proxy-based sliding mode control on platform of 3 degree of freedom (3-DOF). Adv. Robot. 2013, 27, 773–784. [Google Scholar] [CrossRef]

- Ryo, K. Sliding motion accuracy of proxy-based sliding mode control subjected to measurement noise and disturbance. Eur. J. Control 2021, 58, 114–122. [Google Scholar]

- Zhao, W.; Song, A.; Cao, Y. An Extended Proxy-Based Sliding Mode Control of Pneumatic Muscle Actuators. Appl. Sci. 2019, 9, 1571. [Google Scholar] [CrossRef]

- Long, Y.; Du, Z.; Cong, L.; Wang, W.; Zhang, Z.; Dong, W. Active disturbance rejection control based human gait tracking for lower extremity rehabilitation exoskeleton. ISA Trans. 2017, 67, 389–397. [Google Scholar] [CrossRef]

- Hwang, B.; Jeon, D. A method to accurately estimate the muscular torques of human wearing exoskeletons by torque sensors. Sensors 2015, 15, 8337–8357. [Google Scholar] [CrossRef]

- Gurav, B.; Economou, J.; Saddington, A.; Knowles, K. Multi-Mode Electric Actuator Dynamic Modelling for Missile Fin Control. Aerospace 2017, 4, 30. [Google Scholar] [CrossRef]

- Hipolito, A.S.; Wen, Y.; Sergio, S.; Ricardo, L. Design and control of hybrid actuation lower limb exoskeleton. Adv. Mech. Eng. 2015, 7, 1687814015590988. [Google Scholar]

- Jiang, W.; Zhu, G.; Zheng, Y. Iterative Learning Control for AGV Drive Motor Based on Linear Extended State Observer. Machines 2021, 9, 324. [Google Scholar] [CrossRef]

- Gao, Z. Scaling and bandwith-parameterization based controller tuning. In Proceedings of the American Control Conference 2003, Denver, CO, USA, 4–6 June 2003; pp. 4989–4996. [Google Scholar]

- Zhao, L.; Zheng, C.; Wang, Y.; Liu, B. A Finite-Time Control for a Pneumatic Cylinder Servo System Based on a Super-Twisting Extended State Observer. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 1164–1173. [Google Scholar] [CrossRef]

- Madonski, R.; Shao, S.; Zhang, H.; Gao, Z.; Yang, J.; Li, S. General error-based active disturbance rejection control for swift industrial implementations. Control Eng. Pract. 2019, 84, 218–229. [Google Scholar] [CrossRef]

- Li, S.H.; Yang, J.; Chen, W.H.; Chen, X.S. Generalized Extended State Observer Based Control for Systems with Mismatched Uncertainties. IEEE Trans. Ind. Electron. 2012, 59, 4792–4802. [Google Scholar] [CrossRef]

- Xu, B.; Ji, S.; Zhang, C.; Chen, C.; Ni, H.; Wu, X. Linear-extended-state-observer-based prescribed performance control for trajectory tracking of a robotic manipulator. Ind. Robot. 2021, 48, 544–555. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, L.; Wang, Y.W.; Zhang, W.A. LESO-based position synchronization control for networked multi-axis servo systems with time-varying delay. IEEE CAA J. Autom. Sin. 2020, 7, 1116–1123. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, L.; Zhou, X.; Yang, X. Second-order linear active disturbance rejection control and stability analysis of energy storage grid-connected inverter. IEEE Access 2020, 8, 160738–160748. [Google Scholar] [CrossRef]

| Control parameters | ||||||

| 15 | 5 | 10 | 7 | 9 | 15 |

| Control parameters | Joint | ||||||

| Hip | 400 | 5 | 800 | 5 | 5 | 3000 | |

| Knee | 600 | 10 | 2000 | 10 | 10 | 3000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, L.-W.; Li, I.-H.; Lu, L.-Y.; Hsu, Y.-B.; Chiou, S.-J.; Su, T.-J. Hardware Development and Safety Control Strategy Design for a Mobile Rehabilitation Robot. Appl. Sci. 2022, 12, 5979. https://doi.org/10.3390/app12125979

Lee L-W, Li I-H, Lu L-Y, Hsu Y-B, Chiou S-J, Su T-J. Hardware Development and Safety Control Strategy Design for a Mobile Rehabilitation Robot. Applied Sciences. 2022; 12(12):5979. https://doi.org/10.3390/app12125979

Chicago/Turabian StyleLee, Lian-Wang, I-Hsum Li, Liang-Yu Lu, Yu-Bin Hsu, Shean-Juinn Chiou, and Te-Jen Su. 2022. "Hardware Development and Safety Control Strategy Design for a Mobile Rehabilitation Robot" Applied Sciences 12, no. 12: 5979. https://doi.org/10.3390/app12125979