The Effect of Fines Content on Compressional Behavior When Using Sand–Kaolinite Mixtures as Embankment Materials

Abstract

:1. Introduction

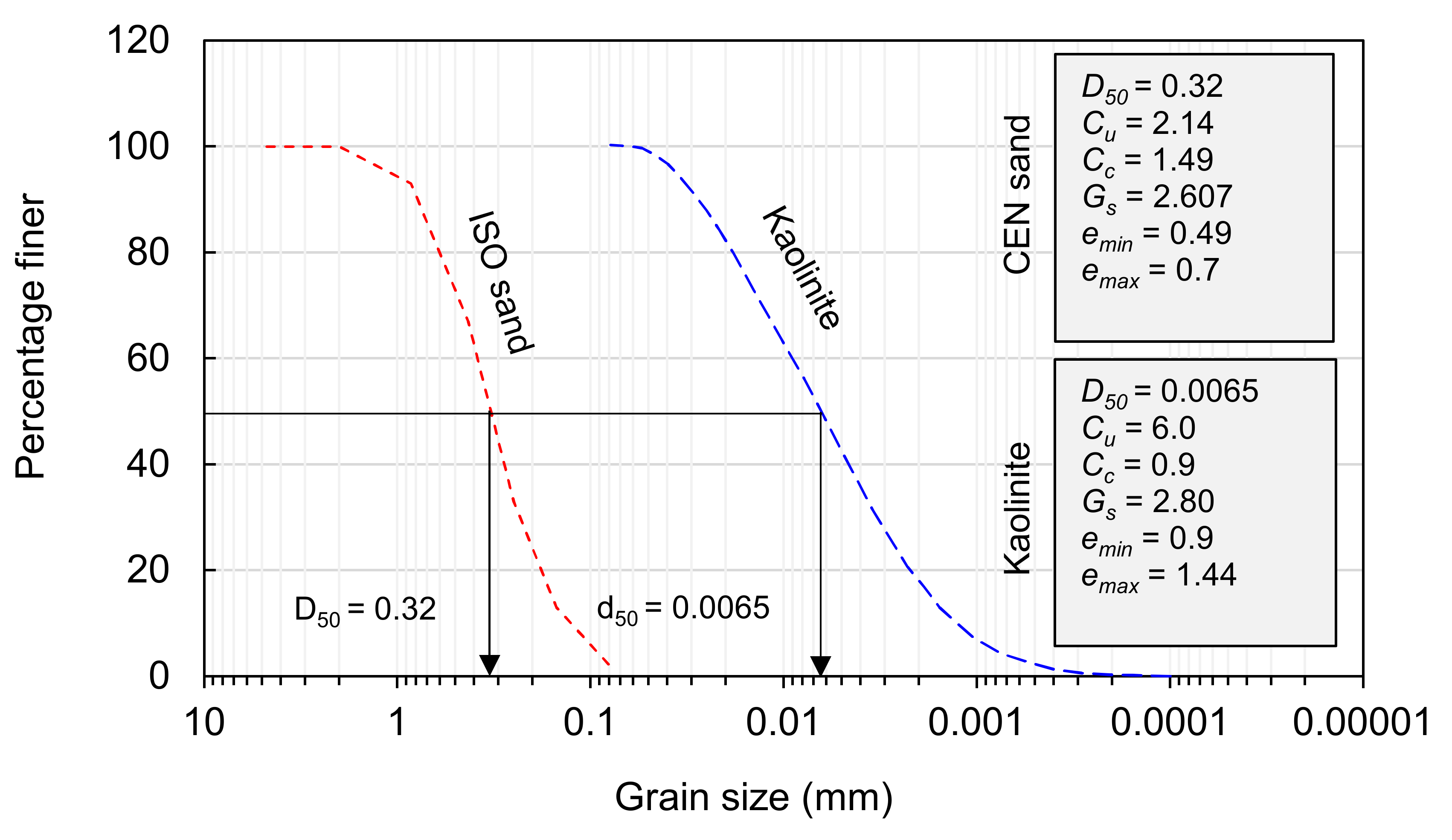

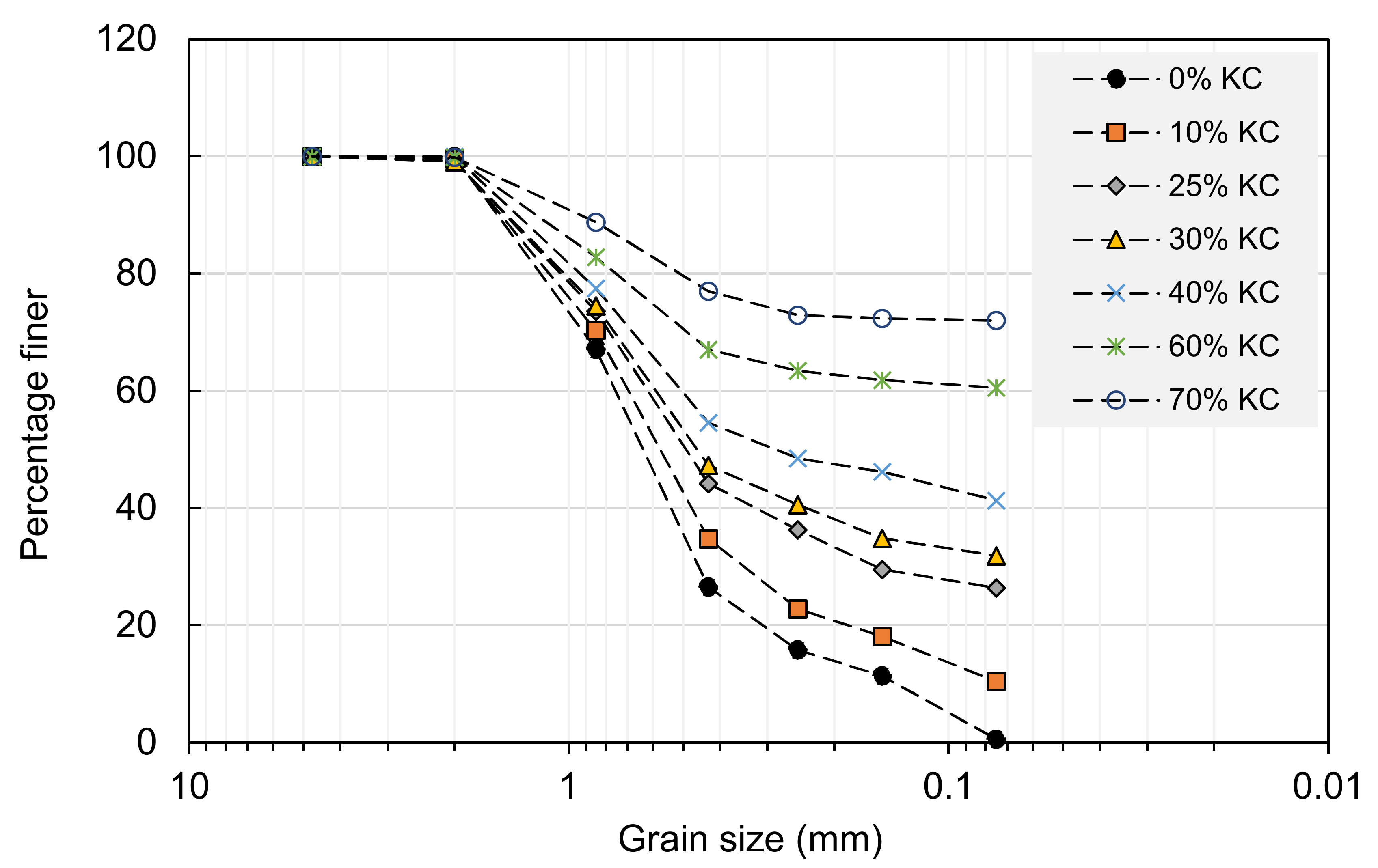

2. Test Materials and Program

2.1. Index Properties of Mixtures

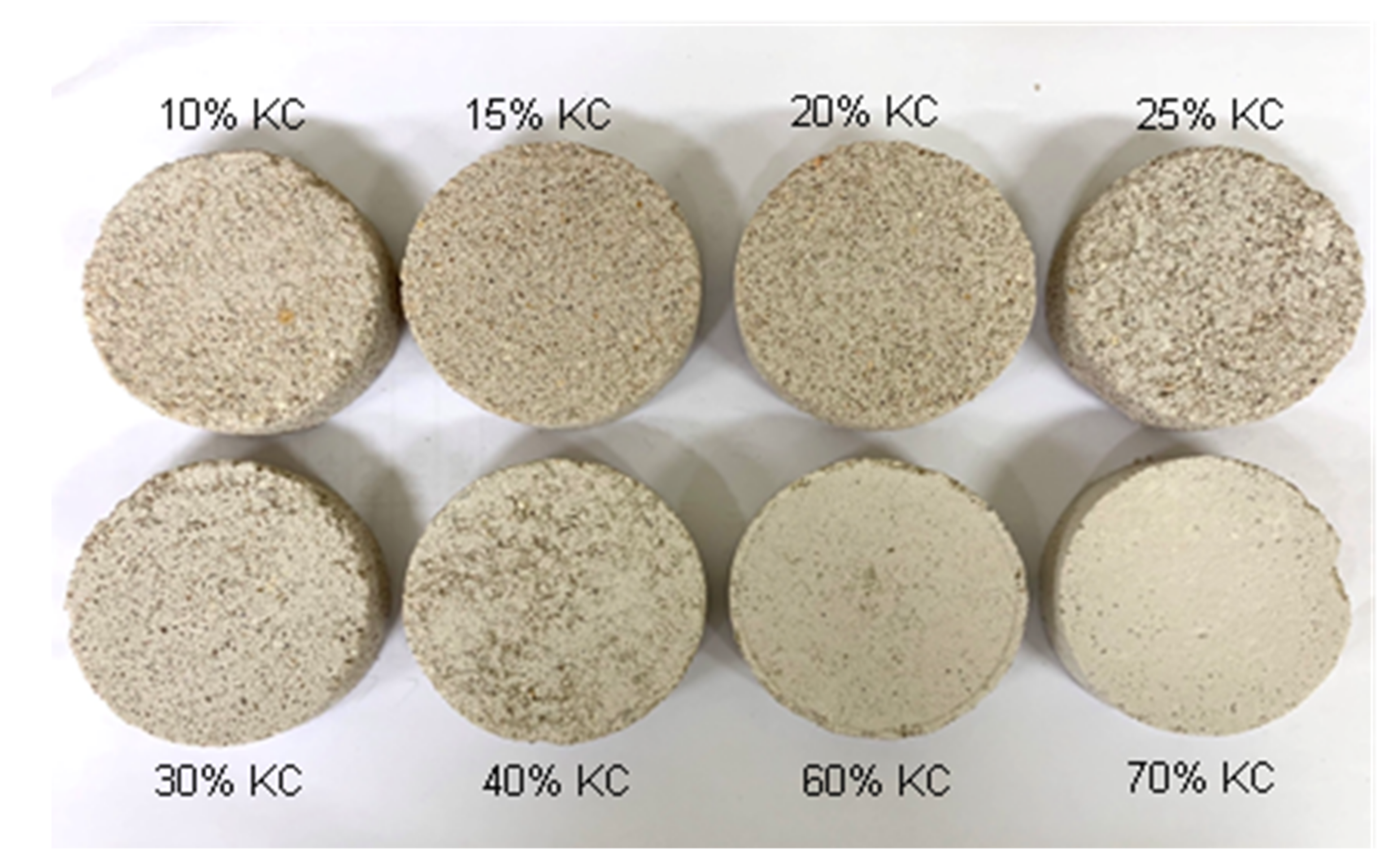

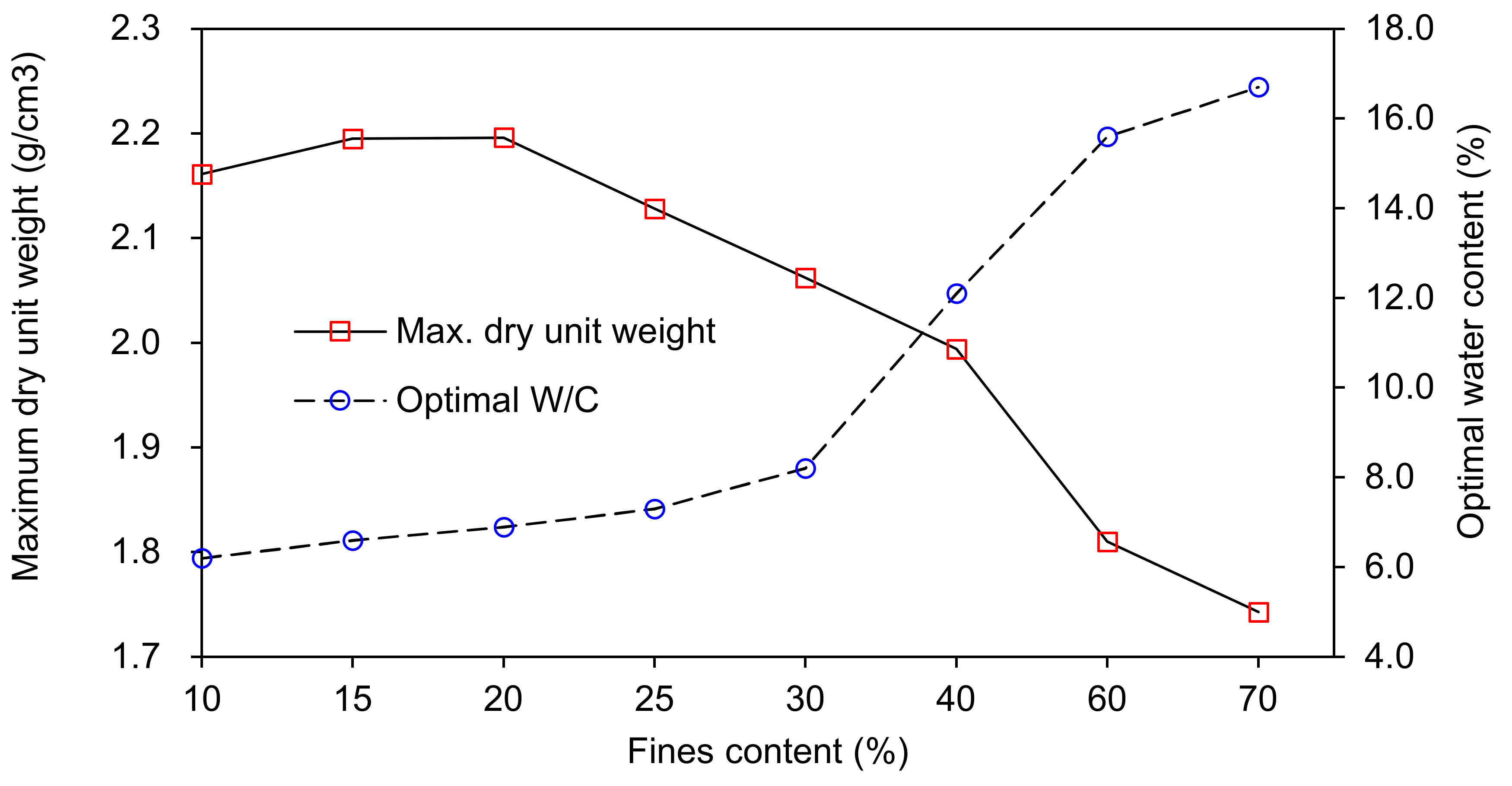

2.2. Compaction Test

2.3. Oedometer Test

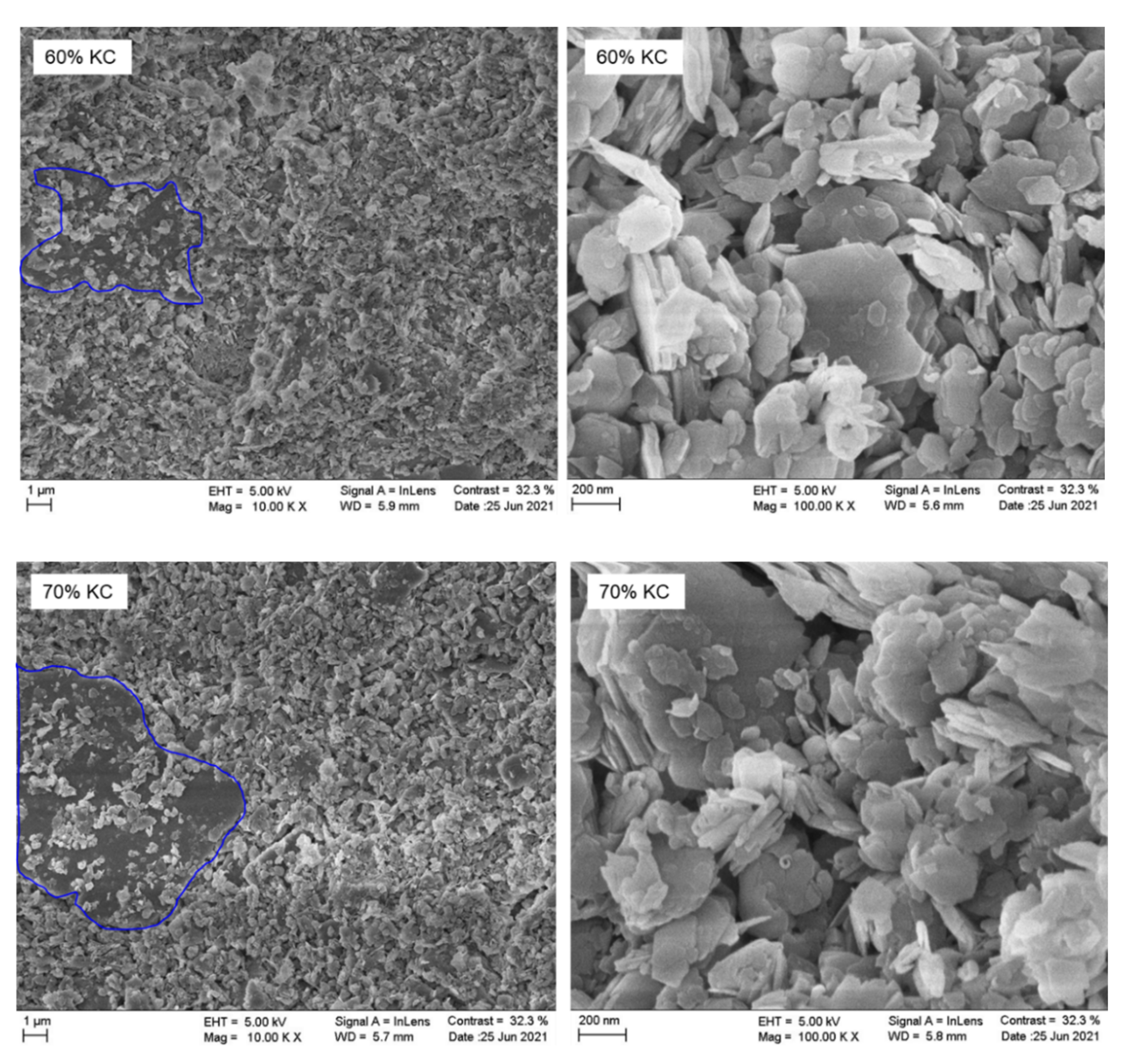

2.4. Scanning Electron Microscope Image

3. Test Results and Discussion

3.1. Compaction Test Results

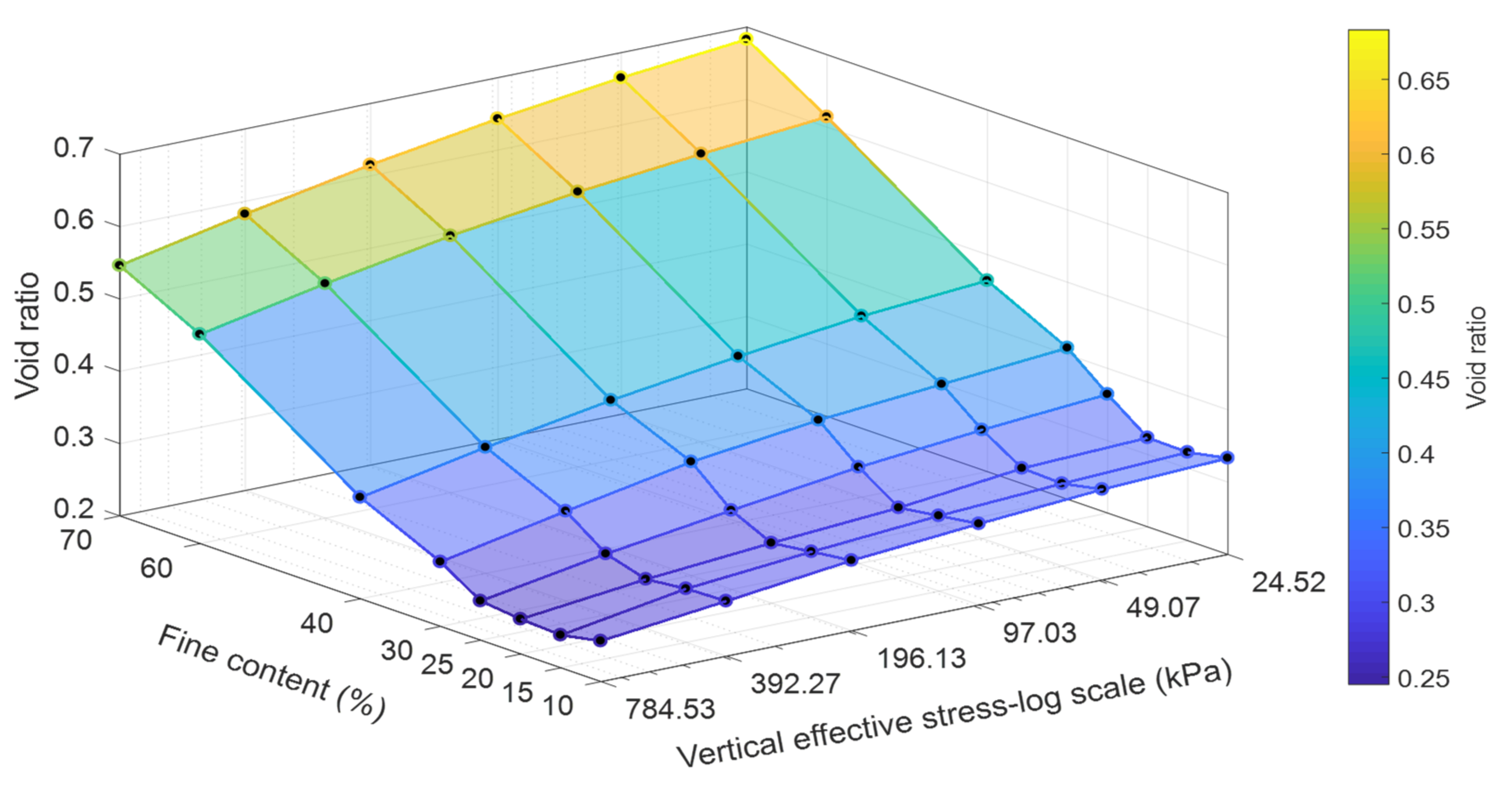

3.2. Void Ratio

3.3. Behavioral Analysis

3.3.1. Transition Fines Content

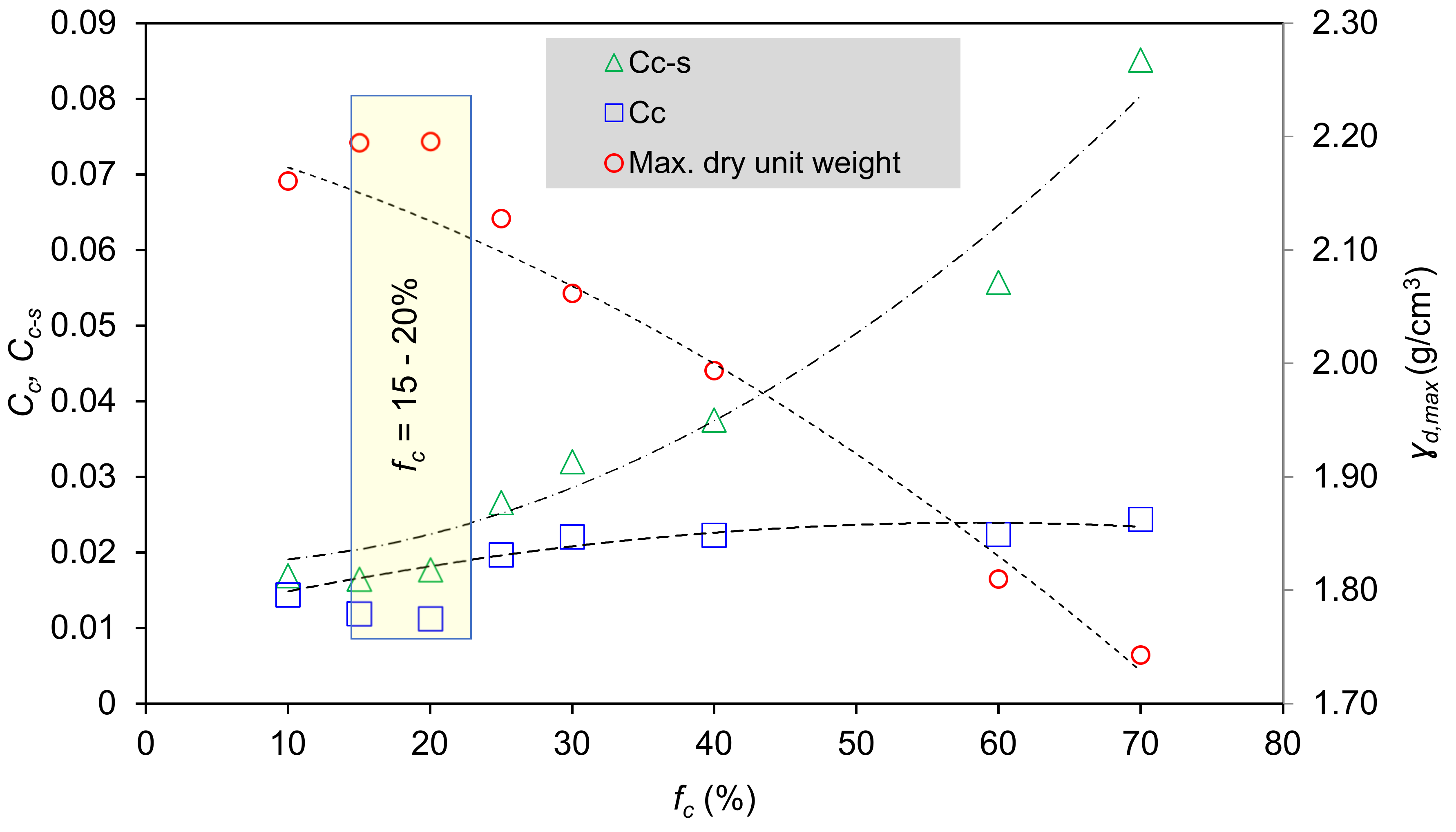

3.3.2. Behavioral Threshold Analysis

3.3.3. Compression Behavior

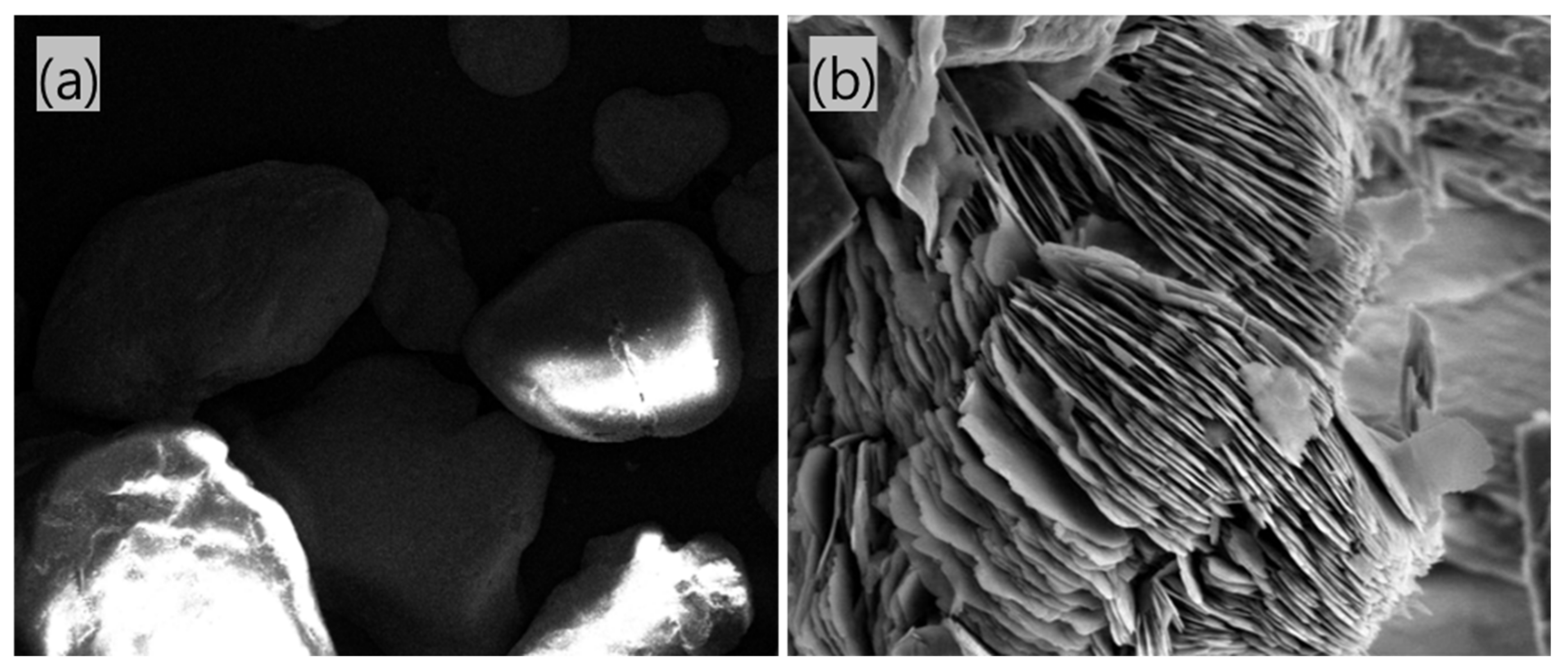

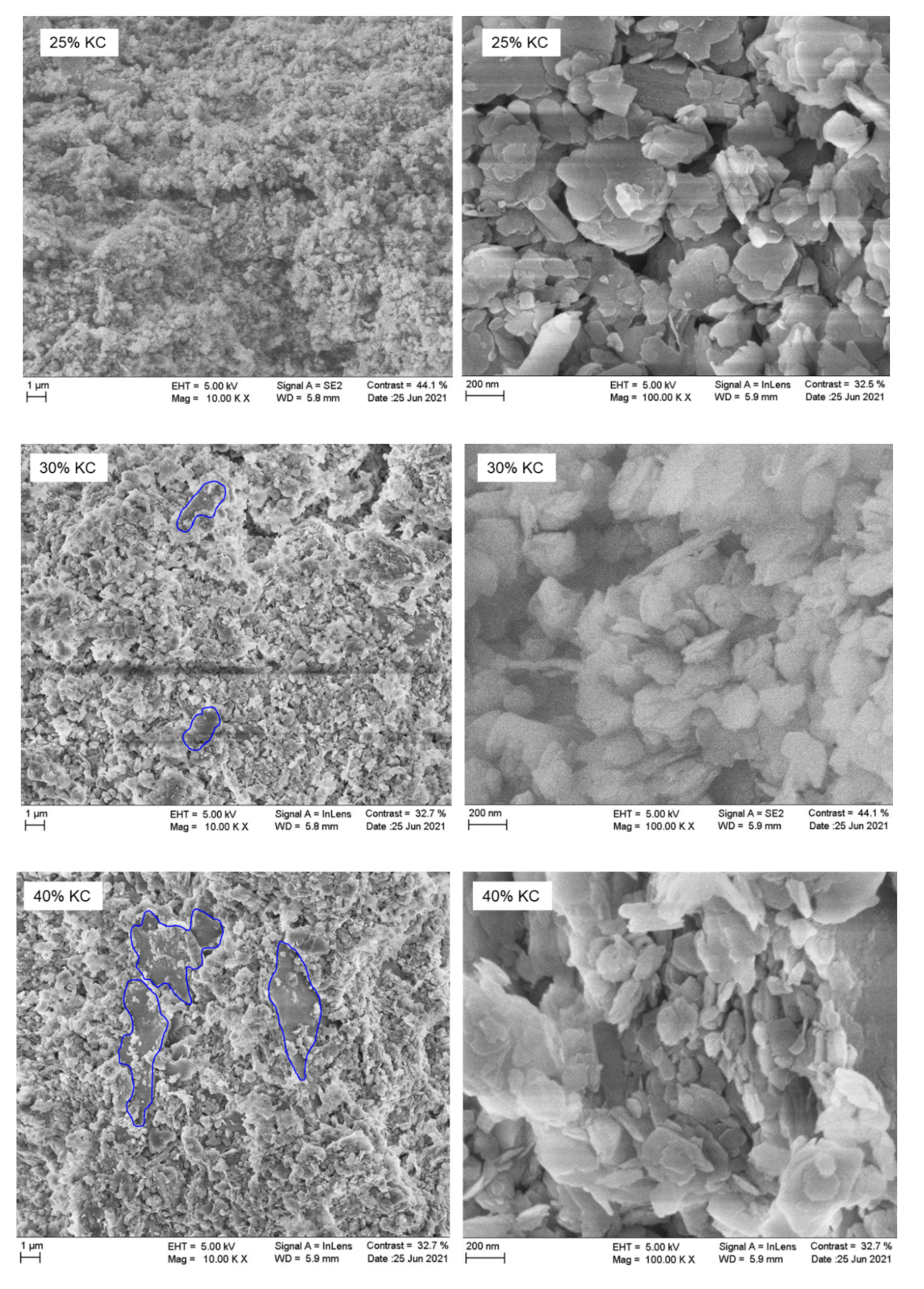

3.3.4. Particle Shape Analysis

3.3.5. Behavioral Variation

4. Summary and Conclusions

- An increase in fines content caused an increase in both void ratio and compression index. However, settlement-related properties such as e, Cc, and Cc-s decreased or showed the smallest values. Maximum dry density of 15% and 20% of fines content was also the greatest.

- Presence of fine materials at a certain amount, 15% and 20% of kaolinite in this study, played a role in helping ensure better compaction. Therefore, appropriate fines content of embankment materials resulted in less deformation.

- With the mixture of 10% KC, the smooth surface of a sand particle under kaolinite particles can be seen in the SEM images. However, in the mixture with up to 25% kaolinite content, the kaolinite particles were found to take over the sand grains. Moreover, the kaolinite particles were overlapped, creating large flat surfaces with the fines content higher than 30%, and inducing the claylike behavior of mixtures.

- Transition fines content of sand–kaolinite mixture was about 21% to 26%. Different types of behavior were identified: a transition zone (21% ≤ fc ≤ 26%), which was a behavioral change point of the mixture; sand-like behavior (fc < 15%), which was when the mixture behaved like sand; clay-like behavior (fc ≥ 30%), which was when the mixture behaved like clay, and an optimum fines content (15% ≤ fc ≤ 20%) which induced a low compression index.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- KGS. A Study on Honam High-Speed Railway; Report No. KGS20-180; Korean Geotechnical Society: Seoul, Korea, 2020. [Google Scholar]

- Soeung, S.; Lee, S.H.; Lee, S.J.; Kim, B.J.; Yune, C.Y. Causing factors of additional settlement in high-speed railways in Korea. KSCE J. Civ. Eng. 2018, 22, 3843–3851. [Google Scholar] [CrossRef]

- Lade, P.V.; Liggio, C.D.; Yamamuro, J.A. Effects of non-plastic fines on minimum and maximum void ratios of sand. Geotech. Test. J. 1998, 21, 336–347. [Google Scholar]

- Thevanayagam, S.; Shenthan, T.; Mohan, S.; Liang, J. Undrained fragility of clean sands, silty sands, and sandy silts. J. Geotech. Geoenviron. Eng. 2002, 128, 849–859. [Google Scholar] [CrossRef]

- Yang, S.L.; Lacasse, S.; Sandven, R. Determination of the transitional fines content of mixtures of sand and non-plastic fines. Geotech. Test. J. 2006, 29, 102–107. [Google Scholar]

- Pitman, T.D.; Robertson, P.K.; Sego, D.C. Influence of fines on the collapse of loose sands. Can. Geotech. J. 1994, 31, 728–739. [Google Scholar] [CrossRef]

- Osipov, V.I.; Gratchev, I.B.; Sassa, K. The mechanism of liquefaction of clayey soils (M124). In Landslides; Springer: Berlin/Heidelberg, Germany, 2005; pp. 127–131. [Google Scholar]

- Monkul, M.M.; Ozden, G. Compressional behavior of clayey sand and transition fines content. Eng. Geol. 2007, 89, 195–205. [Google Scholar] [CrossRef]

- Belkhatir, M.; Schanz, T.; Arab, A. Effect of fines content and void ratio on the saturated hydraulic conductivity and undrained shear strength of sand–silt mixtures. Environ. Earth Sci. 2013, 70, 2469–2479. [Google Scholar] [CrossRef]

- Phan, V.T.A.; Hsiao, D.H.; Nguyen, P.T.L. Effects of fines contents on engineering properties of sand-fines mixtures. Procedia Eng. 2016, 142, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Hsiao, D.H.; Phan, V.T.A. Evaluation of static and dynamic properties of sand–fines mixtures through the state and equivalent state parameters. Soil Dyn. Earthq. Eng. 2016, 84, 134–144. [Google Scholar] [CrossRef]

- I.S. EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. Turkish Standard Institute: Ankara, Turkey, 2002.

- Chen, J.; Anandarajah, A.; Inyang, H. Pore fluid properties and compressibility of kaolinite. J. Geotech. Geoenviron. Eng. 2000, 126, 798–807. [Google Scholar] [CrossRef]

- Huertas, F.J.; Fiore, S.; Huertas, F.; Linares, J. Experimental study of the hydrothermal formation of kaolinite. Chem. Geol. 1999, 156, 171–190. [Google Scholar] [CrossRef]

- ASTM D-854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- ASTM D-2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- ASTM D-4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Shrinkage Limit of Soils. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D-698; Standard Test Method for Laboratory Compaction Characteristics of Soil Using Standard Effort. Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- ASTM D-1557; Standard Test Method for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)). Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- ASTM D-2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils. ASTM International: West Conshohocken, PA, USA, 1996. [CrossRef]

- KDS 47 10 25; Korean Design Standard. Earth Structure. Ministry of Land, Infrastructure and Transport Railway Construction Division: Sejong City, Korea, 2021. Available online: http://www.kcsc.re.kr (accessed on 15 May 2021).

- Kaothon, P.; Lee, S.H.; Choi, Y.T.; Yune, C.Y. Effect of Low-Plastic Fines Content on the Engineering Properties of Kaolinite-Sand Mixture. J. Korean Geotech. Soc. 2021, 37, 35–42. [Google Scholar]

- White, W.A.; Pichler, E. Water-Sorption Characteristics of Clay Minerals; Circular no. 266; Illinois State Geological Survey: Champaign, IL, USA, 1959. [Google Scholar]

- Chhun, K.T.; Lee, S.H.; Choi, Y.T.; Yune, C.Y. Experimental Study on the Effect of Compaction on Long-term Settlement of the Embankment of High-speed Railways. In Proceedings of the 28th International Ocean and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018. [Google Scholar]

- Murthy, T.G.; Loukidis, D.; Carraro, J.A.H.; Prezzi, M.; Salgado, R. Undrained monotonic response of clean and silty sands. Géotechnique 2007, 57, 273–288. [Google Scholar] [CrossRef]

- Ni, Q.T.S.T.; Tan, T.S.; Dasari, G.R.; Hight, D.W. Contribution of fines to the compressive strength of mixed soils. Géotechnique 2004, 54, 561–569. [Google Scholar] [CrossRef]

- Papadopoulou, A.; Tika, T. The effect of fines on critical state and liquefaction resistance characteristics of non-plastic silty sands. Soils Found. 2008, 48, 713–725. [Google Scholar] [CrossRef] [Green Version]

- Thevanayagam, S.; Martin, G.R. Liquefaction in silty soils—Screening and remediation issues. Soil Dyn. Earthq. Eng. 2002, 22, 1035–1042. [Google Scholar] [CrossRef]

- Yamamuro, J.A.; Covert, K.M. Monotonic and cyclic liquefaction of very loose sands with high silt content. J. Geotech. Geoenviron. Eng. 2001, 127, 314–324. [Google Scholar] [CrossRef]

- Monkul, M.M. Influence of Inter-granular Void Ratio on One Dimensional Compression. Ph.D. Thesis, Dokuz Eylul University, Izmir, Turkey, 2005. [Google Scholar]

- Monkul, M.M.; Ozden, G. Effect of intergranular void ratio on one-dimensional compression behavior. In Proceedings of the International Conference on Problematic Soils, Famagusta, Cyprus, 25–27 May 2005; Volume 25, p. 27. [Google Scholar]

- ASTM D4254–91; Standard Test Method for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2006.

- Simpson, D.C.; Evans, T.M. Behavioral thresholds in mixtures of sand and kaolinite clay. J. Geotech. Geoenviron. Eng. 2016, 142, 04015073. [Google Scholar] [CrossRef]

- Choo, H.; Burns, S.E. Effect of over consolidation ratio on dynamic properties of binary mixtures of silica particles. Soil Dyn. Earthq. Eng. 2014, 60, 44–50. [Google Scholar] [CrossRef]

- Terzaghi, K. Erdbaumechanik auf Bodenphysikalischer Grundlage; F. Deuticke: Vienna, Austria, 1925. [Google Scholar]

- Santamarina, J.C.; Cho, G.C. Soil behavior: The role of particle shape. In Advances in Geotechnical Engineering: The Skempton Conference, Proceedings of the Three-Day Conference on Advances in Geotechnical Engineering, Organized by the Institution of Civil Engineers and Held at the Royal Geographical Society, London, UK, 29–31 March 2004; Thomas Telford Publishing: London, UK, 2004; pp. 604–617. [Google Scholar]

| Material | KC (%) | Gs | fc (%) | LL | PL | PI |

|---|---|---|---|---|---|---|

| 10% KC | 10 | 2.608 | 10.38 | 11.30 | 0.00 | 11.30 |

| 15% KC | 15 | 2.611 | 15.90 | 14.96 | 5.00 | 9.96 |

| 20% KC | 20 | 2.615 | 20.41 | 16.60 | 7.20 | 9.40 |

| 25% KC | 25 | 2.619 | 26.33 | 17.50 | 8.81 | 8.69 |

| 30% KC | 30 | 2.632 | 31.81 | 18.60 | 9.66 | 8.94 |

| 40% KC | 40 | 2.640 | 41.31 | 21.50 | 17.57 | 3.93 |

| 50% KC | 60 | 2.655 | 60.49 | 25.70 | 21.48 | 4.22 |

| 60% KC | 70 | 2.659 | 71.95 | 26.20 | 22.52 | 3.68 |

| Effective Stress (kPa) | TFC (%) |

|---|---|

| 24.52 | 21 |

| 49.03 | 22 |

| 98.07 | 23 |

| 196.13 | 24 |

| 392.27 | 25 |

| 784.53 | 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaothon, P.; Lee, S.-H.; Choi, Y.-T.; Yune, C.-Y. The Effect of Fines Content on Compressional Behavior When Using Sand–Kaolinite Mixtures as Embankment Materials. Appl. Sci. 2022, 12, 6050. https://doi.org/10.3390/app12126050

Kaothon P, Lee S-H, Choi Y-T, Yune C-Y. The Effect of Fines Content on Compressional Behavior When Using Sand–Kaolinite Mixtures as Embankment Materials. Applied Sciences. 2022; 12(12):6050. https://doi.org/10.3390/app12126050

Chicago/Turabian StyleKaothon, Panyabot, Su-Hyung Lee, Yeong-Tae Choi, and Chan-Young Yune. 2022. "The Effect of Fines Content on Compressional Behavior When Using Sand–Kaolinite Mixtures as Embankment Materials" Applied Sciences 12, no. 12: 6050. https://doi.org/10.3390/app12126050