Simultaneous DC Railway Power System Analysis Method Using Model-Based TPS

Abstract

:1. Introduction

- This paper provides a complete form of model-based TPS, by solving practical computational issues.

- The model-based TPS results were verified with previous tools with C-scripts, and input data complies with universal requirements.

- Furthermore, simultaneous and multi-rates simulation of DC 1500 V metro with TPS is given at the end of this paper.

2. Background of the TPS Algorithm

2.1. Train Motion Equation

2.2. Calculation of TPS Dynamic

Forward and Backward Moving Calculation

3. Development of Model-Based TPS Construction

3.1. Structure for Model-Based TPS

- A scalable step size. (Scalability);

- Response capacity for abrupt advent of lower speed limit. (Adaptive);

- A compatibility between TPSS and train load. (Concurrency);

- Train stops and starts at the same position. (Continuity).

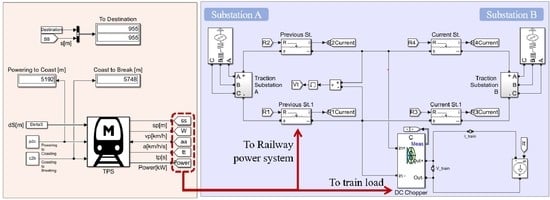

3.2. DC Railway Power System Model

4. Train Performance Simulation Results

4.1. Model-Based TPS Description

4.2. Model-Based TPS Results

4.2.1. mTPS Result and Dynamic Behavior of Train

4.2.2. Simultaneous DC Railway Power System Simulation

5. Discussion

6. Conclusions

- The mTPS provides fully integrated performance with input vehicle and track data.

- The mTPS results complies with reasonable requirements.

- The mTPS can provide detailed dynamics of the train comparing previous TPS works.

- Simultaneous multi-rates simulation of DC metro with mTPS were shown in the previous section.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| TPS | Train Performance Simulation |

| mTPS | model-based Train Performance Simulation |

| TPSS | Traction Power Supply System |

| KEPCO | Korea Electric Power Corporation |

| EMTDC | Electromagnetic Transients including DC |

| VVVF | Variable Voltage Variable Frequency |

| KRRI | Korea Railroad Research Institute |

| ESS | Energy Storage System |

| HILS | Hardware-in-the-loop simulation |

| RCP | Rapid Control Prototyping |

References

- Lee, J.; Ryu, J. Hydrogen Fuel-Cell/Battery Hybrid Train. J. Korean Soc. Railw. 2019, 22, 19–26. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Xia, H.; Lin, F. Brake Voltage Following Control of Supercapacitor-Based Energy Storage Systems in Metro Considering Train Operation State. IEEE Trans. Ind. Electron. 2018, 65, 6751–6761. [Google Scholar] [CrossRef]

- Goodman, C.; Siu, L.; Ho, T. A review of simulation models for railway systems. In Proceedings of the 1998 International Conference on Developments in Mass Transit Systems, London, UK, 20–23 April 1998; Volume 543, pp. 80–85. [Google Scholar]

- Oh, H. Model Based Design application for Power electronics development. Korean Inst. Electr. Eng. 2021, 70, 15–22. [Google Scholar]

- Liu, C.; Guo, X.; Ma, R.; Li, Z.; Gechter, F.; Gao, F. A System-Level FPGA-Based Hardware-in-the-Loop Test of High-Speed Train. IEEE Trans. Transp. Electrif. 2018, 4, 912–921. [Google Scholar] [CrossRef]

- Ning, L.; Zhou, M.; Hou, Z.; Goverde, R.M.; Wang, F.Y.; Dong, H. Deep Deterministic Policy Gradient for High-Speed Train Trajectory Optimization. IEEE Trans. Intell. Transp. Syst. 2021, 1–13. [Google Scholar] [CrossRef]

- Zhou, K.; Song, S.; Xue, A.; You, K.; Wu, H. Smart Train Operation Algorithms Based on Expert Knowledge and Reinforcement Learning. IEEE Trans. Syst. Man, Cybern. Syst. 2022, 52, 716–727. [Google Scholar] [CrossRef]

- Xiao, Z.; Wang, Q.; Sun, P.; Zhao, Z.; Rao, Y.; Feng, X. Real-Time Energy-Efficient Driver Advisory System for High-Speed Trains. IEEE Trans. Transp. Electrif. 2021, 7, 3163–3172. [Google Scholar] [CrossRef]

- Zhong, W.; Li, S.; Xu, H.; Zhang, W. On-Line Train Speed Profile Generation of High-Speed Railway With Energy-Saving: A Model Predictive Control Method. IEEE Trans. Intell. Transp. Syst. 2022, 23, 4063–4074. [Google Scholar] [CrossRef]

- Jong, J.C.; Chang, S. Algorithms for generating train speed profiles. J. East. Asia Soc. Transp. Stud. 2005, 6, 356–371. [Google Scholar]

- Hwang, H.S. Control strategy for optimal compromise between trip time and energy consumption in a high-speed railway. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 1998, 28, 791–802. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, T.K. Dynamic coast control of train movement with genetic algorithm. Int. J. Syst. Sci. 2004, 35, 835–846. [Google Scholar] [CrossRef] [Green Version]

- Zhao, N.; Roberts, C.; Hillmansen, S.; Western, P.; Chen, L.; Tian, Z.; Xin, T.; Su, S. Train trajectory optimisation of ATO systems for metro lines. In Proceedings of the 17th International IEEE Conference on Intelligent Transportation Systems (ITSC), Qingdao, China, 8–11 October 2014; pp. 1796–1801. [Google Scholar]

- Lee, H.; Kim, J.; Lee, C.; Kim, J.R.; Jang, G. Numerical Analysis Model on PSCAD/EMTDC for Train Performance Simulation. In Proceedings of the The 51st Summer Conference of the Korean Electrical Society in 2020, Busan, Korea, 15–17 July 2020; pp. 2012–2013. [Google Scholar]

- Kang, M.; Han, M. A Train Performance Simulation using Simulink for Generating Energy-efficient Speed Profiles. Trans. Korean Inst. Electr. Eng. 2010, 59, 1816–1822. [Google Scholar]

- Nitsch, A.; Beichler, B.; Golatowski, F.; Haubelt, C. Model-based Systems Engineering with Matlab/Simulink in the Railway Sector. In Proceedings of the MBMV 2015, Chemnitz, Germany, 3–4 March 2015. [Google Scholar]

- Brenna, M.; Foiadelli, F.; Zaninelli, D. Electrical Railway Transportation Systems; IEEE Press Series on Power and Energy Systems; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Alnuman, H.; Gladwin, D.; Foster, M. Electrical Modelling of a DC Railway System with Multiple Trains. Energies 2018, 11, 3211. [Google Scholar] [CrossRef] [Green Version]

- Railway Applications—Supply Voltages of Traction Systems; International Standard, International Electrotechnical Commission: Geneva, Switzerland, 2014.

- Saleh, M.; Dutta, O.; Esa, Y.; Mohamed, A. Quantitative analysis of regenerative energy in electric rail traction systems. In Proceedings of the 2017 IEEE Industry Applications Society Annual Meeting, Cincinnati, OH, USA, 1–5 October 2017; pp. 1–7. [Google Scholar]

| Quantity | Values | Quantity | Values |

|---|---|---|---|

| Weight | 191 tons | Traction and breaking efficiency | 0.91 |

| 204 tons | Nominal voltage | 1500 V | |

| Set of train | 4 trains (2M-2T 1-set) | Time step | 0.5 s |

| Acceleration | 3.0 km/h/s | Speed range | 5 km/h |

| Deceleration | 3.5 km/h/s | Dwell | 30 s |

| Maximum speed | 80 km/h | Scheduled speed | 35 km/h |

| Motor Data | Value | Quantity | Description |

|---|---|---|---|

| Total traction torque | 18,105 | kgf | - |

| Traction torque per motor | 2263 | kgf/motor | 4 motors × 2 M-cars |

| Output power per motor | 216 | kW | Gear efficiency 0.975 |

| Maximum output of traction motor | 221 | kW | at maximum acceleration |

| Input power of traction motor | 283 | kVA | at maximum acceleration |

| DC 1500 V Electrification System | Voltage (V)—DC (Mean Values) |

|---|---|

| Lowest non-permanent voltage | 1000 |

| Lowest permanent voltage | 1000 |

| Nominal voltage | 1500 |

| Highest permanent voltage | 1800 |

| Highest non-permanent voltage | 1950 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, H.; Kim, J.; Jung, H.; Kim, H. Simultaneous DC Railway Power System Analysis Method Using Model-Based TPS. Appl. Sci. 2022, 12, 6929. https://doi.org/10.3390/app12146929

Cho H, Kim J, Jung H, Kim H. Simultaneous DC Railway Power System Analysis Method Using Model-Based TPS. Applied Sciences. 2022; 12(14):6929. https://doi.org/10.3390/app12146929

Chicago/Turabian StyleCho, Hwanhee, Jaewon Kim, Hosung Jung, and Hyungchul Kim. 2022. "Simultaneous DC Railway Power System Analysis Method Using Model-Based TPS" Applied Sciences 12, no. 14: 6929. https://doi.org/10.3390/app12146929