Ultrasonic Inspection for Welds with Irregular Curvature Geometry Using Flexible Phased Array Probes and Semi-Auto Scanners: A Feasibility Study

Abstract

:1. Introduction

2. FPAPr Design and Fabrication

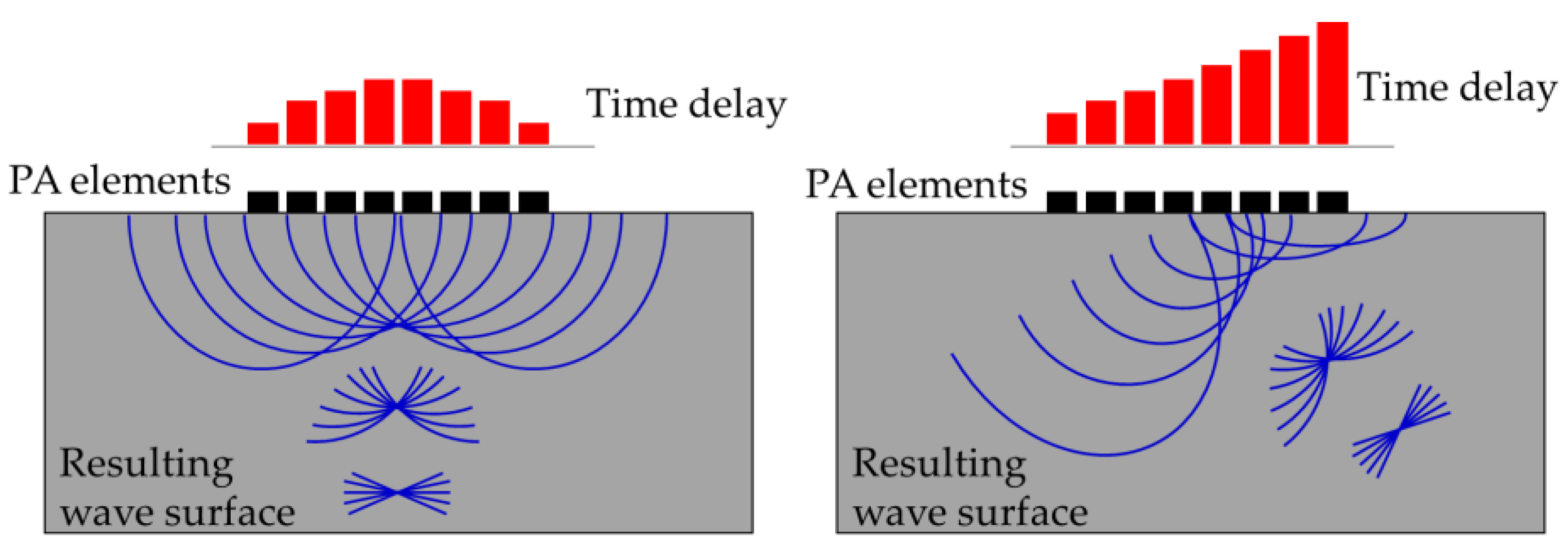

2.1. Basic Principles of Phased Array Probe

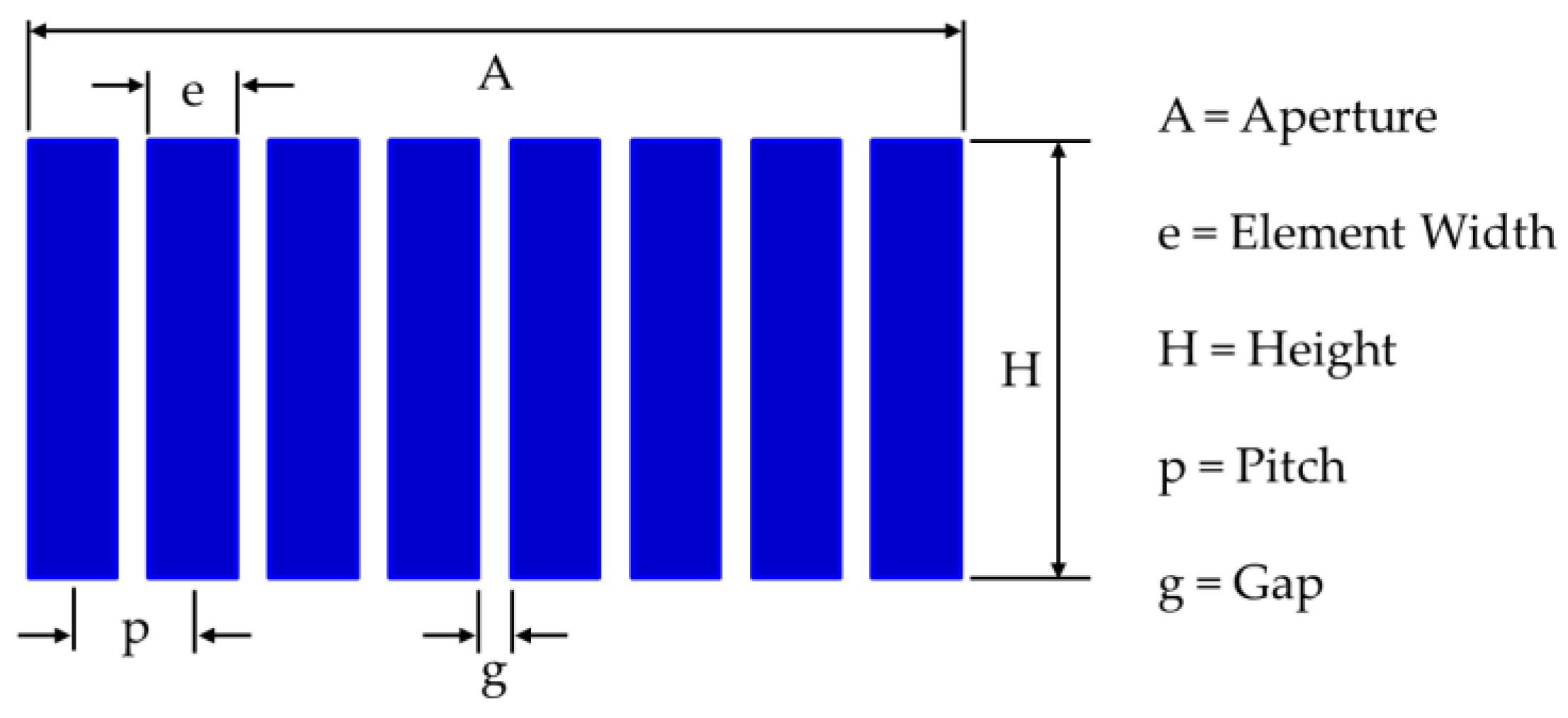

2.2. The Custom Linear FPAPr Design

2.3. Simulation

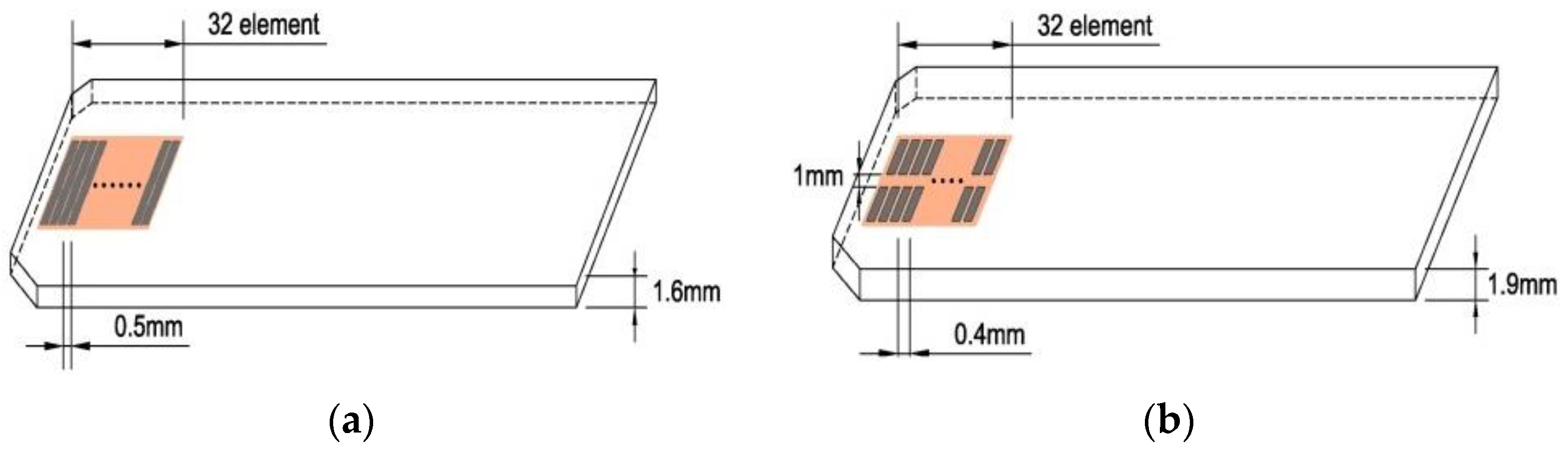

2.4. FPAPr Fabrication

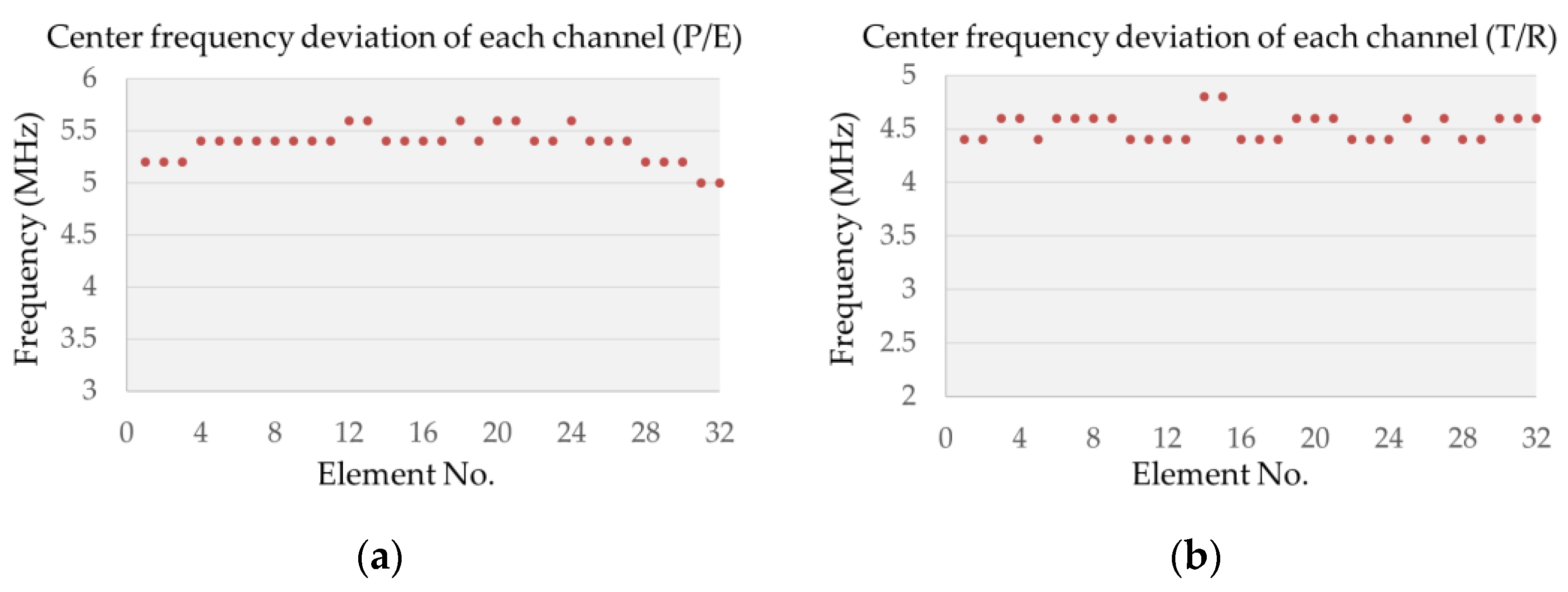

3. Experiments

3.1. Experimental Setup

3.2. The Custom Semi-Auto Scanner

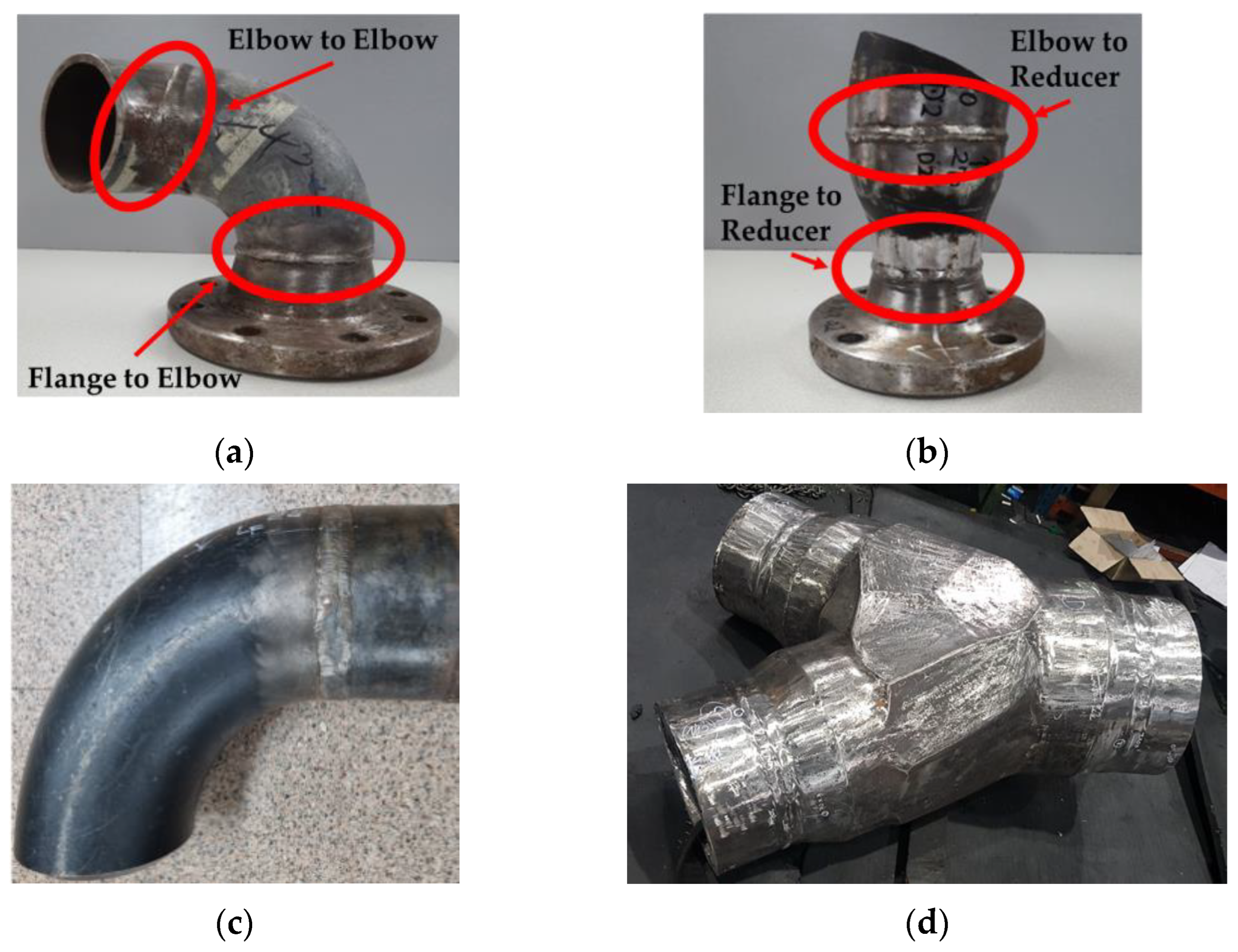

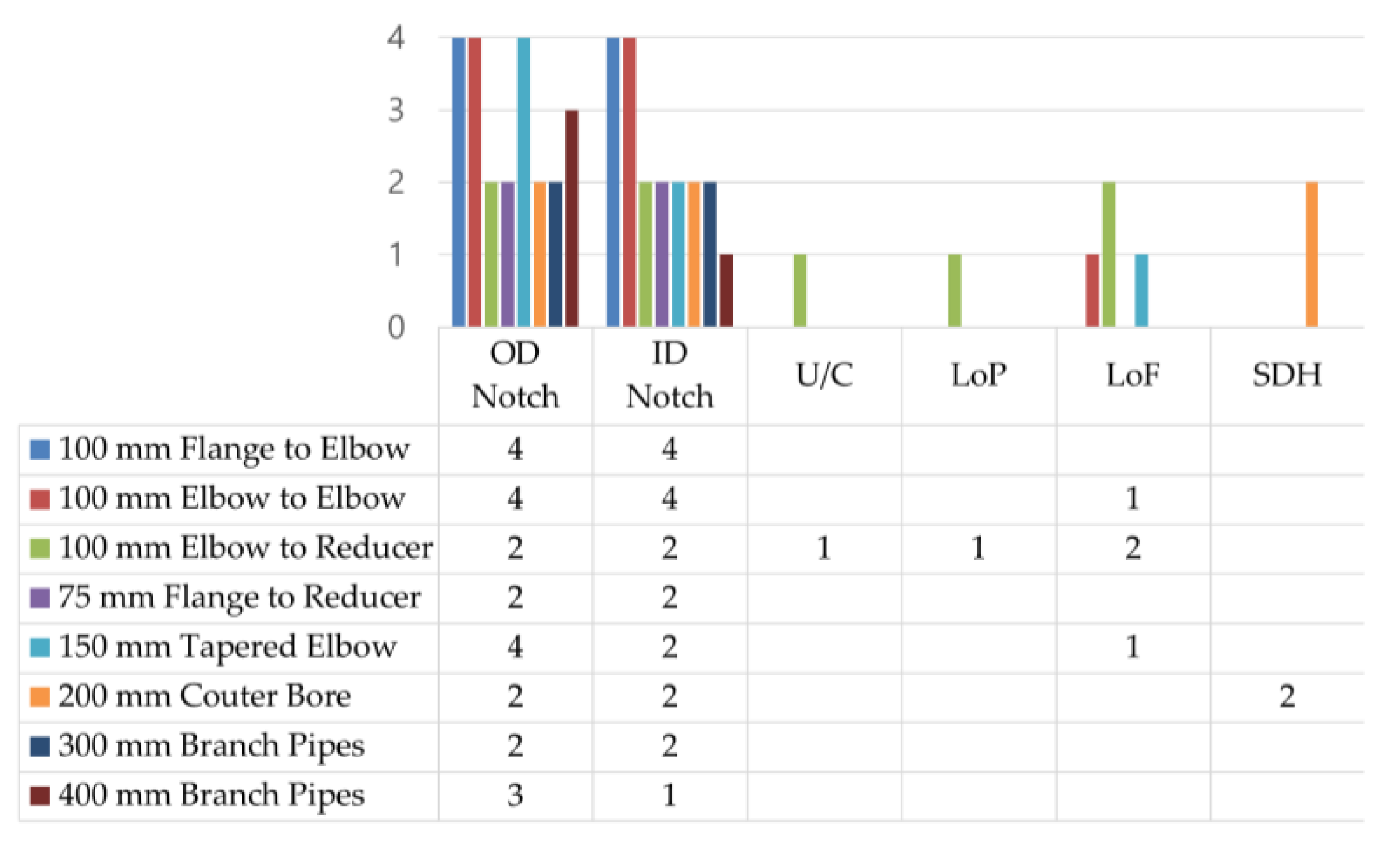

3.3. Specimens

4. Results and Discussion

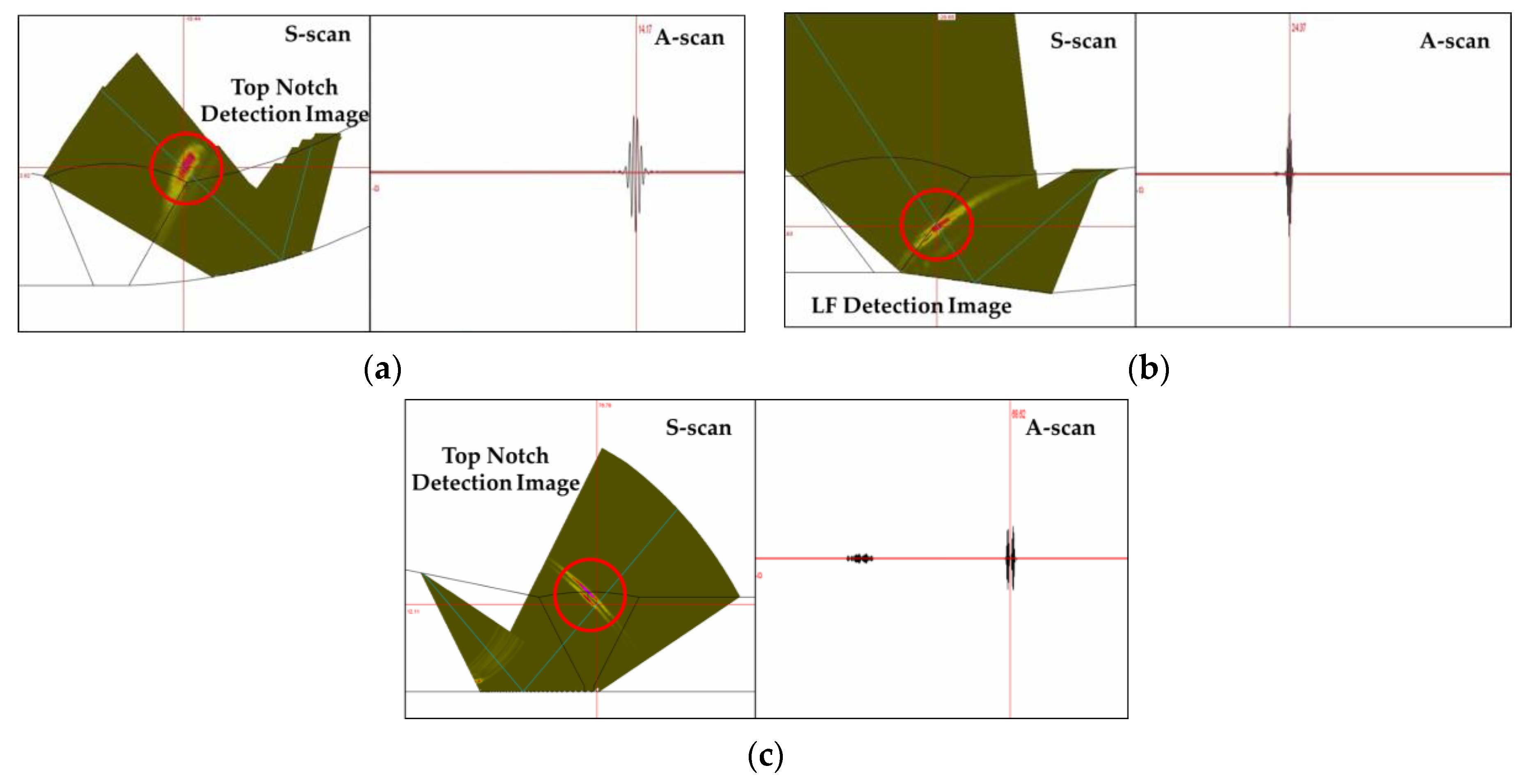

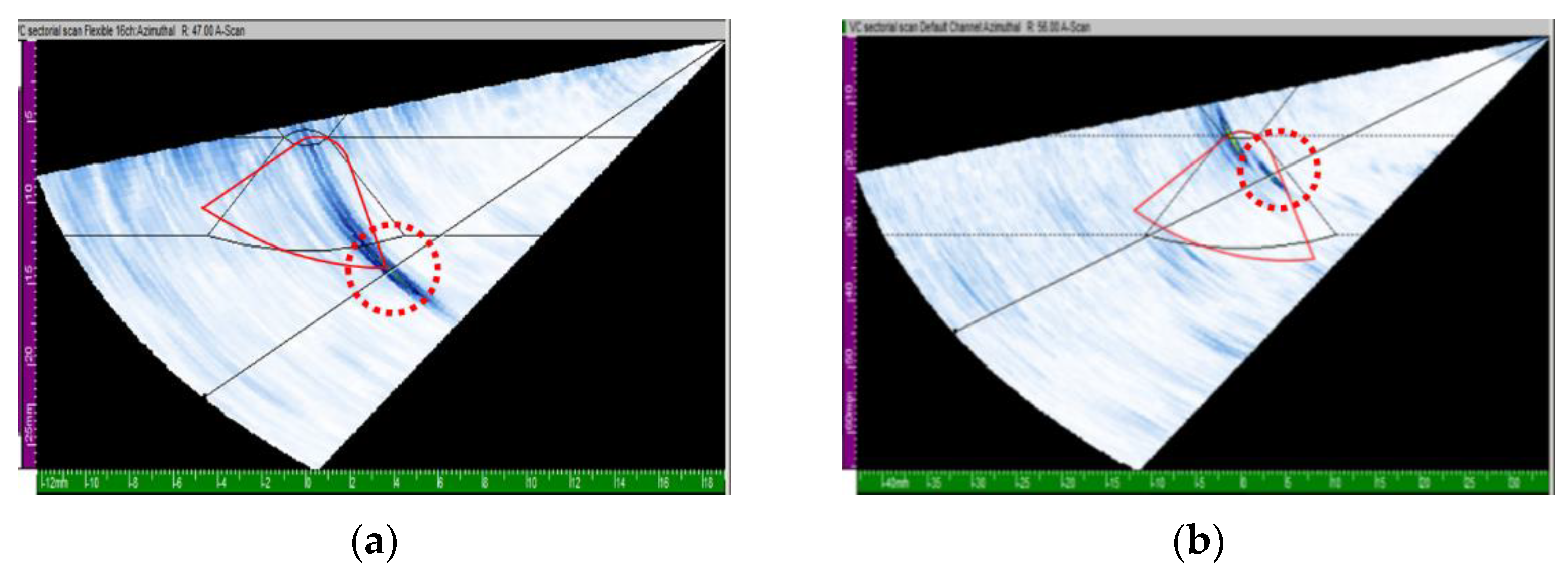

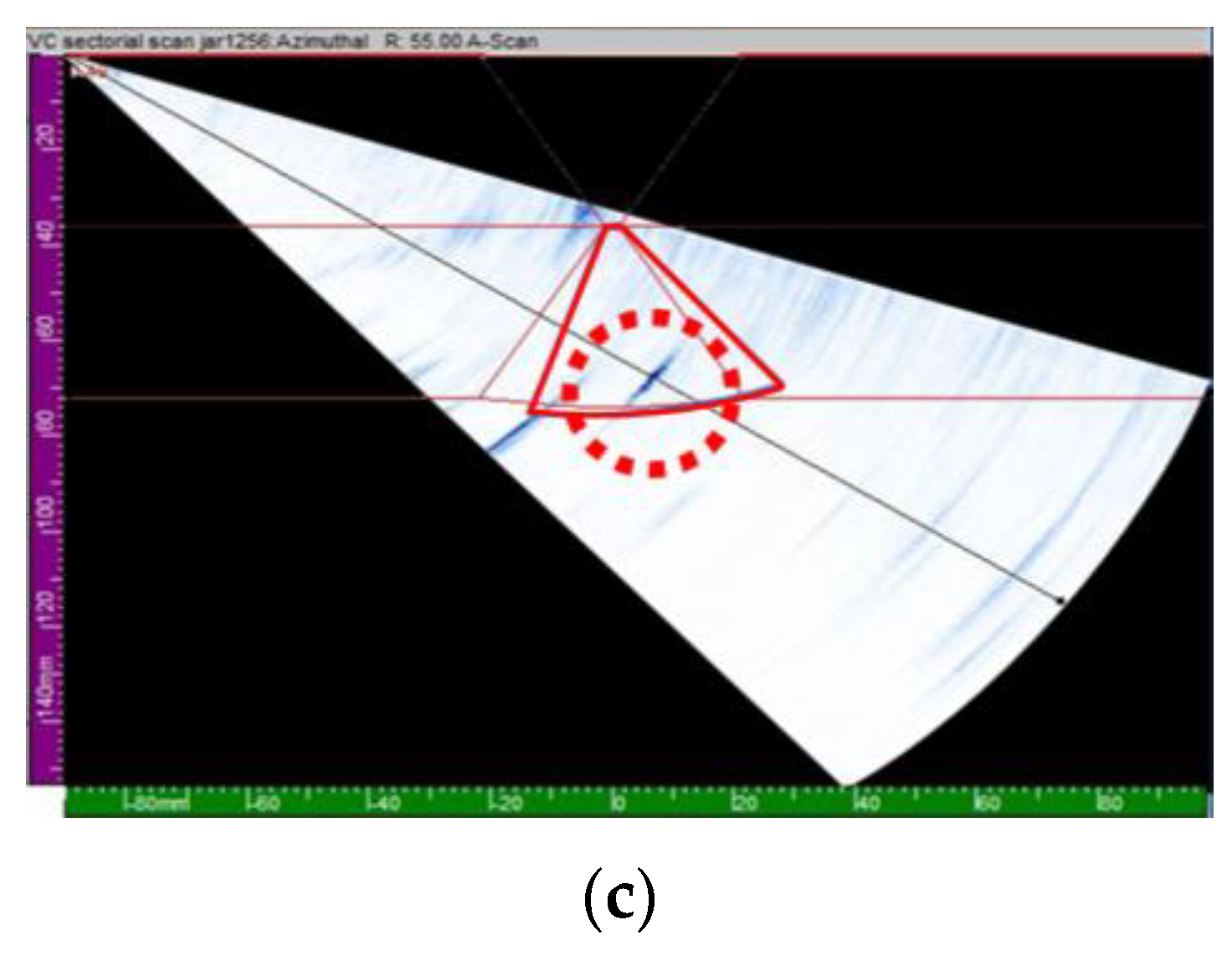

4.1. Comparison of Simulation and Experimental Results

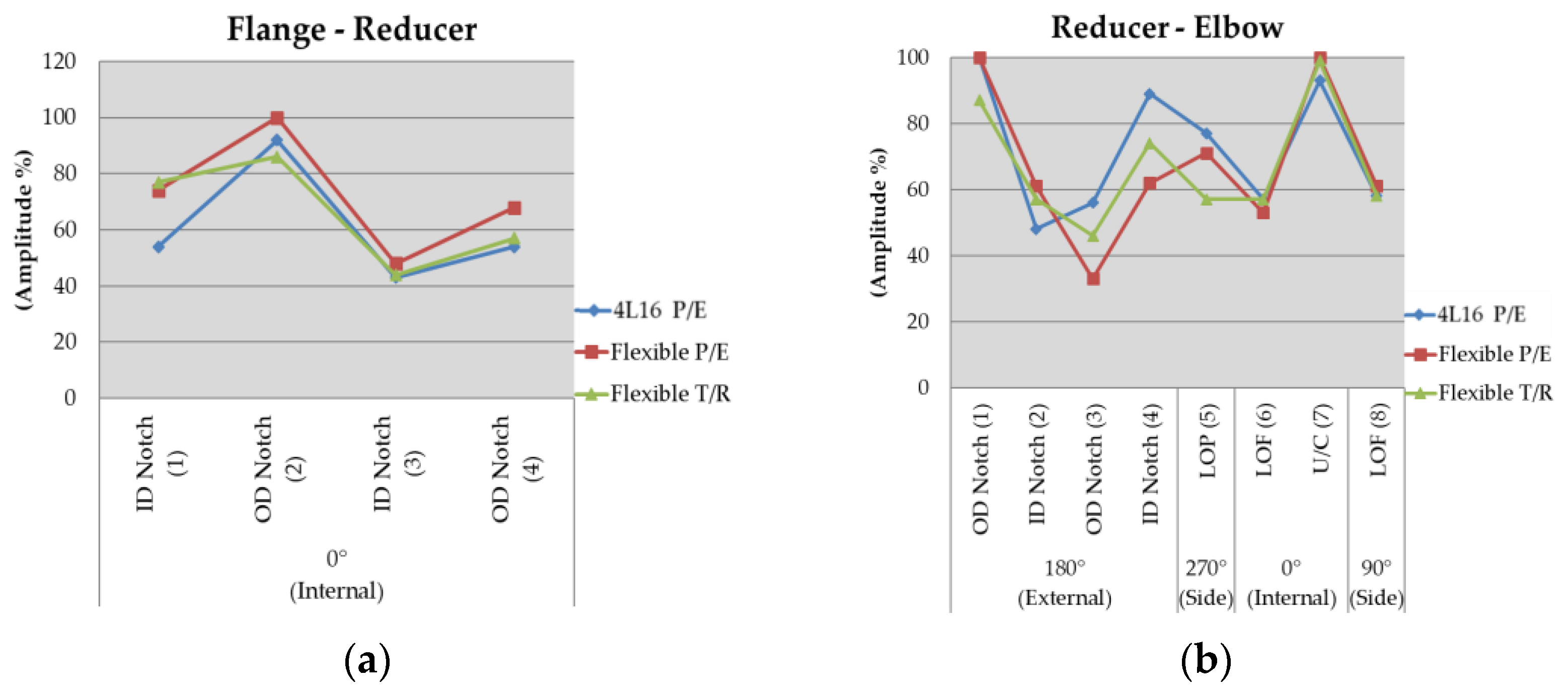

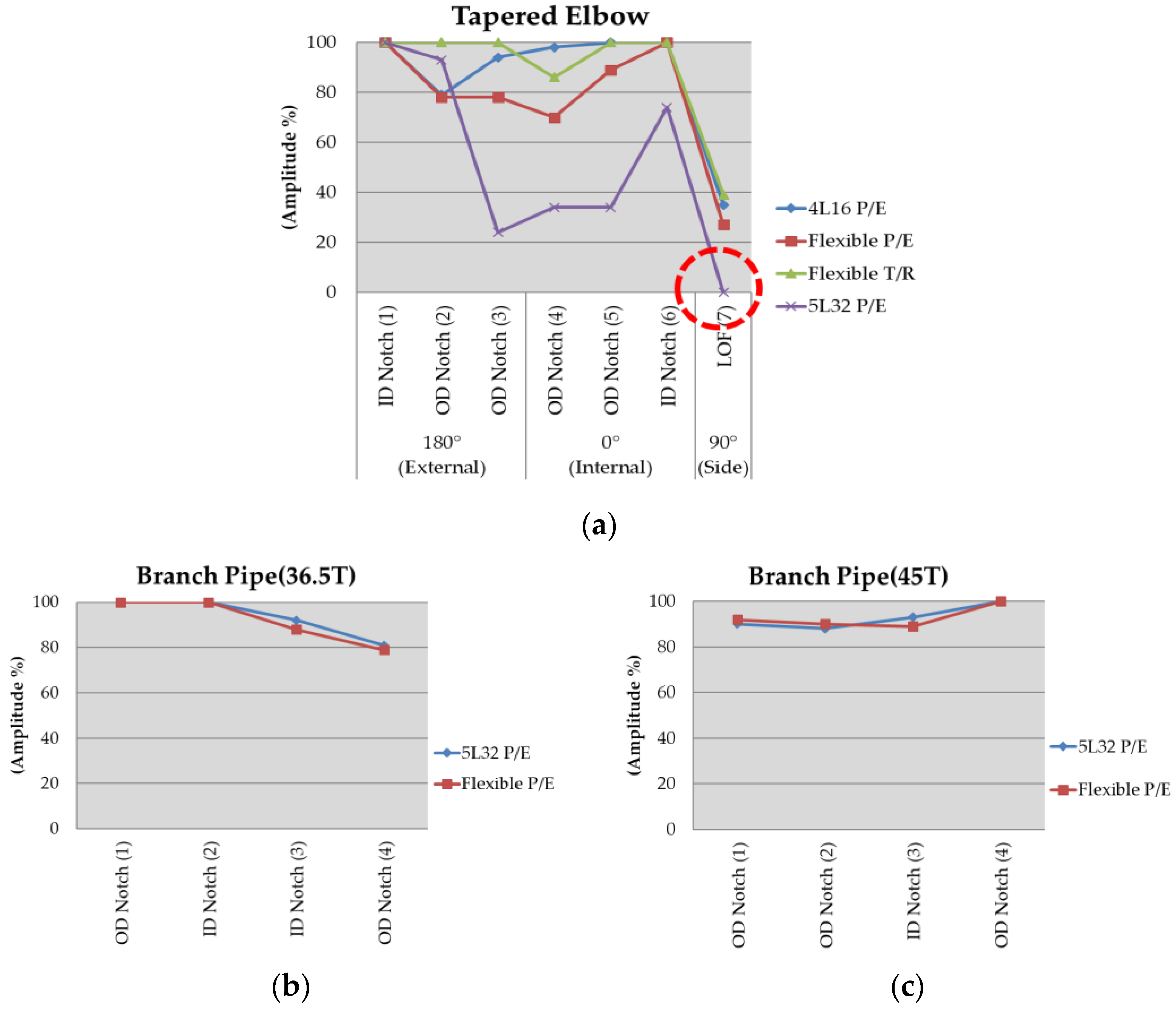

4.2. Comparison of FPAPr and Conventional PA Probe

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Olympus NDT. Advances in Phased Array Ultrasonic Technology Applications; Olympus NDT: Waltham, MA, USA, 2007; pp. 7–18. [Google Scholar]

- Ginzel, E. Phased Array Ultrasonic Technology, 2nd ed.; Eclipse Scientific Products Inc.: Waterloo, ON, Canada, 2013; pp. 23–37. [Google Scholar]

- Casual, O.; Poidevin, C.; Cattiaux, G.; Dumas, P. Control of Complex Components with Smart Flexible Phased Arrays. Ultrasonics 2006, 44, e647–e651. [Google Scholar] [CrossRef] [PubMed]

- Casula, O.; Toullelan, G.; Roy, O.; Dumas, P. Ultrasonic Nondestructive Testing of Complex Components with Flexible Phased-Array Transducers. In Proceedings of the 10th European Conference on Non-Destructive Testing, Moscow, Russia, 7–11 June 2010. [Google Scholar]

- Shin, H.J.; Song, S.J.; Jang, Y.H. Nondestructive Inspection of Steel Structures Using Phased Array Ultrasonic Technique. J. Korean Soc. Nondestruct. Test. 2000, 20, 538–544. [Google Scholar]

- Lee, S.; Moon, Y.; Jung, N. Feasibility Study of Flexible Phased Array Ultrasonic Technology Using Irregular Surface Specimen. J. Korean Soc. Nondestruct. Test. 2015, 35, 52–60. [Google Scholar] [CrossRef] [Green Version]

- Yoon, B.S.; Yang, S.H.; Kim, Y.S.; Lee, H.J. Procedure Development and Qualification of the Phased Array Ultrasonic Testing for the Nuclear Power Plant Piping Weld. Korean Soc. Nondestruc. Test. 2010, 5, 317–323. [Google Scholar]

- Hunter, A.; Drinkwater, B.; Wilcox, P. Autofocusing Ultrasonic Imagery for Non-Destructive Testing and Evaluation of Specimens with Complicated Geometries. NDT E Int. 2010, 43, 78–85. [Google Scholar] [CrossRef]

- Jayasinghe, V. Application of Flexible PAUT Probes for Small Diameter Flow Assisted Corrosion Elbow Inspection. In ASNT Annual Conference Paper Summaries; The American Society for Nondestructive Testing, Inc.: Columbus, OH, USA, 2015; pp. 82–86. [Google Scholar]

- Chatillon, S.; Cattiaux, G.; Serre, M.; Roy, O. Ultrasonic Non-Destructive Testing of Pieces of Complex Geometry with a Flexible Phased Array Transducer. Ultrasonics 2000, 38, 131–134. [Google Scholar] [CrossRef]

- Moran, T.L.; Prowant, M.; Nove, C.A.; Pardini, A.F.; Carwford, S.L.; Cinson, A.D.; Anderson, M.T. Applying Ultrasonic Testing in Lieu of Radiography for Volumetric Examination of Carbon Steel Piping; U.S.NRC: Rockville, MD, USA, 2015; pp. 1–57. [Google Scholar]

- Nagai, M.; Lin, S.; Fukutomi, H. Determination of Shape Profile by Saft for Application of Phased Array Technique to Complex Geometry Surface. AIP Conf. Proc. 2012, 1430, 849–856. [Google Scholar]

- Shi, K.; Que, K.; Guo, D. Flexible Ultrasonic Phased-Array Probe. Tsinghua Sci. Technol. 2004, 9, 574–577. [Google Scholar]

- Lhémery, A.; Calmon, P.; Lecœur-Taıbi, I.; Raillon, R.; Paradis, L. Modeling Tools for Ultrasonic Inspection of Welds. NDT E Int. 2000, 44, 499–513. [Google Scholar] [CrossRef]

- Roy, O.; Mahaut, S.; Casula, O. Control of the Ultrasonic Beam Transmitted Through an Irregular Profile Using a Smart Flexible Transducer: Modelling and Application. Ultrasonics 2002, 40, 243–246. [Google Scholar] [CrossRef]

- Long, R.; Cawley, P. Further Development of a Conformable Phased Array Device for Inspection over Irregular Surfaces. Am. Inst. Phys. 2008, 975, 754–761. [Google Scholar]

- Casula, O.; Poidevin, C.; Cattiaux, G.; Fleury, G. A Flexible Phased Array Transducer for Contact Examination of Components with Complex Geometry. In Proceedings of the 16th World Conference on Nondestructive Testing, Montreal, QC, Canada, 30 August–3 September 2004; pp. 80–87. [Google Scholar]

- Lane, C.J. The Inspection of Curved Components Using Flexible Ultrasonic Arrays and Shape Sensing Fibres. Case Stud. Nondestruct. Test. Eval. 2014, 1, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Tremblay, P.; Enenkel, L.; Berlanger, J.; Maes, G.; Poirier, J. A Turnkey Weld Inspection Solution Combining PAUT & TOFD. In Proceedings of the NDT in Canada 2014 Conference, Toronto, ON, Canada, 16–18 June 2014. [Google Scholar]

- Drinkwater, B.W.; Wilcox, P.D. Ultrasonic Arrays for Non-destructive. Ultrasonic 2006, 39, 525–541. [Google Scholar]

- Lemon, D.K.; Posakony, G.J. Linear Array Technology in NDE Applications. Mater. Eval. 1980, 38, 34–37. [Google Scholar]

- Bardouillet, P. Application of Electronic Focussing and Scanning Systems to Ultrasonic Testing. NDT Int. 1984, 17, 81–85. [Google Scholar] [CrossRef]

- Wooh, S.C.; Shi, Y. Influence of Phased Array Element size on Beam Steering Behavior. Ultrasonic 1998, 36, 737–749. [Google Scholar] [CrossRef]

- Azar, L.; Shi, Y.; Wooh, S.-C. Beam Focusing Behavior of Linear Phased Arrays. NDT E Int. 2000, 33, 189–198. [Google Scholar] [CrossRef]

- Wooh, S.C.; Shi, Y. Optimization of Ultrasonic Phased Array. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 1999; Volume 17, pp. 883–890. [Google Scholar]

- Schmerr, L.W. Fundamentals of Ultrasonic Nondestructive Evaluation; Plenum Press: New York, NY, USA, 1988. [Google Scholar]

- Usamentiaga, R.; Ibarra-Castanedo, C.; Maldague, X. More than fifty shades of grey: Quantitative characterization of defects and interpretation using SNR and CNR. J. Nondestruct. Eval. 2018, 37, 1–17. [Google Scholar] [CrossRef]

- Olympus NDT. Introduction to Phased Array Ultrasonic Technology Applications; Olympus NDT: Waltham, MA, USA, 2004; pp. 61–64. [Google Scholar]

- American Society for Nondestructive Testing. Nondestructive Testing Handbook, 3rd ed.; American Society for Nondestructive Testing: Columbus, OH, USA, 2007; Volume 7, pp. 90–91, 144–145. [Google Scholar]

- Wooh, S.C.; Shi, Y. Optimum Beam Steering of Linear Phased Array. Wave Motion 1999, 29, 245–265. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, C.; Wu, D. Flexible and Stretchable Ultrasonic Transducer Array Conformed to Complex Surfaces. IEEE Electron Device Lett. 2021, 42, 240–243. [Google Scholar] [CrossRef]

- Puel, B.; Lesselier, D.; Chatillon, S.; Calmon, P. Optimization of Ultrasonic Arrays Design and Setting Using a Differential Evolution. NDT E Int. 2011, 44, 797–803. [Google Scholar] [CrossRef]

- Wooh, S.C.; Shi, Y. A Simulation study of the Beam Steering Characteristics for Linear Phased Arrays. J. Nondestruct. Eval. 1999, 18, 39–57. [Google Scholar] [CrossRef]

- Schmerr, L.W. A Multi Gaussian Ultrasonic Beam Model for High Performance Simulations on a Personal Computer. Mater. Eval. 2000, 58, 882–888. [Google Scholar]

- Nakahata, K.; Kono, N. 3-D modeling of an ultrasonic Phased Array Transducer and its Radiation Properties in solid. In Ultrasonic Waves; Intech: London, UK, 2012; pp. 60–80. [Google Scholar]

- Jung, M.J.; Park, B.C.; Lim, C.O.; Lee, J.C.; Shin, S.C. Selection of PAUT Probes for Submarine Pressure Hull Integrity Assessment. Int. J. Naval Archit. Ocean Eng. 2020, 12, 578–595. [Google Scholar] [CrossRef]

- Jing, H.; She-yu, Z.; Shi-guan, Z.; Pei-wen, Q. Characteristic Research on Focused Acoustic Field of Linear Phased Array Transducer. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009; pp. 792–795. [Google Scholar]

- Schumacher, E.; Roth, D. CIVA Simulation Software for NDT Applications. In Proceedings of the NDT in Canada 2009 National Conference, London, ON, Canada, 25–27 August 2009. [Google Scholar]

- Mendelsohn, Y.; Wiener-Avnear, E. Simulations of Circular 2D Phased-Array Ultrasonic Imaging Transducers. Ultrasonics 2002, 39, 657–666. [Google Scholar] [CrossRef]

- Dheeraj, P.R.; Mohsin, I.; Mohiuddin, S.K.; Masroor, S.H. Effect of Focal Law Parameters on Probability of Detection in Phased Array Ultrasonic Testing Using a Simulation and Case Study Approach. Mater. Eval. 2016, 74, 1574–1591. [Google Scholar]

- Roy, O.; Chatillon, M.S. Ultrasonic Inspection of Complex Geometry Component Specimen with a Smart Flexible Contact Phased Array Transducer: Modeling and Application. In Proceedings of the 2000 IEEE Ultrasonics Symposium, San Juan, PR, USA, 22–25 October 2000; pp. 763–766. [Google Scholar]

- Tremblay, P.; Verspeelt, D. Design&Validation of a Semi-Flexible PAUT Probe for the Manufacturing Inspections of Large Forged Rotors. In Proceedings of the 9th International Conference on NDE in Relation to Structural Integrity for Nuclear and Pressurized Components, Seattle, WA, USA, 22–24 May 2012; pp. 371–379. [Google Scholar]

- Ahmad, R.; Kundu, T.; Placko, D. Modeling of Phased Array Transducers. Acoust. Soc. Am. 2005, 117, 1762–1776. [Google Scholar] [CrossRef] [PubMed]

- Jen, C.K.; Kobayashi, M. Flexible Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1478–1486. [Google Scholar]

- Lim, S.; Park, I.; Park, T. Application of Stainless Steel with Weld Curvature. J. Korean Soc. Nondestruc. Test. 2020, 40, 139–144. [Google Scholar] [CrossRef]

- Shih, J.L.; Wu, K.T.; Jen, C.K.; Chiu, C.H.; Tzeng, J.C.; Liaw, J.W. Applications of Flexible Ultrasonic Transducer Array for Defect Detection at 150 °C. Sensors 2013, 13, 975–983. [Google Scholar] [CrossRef]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef] [Green Version]

- Kino, G.S. Acoustic Waves: Devices, Imaging and Analog Signal Processing; Prentice-Hall: Englewood Cliffs, NJ, USA, 1987; pp. 4–8. [Google Scholar]

- Schwartz, H.P. Development of a Divided-Ring Array for Three-Dimensional Beam Steering in Ultrasonic Nondestructive Testing: Theoretical and Experimental results of a Prototype. Mater Eval. 1987, 45, 951–957. [Google Scholar]

- Lei, X.; Wirdelius, H.; Rosell, A. Experimental Validation of a Phased Array Probe Model in Ultrasonic. Ultrasonics 2020, 108, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Japan Probe JPR-50p Specifications. Available online: http://www.jp-probe.com/en/product/up_img/1406701067-594654_f1.pdf (accessed on 5 December 2021).

- Markel, J. FFT pruning. IEEE Trans. Audio Electroacoust. 1971, 19, 305–311. [Google Scholar] [CrossRef]

- Holmberg, P. Robust ultrasonic range finder-an FFT analysis. Meas. Sci. Technol. 1992, 3, 1025. [Google Scholar] [CrossRef]

- Vezzetti, D.J. Propagation of Bounded Ultrasonic beams in Anisotropic media. J. Acoust. Soc. Am. 1985, 78, 1103–1108. [Google Scholar] [CrossRef]

- Maes, G.; Berlanger, J.; Reilly, D.; Richard, D. Advanced 3D Visualization and Analysis of Phased Array UT Inspection Data; ZETEC: Quebec, QC, Canada, 2012; pp. 859–868. [Google Scholar]

- Holmes, C.; Drinkwater, B.W.; Wilcox, P.D. Advanced Post-Processing for Scanned Ultrasonic Arrays: Application to Defect Detection and Classification in Non-Destructive Evaluation. Ultrasonic 2008, 48, 636–642. [Google Scholar] [CrossRef] [PubMed]

| Probe Type | FPAPr(P/E) | FPAPr(T/R) |

|---|---|---|

| Total Elements (ch) | 32 | 32 × 2 |

| Nominal frequency (MHz) | 5 | 5 |

| Aperture (mm) | 16 | 12.8 |

| Elevation (mm) | 10 | 5 |

| Pitch (mm) | 0.5 | 0.4 |

| Gap (mm) | 0.1 | 0.1 |

| Type | Elbow–Flange–Reducer | Tapered Elbow to Pipe | Upper-Tapered Pipe |

|---|---|---|---|

| Material | Carbon Steel | Carbon Steel | Carbon Steel |

| Longitudinal Velocity | |||

| Transverse Velocity | |||

| Density | 7.8 × 103 kg/m3 | 7.8 × 103 kg/m3 | 7.8 × 103 kg/m3 |

| A diameter | 100 mm | 150 mm | 300, 350 mm |

| Thickness | 8 mm | 14.8, 20.0 mm | 36.5, 51 mm |

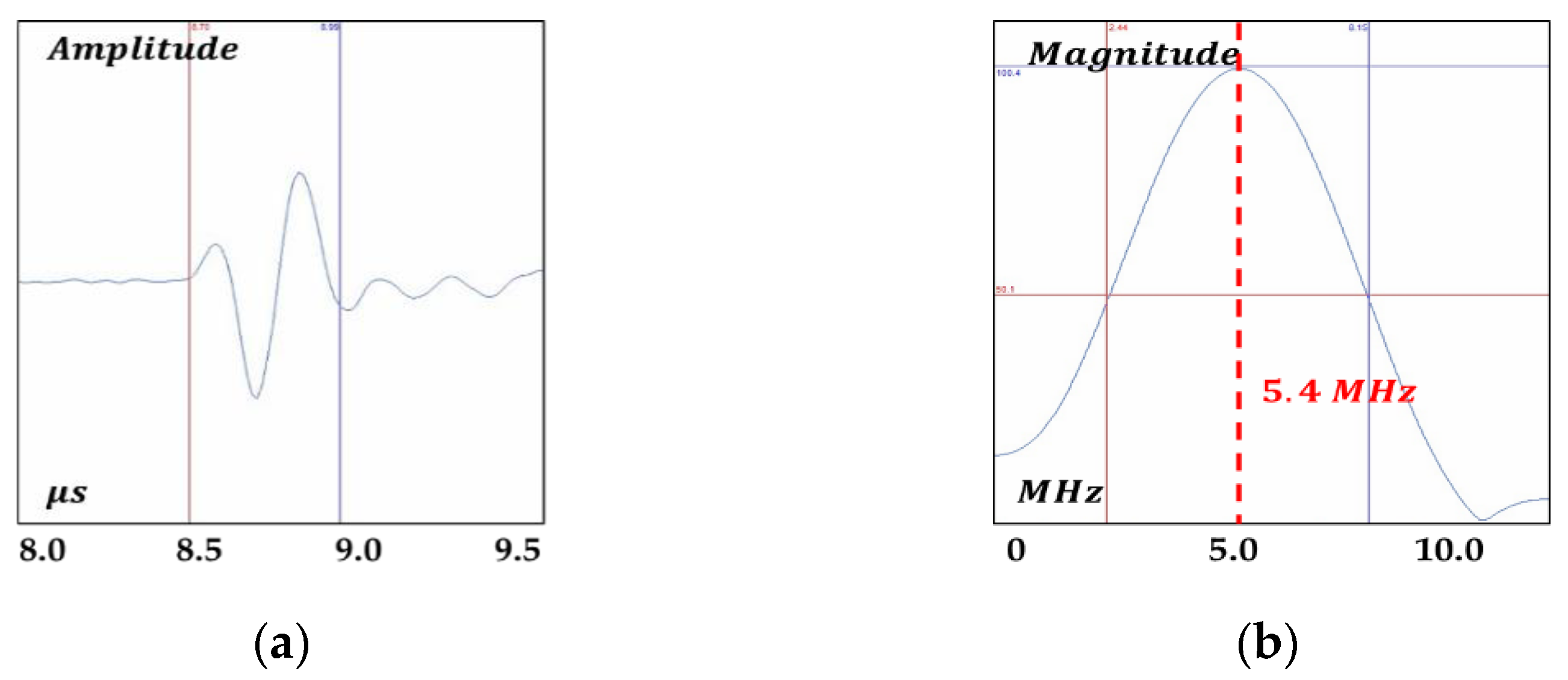

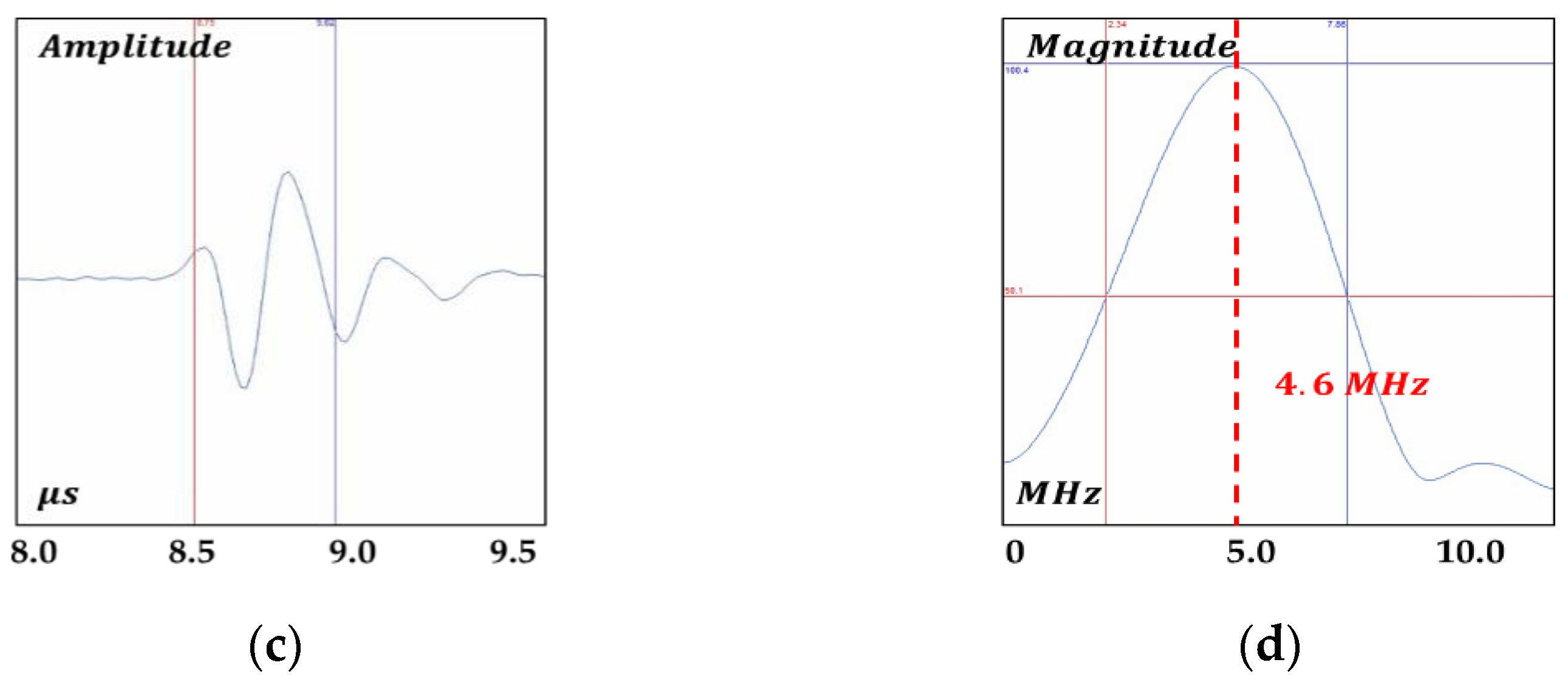

| Probe Type | FPAPr (P/E) | FPAPr (T/R) |

|---|---|---|

| Total elements (ch) | 32 | 32 × 2 (64) |

| Center Frequency (MHz) | 5.4 | 4.5 |

| Center Frequency Dispersion (%) | Max + 4.2% Min − 7.0% | Max + 6.5% Min − 2.7% |

| Sensitive Dispersion (dB) | 2.8 dB | 1.5 dB |

| Rel.BW (%) | 114 | 113 |

| Probe Type (Mounted Rigid Wedge) | Conventional PA(P/E) | |

|---|---|---|

| 4L16 | 5L32 | |

| Total elements (ch) | 16 | 32 |

| Nominal center frq.(MHz) | 4 | 5 |

| Rel.BW (%) | 131 | 91 |

| Pitch (mm) | 0.5 | 1 |

| Aperture (mm) | 8 | 32 |

| Elevation (mm) | 10 | 10 |

| Flaw Type | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|

| Notch | 6, 10~30 | 1~2 | 0.6~2 |

| LoP | 10~20, 5 | 2 | 2~3 |

| LoF | 6~10, 12 | 2 | 2~2.5 |

| SDH | 25 | - | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, S.J.; Kim, Y.L.; Cho, S.; Park, I.K. Ultrasonic Inspection for Welds with Irregular Curvature Geometry Using Flexible Phased Array Probes and Semi-Auto Scanners: A Feasibility Study. Appl. Sci. 2022, 12, 748. https://doi.org/10.3390/app12020748

Lim SJ, Kim YL, Cho S, Park IK. Ultrasonic Inspection for Welds with Irregular Curvature Geometry Using Flexible Phased Array Probes and Semi-Auto Scanners: A Feasibility Study. Applied Sciences. 2022; 12(2):748. https://doi.org/10.3390/app12020748

Chicago/Turabian StyleLim, Seong Jin, Young Lae Kim, Sungjong Cho, and Ik Keun Park. 2022. "Ultrasonic Inspection for Welds with Irregular Curvature Geometry Using Flexible Phased Array Probes and Semi-Auto Scanners: A Feasibility Study" Applied Sciences 12, no. 2: 748. https://doi.org/10.3390/app12020748

APA StyleLim, S. J., Kim, Y. L., Cho, S., & Park, I. K. (2022). Ultrasonic Inspection for Welds with Irregular Curvature Geometry Using Flexible Phased Array Probes and Semi-Auto Scanners: A Feasibility Study. Applied Sciences, 12(2), 748. https://doi.org/10.3390/app12020748