Soil Characterization and Soiling Impact to Facilitate Photovoltaic Installation

Abstract

:1. Introduction

2. Methodology

3. Results and Discussion

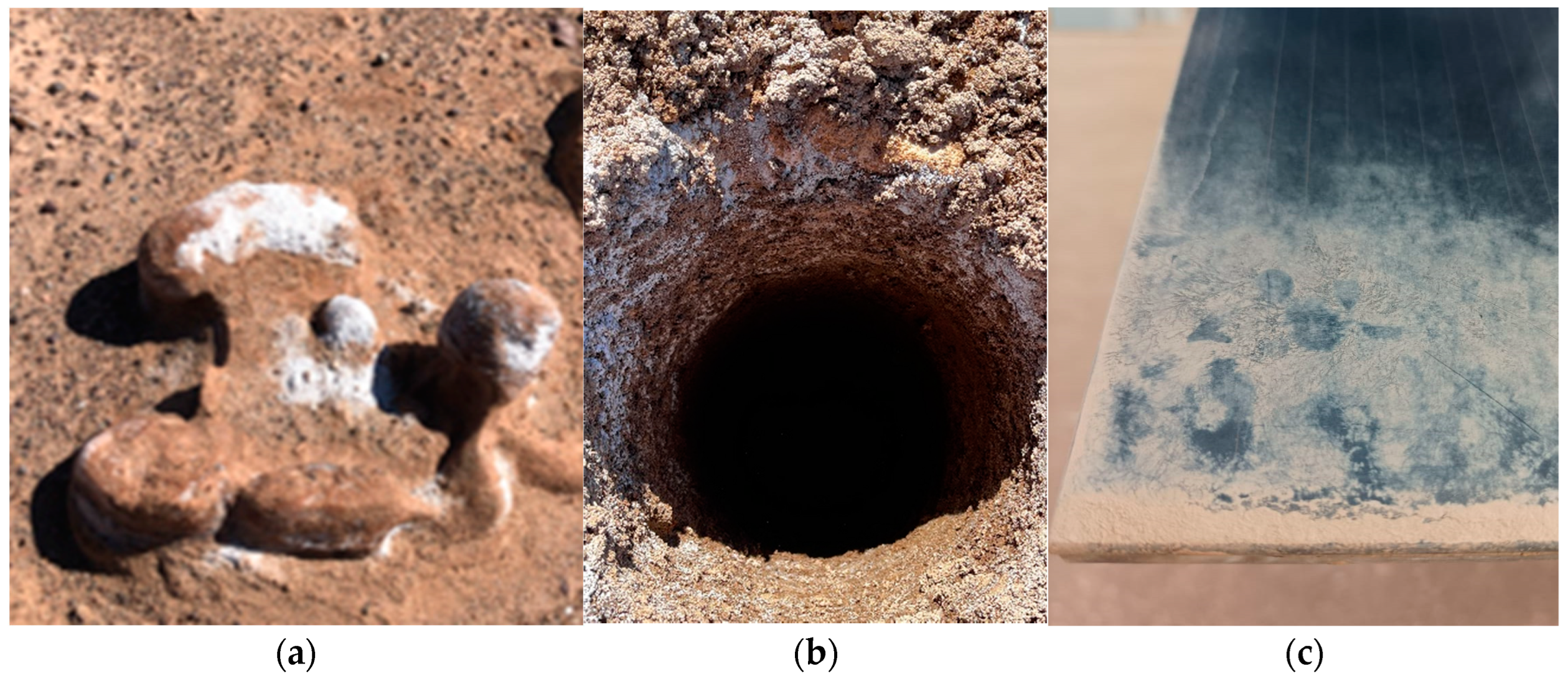

3.1. Stratigraphic Description

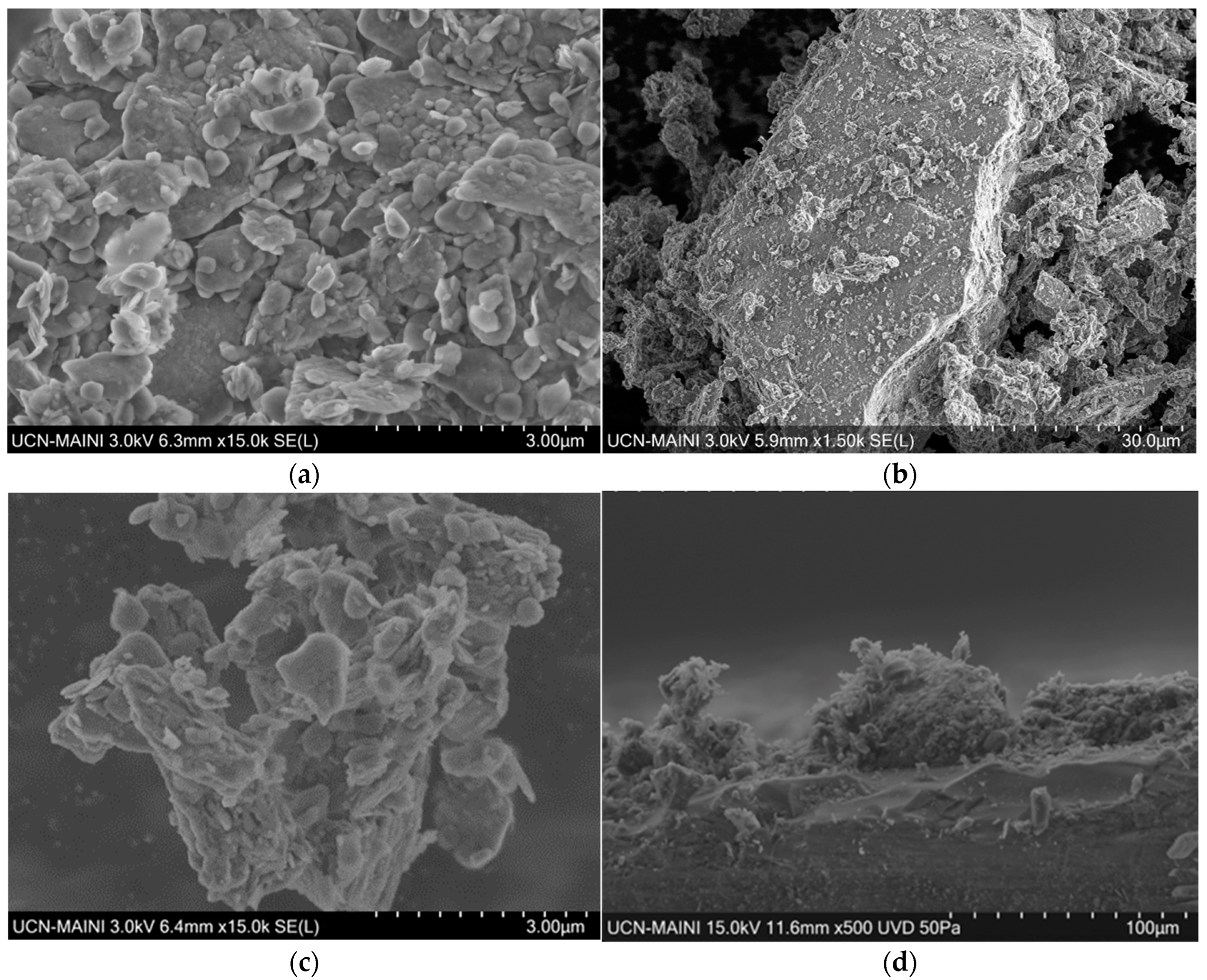

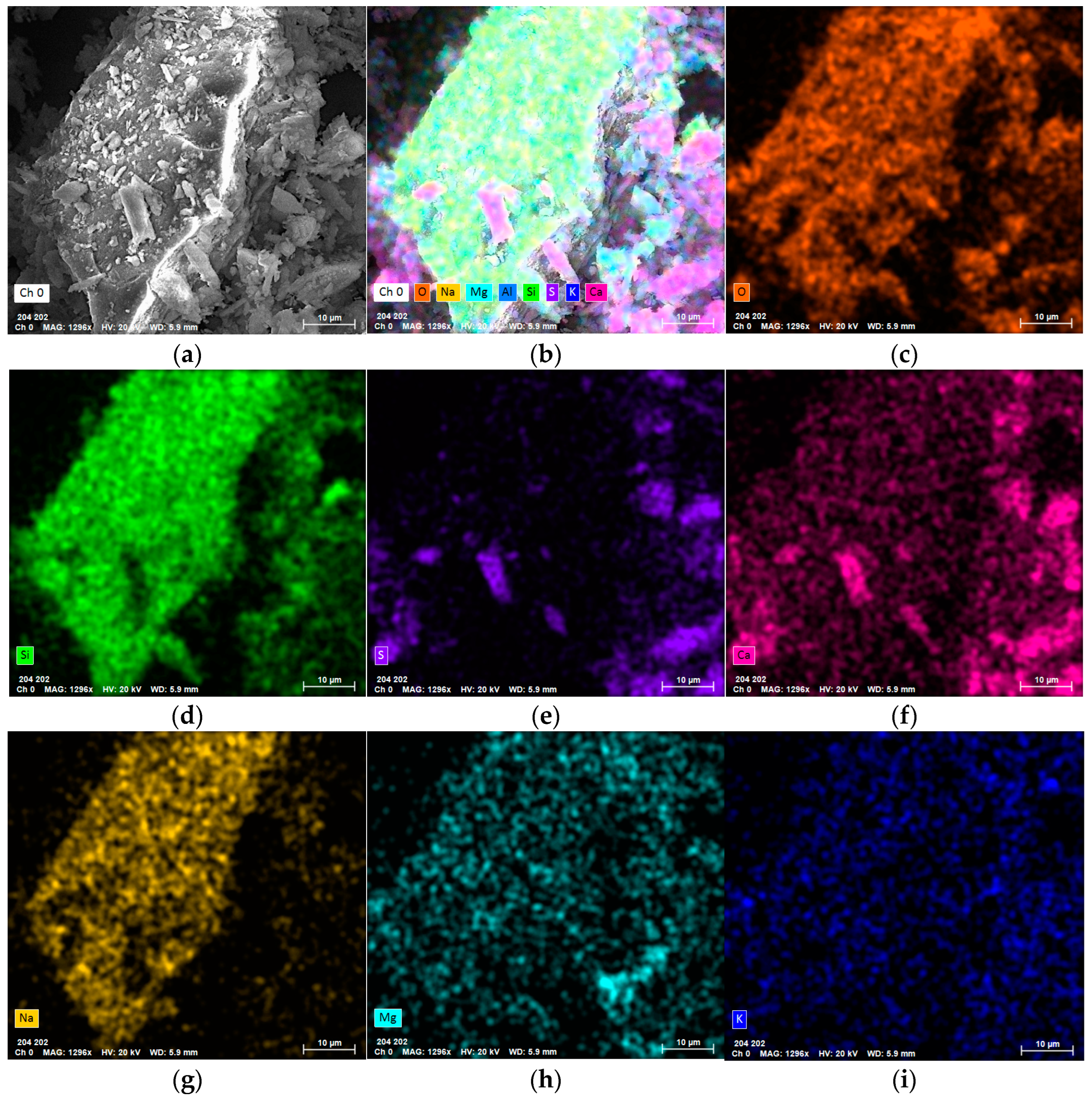

3.2. Microstructural Characterization

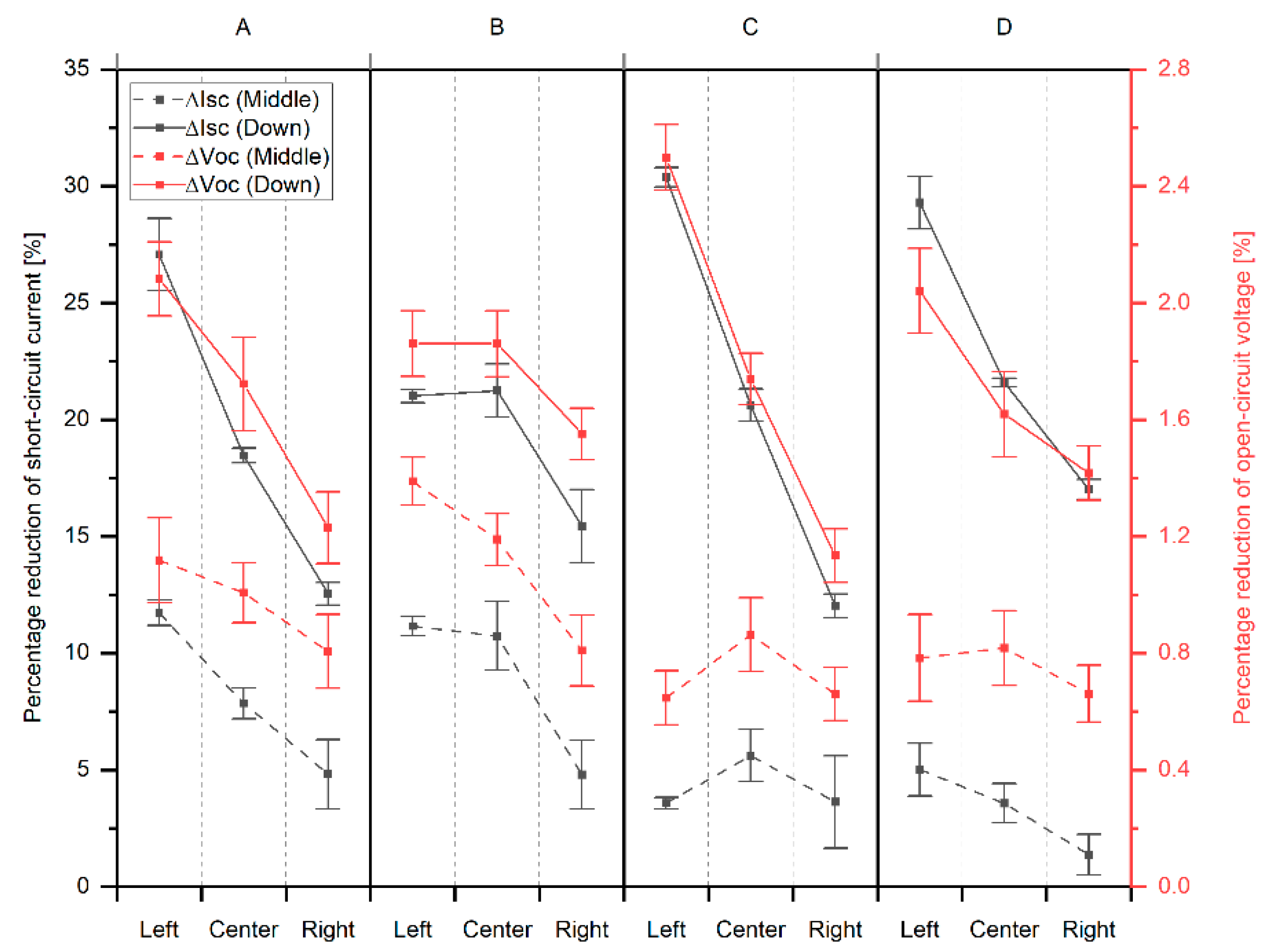

3.3. Non-Homogeneous Soiling Effects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zaihidee, F.M.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Dust as an unalterable deteriorative factor affecting PV panel’s efficiency: Why and how. Renew. Sustain. Energy Rev. 2016, 65, 1267–1278. [Google Scholar] [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R.; et al. Techno-Economic Assessment of Soiling Losses and Mitigation Strategies for Solar Power Generation. Joule 2019, 310, 2303–2321. [Google Scholar] [CrossRef] [Green Version]

- Priya, S.S.; Cuce, E.; Sudhakar, K. A perspective of COVID 19 impact on global economy, energy and environment. Int. J. Sustain. Eng. 2021, 14, 1290–1305. [Google Scholar] [CrossRef]

- Muñoz-García, M.Á.; Fouris, T.; Pilat, E. Analysis of the soiling effect under different conditions on different photovoltaic glasses and cells using an indoor soiling chamber. Renew. Energy 2021, 163, 1560–1568. [Google Scholar] [CrossRef]

- Hussain, N.; Shahzad, N.; Yousaf, T.; Waqas, A.; Hussain Javed, A.; Khan, S.; Ali, M.; Liaquat, R. Designing of homemade soiling station to explore soiling loss effects on PV modules. Sol. Energy 2021, 225, 624–633. [Google Scholar] [CrossRef]

- Olivares, D.; Marzo, A.; Ferrada, P.; Campo, V.; Llanos, J.; Pilat, E.; Muñoz, D.; Fuentealba, E. Characterization of Changes in the Soiling Properties and Deposition Rates Because of Groundworks Near a PV Plant in the Atacama Desert. In Proceedings of the Online Solar World Congress (SWC2021), International Solar Energy Society (ISES 2021), 25–29 October 2021; pp. 305–314. Available online: http://proceedings.ises.org/paper/swc2021/swc2021-0033-Olivares.pdf (accessed on 8 August 2022).

- Song, Z.; Liu, J.; Yang, H. Air pollution and soiling implications for solar photovoltaic power generation: A comprehensive review. Appl. Energy 2021, 298, 117247. [Google Scholar] [CrossRef]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Figgis, B.; Ennaoui, A.; Ahzi, S.; Rémond, Y. Review of PV soiling particle mechanics in desert environments. Renew. Sustain. Energy Rev. 2017, 76, 872–881. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol. Energy 2020, 203, 46–68. [Google Scholar] [CrossRef]

- Figgis, B.; Brophy, B. PV Coatings and Particle Adhesion Forces. In Conference Proceedings PV-Days Halle; 2015; Volume 20, pp. 1–9. Available online: https://scholar.google.com/scholar_lookup?title=PV%20coatings%20and%20particle%20adhesion%20forces&publication_year=2015&author=B.W.%20Figgis&author=B.%20Brophy (accessed on 8 August 2022).

- Wasim, J.; Bing, G.; Yiming, W.; Figgis, B. Photovoltaic performance degradation due to soiling and Characterization of the accumulated dust. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy (ICPRE) 2016, Shanghai, China, 21–23 October 2016; pp. 580–584. [Google Scholar] [CrossRef]

- Javed, W.; Wubulikasimu, Y.; Figgis, B.; Guo, B. Characterization of dust accumulated on photovoltaic panels in Doha, Qatar. Sol. Energy 2017, 142, 123–135. [Google Scholar] [CrossRef]

- Said, S.A.M.; Hassan, G.; Walwil, H.M.; Al-Aqeeli, N. The effect of environmental factors and dust accumulation on photovoltaic modules and dust-accumulation mitigation strategies. Renew. Sustain. Energy Rev. 2018, 82, 743–760. [Google Scholar] [CrossRef]

- Marzo, A.; Ferrada, P.; Beiza, F.; Besson, P.; Alonso-Montesinos, J.; Ballestrín, J.; Román, R.; Portillo, C.; Escobar, R.; Fuentealba, E. Standard or local solar spectrum? Implications for solar technologies studies in the Atacama desert. Renew. Energy 2018, 127, 871–882. [Google Scholar] [CrossRef]

- Gostein, M.; Marion, B.; Stueve, B. Spectral Effects in Albedo and Rearside Irradiance Measurement for Bifacial Performance Estimation. Conf. Rec. IEEE Photovolt. Spec. Conf. 2020, 2020, 0515–0519. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Olivares, D.; Ferrada, P.; Marzo, A.; Llanos, J.; Miranda-Ostojic, C.; del Campo, V.; Bravo, S.; Fuentealba, E. Microstructural analysis of the PV module cementation process at the Solar Platform of the Atacama Desert. Sol. Energy Mater. Sol. Cells 2021, 227, 111109. [Google Scholar] [CrossRef]

- White, W.A. Atterberg plastic limits of clay minerals. Am. Mineral. 1949, 34, 508–512. [Google Scholar]

- Ferrada, P.; Olivares, D.; del Campo, V.; Marzo, A.; Araya, F.; Cabrera, E.; Llanos, J.; Correa-Puerta, J.; Portillo, C.; Román Silva, D.; et al. Physicochemical characterization of soiling from photovoltaic facilities in arid locations in the Atacama Desert. Sol. Energy 2019, 187, 47–56. [Google Scholar] [CrossRef]

- Paudyal, B.R.; Shakya, S.R. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: A case study of Kathmandu. Sol. Energy 2016, 135, 103–110. [Google Scholar] [CrossRef]

- Sayyah, A.; Horenstein, M.N.; Mazumder, M.K. Energy yield loss caused by dust deposition on photovoltaic panels. Sol. Energy 2014, 107, 576–604. [Google Scholar] [CrossRef]

- Luo, W.; Khoo, Y.S.; Hacke, P.; Naumann, V.; Lausch, D.; Harvey, S.P.; Singh, J.P.; Chai, J.; Wang, Y.; Aberle, A.G.; et al. Potential-induced degradation in photovoltaic modules: A critical review. Energy Environ. Sci. 2017, 10, 43–68. [Google Scholar] [CrossRef]

- Curcio, J.A. Adsorption and Condensation of Water on Mirror and Lens Surfaces. NRL Memo. Rep. 1976, 3359, 5–21. [Google Scholar] [CrossRef]

- Ilse, K.; Werner, M.; Naumann, V.; Figgis, B.W.; Hagendorf, C.; Bagdahn, J. Microstructural analysis of the cementation process during soiling on glass surfaces in arid and semi-arid climates. Phys. Status Solidi—Rapid Res. Lett. 2016, 10, 525–529. [Google Scholar] [CrossRef]

- Kazmerski, L.L.; Diniz, A.S.A.C.; Maia, C.B.; Viana, M.M.; Costa, S.C.; Brito, P.P.; Campos, C.D.; De Morais Hanriot, S.; De Oliveira Cruz, L.R. Soiling particle interactions on PV modules: Surface and inter-particle adhesion and chemistry effects. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference, PVSC 2017, Washington, DC, USA, 25–30 June 2017; pp. 2551–2553. [Google Scholar]

- Ilse, K.K.; Rabanal, J.; Schönleber, L.; Khan, M.Z.; Naumann, V.; Hagendorf, C.; Bagdahn, J. Comparing indoor and outdoor soiling experiments for different glass coatings and microstructural analysis of particle caking processes. IEEE J. Photovolt. 2018, 8, 203–209. [Google Scholar] [CrossRef]

- Figgis, B.; Nouviaire, A.; Wubulikasimu, Y.; Javed, W.; Guo, B.; Ait-Mokhtar, A.; Belarbi, R.; Ahzi, S.; Rémond, Y.; Ennaoui, A. Investigation of factors affecting condensation on soiled PV modules. Sol. Energy 2018, 159, 488–500. [Google Scholar] [CrossRef]

- Cuddihy, E.F. Soiling mechanism and performance of anti-soiling surface coating. Part. Surfaces 1988, 1, 91–111. [Google Scholar] [CrossRef]

- Olivares, D.; Trigo-González, M.; Marzo, A.; Ferrada, P.; Llanos, J.; Araya, F.; López, G.; Polo, J.; Alonso-Montesinos, J.; Gueymard, C. Analysis of the local factors that influence the cementation of soil and effects on PV generation at the plataforma solar del desierto de atacama, Chile. In Proceedings of the ISES Solar World Congress, Santiago, Chile, 4–7 November 2019; pp. 1051–1060. [Google Scholar] [CrossRef]

- Bethea, R.M.; Barriger, M.T.; Williams, P.F.; Chin, S. Environmental effects on solar concentrator mirrors. Sol. Energy 1981, 27, 497–511. [Google Scholar] [CrossRef]

- Lin, J.; Zheng, Z.J.; Yu, J.L.; Bai, Y.L. A thin liquid film and its effects in an atomic force microscopy measurement. Chinese Phys. Lett. 2009, 26, 8–12. [Google Scholar] [CrossRef]

- Varga, H.F.; Wiesner, M.R. Relationship between Atomic Force Microscopy and Centrifugation Measurements for Dust Fractions Implicated in Solar Panel Soiling. Environ. Sci. Technol. 2022, 56, 9604–9612. [Google Scholar] [CrossRef] [PubMed]

- Ghazi, S.; Sayigh, A.; Ip, K. Dust effect on flat surfaces—A review paper. Renew. Sustain. Energy Rev. 2014, 33, 742–751. [Google Scholar] [CrossRef]

- Ghosh, A. Soiling Losses: A Barrier for India’s Energy Security Dependency from Photovoltaic Power. Challenges 2020, 11, 9. [Google Scholar] [CrossRef]

- Olivares, D.; Ferrada, P.; Bijman, J.; Rodríguez, S.; Trigo-González, M.; Marzo, A.; Rabanal-Arabach, J.; Alonso-Montesinos, J.; Batlles, F.J.; Fuentealba, E. Determination of the Soiling Impact on Photovoltaic Modules at the Coastal Area of the Atacama Desert. Energies 2020, 13, 3819. [Google Scholar] [CrossRef]

- Zefri, Y.; Elkettani, A.; Sebari, I.; Lamallam, S.A. Thermal infrared and visual inspection of photovoltaic installations by uav photogrammetry—Application case: Morocco. Drones 2018, 2, 41. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olivares, D.; Taquichiri, A.; Ferrada, P.; Marzo, A.; Henríquez, M.; Espinoza, D.; Fuentealba, E.; Llanos, J. Soil Characterization and Soiling Impact to Facilitate Photovoltaic Installation. Appl. Sci. 2022, 12, 10582. https://doi.org/10.3390/app122010582

Olivares D, Taquichiri A, Ferrada P, Marzo A, Henríquez M, Espinoza D, Fuentealba E, Llanos J. Soil Characterization and Soiling Impact to Facilitate Photovoltaic Installation. Applied Sciences. 2022; 12(20):10582. https://doi.org/10.3390/app122010582

Chicago/Turabian StyleOlivares, Douglas, Abel Taquichiri, Pablo Ferrada, Aitor Marzo, Mauro Henríquez, Darío Espinoza, Edward Fuentealba, and Jaime Llanos. 2022. "Soil Characterization and Soiling Impact to Facilitate Photovoltaic Installation" Applied Sciences 12, no. 20: 10582. https://doi.org/10.3390/app122010582