Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding

Abstract

:1. Introduction

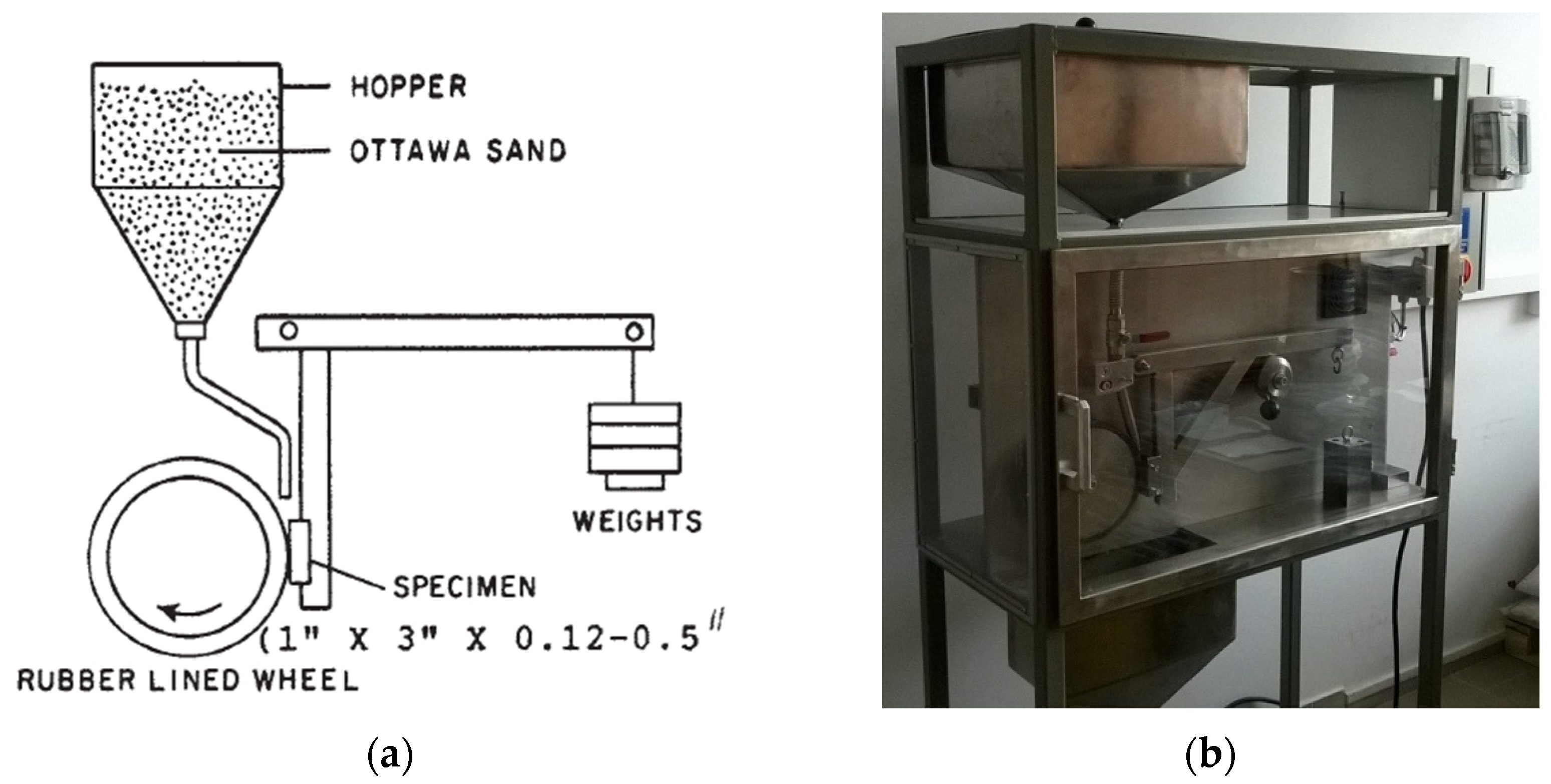

2. Materials and Methods

3. Results and Discussion

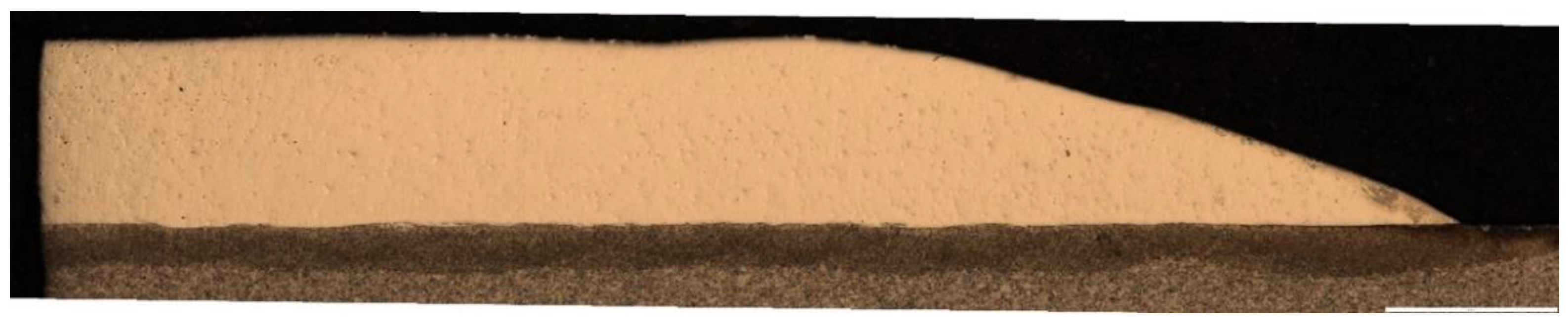

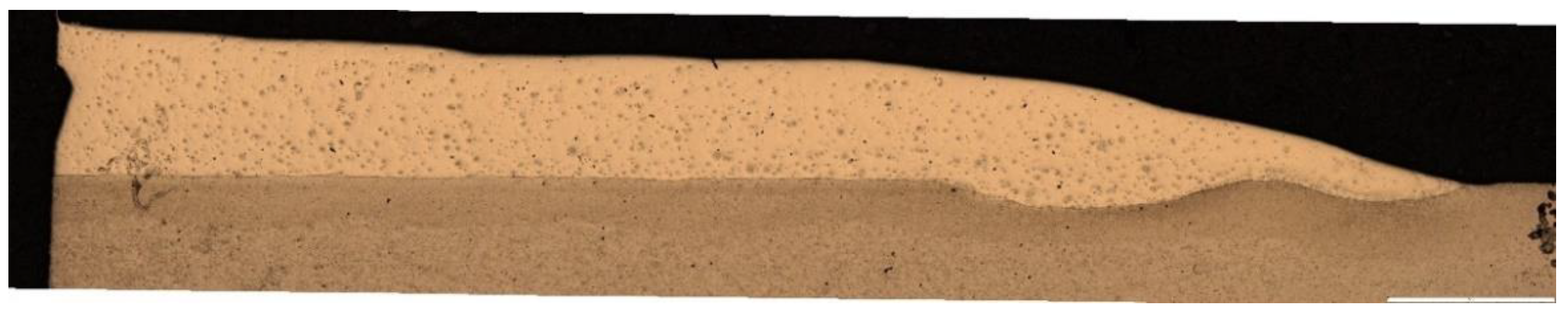

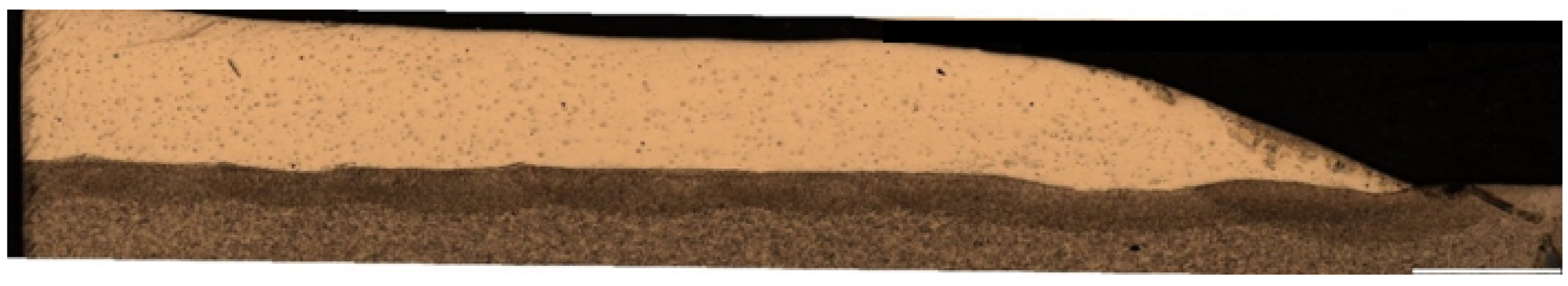

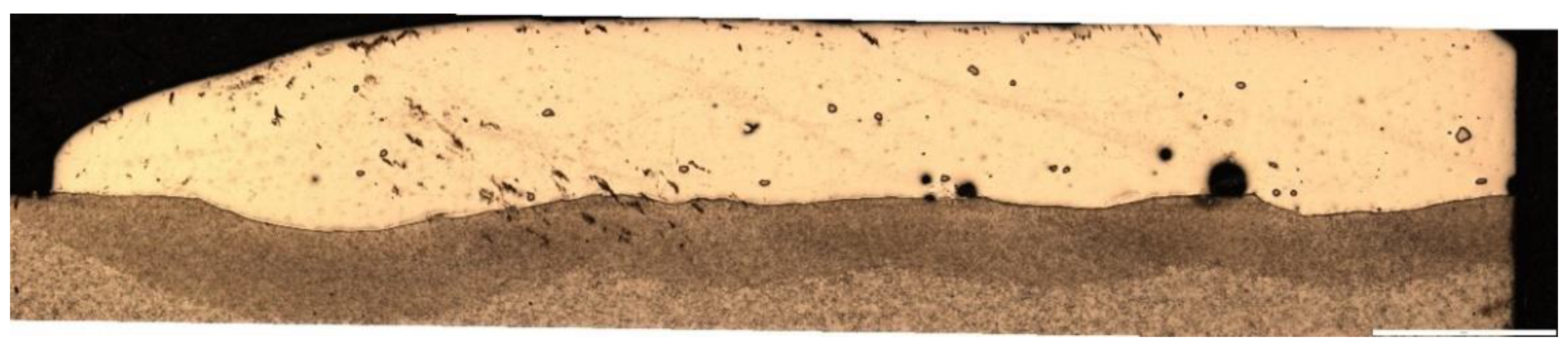

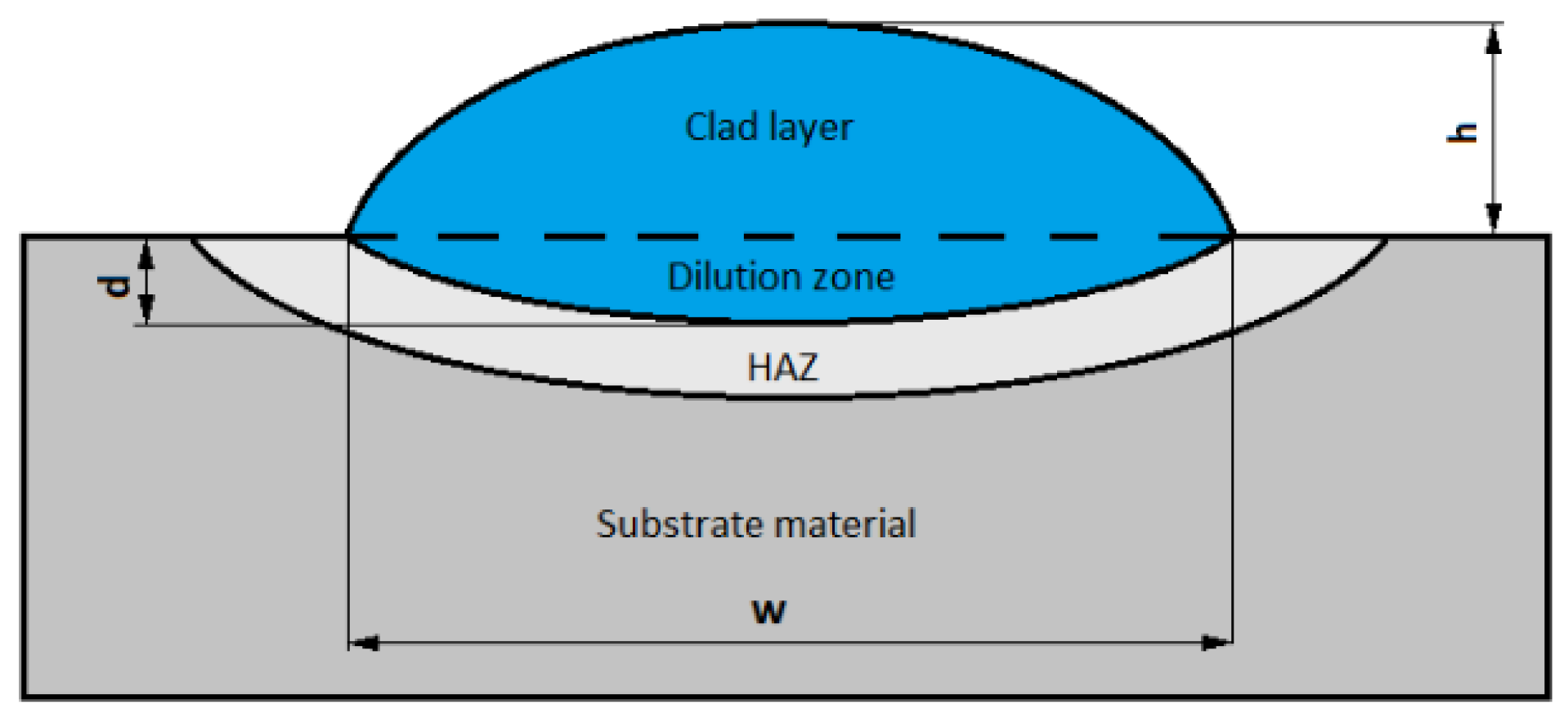

3.1. Metallographic Research

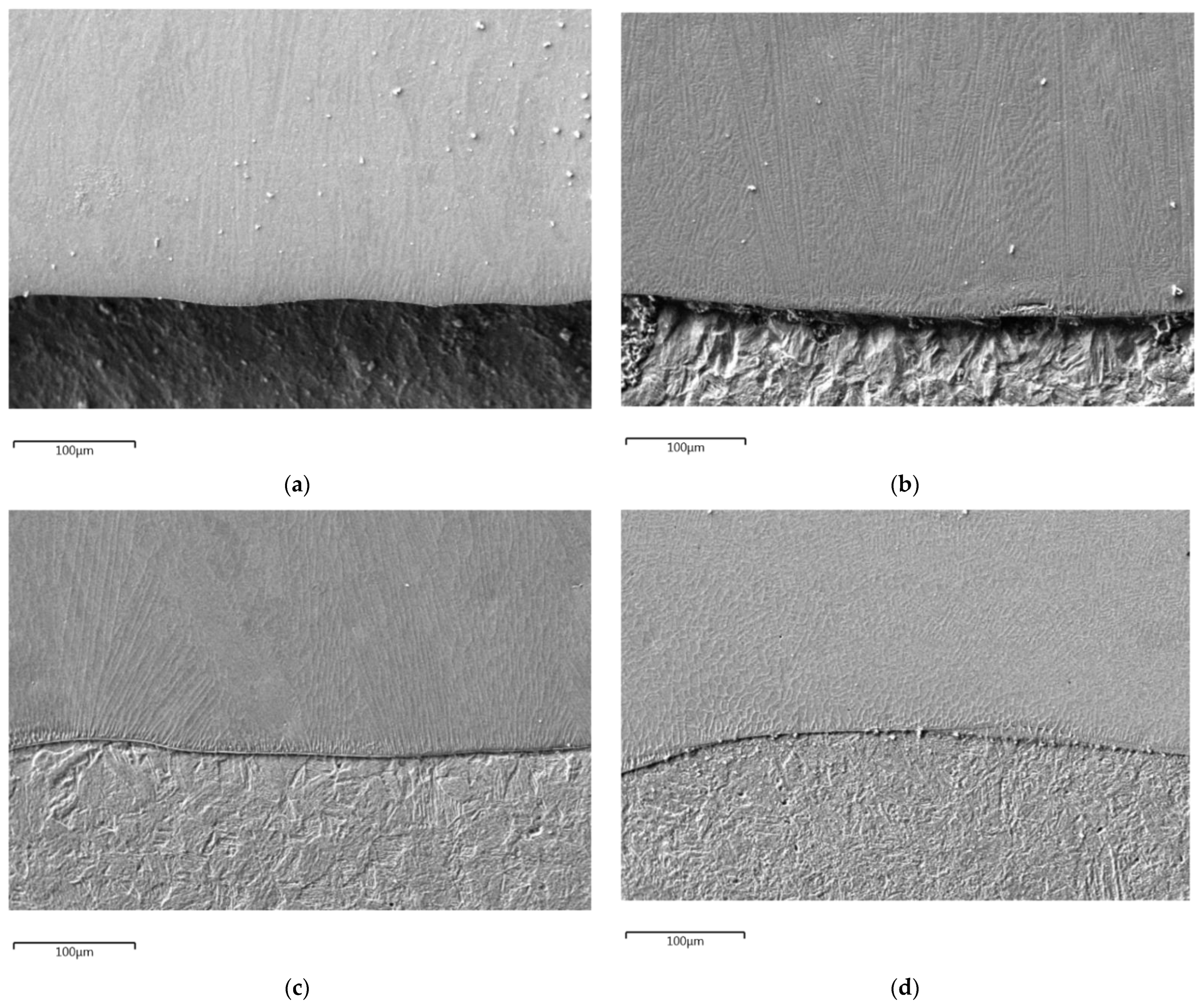

3.2. Coatings Characterization by Means of SEM and EDX

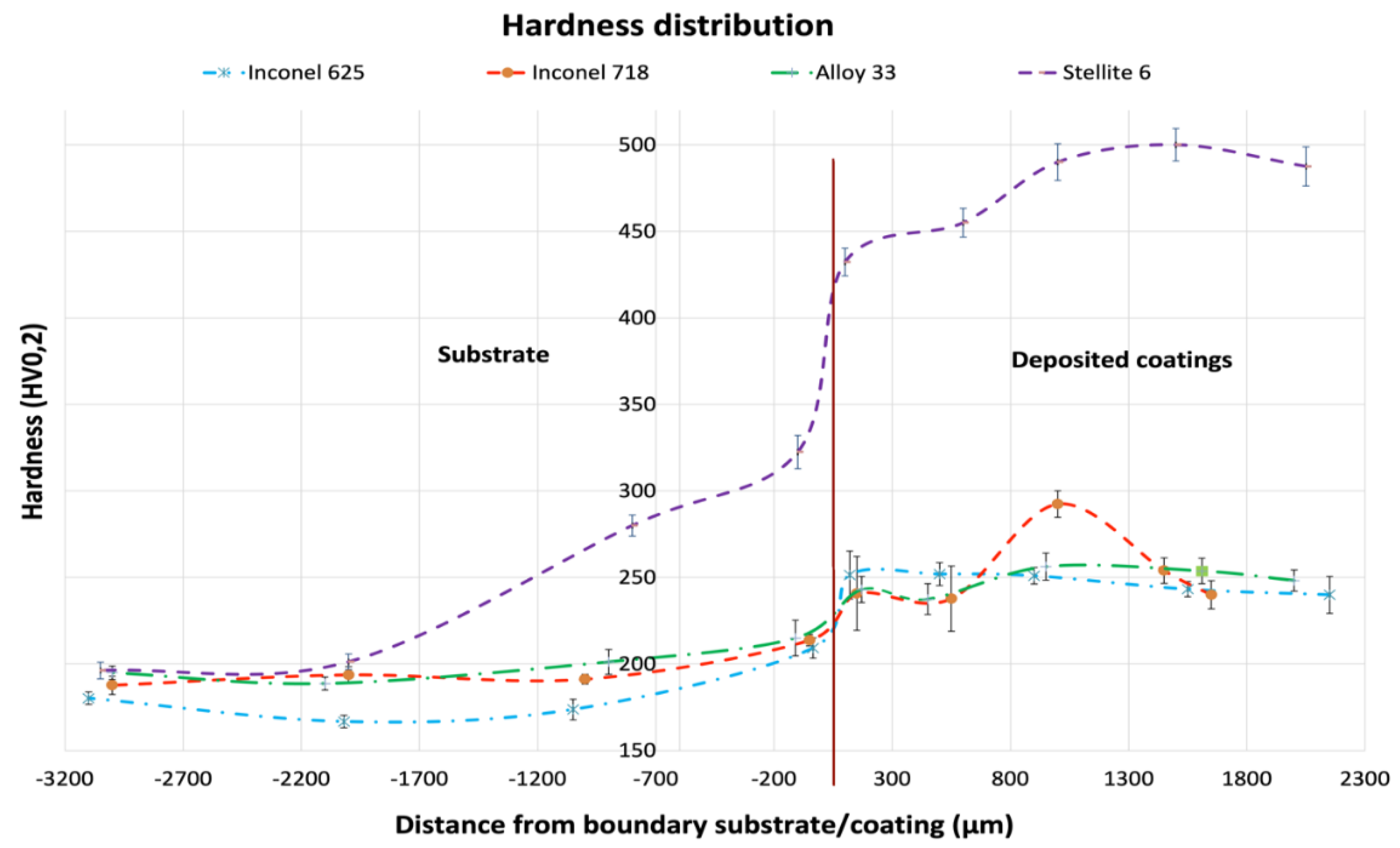

3.3. Hardness of the Coating-Substrate System

3.4. Wear Friction Resistance Test

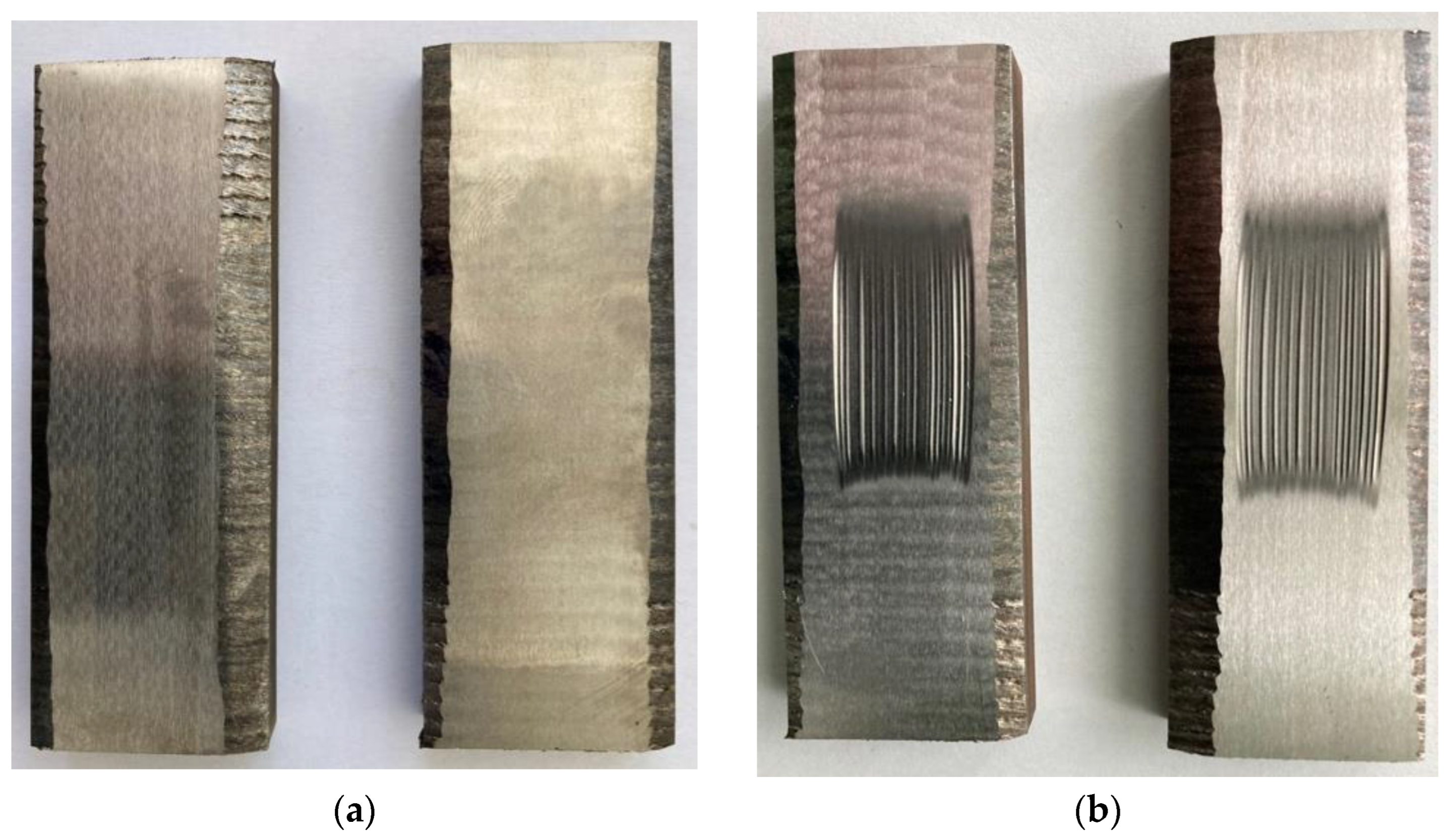

3.5. Wear Resistance under Abrasive Blasting

- Type and granulation of the abrasive: broken steel grit WGH 40 (according to ISO 11124-3) with a hardness of 60–68 HRC, with a homogeneous martensitic and/or bainitic microstructure, with fine, well-spaced carbides, nominal fraction 0.43 mm;

- Angle of incidence of the abrasive jet in relation to the sample surface—60°;

- Length of blasting jet: 100 mm;

- Diameter of pneumatic nozzle: 9 mm;

- Air pressure supplied to the nozzle: 4.3 bar (shown on the pressure gauge);

- Duration of the impact of the abrasive jet on the tested surface: six cycles, 10 s each.

4. Conclusions

- The use of the CMT hardfacing process enables the production of cladder welds with a minimal-volume fraction substrate material in coatings (small value of dilution), which results in high layer properties.

- Among the investigated coatings, Stellite 6 layer is the hardest, at about 500 HV0.2, compared to materials such as Inconel 625, Inconel 718 and Alloy 33, which represent a cladded zone hardness about 250 HV0.2.

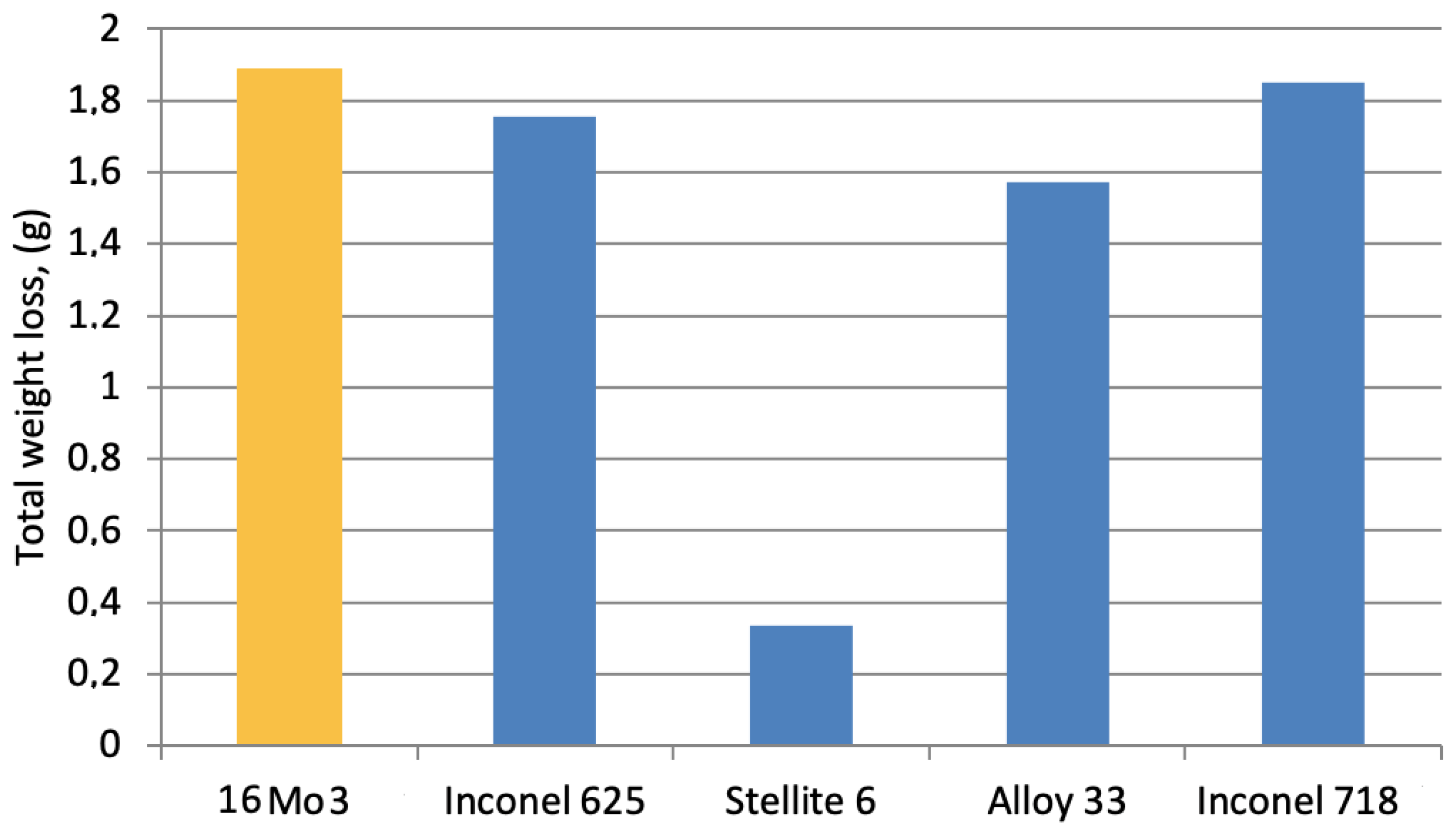

- Stellite 6 layer have the lowest wear resistance in the dry sand/rubber wheel test and the highest wear resistance in the erosive blasting test. This proves the existence of different wear mechanisms in the two test methods used.

- In the dry sand/rubber wheel test, Alloy 33 and Inconel 718 only represent higher wear resistance than substrate 16Mo3 steel.

- In the abrasive blasting tests all coatings have a higher wear resistance than 16Mo3 steel; however, Stellite 6 coatings represents an approximately 5 times higher durability than other investigated (Inconel 625, Inconel 718 and Alloy 33) coatings.

Author Contributions

Funding

Conflicts of Interest

References

- Lindar, T.; Günen, A.; Töberling, G.; Vogt, S.; Karakas, M.S.; Löbel, M.; Lampke, T. Boriding of Laser-Clad Inconel 718 Coatings for Enhanced Wear Resistance. Appl. Sci. 2021, 11, 11935. [Google Scholar] [CrossRef]

- Skowrońska, B.; Sokołowski, W.; Rostamian, R. Structural investigation of the Plasma Transferred Arc hardfaced glass mold after operation. Weld. Technol. Rev. 2020, 92, 55–56. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, M.; Handa, A. Combating hot corrosion of boiler tubes—A study. Eng. Fail. Anal. 2018, 94, 379–395. [Google Scholar] [CrossRef]

- Szala, M.; Chocyk, D.; Skic, A.; Kamiński, M.; Macek, W.; Turek, M. Effect of nitrogen ion implantation on the cavitation erosion resistance and cobalt-based solid solution phase transformations of HIPed stellite 6. Materials 2021, 14, 2324. [Google Scholar] [CrossRef] [PubMed]

- Fabijański, M. Effect of calcium carbonate addition on mechanical properties of polylactide. Przem. Chem. 2017, 96, 894–896. [Google Scholar] [CrossRef]

- Włosiński, W.; Krajewski, A.; Piekoszewski, J.; Stanisławski, J.; Waliś, L. Intense pulsed plasma beams in ceramic/metal brazing. Nukleonika 2000, 45, 145–146. [Google Scholar]

- Bober, M.; Senkara, J.; Li, H. Comparative analysis of the phase interaction in plasma surfaced nibsi overlays with ivb and vib transition metal carbides. Materials 2021, 14, 6617. [Google Scholar] [CrossRef]

- Chmielewski, T.; Golański, D.; Hudycz, M.; Sałacinski, T.; Świercz, R. Surface and structural properties of titanium coating deposited onto aln ceramics substrate by friction surfacing process. Przem. Chem. 2019, 98, 208–213. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Golanski, D.; Chmielewski, T.; Chmielewski, M. Microstructure of rhenium doped ni-cr deposits produced by laser cladding. Materials 2021, 14, 2745. [Google Scholar] [CrossRef]

- Chmielewski, T.; Chmielewski, M.; Piątkowska, A.; Grabias, A.; Skowrońska, B.; Siwek, P. Phase structure evolution of the fe-al arc-sprayed coating stimulated by annealing. Materials 2021, 14, 3210. [Google Scholar] [CrossRef]

- Chmielewski, T.; Hudycz, M.; Krajewski, A.; Salaciński, T.; Skowrońska, B.; Świercz, R. Structure investigation of titanium metallization coating deposited onto AlN ceramics substrate by means of friction surfacing process. Coatings 2019, 9, 845. [Google Scholar] [CrossRef] [Green Version]

- Winczek, J.; Gucwa, M.; Mičian, M.; Koňár, R.; Parzych, S. The evaluation of the wear mechanism of high-carbon hardfacing layers. Arch. Metall. Mater. 2019, 64, 1111–1115. [Google Scholar] [CrossRef]

- Górka, J.; Czupryński, A.; Zuk, M.; Adamiak, M.; Kopyść, A. Properties and structure of deposited nanocrystalline coatings in relation to selected construction materials resistant to abrasive wear. Materials 2018, 11, 1184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tomków, J.; Czupryński, A.; Fydrych, D. The Abrasive Wear Resistance of Coatings Manufactured on High-Strength Low-Alloy (HSLA) Offshore Steel in Wet Welding Conditions. Coatings 2020, 10, 219. [Google Scholar] [CrossRef] [Green Version]

- Xin, B.; Ren, J.; Wang, X.; Zhu, L.; Gong, Y. Effect of laser remelting on cladding layer of inconel 718 superalloy formed by laser metal deposition. Materials 2020, 13, 4927. [Google Scholar] [CrossRef]

- Arbo, S.M.; Tomovic-Petrovic, S.; Aunemo, J.; Dahle, N.; Jensrud, O. On weldability of aerospace grade Al-Cu-Li alloy AA2065 by wire-feed laser metal deposition. J. Adv. Join. Process. 2022, 5, 100096. [Google Scholar] [CrossRef]

- Meng, L.; Zeng, X.; Hou, K.; Hu, Q.; Wang, D. Effect of laser cladding and laser-induction hybrid cladding coatings on the bending properties and fracture behavior of rails. Surf. Coat. Technol. 2019, 374, 1038–1050. [Google Scholar] [CrossRef]

- Grzybicki, M.; Jakubowski, J. Comparative tests of steel car body sheet welds made using CMT and MIG/MAG methods. Weld. Int. 2013, 27, 610–615. [Google Scholar] [CrossRef]

- Brezinová, J.; Džupon, M.; Viňáš, J.; Guzanová, A.; Puchý, V.; Brezina, J.; Draganovská, D.; Vojtko, M. Progressive CMT cladding for renovation of casting mold. Acta Metall. Slovaca 2020, 26, 104–110. [Google Scholar] [CrossRef]

- Imoudu, N.E.; Ayele, Y.Z.; Barabadi, A. The characteristic of cold metal transfer (CMT) and its application for cladding. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 10–13 December 2017; pp. 1883–1887. [Google Scholar]

- Yu, W.; Tao, K.; Dai, Z.; Zhang, Y.; Chu, X. Failure Mechanism of Water Wall Coating Prepared by Supersonic Arc Spraying. J. Phys. Conf. Ser. 2022, 2168, 012019. [Google Scholar] [CrossRef]

- Broda, T.; Keitel, S. Resistance seam hardfacing and cladding of WC-Co in a NiCrBSi-Matrix. Weld. Technol. Rev. 2015, 88, 45–49. [Google Scholar] [CrossRef]

- Wegrzyn, T.; Piwnik, J.; Wszolek, L.; Tarasiuk, W. Shaft wear after surfacing with microjet cooling. Arch. Metall. Mater. 2015, 60, 2625–2630. [Google Scholar] [CrossRef]

- Klimpel, A. Industrial surfacing and hardfacing technology, fundamentals and applications. Weld. Technol. Rev. 2020, 91, 33–42. [Google Scholar] [CrossRef] [Green Version]

- Lankiewicz, K.; Baranowski, M.; Babul, T.; Kowalski, S. The study of the impact of surface preparation methods of inconel 625 and 718 nickel-base alloys on wettability by BNi-2 and BNi-3 brazing filler metals. Arch. Metall. Mater. 2015, 60, 159–165. [Google Scholar] [CrossRef] [Green Version]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Nandan, G.; Kumar, G.; Arora, K.S.; Kumar, A. MIG and CMT brazing of aluminum alloys and steel: A review. Mater. Today Proc. 2022, 56, 481–488. [Google Scholar] [CrossRef]

- Medvedovski, E.; Chinski, F.A.; Stewart, J. Wear- and corrosion-resistant boride-based coatings obtained through thermal diffusion CVD processing. Adv. Eng. Mater. 2014, 16, 713–738. [Google Scholar] [CrossRef]

- Doering, A.; Danks, D.; Mahmoud, S.; Scott, J. Evaluation of ASTM G65 abrasive -Spanning 13 years of sand. Wear 2011, 271, 1252–1257. [Google Scholar] [CrossRef]

- Kik, T.; Moravec, J.; Novakova, I. Numerical simulations of X22CrMoV12-1 steel multilayer welding. Arch. Metall. Mater. 2019, 64, 1441–1448. [Google Scholar] [CrossRef]

- Kik, T.; Moravec, J.; Nováková, I. Application of Numerical Simulations on 10GN2MFA Steel Multilayer Welding. In Proceedings of the Springer Proceedings in Mathematics and Statistics; 2018; Volume 249, pp. 193–204. [Google Scholar] [CrossRef]

- Sauraw, A.; Sharma, A.K.; Fydrych, D.; Sirohi, S.; Gupta, A.; Świerczyńska, A.; Pandey, C.; Rogalski, G. Study on microstructural characterization, mechanical properties and residual stress of gtaw dissimilar joints of p91 and p22 steels. Materials 2021, 14, 6591. [Google Scholar] [CrossRef]

- Chand, N.; Neogi, S. Mechanism of material removal during three-body abrasion of FRF composite. Tribol. Lett. 1998, 4, 81. [Google Scholar] [CrossRef]

- Singh, T.P.; Singla, A.K.; Singh, J.; Singh, K.; Gupta, M.K.; Ji, H.; Song, Q.; Liu, Z.; Pruncu, C.I. Abrasive wear behavior of cryogenically treated boron steel (30MnCrB4) used for rotavator blades. Materials 2020, 13, 436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Process Parameters | Unit | INCONEL 718 | INCONEL 625 | ALLOY 33 | STELLITE 6 |

|---|---|---|---|---|---|

| Travel speed | mm/min | 26 | 24 | 33 | 14 |

| Rotational speed of cladded pipe | RPM | 13.1 | 14.5 | 12.7 | 7.2 |

| Welding current | A | 243 | 245 | 256 | 245 |

| Welding arc voltage | V | 20.5 | 20 | 20.5 | 19 |

| Wire feed rate | m/min | 9.5 | 10.5 | 10.6 | 10.5 |

| Gas flow rate | L/min | 15 | 14.5 | 15 | 14 |

| Wire diameter | mm | 1.2 | 1.2 | 1.2 | 1.2 |

| Shielding gas | - | Ar | Ar | Ar | Ar |

| Process Parameters | Unit | INCONEL 718 | INCONEL 625 | ALLOY 33 | STELLITE 6 |

|---|---|---|---|---|---|

| Travel speed | mm/min | 26 | 24 | 33 | 14 |

| Rotational speed of cladded pipe | RPM | 13.1 | 14.5 | 12.7 | 7.2 |

| Welding current | A | 250 | 250 | 250 | 250 |

| Gas flow rate | L/min | 16 | 16 | 16 | 16 |

| Shielding gas | - | Ar | Ar | Ar | Ar |

| Coating Material | Coating Thickness, h (mm) | Dilution, D (%) |

|---|---|---|

| Inconel 625 | 2.2 (0.15) | 1.47 |

| Inconel 718 | 1.7 (0.22) | 6.55 |

| Alloy 33 | 2.06 (0.17) | 3.74 |

| Stellite 6 | 2.1 (0.13) | 5.51 |

| Coating Material | Ni | Cr | Mo | Co | C | Mn | Si | Fe | Ti | Al | W | Nb + Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 625 | ||||||||||||

| nominal | base (63.43) | 20 ÷ 23 | 8 ÷ 10 | 0 ÷ 1 | 0 ÷ 0.1 | 0 ÷ 0.5 | 0 ÷ 0.5 | 0 ÷ 1 | 0 ÷ 0.4 | 0 ÷ 0.4 | - | 3.15 ÷ 4.15 |

| cladded coating | 1.93 | 9.42 | - | 0.1 | - | - | 0.81 | 0.23 | 0.17 | - | 3.94 | |

| Inconel 718 | ||||||||||||

| nominal | 50 ÷ 55 (50.68) | 17 ÷ 21 | 2.8–3.3 | 0 ÷ 1 | 0 ÷ 0.08 | 0 ÷ 0.35 | 0 ÷ 0.35 | 18 | 0.65 ÷ 1.15 | 0.2 ÷ 0.8 | - | 4.75 ÷ 5.5 |

| cladded coating | 17.49 | 3.22 | - | 0.08 | - | 0.02 | 21.45 | (0.92) | 0.49 | - | 5.5 | |

| Alloy 33 | ||||||||||||

| nominal | 30 ÷ 33 (29.04) | 31 ÷ 35 | - | - | 0 ÷ 015 | 0 ÷ 2 | 0 ÷ 0.5 | Rest | - | - | - | - |

| cladded coating | 32.34 | 1.7 | - | 0.01 | 0.6 | 0.2 | 35.33 | - | - | - | - | |

| Stellite 6 | ||||||||||||

| nominal | 2.5 | 28.92 | 0.013 | rest | 1.38 | 1.56 | 0.92 | 4.19 | - | - | 3.9 | - |

| cladded coating | 27.55 | 1.2 | 1.1 | 0.92 | 13.14 | - | - | 4.31 | - |

| Material | Sample No. | Weight before Test, (g) | Weight after Test, (g) | Loss of Weight ∆g, (g) | Average Value ∆g, (g) | Relative 1 Abrasion Resistance |

|---|---|---|---|---|---|---|

| 16Mo3 | 1 2 | 85.489 83.369 | 84.865 82.764 | 0.624 0.605 | 0.6145 | 0.90 |

| Alloy 33 | 1 2 | 109.992 112.522 | 109.436 111.966 | 0.556 0.556 | 0.556 | 1.0 |

| Inconel 718 | 1 2 | 120.581 114.15 | 120.007 113.611 | 0.574 0.539 | 0.5565 | 0.99 |

| Inconel 625 | 1 2 | 110.885 117.208 | 110.26 116.577 | 0.625 0.631 | 0.628 | 0088 |

| Stellite 6 | 1 2 | 116.431 108.292 | 115.575 107.413 | 0.856 0.879 | 0.8675 | 0.64 |

| Material | Starting Weight (g) | Loss of Weight after the Next Machining Cycle | Total Weight Loss (g) | Relative 1 Abrasion Resistance | |||||

|---|---|---|---|---|---|---|---|---|---|

| 10 s | 20 s | 30 s | 40 s | 50 s | 60 s | ||||

| 16Mo3 | 348.258 | 347.962 | 347.641 | 347.29 | 346.997 | 346.997 | 346.374 | 1.884 | 0.17 |

| Inconel 625 | 387.205 | 386.929 | 386.636 | 386.337 | 386.045 | 385.75 | 385.451 | 1.754 | 0.19 |

| Stellite 6 | 393.318 | 393.251 | 393.192 | 393.129 | 393.075 | 393.023 | 392.983 | 0.335 | 1 |

| Alloy 33 | 396.202 | 395.994 | 395.719 | 395.453 | 395.174 | 394.898 | 394.628 | 1.574 | 0.21 |

| Inconel 718 | 457.531 | 457.315 | 456.952 | 456.638 | 456.31 | 456.001 | 455.681 | 1.85 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. https://doi.org/10.3390/app12094568

Kołodziejczak P, Bober M, Chmielewski T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Applied Sciences. 2022; 12(9):4568. https://doi.org/10.3390/app12094568

Chicago/Turabian StyleKołodziejczak, Paweł, Mariusz Bober, and Tomasz Chmielewski. 2022. "Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding" Applied Sciences 12, no. 9: 4568. https://doi.org/10.3390/app12094568

APA StyleKołodziejczak, P., Bober, M., & Chmielewski, T. (2022). Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Applied Sciences, 12(9), 4568. https://doi.org/10.3390/app12094568