The Numerical Study for the Effect of Stiffness Matching on Wheel–Rail Curve Squeal Noise

Abstract

:1. Introduction

- We establish a finite element dynamics model of a wheel-ballastless track system for small-radius curve sections. The finite element model includes a wheel, rail, fastener system, and track plate to simulate the force characteristics of a ballastless track system to the maximum extent. By analyzing the characteristics of wheel–rail sliding friction vibration under the condition of transverse creep force saturation, the stability of the system is judged and the occurrence trend of wheel–rail curve squeal noise is predicted.

- We explain the process of self-excited vibration of the wheel–rail system based on the modal coupling theory. According to the modal characteristics of the unstable modes in the system, combining the modal coupling theory, the causes of the system instability are analyzed, and the mode shape and frequency of unstable modes of the wheel–rail system are explained. The curve squeal noise is mainly caused by the vibration at the rim, railhead, and rail foot.

- This study explores the wheel–rail stiffness matching problem from the perspective of material stiffness and constraint stiffness respectively and analyzes the influence of both on the occurrence trend of curve squeal noise. The results show that the selection of suitable wheel–rail stiffness matching parameters can suppress squeal noise.

2. Methodology

2.1. Theoretical Modal Analysis

2.2. Finite Element Complex Eigenvalue Analysis of Wheel–Rail System

2.3. Theoretical Approach Analytical Framework

3. Results

3.1. Establishment and Verification of Complex Modal Analysis Model for Wheel–Rail System

3.1.1. Establishment of Complex Modal Analysis of Wheel–Rail System

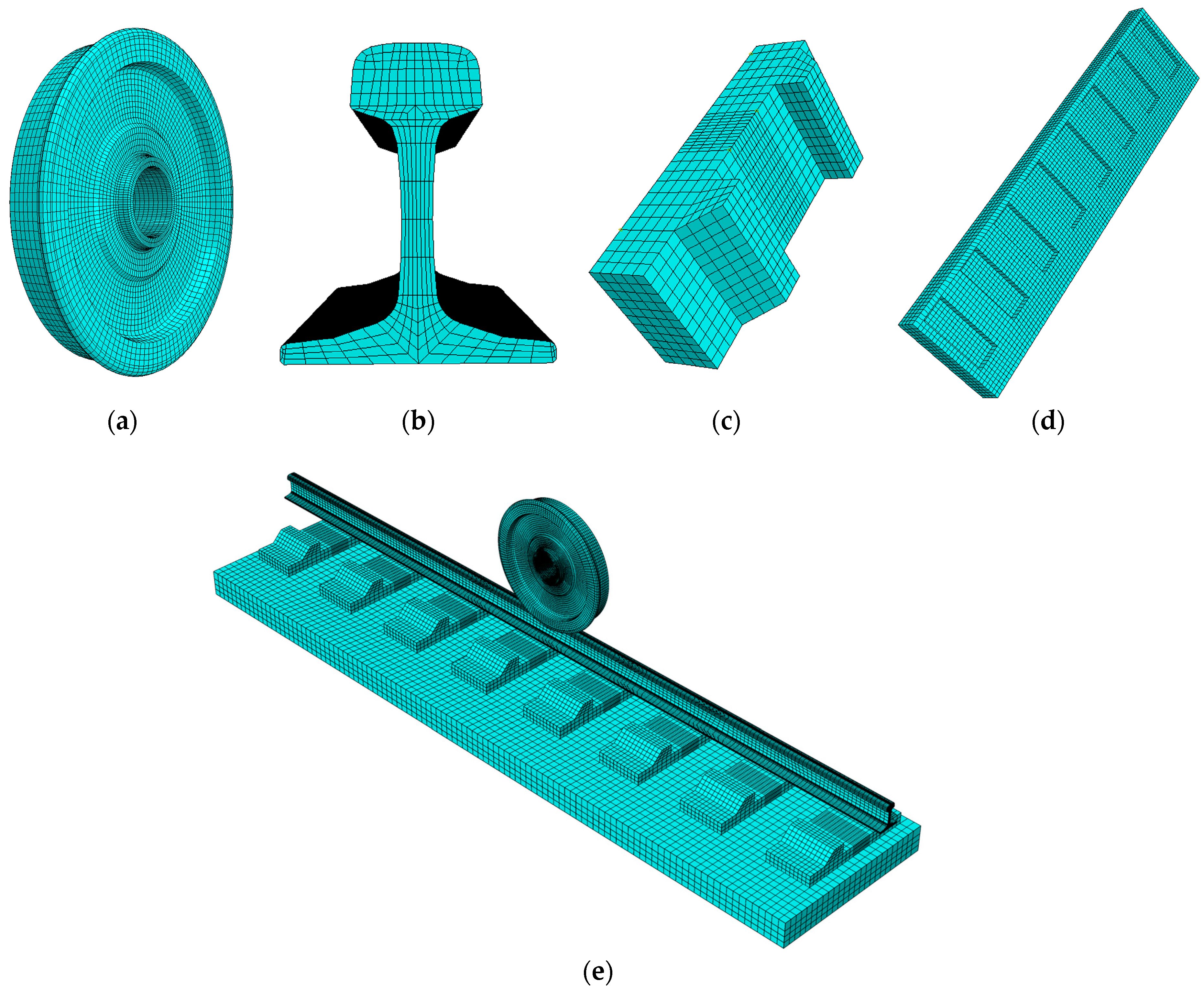

- Finite element model of a wheel–rail system. Software Solidworks 2020 is used to geometrically model the wheel, rail, sleeper, and track plate, and is geometrically cleaned in software Hypermesh 2020 and meshed by 8-node hexahedral incompatible element (C3D8I); the finite element model of each part is imported into software ABAQUS 2022, and each part is assembled according to the actual action relationship. The finite element model of the wheel–rail system and each part is shown in Figure 2. The sliding process of the wheel is pure sliding, and the sliding friction is Coulomb friction with a constant friction coefficient.

- 2.

- Defining material properties. Define the material properties of each structure specifically as shown in Table 1.

- 3.

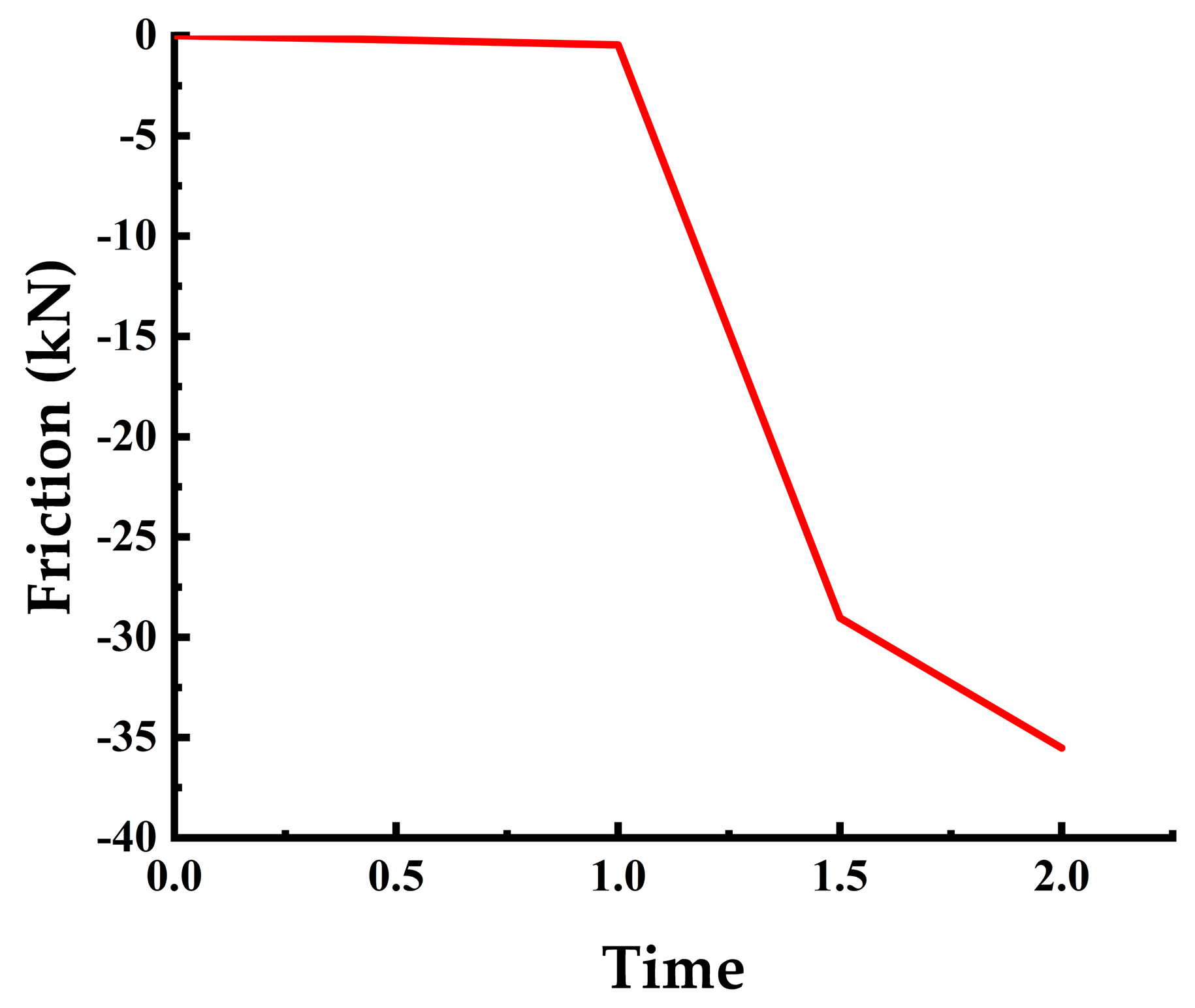

- Analysis step settings. Four analysis steps are defined: the first one applies the normal load, the second one introduces the transverse sliding between the wheel and rail, and the last two analysis steps extract the real modes and complex modes.

- 4.

- Connection relationship settings. The contact relationship between wheel and rail is simulated by “Surf-to-Surf Contact”, the rigid connection between wheel and axle is simulated by “MPC-Beam”, and the fastener system between rail and sleeper is simulated by “Spring”.

- 5.

- Determining the solution condition setting. Considering that this model is a system stability analysis of a unilateral wheel–rail, for the track plate, six degrees of freedom (three translational degrees of freedom and three rotational degrees of freedom) are restricted in the symmetry plane and the bottom plane; for the rail, three translational degrees of freedom are restricted in both end faces; for the wheel, the longitudinal and lateral translational degrees of freedom are initially restricted and the vertical load of 90 kN is applied to it, but the wheel can slide, and the sliding effect of the wheel in the second analysis step is added in Keywords.

3.1.2. Verification of Complex Modal Analysis Model for Wheel–Rail System

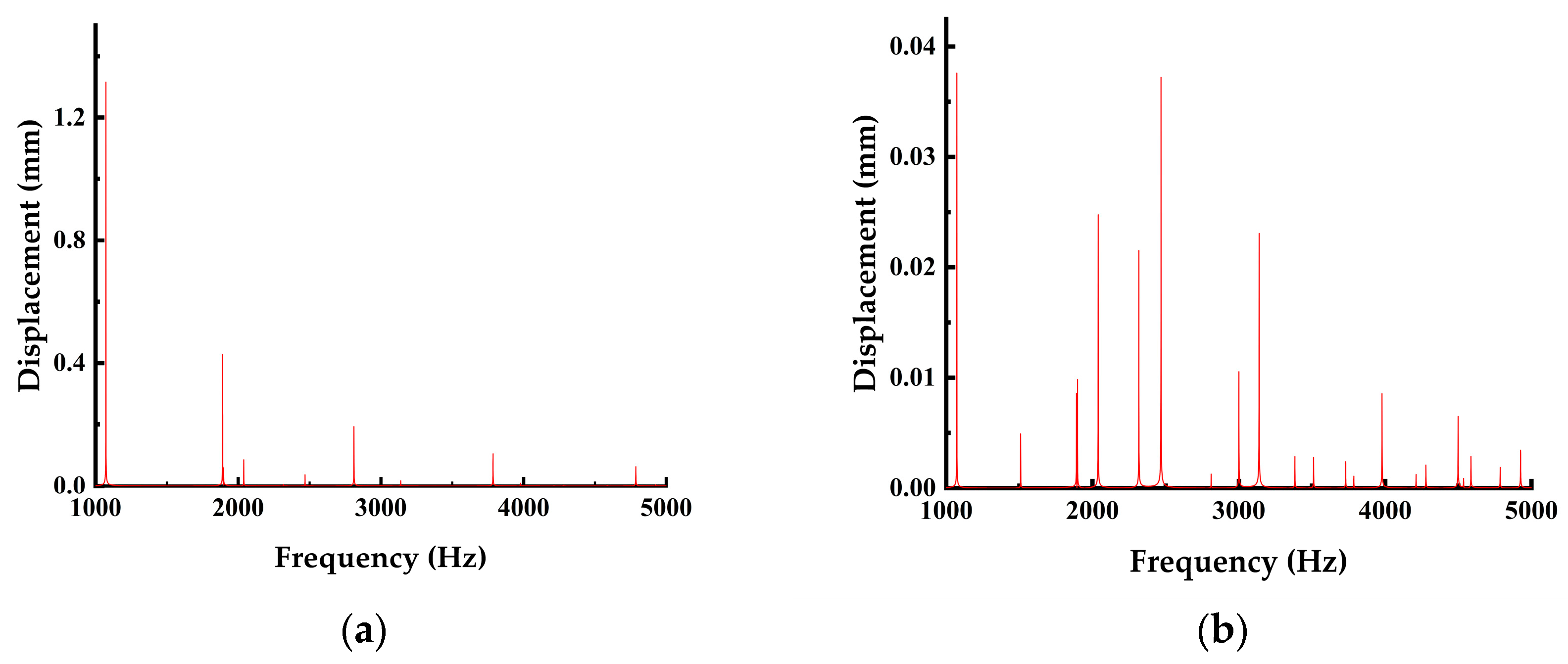

3.2. Frequency Response Analysis of Wheel and Rail

3.2.1. Modal Analysis of Wheel

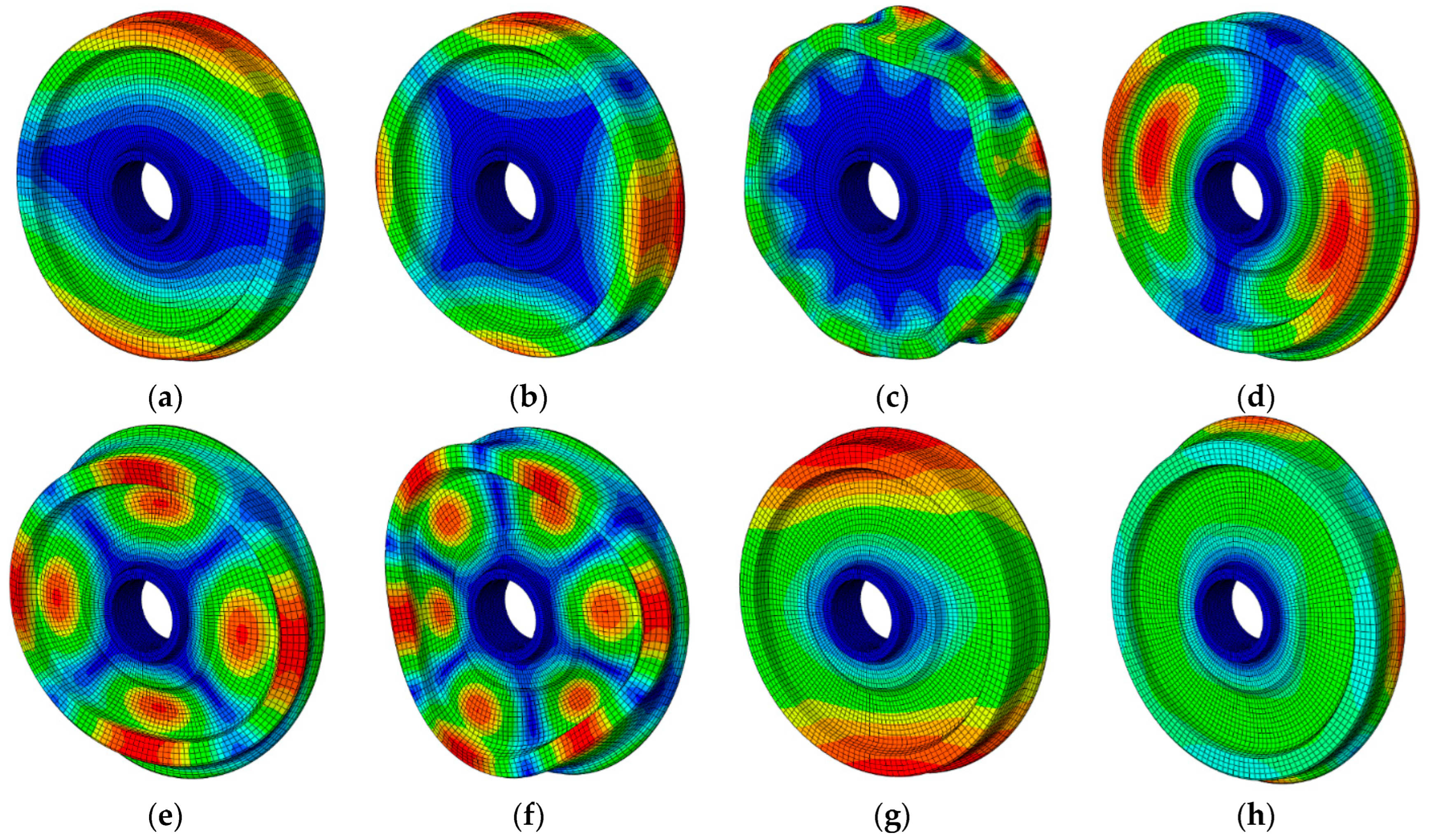

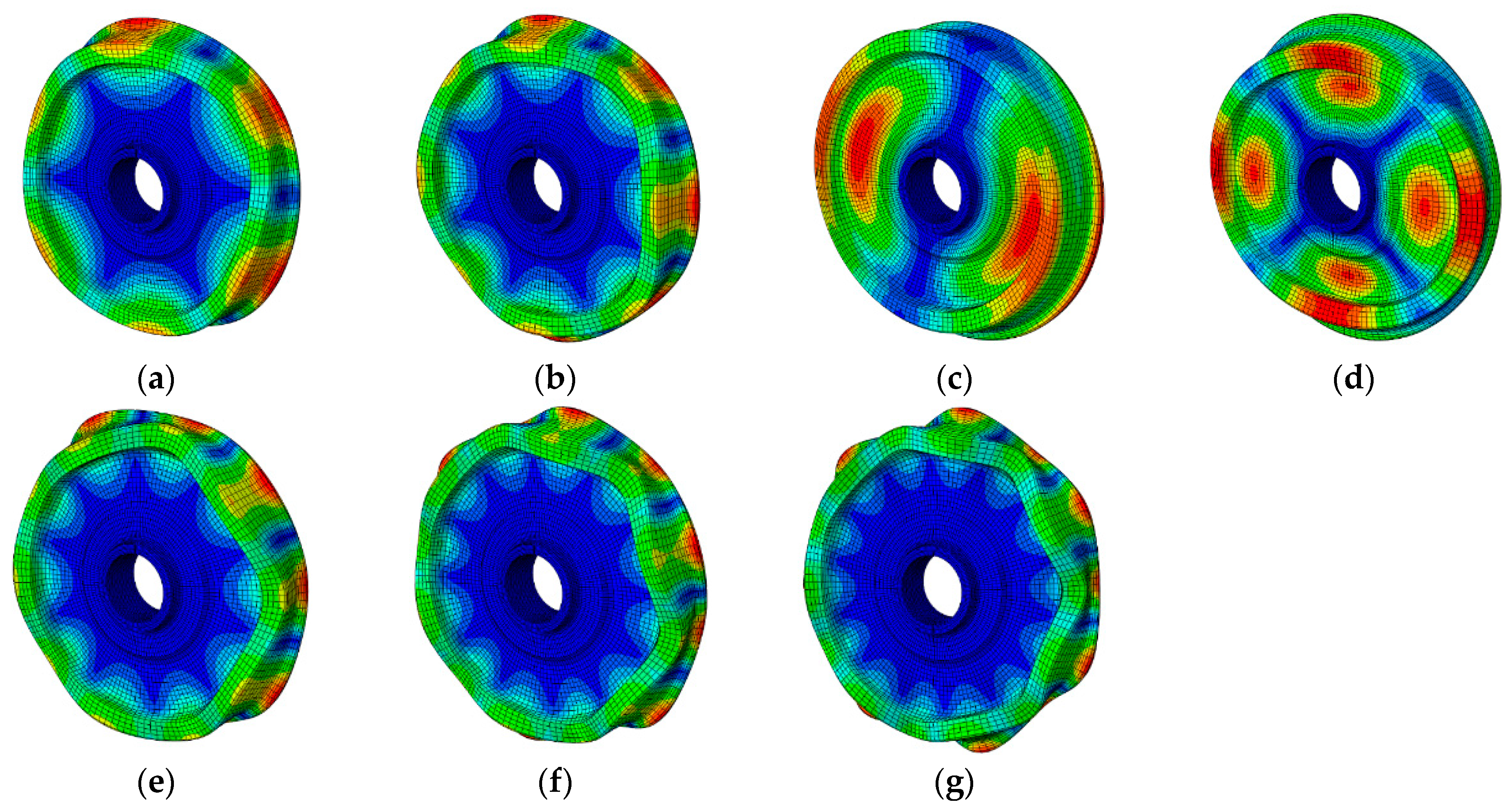

- Axial Modes with 0 Pitch Circles: These modes predominantly exhibit out-of-plane bending primarily focused on the rim of the wheel. The deformation primarily occurs along the rim, emphasizing its importance in these modes.

- Axial Modes with 1 Pitch Circle: In these modes, the primary vibration pattern involves out-of-plane bending, similar to the 0-pitch-circle axial modes. However, there is an additional contribution from the spoke plate, resulting in a more complex vibration pattern that combines both rim and spoke plate deformations.

- Radial Modes: Radial modes display a distinctive pattern. They entail not only the bending deformation observed on the spoke plate but also include bending deformations along the rim. These modes manifest more comprehensive deformations, incorporating both the rim and the spoke plate, setting them apart from the axial modes.

3.2.2. Frequency Response Analysis of The Wheel

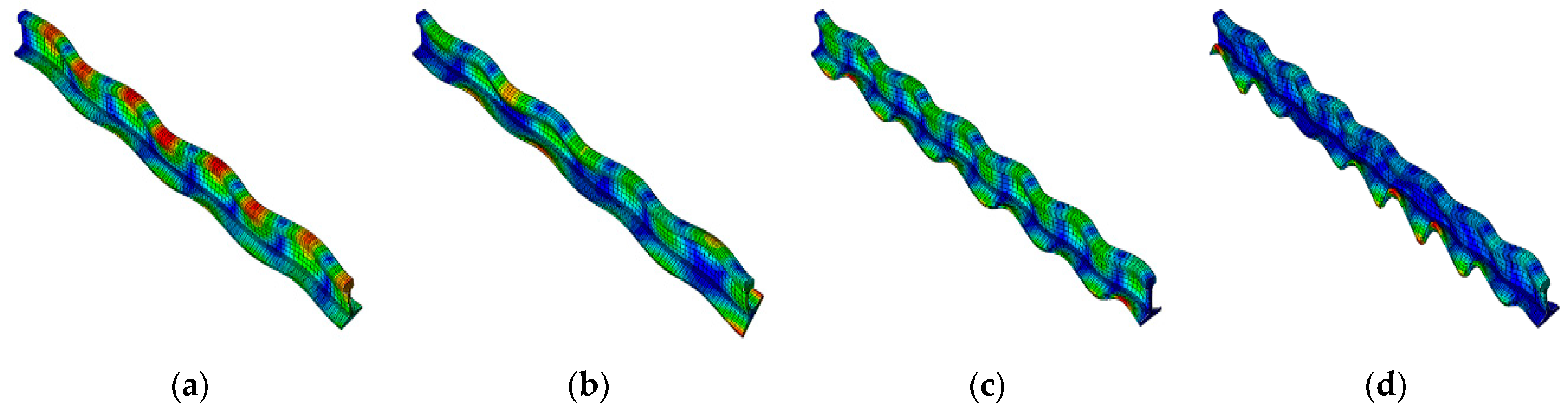

3.2.3. Frequency Response Analysis of The Rail

4. Discussion

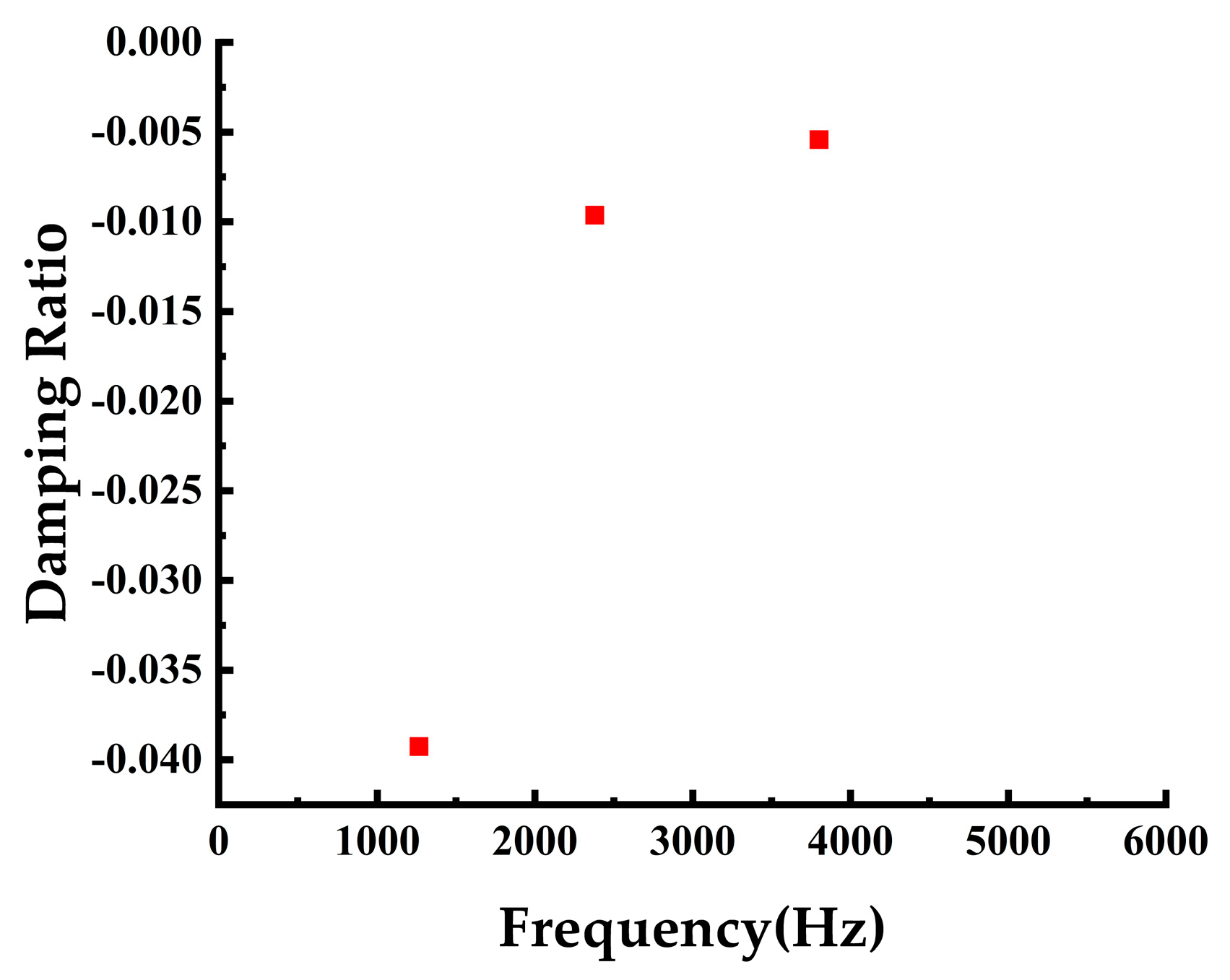

4.1. Complex Modal Analysis of Wheel–Rail System

- Real Part Mode: When the phase aligns with the real phase, the modal shape is referred to as a real part mode;

- Imaginary Part Mode: Imaginary part modes are characterized by a 90° phase difference from the real phase.

4.2. Setting Scheme of Wheel–Rail Stiffness Match

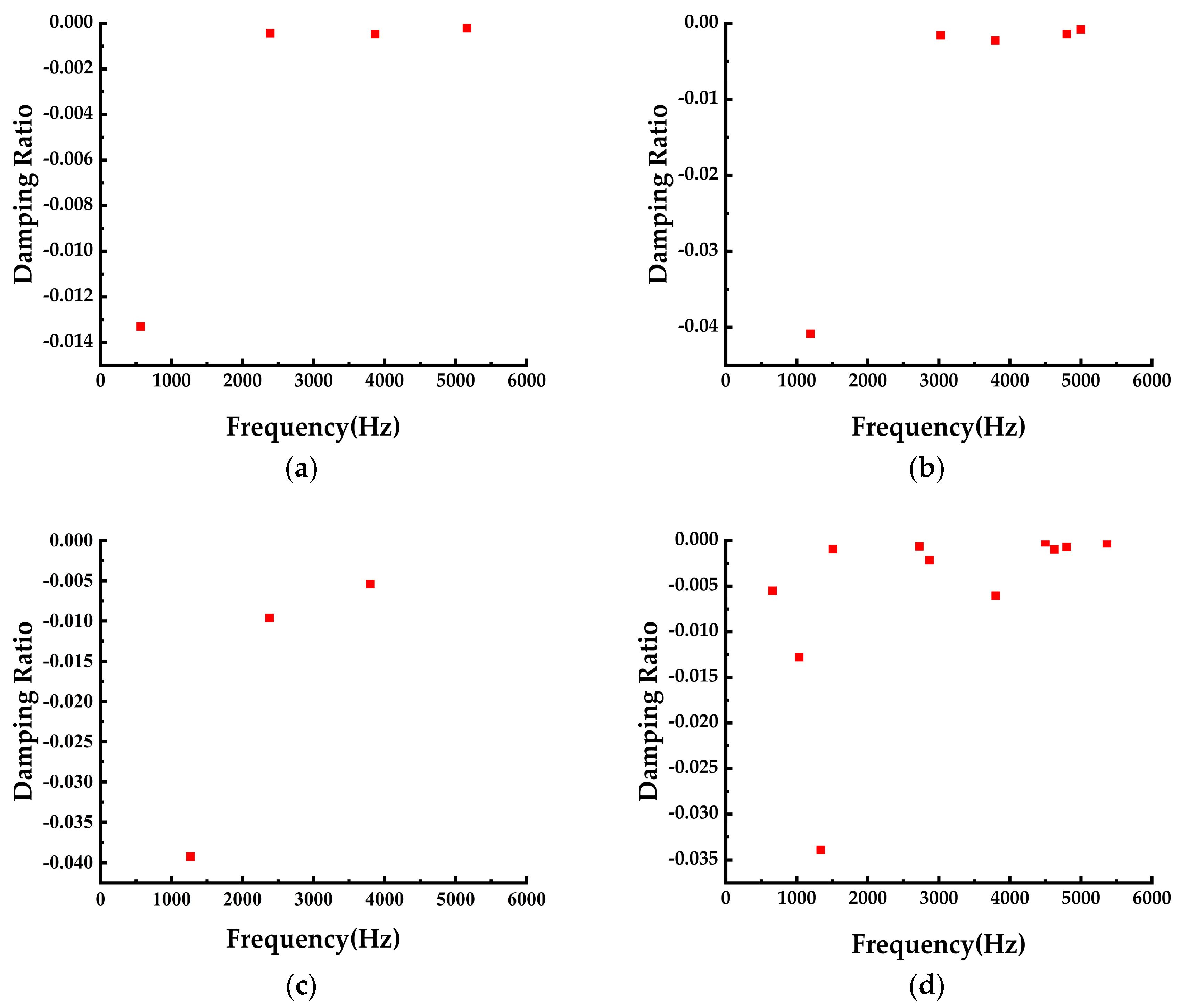

4.3. The Effect of Elastic Modulus of Rail on The Propensity of Squeal Noise

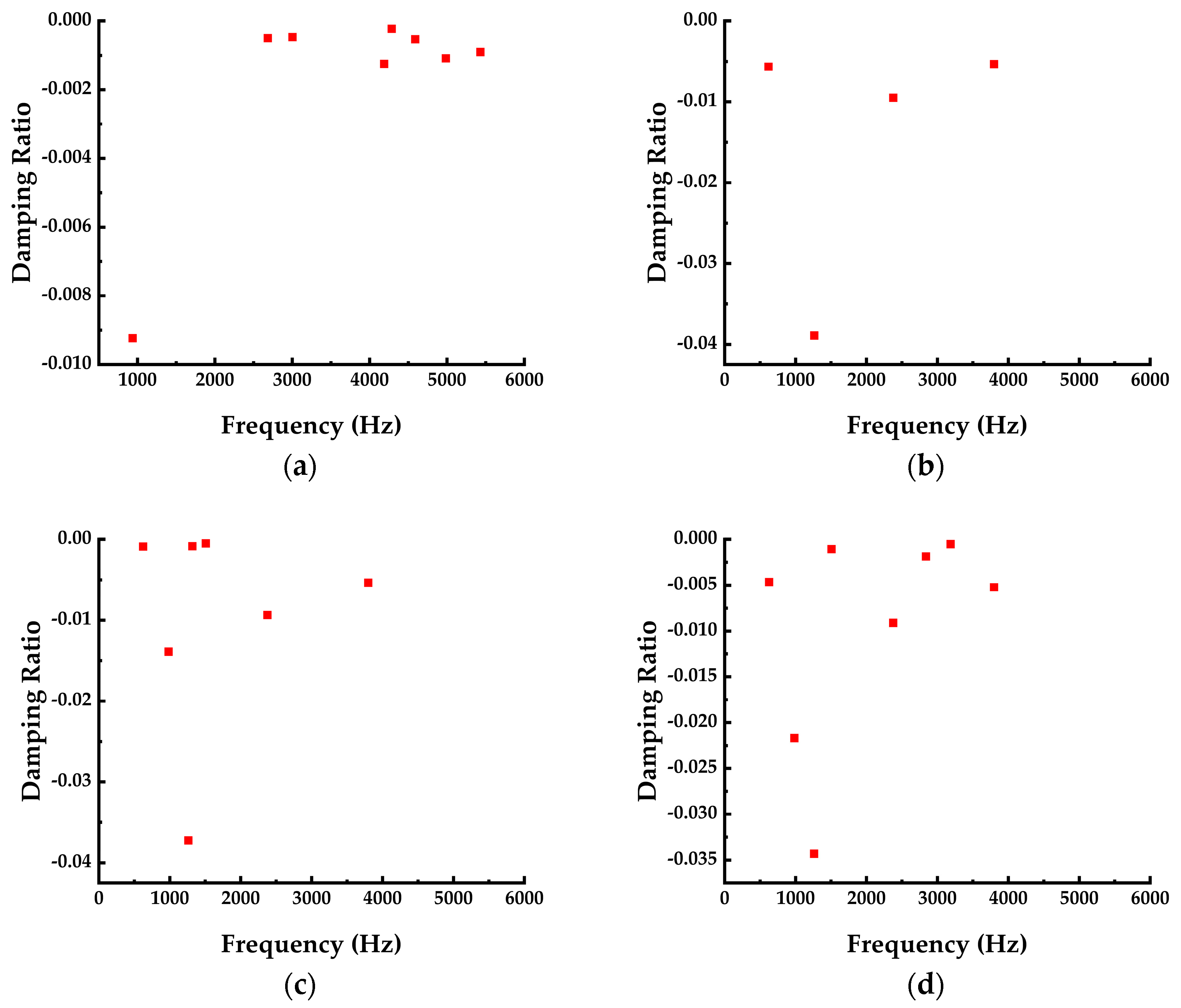

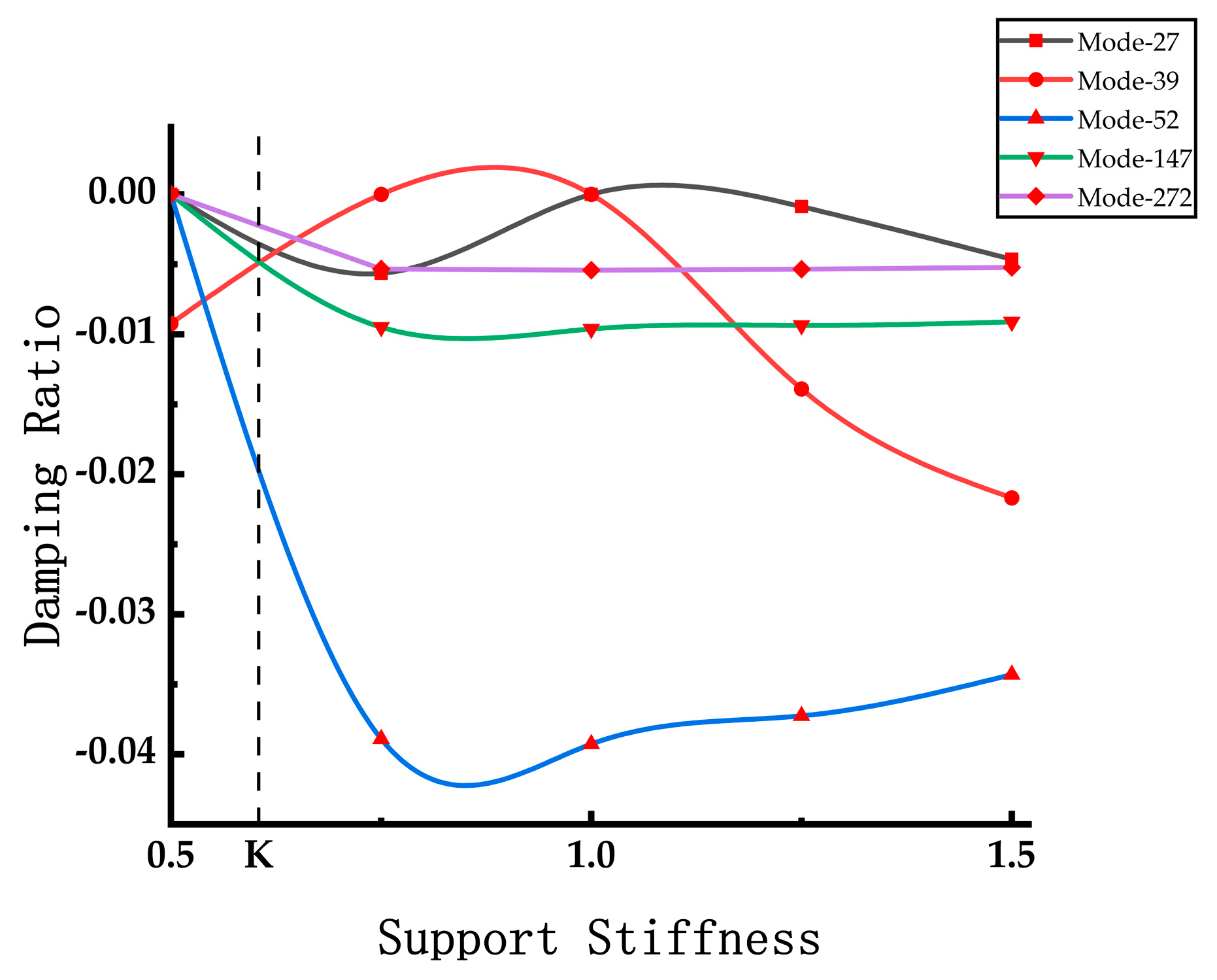

4.4. The Effect of Rail Support Stiffness on The Propensity of Squeal Noise

5. Conclusions

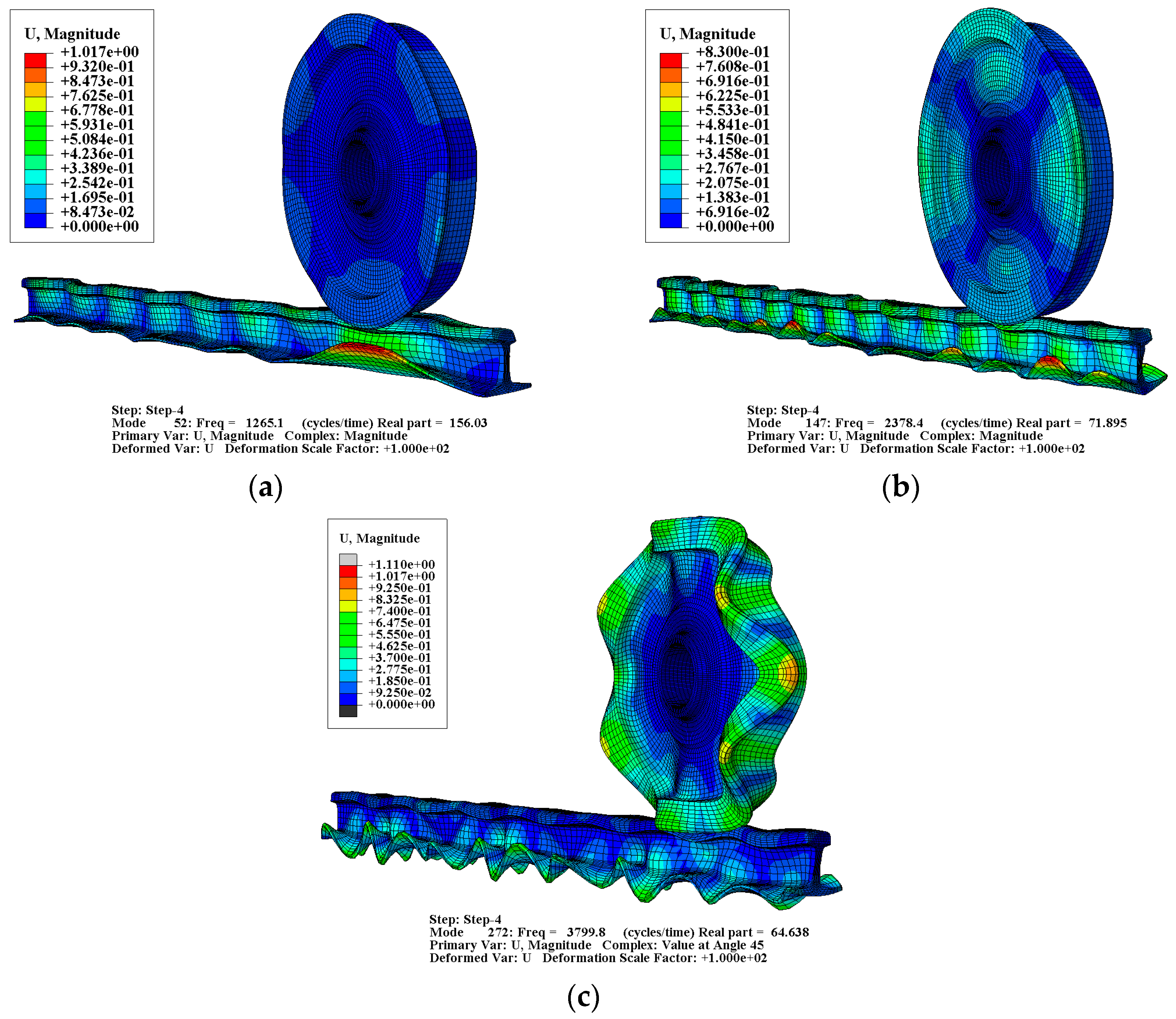

- In comparison to the resonant modes of the wheel and rail, as well as the unstable modes within the wheel–rail system, it is evident that the frequencies of these unstable modes closely align with the resonant frequencies of the wheel and rail. Furthermore, the mode shapes of these unstable modes bear a striking resemblance to the resonant mode shapes of the wheel and rail. Specifically, the wheel predominantly exhibits axial vibrations along the 0-pitch-circle axial mode, while the rail primarily experiences vertical bending vibrations. Notably, the axial vibration of the wheel interacts with the vertical vibration of the rail, resulting in the occurrence of frictional self-excited vibrations.

- When considering the amplitude of complex mode shapes concerning the occurrence of wheel–rail curve squeal noise, it becomes evident that the noise primarily originates from vibrations occurring at three key positions: the rim, railhead, and rail foot.

- The wheel–rail stiffness exerts a significant influence on curve squeal noise. Analyzing its impact from the perspective of wheel–rail stiffness matching offers valuable insights into controlling curve squeal noise effectively. When the difference in elastic modulus between the rail and wheel is excessively large or small, it tends to increase the likelihood of squeal noise occurrence. The optimal ratio of elastic modulus between the rail and wheel is approximately 1.2, providing a guideline for effective noise control measures.

- The rail support stiffness does have a discernible impact on curve squeal noise. Theoretically, maintaining an appropriate support stiffness level keeps the negative damping ratio of the system’s unstable modes at a minimal level, thereby reducing the energy input into the system during self-excited vibration. Consequently, control of wheel–rail curve squeal noise can be achieved by carefully managing the rail support stiffness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, B.; Yang, Z.; Yu, Y.; Qian, L.; Chen, J.; Ran, J.; Sun, Y.; Xi, Z.; Lu, F. Statistical Analysis of Urban Rail Transit Operation in the World in 2020: A Review. Urban Rapid Rail Transit 2021, 34, 5–11. [Google Scholar]

- Hou, X.F.; Mei, J.P.; Zuo, C.; Liu, G.Y. Statistics and Analysis of Urban Rail Transit in 2020. Urban Rapid Rail Transit 2021, 34, 1–9+64. [Google Scholar]

- Da-xin, S.; Liang, G. Wheel/Rail Noise on High Speed Railway and Its Control Measures. China Saf. Sci. J. 2005, 15, 87–90. [Google Scholar]

- Jia-hua, L.; Song-liang, L. Vibration and noise of the urban rail transit. J. Traffic Transp. Eng. 2002, 2, 29–33. [Google Scholar]

- Zhang, B.; Lu, X.; Di, G. Effects of Railwav Noise on Residential Quarter. Environ. Sci. 2003, 24, 157–160. [Google Scholar]

- Kurzweil, L. Wheel/rail noise—Means for control. J. Sound. Vib. 1983, 87, 197–220. [Google Scholar] [CrossRef]

- Eadie, D.T.; Santoro, M. Top-of-rail friction control for curve noise mitigation and corrugation rate reduction. J. Sound. Vib. 2006, 293, 747–757. [Google Scholar] [CrossRef]

- Gao, C.; Kuhlmann-Wilsdorf, D. On stick-slip and the velocity dependence of friction at low speeds. J. Tribol. 1990, 112, 354–360. [Google Scholar] [CrossRef]

- Ibrahim, R.A. Friction-induced vibration, chatter, squeal, and chaos—Part II: Dynamics and modeling. Appl. Mech. Rev. 1994, 47, 227–253. [Google Scholar] [CrossRef]

- Chen, G.; Liu, Q.; Jin, X.; Zhou, Z. Stability analysis of a squealing vibration model with time delay. J. Sound. Vib. 2008, 311, 516–536. [Google Scholar] [CrossRef]

- Gdaniec, P.; Weiß, C.; Hoffmann, N. On chaotic friction induced vibration due to rate dependent friction. Mech. Res. Commun. 2010, 37, 92–95. [Google Scholar] [CrossRef]

- Heckl, M.A.; Abrahams, I.D. Curve squeal of train wheels, part 1: Mathematical model for its generation. J. Sound. Vib. 2000, 229, 669–693. [Google Scholar] [CrossRef]

- Shin, K.; Brennan, M.; Oh, J.-E.; Harris, C. Analysis of disc brake noise using a two-degree-of-freedom model. J. Sound. Vib. 2002, 254, 837–848. [Google Scholar] [CrossRef]

- Paliwal, M.; Mahajan, A.; Don, J.; Chu, T.; Filip, P. Noise and vibration analysis of a disc–brake system using a stick–slip friction model involving coupling stiffness. J. Sound. Vib. 2005, 282, 1273–1284. [Google Scholar] [CrossRef]

- Liu, X.; Meehan, P.A. Investigation of the effect of lateral adhesion and rolling speed on wheel squeal noise. Proc. Inst. Mech. Eng. Part. F J. Rail Rapid Transit 2013, 227, 469–480. [Google Scholar] [CrossRef]

- Liu, X.; Meehan, P.A. Investigation of the effect of relative humidity on lateral force in rolling contact and curve squeal. Wear 2014, 310, 12–19. [Google Scholar] [CrossRef]

- Liu, X.; Meehan, P.A. Wheel squeal noise: A simplified model to simulate the effect of rolling speed and angle of attack. J. Sound. Vib. 2015, 338, 184–198. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, Z.; Kapsa, P.; Vincent, L. Experimental investigation into squeal under reciprocating sliding. Tribol. Int. 2003, 36, 961–971. [Google Scholar] [CrossRef]

- Liu, X.; Meehan, P.A. Investigation of squeal noise under positive friction characteristics condition provided by friction modifiers. J. Sound. Vib. 2016, 371, 393–405. [Google Scholar] [CrossRef]

- Hoffmann, N.; Fischer, M.; Allgaier, R.; Gaul, L. A minimal model for studying properties of the mode-coupling type instability in friction induced oscillations. Mech. Res. Commun. 2002, 29, 197–205. [Google Scholar] [CrossRef]

- Hoffmann, N.; Gaul, L. Effects of damping on mode-coupling instability in friction induced oscillations. ZAMM-J. Appl. Math. Mech./Z. Für Angew. Math. Und Mech. Appl. Math. Mech. 2003, 83, 524–534. [Google Scholar] [CrossRef]

- Han, M.-G.; Park, C.-K.; Chang, S. A study of drum brake squeal using complex eigenvalue analysis. In Proceedings of the 32nd International Congress and Exposition on Noise Control Engineering, Seogwipo, Republic of Korea, 25–28 August 2003; pp. 4578–4585. [Google Scholar]

- Ouyang, H.; Nack, W.; Yuan, Y.; Chen, F. On Automotive Disc Brake Squeal Part II: Simulation and Analysis; SAE Technical Paper: Warrendale, PA, USA, 2003. [Google Scholar]

- Brunel, J.F.; Dufrenoy, P.; Nat, M.; Muoz, J.L.; Demilly, F. Transient models for curve squeal noise. J. Sound. Vib. 2006, 293, 758–765. [Google Scholar] [CrossRef]

- Chen, G.X.; Xiao, J.B.; Liu, Q.Y.; Zhou, Z.R. Complex Eigenvalue Analysis of Railway Curve Squeal. Notes Numer. Fluid. Mech. Multidiscip. Des. 2008, 99, 433–439. [Google Scholar]

- Pieringer, A. A numerical investigation of curve squeal in the case of constant wheel/rail friction. J. Sound. Vib. 2014, 333, 4295–4313. [Google Scholar] [CrossRef]

- Liu, S.; De Silva, U.; Chen, D.; Leslie, A.C.; Meehan, P.A. Investigation of wheel squeal noise under mode coupling using two-disk testrig experiments. Wear 2023, 530, 205035. [Google Scholar] [CrossRef]

- Ding, B.; Squicciarini, G.; Thompson, D. Effect of rail dynamics on curve squeal under constant friction conditions. J. Sound. Vib. 2019, 442, 183–199. [Google Scholar] [CrossRef]

- Lai, V.-V.; Chiello, O.; Brunel, J.-F.; Dufrenoy, P. The critical effect of rail vertical phase response in railway curve squeal generation. Int. J. Mech. Sci. 2020, 167, 105281. [Google Scholar] [CrossRef]

- Zhan, B.; Sun, T.; Shen, Y.; Yu, J.; Tao, Z.; Hu, H. Improvement of brake squeal of a disc brake based on complex eigenvalue analysis. Zhendong Yu Chongji/J. Vib. Shock. 2021, 40, 108–112+135. [Google Scholar]

- Guan, D.; Jiang, D. A Study on Disc Brake Squeal Using Finite Element Methods; SAE Technical Paper: Warrendale, PA, USA, 1998. [Google Scholar]

| Structure Name | Elastic Modulus (MPa) | Density (kg/m3) | Poisson Ratio |

|---|---|---|---|

| Wheel | 1.8 × 105 | 7800 | 0.28 |

| Rail | 2.1 × 105 | 7800 | 0.3 |

| Sleeper | 3.45 × 104 | 2500 | 0.2 |

| Track plate | 3.45 × 104 | 2500 | 0.2 |

| Modal Order | Modal Frequency | Main Vibration Position | Max. Amplitude |

|---|---|---|---|

| 52 | 1265.1 Hz | Rail foot | 1.02 |

| 147 | 2378.4 Hz | Rail foot | 0.83 |

| 272 | 3799.8 Hz | Wheel Rims | 1.11 |

| Elastic Modulus (MPa) | Number of Unstable Modes | TOI |

|---|---|---|

| 1.5 × 105 | 4 | 14.398 |

| 1.8 × 105 | 5 | 54.293 |

| 2.1 × 105 | 3 | 46.870 |

| 2.4 × 105 | 11 | 64.067 |

| ) | Number of Unstable Modes | TOI |

|---|---|---|

| 0.5 | 8 | 14.198 |

| 0.75 | 4 | 59.383 |

| 1 | 3 | 54.293 |

| 1.25 | 7 | 68.101 |

| 1.5 | 11 | 78.444 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zhang, G.; Yuan, M.; Ji, J.; Cui, N.; Huang, S. The Numerical Study for the Effect of Stiffness Matching on Wheel–Rail Curve Squeal Noise. Appl. Sci. 2023, 13, 11615. https://doi.org/10.3390/app132111615

Gao Y, Zhang G, Yuan M, Ji J, Cui N, Huang S. The Numerical Study for the Effect of Stiffness Matching on Wheel–Rail Curve Squeal Noise. Applied Sciences. 2023; 13(21):11615. https://doi.org/10.3390/app132111615

Chicago/Turabian StyleGao, Yanxin, Gongde Zhang, Miaomiao Yuan, Jianyi Ji, Nannan Cui, and Shiping Huang. 2023. "The Numerical Study for the Effect of Stiffness Matching on Wheel–Rail Curve Squeal Noise" Applied Sciences 13, no. 21: 11615. https://doi.org/10.3390/app132111615