Cascade Analysis Method of Multilayer Optical Films Structure Based on Two Port Transmission Line Theory

Abstract

:1. Introduction

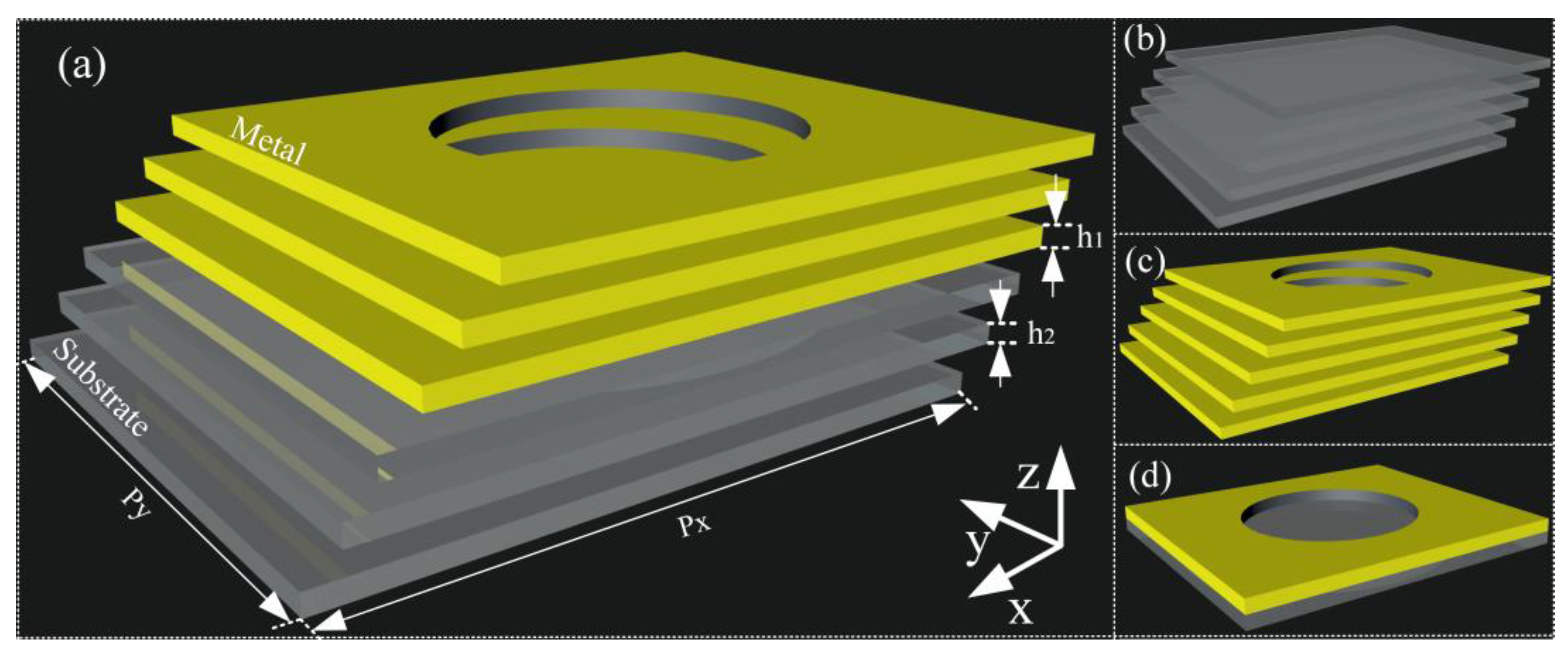

2. Design and Modeling

3. Results and Discussions

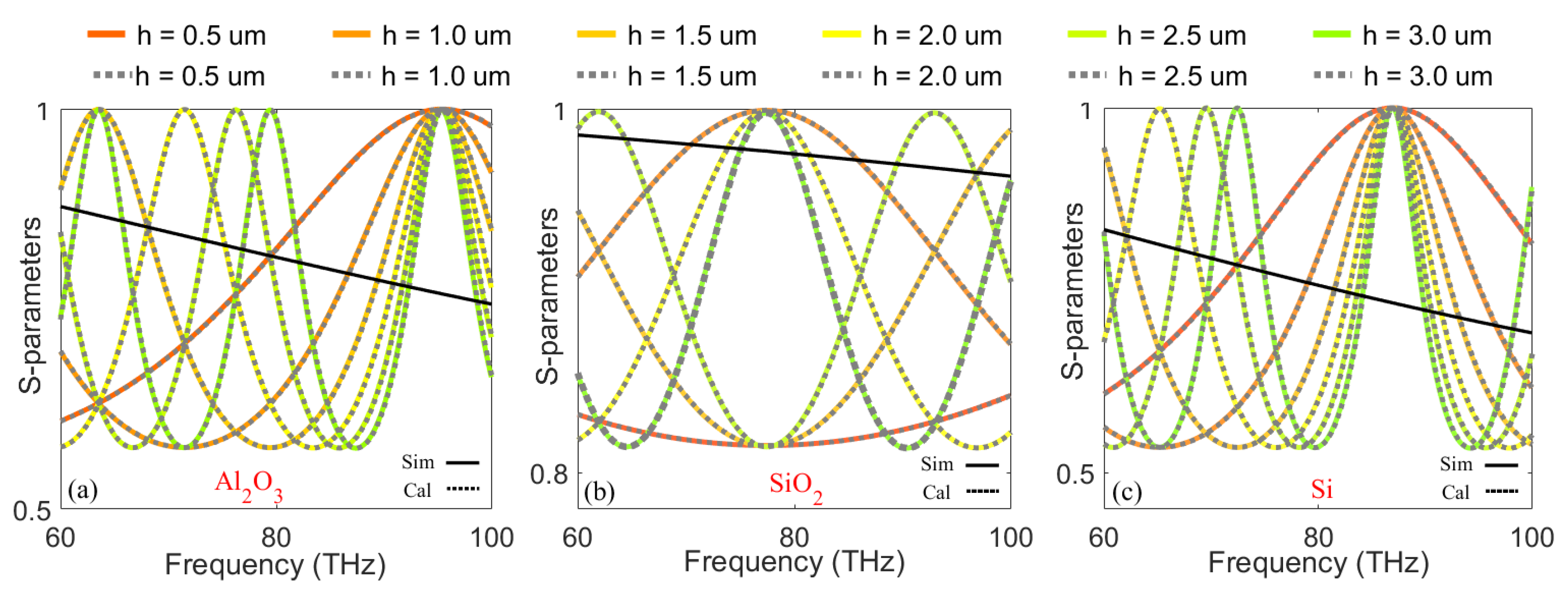

3.1. The Cascade Calculation of the Single Material Type

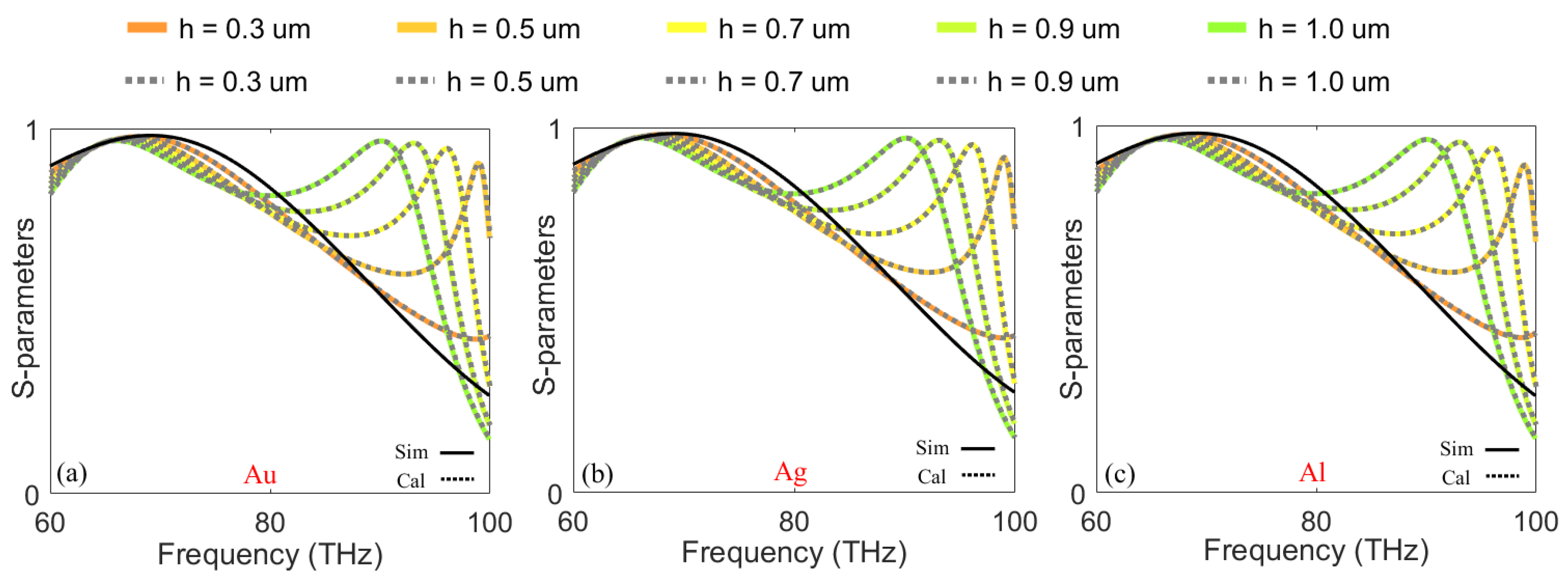

3.2. The Multiple Hybrid Cascade Calculation of the Transparent Substrate and Metal Film

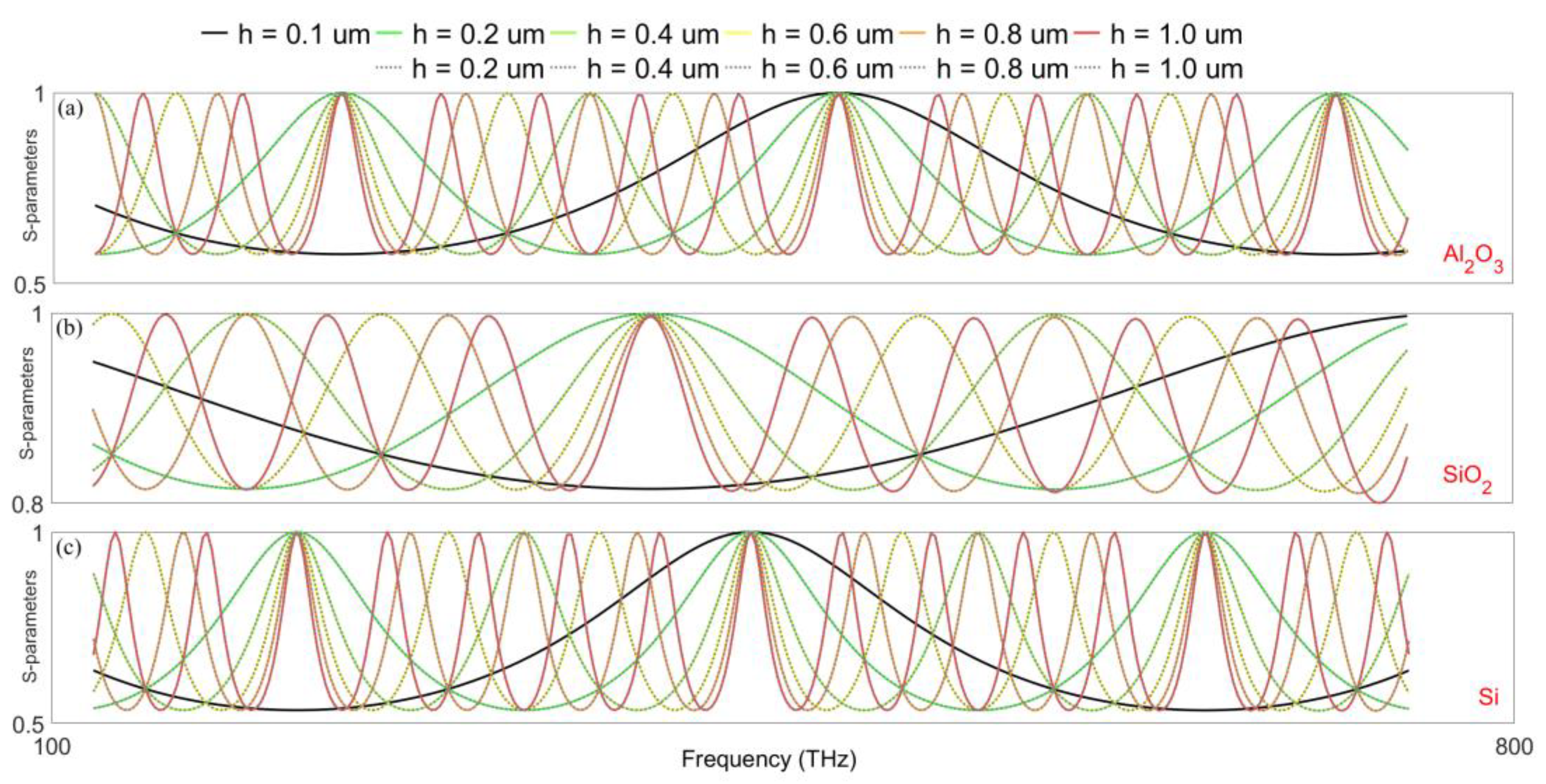

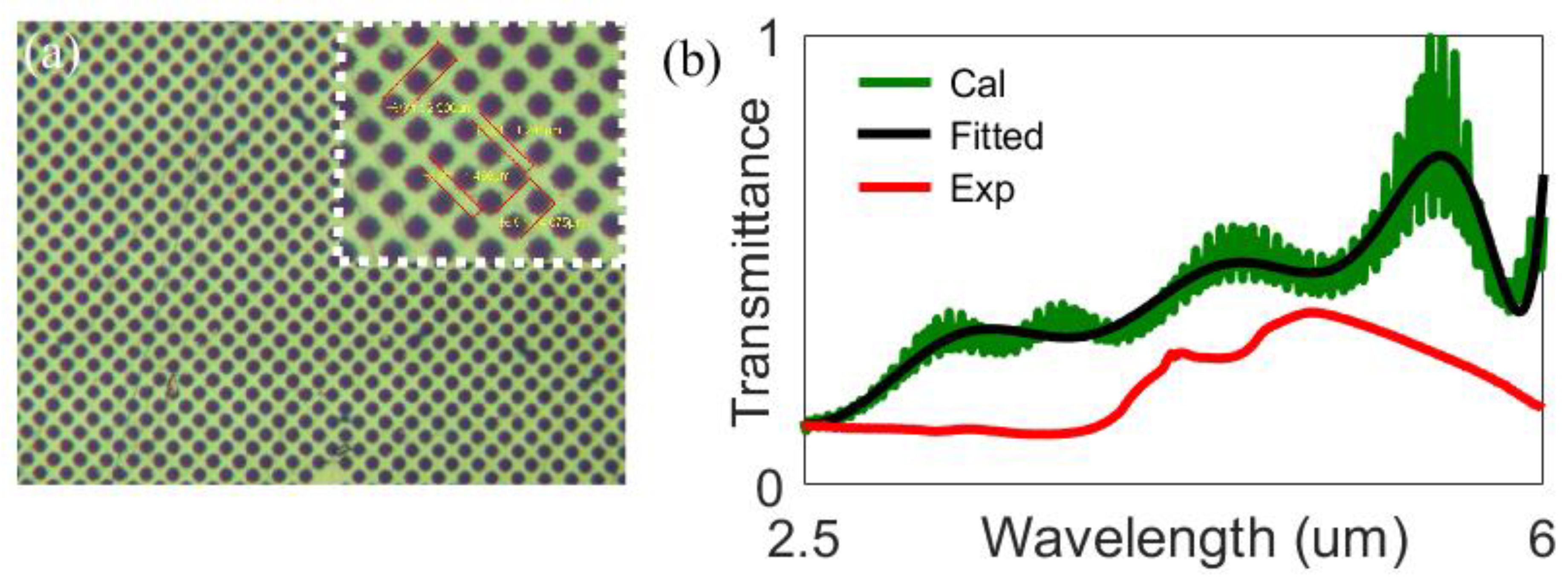

3.3. Surface Plasmon Filter Based on Two Port Transmission Line Theory

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.; Song, J.; Xu, T.; Yang, T.; Zhou, J. Controllable linear asymmetric transmission and perfect polarization conversion in a terahertz hybrid metal-graphene metasurface. Opt. Express 2019, 27, 9773–9781. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Wang, L. Surface plasmon resonance sensor working at terahertz frequency. Spectrosc. Spectr. 2011, 31, 2017–2020. [Google Scholar]

- Xie, H.; Pan, Y.; Fedder, G. A CMOS-MEMS mirror with curled-hinge comb drives. J. Microelectromech. Syst. 2003, 12, 450–457. [Google Scholar]

- Bernstein, J.; Miller, R.; Kelley, W.; Ward, P. Low-noise MEMS vibration sensor for geophysical applications. J. Microelectromech. Syst. 2002, 8, 433–438. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, R.; Li, X. MEMS vertical probe cards with ultra densely arrayed metal probes for wafer-level IC testing. J. Microelectromech. Syst. 2009, 18, 933–941. [Google Scholar] [CrossRef]

- Jang, J.; Javidi, B. Improved viewing resolution of three-dimensional integral imaging by use of nonstationary micro-optics. Opt. Lett. 2002, 27, 324–326. [Google Scholar] [CrossRef] [PubMed]

- Nikolajeff, F.; Karlsson, M. Diamond micro-optics: Microlenses and antireflection structured surfaces for the infrared spectral region. Opt. Express 2003, 11, 502–507. [Google Scholar]

- Xu, H.; Yu, C.; Wang, S.; Viktor, M.; Xie, T.; Rogers, J. Deformable, programmable, and shape-memorizing micro-optics. Adv. Funct. Mater. 2013, 23, 3299–3306. [Google Scholar] [CrossRef]

- Pregibon, D.; Toner, M.; Doyle, P. Multifunctional encoded particles for high-throughput biomolecule analysis. Science 2007, 315, 1393–1396. [Google Scholar] [CrossRef] [Green Version]

- Song, S.; Kim, K.; Choi, S.; Han, S.; Lee, H.; Kwon, S.; Park, W. Fine-tuned grayscale optofluidic maskless lithography for three-dimensional freeform shape microstructure fabrication. Opt. Lett. 2014, 39, 5162–5165. [Google Scholar] [CrossRef]

- Dendukuri, D.; Pregibon, D.; Collins, J.; Hatton, T.; Doyle, P. Continuous-flow lithography for high-throughput microparticle synthesis. Nat. Mater. 2006, 5, 365–369. [Google Scholar] [CrossRef]

- Wen, K.; Zhang, Z.; Jiang, X.; He, J.; Yang, J. Image representation of structural color based on edge detection algorithm. Results Phys. 2020, 19, 103440–103447. [Google Scholar] [CrossRef]

- Wen, K.; Zhang, Z.; Jiang, X.; He, J.; Yang, J. Plasmonics induced multifunction optical device via hoof-shaped subwavelength structure. Appl. Sci. 2020, 10, 2713. [Google Scholar] [CrossRef]

- Filippo, C.; Agostino, M.; Giuliano, M. Efficient analysis of frequency-selective surfaces by a simple equivalent-circuit model. IEEE Antennas Propag. Mag. 2012, 54, 35–48. [Google Scholar]

- Zhang, S.; Ren, Y.; Cai, H.; Chen, X.; Qu, G.; Xin, M. Research on transmission spectra of mid infrared metal micro nano structure. Opt. Tech. 2022, 48, 177–183. [Google Scholar]

- Romanini, D.; Kachanov, A.; Sadeghi, N.; Stoeckel, F. CW cavity ring down spectroscopy. Chem. Phys. Lett. 1997, 264, 316–322. [Google Scholar] [CrossRef]

- Wen, K.; Luo, X.; Chen, Z.; Zhu, W.; Guo, W.; Wang, X. Enhanced optical transmission assisted near-infrared plasmonic optical filter via hybrid subwavelength structures. Plasmonics 2019, 14, 1649–1657. [Google Scholar] [CrossRef]

- Padooru, Y.; Yakovlev, A.; Kaipa, C. Dual capacitive-inductive nature of periodic graphene patches: Transmission characteristics at low-terahertz frequencies. Phys. Rev. B 2013, 87, 115401–115410. [Google Scholar] [CrossRef]

- Luukkonen, O.; Simovski, C.; Granet, G. Simple and accurate analytical model of planar grids and high-impedance surfaces comprising metal strips or patches. IEEE Trans. Antennas Propag. 2008, 56, 1624–1632. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Zhang, X.; Hu, Z.; Aqeeli, M.; Alburaikan, A. Design of broadband and tunable terahertz absorbers based on graphene metasurface: Equivalent circuit model approach. IET Microw. Antennas Propag. 2015, 9, 307–312. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, J.; Shi, D.J.; Wu, Q.Y.; Ren, F.F.; Xu, J.; Fan, Y.X.; Ding, J.P.; Wang, H.T. Physical mechanism of extraordinary electromagnetic transmission in dual-metallic grating structures. Phys. Rev. B 2008, 78, 075406–075415. [Google Scholar] [CrossRef]

- Suckling, J.R.; Hibbins, A.P.; Lockyear, M.J.; Preist, T.W.; Sambles, J.R.; Lawrence, C.R. Finite conductance governs the resonance transmission of thin metal slits at microwave frequencies. Phys. Rev. Lett. 2004, 92, 147401–147404. [Google Scholar] [CrossRef] [PubMed]

- Sambles, J.R.; Bradbery, G.W.; Yang, F. Optical excitation of surface plasmons: An introduction. Contemp. Phys. 1991, 32, 173–183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, K.; Huang, X.; Liang, Y.; Liu, W.; Xu, Y.; Liu, P. Cascade Analysis Method of Multilayer Optical Films Structure Based on Two Port Transmission Line Theory. Appl. Sci. 2023, 13, 1337. https://doi.org/10.3390/app13031337

Wen K, Huang X, Liang Y, Liu W, Xu Y, Liu P. Cascade Analysis Method of Multilayer Optical Films Structure Based on Two Port Transmission Line Theory. Applied Sciences. 2023; 13(3):1337. https://doi.org/10.3390/app13031337

Chicago/Turabian StyleWen, Kui, Xianjun Huang, Yuanlong Liang, Wencong Liu, Yanlin Xu, and Peiguo Liu. 2023. "Cascade Analysis Method of Multilayer Optical Films Structure Based on Two Port Transmission Line Theory" Applied Sciences 13, no. 3: 1337. https://doi.org/10.3390/app13031337