Mechanical Characteristics and Damage Constitutive Model of Fiber-Reinforced Cement-Stabilized Soft Clay

Abstract

:1. Introduction

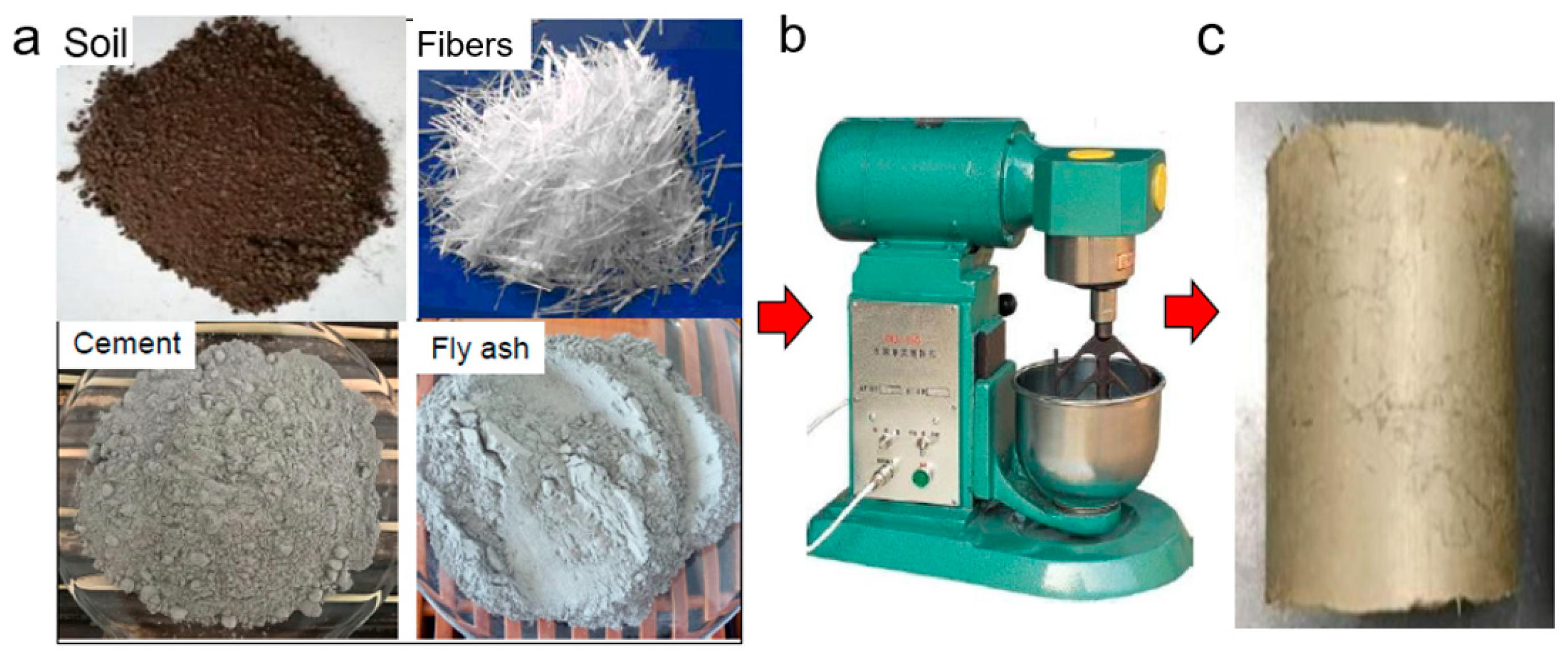

2. Materials and Methods

2.1. Testing Materials

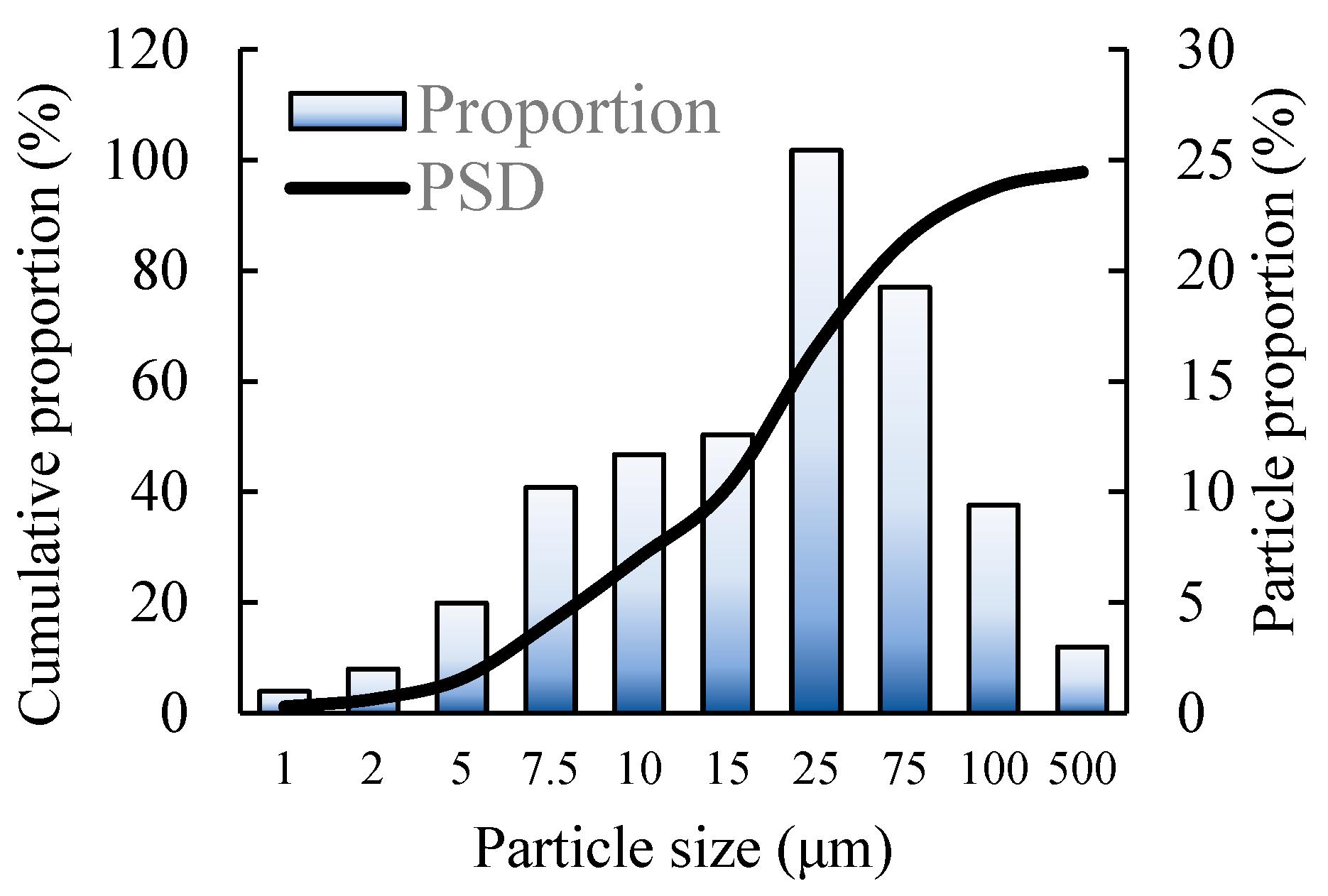

2.1.1. Soft Clay

2.1.2. Gelling Agent

2.1.3. Glass Fibers

2.2. Experimental Method and Design Ratio

2.3. Testing Method

2.3.1. Unconfined Compressive Tests

2.3.2. Scanning Electron Microscopy

3. Results

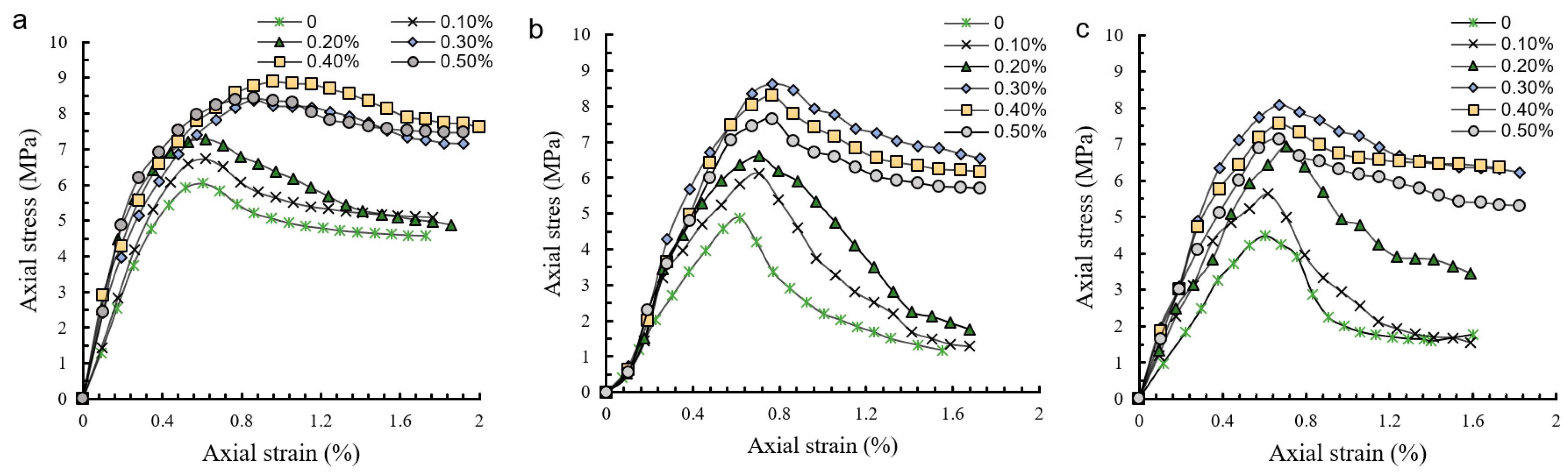

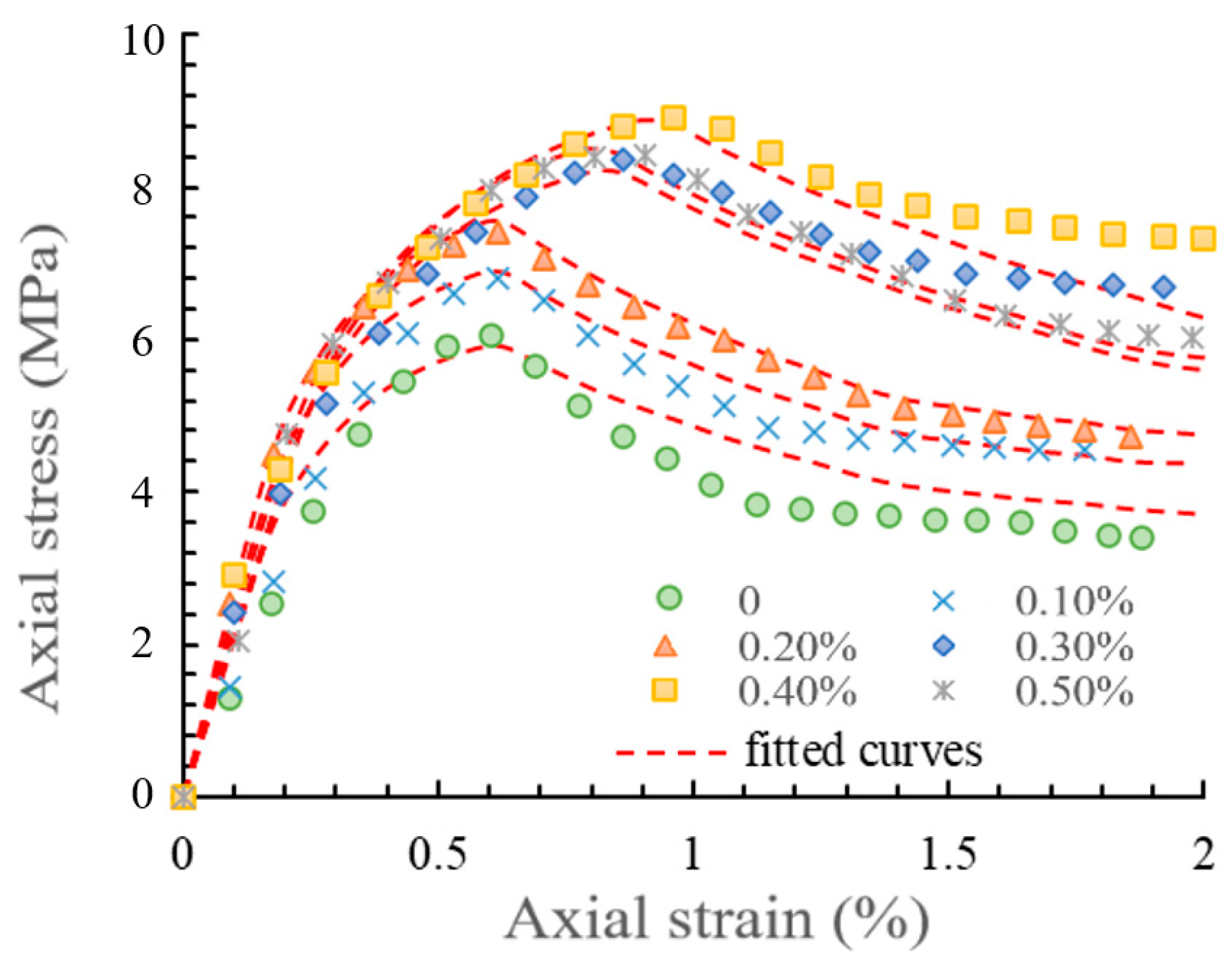

3.1. Stress–Strain Curves

3.2. Effect of Curing Time, Fiber Length, and Fiber Amount on Strength

3.3. Microscopic Characteristics of Fiber-Reinforced Cement-Stabilized Soft Clay

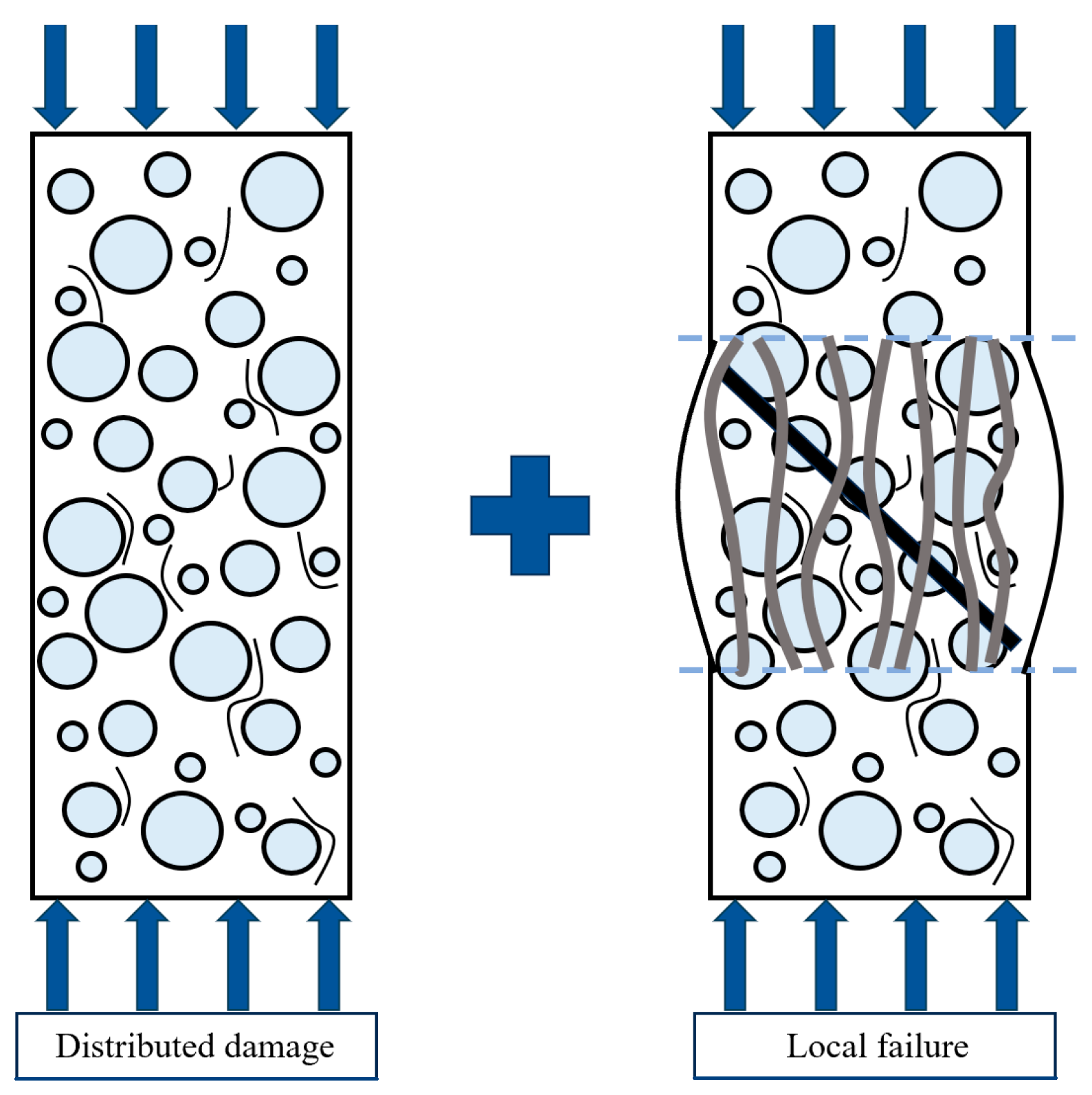

4. Damage Constitutive Model

5. Conclusions

- (1)

- The utilization of glass fibers enhances the performance of FCSSC in plastic deformation and compressive strength. At a curing age of 7 days, the stabilized soft clay demonstrates heightened compressive strength, contributing to an improved early strength profile.

- (2)

- The length of the glass fibers in FCSSC plays a pivotal role in determining the unconfined compressive strength of stabilized soft clay. The reinforcing effect is most pronounced for short-cut fibers, followed by medium-cut fibers and long-cut fibers. This is attributed to the intimate contact of shorter-chopped fibers with the hydration gel, enabling the sample to withstand greater compressive stress.

- (3)

- The impact of increasing the fiber content on the strength index follows an initial increase and subsequently decreases. Considering both mechanical properties and engineering economy, the optimal amount is determined to be 0.3%. Excessive fiber content and excessively long fibers may result in cross-linking and entanglement, increasing porosity in the fiber aggregation area and diminishing the sample’s ability to resist loading and deformation.

- (4)

- Glass fibers function as a bridge in stabilized soft clay, effectively inhibiting the expansion of compression cracks and the formation of additional cracks. This action mitigates the overall severity of deformation and compression fractures in the sample. The synergistic interplay between glass fibers and hydration gel constitutes a significant factor involved in enhancing the mechanical properties of stabilized soft clay.

- (5)

- The proposed constitutive model based on mesoscopic damage mechanics proves effective in describing the strain evolution of stabilized soft clay and accurately reflects the softening characteristics observed in the stress–strain curves under uniaxial compression.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajasekaran, G. Sulphate attack and ettringite formation in the lime and cement stabilized marine clays. Ocean Eng. 2005, 32, 1133–1159. [Google Scholar] [CrossRef]

- Xu, G.; Liu, J.; Liu, S.F.; Wang, Z.B.; Hu, G.; Kong, X.H. Modern muddy deposit along the Zhejiang coast in the East China Sea: Response to large-scale human projects. Cont. Shelf Res. 2016, 130, 68–78. [Google Scholar] [CrossRef]

- Xiao, Z.; Yu, N.; An, J.; Zou, H.; Zhang, Y. Soil compressibility and resilience based on uniaxial compression loading test in response to soil water suction and soil organic matter content in northeast China. Sustainability 2022, 14, 2620. [Google Scholar] [CrossRef]

- An, R.; Wang, Y.X.; Zhang, X.; Chen, C.; Liu, X.; Cai, S. Quantitative characterization of drying-induced cracks and permeabilityof granite residual soil using micron-sized x-ray computed tomography. Sci. Total Environ. 2023, 876, 163213. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Tang, Y. Practical model of deformation prediction in soft clay after artificial ground freezing under subway low-level cyclic loading. Tunn. Undergr. Space Technol. 2018, 76, 30–42. [Google Scholar] [CrossRef]

- Tang, Y.Q.; Zhou, J.; Zhang, M.D.; Liu, Y.D. Research on the thermal conductivity and moisture migration characteristics of Shanghai saline soil. I: Experimental modeling. Bull. Eng. Geol. Environ. 2015, 74, 577–593. [Google Scholar] [CrossRef]

- Zhu, J.F.; Tao, Y.L.; Xu, R.Q.; Yang, H.; Pan, B.J. Investigation on the optimal formulation and mechanism of marine organic silt improved with magnesium-cement-based stabilizer. Constr. Build. Mater. 2022, 341, 127233. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Myint, W.B.; Stephen, D. Effects of industrial by-product based geopolymers on the strength development of a soft soil. Soils Found. 2018, 58, 716–728. [Google Scholar] [CrossRef]

- Song, Y.; Cao, J.; Ding, W.; Song, Z.; Liu, H.; Huang, S.; Zhu, W. Influence of Peat Soil Environment on Mechanical Properties of Cement-Soil and Its Mechanism. Sustainability 2023, 15, 4580. [Google Scholar] [CrossRef]

- Pheng, L.S.; Chuan, Q.T. Environmental factors and work performance of project managers in the construction industry. Int. J. Proj. Manag. 2006, 24, 24–37. [Google Scholar] [CrossRef]

- Hu, J.F.; Chen, H.Q.; Zhang, Z.B. Mechanical properties of melamine formaldehyde microcapsules for self-healing materials. Mater. Chem. Phys. 2009, 118, 63–70. [Google Scholar] [CrossRef]

- Savvilotidou, M.; Vassilopoulos, A.P.; Frigione, M.; Keller, T. Effects of aging in dry environment on physical and mechanical properties of a cold-curing structural epoxy adhesive for bridge construction. Constr. Build. Mater. 2017, 140, 552–561. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, H.; Chen, P.; Liu, E.; Chen, Y. Mechanical Properties and Binary-Medium-Based Constitutive Model for Coral-Reef Limestone Samples Subjected to Uniaxial Loading. Sustainability 2022, 14, 12193. [Google Scholar] [CrossRef]

- Somani, M.V.; Khandelwal, M.; Punia, V.; Sharma, V. The effect of incorporating various reinforcement materials on flexural strength and impact strength of polymethylmethacrylate: A meta-analysis. J. Indian Prosthodont. Soc. 2019, 19, 101. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.Q.; Yan, J.J. Effect of freeze–thaw on hydraulic conductivity and microstructure of soft soil in Shanghai area. Environ. Earth Sci. 2015, 73, 7679–7690. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Gustavo, J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Shi, X.Z.; Zhang, C.; Zhou, X.D. The statistical damage constitutive model of the mechanical properties of Alkali-resistant glass fiber reinforced concrete. Symmetry 2020, 12, 1139. [Google Scholar] [CrossRef]

- Wang, D.H.; Ju, Y.Z.; Shen, H.; Xu, L.B. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Schneider, K.; Lieboldt, M.; Liebscher, M.; Fröhlich, M.; Hempel, S.; Butler, M.; Schröfl, C.; Mechtcherine, V. Mineral-based coating of plasma-treated carbon fiber rovings for carbon concrete composites with enhanced mechanical performance. Materials 2017, 10, 360. [Google Scholar] [CrossRef] [PubMed]

- He, G.S.; Li, J.; Zhang, F.S.; Wang, C.; Guo, S.Y. Effect of multistage tensile extrusion induced fiber orientation on fracture characteristics of high density polyethylene/short glass fiber composites. Compos. Sci. Technol. 2014, 100, 1–9. [Google Scholar] [CrossRef]

- Liu, J.; Xie, X.; Li, L. Experimental study on mechanical properties and durability of grafted nano-SiO2 modified rice straw fiber reinforced concrete. Constr. Build. Mater. 2022, 347, 128575. [Google Scholar] [CrossRef]

- Wu, Z.M.; Khayat, K.H.; Shi, C.J. Effect of nano-SiO2 particles and curing time on development of fiber-matrix bond properties and microstructure of ultra-high strength concrete. Cem. Concr. Res. 2017, 95, 247–256. [Google Scholar] [CrossRef]

- Sun, J.F.; Zhao, F.; Yao, Y.; Jin, Z.; Liu, X.; Huang, Y.D. High efficient and continuous surface modification of carbon fibers with improved tensile strength and interfacial adhesion. Appl. Surf. Sci. 2017, 412, 424–435. [Google Scholar] [CrossRef]

- ASTM D4926-15; Standard Test Method for Gamma Alumina Content in Catalysts and Catalyst Carriers Containing Silica and Alumina by X-Ray Powder Diffraction. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D6938-17ae1; Standard Test Methods for In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth). ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D698-12; Standard Test Methods For Laboratory Compaction Characteristics Of Soil Using Standard Effort (12 400 Ft-Lbf/Ft3 (600 KN-M/M3)). ASTM: West Conshohocken, PA, USA, 2021.

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Borodulina, S.; Kulachenko, A.; Nygårds, M.; Galland, S. Stress-strain curve of paper revisited. Nord. Pulp Pap. Res. J. 2012, 27, 318–328. [Google Scholar] [CrossRef]

- Park, J.; Hyun, C.U.; Park, H.D. Changes in microstructure and physical properties of rocks caused by artificial freeze–thaw action. Bull. Eng. Geol. Environ. 2015, 74, 555–565. [Google Scholar] [CrossRef]

- Zhang, D.W.; Cao, Z.G.; Fan, L.B.; Liu, S.Y.; Liu, W.Z. Evaluation of the influence of salt concentration on cement stabilized clay by electrical resistivity measurement method. Eng. Geol. 2014, 170, 80–88. [Google Scholar] [CrossRef]

- Krajcinovic, D.; Basista, M.; Sumarac, D. Micromechanically Inspired Phenomenological Damage Model. J. Appl. Mech. 1991, 58, 305–310. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2018, 207, 1059–1071. [Google Scholar] [CrossRef]

- Owusu-Ansah, D.; Tinoco, J.; Correia, A.A.S.; Oliveira, P.J.V. Prediction of Elastic Modulus for Fibre-Reinforced Soil-Cement Mixtures: A Machine Learning Approach. Appl. Sci. 2022, 12, 8540. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Ling, X.Z.; Gong, W.G.; Li, P.; Li, G.Y.; Wang, L.N. Mechanical Properties of Fiber-Reinforced Soil under Triaxial Compression and Parameter Determination Based on the Duncan-Chang Model. Appl. Sci. 2020, 10, 9043. [Google Scholar] [CrossRef]

- Xie, S.; Lin, H.; Chen, Y.; Yong, R.; Xiong, W.; Du, S. A damage constitutive model for shear behavior of joints based on determination of the yield point. Int. J. Rock Mech. Min. Sci. 2020, 128, 104269. [Google Scholar] [CrossRef]

| Properties | Moisture Content (%) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Relative Density | Clay Content (%) | Organic Matter Content (%) | pH Value |

|---|---|---|---|---|---|---|---|---|

| Value | 29.40 | 41.54 | 21.01 | 20.53 | 2.71 | 91.10 | 3.71 | 7.91 |

| Ion Types | Cl− | SO42− | Al3+ | Mg+ | Na+ | Ca+ |

|---|---|---|---|---|---|---|

| Content (%) | 9.4 | 2.3 | 5.0 | 2.4 | 15.1 | 1.6 |

| Fiber Length (mm) | Single Filament Diameter (μm) | Density (g/cm3) | Elongation (%) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Corrosion Resistance | Dispersion |

|---|---|---|---|---|---|---|---|

| 3–20 | 10 | 2.13 | 29 | 12.02 | 948 | Strong | Good |

| Materials | Clay | Cement | Fly Ash | Water |

|---|---|---|---|---|

| Mass ratio (%) | 62.5 | 12 | 3 | 22.5 |

| Test No. | Fiber Length (mm) | Fiber Content (%) |

|---|---|---|

| F0 | - | 0 |

| F1, F2, F3, F4, F5 | 15 | 0.1, 0.2, 0.3, 0.4, 0.5 |

| F6, F7, F8, F9, F10 | 10 | 0.1, 0.2, 0.3, 0.4, 0.5 |

| F11, F12, F13, F14, F15 | 5 | 0.1, 0.2, 0.3, 0.4, 0.5 |

| Fiber Content (%) | a | b |

|---|---|---|

| 0 | 1.895 | 0.671 |

| 0.1 | 1.901 | 0.543 |

| 0.2 | 2.231 | 0.488 |

| 0.3 | 2.522 | 0.501 |

| 0.4 | 2.813 | 0.613 |

| 0.5 | 2.864 | 0.726 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, T.; Zhang, X.; Cai, S.; Zhou, Z.; An, R.; Zhang, X. Mechanical Characteristics and Damage Constitutive Model of Fiber-Reinforced Cement-Stabilized Soft Clay. Appl. Sci. 2024, 14, 1378. https://doi.org/10.3390/app14041378

Yan T, Zhang X, Cai S, Zhou Z, An R, Zhang X. Mechanical Characteristics and Damage Constitutive Model of Fiber-Reinforced Cement-Stabilized Soft Clay. Applied Sciences. 2024; 14(4):1378. https://doi.org/10.3390/app14041378

Chicago/Turabian StyleYan, Tiecheng, Xingyuan Zhang, Sutong Cai, Zefeng Zhou, Ran An, and Xianwei Zhang. 2024. "Mechanical Characteristics and Damage Constitutive Model of Fiber-Reinforced Cement-Stabilized Soft Clay" Applied Sciences 14, no. 4: 1378. https://doi.org/10.3390/app14041378