1. Introduction

Nowadays, ultra-precision machining technology is developing towards the scales of micron, submicron and nano. Therefore, traditional cast iron machine tools can hardly satisfy the needs of actual application. The idea of using resin concrete as a bed material emerges for solving this problem. It is a kind of composite material that is mainly composed of aggregates of different sizes and liquid organic resin which hardens through polymerization reaction. Due to its outstanding properties such as high strength, excellent vibration attenuation and thermal stability, resin concrete attracts considerable attention.

Thermal deformation plays a vital role in the appearances of manufacturing errors. Aiming at special demand of ultra-precision computer numerical control (CNC) machine tool for high thermal stability, negative thermal expansion (NTE) material is urgently needed. It contracts upon heating within a certain range of temperature rises and adding NTE material can make the composite in CTE change. Cubic Zirconium Tungstate (ZrW

2O

8) exhibits strong, isotropic NTE behavior in a wide temperature scope from 0.3 K to 1050 K. Kofteros [

1] conducted an experiment of CTE of cement by adding ZrW

2O

8. The experiment results showed addition of ZrW

2O

8 played a vital role in reduction of CTE. By finite element analysis, Yilmaz [

2] studied thermal mismatch stresses of a Cu-ZrW

2O

8composite. Hence, we consider that the addition of ZrW

2O

8 can have a great effect on the thermal ability of resin concrete. The use of ZrW

2O

8 in concrete contributes in providing new advanced composites.

Numerous analytical approaches aiming at effective CTE prediction has been studied extensively in the literature. Turner [

3] assumed that inner material does not exhibit internal stress at initial temperature and the CTE has no relation with the shape and size of the inclusions. It is also assumed that the components only bear isostatic pressure and the dimensional changes of the components and the macro composite material in terms of temperature occur at the same rate. In this model, the CTE of composites depends on volume fraction and bulk modulus of each component. Although this model is in accord with experimental results on some composite systems, deviations can also be observed because of the model assumption [

4]. Considering internal boundaries of composites and shear effects between phase boundaries, Kerner’s model is widely applied for CTE prediction [

5]. The derivation process is based on self-consistent algorithms. In this model, shear modulus of the matrix has an effect on the CTE of composites. This model completely accords with a linear correlation between the CTE of the components and volume fraction of each component [

6]. Schapery [

7] further developed the prediction model and studied bounds on effective CTE of composite materials made up of isotropic phases based onthermo-elastic principles. Upper and lower bounds can be obtained based on the Hashin-Shtrikman [

8] model.

There are also many studies related to the CTE of concrete. Hulsey [

9] investigated the effect of age, moisture content and mix proportion on concrete CTE. Venecanin [

10] explored the influence of aggregate of low CTE to the whole CTE. Sellevold [

11] held that moisture has a big impact on the CTE and proved it. Wyrzykowski [

12] considered that superabsorbent polymers (SAP) can suppress the negative effect of self-desiccation which leads to increase of the CTE. In recent years, some scholars [

13,

14,

15] have developed prediction models for CTE of concrete. Many aspects, such as volume fractions of aggregate, elastic moduli of components, and aggregate type, were investigated to analyze their effects on concrete CTE. However, up to now there is no special model or theory for the CTE of resin concrete. Experiments of the CTE of resin concrete were conducted by Kim [

16] and Haddad [

17]. Nonetheless, adding ZrW

2O

8 as filler to resin concrete has never been taken into account.

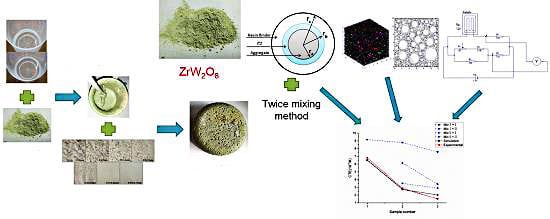

In order to reduce the CTE of resin concrete, we have tried to conduct research from three aspects: the first, making a prediction model; the second, establishing an irregular polygon aggregate particles packing model; the last, conducting experiments.

2. Prediction of the CTE of Resin Concrete Made by Adding ZrW2O8 Powders

The fillers used in the paper are α-phase of ZrW2O8 powders and the average particle size is 250 mesh. Mesh is the number of meshes per unit length (1 inch in Tyler standard screen scale), which can indicate mesh size. Two hundred and fifty mesh is about 58 μm. There is obvious difference between quartz sand and ZrW2O8 powders in aggregate gradation. Therefore, ZrW2O8 powders (fillers) are mixed with resin binder initially (first mixing). Then, the mixtures generated in the previous step are mixed with quartz sand (aggregates) (second mixing). Through the process of “first mixing” and “second mixing", the finished product can be obtained. Cement particle size of common cement mortar is rarely more than 80 μm. Because the maximum particle size of ZrW2O8 powders is 61 μm, the mixing process of resin binder and ZrW2O8 powders is just similar to that of water and cement flour. The descriptions of resin binder, ZrW2O8 and quartz sand are shown in the following sections.

2.1. First Mixing

ZrW

2O

8 powders and resin binder are mixed. Denoting

and

are the volume fractions of ZrW

2O

8 and resin binder in concrete, respectively. Let

be the Young’s modulus, Poisson’s ratio and CTE of the resin binder as matrix and

those of the ZrW

2O

8 powders as fillers. Model-A and Model-B are two different computing methods of CTE for determining the interactions between components of resin concrete. Filler strain is approximately equal to the CTE

of isolated filler embedded in an infinite matrix under the constraint of matrix without considering the interactions between ZrW

2O

8 powders and between matrix and ZrW

2O

8 powders. It is named Model-A of “first mixing”. Thus, the CTE

of the mixtures can be given by [

18]:

where

Due to the dense distribution of fillers, the correlations and interactions between fillers and between the matrix and the filler are under consideration. It is named Model-B of “first mixing”.

represents the macro effective shear modulus of the mixture. Thus, the CTE

of the mixtures can be given by [

18]:

where

As pointed out in [

19], a three-phase model is presented for the prediction of Young’s modulus of concrete. The three phases are inclusion, Interfacial Transition Zone (ITZ) and matrix, as shown in

Figure 1. The Poisson’s ratio of concrete experiences a smaller change than the shear modulus. Hence, in order to simplify the calculation process and be convenient for engineering applications, the transverse series model is used [

20]. Thus, the Poisson’s ratio

of concrete is approximated by:

Where

are the Young’s modulus, Poisson’s ratio and CTE of matrix phase and

those of ITZ layer and

those of inclusion. According to [

20],

Figure 1.

Three-phase model for concrete with Interfacial Transition Zone (ITZ).

Figure 1.

Three-phase model for concrete with Interfacial Transition Zone (ITZ).

According to the inference result in [

19], the Young’s modulus

after mixing can be given by:

where

Therefore, and of the mixture can be solved by Equations (5) and (6).

2.2. Second Mixing

Quartz sand and the mixtures after the first mixing process are mixed. Let

be the Young’s modulus, Poisson’s ratio and CTE of the quartz sand as aggregates. Denoting

and

are the volume fractions of quartz sand and resin binder in concrete, respectively.

and

are the restraint CTE of isolated aggregate embedded in an infinite matrix in “Model-A + Model-A” and “Model-B + Model-A” model, respectively.

is the macro effective shear modulus of the final mixture. Due to the prediction models that are presented in the previous paper, Model-A and Model-B are also available in “second mixing” while replacing ZrW

2O

8 powders with quartz sand. They are named Model-A of “second mixing” and Model-B of “second mixing”, respectively. Thus, we also have two choices in the second mixing process, so there are four prediction results in all. For instance, “Model-B + Model-A” means that Model-B is used in “first mixing” and Model-A is applied to “second mixing”. These results can be obtained from

by the replacement as shown in

Table 1

Table 1.

Substitution table.

Table 1.

Substitution table.

| Model | | Substitute | For |

|---|

| Model-A + Model-A | | | |

| Model-B + Model-A | | |

| Model-A + Model-B | | | |

| Model-B + Model-B | | |

According to optimum proportion of resin binder to the sum of fillers and aggregates provided by the manufacturer, three mixing compositions used in this study are outlined in

Table 2. Results of the prediction formula are shown in

Table 3. Sample No.1 is a mixture of resin binder and quartz sand without ZrW

2O

8 powder. Hence, the mixing process cannot be divided into “first mixing” and “second mixing”. So, “Model-A + Model-B” and “Model-B + Model-A” do not exist. For Sample No.1, “Model-A + Model-A” means that Model-A is used in whole mixing process. Similarly, “Model-B + Model-B” means that Model-B is applied.

Table 2.

Comparison of the proportions of three mixing compositions.

Table 2.

Comparison of the proportions of three mixing compositions.

| No. | Subject | Mass ratio | Volume ratio |

|---|

| 1 | Resin binder:quartz | 0.073:0.927 | 0.148:0.852 |

| 2 | Resin binder:quartz:ZrW2O8 | 0.066:0.742:0.192 | 0.148:0.767:0.085 |

| 3 | Resin binder:quartz:ZrW2O8 | 0.059:0.597:0.344 | 0.148:0.682:0.170 |

Table 3.

Results of the prediction formula.

Table 3.

Results of the prediction formula.

| No. | CTE (× 10−6/K) |

|---|

| Model A + A | Model A + B | Model B + A | Model B + B |

|---|

| 1 | 9.161 | --- | --- | 6.598 |

| 2 | 8.777 | 3.512 | 6.158 | 2.768 |

| 3 | 7.577 | 2.909 | 3.403 | 1.536 |

5. Results and Discussion

In order to facilitate the discussion, the experimental data of

Table 3,

Table 6 and

Table 7 are all shown in

Figure 6. As seen in

Figure 6, it might be concluded that the prediction equation of “Model-B + Model-B” and the irregular polygon model has higher accuracy because the broken lines of “Model-B + Model-B”, simulation and experiment match well with each other. For “Model-A + Model-A”, “Model-A + Model-B” and “Model-B + Model-A”, there are obvious deviations due to neglecting interactions between components. The addition of ZrW

2O

8 can significantly reduce the CTE of resin concrete. Sample No.3 has lower CTE than the other two samples. The volume ratio of aggregate to ZrW

2O

8 powders is an important factor which influences the concrete CTE.

Figure 6.

Comparison between prediction, simulation and experimental results.

Figure 6.

Comparison between prediction, simulation and experimental results.