A Metal-Insulator-Metal Deep Subwavelength Cavity Based on Cutoff Frequency Modulation

Abstract

:1. Introduction

2. Dispersion Properties and Cutoff Frequency

3. Results

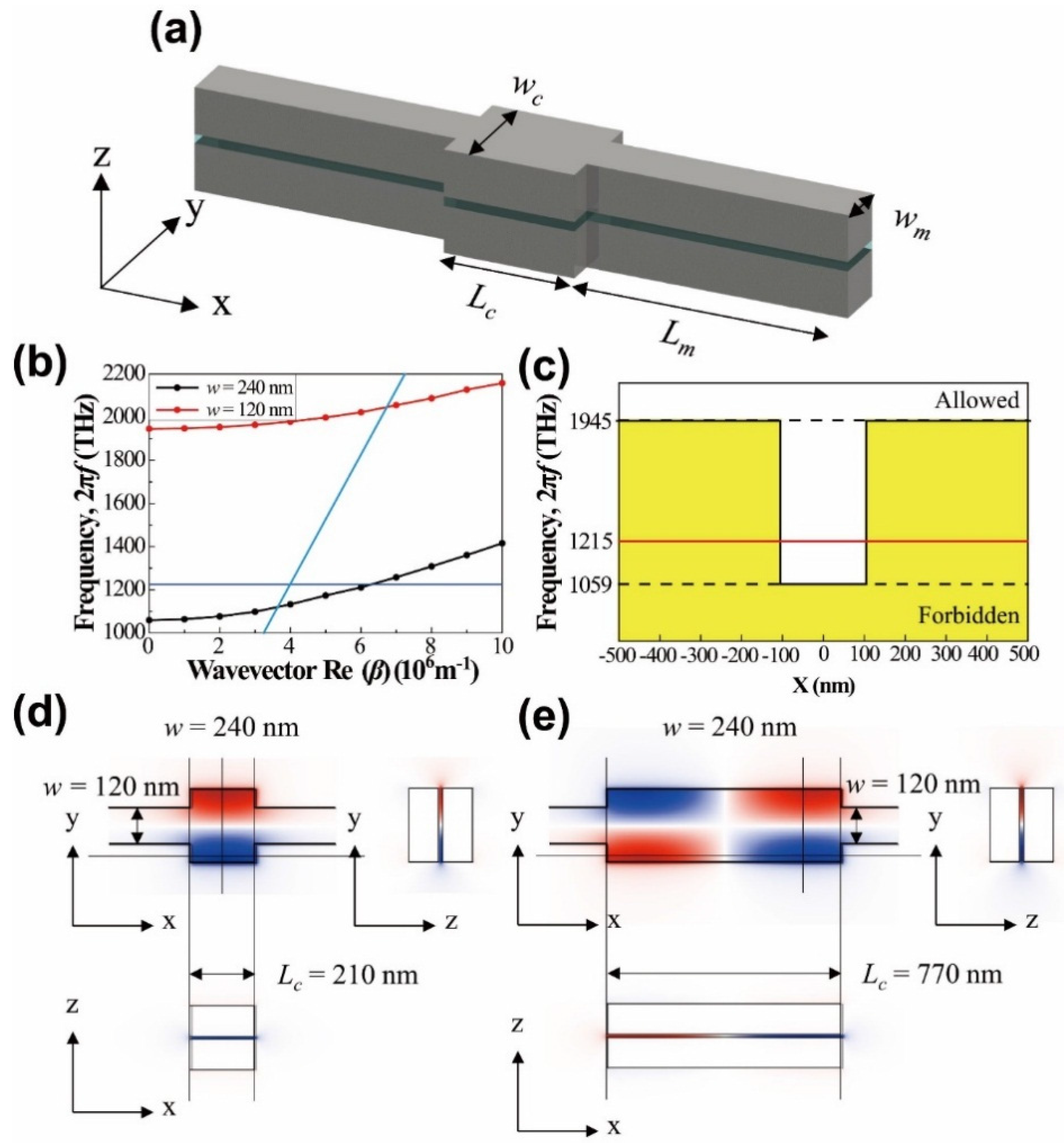

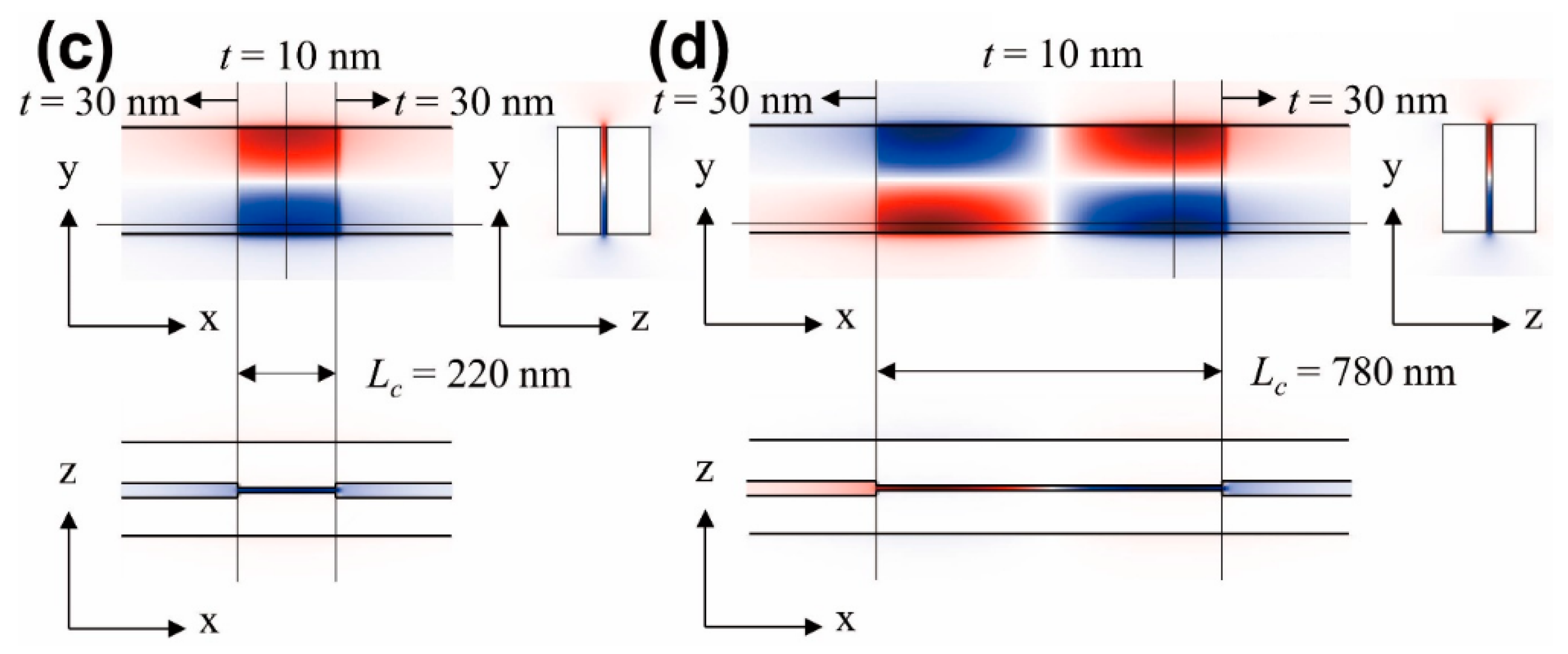

3.1. Waveguide Width-Modulated Cavity

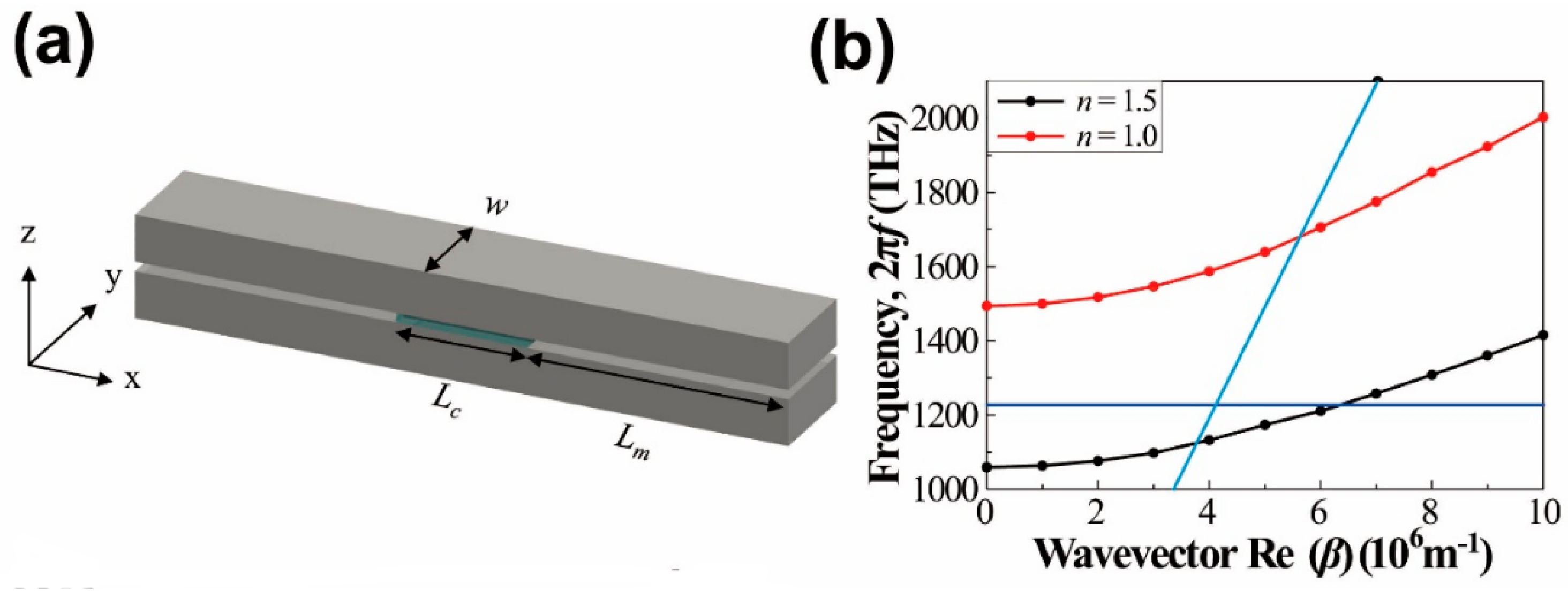

3.2. Refractive Index-Modulated Cavity

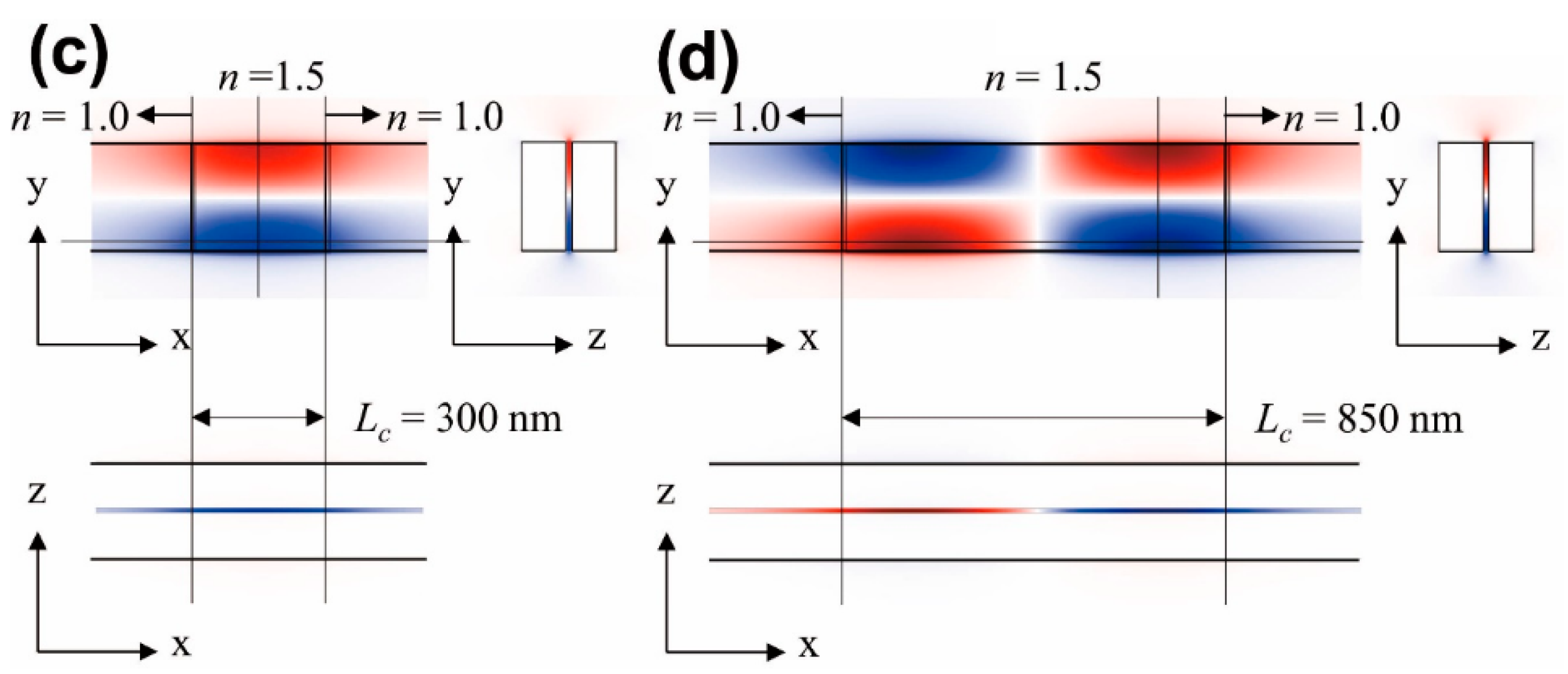

3.3. Gap Size-Modulated Cavity

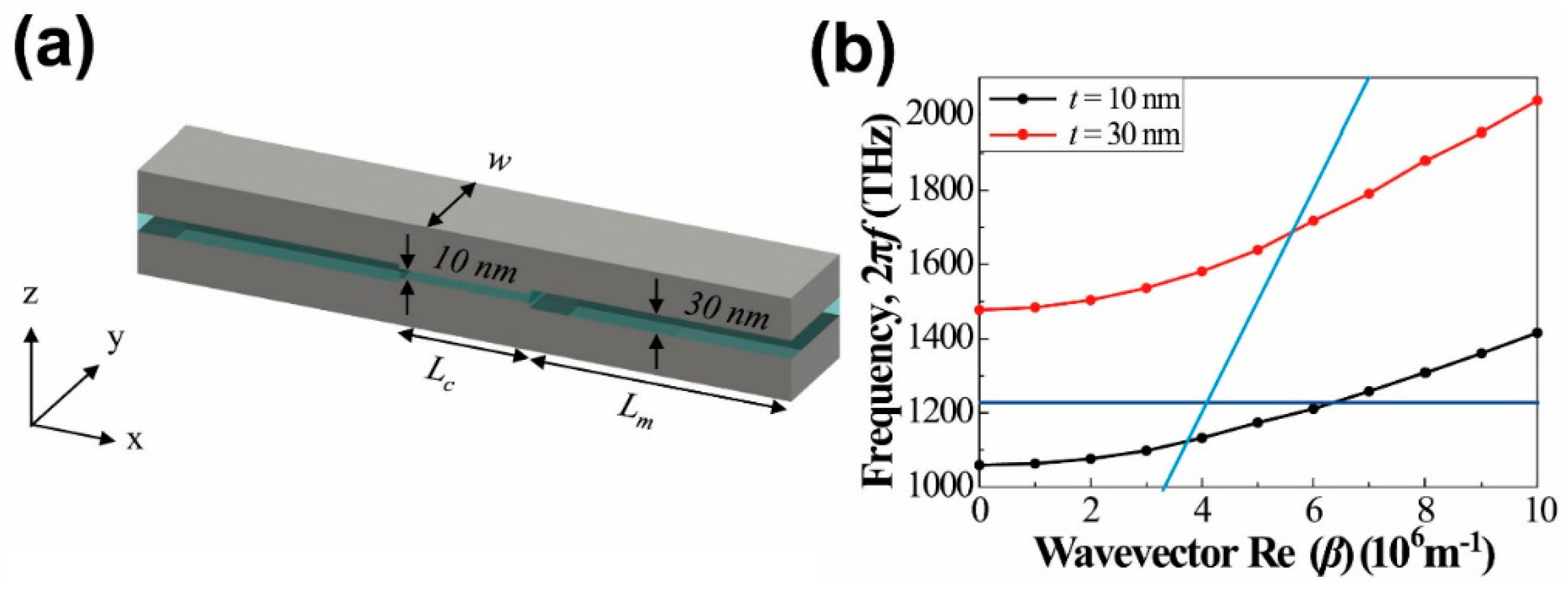

3.4. Loss Analysis for the Three Cavities

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Suface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef] [PubMed]

- Gramotnev, D.K.; Bozhevolnyi, S.I. Plasmonics beyond the diffraction limit. Nat. Photonics 2010, 4, 83–91. [Google Scholar] [CrossRef]

- Wei, H.; Li, Z.P.; Tian, X.R.; Wang, Z.X.; Cong, F.Z.; Liu, N.; Zhang, S.P.; Nordlander, P.; Halas, N.J.; Xu, H.X. Quantum dot-based local field imaging reveals plasmon-based interferometric logic in silver nanowire networks. Nano Lett. 2010, 11, 471–475. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.M.; Oulton, R.F.; Sorger, V.J.; Bartal, G.; Zhang, X. Room-temperature sub-diffraction-limited plasmon laser by total internal reflection. Nat. Mater. 2011, 10, 110–113. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.P.; Xu, H.X. Optimizing substrate-mediated plasmon coupling toward high-performance plasmonic nanowire waveguides. ACS Nano 2012, 6, 8128–8135. [Google Scholar] [CrossRef] [PubMed]

- Oulton, R.F.; Sorger, V.J.; Zentgraf, T.; Ma, R.M. Plasmon lasers at deep subwavelength scale. Nature 2009, 461, 629–632. [Google Scholar] [CrossRef] [PubMed]

- Nikolajsen, T.; Leosson, K.; Bozhevolnyi, S.I. Surface plasmon based modulators and switches operating at telecom wavelengths. Appl. Phys. Lett. 2004, 85, 5833–5835. [Google Scholar] [CrossRef]

- Fang, Y.R.; Li, Z.P.; Huang, Y.Z.; Zhang, S.P.; Nordlander, P.; Halas, N.J.; Xu, H.X. Branched silver nanowires as controllable plasmon routers. Nano Lett. 2010, 10, 1950–1954. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.Y.; Lu, S.P.; Lin, J.W.; Lee, P.T. High sensitivity plasmonic index sensor using slablike gold nanoring arrays. Appl. Phys. Lett. 2011, 98, 153108. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.H. Deep subwavelength-scale metal-insulator-metal plasmonic disk cavities for refractive index sensor. IEEE Photonics J. 2013, 5, 4800107. [Google Scholar] [CrossRef]

- Volkov, V.S.; Bozhevolnyi, S.I.; Devaux, E.; Laluet, J.Y.; Ebbesen, T.W. Wavelength selective nanophotonic components utilizing channel plasmon polaritons. Nano Lett. 2007, 7, 880–884. [Google Scholar] [CrossRef] [PubMed]

- Rahimzadegan, A.; Granpayyeh, N.; Hosseini, S.P. Improved plasmonic filter, ultra-compact demultiplexer, and splitter. J. Opt. Soc. Korea 2014, 18, 261–273. [Google Scholar] [CrossRef]

- Lee, T.W.; Lee, D.E.; Kwon, S.H. Dual-function metal-insulator-metal plasmonic opticla filter. IEEE Photonics J. 2015, 7, 4800108. [Google Scholar] [CrossRef]

- Veronis, G.; Fan, S.H. Modes of subwavelength plasmonic slot waveguides. J. Lightwave Technol. 2007, 25, 2511–2521. [Google Scholar] [CrossRef]

- Pile, D.F.P.; Ogawa, T.; Gramotnev, D.K.; Matsuzaki, Y.; Vernon, K.C.; Yamaguchi, K.; Okamoto, T.; Haraguchi, M.; Fukui, M. Two-dimensionally localized modes of a nanscale gap plasmon waveguide. Appl. Phys. Lett. 2005, 87, 261114. [Google Scholar] [CrossRef]

- Tagliabue, G.; Poulikakos, D.; Eghlidi, H. Three-dimensional concentration of light in deeply sub-wavelength, laterally tapered gap-plasmon nanocavities. Appl. Phys. Lett. 2016, 108, 221108. [Google Scholar] [CrossRef]

- Kuttge, M.; de Abajo, F.J.G.; Polman, A. Ultasnall mode volume plasmonic nanodisk trsonators. Nano Lett. 2010, 10, 1537–1541. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.H. Deep subwavelength plasmonic whispering-gallery-mode cavity. Opt. Express 2012, 20, 24918–24924. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.H.; Bozhevolnyi, S.I. Plasmon-induced transparency with detuned ultracompact Fabry-Perot resonators in integrated plasmonic devices. Opt. Express 2011, 19, 3251–3257. [Google Scholar] [CrossRef] [PubMed]

- Zand, I.; Abrichamian, M.S.; Berini, P. Highly tunable nanoscale metal-insulator-metal split ring core ring resonators (SRCRRs). Opt. Express 2013, 21, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.H. Plasmonic ruler with angstrom distance resolution based on double metal block. IEEE Photonics Technol. Lett. 2013, 25, 1619–1622. [Google Scholar] [CrossRef]

- Lassiter, J.B.; McGuire, F.; Mock, J.J.; Ciralci, C.; Hill, R.T.; Wiley, B.J.; Chilkoti, A.; Smith, D.R. Plasmonic waveguide modes of film-coupled metallic nanocubes. Nano Lett. 2013, 13, 5866–5872. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, M.G.; Gramotnev, D.K.; Pors, A.; Albrektsen, O.; Bozhevolnyi, S.I. Continuous layer gap plasmon resonators. Opt. Express 2011, 19, 19310–19322. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, H.T.; Kurokawa, Y. Contolled plasmon resonance in closed metal/insulator/metal nanocavities. Appl. Phys. Lett. 2006, 89, 211126. [Google Scholar] [CrossRef]

- Oulton, R.F.; Sorger, V.J.; Genov, D.A.; Pile, D.F.P.; Zhang, X. A hybrid plasmonic waveguide for subwavelength confinement and long-range propagation. Nat. Photonics 2008, 2, 496–500. [Google Scholar] [CrossRef]

- Johnson, S.G.; Fan, S.; Mekis, A.; Joannopoulos, J.D. Multipole-cancellation mechanism for high-Q cavities in the absence of a complete photonic and gap. Appl. Phys. Lett. 2001, 78, 3388–3390. [Google Scholar] [CrossRef]

- Hill, M.T.; Oei, Y.S.; Smalbrugge, B.; Zhu, Y.; De Vries, T.; Van Veldhoven, P.J.; Van Otten, F.W.M.; Eijkemans, T.J.; Turkiewicz, J.P.; De Waardt, H.; et al. Lasing in metallic-coated nanocavities. Nat. Photonics 2007, 1, 589–594. [Google Scholar] [CrossRef]

- Lu, H.; Liu, X.M.; Wang, L.R.; Gong, Y.K.; Mao, D. Ultrafast all-optical switching in nanoplasmonic waveguide Kerr nonlinear resonator. Opt. Express 2011, 19, 2910–2915. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.Y.; Lo, G.Q.; Kwong, D.L. Theorical investigation of silicide Schottky barrier detector integrated in horizontal metal-insulator-metal nanoplasmonic slot waveguide. Opt. Express 2011, 19, 15843–15854. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Yang, Q.; Fan, F.; Xu, H.; Wang, Z.L. Light Propagation in Curved Silver Nanowire Plasmonic Waveguides. Nano Lett. 2011, 11, 1603–1608. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Xu, H. Nanowire-based plasmonic waveguides and devices for integrated nanophotonic circuits. Nanophotonics 2012, 1, 155–169. [Google Scholar] [CrossRef]

- Gramotnev, D.K.; Nielsen, M.G.; Tan, S.J.; Kurth, M.L.; Bozhevolnyi, S.I. Gap surface plasmon waveguides with enhanced integration and functionality. Nano Lett. 2012, 12, 359–363. [Google Scholar] [CrossRef] [PubMed]

- Veronis, G.; Fan, S.H. Theoretical investigation of compact couplers between dielectric slab waveguides and two-dimensional metal-dielectric-metal plasmonic waveguides. Opt. Express 2007, 15, 1211–1221. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.Q.; Tsang, H.K. High Coupling Efficiency Silicon Waveguide to Metal-Insulator-Metal Waveguide Mode Converter. J. Lightwave Technol. 2016, 34, 2467–2472. [Google Scholar] [CrossRef]

| Cavity Type | Fundamental Mode | Second Order Mode | ||||||

|---|---|---|---|---|---|---|---|---|

| Qtotal | Qrad | Qabs | Qm | Qtotal | Qrad | Qabs | Qm | |

| Width-modulated cavity (Figure 2) | 45.5 | 101 | 82.8 | 9.05 × 105 | 63.2 | 260 | 83.6 | 1.81 × 106 |

| Index-modulated cavity (Figure 3) | 38.6 | 71.7 | 83.7 | 9.68 × 104 | 56.8 | 175 | 84.2 | 1.71 × 105 |

| Gap-modulated cavity (Figure 4) | 37.3 | 64.0 | 89.7 | 1.42 × 104 | 56.6 | 164 | 86.6 | 2.82 × 104 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, K.; Lee, T.-W.; Lee, Y.J.; Kwon, S.-H. A Metal-Insulator-Metal Deep Subwavelength Cavity Based on Cutoff Frequency Modulation. Appl. Sci. 2017, 7, 86. https://doi.org/10.3390/app7010086

Moon K, Lee T-W, Lee YJ, Kwon S-H. A Metal-Insulator-Metal Deep Subwavelength Cavity Based on Cutoff Frequency Modulation. Applied Sciences. 2017; 7(1):86. https://doi.org/10.3390/app7010086

Chicago/Turabian StyleMoon, Kihwan, Tae-Woo Lee, Young Jin Lee, and Soon-Hong Kwon. 2017. "A Metal-Insulator-Metal Deep Subwavelength Cavity Based on Cutoff Frequency Modulation" Applied Sciences 7, no. 1: 86. https://doi.org/10.3390/app7010086

APA StyleMoon, K., Lee, T.-W., Lee, Y. J., & Kwon, S.-H. (2017). A Metal-Insulator-Metal Deep Subwavelength Cavity Based on Cutoff Frequency Modulation. Applied Sciences, 7(1), 86. https://doi.org/10.3390/app7010086