Automated Defect Recognition as a Critical Element of a Three Dimensional X-ray Computed Tomography Imaging-Based Smart Non-Destructive Testing Technique in Additive Manufacturing of Near Net-Shape Parts

Abstract

:1. Introduction

1.1. Computed Tomography in Comparison with Destructive Testing Methods

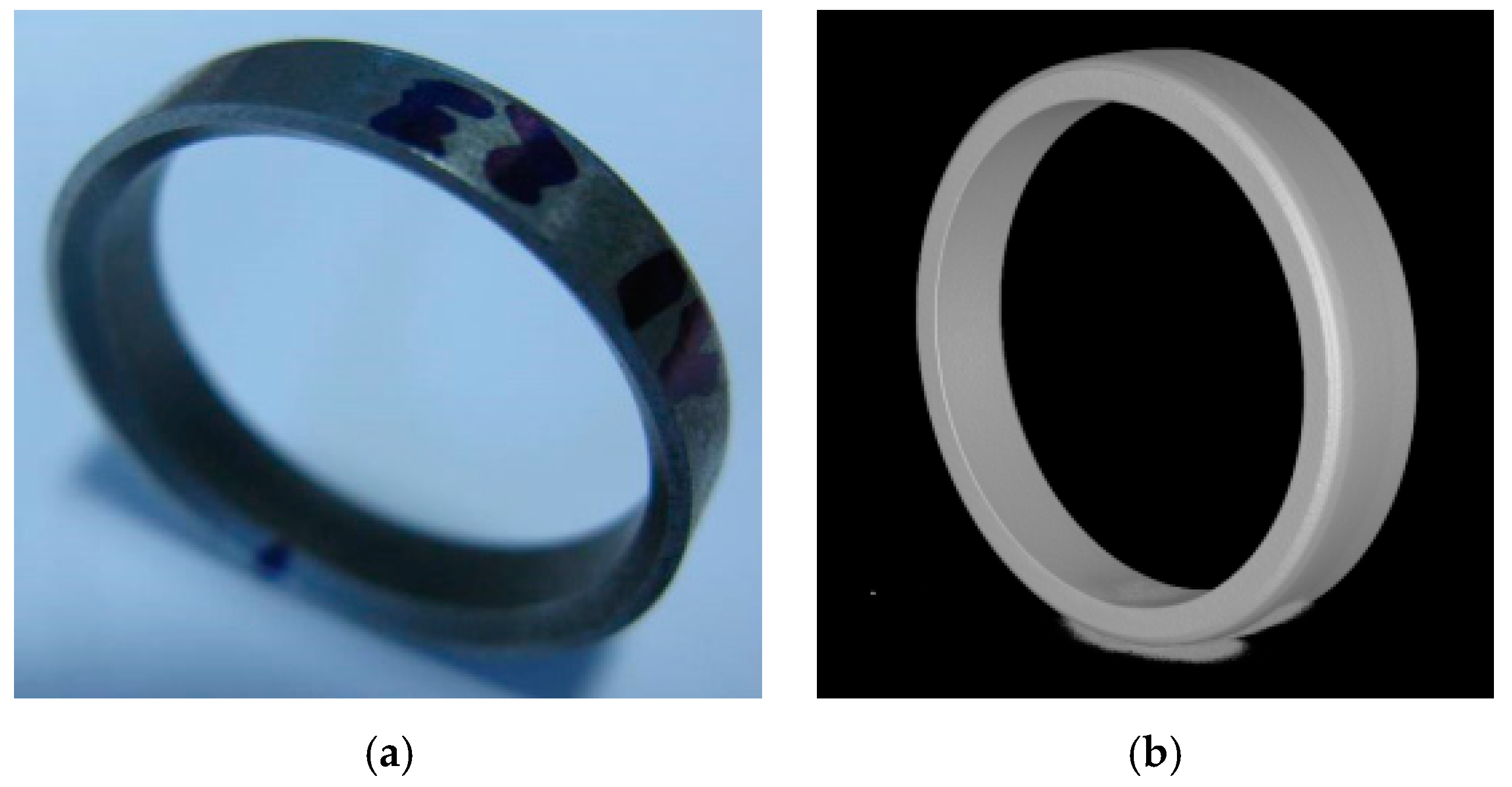

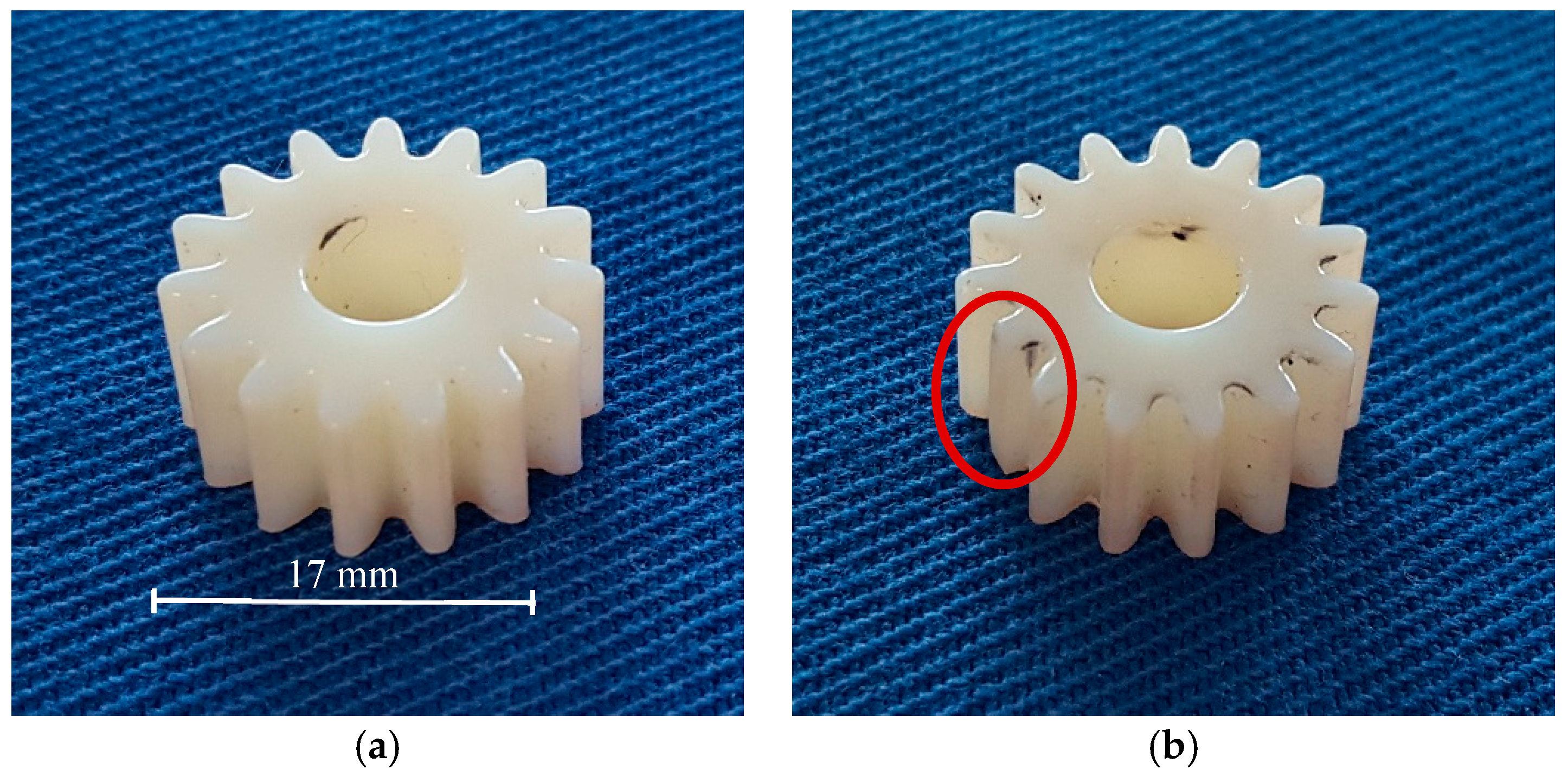

1.2. Brief Theory of Computed Tomography; from Medical to Industrial

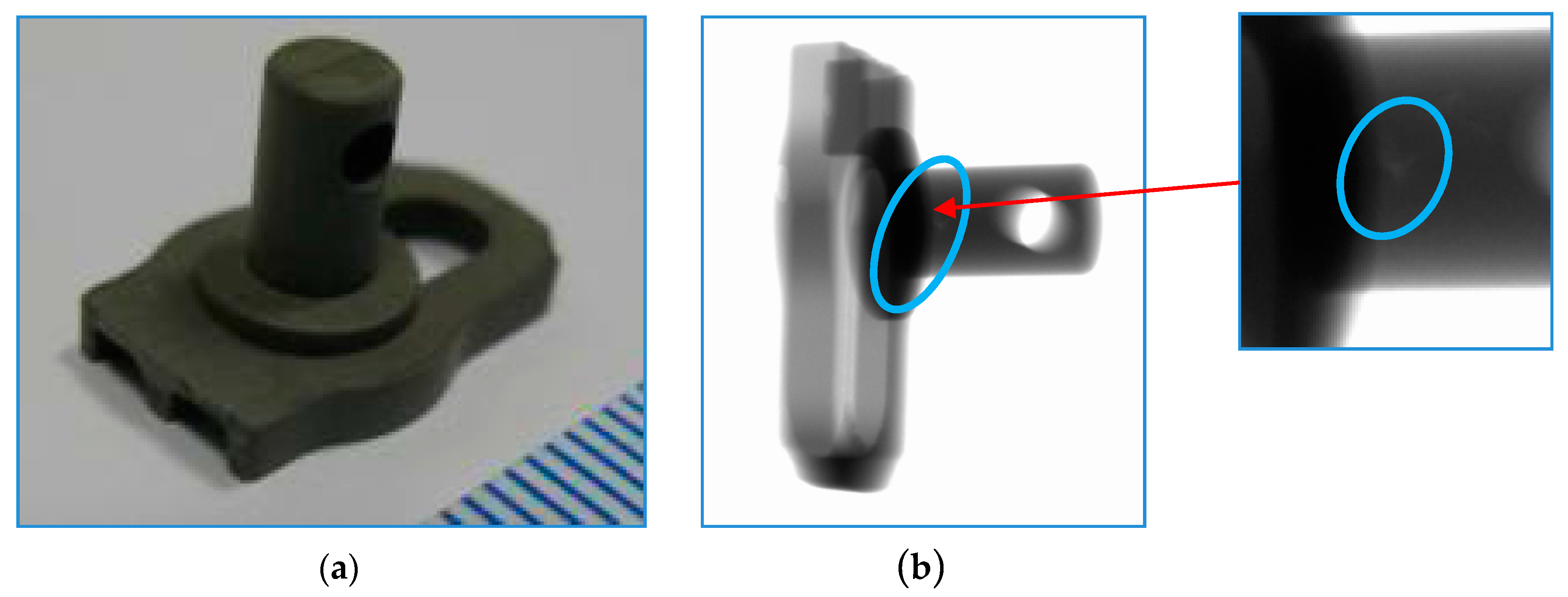

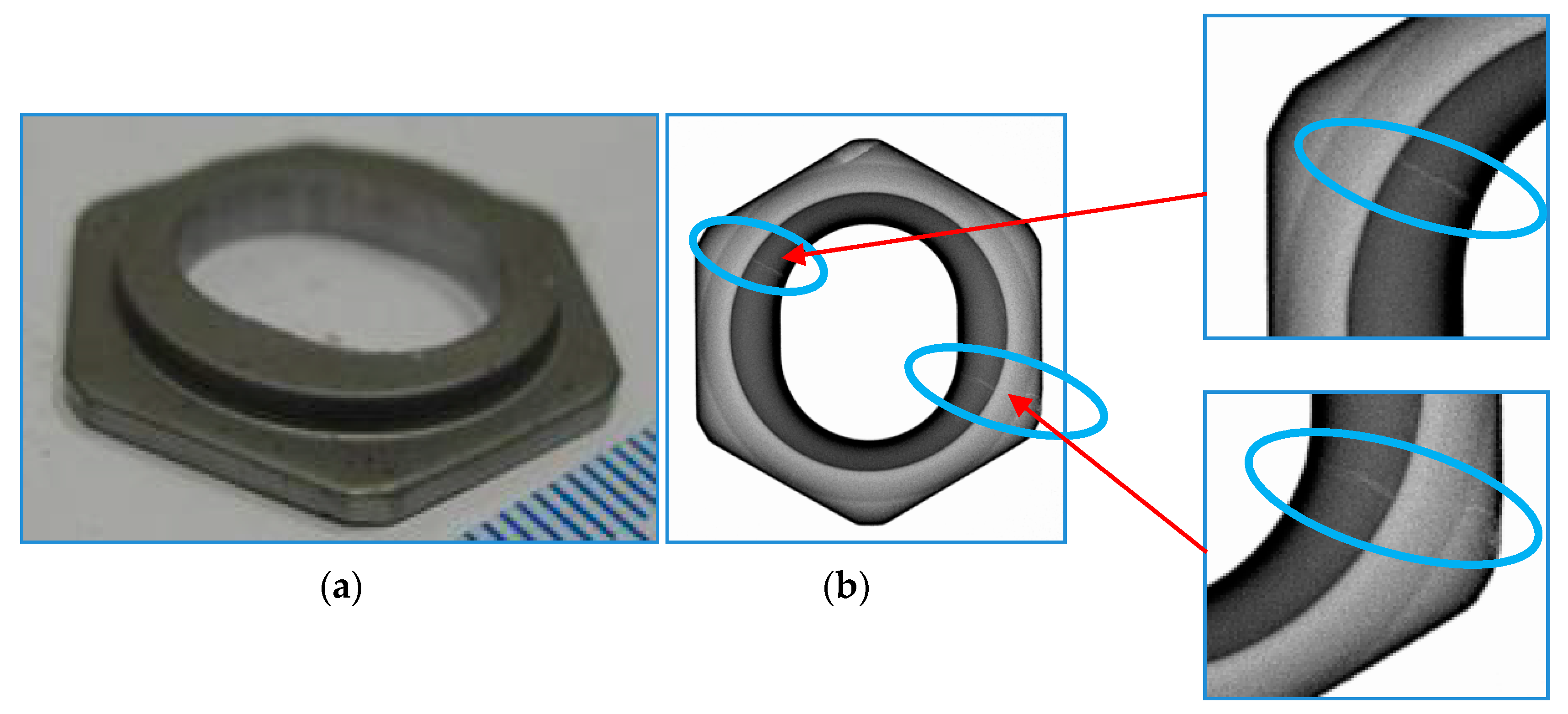

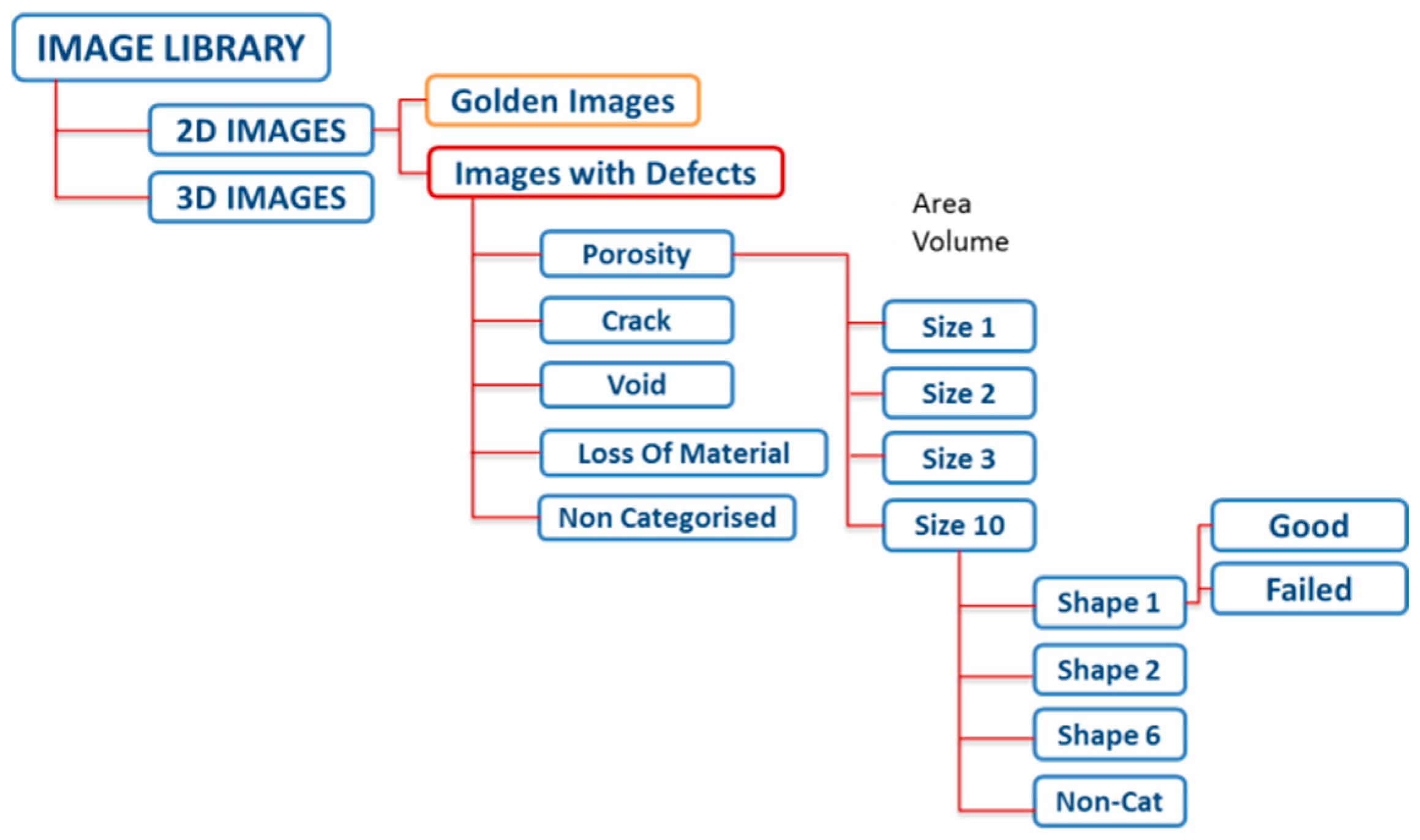

2. Structure of Defect Image Library and CT Simulation with CIVA X-ray Simulation Software

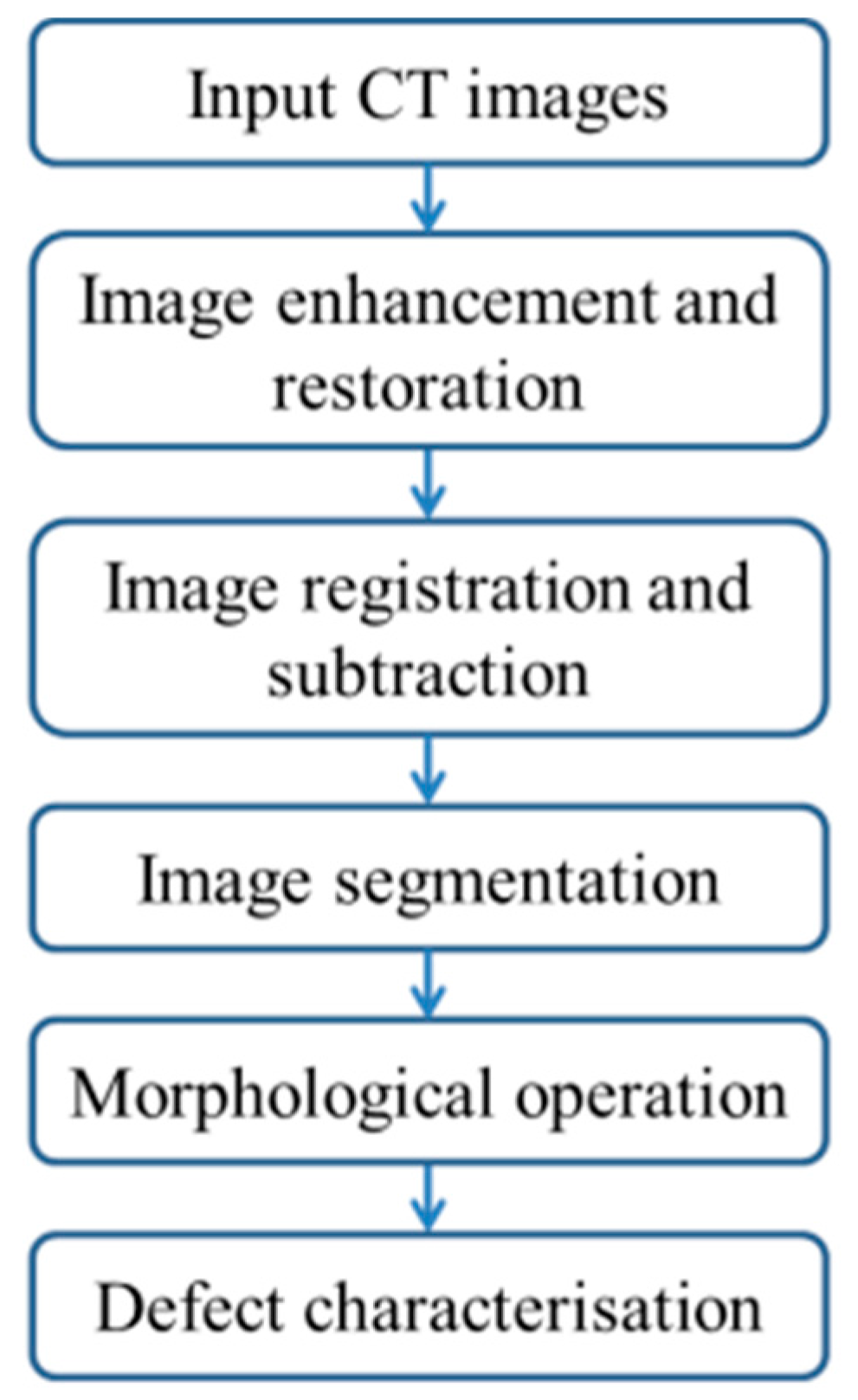

3. Image Processing Procedure

3.1. Image Restoration and Enhancement

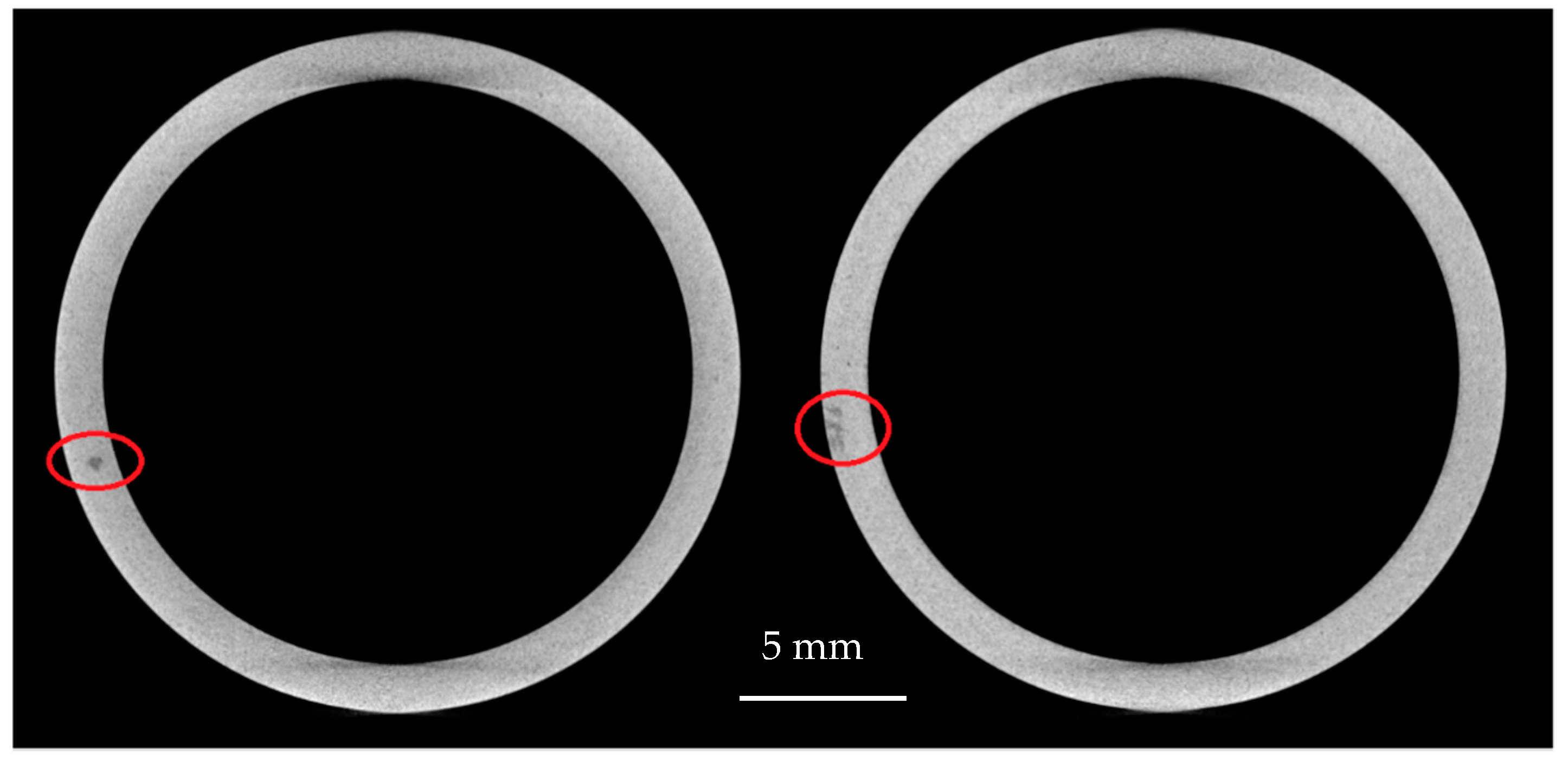

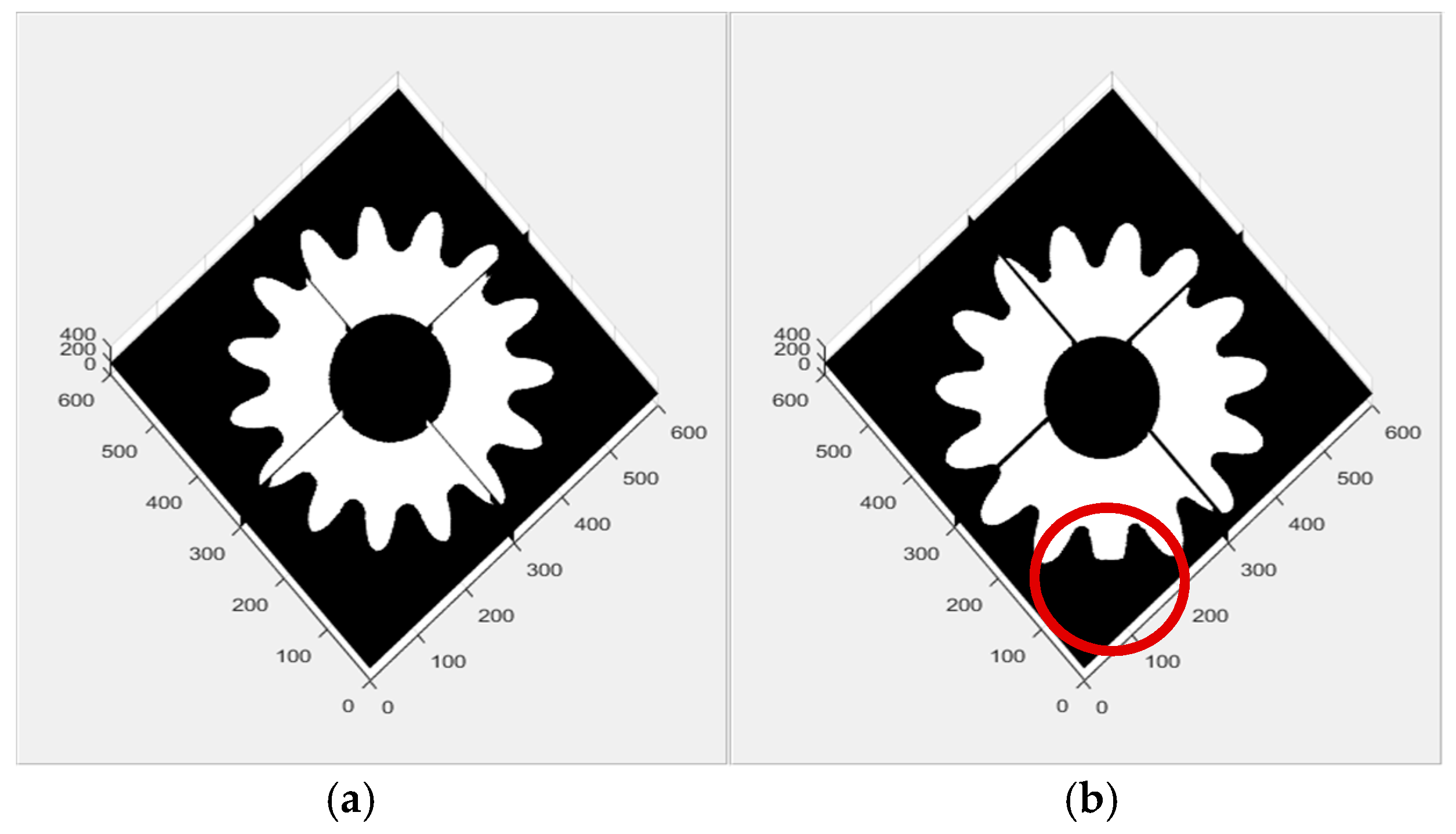

3.2. Image Registration and Subtraction

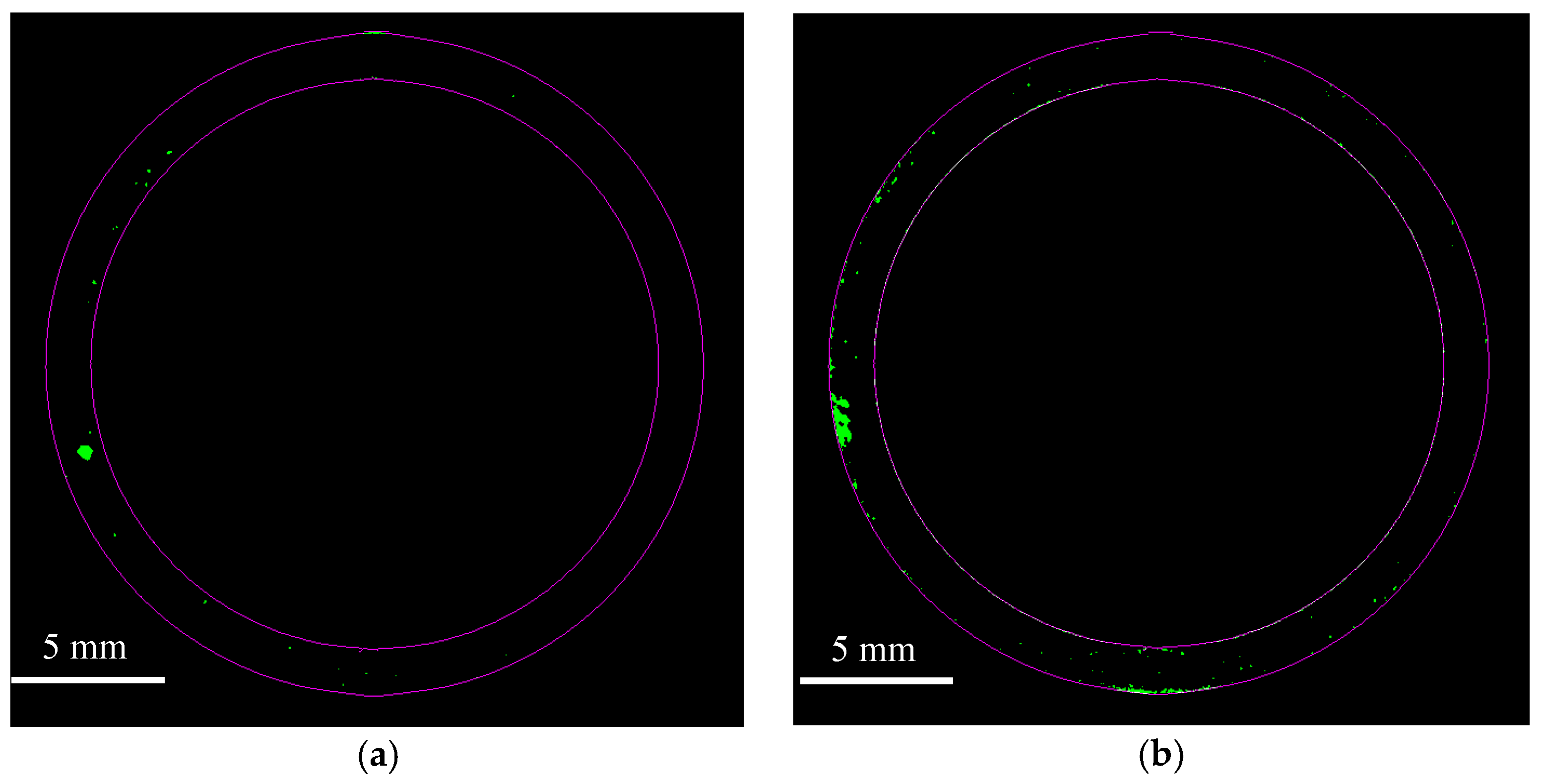

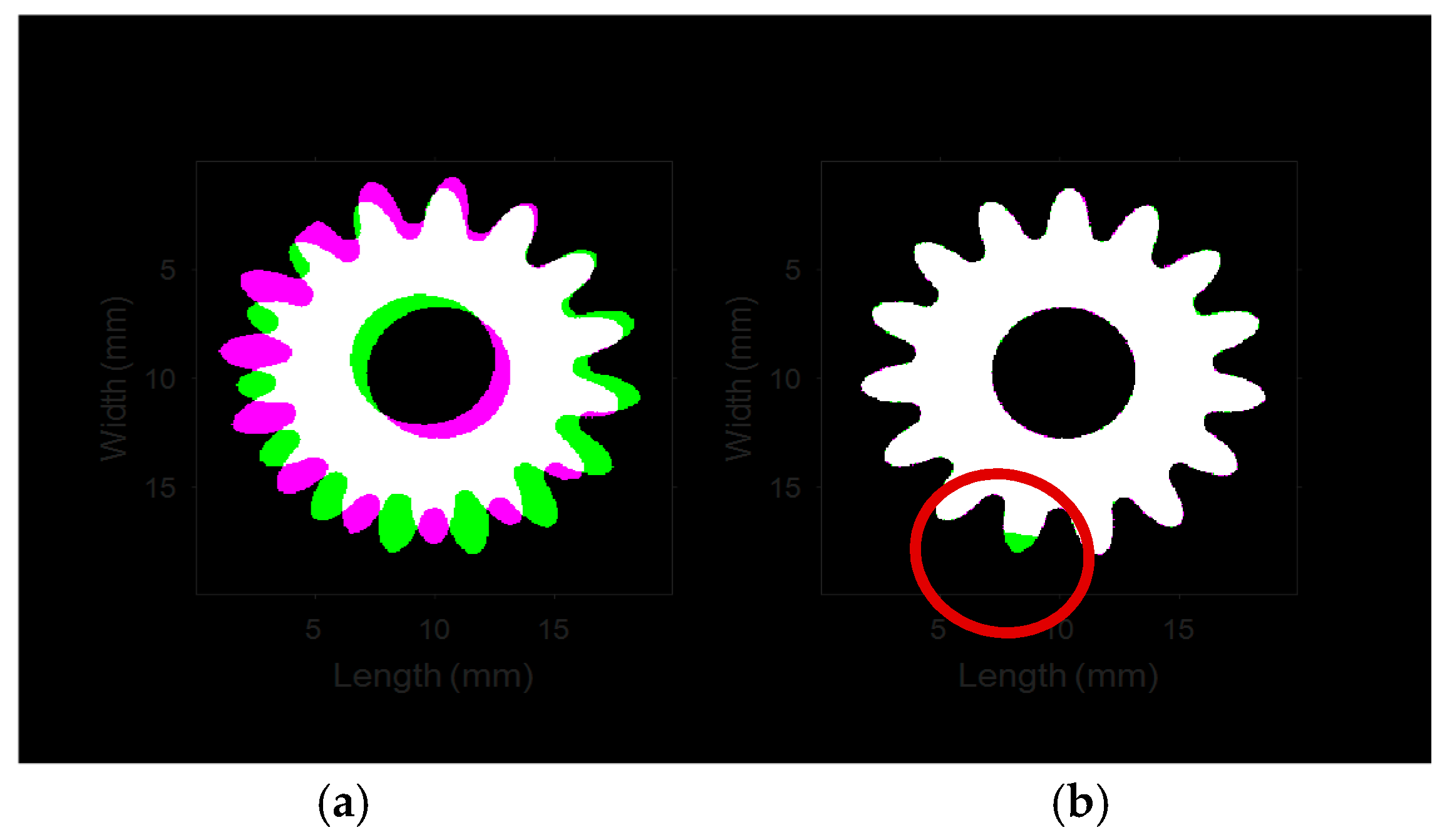

3.3. Image Segmentation

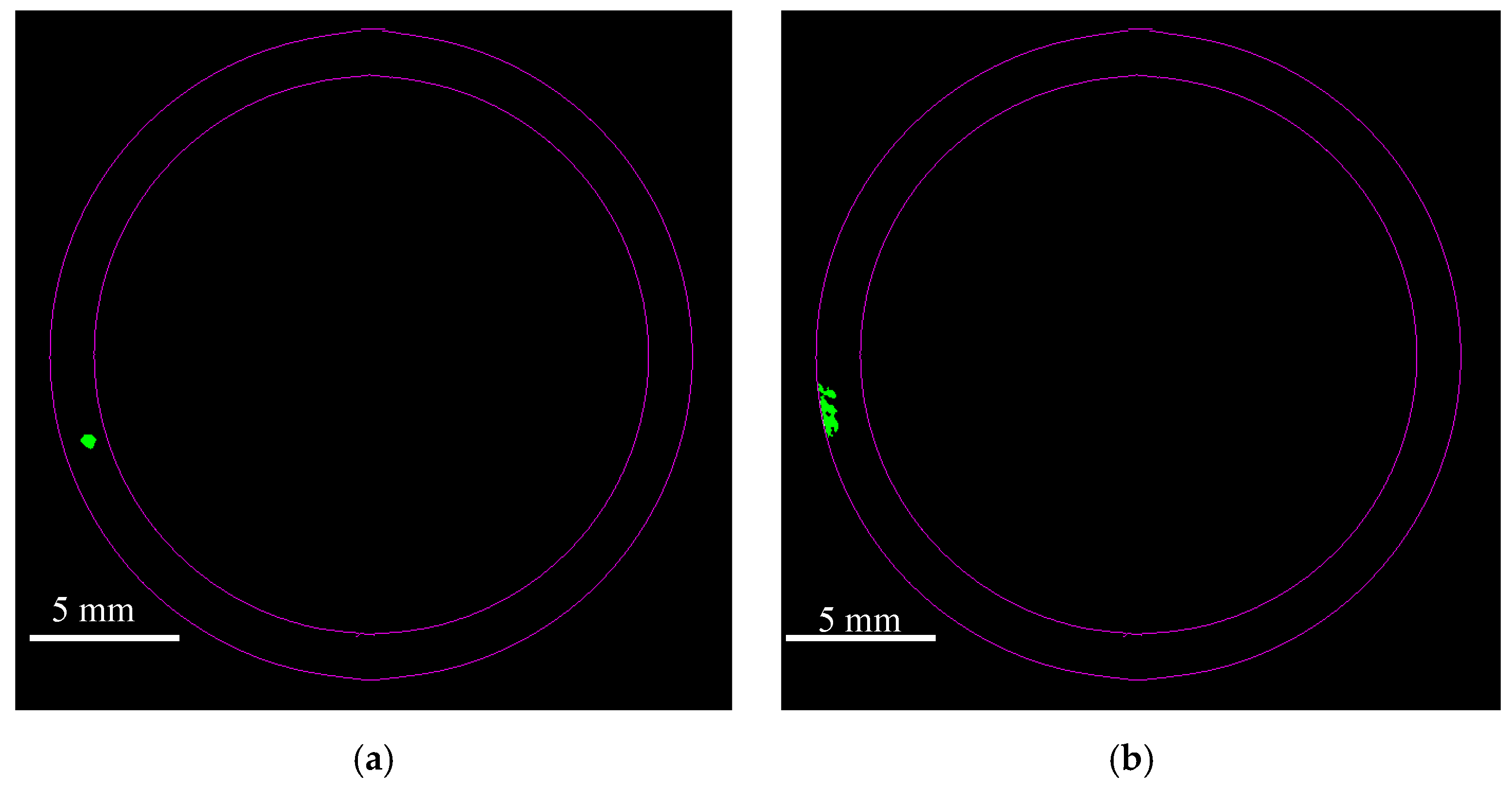

3.4. Morphological Operation

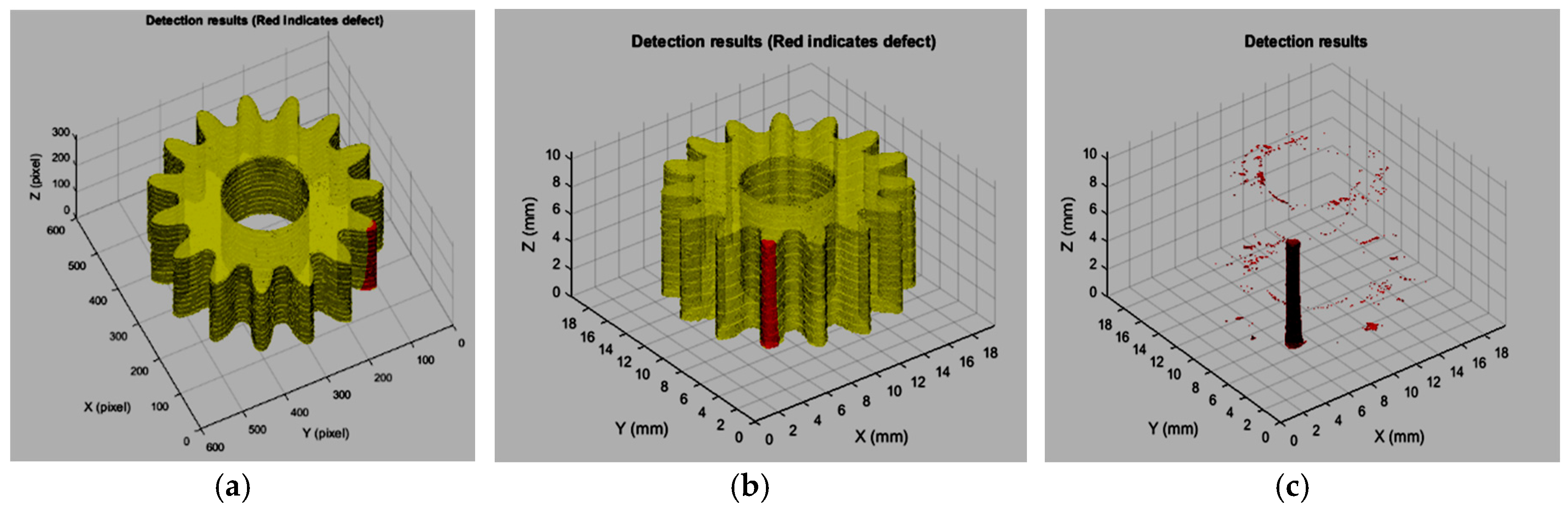

4. Experimental Results

5. Automated Defect Recognition across the Whole 3D Reconstructed CT Image

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- German, R.M. Powder Metallurgy Science; Metal Powder Industries Federation: Princeton, NJ, USA, 1994. [Google Scholar]

- Klar, E. (Ed.) Powder Metallurgy: Applications, Advantages and Limitations; American Society for Metals: Metals Park, OH, USA, 1983. [Google Scholar]

- Selcuk, C. Advanced Powder Metallurgy, Properties, Processing and Applications; Chang, I., Zhao, Y., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2013; p. 380. [Google Scholar]

- Zenger, D.; Cai, H. The Common Cracks in Green P/M Compacts Handbook; Powder Metallurgy Research Centre, Worcester Polytechnic Institute: Worcester, MA, USA, 1996. [Google Scholar]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. Densification mechanism and microstructural evolution in selective laser sintering of Al–12Si Powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Moore, E.H.; Semiatin, S.L. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti–6Al–4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar] [CrossRef]

- Vander Voort, G.F. ASM Handbook—Metallography and Microstructures Volume 9; ASM International: Almere, The Netherlands, 2004; ISBN 978-0-87170-706-2. [Google Scholar]

- DeGarmo, E.P.; Black, J.T.; Kohser, R.A. DeGarmo’s Materials and Processes in Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 660. [Google Scholar]

- Clark, L.A.; Vieyra, M.; Nicholson, P.I.; Szabo, I.; Logeswaran, G.; Kappatos, V.; Selcuk, C. Development of an automated digital radiography system for the non-destructive inspection of green powder metallurgy parts. In Proceedings of the Euro PM2014 Congress, Salzburg, Austria, 21–24 September 2014. [Google Scholar]

- Bulkai, A.; Baranyai, Z.; Halmi, G.; Their, F.; Ignatev, M.; Scharff, W.; Szabo, I.; Logeswaran, G.; Kappatos, V.; Selcuk, C.; et al. Enable the powder metallurgy process to expand to new markets with more reliable parts and lower manufacturing costs through the inspection of green parts. In Proceedings of the Euro PM2014, Salzburg, Austria, 21–4 September 2014. [Google Scholar]

- Vander Voort, G.F. Metallography: Principles and Practice; Materials Park, ASM International: Almere, The Netherlands; Mc Grow Hill Ltd.: New York, NY, USA, 1999; Chapter 2; p. 60. [Google Scholar]

- Ketcham, R.A.; Carlson, W.D. Acquisition, optimization and interpretation of X-ray computed tomographic imagery: Applications to the geosciences. Comput. Geosci. 2001, 27, 381–400. [Google Scholar] [CrossRef]

- De Chiffre, L.; Carmignato, S.; Kruth, J.P.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. CIRP Ann. Manuf. Technol. 2014, 63, 655–677. [Google Scholar] [CrossRef]

- Sterzing, A.; Neugebauer, R.; Drossel, W.-G. Metal Forming—Challenges from a Green Perspective. In Proceedings of the International Conference on Competitive Manufacturing (COMA 2013), Stellenbosch, South Africa, 30 January–1 February 2013; pp. 19–24. [Google Scholar]

- Christoph, R.; Neumann, H.J. X-ray Tomography in Industrial Metrology; Suddeutscher Verlag onpact GmbH: Munich, Germany, 2011; ISBN 978-3-86236-020-8. [Google Scholar]

- Szabo, I.; Sun, J.; Kappatos, V.; Selcuk, C.; Gan, T.H. Enclosure design and development for non-destructive inspection tool based on digital radiography of green PM parts. In Proceedings of the 7th International Powder Metallurgy Conference and Exhibition (TPM-7), Ankara Turkey, 24–28 June 2014. [Google Scholar]

- Yoon, J.; Lee, J.; Kim, B.; Shin, Y.G. An Automated Detection Method of Solder Joint Defects using 3D Computed Tomography for IC Package Inspection. In Proceedings of the 2011 First ACIS International Symposium on Software and Network Engineering, Seoul, Korea, 19–20 December 2011. [Google Scholar]

- Katunin, A.; Dańczak, M.; Kostka, P. Automated identification and classification of internal defects in composite structures using computed tomography and 3D wavelet analysis. Arch. Civ. Mech. Eng. 2015, 15, 436–448. [Google Scholar] [CrossRef]

- Fernandez, R.; Legoupil, S.A.; Costin, M.; Leveque, A. CIVA computed tomography modelling. In Proceedings of the 18th World Conference on Non-destructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Rosenfeld, A.; Kak, A.C. Digital Picture Processing, Vol. 2; Academic Press: Cambridge, MA, USA, 1982. [Google Scholar]

- Kong, T.Y.; Rosenfeld, A. Digital topology: Introduction and survey. Comput. Vis. Graph. Image Process. 1989, 48, 357–393. [Google Scholar] [CrossRef]

- Udupa, J.K. Multidimensional digital boundaries. CVGIP Graph. Models Image Process. 1994, 56, 311–323. [Google Scholar] [CrossRef]

- Available online: http://uk.mathworks.com/help/images/intensity-based-automatic-image-registration.html (accessed on 7 November 2017).

- Khunt, D.P.; Makwana, Y.N. Image registration using intensity based technique. J. Inf. Knowl. Res. Electron. Commun. Eng. 2013, 2, 607–609. [Google Scholar]

- Wong, A.K.; Sahoo, P.K.; Soltani, S.A.K.C. Chen A survey of thresholding techniques. Comput. Vis. Graph. Image Process. 1988, 41, 233–260. [Google Scholar]

- Sezgin, M.; Sankur, B. Selection of thresholding methods for non-destructive testing applications. In Proceedings of the 2001 International Conference on Image Processing, Thessaloniki, Greece, 7–10 October 2001; pp. 764–767. [Google Scholar]

- Kapur, J.N.; Sahoo, P.K.; Wong, A.K.C. A new method for grey-level picture thresholding using the entropy of the histogram. Comput. Vis. Graph. Image Process. 1985, 29, 273–285. [Google Scholar] [CrossRef]

- Haralick, R.M.; Sternberg, S.R.; Zhuang, X. Image analysis using mathematical morphology. IEEE Trans. Pattern Anal. Mach. Intell. 1987, 9, 532–550. [Google Scholar] [CrossRef] [PubMed]

- Ponomarev, M.G.; Kappatos, V.; Selcuk, C.; Gan, T.-H.; Amos, M.; Halai, H.; Gierl, C.; Iovea, M. Digital radiographic inspection technique for production friendly quality assessment of PM parts. Powder Metall. 2013, 56, 92–95. [Google Scholar] [CrossRef]

- Ponomarev, M.G.; Secuk, C.; Gan, T.-H.; Amos, M.; Nicholson, I.; Iovea, M.; Neagu, M.; Stefanescu, B.; Mateiasi, G. Defect detection and classification system for automatic analysis of digital radiography images of PM parts. Powder Metall. 2014, 57, 17–20. [Google Scholar] [CrossRef]

| Type of Equipment: X-Tek HMXCT 225 | Source to Detector Distance: 1112 mm |

| Detector: Perkin Elmer 1620 16-bit flat-panel | Source to object distance: 125 mm |

| Focal spot/source size: 0.005 mm | Magnification: 8.9 |

| Target Material: Tungsten (W) | Tube voltage: 210 kV |

| Beam angle: 90° | Tube current: 280 µA |

| Exposure: 354 ms | Filters: 2 mm Copper at source |

| Number of frames averaged: 4/projection | IQI: NA |

| Number of projections: 1000 | Voxel Resolution: 0.023 µm3 |

| Rotation Angle Step: 0.36 degrees | Reconstruction Algorithm: Filter back projection |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabo, I.; Sun, J.; Feng, G.; Kanfoud, J.; Gan, T.-H.; Selcuk, C. Automated Defect Recognition as a Critical Element of a Three Dimensional X-ray Computed Tomography Imaging-Based Smart Non-Destructive Testing Technique in Additive Manufacturing of Near Net-Shape Parts. Appl. Sci. 2017, 7, 1156. https://doi.org/10.3390/app7111156

Szabo I, Sun J, Feng G, Kanfoud J, Gan T-H, Selcuk C. Automated Defect Recognition as a Critical Element of a Three Dimensional X-ray Computed Tomography Imaging-Based Smart Non-Destructive Testing Technique in Additive Manufacturing of Near Net-Shape Parts. Applied Sciences. 2017; 7(11):1156. https://doi.org/10.3390/app7111156

Chicago/Turabian StyleSzabo, Istvan, Jiangtao Sun, Guojin Feng, Jamil Kanfoud, Tat-Hean Gan, and Cem Selcuk. 2017. "Automated Defect Recognition as a Critical Element of a Three Dimensional X-ray Computed Tomography Imaging-Based Smart Non-Destructive Testing Technique in Additive Manufacturing of Near Net-Shape Parts" Applied Sciences 7, no. 11: 1156. https://doi.org/10.3390/app7111156