Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway

Abstract

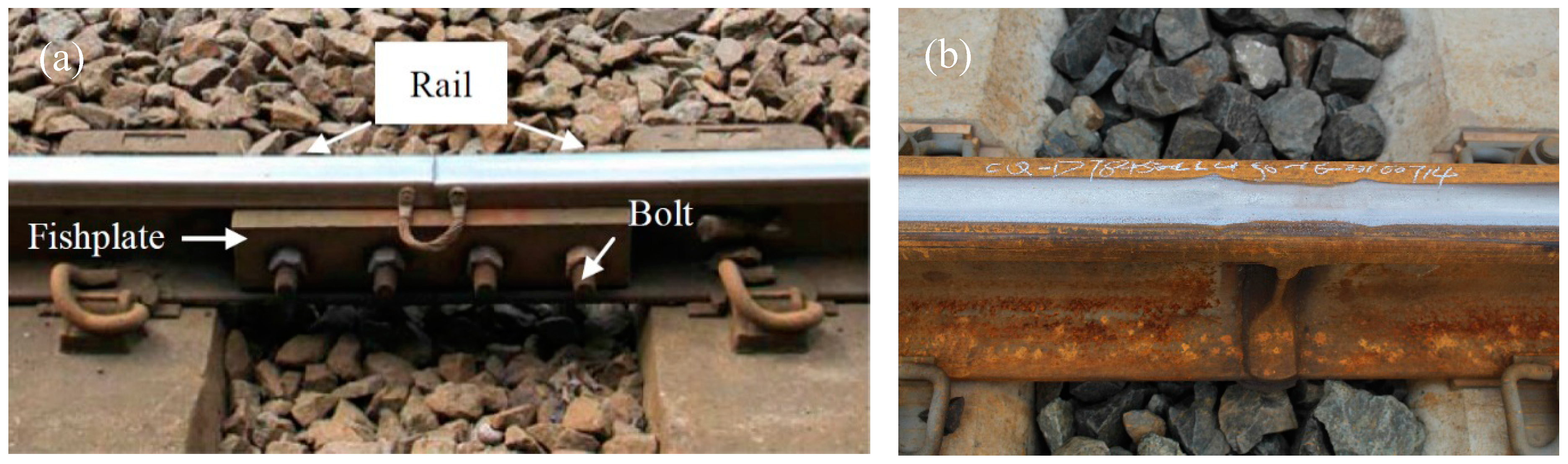

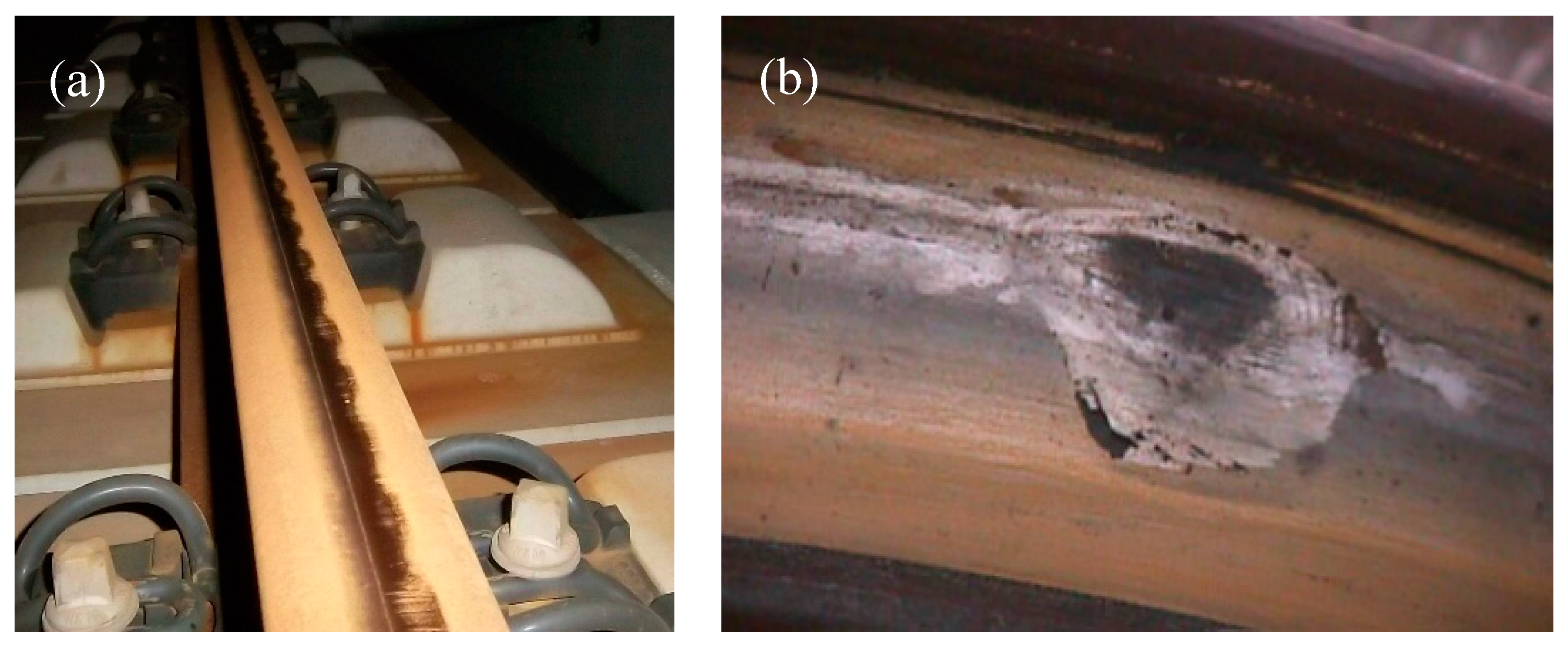

:1. Introduction

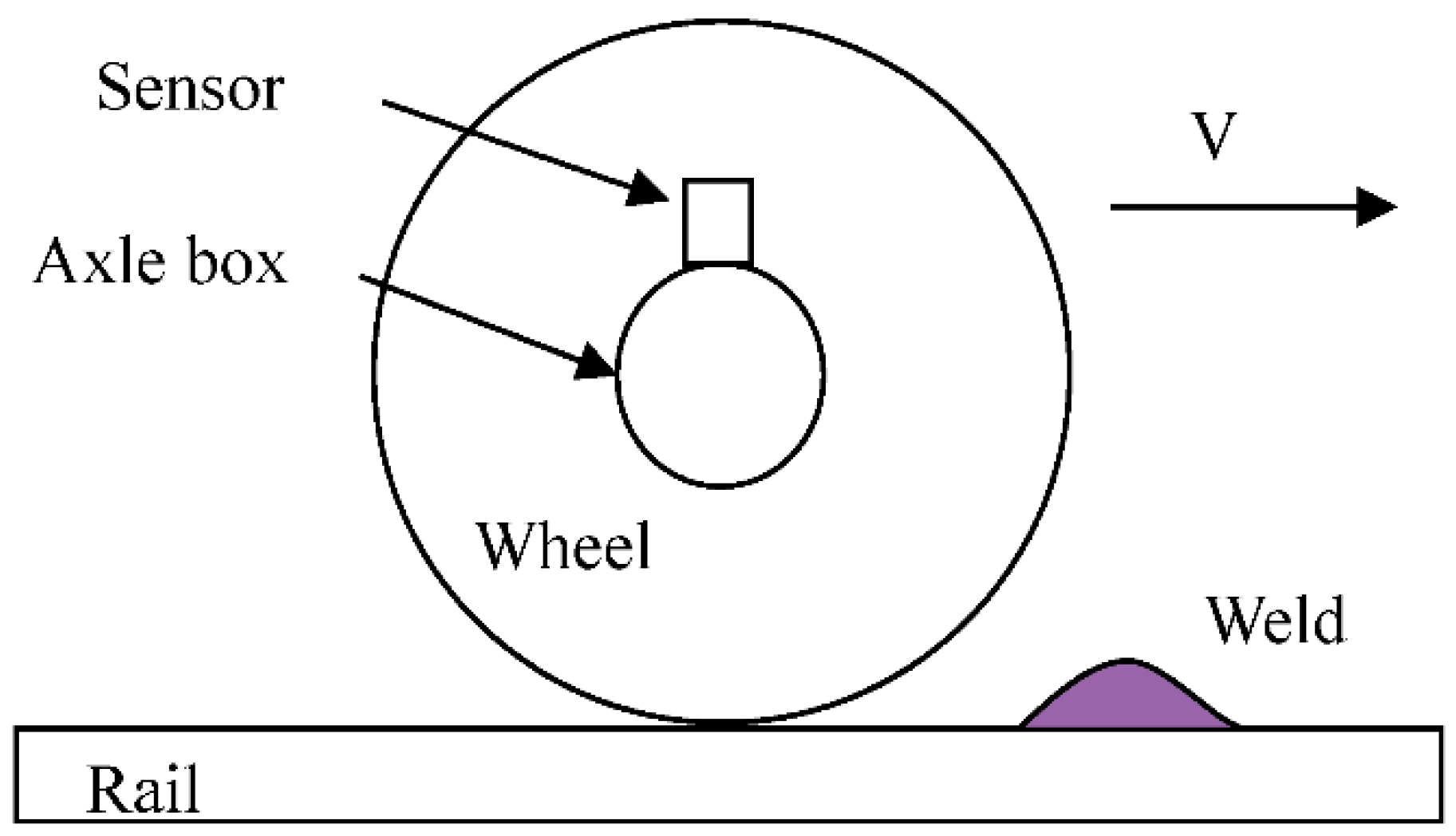

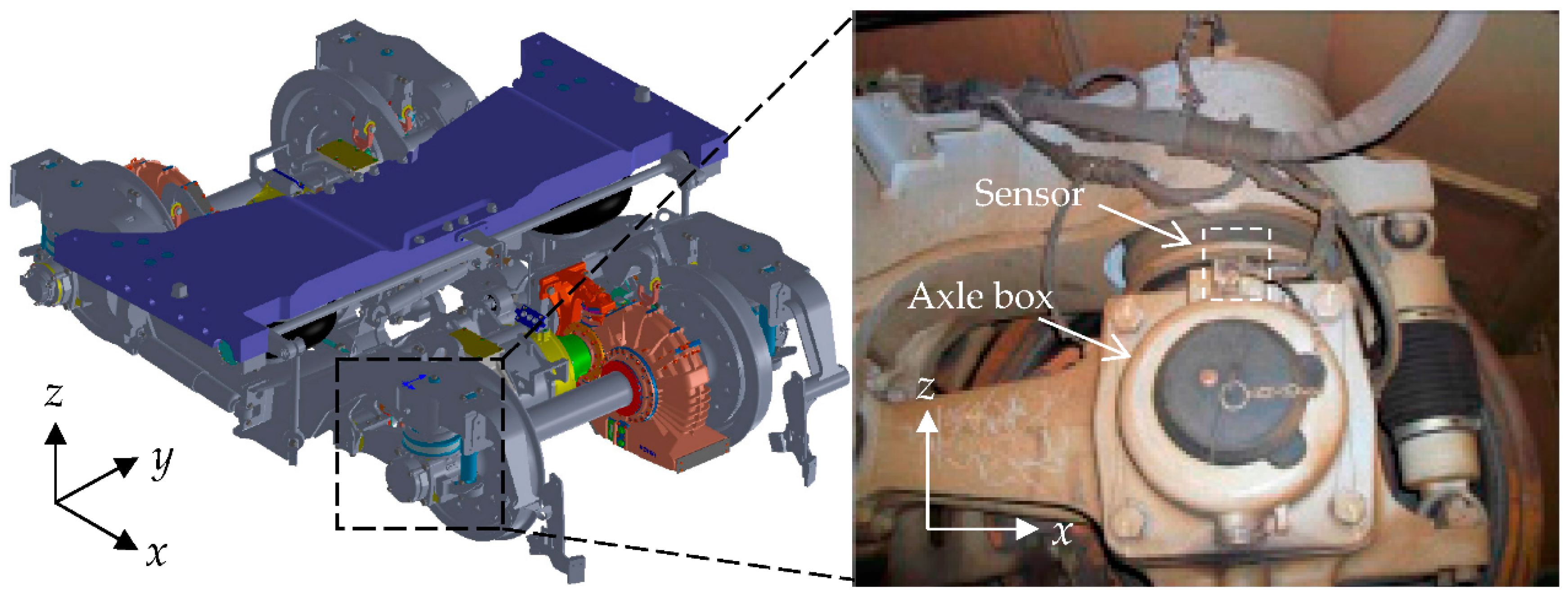

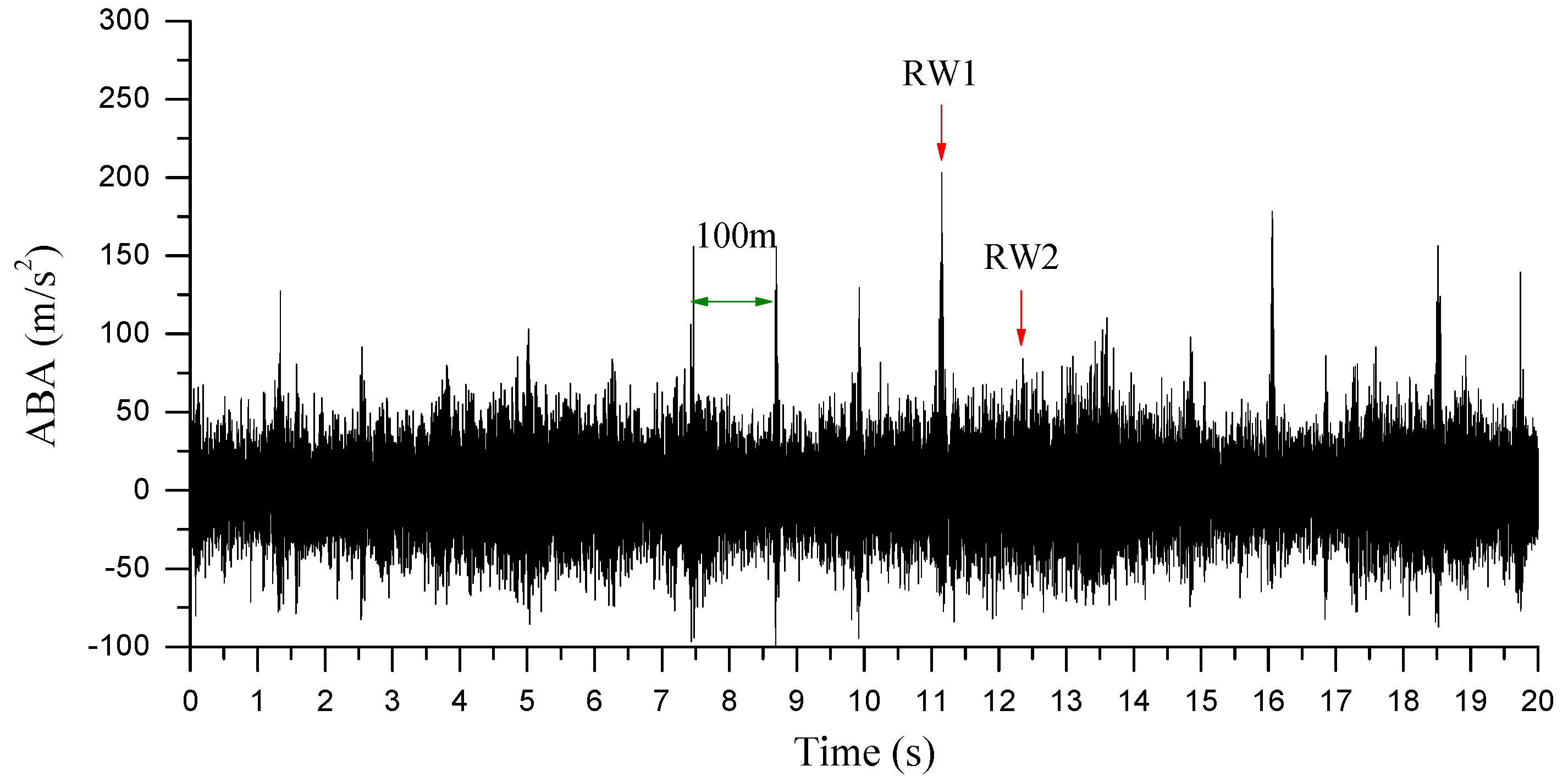

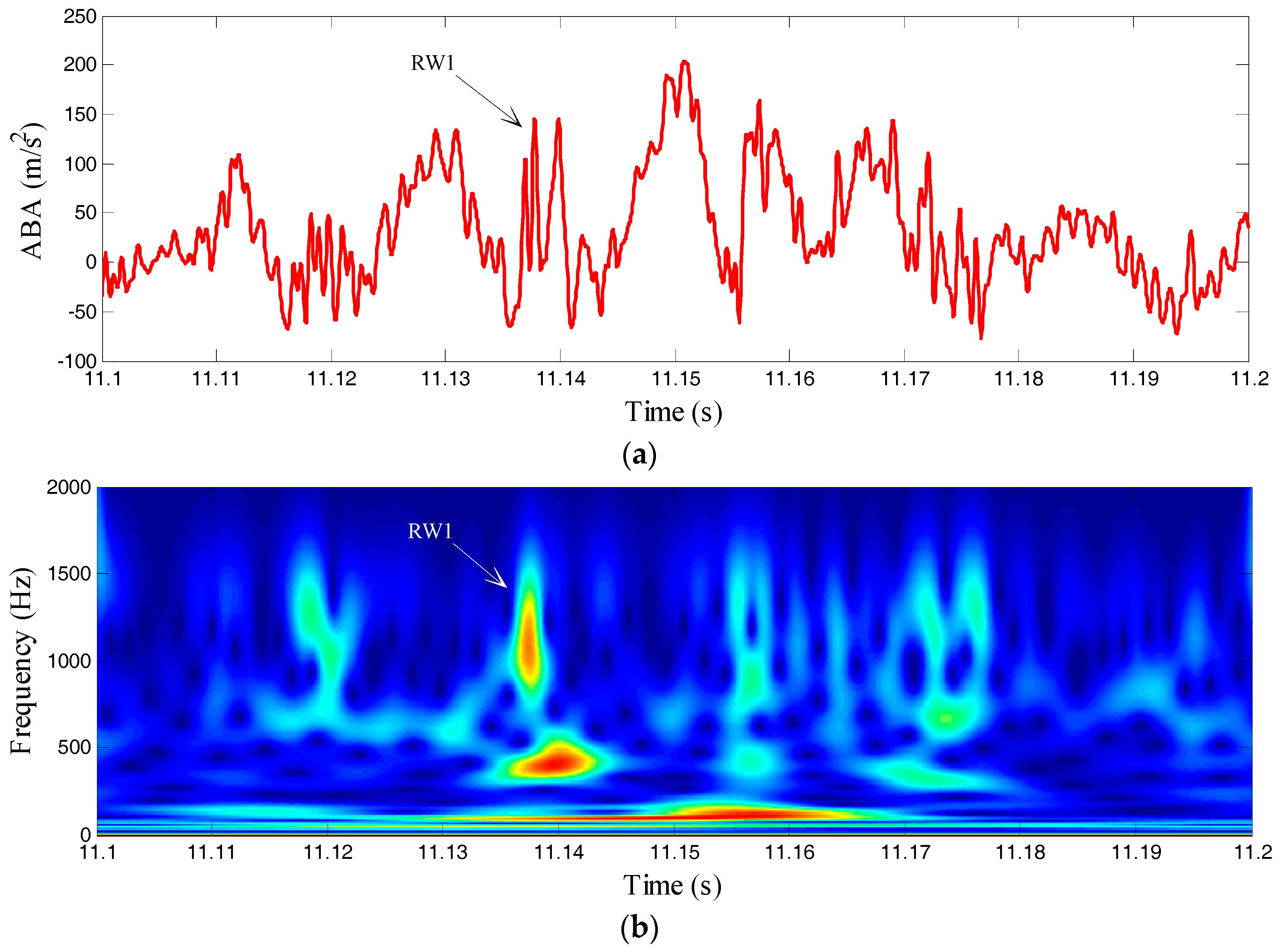

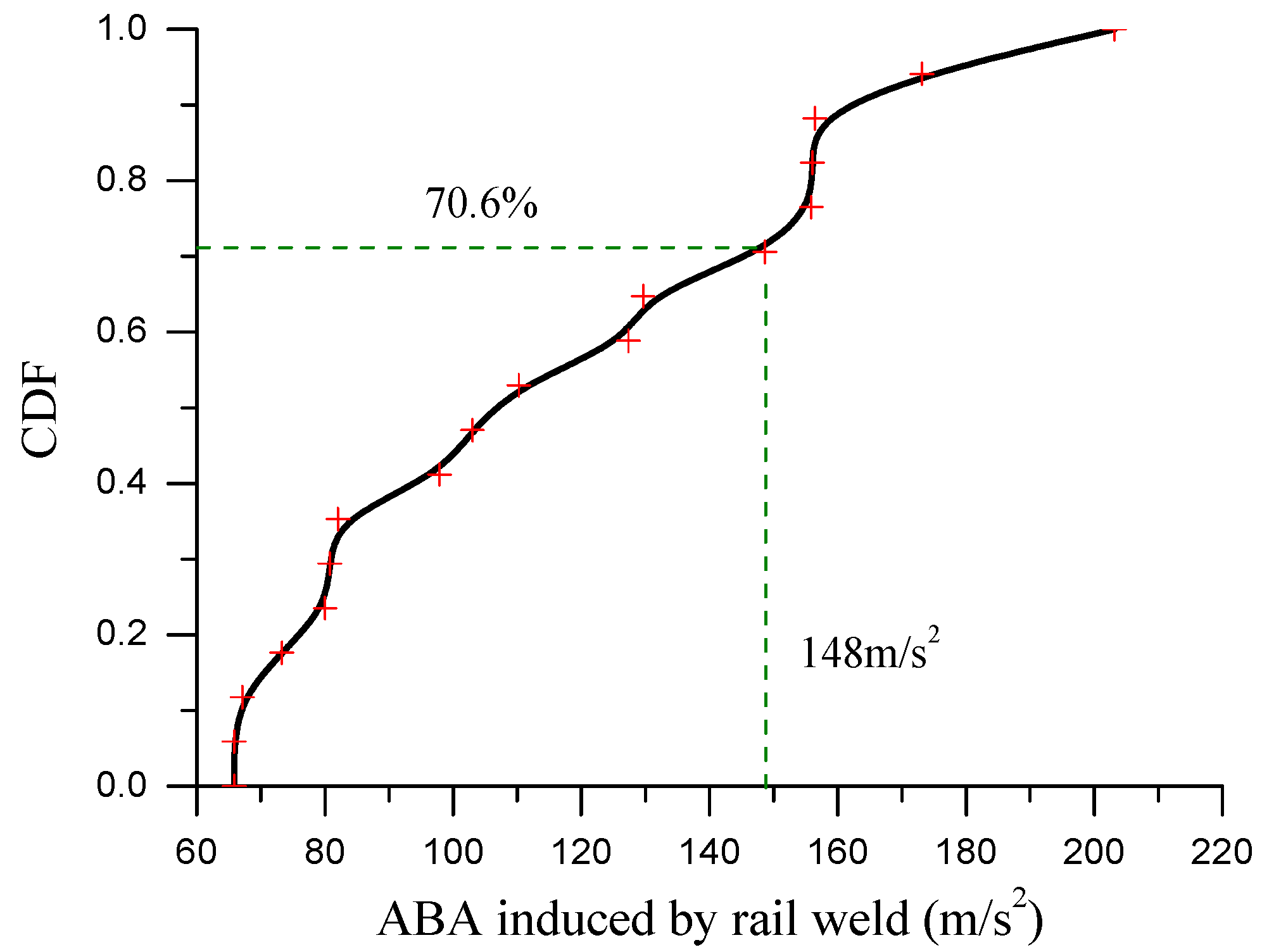

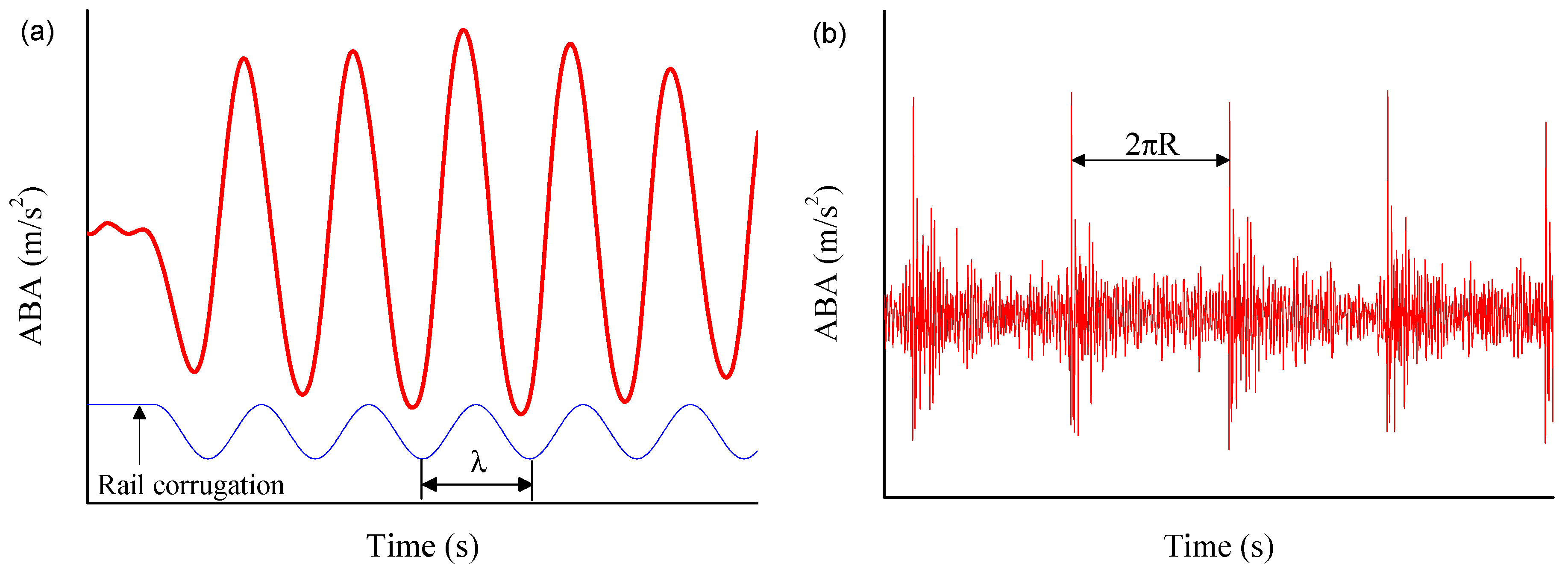

2. Observation of Time–Frequency Vibration of the Measured Axle Box Acceleration

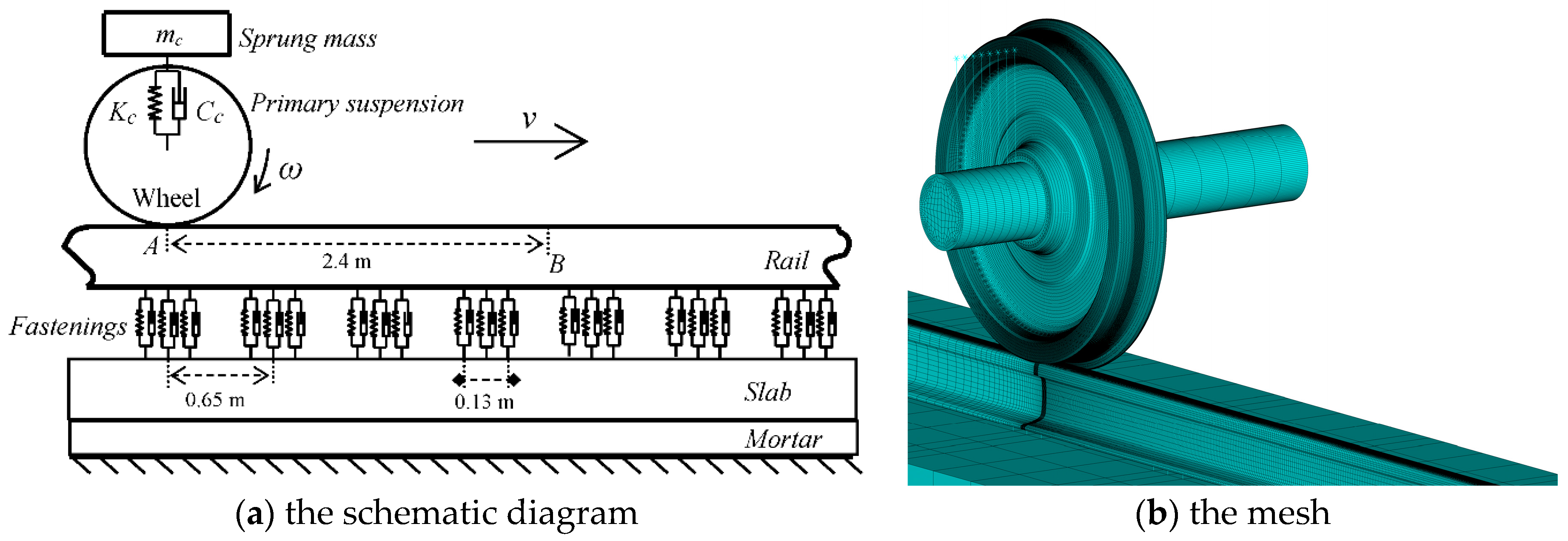

3. 3D High-Speed Wheel/Rail Rolling Contact Finite Element Model

3.1. Overview of the Finite Element Model

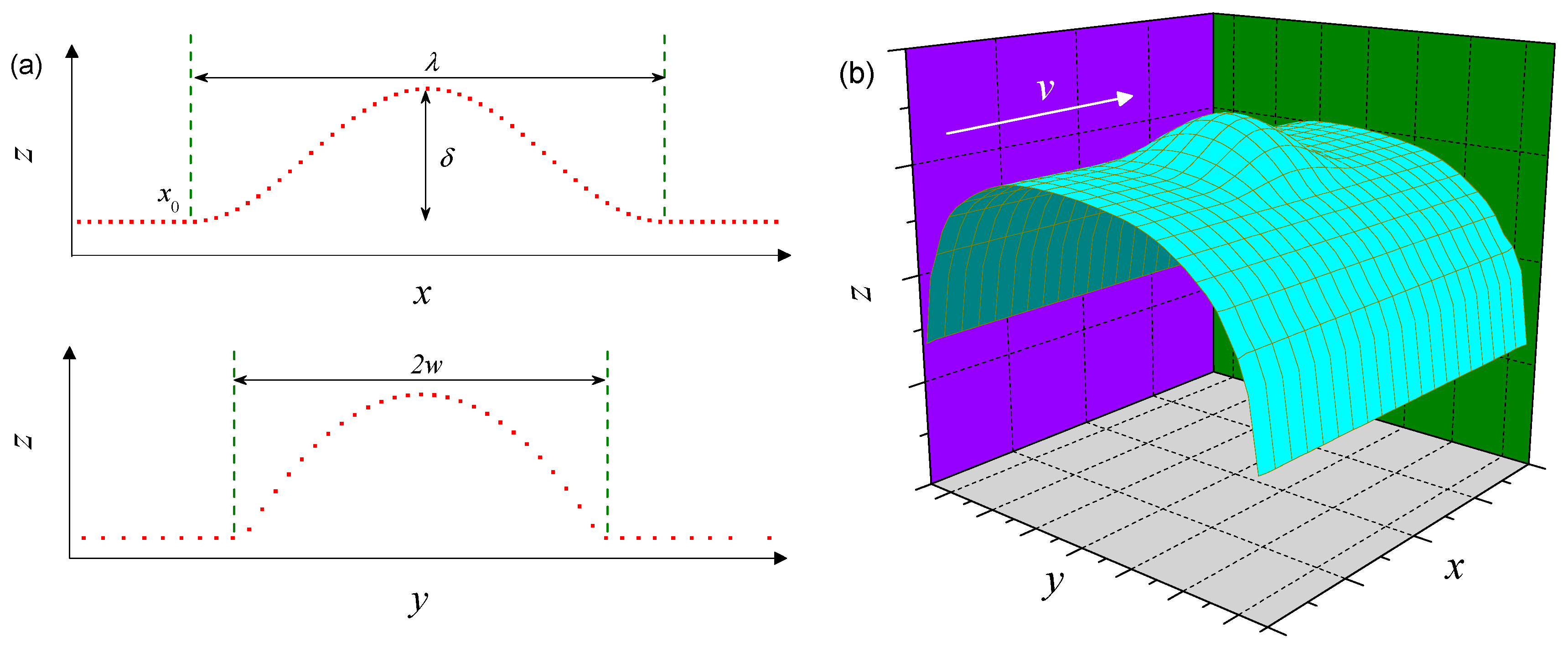

3.2. Rail Weld in 3D

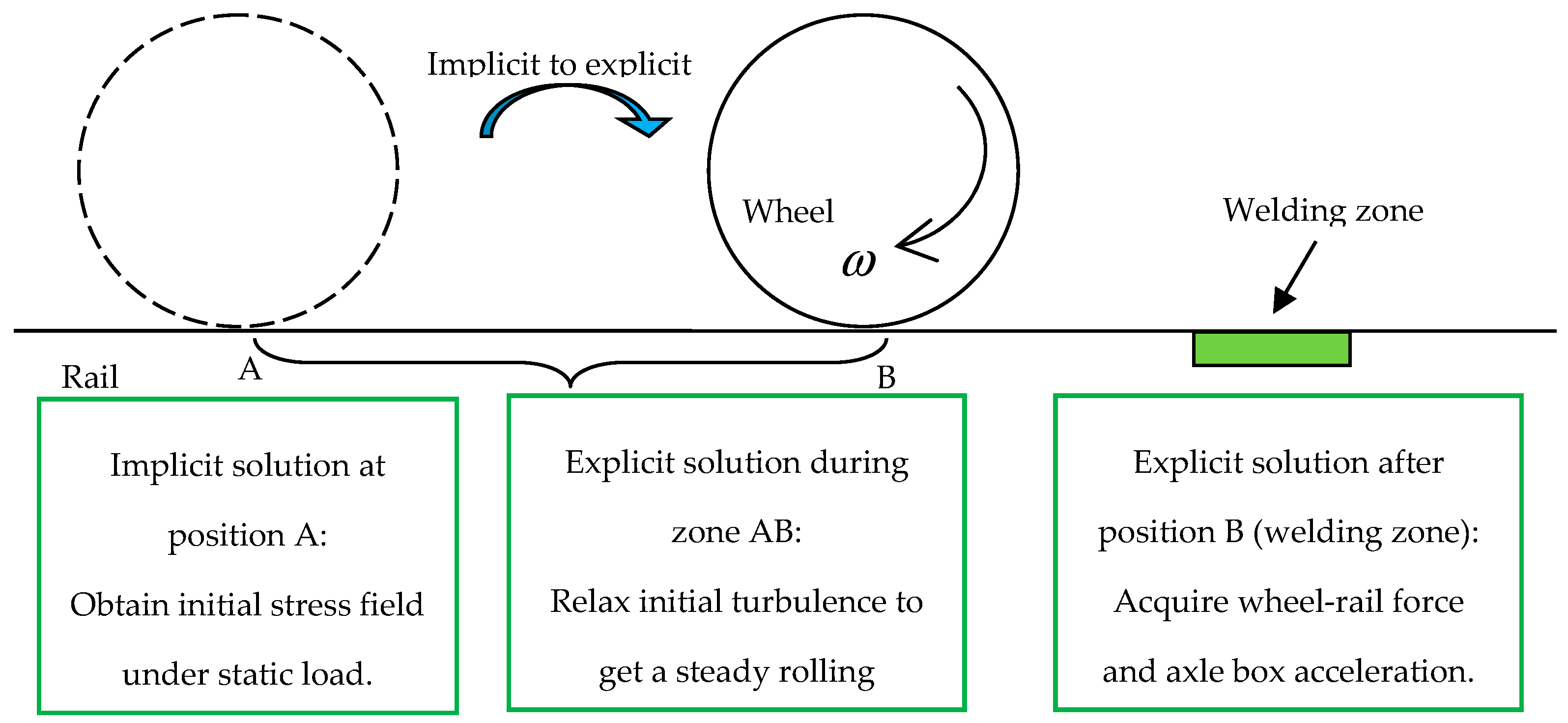

3.3. Simulation Process

4. Results and Discussion

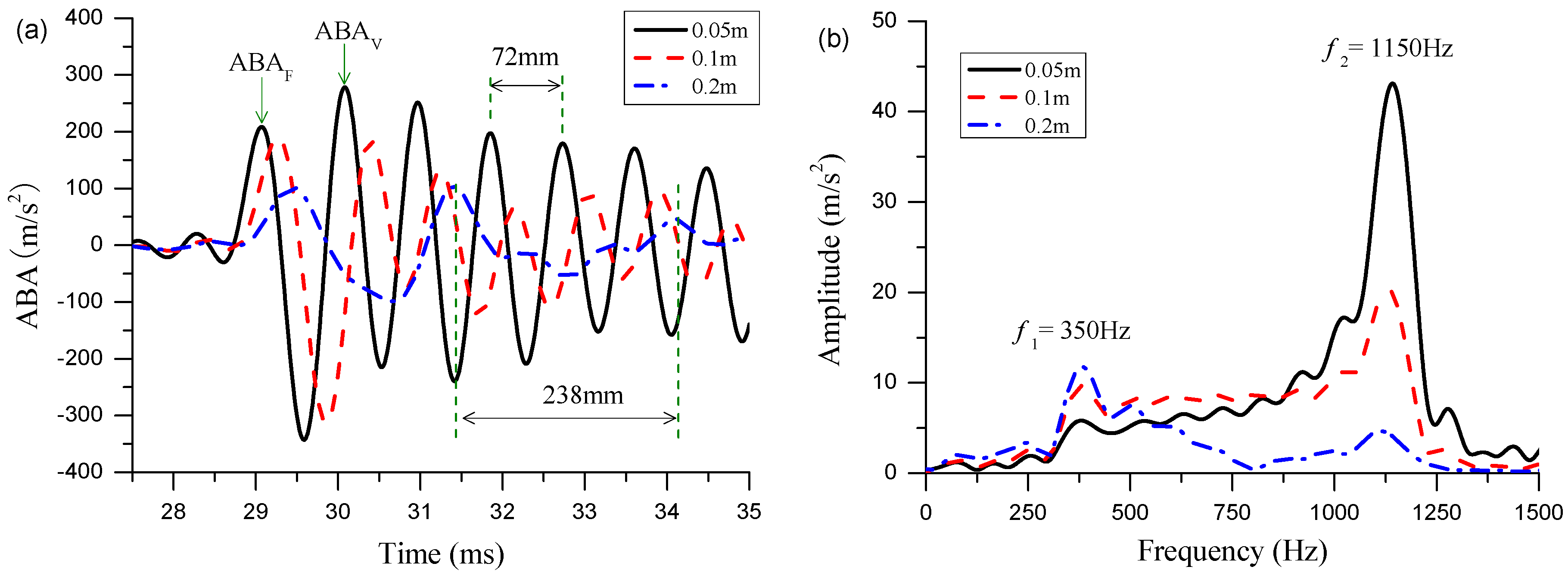

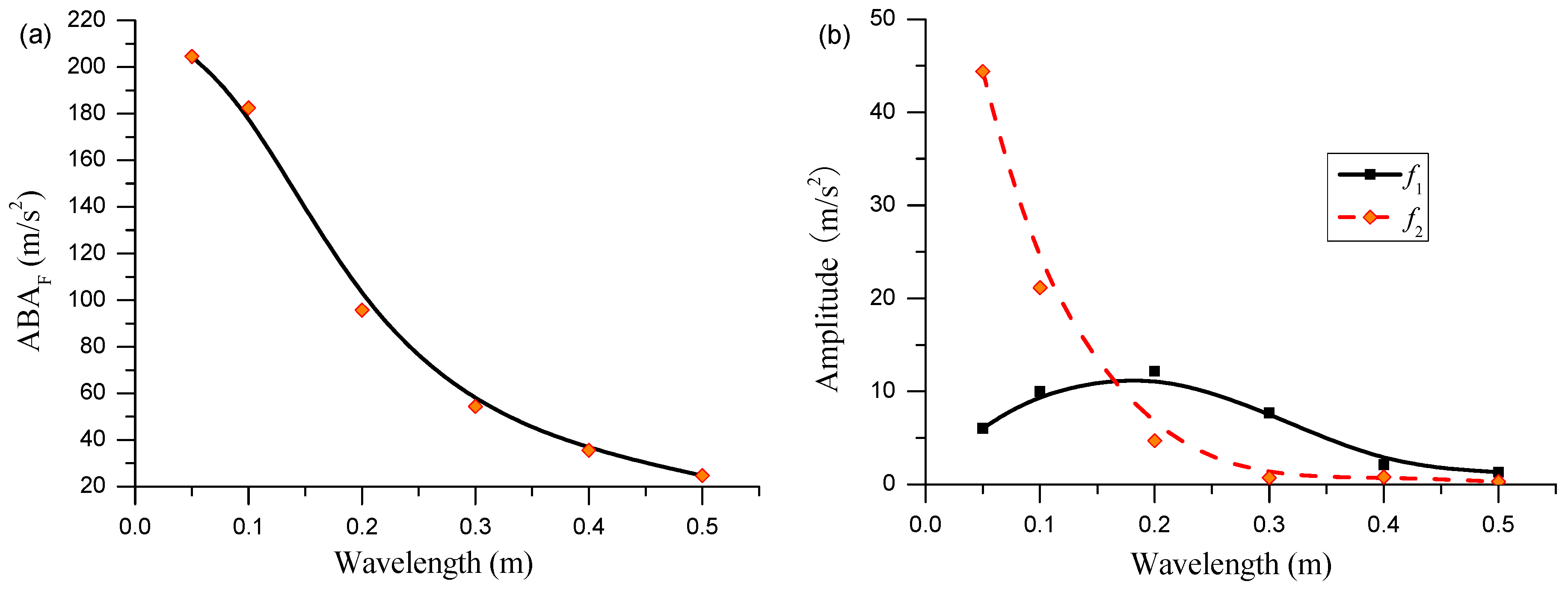

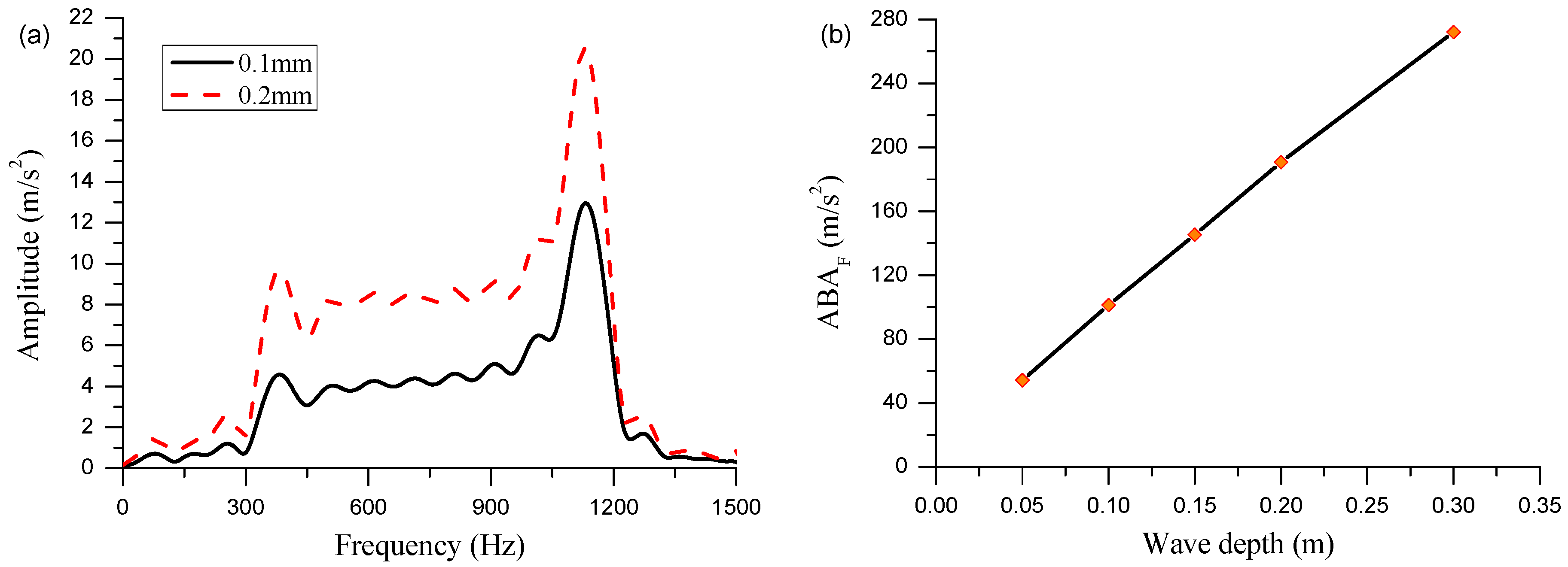

4.1. The Influence of Rail Weld Geometry on ABA

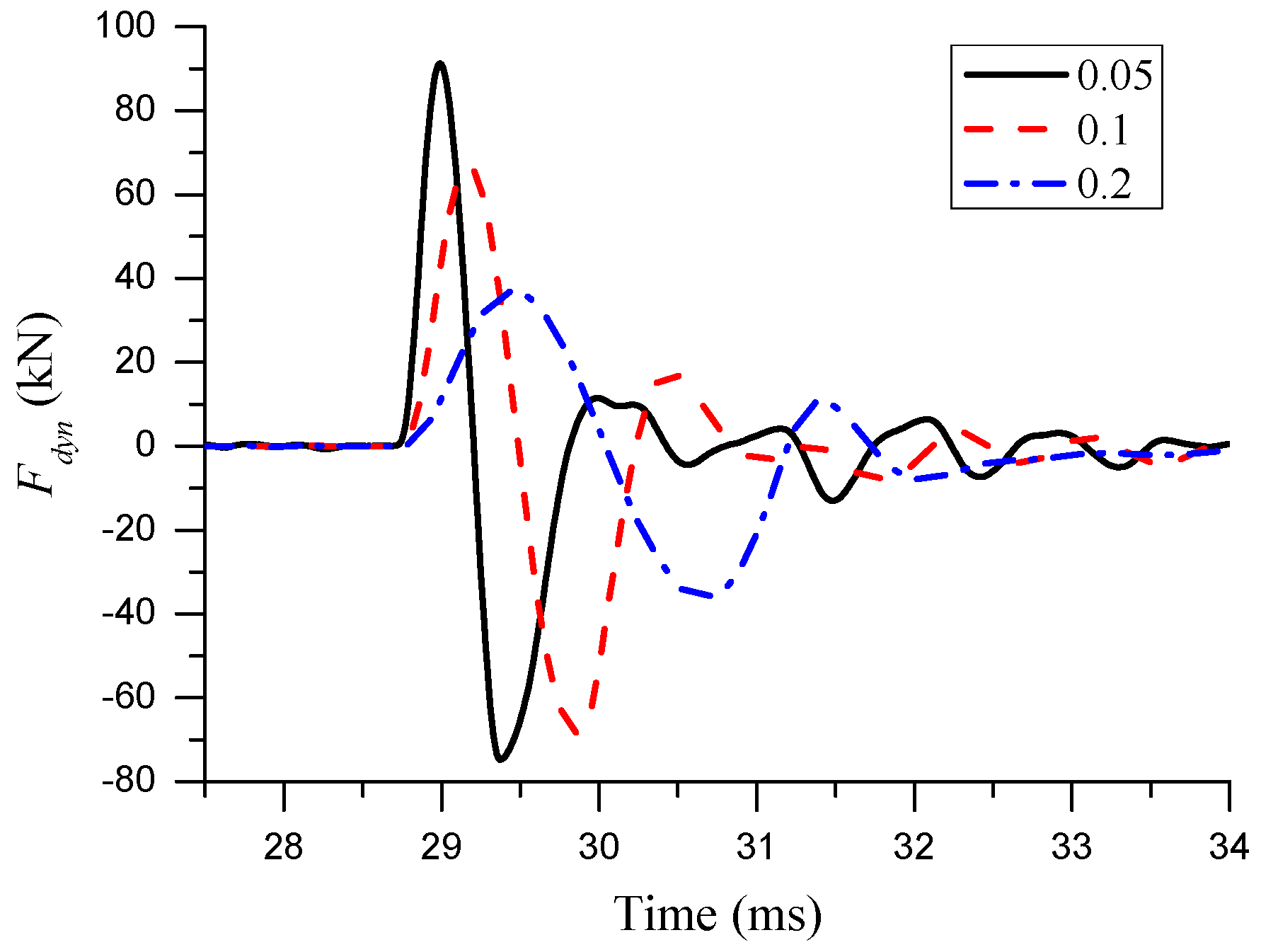

4.2. The Relationship between ABA and Wheel/Rail Force

4.3. Discussion of This Paper

4.3.1. Qualitative Analysis on the Effectiveness of the Model

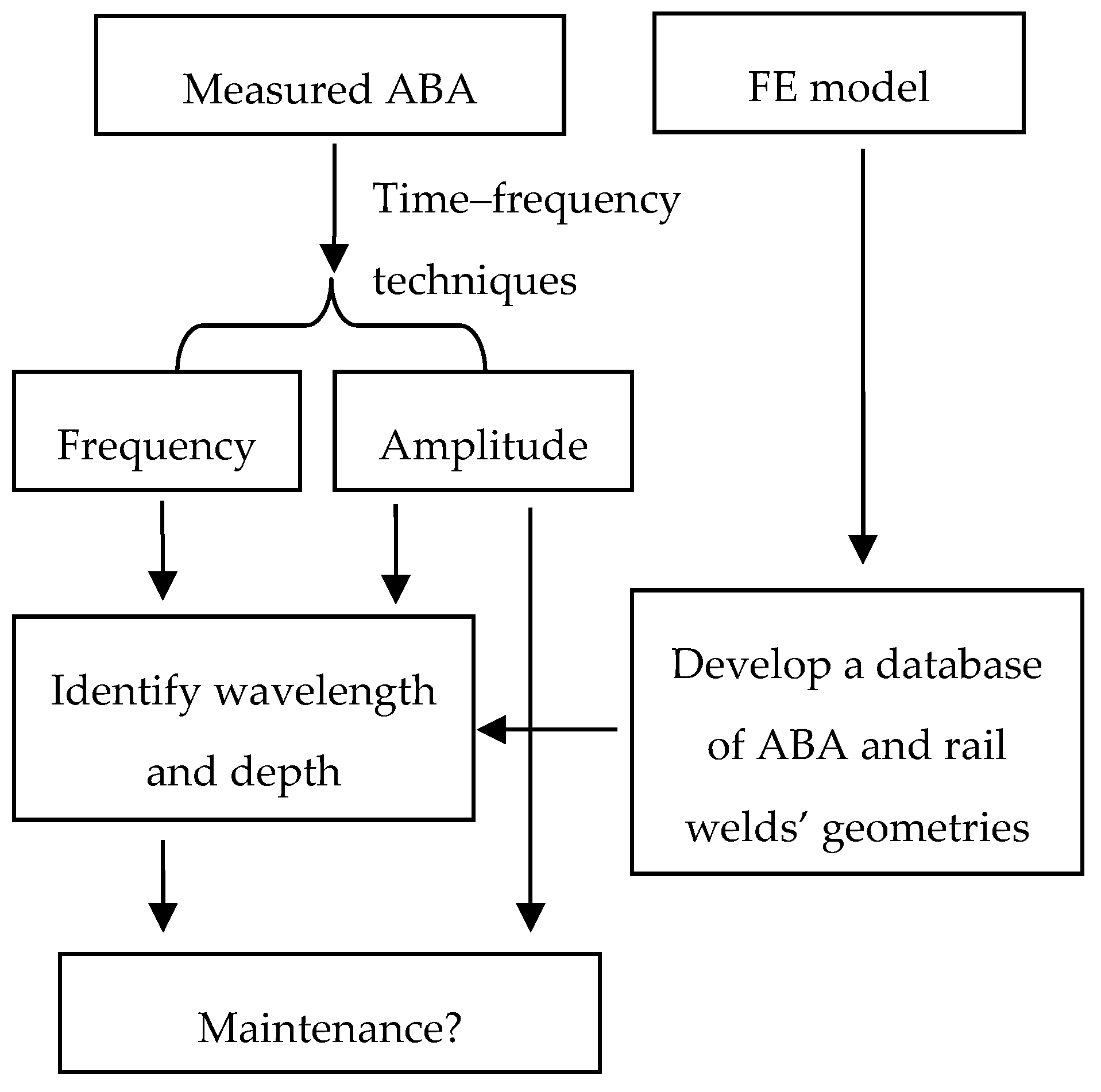

4.3.2. Estimation of Rail Weld Based on ABA Signal Using Time–Frequency Techniques

4.3.3. Comparison of Other Defects and Rail Weld on ABA

5. Conclusions

- (1)

- According to field tests, the acceleration of an axle box changed within the range of ±50 m/s2 under normal operation, which significantly increased at the welds to amplitudes ranging from 66 to 200 m/s2. High-frequency vibrations at welds existed for a very short time, around 2 to 5 ms. Energy of the high-frequency vibration centralized mainly in two frequency bands: 350 to 500 Hz and 1000 to 1200 Hz.

- (2)

- ABA at rail welds exhibited drastic fluctuations both in measured data and in simulations. The first wave was caused by the impact of the wheel/rail force, while the continued vibration depended on the resonance of the vehicle–track system, for which the amplitude was greater than that generated by the wheel/rail force in certain conditions. Therefore, the maximum value of ABA in the time domain always overestimated the wheel/rail dynamic interaction. To deal with this problem, the position of the rail welds should be determined first by means of time–frequency analysis.

- (3)

- A linear relationship was found between the ABAF and Fdyn,max, and corresponding expressions were established. A value of 220 m/s2 after 1500 Hz LPF can be used as a safety value for real-time onsite monitoring in judging the necessity of maintaining the rail welds.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ABA | Axle Box Acceleration |

| LPF | Low Frequency Filter |

| CDF | Cumulative Distribution Function |

| 3D | Three Dimensional |

References

- Oregui, M.; Li, S.; Núñez, A.; Li, Z.; Carroll, R.; Dollevoet, R. Monitoring bolt tightness of rail joints using axle box acceleration measurements. Struct. Control Health Monit. 2017, 24, 2. [Google Scholar] [CrossRef]

- Esveld, C. Modern Railway Track; MRT-Productions: Zaltbommel, The Netherlands, 2001. [Google Scholar]

- Mutton, P.; Alvarez, E. Failure modes in aluminothermic rail welds under high axle load conditions. Eng. Fail. Anal. 2004, 11, 151–166. [Google Scholar] [CrossRef]

- Steenbergen, M. Rolling contact fatigue in relation to rail grinding. Wear 2016, 356, 110–121. [Google Scholar] [CrossRef]

- Gao, J.; Zhai, W.; Guo, Y. Wheel–rail dynamic interaction due to rail weld irregularity in high-speed railways. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016. [Google Scholar] [CrossRef]

- Wen, Z.; Xiao, G.; Xiao, X.; Jin, X.; Zhu, M. Dynamic vehicle–track interaction and plastic deformation of rail at rail welds. Eng. Fail. Anal. 2009, 16, 1221–1237. [Google Scholar] [CrossRef]

- Correa, N.; Vadillo, E.G.; Santamaria, J.; Herreros, J. A versatile method in the space domain to study short-wave rail undulatory wear caused by rail surface defects. Wear 2016, 352, 196–208. [Google Scholar] [CrossRef]

- Mandal, N.; Dhanasekar, M. Sub-modelling for the ratchetting failure of insulated rail joints. Int. J. Mech. Sci. 2013, 75, 110–122. [Google Scholar] [CrossRef] [Green Version]

- Xiao, G.; Xiao, X.; Guo, J.; Wen, Z.; Jin, X. Track dynamic behavior at rail welds at high speed. Acta Mech. Sin. 2010, 26, 449–465. [Google Scholar] [CrossRef]

- Steenbergen, M.; Esveld, C. Rail weld geometry and assessment concepts. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2006, 220, 257–271. [Google Scholar] [CrossRef]

- Steenbergen, M.; Esveld, C. Relation between the geometry of rail welds and the dynamic wheel-rail response: Numerical simulations for measured welds. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2006, 220, 409–423. [Google Scholar] [CrossRef]

- Haigermoser, A.; Luber, B.; Rauh, J.; Gräfe, G. Road and track irregularities: Measurement, assessment and simulation. Veh. Syst. Dyn. 2015, 53, 878–957. [Google Scholar] [CrossRef]

- Grassie, S. Measurement of railhead longitudinal profiles: A comparison of different techniques. Wear 1996, 191, 245–251. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.; Zhao, Y.; Crosbee, D. Railway wheel-flat and rail surface defect modelling and analysis by time–frequency techniques. Veh. Syst. Dyn. 2013, 51, 1403–1421. [Google Scholar] [CrossRef]

- Molodova, M.; Oregui, M.; Núñez, A.; Li, Z.; Dollevoet, R. Health condition monitoring of insulated joints based on axle box acceleration measurements. Eng. Struct. 2016, 123, 225–235. [Google Scholar] [CrossRef]

- Li, Z.; Molodova, M.; Núñez, A.; Dollevoet, R. Improvements in axle box acceleration measurements for the detection of light squats in railway infrastructure. IEEE Trans. Ind. Electron. 2015, 62, 4385–4397. [Google Scholar] [CrossRef]

- Zhai, W.; Liu, P.; Lin, J.; Wang, K. Experimental investigation on vibration behaviour of a CRH train at speed of 350 km/h. Int. J. Rail Transp. 2015, 3, 1–16. [Google Scholar] [CrossRef]

- Zhai, W. Vehicle–Track Coupling Dynamics, 3rd ed.; Science Publishing House: Beijing, China, 2007. [Google Scholar]

- Molodova, M.; Li, Z.; Dollevoet, R. Axle box acceleration: Measurement and simulation for detection of short track defects. Wear 2011, 271, 349–356. [Google Scholar] [CrossRef]

- Molodova, M.; Li, Z.; Núñez, A.; Dollevoet, R. Validation of a finite element model for axle box acceleration at squats in the high frequency range. Comput. Struct. 2014, 141, 84–93. [Google Scholar] [CrossRef]

- Zong, N.; Dhanasekar, M. Sleeper embedded insulated rail joints for minimising the number of modes of failure. Eng. Fail. Anal. 2017, 76, 27–43. [Google Scholar] [CrossRef]

- Zhao, X.; An, B.; Zhao, X.; Wen, Z.; Jin, X. Local rolling contact fatigue and indentations on high-speed railway wheels: Observations and numerical simulations. Int. J. Fatigue 2017, 103, 5–16. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Núñez, A.; Dollevoet, R. New insights into the short pitch corrugation enigma based on 3D-FE coupled dynamic vehicle-track modeling of frictional rolling contact. Appl. Sci. 2017, 7, 807. [Google Scholar] [CrossRef]

- Stockwell, R.; Mansinha, L.; Lowe, R. Localization of the complex spectrum: The S transform. IEEE Trans. Signal Process. 1996, 44, 998–1001. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Gao, Y.; Chen, J.; Chen, R. Geometry evolution of rail weld irregularity and the effect on wheel-rail dynamic interaction in heavy haul railways. Eng. Fail. Anal. 2017, 81, 31–44. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Dollevoet, R.; Molodova, M. An investigation into the causes of squats—Correlation analysis and numerical modeling. Wear 2008, 265, 1349–1355. [Google Scholar] [CrossRef]

- Askarinejad, H.; Dhanasekar, M.; Cole, C. Assessing the effects of track input on the response of insulated rail joints using field experiments. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 176–187. [Google Scholar] [CrossRef]

- Zhang, Z.; Dhanasekar, M. Dynamics of railway wagons subjected to braking torques on defective tracks. Veh. Syst. Dyn. 2012, 50, 109–131. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Values | |

|---|---|---|

| Lumped sprung mass | 7500 kg | |

| Stiffness of primary suspension | 880 kN/m | |

| Damping of primary suspension | 4 kNs/m | |

| Stiffness of fastenings | 22 MN/m | |

| Damping of fastenings | 200 kNs/m | |

| Wheel and rail material | Young’s modulus | 205.9 GPa |

| Poisson’s ratio | 0.3 | |

| Density | 7790 kg/m3 | |

| Material of pre-fabricated slabs | Young’s modulus | 34.5 GPa |

| Poisson’s ratio | 0.25 | |

| Density | 2400 kg/m3 | |

| Mortar material | Young’s modulus | 8 GPa |

| Poisson’s ratio | 0.2 | |

| Density | 1600 kg/m3 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, B.; Wang, P.; Xu, J.; Chen, R.; Cui, D. Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway. Appl. Sci. 2017, 7, 1259. https://doi.org/10.3390/app7121259

An B, Wang P, Xu J, Chen R, Cui D. Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway. Applied Sciences. 2017; 7(12):1259. https://doi.org/10.3390/app7121259

Chicago/Turabian StyleAn, Boyang, Ping Wang, Jingmang Xu, Rong Chen, and Dabin Cui. 2017. "Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway" Applied Sciences 7, no. 12: 1259. https://doi.org/10.3390/app7121259