Effects of a Nano-Silica Additive on the Rock Erosion Characteristics of a SC-CO2 Jet under Various Operating Conditions

Abstract

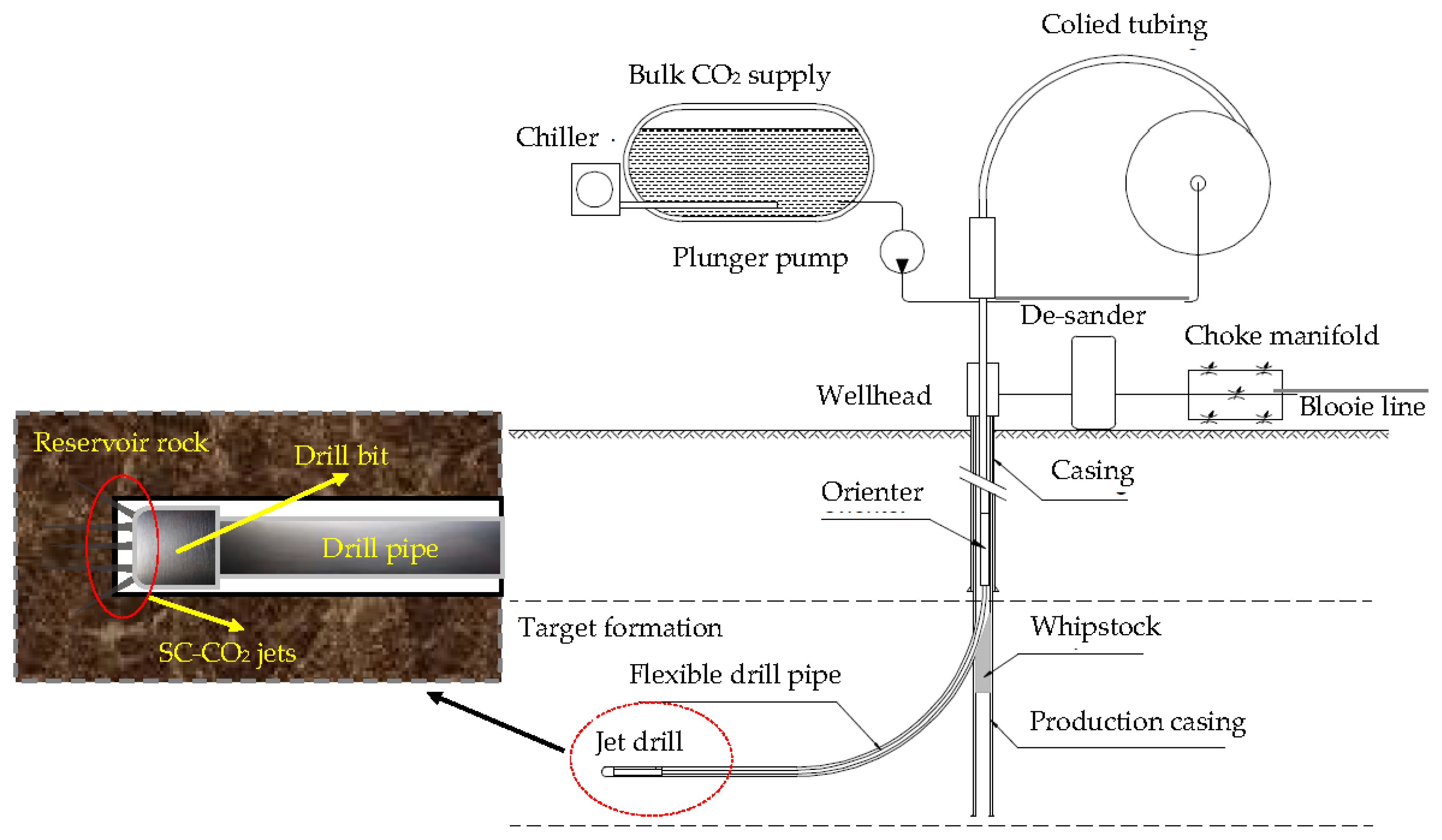

:1. Introduction

2. Materials and Methods

2.1. Materials

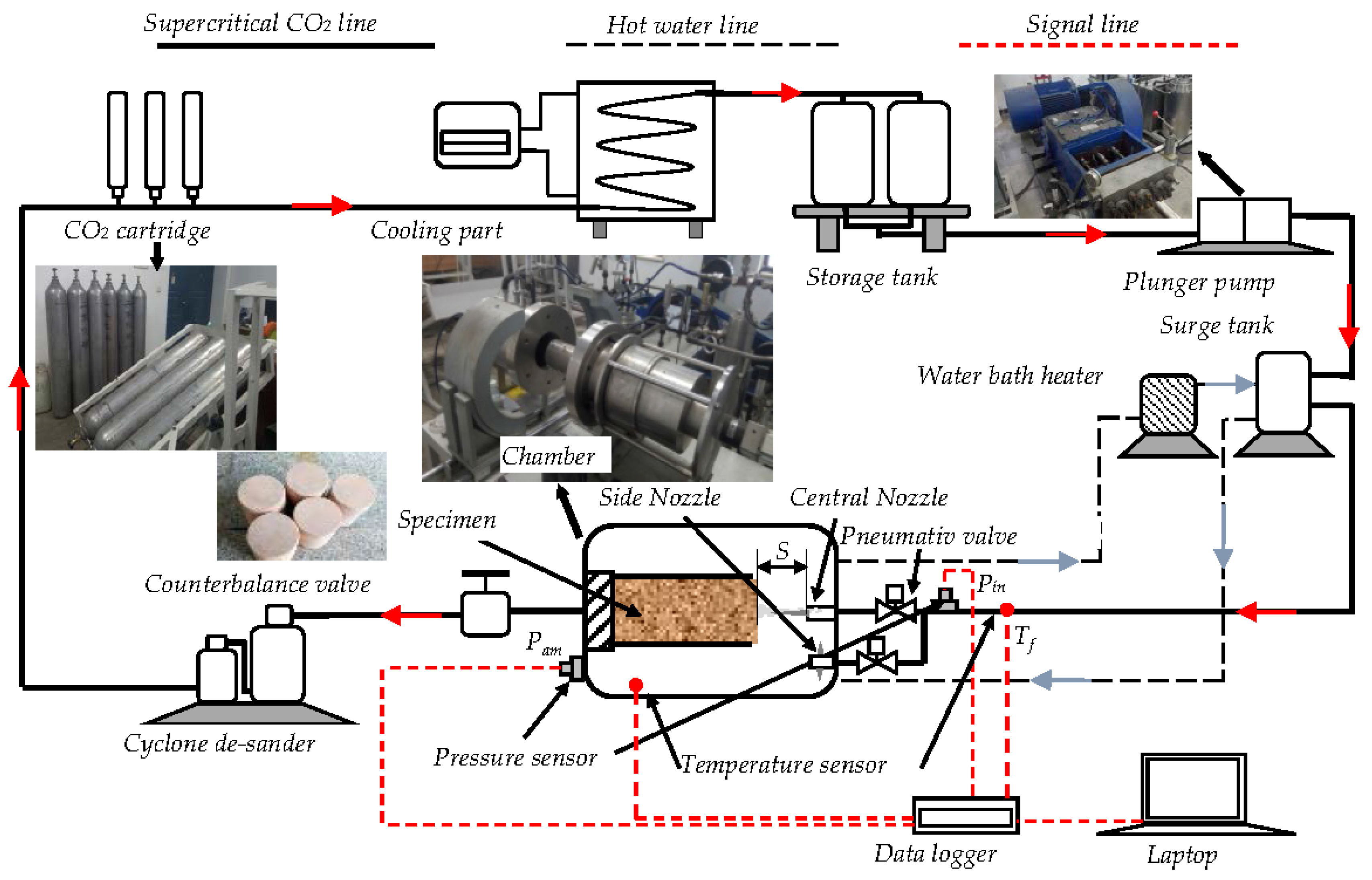

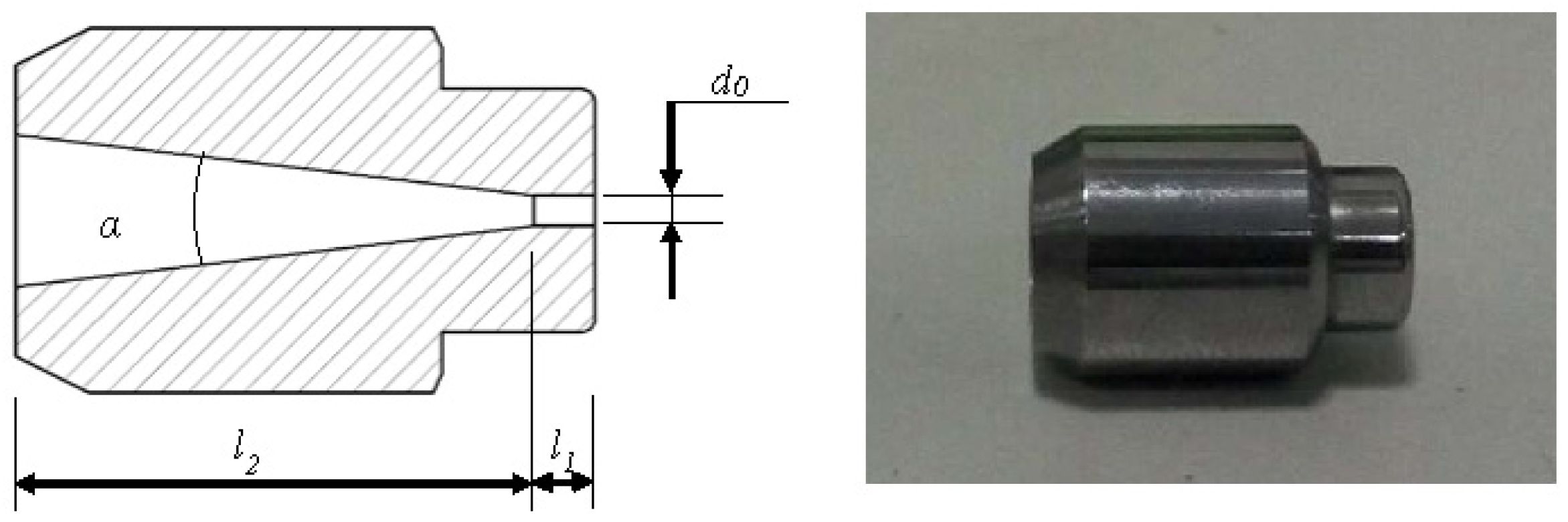

2.2. Facilities

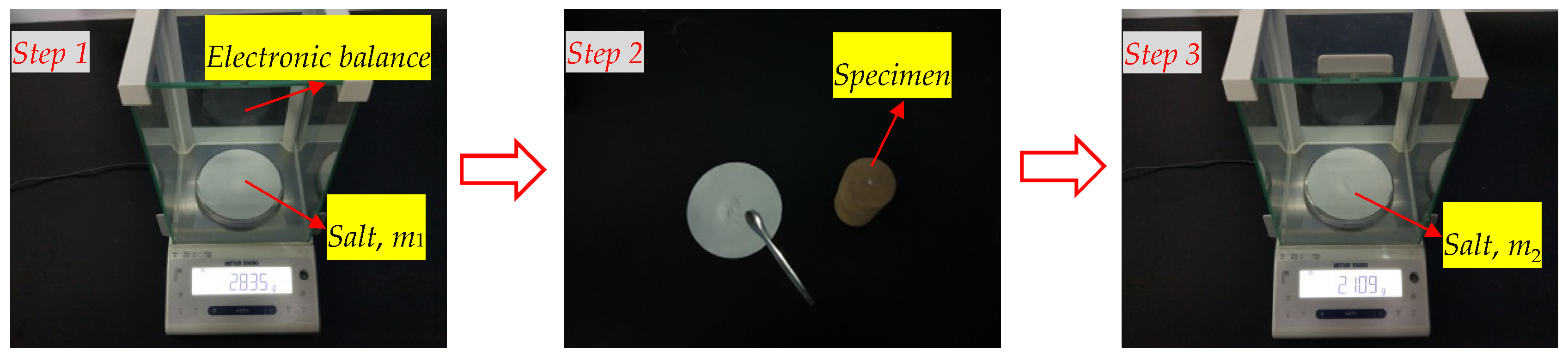

2.3. Experimental Procedures

2.4. Experimental Uncertainty

3. Results

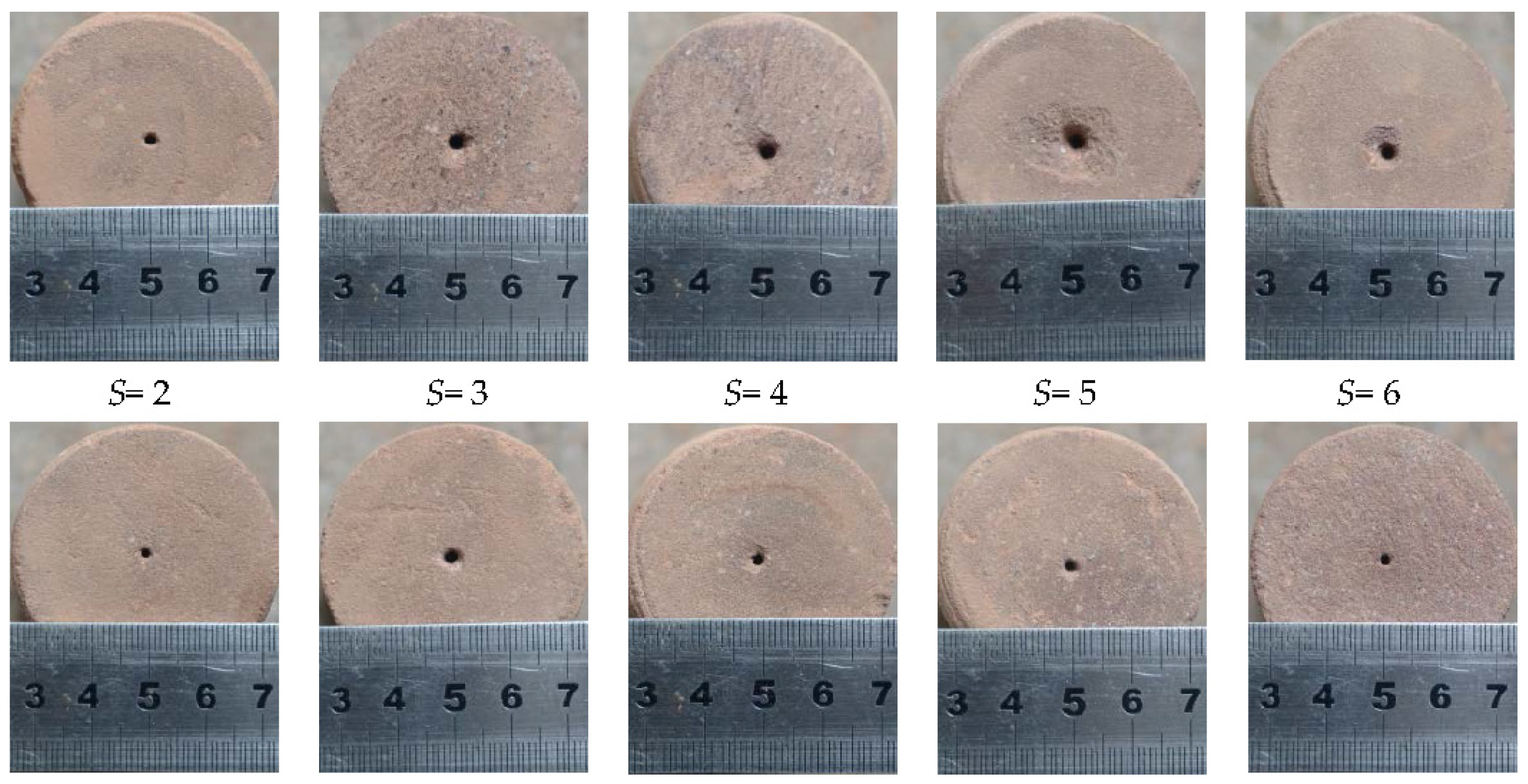

3.1. Macroscopic Appearances of Eroded Specimens

3.2. Effect of Nano-Silica Additive under Different Standoff Distances

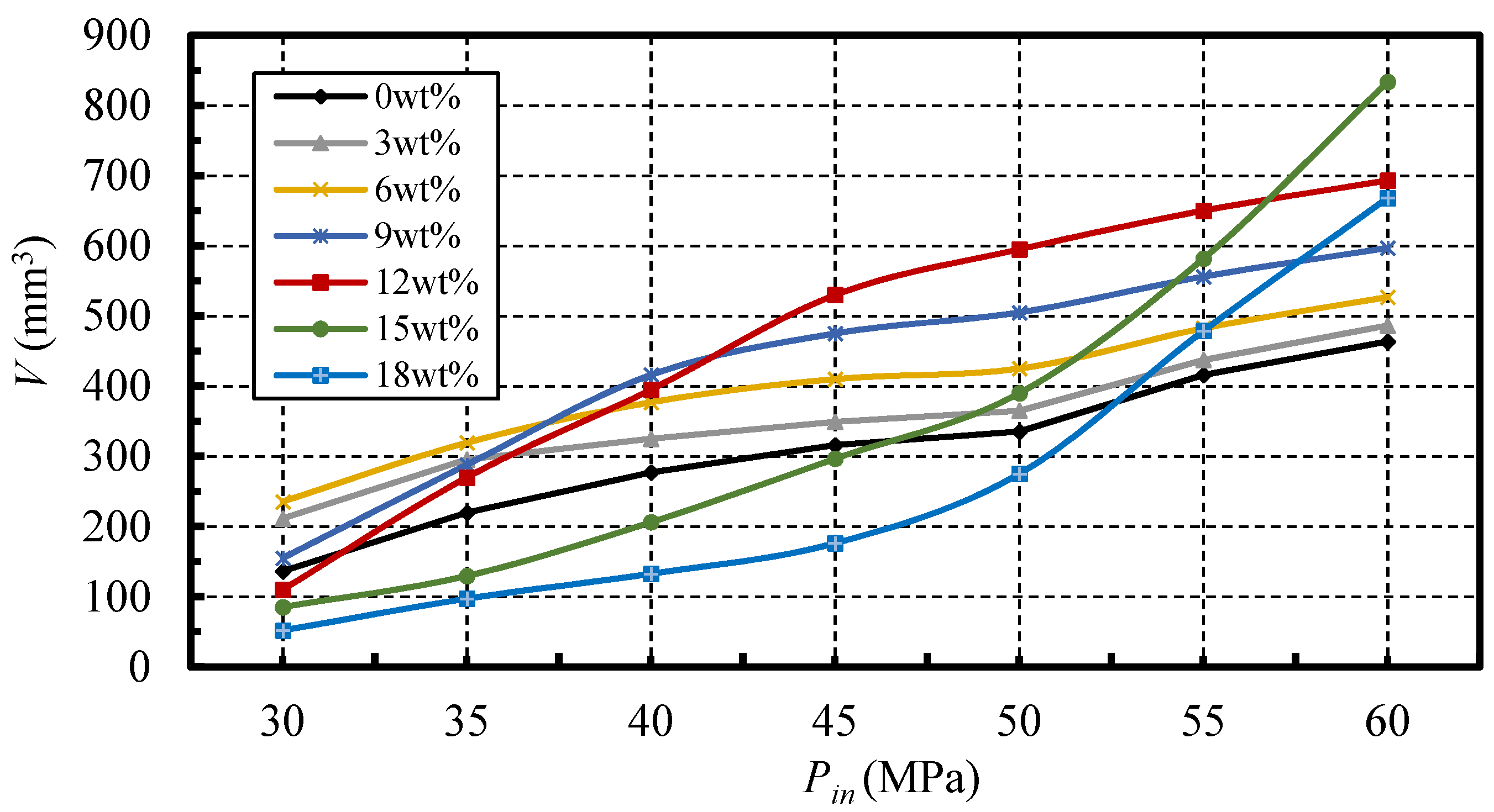

3.3. Effect of the Nano-Silica Additive under Different Inlet Pressures

3.4. Effect of Nano-Silica Additive under Different Ambient Pressures and Constant Inlet Pressure

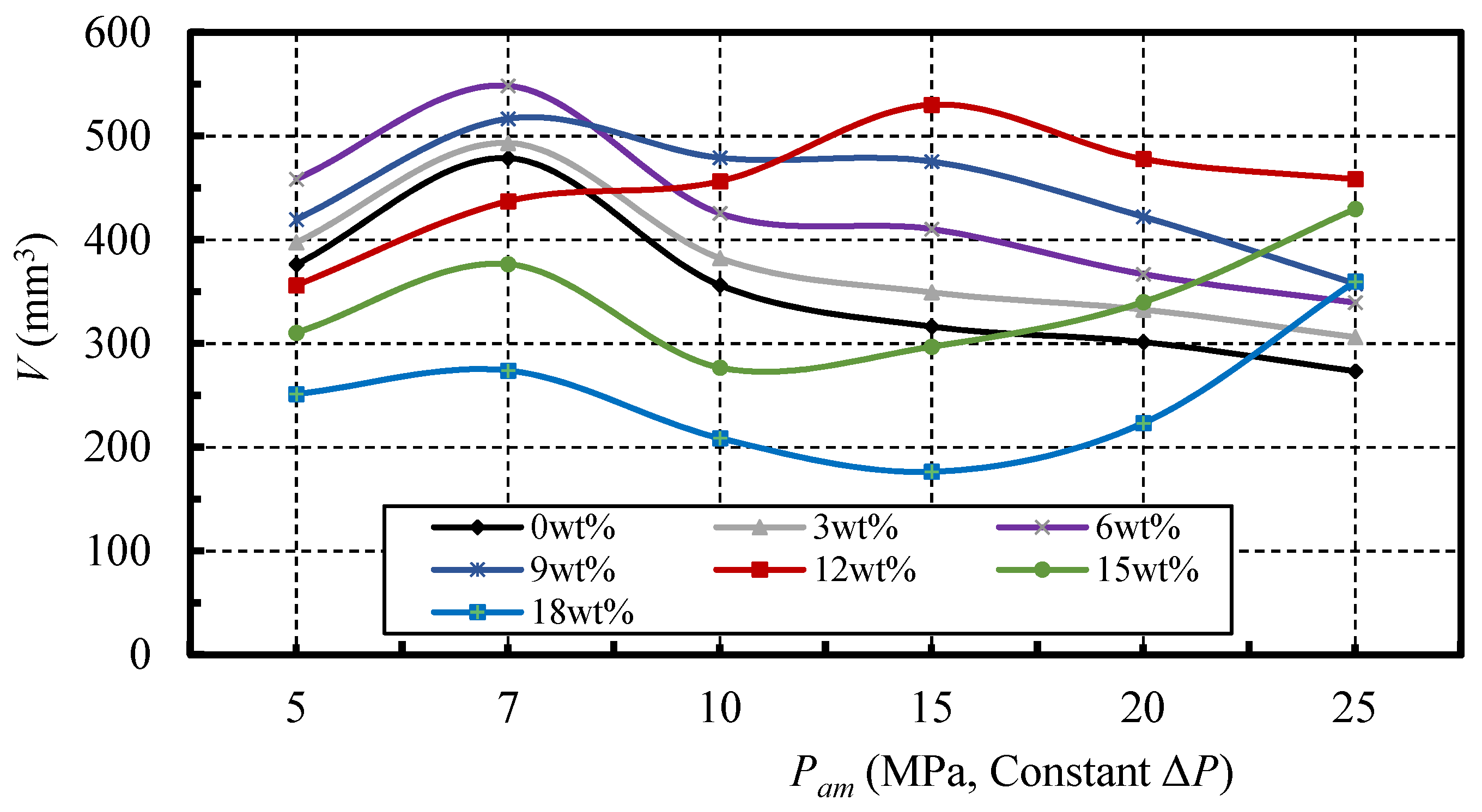

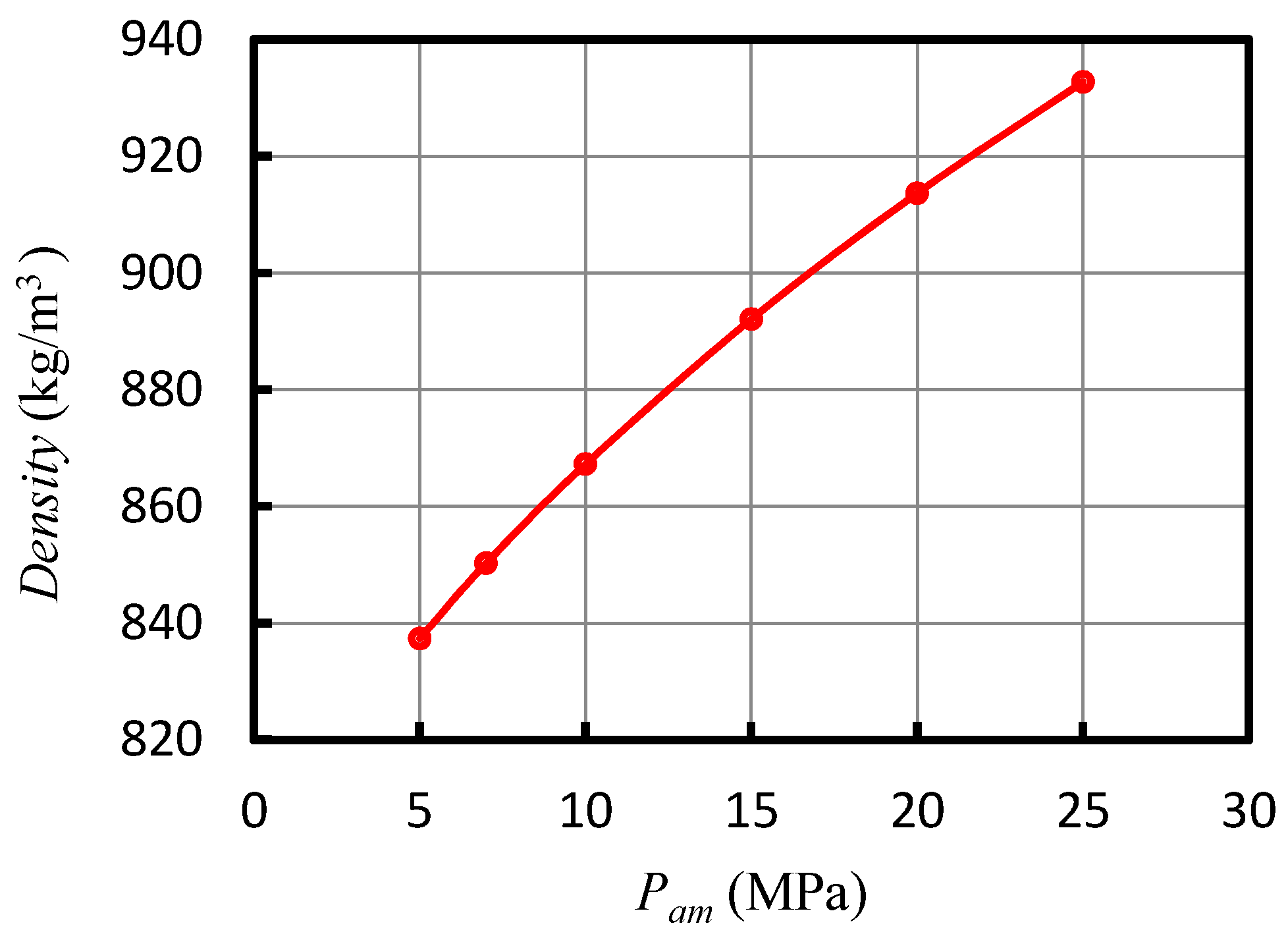

3.5. Effect of Nano-Silica Additive under Different Ambient Pressures And Constant Pressure Drop

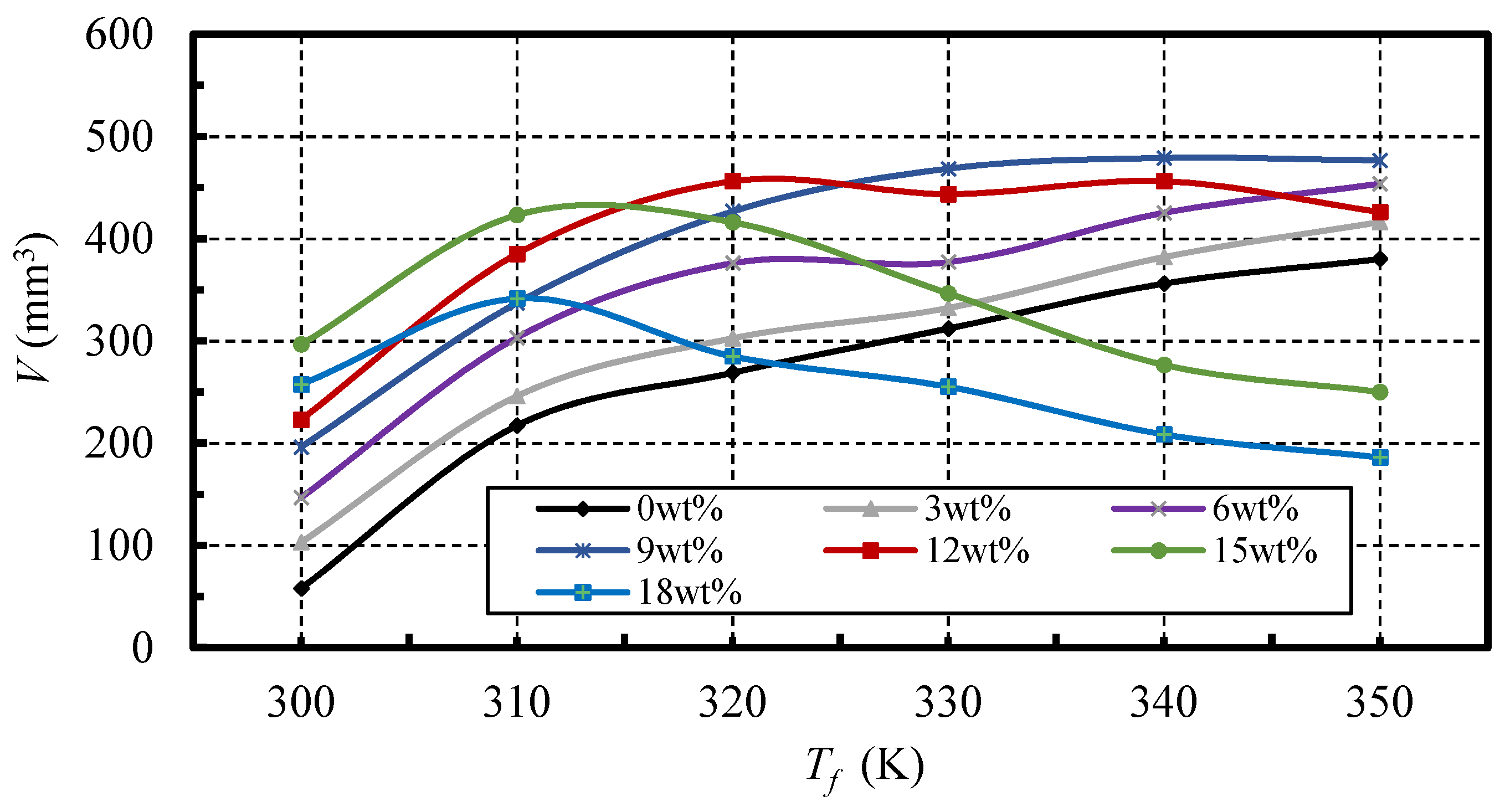

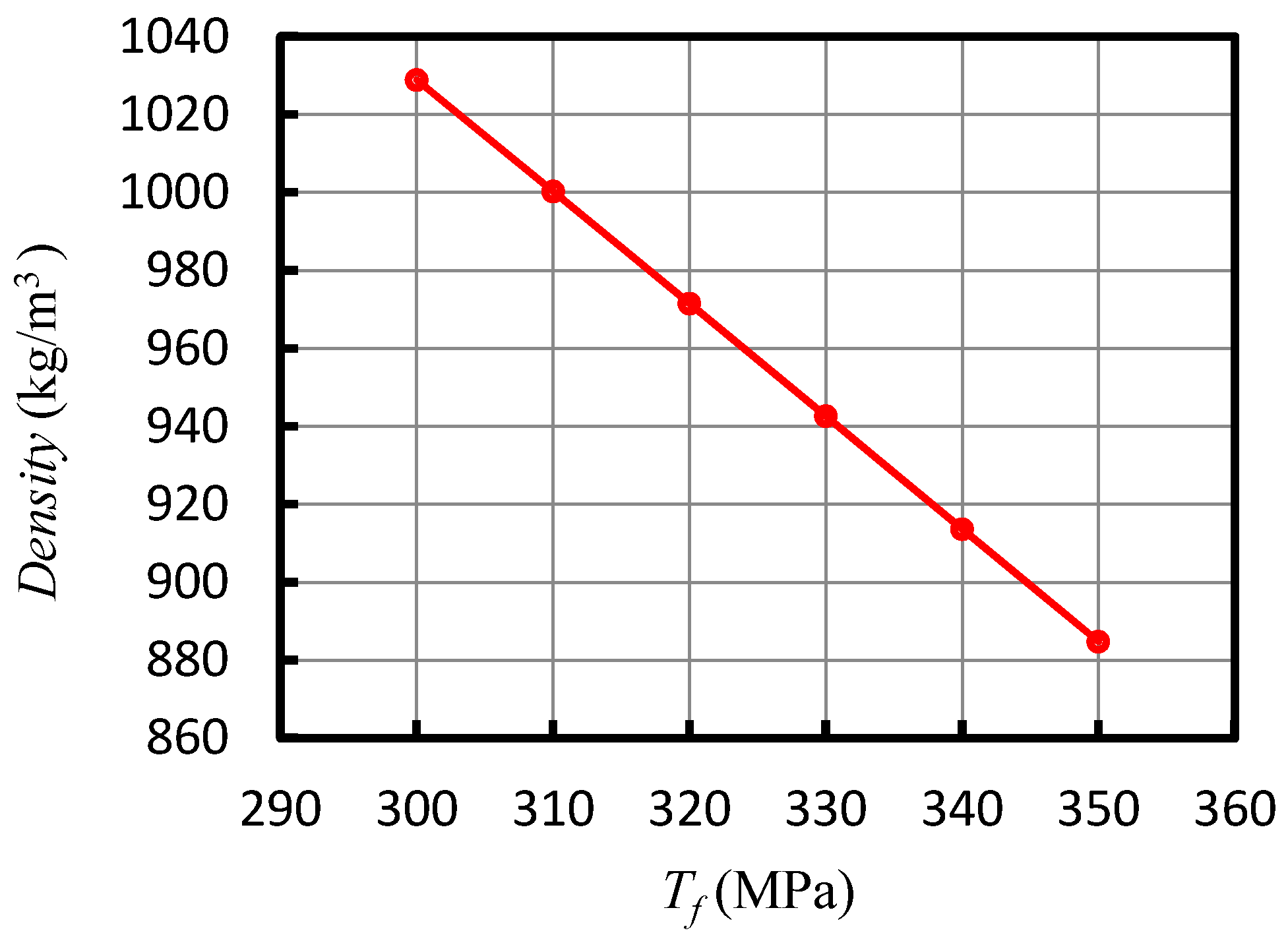

3.6. Effect of the Nano-Silica Additive under Different Fluid Temperatures

4. Discussion

5. Conclusions

- The erosion of the rock specimen caused by the impingement of the SC-CO2 jet, is the typical “drilling type” damage characterized by rather deep cavities with small diameters.

- The optimal standoff distances are about five times the nozzle diameter of the nano-silica SC-CO2 jets, and three times those of the pure SC-CO2 jet. After the standoff distance exceeds the optimum value, the erosion ability of all the jets greatly decreases.

- The erosion abilities of all the jets show an increasing trend with the increase of inlet pressure. At the inlet pressures of 30 MPa and 35 MPa, a mass fraction of 6 wt % can achieve a better erosion ability than the others, while at an inlet pressure of 40 MPa, 9 wt % is the optimum mass fraction. Also, at inlet pressures of 45 MPa and 50 MPa, a mass fraction of 12 wt % is the optimum condition. In addition, when the inlet pressure is increased to 60 MPa, the jet with a mass fraction of 15 wt % has the best erosion ability.

- Under a constant inlet pressure, the rock erosion ability of all the jets decreases with the increasing ambient pressure. Also, the optimum mass fraction is 12 wt %.

- Under the constant ΔP, the SC-CO2 jet with a nano-silica mass fraction of 6 wt % has the best erosion ability at ambient pressures of 5 MPa and 7 MPa. Then, with the increase of ambient pressure, mass fractions of 9 wt % and 12 wt %, take turns to achieve the best erosion ability. Moreover, a further increase of ambient pressure can enhance the erosion capability of the jets with mass fractions of 15 wt % and 18 wt %.

- At fluid temperatures of 300 K and 310 K, a mass fraction of 15 wt % can achieve the strongest erosion ability. Additionally, at a fluid temperature of 320 K, a mass fraction of 12 wt % becomes the optimum condition. In addition, at fluid temperatures above 330 K, the mass fraction of 6 wt % is the most appropriate choice.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclatures

| d0 | nozzle exit diameter, mm |

| α | nozzle convergent angle, |

| l1 | length of the cylinder section of the nozzle, mm |

| l2 | length of the conical section of the nozzle, mm |

| Pin | nozzle inlet pressure, MPa |

| Pam | ambient pressure, MPa |

| Tf | fluid temperature, K |

| ΔP | pressure drop across the nozzle |

| V | erosion volume, mm3 |

| S | standoff distance, mm |

| Vp | particle velocity, m/s |

| Vf | fluid velocity, m/s |

| ρf | fluid densiy, kg/m3 |

| ρs | density of salt, kg/m3 |

| Fd | drag force, N |

| Fv | virtual mass force, N |

| Cd | interfacial drag coefficient |

| Da | diameter of particle, mm |

| m | mass of particle, kg |

| m1, m2 | mass of salt, kg |

| a | acceleration of particle, m/s2 |

References

- Bellan, J. Supercritical (and subcritical) fluid behavior and modeling: Drops, streams, shear and mixing layers, jets and sprays. Prog. Energ. Combust. 2000, 26, 329–366. [Google Scholar] [CrossRef]

- Brunner, G. Applications of supercritical fluids. Annu. Rev. Chem. Biomol. 2010, 1, 321–342. [Google Scholar] [CrossRef] [PubMed]

- Vatai, T.; Škerget, M.; Knez, Ž. Extraction of phenolic compounds from elder berry and different grape marc varieties using organic solvents and/or supercritical carbon dioxide. J. Food. Eng. 2009, 90, 246–254. [Google Scholar] [CrossRef]

- Zhang, X.R.; Yamaguchi, H.; Uneno, D.; Fujima, K.; Enomoto, M.; Sawada, N. Analysis of a novel solar energy-powered rankine cycle for combined power and heat generation using supercritical carbon dioxide. Renew. Energy 2006, 31, 1839–1854. [Google Scholar] [CrossRef]

- Aroso, I.M.; Duarte, A.R.C.; Pires, R.R.; Mano, J.F.; Reis, R.L. Cork processing with supercritical carbon dioxide: Impregnation and sorption studies. J. Supercrit. Fluids 2015, 104, 251–258. [Google Scholar] [CrossRef]

- Knez, Ž.; Markočič, E.; Leitgeb, M.; Primožič, M.; Knez Hrnčič, M.; Škerget, M. Industrial applications of supercritical fluids: A review. Energy 2014, 77, 235–243. [Google Scholar] [CrossRef]

- Gupta, A.P.; Gupta, A.; Langlinais, J. Feasibility of supercritical carbon dioxide as a drilling fluid for deep underbalanced drilling operation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005.

- ALAdwani, F.A. Mechanistic Modeling of an Underbalanced Drilling Operation Utilizing Supercritical Carbon Dioxide. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, August 2007. [Google Scholar]

- Shen, Z.; Wang, H.; Li, G. Feasibility analysis of coiled tubing drilling with supercritical carbon dioxide. Pet. Explor. Dev. 2010, 37, 743–747. [Google Scholar] [CrossRef]

- Middleton, R.S.; Carey, J.W.; Currier, R.P.; Hyman, J.D.; Kang, Q.; Karra, S.; Jiménez-Martínez, J.; Porter, M.L.; Viswanathan, H.S. Shale gas and non-aqueous fracturing fluids: Opportunities and challenges for supercritical CO2. Appl. Energy 2015, 147, 500–509. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Shen, Z. A feasibility analysis on shale gas exploitation with supercritical carbon dioxide. Energy Source A 2012, 34, 1426–1435. [Google Scholar] [CrossRef]

- Lyu, Q.; Long, X.P.; Ranjith, P.G.; Kang, Y. Unconventional gas: Experimental study of the influence of subcritical carbon dioxide on the mechanical properties of black shale. Energies 2016, 9. [Google Scholar] [CrossRef]

- He, Z.; Tian, S.; Li, G.; Wang, H.; Shen, Z.; Xu, Z. The pressurization effect of jet fracturing using supercritical carbon dioxide. J. Nat. Gas Sci. Eng. 2015, 27, 842–851. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Tang, J.; Zhou, Z.; Liao, Y. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- Merey, S.; Sinayuc, C. Analysis of carbon dioxide sequestration in shale gas reservoirs by using experimental adsorption data and adsorption models. J. Nat. Gas Sci. Eng. 2016, 36, 1087–1105. [Google Scholar] [CrossRef]

- Reznik, A.A.; Singh, P.K.; Foley, W.L. An analysis of the effect of CO2 injection on the recovery of insitu methane from bituminous coal—An experimental simulation. Soc. Pet. Eng. J. 1984, 24, 521–528. [Google Scholar] [CrossRef]

- Song, W.Q.; Wang, R.H.; Ni, H.J.; Huo, H.J.; Shen, Z.H. Multiphase flow mechanism of sand cleanout with supercritical carbon dioxide in a deviated wellbore. J. Nat. Gas Sci. Eng. 2015, 25, 140–147. [Google Scholar] [CrossRef]

- Sun, X.; Ni, H.J.; Qiao, H.S.; Wang, X.Y.; Ma, B.; Wang, R.H.; Shen, Z.H.; Zhao, M.Y. Experimental study on the mechanism of carbon dioxide removing formation paraffin deposits. J. Nat. Gas Sci. Eng. 2016, 32, 59–65. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, G.; Jiang, Y.; Xian, X.; Liu, Q.; Zhang, D.; Tan, J. Supercritical carbon dioxide fracturing in shale and the coupled effects on the permeability of fractured shale: An experimental study. J. Nat. Gas Sci. Eng. 2016, 36, 369–377. [Google Scholar] [CrossRef]

- Kolle, J.J. Coiled-tubing drilling with supercritical carbon dioxide. In Proceedings of the SPE/CIM International Conference on Horizontal Well Technology, Calgary, AB, Canada, 6–8 November 2000.

- Du, Y.K.; Wang, R.H.; Ni, H.J.; Li, M.K.; Song, W.Q.; Song, H.F. Determination of rock-breaking performance of high-pressure supercritical carbon dioxide jet. J. Hydrodyn. 2012, 24, 554–560. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, G.S.; Shen, Z.H.; Tian, S.C.; Sun, B.J.; He, Z.G.; Lu, P.Q. Experiment on rock breaking with supercritical carbon dioxide jet. J. Pet. Sci. Eng. 2015, 127, 305–310. [Google Scholar] [CrossRef]

- He, Z.; Li, G.; Tian, S.; Wang, H.; Shen, Z.; Li, J. SEM analysis on rock failure mechanism by supercritical CO2 jet impingement. J. Pet. Sci. Eng. 2016, 146, 111–120. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, G.S.; Tian, S.C.; Cheng, Y.X.; He, Z.G.; Yu, S.J. Flow field simulation of supercritical carbon dioxide jet: Comparison and sensitivity analysis. J. Hydrodyn. 2015, 27, 210–215. [Google Scholar] [CrossRef]

- Long, X.; Liu, Q.; Ruan, X.; Kang, Y.; Lyu, Q. Numerical investigation of the flow of supercritical carbon dioxide injected into the bottom hole during drilling with special emphasis on the real gas effects. J. Nat. Gas. Sci. Eng. 2016, 34, 1044–1053. [Google Scholar] [CrossRef]

- Wang, R.H.; Huo, H.J.; Huang, Z.Y.; Song, H.F.; Ni, H.J. Experimental and numerical simulations of bottom hole temperature and pressure distributions of supercritical CO2 jet for well-drilling. J. Hydrodyn. 2014, 26, 226–233. [Google Scholar] [CrossRef]

- Tian, S.C.; He, Z.G.; Li, G.S.; Wang, H.Z.; Shen, Z.H.; Liu, Q.L. Influences of ambient pressure and nozzle-to-target distance on SC-CO2 jet impingement and perforation. J. Nat. Gas Sci. Eng. 2016, 29, 232–242. [Google Scholar] [CrossRef]

- Annoni, M.M.; Bertola, V.; Goletti, M. The role of polymeric additives in water jet cutting. Int. J. Mach. Mach. Mater. 2009, 6. [Google Scholar] [CrossRef]

- Hu, D.; Tang, C.L.; Kang, Y.; Li, X.Y. An investigation on cutting quality by adding polymer in abrasive water jet. Part. Sci. Technol. 2016, 34, 352–358. [Google Scholar] [CrossRef]

- Mao, H.; Qiu, Z.S.; Shen, Z.H.; Huang, W.A.; Zhong, H.Y.; Dai, W.H. Novel hydrophobic associated polymer based nano-silica composite with core-shell structure for intelligent drilling fluid under ultra-high temperature and ultra-high pressure. Prog. Nat. Sci. Mater. 2015, 25, 90–93. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Zhao, h.; Hou, Y. Nanotechnology to improve sealing ability of drilling fluids for shale with micro-cracks during drilling. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012.

- Hoelscher, K.P.; De Stefano, G.; Riley, M.; Young, S. Application of nanotechnology in drilling fluids. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012.

- Huang, T.; Crews, J.B.; Agrawal, G. Nanoparticle pseudocrosslinked micellar fluids: Optimal solution for fluid-loss control with internal breaking. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012.

- Li, Y.Z.; DiCarlo, D.; Li, X.F.; Zang, J.L.; Li, Z.N. An experimental study on application of nanoparticles in unconventional gas reservoir CO2 fracturing. J. Pet. Sci. Eng. 2015, 133, 238–244. [Google Scholar] [CrossRef]

- Gnirk, P.F.; Grams, W.H. Rock Drilling with Pulsed High-Velocity Water Jets; American Rock Mechanics Association: Alexandria, VA, USA, 1972. [Google Scholar]

- Daniel, I.M. Experimental studies of water jet impact on rock and rocklike materials. In Proceedings of the 3rd International Symposium on Jet Cutting Technology, Chicago, IL, USA, 11–13 May 1976; pp. 27–46.

- Zeng, J.; Kim, T.J. An erosion model of polycrystalline ceramics in abrasive waterjet cutting. Wear 1996, 193, 207–217. [Google Scholar]

- Momber, A.W. Deformation and fracture of rocks due to high-speed liquid impingement. Int. J. Fract. 2004, 130, 683–704. [Google Scholar] [CrossRef]

- Zuo, W.Q. Abrasive Accelerated Mechanisms and Distribution Law in Pre-Mixed Abrasive Jet. Ph.D. Thesis, Chongqing University, Chongqing, China, February 2012. [Google Scholar]

- Woolley, R.M.; Fairweather, M.; Wareing, C.J.; Falle, S.A.E.G.; Proust, C.; Hebrard, J.; Jamois, D. Experimental measurement and Reynolds-averaged Navier–Stokes modelling of the near-field structure of multi-phase CO2 jet releases. Int. J. Greenh. Gas Control 2013, 18, 139–149. [Google Scholar] [CrossRef] [Green Version]

- Woolley, R.M.; Fairweather, M.; Wareing, C.J.; Falle, S.A.E.G.; Mahgerefteh, H.; Martynov, S.; Brown, S.; Narasimhamurthy, V.D.; Storvik, I.E.; Sælen, L.; et al. CO2 PipeHaz: Quantitative hazard assessment for next generation CO2 pipelines. Energy Procedia 2014, 63, 2510–2529. [Google Scholar] [CrossRef]

- Lv, Q.; Long, X.P.; Kang, Y.; Xiao, L.Z.; Wu, W. Numerical investigation on the expansion of supercritical carbon dioxide jet. IOP Conf. Ser. Matesr. Sci. Eng. 2013, 52, 072011. [Google Scholar] [CrossRef]

- Tazibt, A.; Parsy, F.; Abriak, N. Theoretical analysis of the particle acceleration process in abrasive water jet cutting. Comp. Mater. Sci. 1996, 5, 243–254. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. Refprop; 9.1; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2016. [Google Scholar]

- Mao, H.; Qiu, Z.S.; Shen, Z.H.; Huang, W.A. Hydrophobic associated polymer based silica nanoparticles composite with core-shell structure as a filtrate reducer for drilling fluid at utra-high temperature. J. Pet. Sci. Eng. 2015, 129, 1–14. [Google Scholar] [CrossRef]

| Specific Surface Area (m2/g) | Purity (%) | Density (g/cm3) | Particle Size (nm) |

|---|---|---|---|

| 200 ± 20 | ≥99.8 | 1.8~2.1 | 30 ± 5 |

| Number | Length (mm) | Diameter (mm) | Density (g/cm3) | Compressive Strength (MPa) | Modulus of Elasticity (GPa) | Poisson’s Ratios |

|---|---|---|---|---|---|---|

| 1 | 98.5 | 50 | 2.6 | 38.2 | 8.38 | 0.12 |

| 2 | 100.5 | 50 | 2.5 | 38.5 | 8.32 | 0.11 |

| 3 | 99.3 | 50 | 2.5 | 37.9 | 8.35 | 0.12 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Kang, Y.; Long, X.; Wang, X.; Hu, Y.; Li, D.; Zhang, M. Effects of a Nano-Silica Additive on the Rock Erosion Characteristics of a SC-CO2 Jet under Various Operating Conditions. Appl. Sci. 2017, 7, 153. https://doi.org/10.3390/app7020153

Huang M, Kang Y, Long X, Wang X, Hu Y, Li D, Zhang M. Effects of a Nano-Silica Additive on the Rock Erosion Characteristics of a SC-CO2 Jet under Various Operating Conditions. Applied Sciences. 2017; 7(2):153. https://doi.org/10.3390/app7020153

Chicago/Turabian StyleHuang, Man, Yong Kang, Xinping Long, Xiaochuan Wang, Yi Hu, Deng Li, and Mingxing Zhang. 2017. "Effects of a Nano-Silica Additive on the Rock Erosion Characteristics of a SC-CO2 Jet under Various Operating Conditions" Applied Sciences 7, no. 2: 153. https://doi.org/10.3390/app7020153

APA StyleHuang, M., Kang, Y., Long, X., Wang, X., Hu, Y., Li, D., & Zhang, M. (2017). Effects of a Nano-Silica Additive on the Rock Erosion Characteristics of a SC-CO2 Jet under Various Operating Conditions. Applied Sciences, 7(2), 153. https://doi.org/10.3390/app7020153