A Novel Denoising Method for an Acoustic-Based System through Empirical Mode Decomposition and an Improved Fruit Fly Optimization Algorithm

Abstract

:1. Introduction

2. Basic Theory

2.1. Empirical Mode Decomposition-Based Denoising

2.2. Fruit Fly Optimization Algorithm

3. The Proposed Method

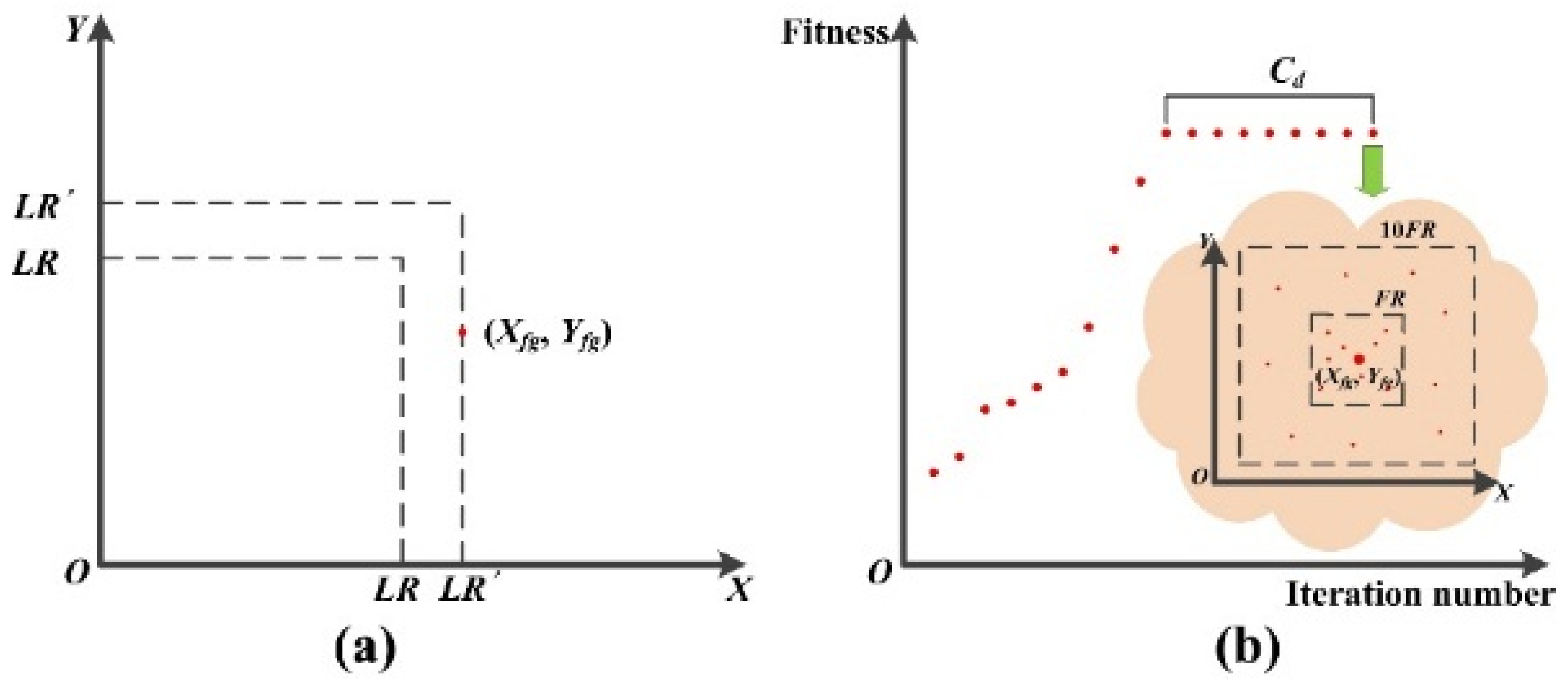

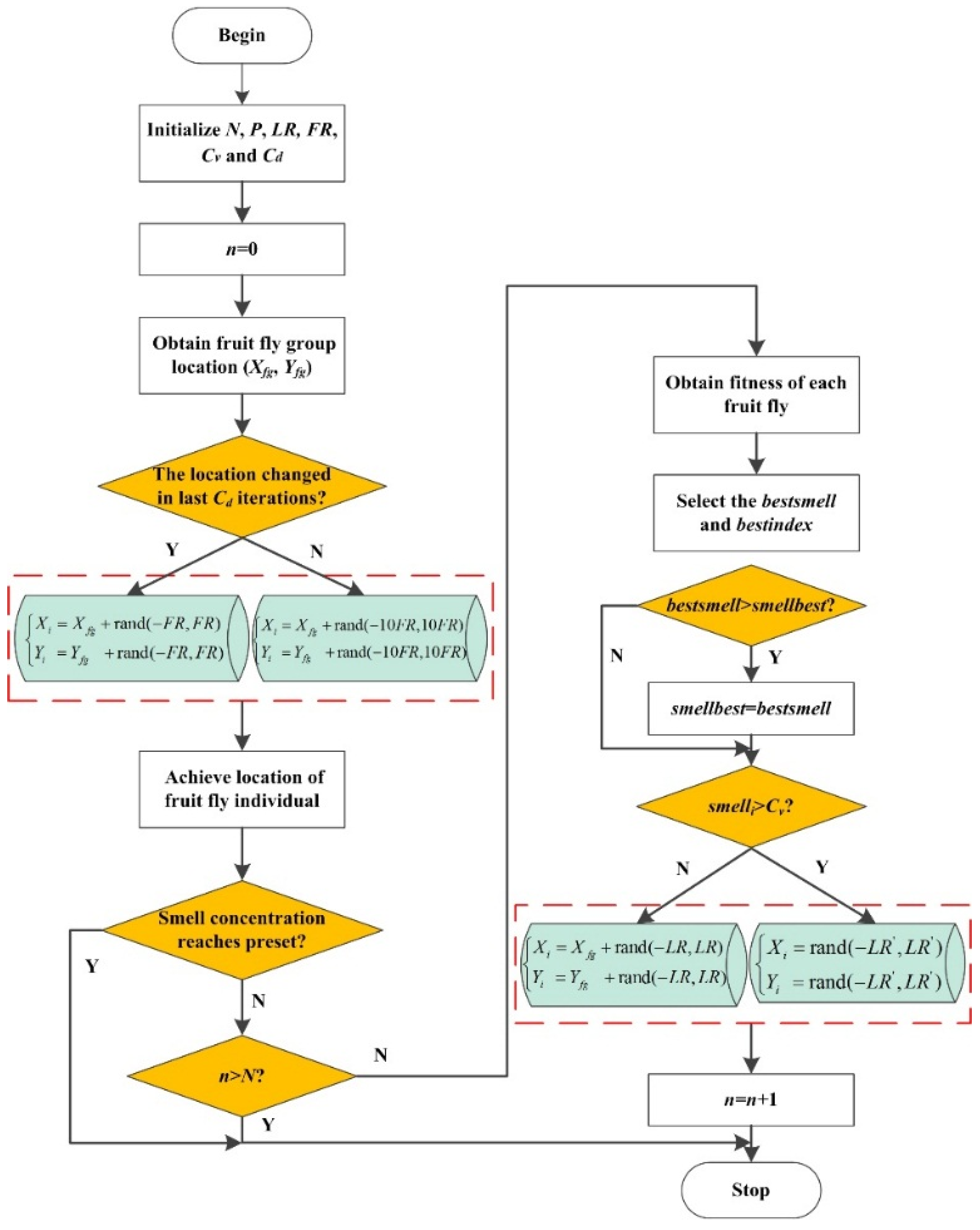

3.1. Improvement on FOA

3.2. Flow of the Proposed Denoising Method

4. Simulation and Analysis

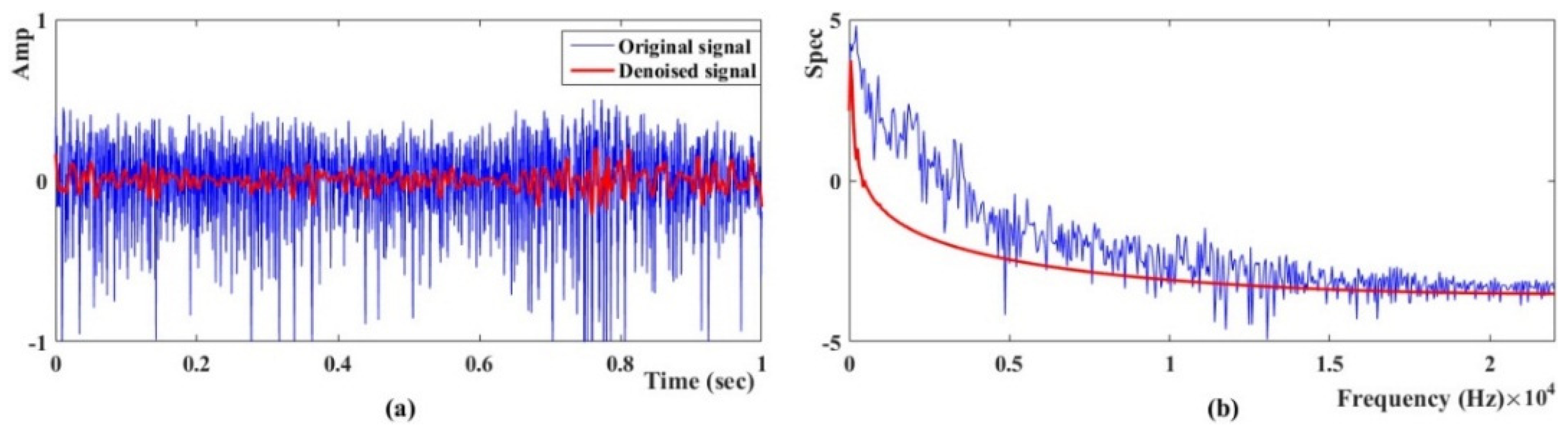

4.1. Signal Preprocessing

4.2. Signal Decomposition and Denoising

- (1)

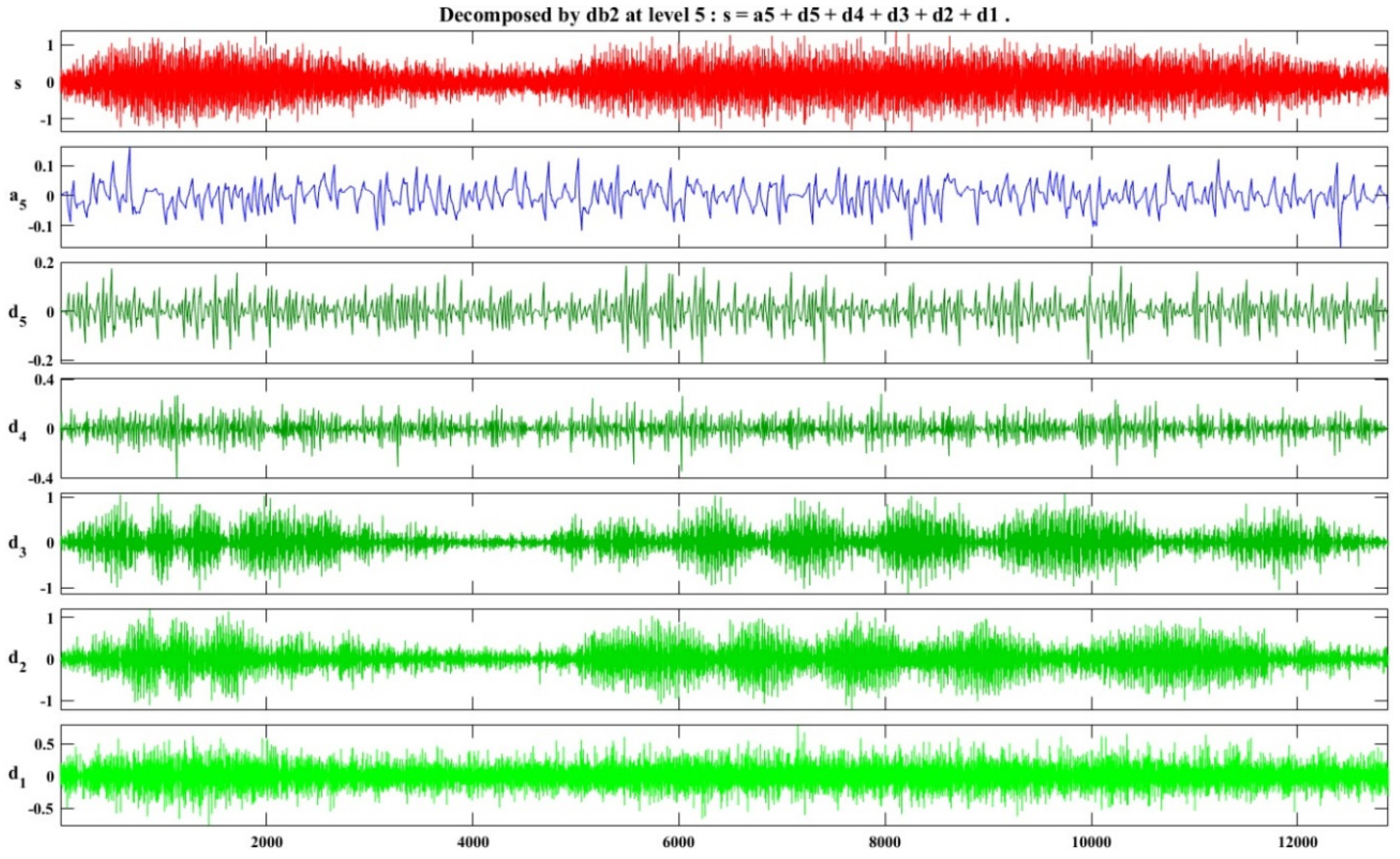

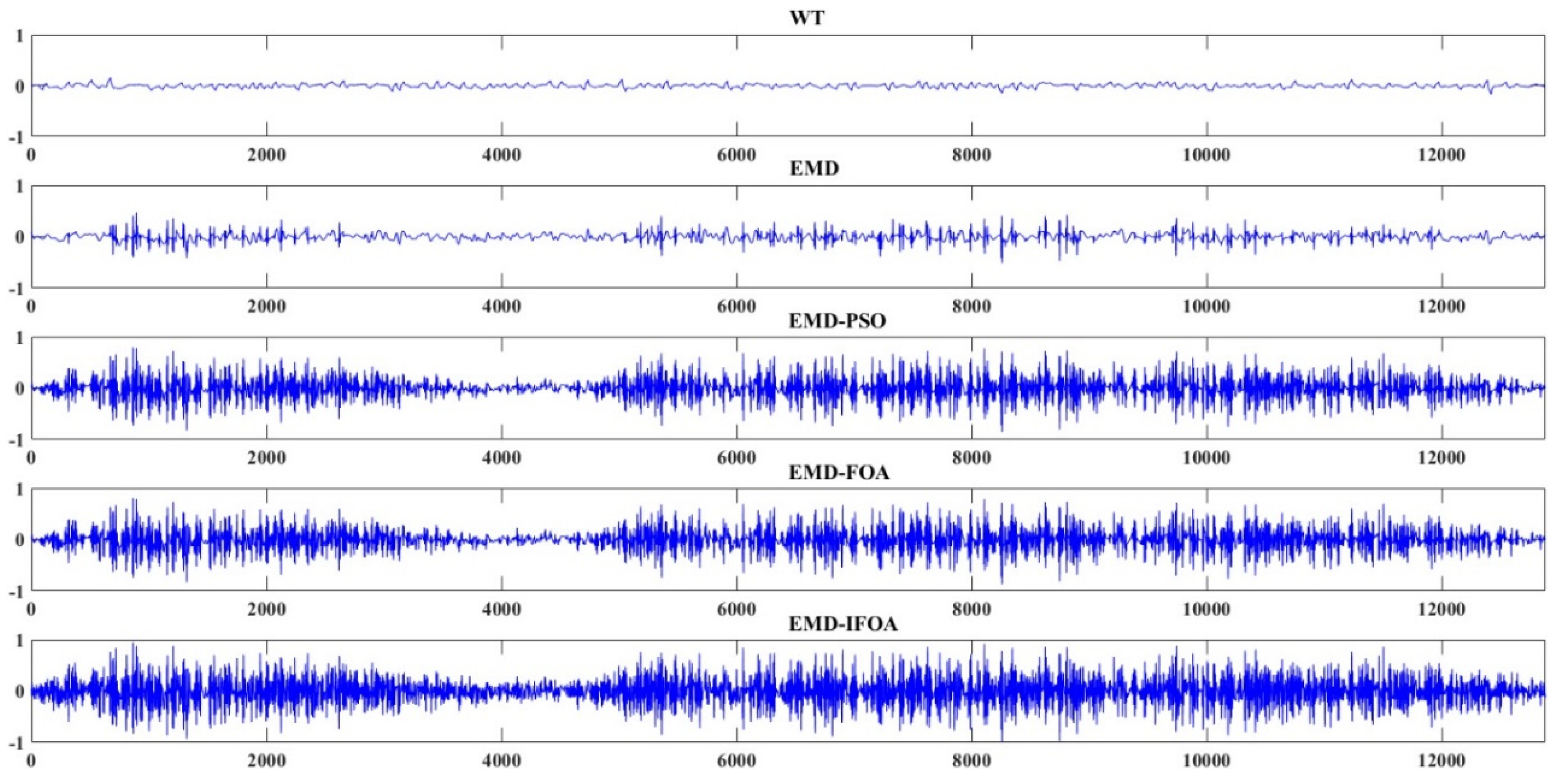

- Wavelet threshold denoising. The noisy signal was first decomposed by db2 wavelet at five levels [32], and the decomposition result was presented in Figure 5. Then, the soft threshold function was adopted to shrink the wavelet coefficients. Inverse wavelet transform was conducted consequently to reconstruct the signal.

- (2)

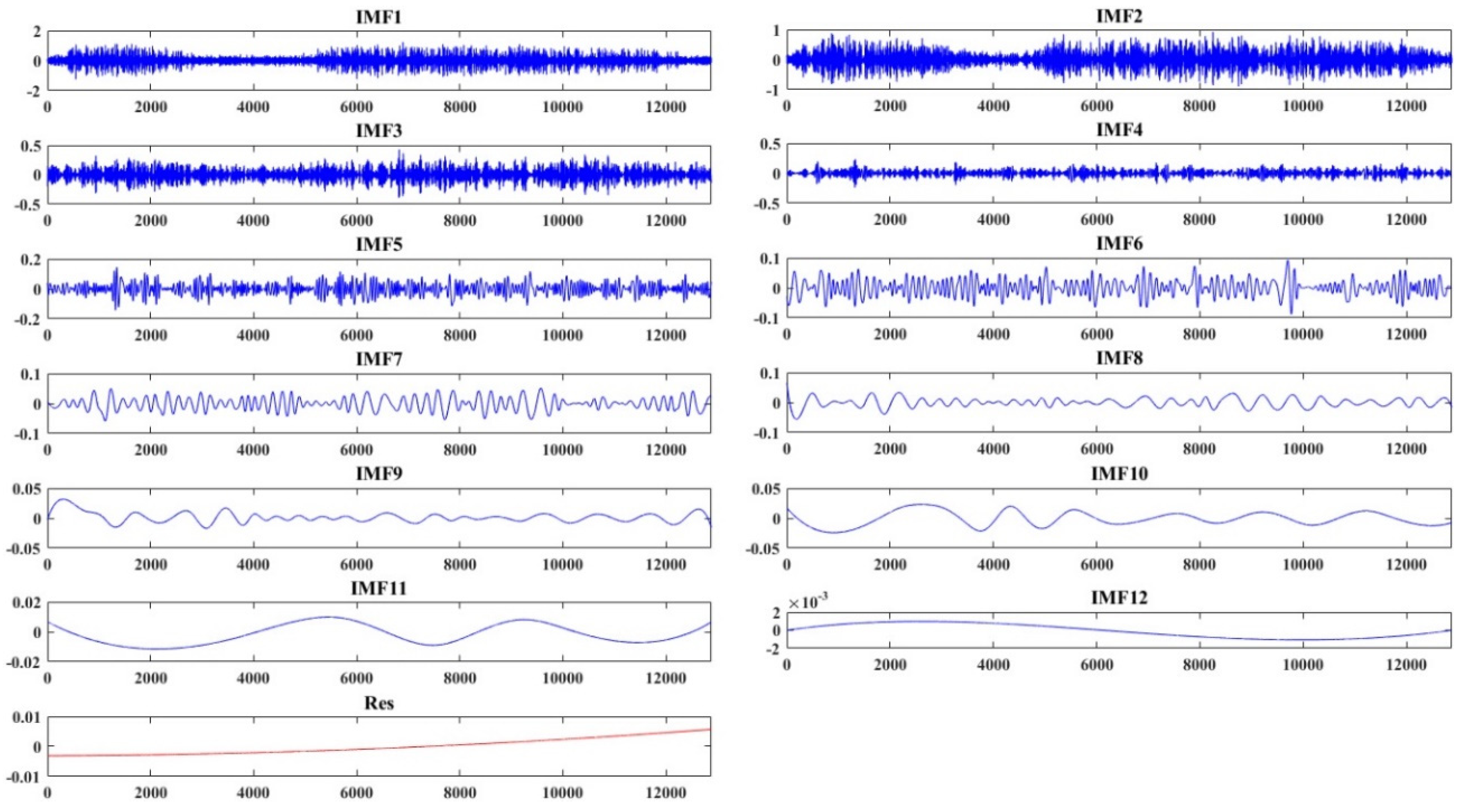

- EMD denoising. The noisy signal was first decomposed by EMD adaptively, which could be shown in Figure 6. The noisy signal could be decomposed as x = imf1 + imf2 + imf3 + … + imf12 + res. Then, the shrinkage threshold of each IMF was determined according to Equations (5) and (6). Soft threshold function was applied and the denoised signal was reconstructed as Equation (9). Some parameters in Equations (5), (6) and (9) were set as follows [10]: C = 0.7, α = 0.719, β = 2.01, M1 = 2 and M2 = 4.

- (3)

- EMD-PSO denoising. The noisy signal was first decomposed by EMD adaptively. Then, the threshold of each IMF was determined according to PSO intelligently. Soft threshold function was applied and the denoised signal was reconstructed as Equation (9). Some parameters during the EMD-PSO were set as recommended in [23]: M1 = 2, M2 = 4, the dimensionality of each particle was M2 − M1 + 1 = 3, the learning factor c1 and c2 were set as 2, the iteration number was 100 and the particle number of the population was 10.

- (4)

- EMD-FOA denoising. The noisy signal was first decomposed by EMD adaptively. Then, the threshold of each IMF was determined according to FOA automatically. Soft threshold function was applied and the denoised signal was reconstructed as Equation (9). Some parameters during the EMD-FOA were set as follows: M1 = 2, M2 = 4, the number of fruit fly population was M2 − M1 + 1 = 3, the iteration number was 100, the fly number in each population was 10, the fruit fly location range and the random fly distance range was 1.

- (5)

- EMD-IFOA denoising. The noisy signal was first decomposed by EMD adaptively. Then, the threshold of each IMF was determined according to IFOA automatically. Soft threshold function was applied and the denoised signal was reconstructed as Equation (9). Some parameters during the EMD-IFOA were set as follows: M1 = 2, M2 = 4, the number of fruit fly population was M2 − M1 + 1 = 3, the iteration number was 100, the fly number in each population was 10, the fruit fly location range and the random fly distance range was 1, the variation coefficient Cv = 0.2 and disturbance coefficient Cd = 5. The denoised signal of the five noise elimination schemes are presented in Figure 7.

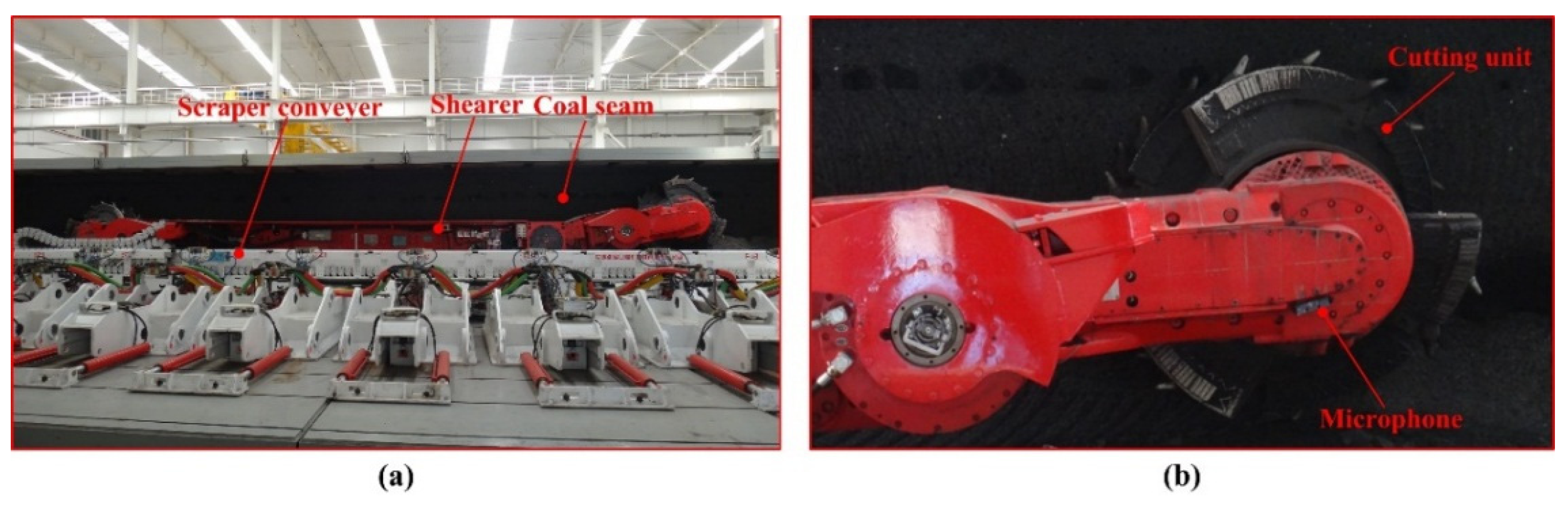

4.3. Application

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Elforjani, M.; Mba, D.; Muhammad, A.; Sire, A. Condition monitoring of worm gears. Appl. Acoust. 2012, 73, 859–863. [Google Scholar] [CrossRef]

- Ai, C.S.; Sun, Y.J.; He, G.W.; Ze, X.B.; Li, W.; Mao, K. The milling tool wear monitoring using the acoustic spectrum. Int. J. Adv. Manuf. Tech. 2012, 61, 457–463. [Google Scholar] [CrossRef]

- Zhu, D.C.; Feng, Y.P.; Chen, Q.; Cai, J.B. Image recognition technology in rotating machinery fault diagnosis based on artificial immune. Smart Struct. Syst. 2010, 6, 389–403. [Google Scholar] [CrossRef]

- Gravalos, I.; Loutridis, S.; Gialamas, T.; Avgousti, A.; Kateris, D.; Xyradakis, P.; Tsiropoulos, Z. Vibrational behavior of tractor engine hood. In Proceedings of the 5th International Scientific Conference on Trends in Agricultural Engineering (TAE 2013), Prague, Czech Republic, 3–6 September 2013.

- Garcia, M.P.; Gherabi, A.; Arsenault, H.H. Image difference detection under varying illumination based on vector space and correlations. Optik 2012, 123, 665–669. [Google Scholar] [CrossRef]

- Figlus, T.; Gnap, J.; Skrucany, T.; Sarkan, B.; Stoklosa, J. The Use of Denoising and Analysis of the Acoustic Signal Entropy in Diagnosing Engine Valve Clearance. Entropy 2016, 18, 253. [Google Scholar] [CrossRef]

- Hassanpour, H. A time-frequency approach for noise reduction. Digit. Signal Process. 2008, 18, 728–738. [Google Scholar] [CrossRef]

- Nelson, D.J.; Smith, D.C. Adaptive interference removal based on concentration of the STFT. Digit. Signal Process. 2006, 16, 597–606. [Google Scholar] [CrossRef]

- Tokmakci, M.; Erdogan, N. Denoising of arterial and venous Doppler signals using discrete wavelet transform: Effect on clinical parameters. Contemp. Clin. Trials 2009, 30, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Kopsinis, Y.; McLaughlin, S. Development of EMD-Based Denoising Methods Inspired by Wavelet Thresholding. IEEE Trans. Signal Process. 2009, 57, 1351–1362. [Google Scholar] [CrossRef]

- Pinnegar, C.R. A new subclass of complex-valued S-transform windows. Signal Process. 2006, 86, 2051–2055. [Google Scholar] [CrossRef]

- Donoho, D.L. De-Noising by Soft-Thresholding. IEEE Trans. Inf. Theory 1995, 41, 613–627. [Google Scholar] [CrossRef]

- Donoho, D.L.; Johnstone, I.M. Adapting to unknown smoothness via wavelet shrinkage. J. Am. Stat. Assoc. 1995, 90, 1200–1224. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.; Tung, C.C.; Liu, H.H. The empirical mode decomposition method and the Hilbert spectrum for non-stationary time series analysis. Proc. R. Soc. Lond. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Colominas, M.A.; Schlotthauer, G.; Torres, M.E. Improved complete ensemble EMD: A suitable tool for biomedical signal processing. Biomed. Signal Process. Control 2014, 14, 19–29. [Google Scholar] [CrossRef]

- Yu, X.; Ding, E.; Chen, C.; Liu, X.; Li, L. A Novel Characteristic Frequency Bands Extraction Method for Automatic Bearing Fault Diagnosis Based on Hilbert Huang Transform. Sensors 2015, 15, 27869–27893. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.H.; Kwak, D.H.; Koh, B.H. Fault Detection of a Roller-Bearing System through the EMD of a Wavelet Denoised Signal. Sensors 2014, 14, 15022–15038. [Google Scholar] [CrossRef] [PubMed]

- Chatlani, N.; Soraghan, J.J. EMD-Based Filtering (EMDF) of Low-Frequency Noise for Speech Enhancement. IEEE Trans. Audio Speech Lang. Process. 2012, 20, 1158–1166. [Google Scholar] [CrossRef]

- Li, M.; Jiang, L.H.; Xiong, X.L. A novel EMD selecting thresholding method based on multiple iteration for denoising LIDAR signal. Opt. Rev. 2015, 22, 477–482. [Google Scholar] [CrossRef]

- Gan, Y.; Sui, L.F.; Wu, J.F.; Wang, B.; Zhang, Q.H.; Xiao, G.R. An EMD threshold de-noising method for inertial sensors. Measurement 2014, 49, 34–41. [Google Scholar] [CrossRef]

- Baskar, V.V.; Abhishek, B.; Logashanmugam, E. Comparison of Fourier Bessel (FB) and EMD-FB Based Noise Removal Techniques for Underwater Acoustic Signals. J. Sci. Ind. Res. 2014, 73, 756–762. [Google Scholar]

- Flandrin, P.; Rilling, G.; Goncalves, P. Empirical mode decomposition as a filter bank. IEEE Signal Process. Lett. 2004, 11, 112–114. [Google Scholar] [CrossRef]

- Lakshmikanth, S.; Natraj, K.R.; Rekha, K.R. Novel approach for industrial noise cancellation in speech using ICA-EMD with PSO. Int. J. Signal Process. Image Process. Pattern Recognit. 2014, 7, 345–358. [Google Scholar] [CrossRef]

- Chu, D.L.; He, Q.; Mao, X.H. Rolling bearing fault diagnosis by a novel fruit fly optimization algorithm optimized support vector machine. J. Vibroeng. 2016, 18, 151–164. [Google Scholar]

- Phuong, N.; Kim, J.M. Adaptive ECG denoising using genetic algorithm-based thresholding and ensemble empirical mode decomposition. Inf. Sci. 2016, 373, 499–511. [Google Scholar]

- Pan, W.T. A new Fruit Fly Optimization Algorithm: Taking the financial distress model as an example. Knowl. Based Syst. 2012, 26, 69–74. [Google Scholar] [CrossRef]

- Li, H.Z.; Guo, S.; Li, C.J.; Sun, J.Q. A hybrid annual power load forecasting model based on generalized regression neural network with fruit fly optimization algorithm. Knowl. Based Syst. 2013, 37, 378–387. [Google Scholar] [CrossRef]

- Zheng, X.L.; Wang, L. A two-stage adaptive fruit fly optimization algorithm for unrelated parallel machine scheduling problem with additional resource constraints. Expert Syst. Appl. 2016, 65, 28–39. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.B.; Wang, J.B.; Tan, C.; Zhang, L.; Liu, X.H. Acoustic-Based Cutting Pattern Recognition for Shearer through Fuzzy C-Means and a Hybrid Optimization Algorithm. Appl. Sci. Basel 2016, 6, 294. [Google Scholar] [CrossRef]

- Shan, D.; Cao, G.H.; Dong, H.J. LGMS-FOA: An improved fruit fly optimization algorithm for solving optimization problems. Math. Probl. Eng. 2013, 2013, 108768. [Google Scholar] [CrossRef]

- Li, T.F.; Gao, L.; Li, P.G.; Pan, Q.K. An ensemble fruit fly optimization algorithm for solving range image registration to improve quality inspection of free-form surface parts. Inf. Sci. 2016, 367, 953–974. [Google Scholar] [CrossRef]

- Abbasiona, S.; Rafsanjania, A.; Farshidianfarb, A.; Iranic, N. Rolling element bearings multi-fault classification based on the wavelet denoising and support vector machine. Mech. Syst. Signal Process. 2007, 21, 2933–2945. [Google Scholar] [CrossRef]

- Wang, B.P.; Wang, Z.C.; Zhang, W.Z. Coal-rock interface recognition method based on EMD and neural network. J. Vib. Meas. Diagn. 2012, 32, 586–590. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Chen, Y.K. Study on the coal-rock interface identification based on the signal analysis. Min. Process. Equip. 2010, 5, 22–25. [Google Scholar]

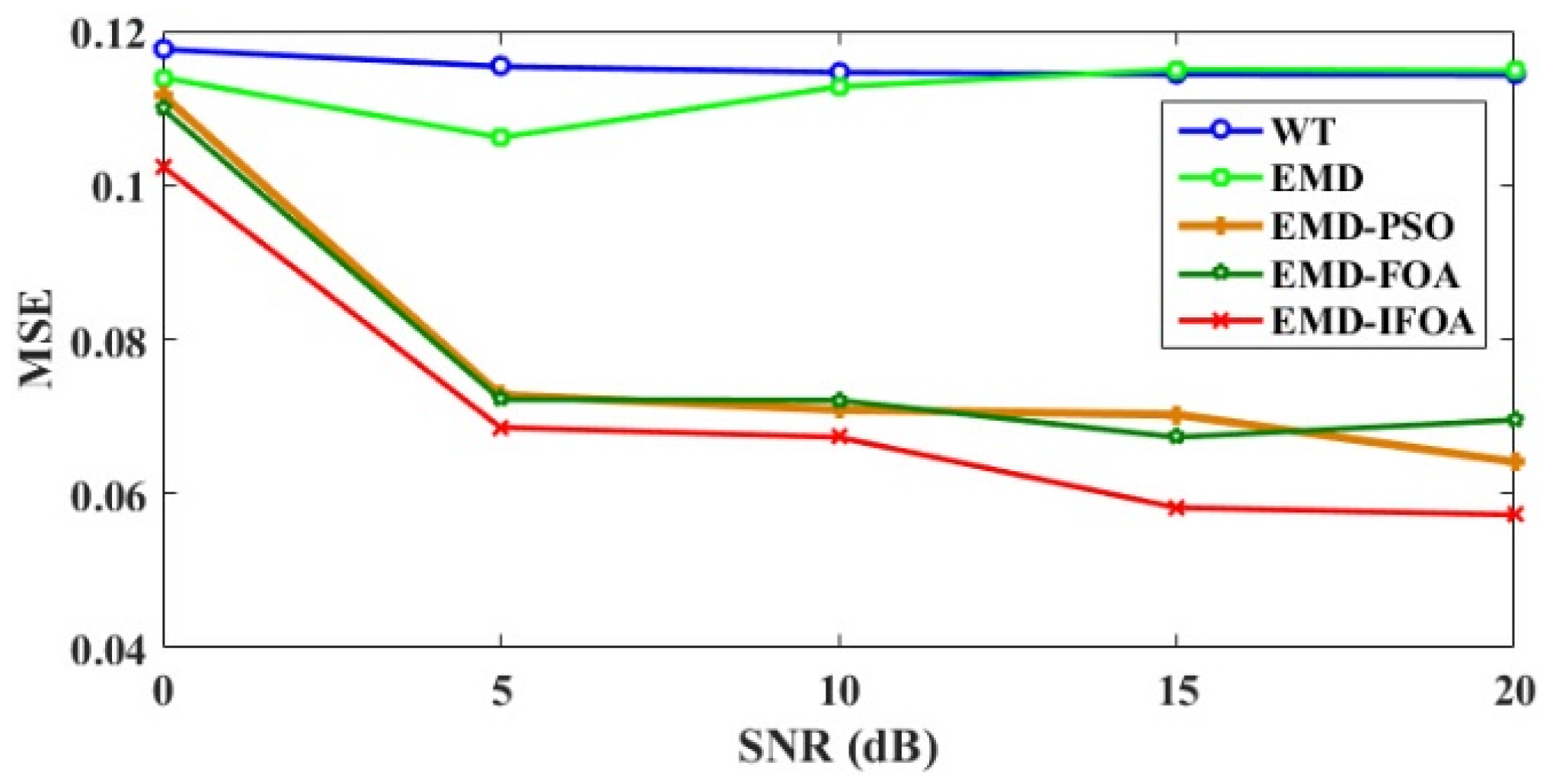

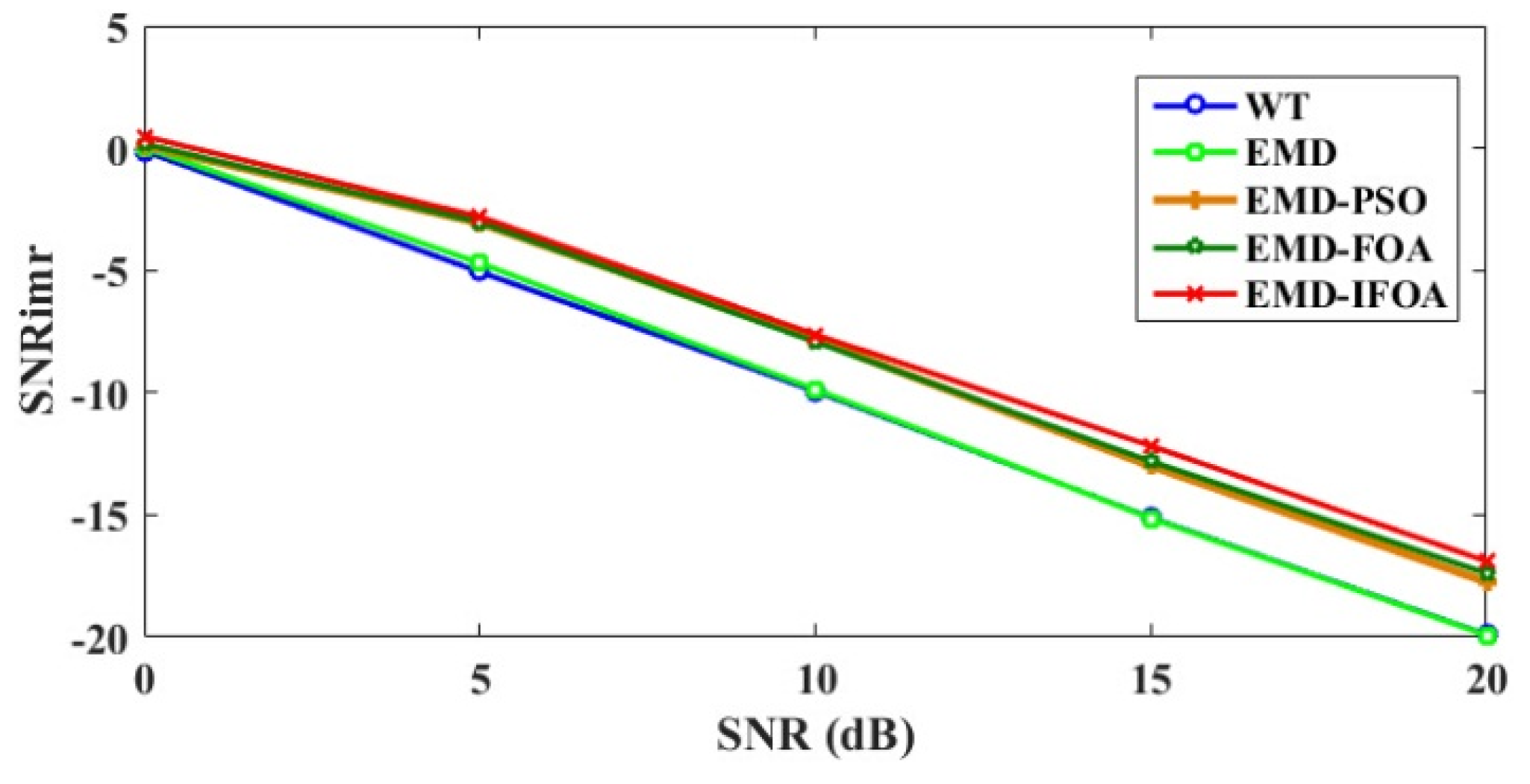

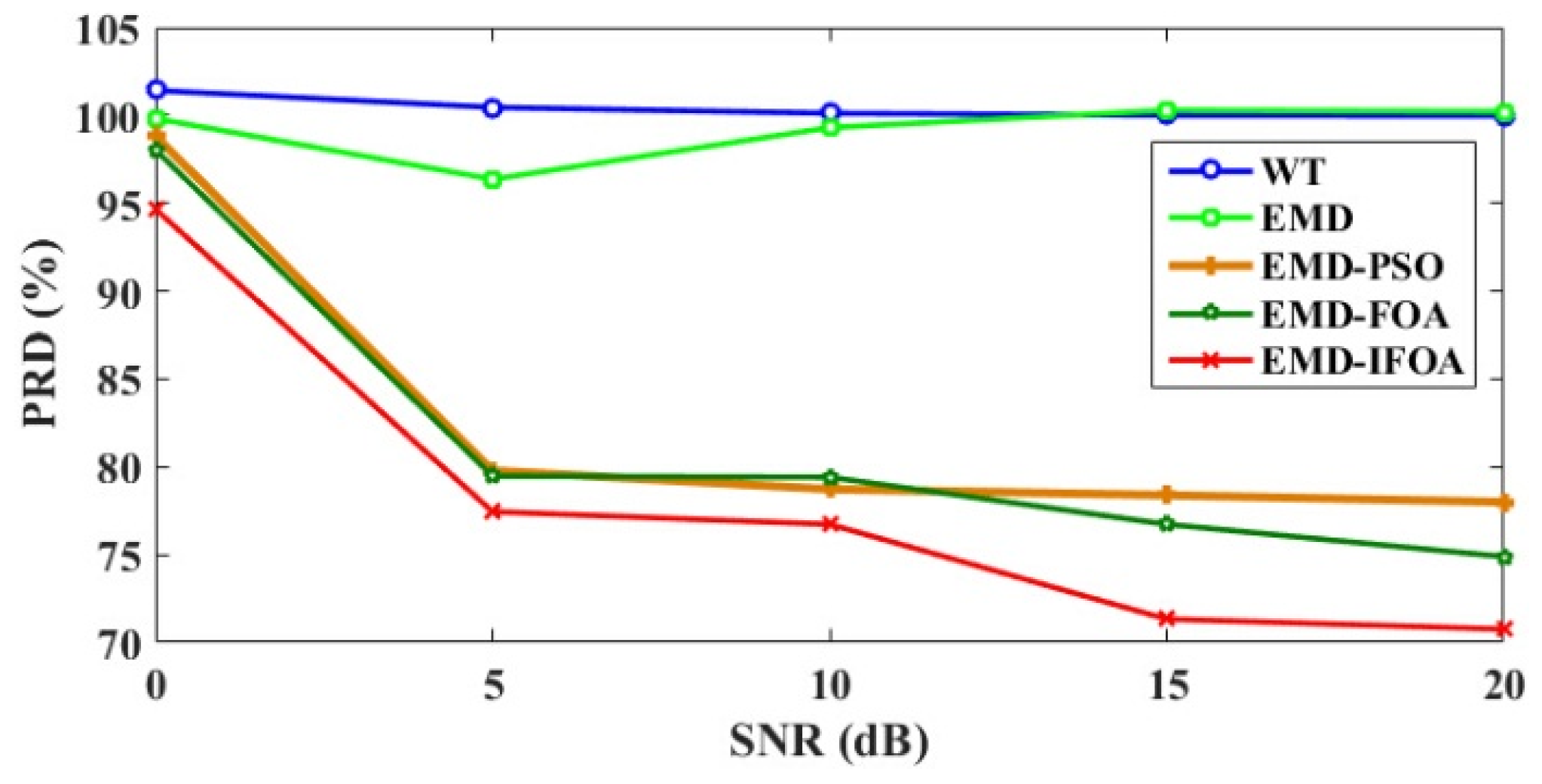

| Index | Wavelet | EMD | EMD-PSO | EMD-FOA | EMD-IFOA |

|---|---|---|---|---|---|

| MSE | 0.1154 | 0.1062 | 0.0728 | 0.0722 | 0.0686 |

| SNRimp (dB) | −5.0651 | −4.7038 | −3.0634 | −3.0298 | −2.8053 |

| PRD | 100.46% | 96.36% | 79.78% | 79.47% | 77.44% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wang, Z.; Tan, C.; Si, L.; Liu, X. A Novel Denoising Method for an Acoustic-Based System through Empirical Mode Decomposition and an Improved Fruit Fly Optimization Algorithm. Appl. Sci. 2017, 7, 215. https://doi.org/10.3390/app7030215

Xu J, Wang Z, Tan C, Si L, Liu X. A Novel Denoising Method for an Acoustic-Based System through Empirical Mode Decomposition and an Improved Fruit Fly Optimization Algorithm. Applied Sciences. 2017; 7(3):215. https://doi.org/10.3390/app7030215

Chicago/Turabian StyleXu, Jing, Zhongbin Wang, Chao Tan, Lei Si, and Xinhua Liu. 2017. "A Novel Denoising Method for an Acoustic-Based System through Empirical Mode Decomposition and an Improved Fruit Fly Optimization Algorithm" Applied Sciences 7, no. 3: 215. https://doi.org/10.3390/app7030215

APA StyleXu, J., Wang, Z., Tan, C., Si, L., & Liu, X. (2017). A Novel Denoising Method for an Acoustic-Based System through Empirical Mode Decomposition and an Improved Fruit Fly Optimization Algorithm. Applied Sciences, 7(3), 215. https://doi.org/10.3390/app7030215