1. Introduction

Rapid technological development has brought automated and intelligent production processes to manufacturing. Numerical control (NC) machines are flexible, high-performance automated machines that can solve complex and sophisticated processing problems. NC machines play an important role in industries that rely on high precision, high productivity and strong adaptability. However, in practice, owing to tool damage or failure, NC machine processing performance degrades, even leading to scraping of the workpiece. According to our statistics, tool faults account for about 20% of machine failures. Therefore, monitoring and identifying NC machine tool faults in a timely and accurate manner has attracted considerable interest. However, it is a challenge to develop and adopt effective signal processing techniques that can discover the crucial damage information from responsive signals [

1].

Owing to the high-speed friction between the tool and the workpiece, the tool is prone to faults such as surface damage or deformation that can lead to a decline in processing quality. The most common resolution is detection of faults by processing and analyzing signals measured by sensors. Traditional signal processing techniques in fault diagnosis include time-domain analysis [

2,

3] and frequency-domain analysis [

4,

5].

The main disadvantage of the above two techniques is that only single-domain information is utilized. Although this information may be enough in some simple systems, it is too little for many complex systems. The time–frequency analysis method was proposed to overcome the disadvantages of the above two methods by characterizing the signal in both time and frequency domains. Time–frequency analysis provides a solution to separate physical signals (such as vibrations, acoustic emissions, or cutting forces) in the frequency domain or in the time domain [

6,

7]. The wavelet analysis method, which can be viewed as an extension of the conventional spectral technique, has been widely used in machinery fault diagnostics, including for rotators, bearings and gears [

8,

9,

10,

11]. Wavelet analysis is a local transform of time and frequency. It can effectively extract the information from the signal, and multi-scale analysis can be performed on a signal using expansion and translation operators through a wavelet basis function. However, selection of the wavelet basis function does not yet have unified theoretical criteria [

12]. A suitable wavelet basis function can achieve good results, but an improper wavelet basis function could get bad results. The selection of wavelet basis function is subjective and informal in many studies for machine fault diagnosis.

Recently, hybrid intelligent methods have attracted considerable interest for tool fault diagnosis, e.g., Wavelet packet transform (WPT), Artificial neural networks (ANN), and support vector machine (SVM), because they can overcome deficiencies in time-domain or frequency-domain analyses and wavelet transforms. Young-Sun Hong et al. [

13] proposed a hybrid tool-wear monitoring method for determining the state of a micro-end mill using wavelet packet transforms and Fisher’s linear discriminant. Xiang et al. [

14] developed a personalized machine fault diagnosis method using finite element method, wavelet packet transform and SVM. Guofeng Wang et al. [

15] proposed a hybrid-learning-based Gaussian ARTMAP (GAM) network to realize online monitoring of the tool condition. Nagaraj et al. [

16] integrated Fisher discriminant ratio and support vector machine (SVM) techniques to classify tool wear states. Amin Jahromi et al. [

17] used fuzzy c-means clustering and wavelet analysis to diagnosis tool faults in a high-speed milling process.

These hybrid intelligent methods typically outperform conventional methods; however, they require the signal analyzed to satisfy certain conditions. Such conditions, including a large number of samples for training diagnosis model, independent and identical distribution, white Gaussian noise, or prior information of data, are difficult to meet in practical situation [

18,

19], especially in time-varying and non-stationary nature of NC machine complex cutting process. Moreover, there is few prior knowledge can be available to detect and diagnose tool faults in NC machine currently [

20]. The study of time-varying and non-stationary processes with less prior information is therefore well motivated. In the present paper, a novel fault diagnosis method based on stationary subspace analysis (SSA) and least squares (LS)-SVM is proposed to improve the accuracy of tool fault diagnosis. SSA is a blind source separation algorithm without the need for independency and without prior information of the source signals. It only assumes that the observed signals are a linear superposition of two groups of latent sources (stationary and non-stationary) and the non-stationaries alter the first two moments (mean and covariance matrix) [

21]. SSA has been applied successfully to Video Classification [

22], electroencephalographic (EEG) [

23], Change-point detection [

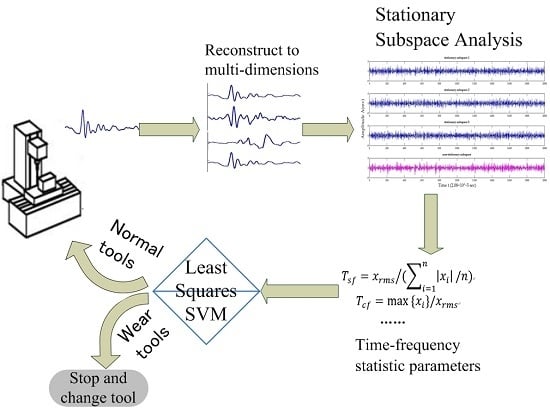

24]. The main goal of this paper is to utilize SSA into tool fault diagnosis of NC Machine, which has been not reported in published researches so far. However, SSA is a multi-dimensional feature exaction method that cannot diagnose tool’ faults directly. LS-SVM and phase space reconstruction technique are introduced in this paper to solve certain requirements of tool fault diagnosis with a single sensor for monitoring cost and processing environment.

The remainder of this paper is organized as follows.

Section 2 details the SSA and LS-SVM algorithms.

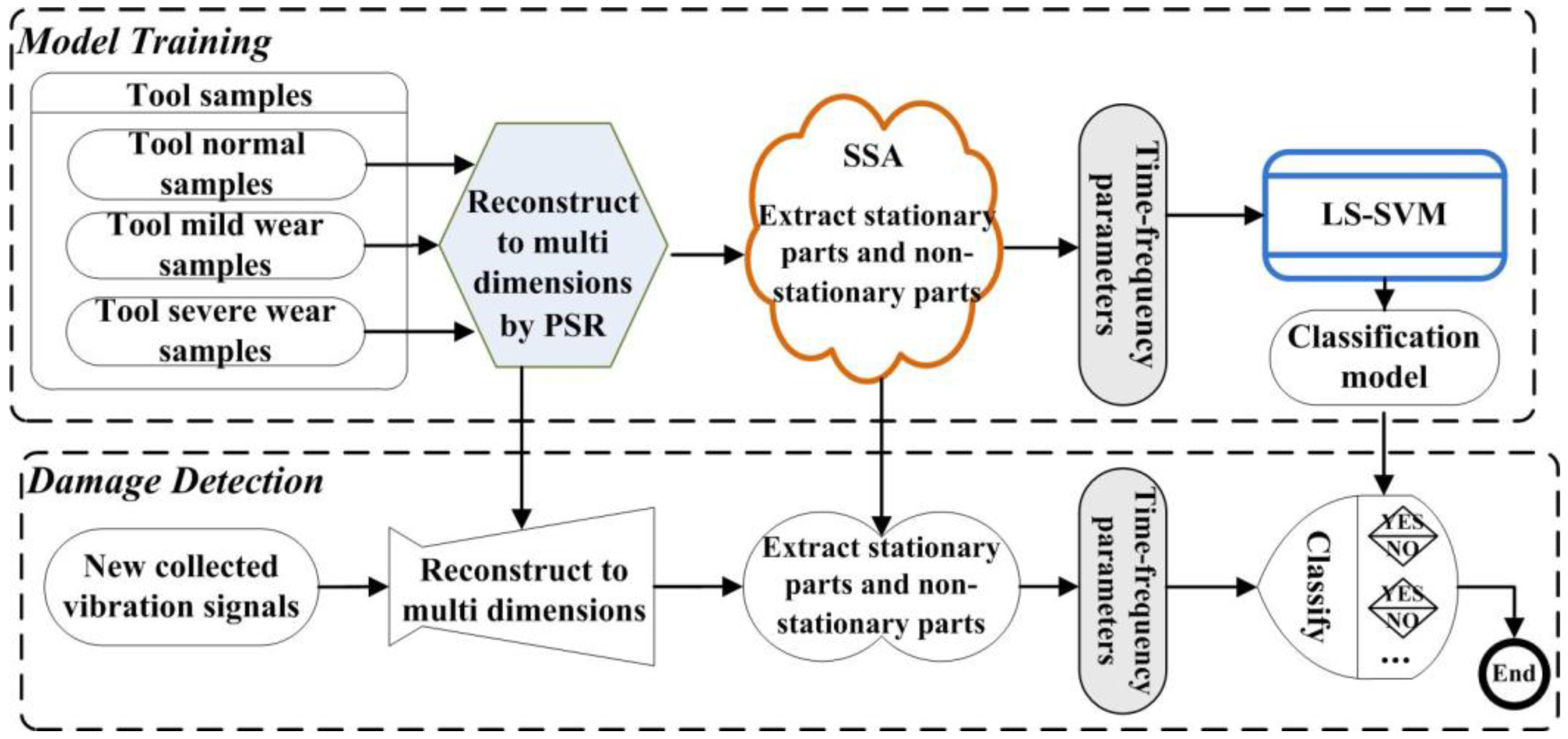

Section 3 provides the architecture of the proposed method.

Section 4 describes the experimental design.

Section 5 presents the results of the experiment and tests the advantage of the proposed method through a comparative study.

4. Experimental Design

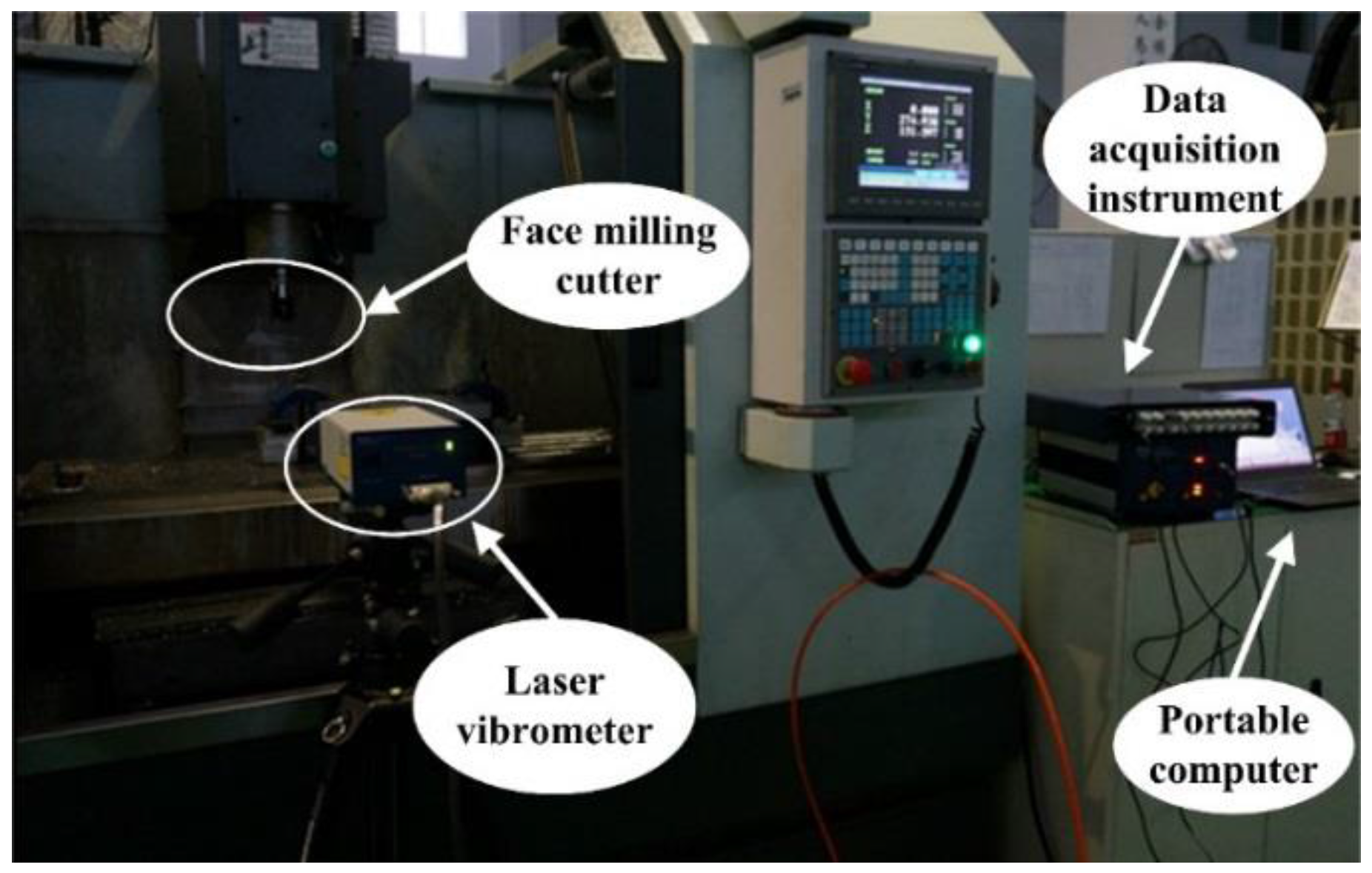

The experimental setup for tool fault detection under operating conditions is illustrated in

Figure 2. The GSVM714A NC milling machine (Deusi Numerical Control Technologies Co., Ltd., Nanjing, China) is used for the experimental test. The tools used in this test are carbide cutting tools (#RPMW1003#) and a face milling cutter with four teeth (#EMR 5R160-40-8T#). Owing to their effectiveness and convenience [

35,

36], vibration signals were collected indirectly in operation states using a laser vibrometer from Polytec Inc. (shown in

Figure 3). These vibration signals were sent to a data acquisition instrument (MI-7016 Avant, Econ Technologies Co., Ltd., Hangzhou, China) and stored on a personal computer.

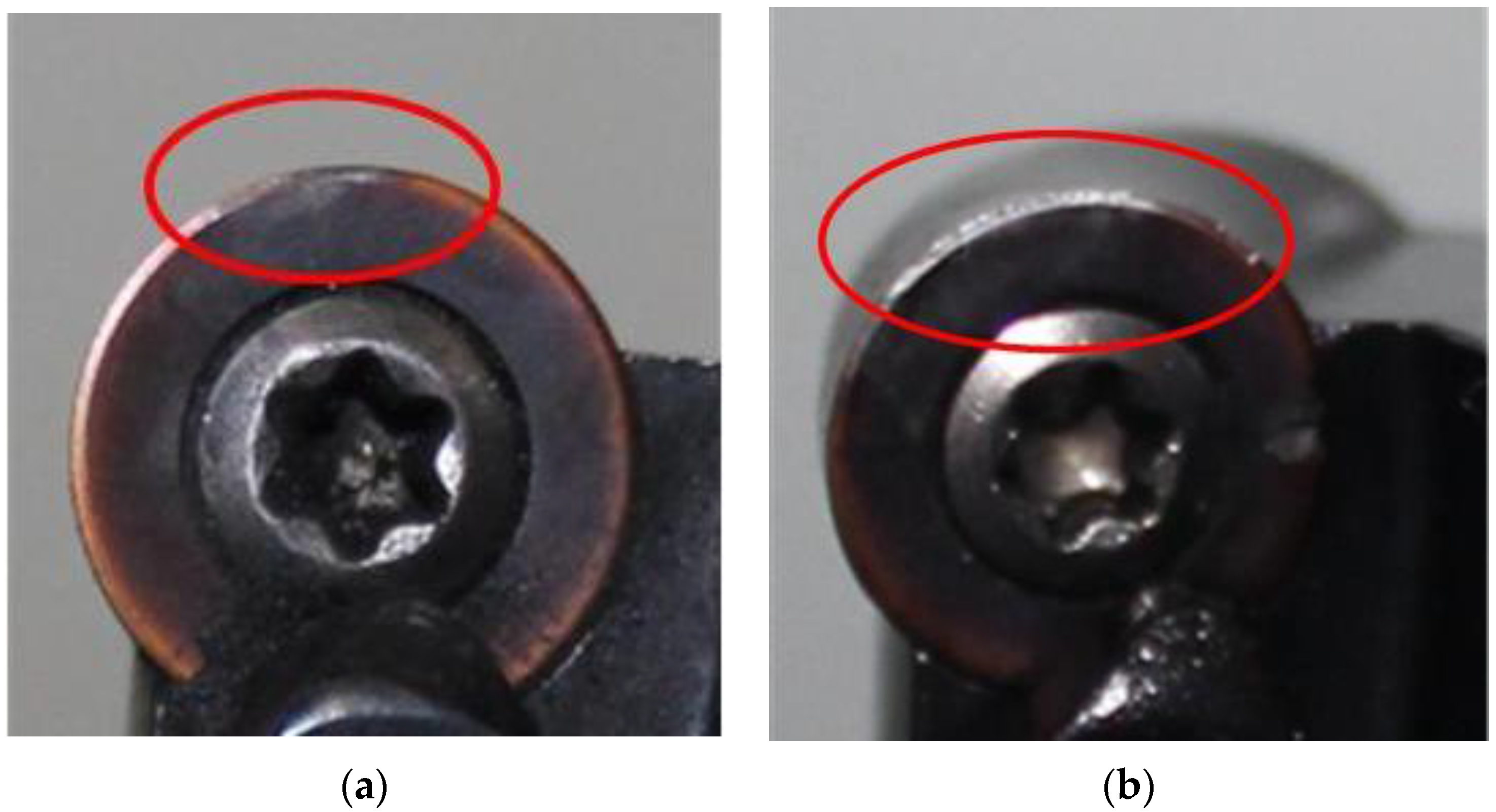

Tools in this experiment are considered to be in one of three states: (1) normal; (2) mild wear; or (3) severe wear (as shown in

Figure 4). Aluminum alloy samples #7075-T351# (150 mm × 100 mm × 500 mm) were fixed on the machining center. Cutting speed was set to 1000 rpm and cutting depth to 1 mm.

It was assumed that all investigated tools have the same damage mechanism. Vibration signals in three tool fault classes are measured and total 180 samples were taken, out of which 60 samples from each condition of the tool for a time interval of 1s at sampling frequency of 48 kHz. 60 samples of each tool condition divided into two parts: 40 samples as training set and 20 samples as testing set. The training set is used to train the LS-SVM model in MATLAB 2012R.

5. Result and Discussion

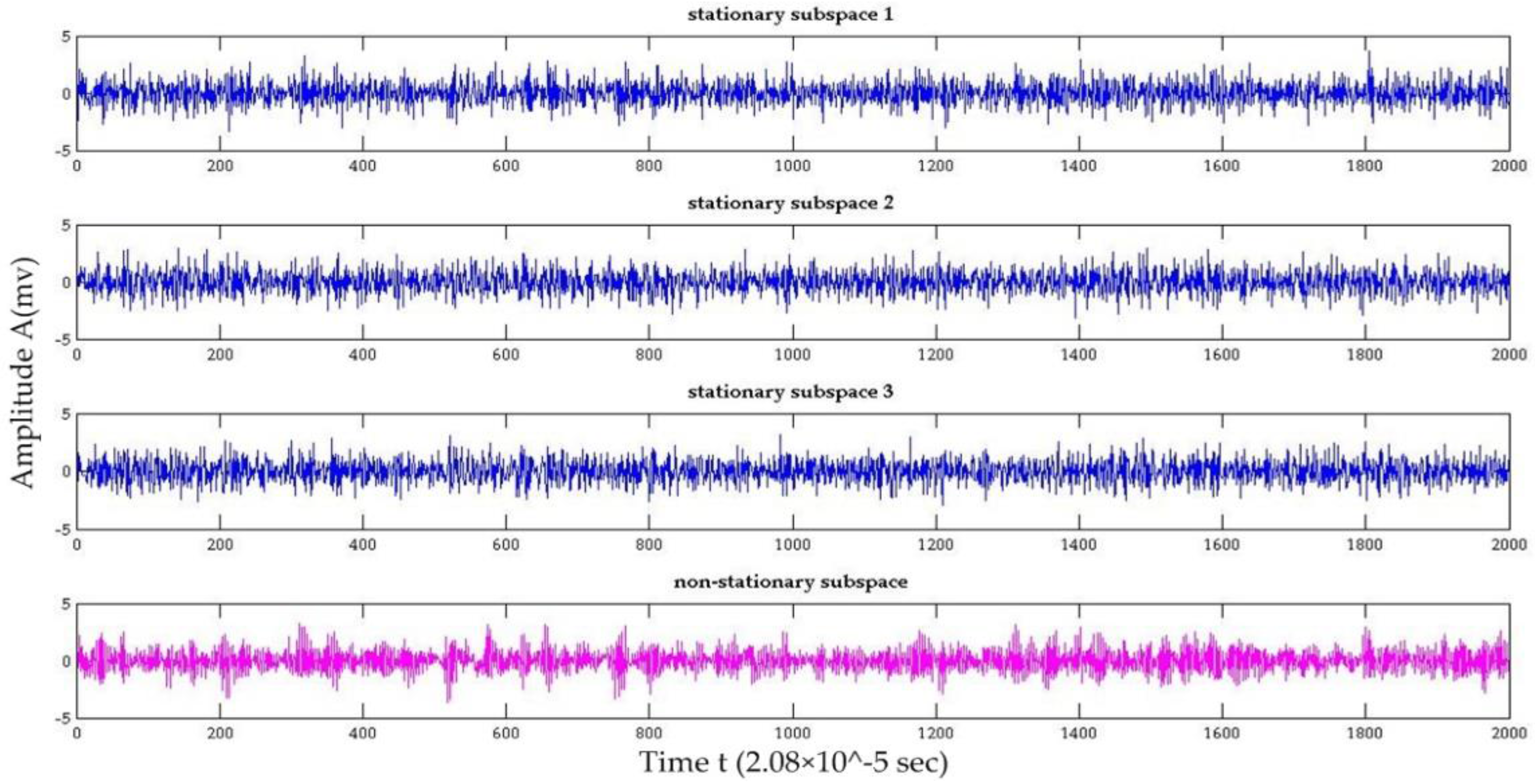

In the first phase model training, values for time delay (

= 10) and embedding dimension (

m = 4) are obtained using the autocorrelation function method and false nearest neighbor method [

27,

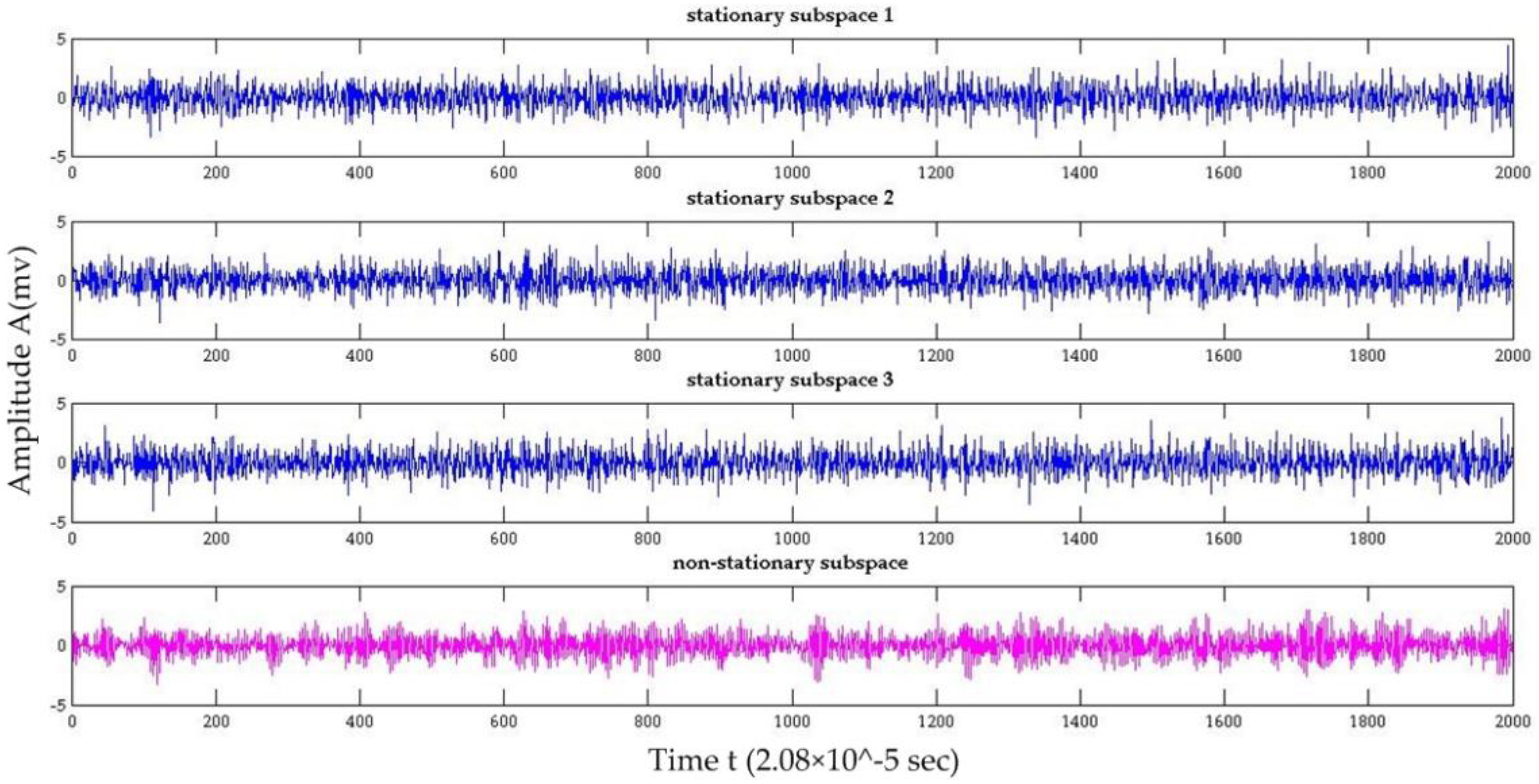

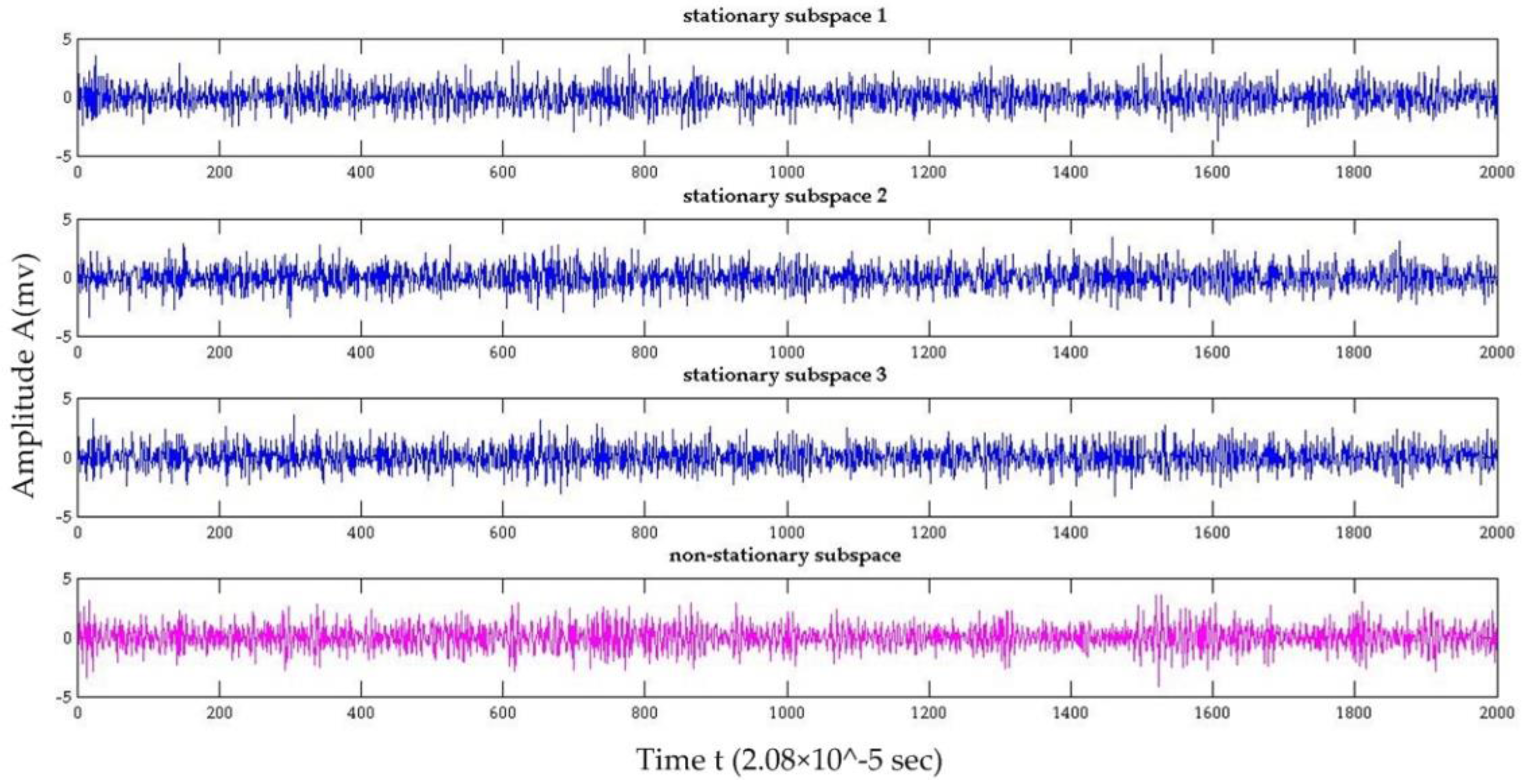

28]. These are chosen as inputs for the SSA decomposition, and one non-stationary source and three stationary sources signals are extracted. There are two reasons for setting one non-stationary source signal: (1) non-stationary source contains more fault feature information to distinguish different fault classes than stationary source; (2) one source signal is convenient to calculate time- and frequency-domain indexes for follow-up process in the proposed approach. SSA training data for three damage classes are shown in

Figure 5,

Figure 6 and

Figure 7. Ten dimensionless time–frequency parameters were chosen from the non-stationary source of each class, and these were used as the input data for LS-SVM. The Gaussian RBF kernel (

) was selected, and the kernel parameter

is optimized usinga fast leave-one-out cross validation optimization proposed in [

32].

The classification results of the proposed SSA + LS-SVM method are shown in

Table 2 and

Table 3.

Table 2 presents the classification results with training set, all normal tools can be correctly identified; however, the accuracy of the mild wear and severe wear tools is 87.5% and 92.5%, respectively. Five mild wear tools were identified wrongly as severe wear tools, and three severe wear tool were identified as mild wear tools.

Table 3 shows the classification results with testing set, all normal tools can be correctly identified; however, the accuracy of the mild wear and severe wear tools is 80% and 85%, respectively. Four mild wear tools were identified as severe wear tools, and three severe wear tool were identified as mild wear tools. Fortunately, as shown in

Table 2 and

Table 3, the proposed method can significantly distinguish between normal tools and wear tools (included mild and severe wears) both in training sets and testing sets.

The proposed SSA + LS-SVM method was compared with the original LS-SVM, PCA (Principal Component Analysis) + LS-SVM, and with SSA + LDA (linear discriminant analysis). The original LS-SVM method means that the original vibration signals measured in experiment are the input of LS-SVM, in which do not extract signals by SSA and PSR. Its algorithm calculates 10 dimensionless time–frequency indexes (described in

Table 1) from the original vibration signals and be used as inputs for training the LS-SVM classifier model. The PCA + LS-SVM method substitute SSA for PCA in Algorithm 3, that is to say, PCA is used to feature extraction. PCA is a popular and powerful blind source separation algorithm. It constructs a low-dimensional representation of the data that describes the variance in the data as much as possible. It is achieved by finding a linear basis of reduced dimensionality for the data, in which the amount of variance in the data is maximal [

37]. To implement the PCA + LS-SVM method, 10 dimensionless time–frequency indexes (described in

Table 1) of each signal are calculated as the input of PCA, and 10 principal components transformed by PCA are selected as the input of LS-SVM. The SSA + LDA method substitute LS-SVM for LDA in Algorithm 3, that is to say, LDA is used as the classifier model. LDA is a linear classifier that uses a generalization of Fisher’s linear discriminant; its aim is to find a linear combination of features that characterizes classes of objects or events [

38].

As shown in

Table 2 and

Table 3, the original LS-SVM, PCA + LS-SVM and SSA + LDA methods are less accurate than the proposed SSA + LS-SVM method. In the original LS-SVM method, the accuracy of the normal, mild wear and severe wear groups with training sets was about 80%, and even low to 65% with testing sets, 22 tools in training sets and 14 tools in testing sets were erroneously categorized. In the PCA + LS-SVM method, the accuracy of the normal, mild wear and severe wear groups with training sets were higher than original LS-SVM method, 20 tools in training sets and twelve tools in testing sets were erroneously categorized. However, with the tool failure gradually becoming serious, its advantage is reduced over original LS-SVM method. In the SSA + LDA method, the accuracy of mild wear group with training sets and testing sets was 65% and 50%, 34 tools in training sets and 23 tools in testing sets were erroneously categorized. The three methods could not discriminate between normal tools and wear tools effectively. The proposed SSA + LS-SVM method in this paper outperformed the original LS-SVM, PCA + LS-SVM and SSA + LDA methods.

6. Conclusions

The present study proposes a damage diagnosis approach to NC machine tools based on SSA and LS-SVM. First, the original data are transformed from one-dimensional data into high-dimensional signals using PSR. The SSA method is applied to extract stationary and non-stationary parts from multi-dimensional signals without the need for independency and without prior information of the source signals. Subsequently, the selected non-stationary components were analyzed for classification using LS-SVM. Ten dimensionless parameters in the time-frequency domain were extracted and used as inputs for LS-SVM. The proposed SSA + LS-SVM method was applied to NC milling machine tools. The results show that the proposed SSA + LS-SVM method outperforms the original LS-SVM, PCA + LS-SVM and SSA + LDA methods. The achieved accuracy of the proposed SSA + LS-SVM method was higher than 80%, whereas that of the original LS-SVM, PCA + LS-SVM and SSA + LDA was as low as 65%, 70% and 50%, respectively. Moreover, the proposed method can significantly distinguish between normal tools and wear tools, which cannot be realized through the other three methods. Furthermore, it is possible to apply the proposed method to other fault diagnosis areas, e.g., electric motors, in which the signals of bars of an induction motor are time varying, and non-stationary [

39,

40].

However, classification accuracy of the proposed SSA + LS-SVM method for mild wear and severe wear with testing sets is just 80% and 85%, respectively. Future work will focus on improvement of this accuracy. The stationary sources extracted by SSA will be utilized in future studies to improve the accuracy in identifying mild wear tools.