1. Introduction

Since a major incident involving contaminated milk in China in 2008, the scale of planting of high-quality forage grass has increased rapidly, in which alfalfa (

Medicago sativa L.) has been the major cultivar [

1]. In 2014, nationally, forage grass was cultivated in more than half a million hectares, of which alfalfa accounted for more than 80%, with the corresponding increasing land use and the need for irrigation globally [

2,

3,

4]. Alfalfa consumes a lot of water during its growing season, usually around 300–2250 mm [

5]. Apart from the limited natural rainfall [

6], high-efficiency irrigation is necessary [

7]. With the evolution of water-lifting devices [

8], the center pivot sprinkler irrigation system (center pivot) has been a popular irrigation method worldwide [

9]. Most of the new planting areas have been irrigated using the center pivot. Center pivots have the advantages of large-scale sprinkling operations, water and energy savings, and the integration of water and fertilizer [

10,

11,

12]. Thus, they have played an important role in modern grass production [

13,

14,

15,

16]. In 2010, the numbers of center pivots increased to 1100 [

17]; there were 15,000 new installations in 2013, covering an irrigation area of nearly 400,000 hm

2 [

18].

According to our field survey in Ar Horqin Banner, Inner Mongolia, China, in a high-quality forage planting base the irrigated area of alfalfa (

Medicago sativa L.) and oats (

Avena sativa L.) has reached 53,000 hectares. There are more than 2000 center pivots. Recently, low pressure spray plates have replaced the previously used medium and high pressure sprinklers [

19]. Two types of low-pressure sprinklers are commonly used with these center pivots: fixed spray plate sprinklers (FSPSs) and rotating spray plate sprinklers (RSPSs) [

20,

21]. The deflection plate of an FSPS is fixed to the sprinkler body, and the streams are sprayed around the sprinkler by deflection by the spray plate. Here, the spray plate was engraved with a jet slot at a certain elevation to increase the radius of the wetted area. The spray plate of an RSPS was rotated under the drive of the streams to spray in the surrounding in a rotational manner. The basic performance parameters of the two types of sprinklers are shown in

Table 1.

As shown in

Table 1, due to the structural differences of RSPSs and FSPSs, they exhibit different characteristics. According to the surveys, it was found that many entrepreneurs do not fully understand the differences in performance between RSPSs and FSPSs. Indeed, in sprinkler selection, more attention was paid to the difference in price between the two sprinklers. Although price is a factor in sprinkler selection for center pivots, the results of sprinkler selection can influence the sprinkling uniformity [

22,

23,

24]. Sprinkling uniformity is important and affects the quality of sprinkling irrigation. Under conditions of low sprinkling uniformity, some irrigated areas will be applied excess water, and the crop yields and qualities will therefore not improve or even become degraded. However, the other area will suffer insufficient irrigation, and this also will cause the deceases of crop yields and qualities, thus leading to low efficiency for irrigation systems [

25]. Center pivots play an important role in the integration of water and fertilizers, so its performance ultimately influences crop productivity and chemical characteristics in the rhizosphere [

26]. Low sprinkling uniformity results in uneven growth of forage grass, reducing the commodity grade, and directly affecting the benefits of forage production [

27,

28,

29]. Furthermore, the center pivot applies water over a fairly extensive area, so the problems of sprinkling uniformity in center pivot must influence the crop production in a wide range.

Previous studies reported the water distribution characteristics of FSPSs [

20,

30] and RSPSs [

21,

31] separately under indoor conditions. Using a translational test device, Playan et al. [

32] measured sprinkling uniformity coefficients of 80% and 90% for RSPSs and FSPSs, respectively. Other researchers obtained sprinkling uniformity coefficients of 80%–90% and 90%–95% for RSPSs and FSPSs [

33], respectively, under conditions of a real center pivot. Ortíz et al. [

34] reported that a higher proportion of small drops was produced with FSPS than with RSPS. Some research studied droplet size distributions in RSPSs [

35,

36] and FSPSs [

20]. However, practical applications need dozens to hundreds of RSPSs or FSPSs to be used on a center pivot, and all of the installed sprinklers need to have nozzles with diameters differing over a wide range. The distances between sprinklers (sprinkler intervals) must vary according to the configurations of center pivot. The differences in performance between RSPSs and FSPSs have not been fully compared under different combinations of nozzle diameters and sprinkler intervals.

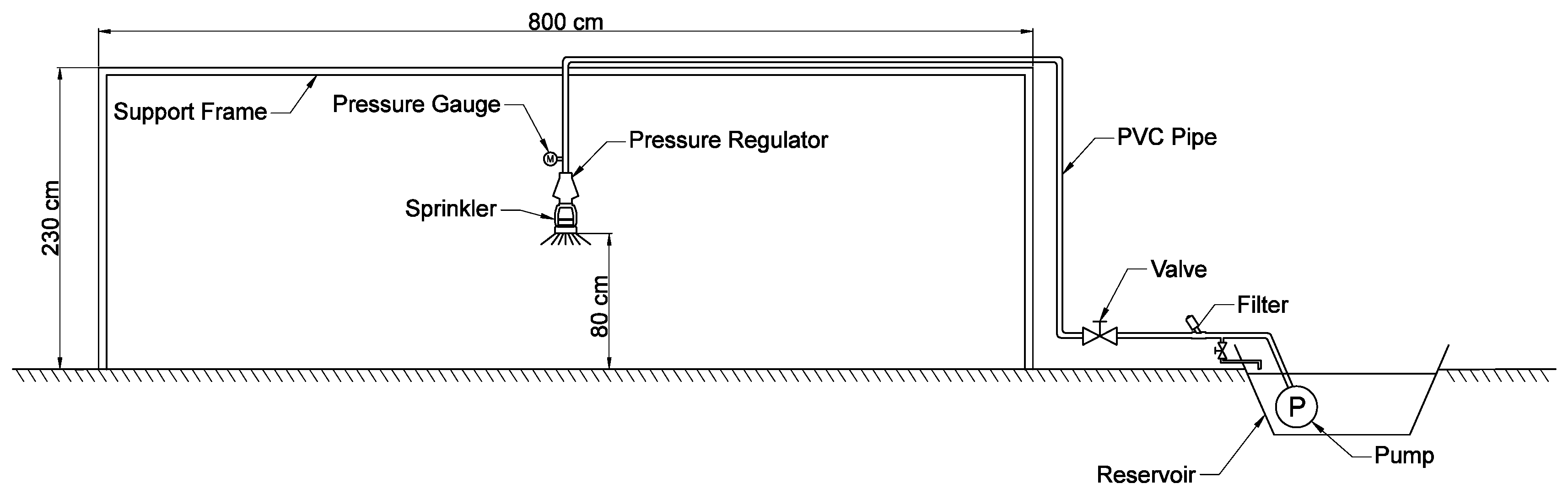

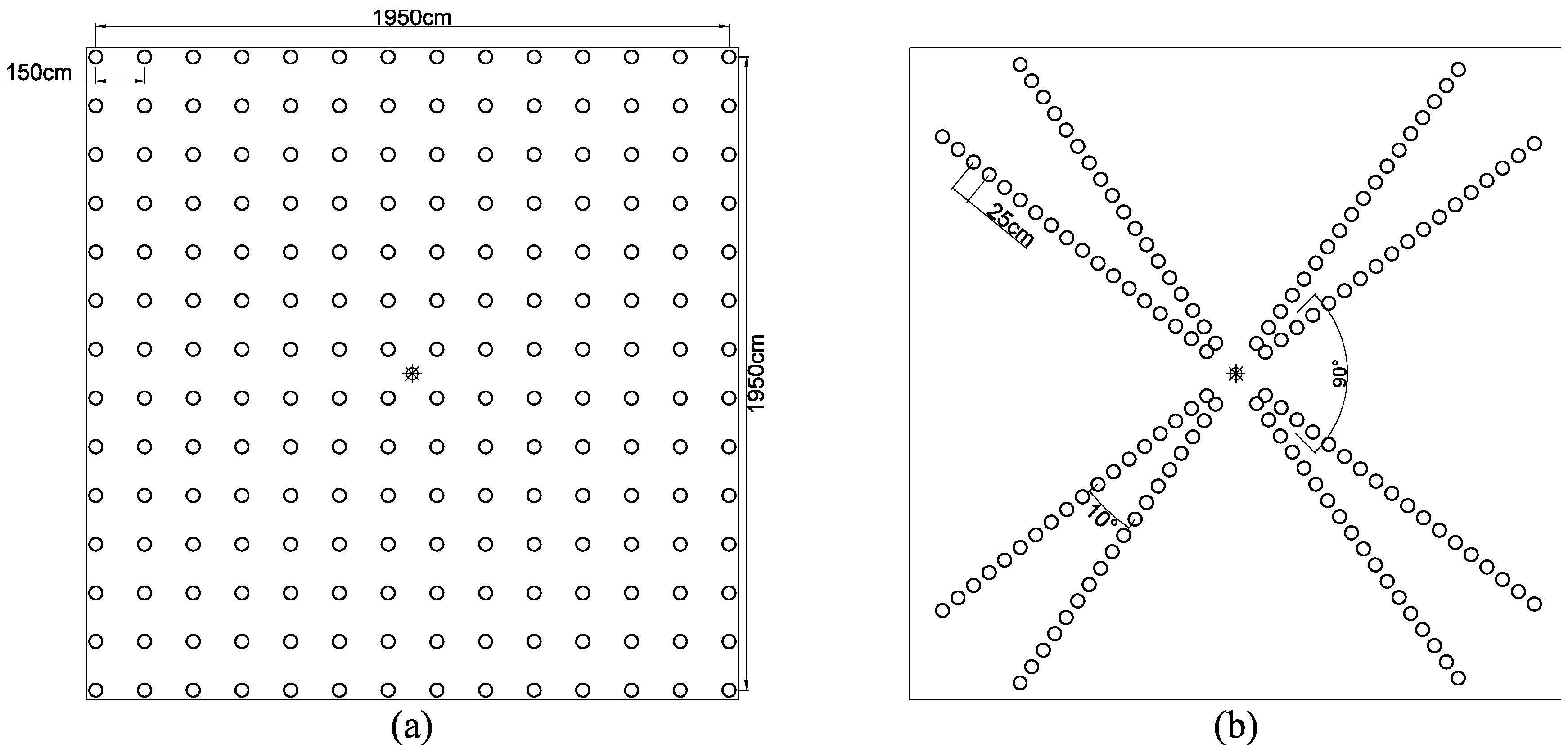

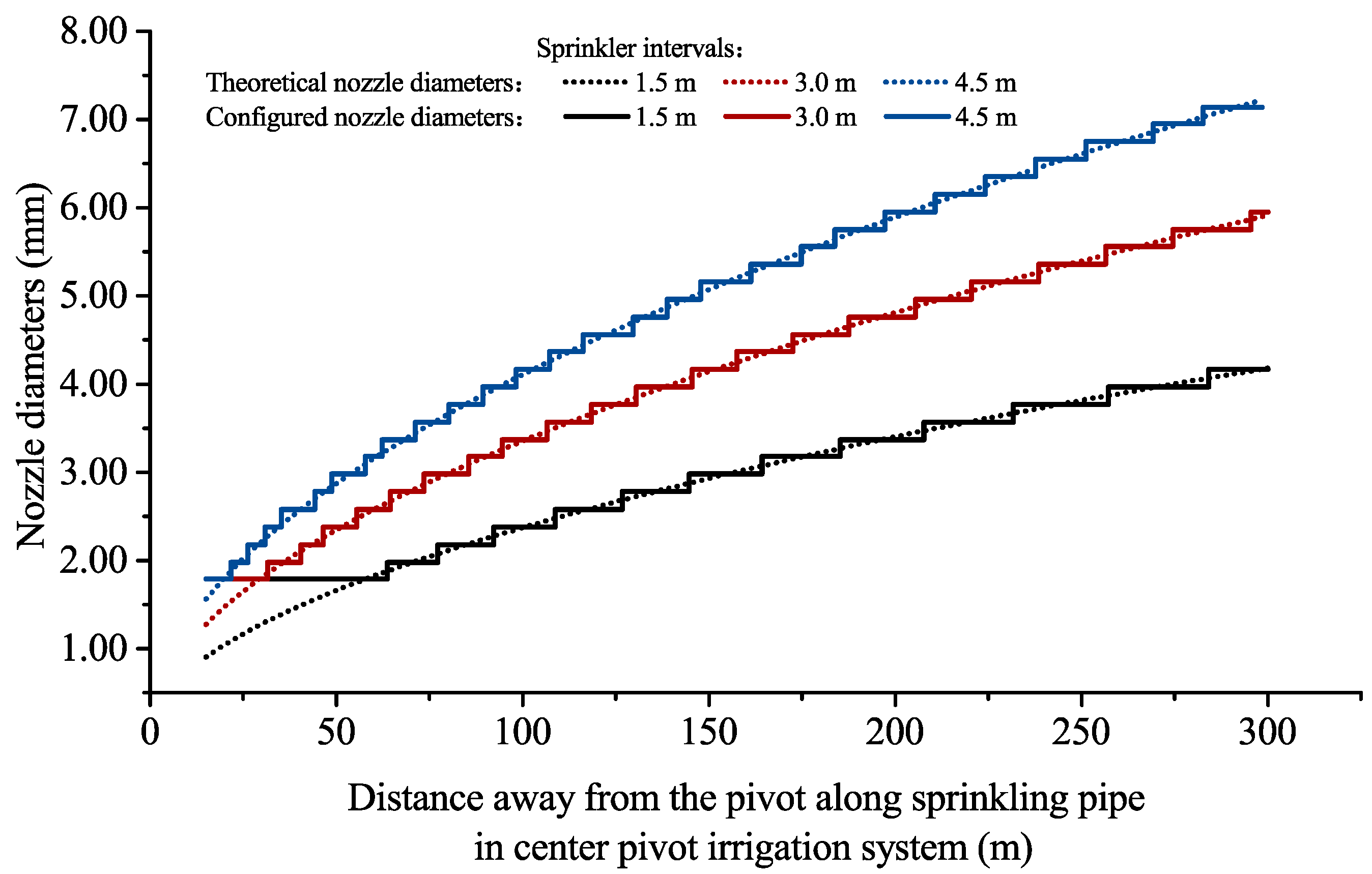

Previous studies tested the application performance of RSPSs and FSPSs, however, those did not study the different performance between them under a wide range of nozzle sizes, different sprinkler intervals and different configurations of the center pivot. These aspects are actual and common situations for center pivot managers, which should to be considered in the cases of evaluating different types of sprinklers. Thus, the present study aims to focus on comparisons of sprinkling performance between RSPSs and FSPSs through a combination of results from field measurements and numerical simulations under conditions with differing nozzle diameters, sprinkler intervals and nozzle configurations in center pivots. The detailed objectives of this study were, under outdoor conditions, (1) to measure and analyze the water distribution characteristics of individual FSPSs and RSPSs with nozzles in different diameters under field conditions, (2) based on the water distribution of individual sprinkler, and following a model for nozzle configuration of a center pivot, to simulate water distributions of pipe sections consisting of multiple RSPSs and multiple FSPSs with differing nozzle diameters and sprinkler intervals, and (3) to simulate the water distribution of the full circular irrigated area of a center pivot using RSPSs and FSPSs at different intervals. These comparative results may provide insights for understanding the different sprinkling performances of RSPSs and FSPSs.

4. Conclusions

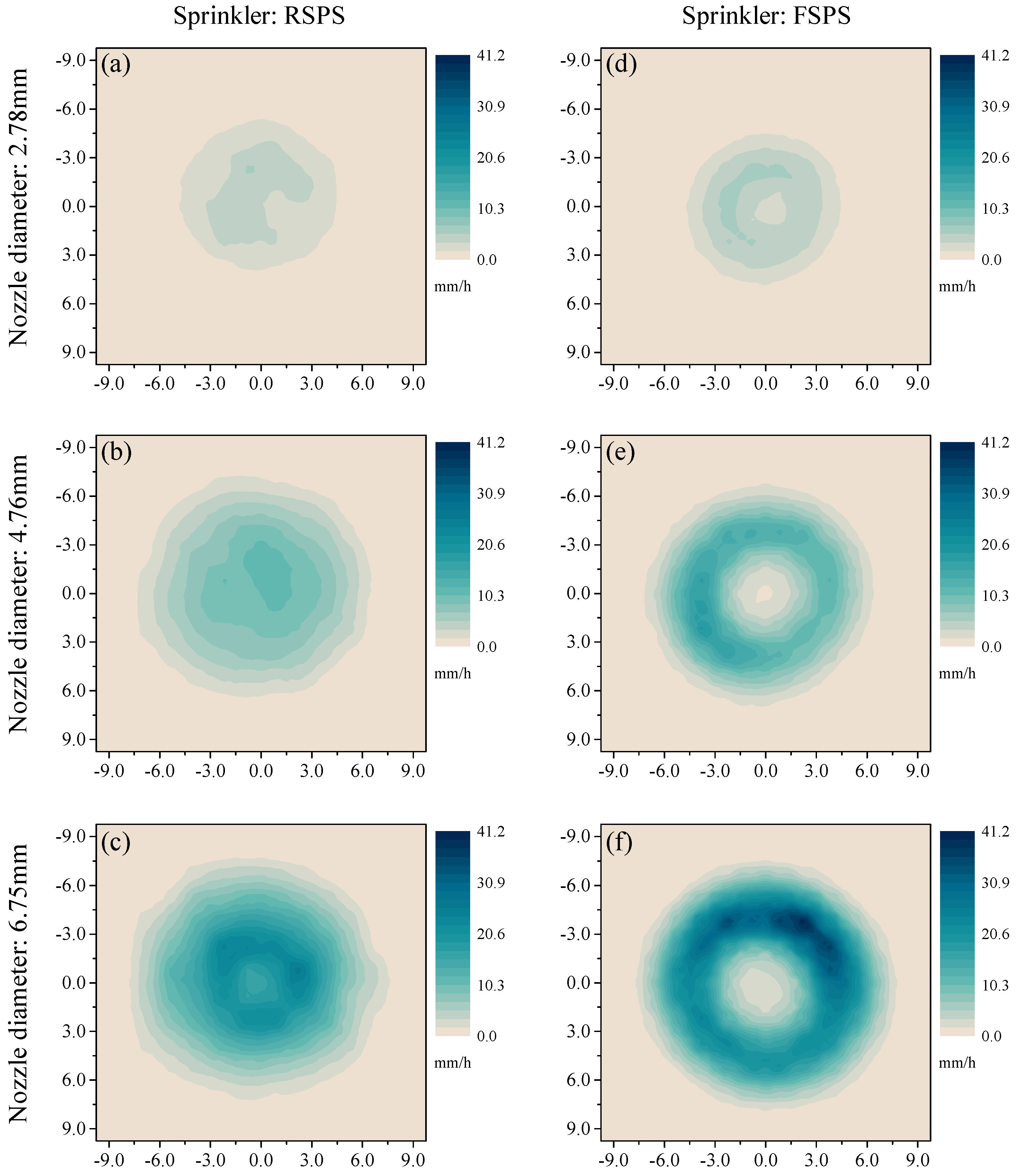

This study focused on the comparisons of sprinkling performance of rotated and fixed spray plate sprinklers (RSPSs and FSPSs) in center pivot irrigation systems (center pivot). The water distribution characteristics of individual sprinkler were observed under field conditions. Then, following the nozzle diameter configuration model, the water distributions of same-nozzle-sprinkler pipe sections (PSs) and full circular irrigated area (FCIA) of the center pivot were simulated to compare the sprinkling performance of RSPSs and FSPSs under different nozzle diameters and sprinkler intervals.

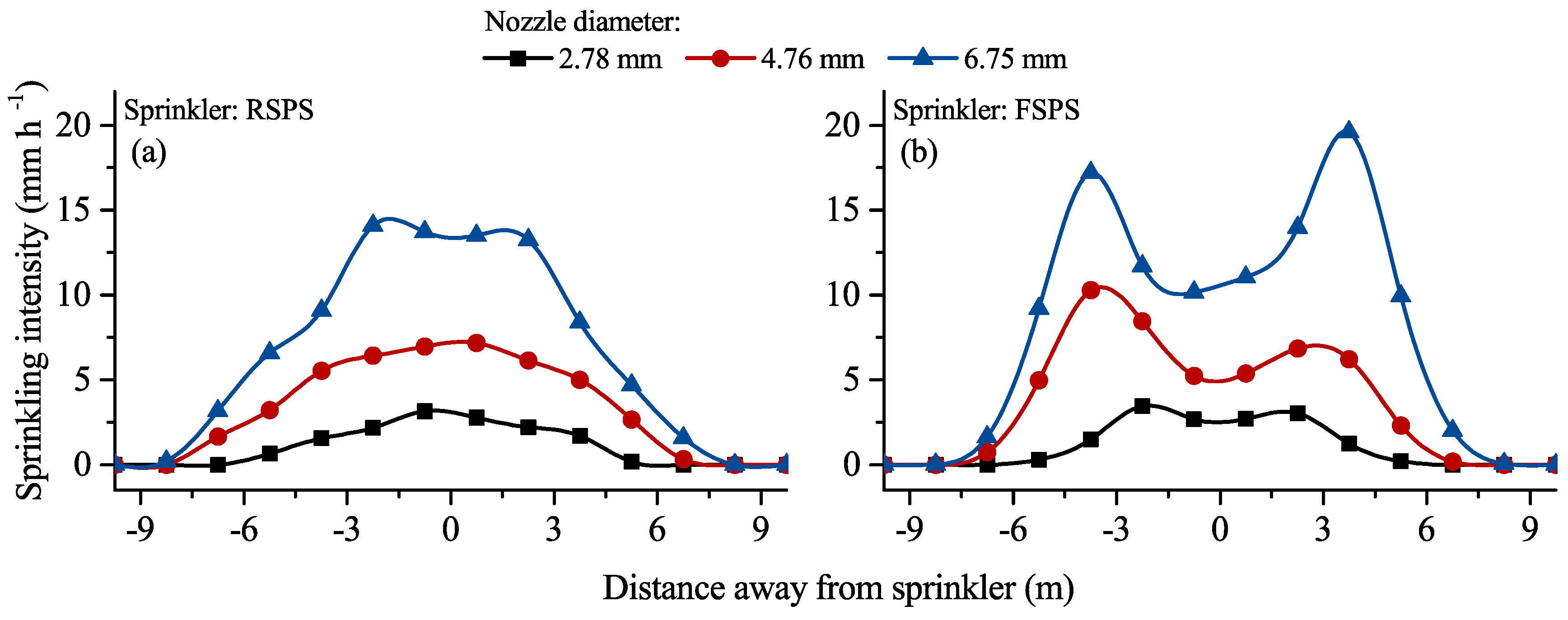

Water distributions between individual RSPSs and FSPSs showed distinct patterns. RSPSs distributed the most water around the sprinkler, whereas FSPSs distributed most water over a ring-shaped region at periphery of the sprinkler. The radial water distribution showed single-peak and double-peak patterns for RSPSs and FSPSs respectively. The effective wetted radiuses of RSPSs and FSPSs were 4.88–7.05 m and 5.02–6.85 m with 2.78, 4.76 and 6.75 mm diameter nozzles being installed, respectively.

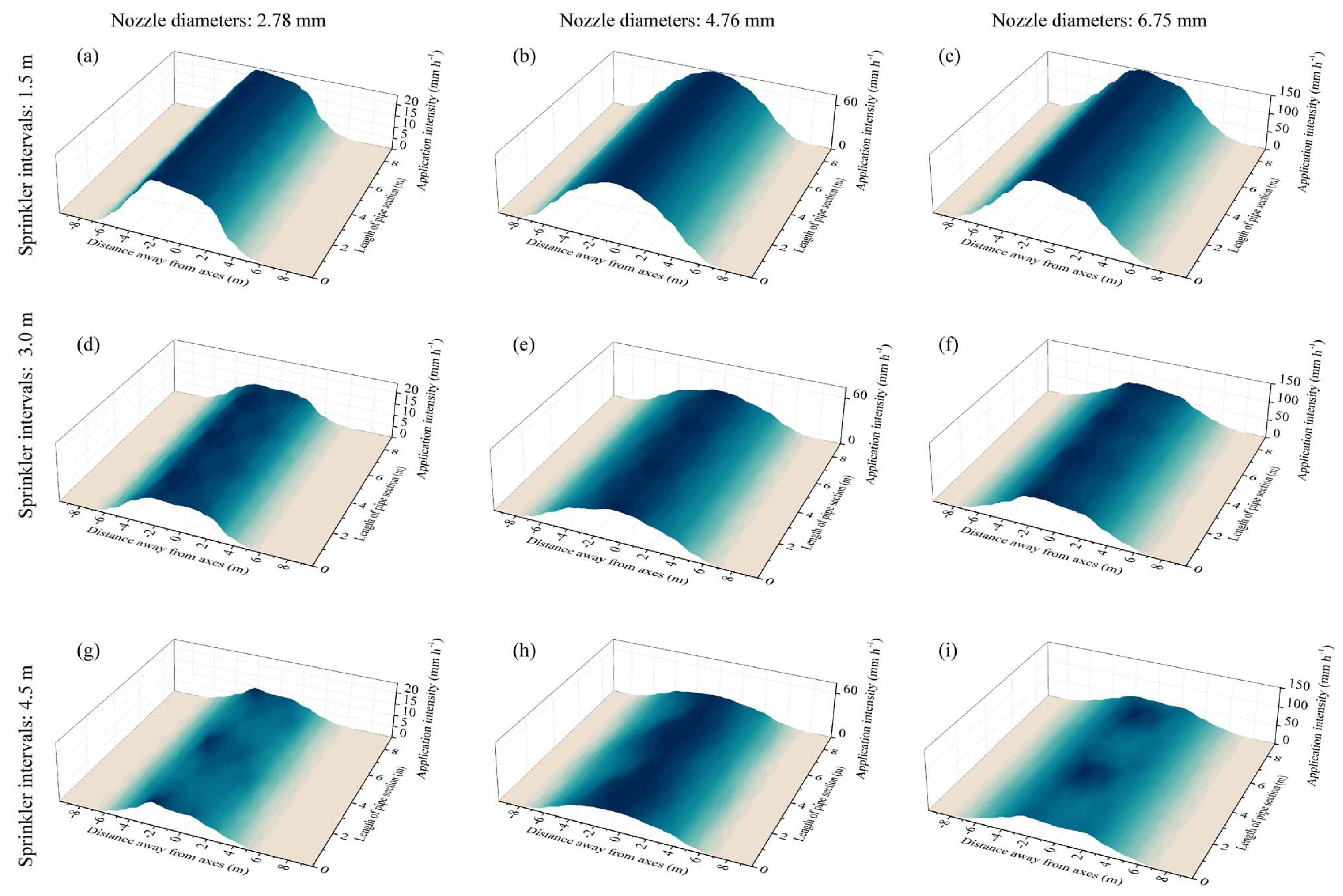

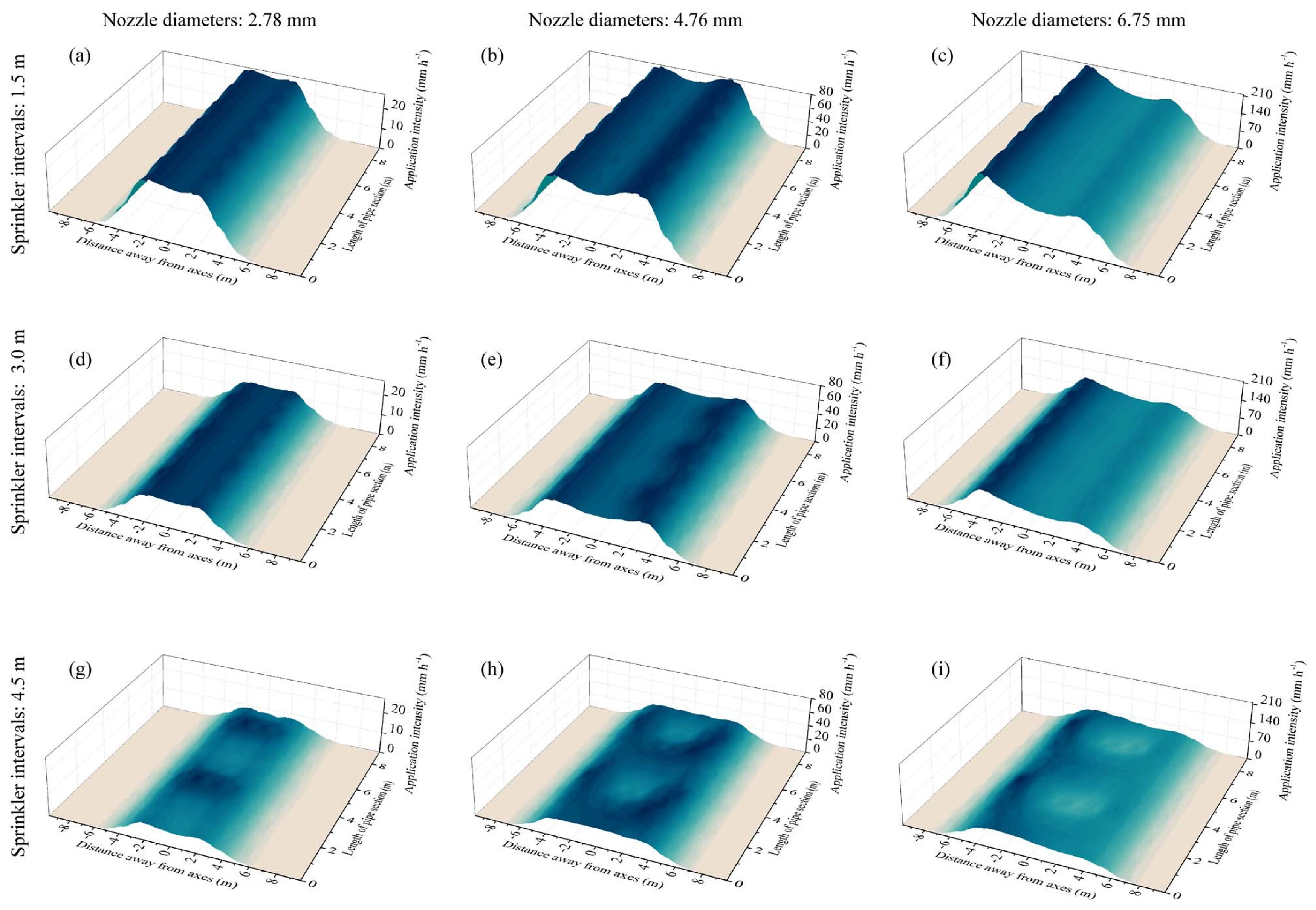

RSPS PS distributed most water around their central axes, and the applied water volumes reduced gradually with the increasing distance from the axes. FSPS PSs distributed the most water over both sides of their axes symmetrically, and lower volumes were distributed around the axes. When the sprinkler intervals increased to 4.5 m, the continuities of water distribution along the axes of the PSs decreased. The CUCs of RSPS PSs and FSPS PSs were 44.7%–51.0% and 40.3%–58.0% respectively under different nozzle diameters (2.78, 4.76 and 6.75 mm) and sprinkler intervals (1.5, 3.0 and 4.5 m).

CUCs of RSPS FCIA were 85.8%, 89.3% and 91.7% under sprinkler intervals of 1.5, 3.0 and 4.5 m, respectively, and CUCs of FSPS FCIAs were 85.8%, 86.2% and 85.8% under sprinkler intervals of 1.5, 3.0 and 4.5 m, respectively. The CUCs of RSPS FCIAs were 3.1% and 6.2% higher than that of FSPS FCIAs when the sprinkler intervals were 3.0 and 4.5 m, respectively. In the center pivot, RSPSs could accommodate larger sprinkler intervals in comparison to FSPS, but also maintained a superior sprinkling performance.

Moreover, works should be conducted to explore the different crop yield, crop quality, soil moisture dynamics and soil moisture distributions between using RSPS and FSPS, under conditions of real commercial center pivots. It might be worthwhile to analyze and compare the cost effectiveness by different types.