Damage Index Calibration of Frame-Supported Concealed Multi-Ribbed Wall Panels with Energy-Efficient Blocks

Abstract

:1. Introduction

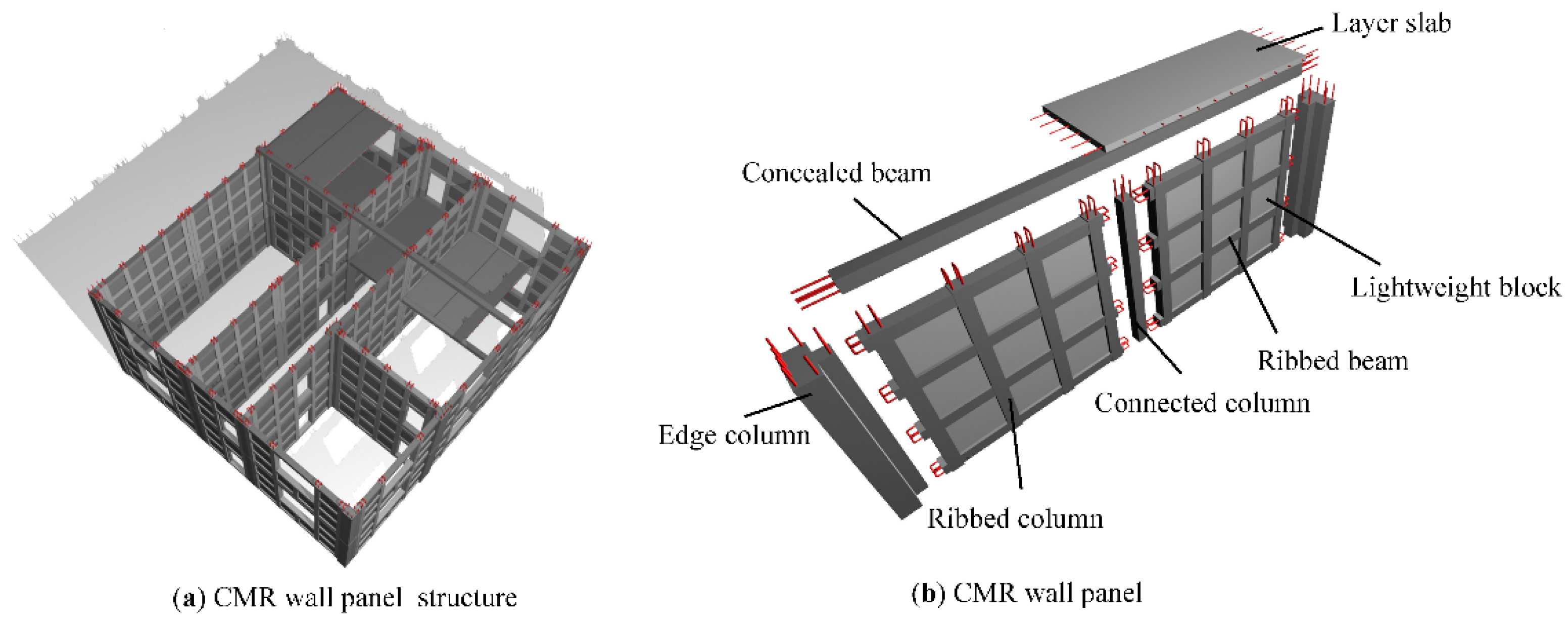

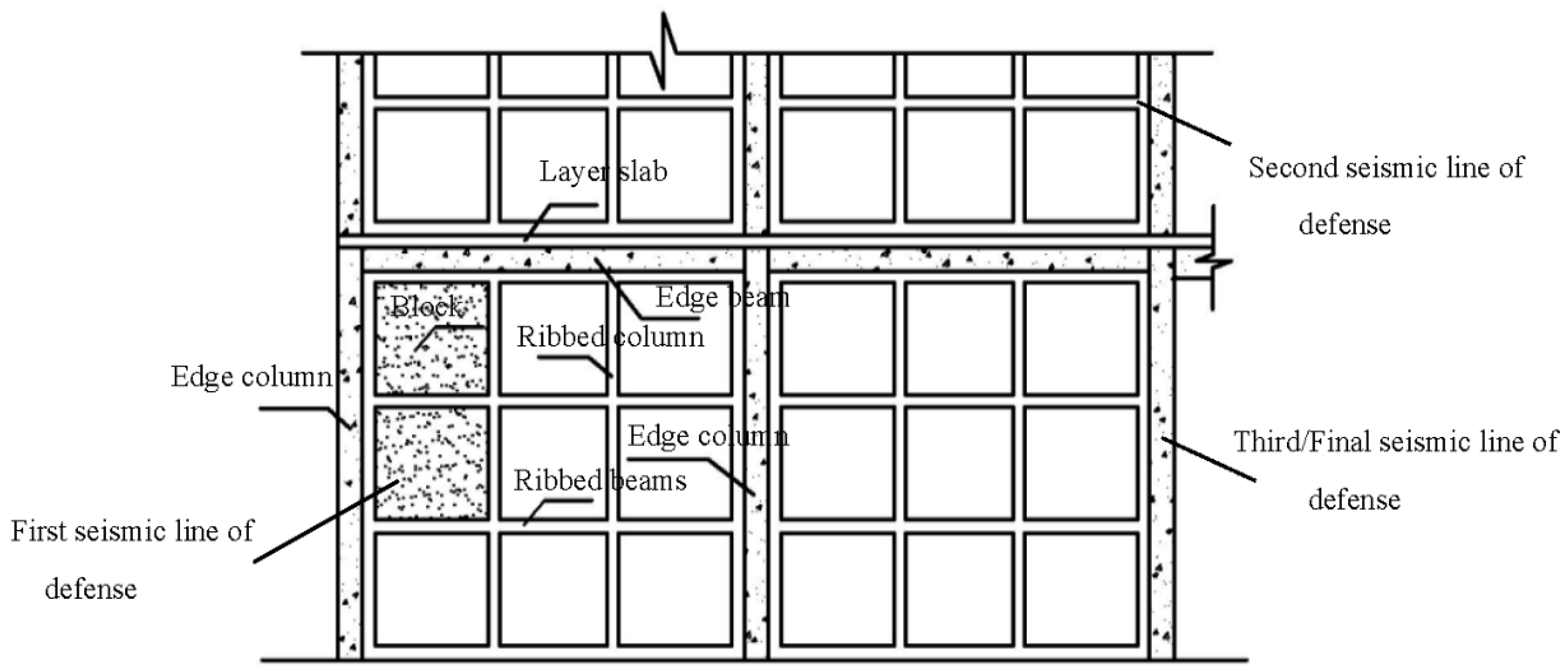

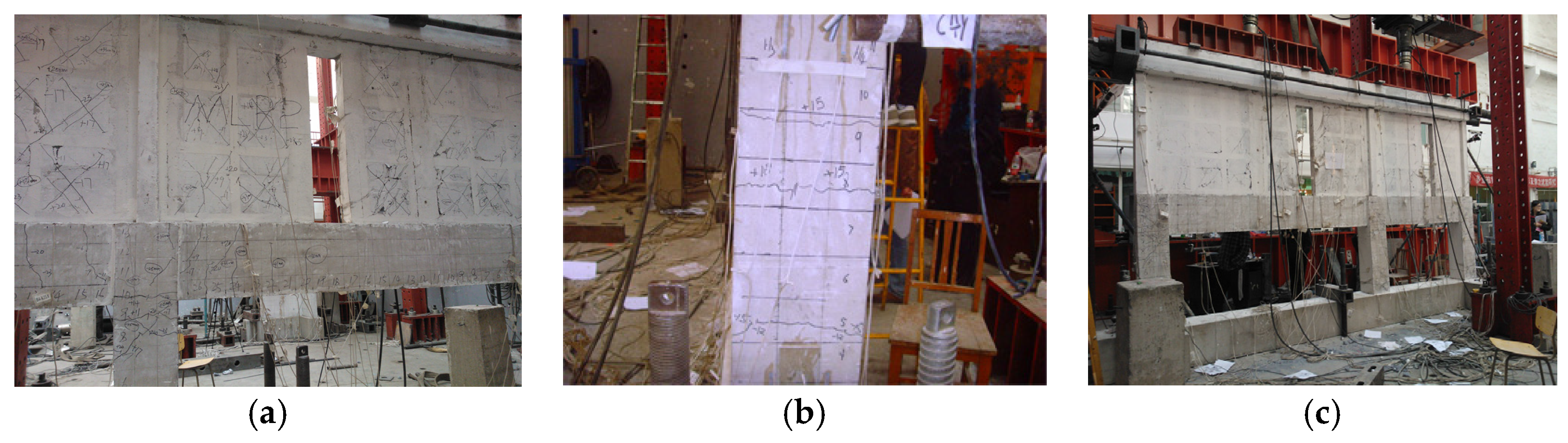

2. FSCMR Wall Panel Structure

2.1. CMR Wall Panel Structure

- (1)

- Outstanding structural integrity and working performance;

- (2)

- Exceptional force-bearing performance;

- (3)

- Easy adjustment of structural stiffness;

- (4)

- Multiple seismic lines of defence;

- (5)

- Effective seismic buffer;

- (6)

- Promising prospects for industrialization;

- (7)

- Strong performance in collapse resistance;

- (8)

- A practical, cost-efficient, energy-saving and environmental friendly choice.

2.2. Functions of CMR Wall Panel Structure with Energy-Efficient Blocks and Its Manufacture and Assembly

2.3. FSCMR Wall Panel Structure

3. Damage Evaluation Model for FSCMR Wall Panel Structure

- (1)

- the interrelation between maximum deformation and accumulative hysteretic energy is not considered; and

- (2)

- the contribution of maximum deformation and accumulative hysteretic energy to damage follows a linear pattern.

- Step 1:

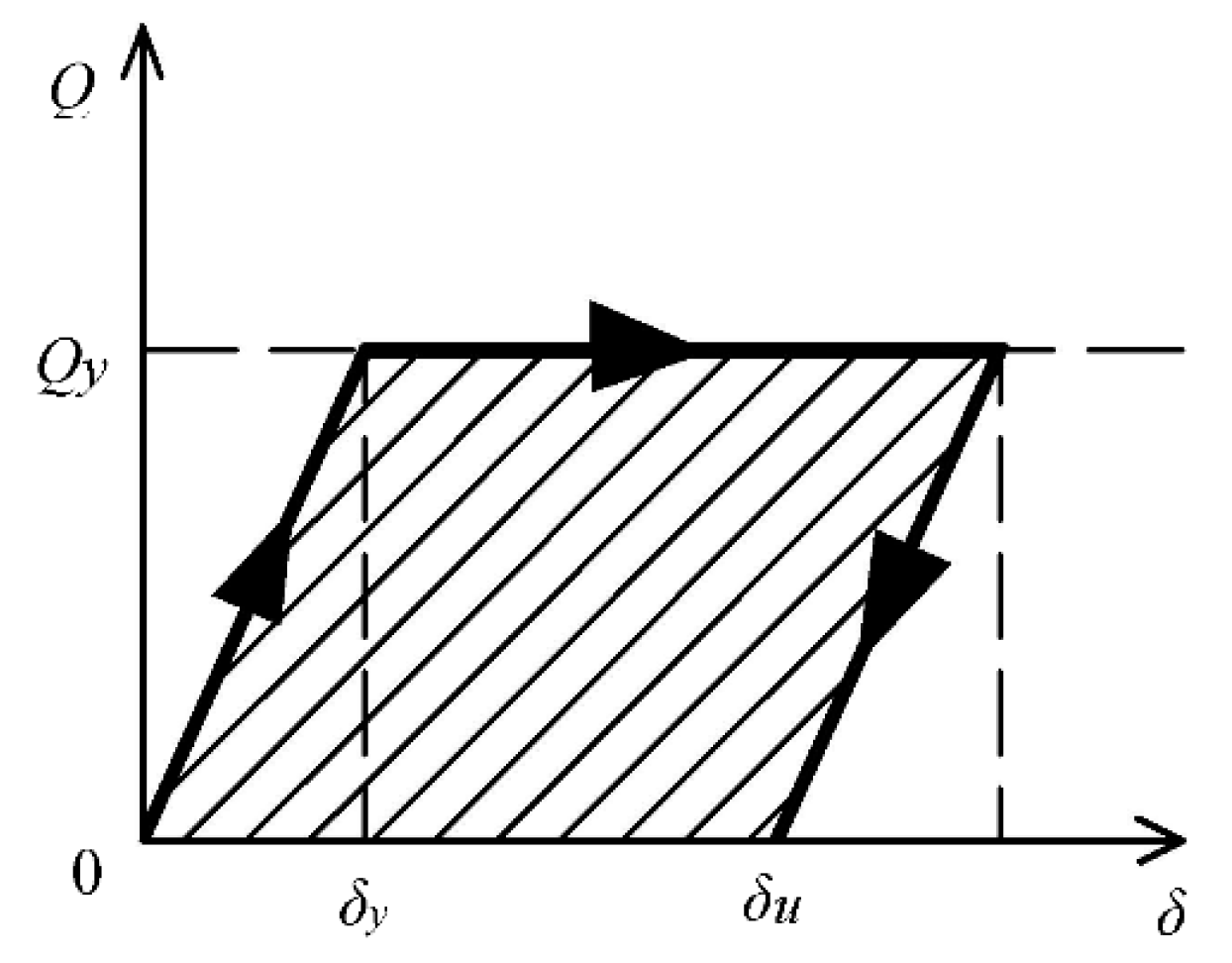

- The modification is conducted under the assumption that the linear superposition of maximum deformation and accumulative hysteretic energy of the Park–Ang model remains unchanged. Under such conditions, the product of the yield strength and the displacement limit in the denominator is replaced by the plastic energy consumption under monotone loading, which has proven to be more physically realistic.

- Qy (δu − δy) is the energy consumption at the limits of the ideal elastic-plastic system under monotone loading;

- Qy is the structural strength at the yielding point;

- δy, δu, δm are the yielding deformation, deformation limit, and maximum deformation;

- ∫dE is the accumulative hysteretic energy of the structure (to the point under calculation);

- β is the weight coefficient of the accumulative hysteretic energy item.

- Step 2:

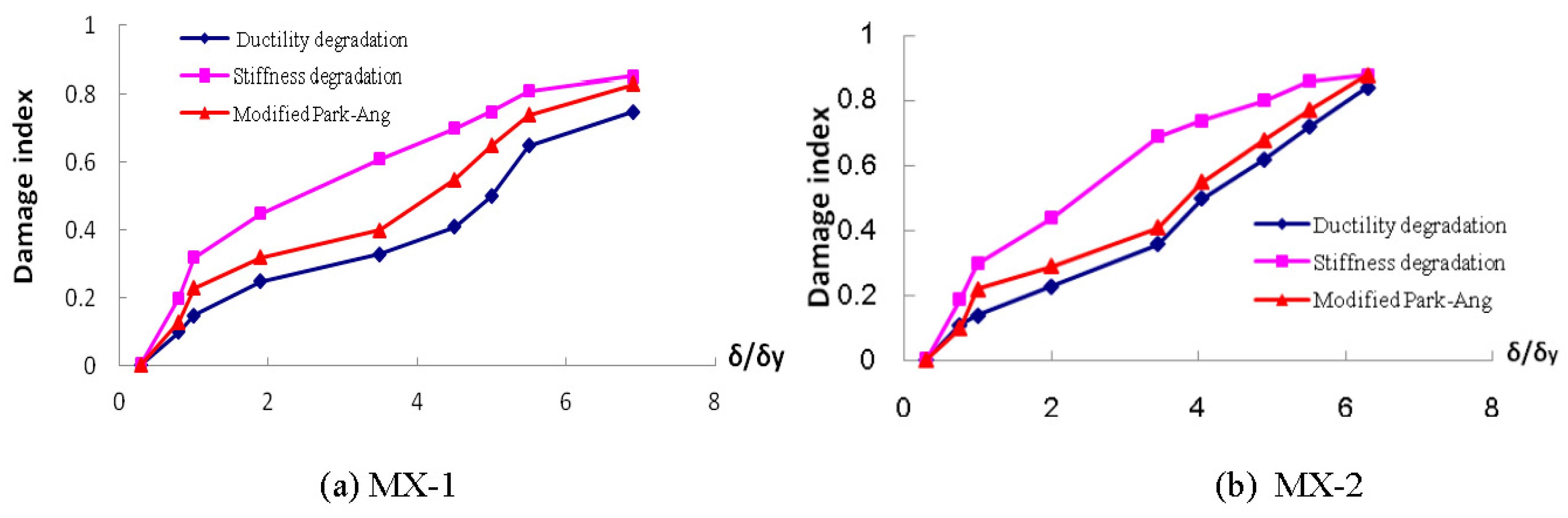

Damage model of ductility degradation

Damage model of stiffness degradation

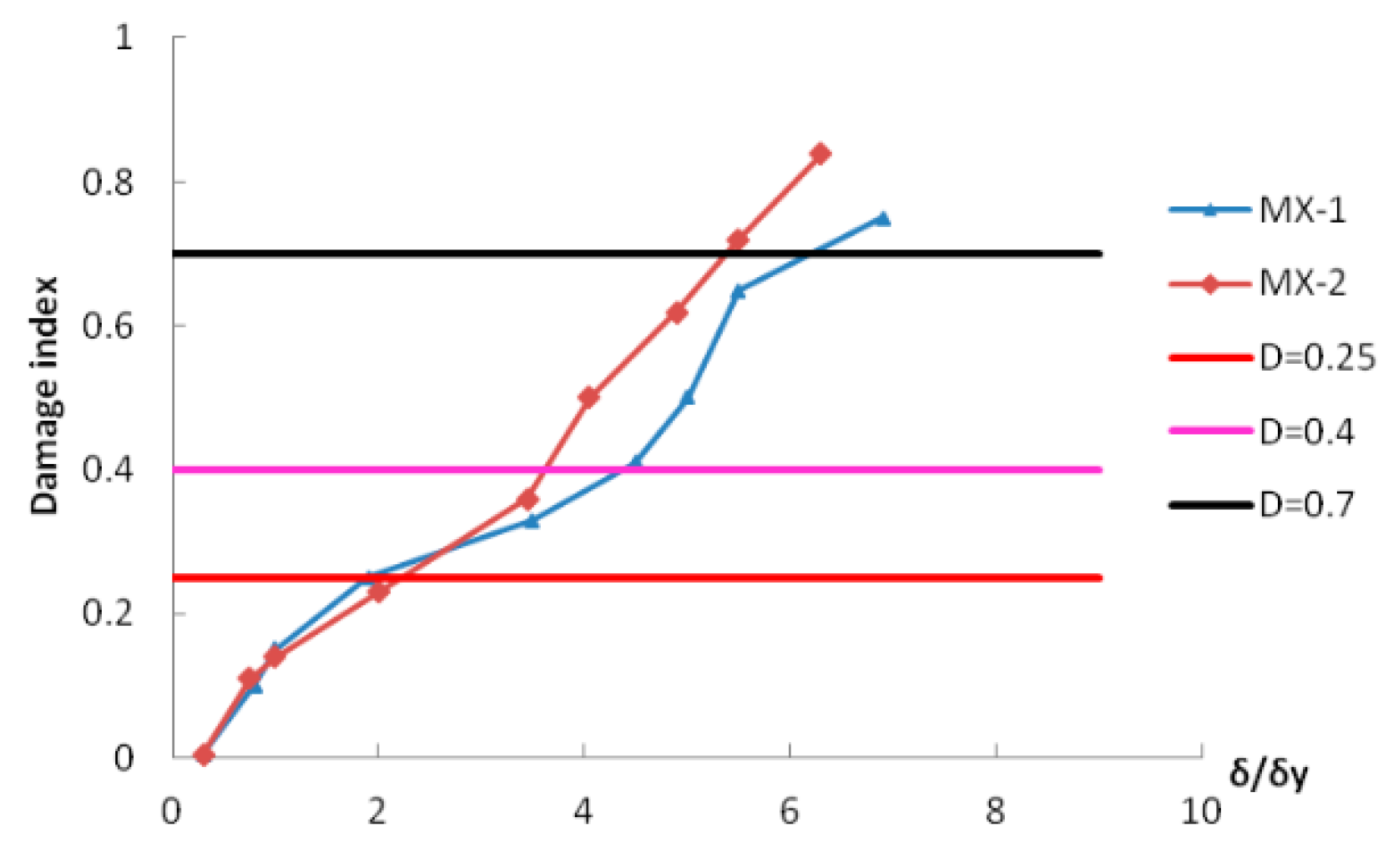

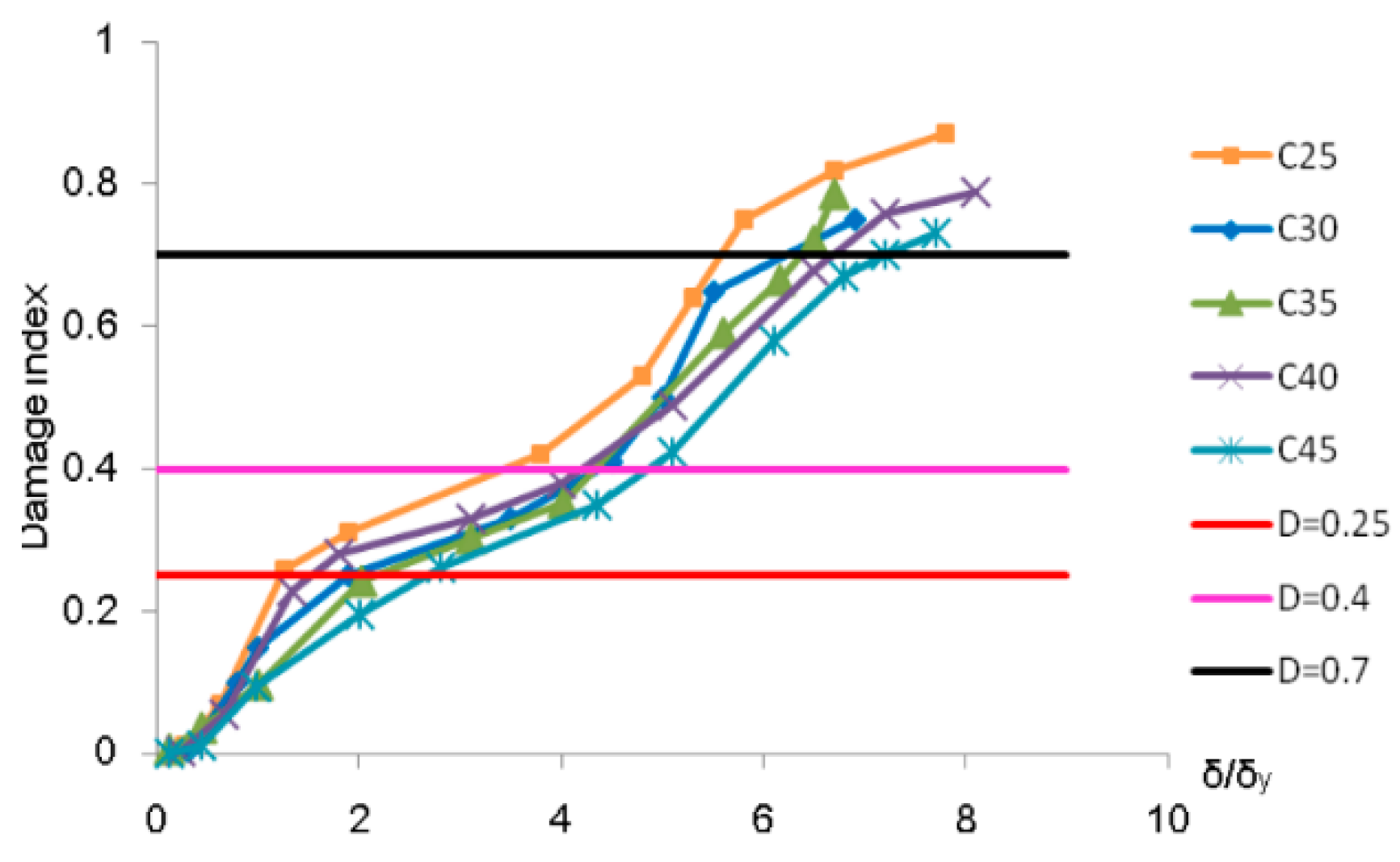

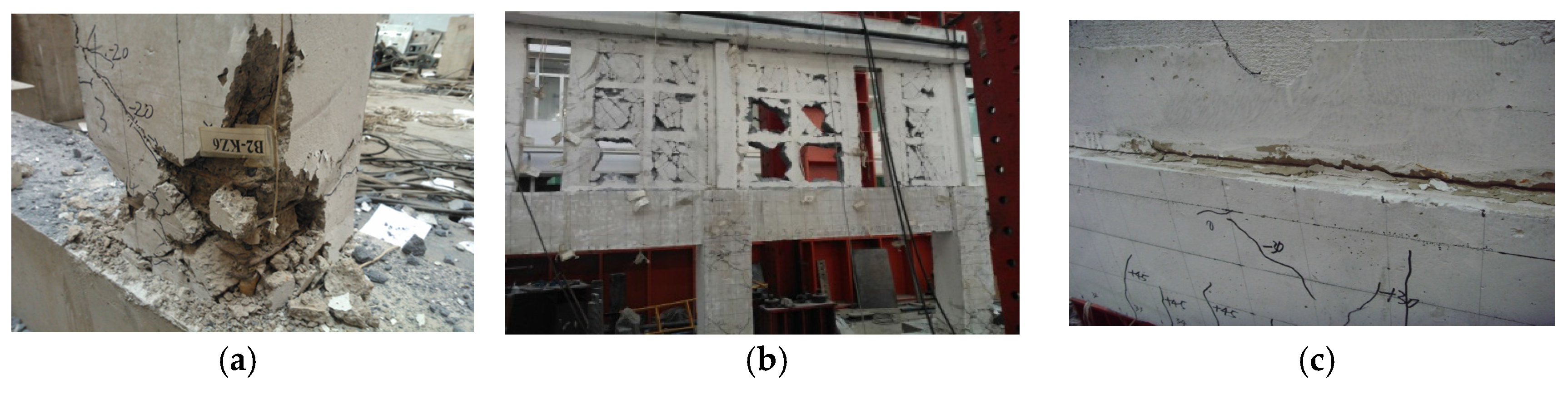

Preliminary development stage (where D = 0–0.25)

Mid-term development stage (where D = 0.25–0.4)

Rapid development Stage (where D = 0.4–0.7)

Failure stage (where D > 0.7)

4. Restoration Approach for FSCMR Wall Panel Structure Using the Damage Index

- (1)

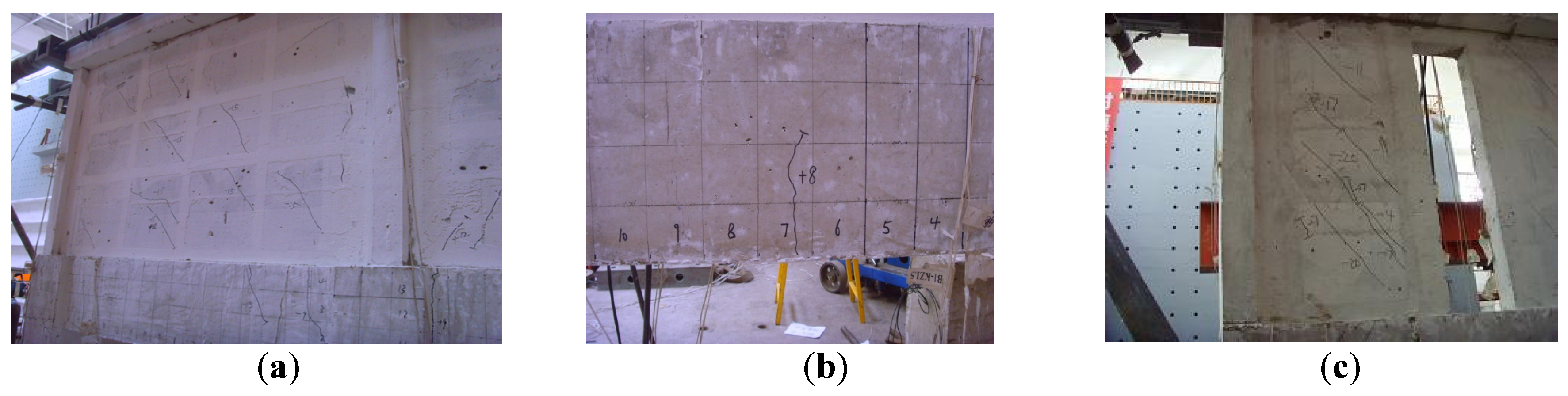

- For Di values below 0.25, where the structure has not yet yielded, the cracks that occur are barely noticeable. Therefore, the structure as a whole does not require substantial functional or exterior restoration to ensure its normal operation.

- (2)

- As Di increases from 0.25 to 0.4, the structure yields. Cracks increase in large quantities, blocks peel off and further exfoliate, and the reinforced steel begins to yield. Structural function can only be guaranteed by necessary restoration. In this study, it is suggested that block replacement can mitigate deterioration in bearing capacity. In the case of visible beam/column cracks, a reinforcement approach for reinforced concrete structures shall be applied.

- (3)

- As Di increases into the range from 0.4 to 0.7, the structure has reached the peak of the failure process, where structural deterioration proceeds but slows down. As block exfoliation continues, the cracking and deformation of beams and columns worsens. However, the structure remains restorable, and the approach applied in stage (2) remains effective.

- (4)

- As Di exceeds 0.7, the structure is gravely damaged. Large-scale exfoliation and sliding at the layer interface mean that the structure, though it has yet to collapse, is no longer serviceable. Technically, the structure can be repaired, but the restoration process is hardly economical.

- (1)

- The replacement does not generally add to the dead weight or seismic response of the wall panel structure, thereby avoiding problems associated with foundation processing.

- (2)

- The restoration requires no support of the beams or to the floor slab, streamlining the operation process and easing construction procedures.

- (3)

- The material applied can be aerated concrete block, fly-ash block, clay bricks, hollow bricks, etc. Given the accessibility and the applicability of the materials, restoration stands out for its cost efficiency.

- (4)

- Flexibility in the replacement location means that the restoration does not alter the spatial arrangement, which is identical to that existing prior to replacement.

5. Conclusions

- (1)

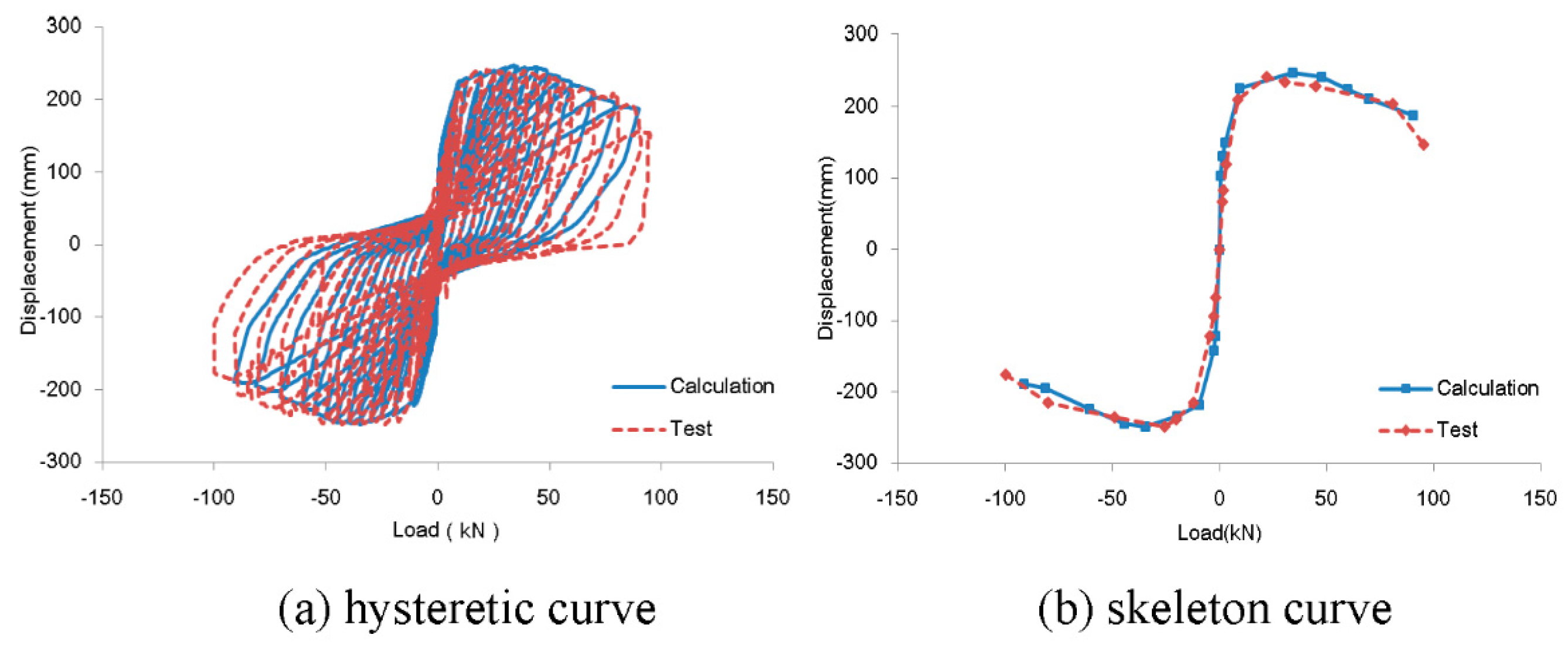

- The double-parameter Park–Ang damage model was modified by introducing the displacement factor α into the deformation items, and by considering energy items in the ratio of accumulative hysteretic energy to plastic energy consumption under monotonic loading. Considering different damage evaluation models, the paper calculates damage index curves at each stage of force impulsion. A close comparison helps identify the preferable model for the damage analysis of an FSCMR wall panel structure (namely, the modified double-parameter Park–Ang damage model).

- (2)

- The paper determines the numerical range for the damage index at each stage of accumulative damage, with primary development, mid-term development, rapid development, and failure stages occurring at Di < 0.25, 0.25 < Di < 0.4, 0.4 < Di < 0.7, and D > 0.7, respectively. It must be noted that the experiments conducted contribute to the detailed stage-by-stage description of damage development.

- (3)

- Accordingly, recommendations are made for structure restoration. For Di values below 0.25, no restoration is required. As Di increases into the range from 0.25 to 0.7, it is essential that the structure be enhanced with either block replacements or beam/column reinforcement repairs. As Di increases above 0.7, the structure is beyond repair. We hope that the suggestions provided in this paper will contribute to an improvement of seismic resistance in structures in the future.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, B.X.; Xie, H.P.; Deng, J.H.; He, C.R.; Wang, Z. Characteristic analysis of performance and damage of buildings in Wenchuan Earthquake and considerations in aseismic design of buildings. J. Disaster Prev. Mitig. Eng. 2009, 29, 224–230. (In Chinese) [Google Scholar]

- Bai, J.M.; Mary-Beth, D.H.; Gardoni, P. Probabilistic assessment of structural damage due to earthquake for buildings in mid-America. J. Struct. Eng. 2009, 135, 1155–1163. [Google Scholar] [CrossRef]

- Ghorbanie-Asl, M. Performance-Based Seismic Design of Building Structures. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2007. [Google Scholar]

- Zhao, B.; Fabio, T.; Tiziana, R. Field investigation on the performance of building structures during the 12 May 2008 Wenchuan earthquake in China. Eng. Struct. 2009, 31, 1707–1732. [Google Scholar] [CrossRef]

- Liang, X.W.; Li, B.; Li, X.W. Lateral load-carrying capacity of continuous masonry wall supported on RC frame. Adv. Struct. Eng. 2009, 10, 305–317. [Google Scholar] [CrossRef]

- Ahmad, R. Lateral stiffness of concrete shear walls for tall buildings. AIC Struct. J. 2011, 108, 755–765. [Google Scholar]

- Abbas, M. Damage-based design earthquake loads for single-degree-of-freedom inelastic structure. J. Struct. Eng. 2011, 137, 456–467. [Google Scholar]

- Liu, P.; Yao, Q.F. Dynamic reliability analysis of multi-ribbed composite wall based on damage accumulation. J. Vib. Shock 2008, 27, 42–46. (In Chinese) [Google Scholar]

- Xiong, Y.Q.; Yao, Q.F.; Xia, L. Study on damage and energy-dissipation of the fundamental element of multi-ribbed composite wall. J. Shenyang Jianzhu Univ. 2010, 27, 859–865. (In Chinese) [Google Scholar]

- Jia, S.Z.; Yuan, Q. Deteriorating hysteretic parameters and energy dissipation performance of multi-ribbed composite wall structures. J. Huazhong Univ. Sci. Technol. 2013, 41, 32–35. (In Chinese) [Google Scholar]

- GB50011-2010. In Code for Seismic Design of Building; China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- GB50010-2010. In Code for Concrete Structure Design; China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- JGJ/T275-2013. In Directive Rules for Muti-Ribbed Wall Structure; China Architecture & Building Press: Beijing, China, 2014. (In Chinese)

- Jia, S.Z.; Cao, W.L.; Yuan, Q. An experimental study of frame-supported multi-ribbed composite walls. Adv. Struct. Eng. 2015, 18, 497–511. [Google Scholar] [CrossRef]

- Jia, S.Z.; Cao, W.L.; Yuan, Q.; Zhang, Y.C. Experimental study on frame-supported multi-ribbed composite walls under low-reversed cyclic loading. Eur. J. Environ. Civ. Eng. 2015, 6, 1–18. [Google Scholar]

- Liu, P.; Yao, Q.F. Dynamic reliability of structures: The example of multi-ribbed composite walls. Struct. Eng. Mech. 2010, 36, 463–479. [Google Scholar] [CrossRef]

- Jia, S.Z.; Cao, W.L.; Zhang, Y.C.; Yuan, Q. Analysis on stiffness ratio at interim layer of frame-supported multi-ribbed lightweight slab. Appl. Sci. 2016, 1. [Google Scholar] [CrossRef]

- Park, Y.; Ang, A.H.; Wen, Y.K. Seismic damage analysis of reinforced concrete buildings. J. Struct. Eng. 1985, 111, 740–757. [Google Scholar] [CrossRef]

- Vamvatsikos, D.; Fragiadakis, M. Incremental dynamic analysis for estimating seismic performance sensitivity and uncertainty. Earthq. Eng. Struct. Dyn. 2010, 39, 141–163. [Google Scholar] [CrossRef]

- Tubaldi, E.; Barbato, M.; Dall′Asta, A. Influence of model parameter uncertainty on seismic transverse response and vulnerability of steel–concrete composite bridges with dual Load path. J. Struct. Eng. 2012, 138, 363–374. [Google Scholar] [CrossRef]

- Yuan, Q.; He, Y.Y. Earthquake Simulation Test on the Multi-Ribbed Composite Wall Supported on Frame; Science Paper Online: Beijing, China, 2014; pp. 1–9. (In Chinese) [Google Scholar]

- Tanaka, H. Effect of Lateral Confining Reinforcement on the Ductile Behavior of Reinforced Concrete Columns. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 1990; pp. 153–164. [Google Scholar]

- Mo, Y.; Wang, S.J. Seismic behavior of RC columns with various tie configurations. J. Struct. Eng. 2000, 126, 1122–1130. [Google Scholar] [CrossRef]

- Roberto, V. Methods to assess the seismic collapse capacity of building structures: State of the art. J. Struct. Eng. 2007, 133, 57–66. [Google Scholar]

- Dimitrios, G.L.; Tsuyoshi, H.; Yuichi, M.; Masayoshi, N. Collapse assessment of steel moment frames based on e-defense full-scale shake table collapse tests. J. Struct. Eng. 2013, 139, 120–132. [Google Scholar]

- Jia, S.Z.; Liu, Y.; Cao, W.L.; Zhou, Z.Y.; Zhang, Y.C. Tests and analysis of the compressive performance of an integrated masonry structure of a Brick-stem-insulating layer. Appl. Sci. 2016, 6, 146. [Google Scholar] [CrossRef]

- Piluso, V.; Montuori, R.; Troisi, M. Innovative structural details in MR-frames for free from damage structures. Mech. Res. Commun. 2014, 58, 146–156. [Google Scholar] [CrossRef]

| Scale | Component | Dimensions (mm) | Strength Grade of Concrete | Longitudinal Reinforced Steel | Stirrup |

|---|---|---|---|---|---|

| 1/2 | Mudsill | 380 × 400 | C40 | 8Ф20 | Φ6@50 |

| FS Column | 300 × 300 | C30 | 6Ф14 | Φ6@50 | |

| FS Beam | 200 × 400 | C30 | 2Ф14 | Φ6@50 | |

| 2Φ10 | |||||

| 2Ф14 | |||||

| Edge Column | 200 × 200 (100) | C30 | 10Φ6 | Φ6@100 | |

| Connected Column | 200 × 200 (100) | C30 | 12Φ6 | Φ6@100 | |

| Structural Column | 100 × 100 | C30 | 4Φ6 | Φ6@100 | |

| Ribbed Beam, Ribbed Column | 100 × 50 | C30 | 4Φ6 | Φ6@100 | |

| Head Beam | 350 × 300 | C30 | 6Ф20 | Φ6@100 |

| Structure Conditions | Fairly Good | Slightly Damaged | Moderately Damaged | Severely Damaged and Collapsed |

|---|---|---|---|---|

| Park | 0~0.1 | 0.1~0.25 | 0.25~0.4 | 0.4~1 |

| Hindi | 0~0.1 | 0.1~0.2 | 0.2~0.6 | 0.6~1 |

| Ghobarah | 0~0.15 | 0.15~0.3 | 0.3~1 | |

| HU Yuxian | 0~0.15 | 0.2~0.4 | 0.4~1 | |

| NIU Ditao | 0~0.2 | 0.2~0.4 | 0.4~0.65 | 0.65~1 |

| Liu Boquan | 0~0.1 | 0.1~0.3 | 0.3~0.6 | 0.6~1 |

| Wang Guangyuan | 0~0.2 | 0.2~0.4 | 0.4~0.6 | 0.6~1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, S.; Cao, W.; Zhang, Y. Damage Index Calibration of Frame-Supported Concealed Multi-Ribbed Wall Panels with Energy-Efficient Blocks. Appl. Sci. 2017, 7, 453. https://doi.org/10.3390/app7050453

Jia S, Cao W, Zhang Y. Damage Index Calibration of Frame-Supported Concealed Multi-Ribbed Wall Panels with Energy-Efficient Blocks. Applied Sciences. 2017; 7(5):453. https://doi.org/10.3390/app7050453

Chicago/Turabian StyleJia, Suizi, Wanlin Cao, and Yuchen Zhang. 2017. "Damage Index Calibration of Frame-Supported Concealed Multi-Ribbed Wall Panels with Energy-Efficient Blocks" Applied Sciences 7, no. 5: 453. https://doi.org/10.3390/app7050453