Failure Response of Simultaneously Pre-Stressed and Laser Irradiated Aluminum Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

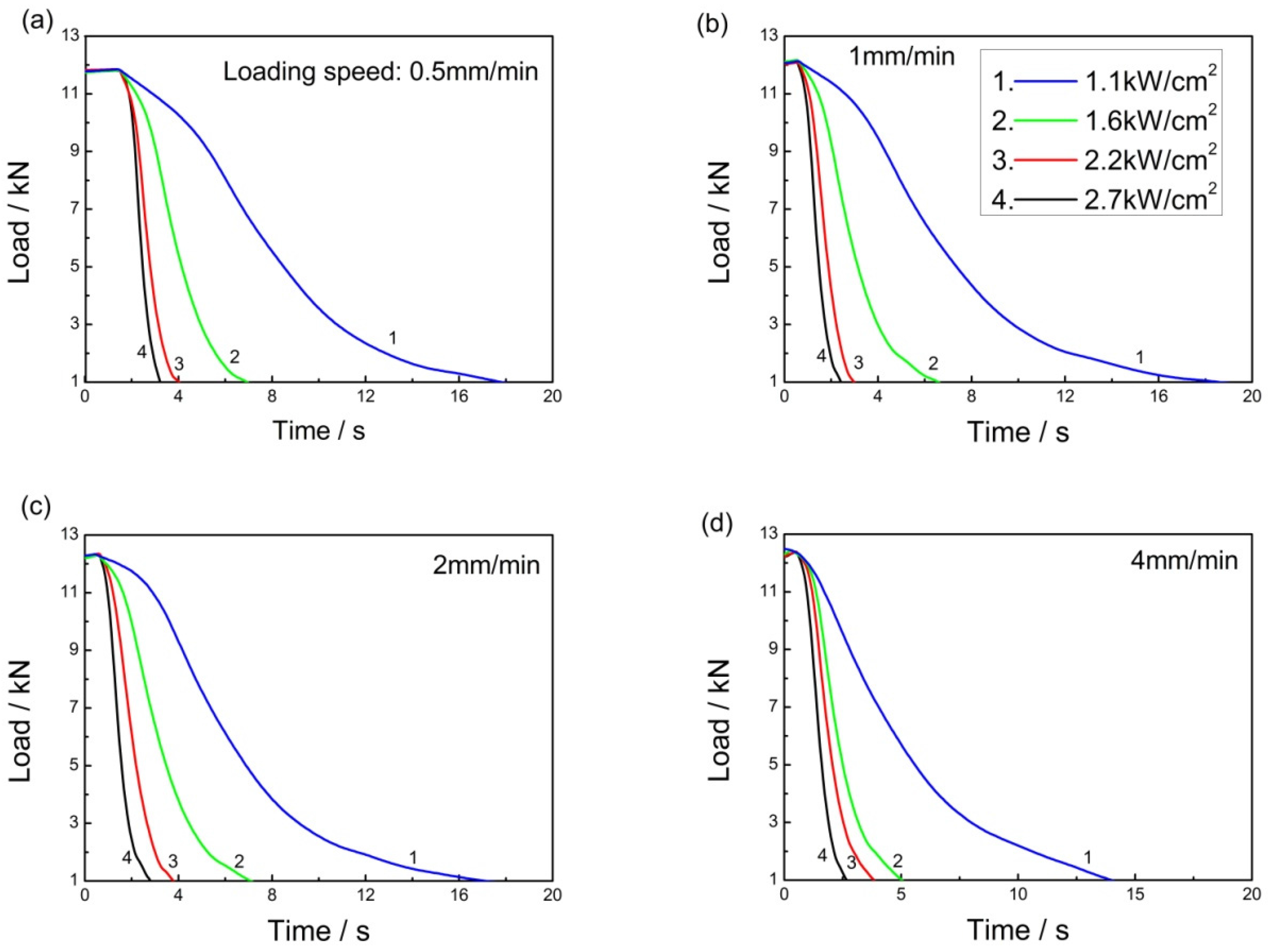

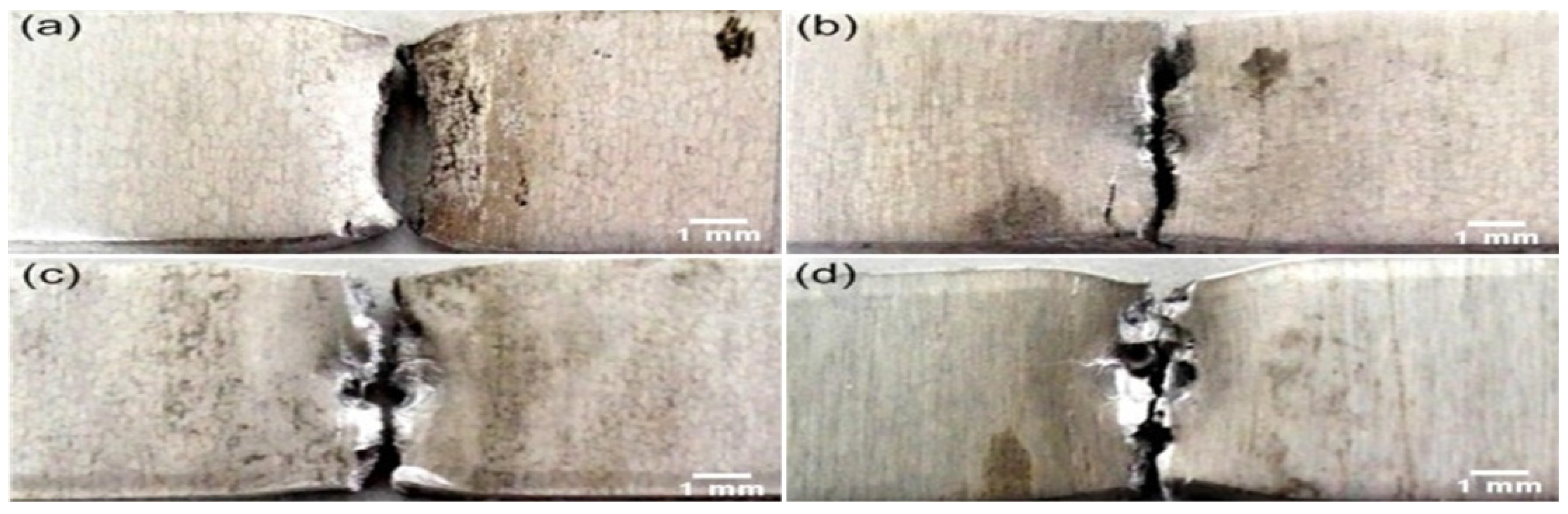

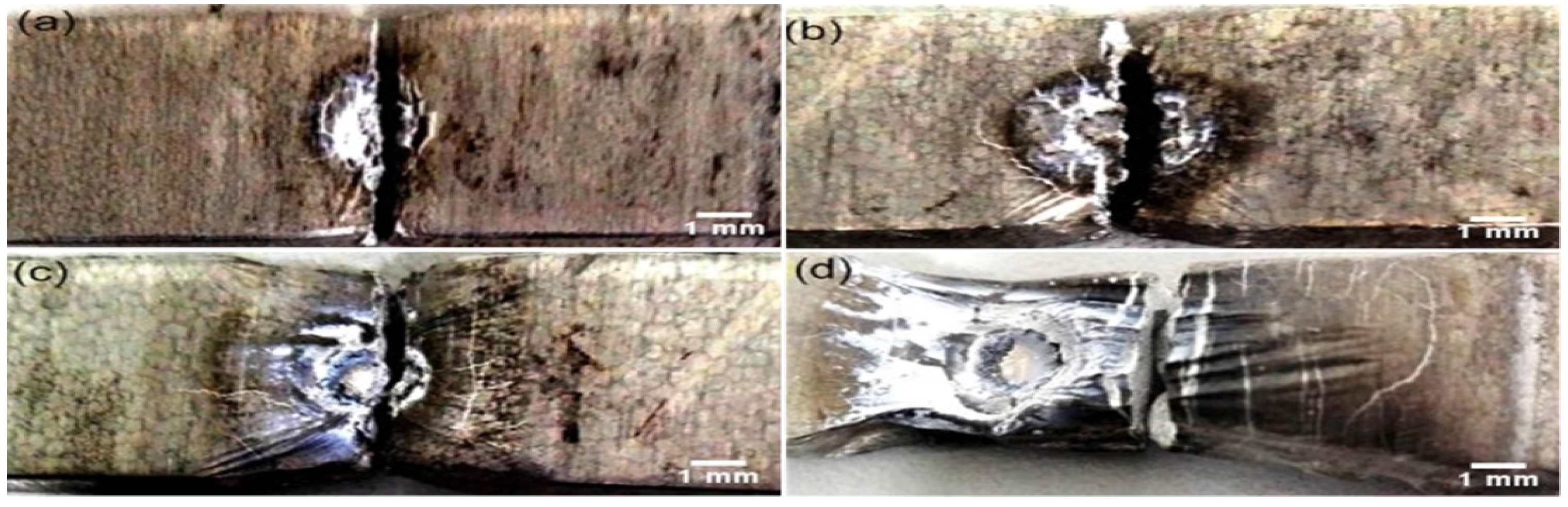

3.1. Failure Behavior

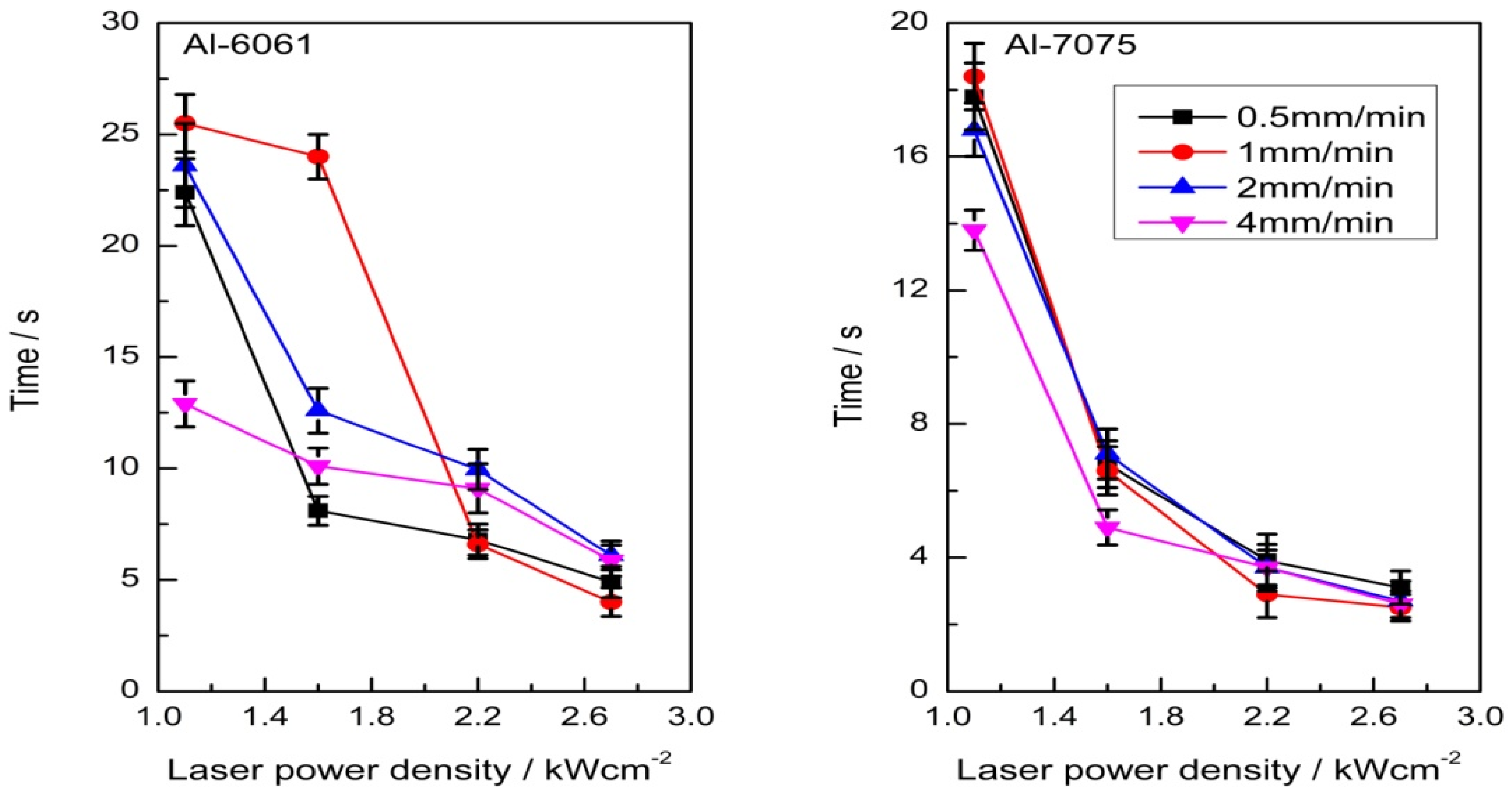

3.2. Failure Time

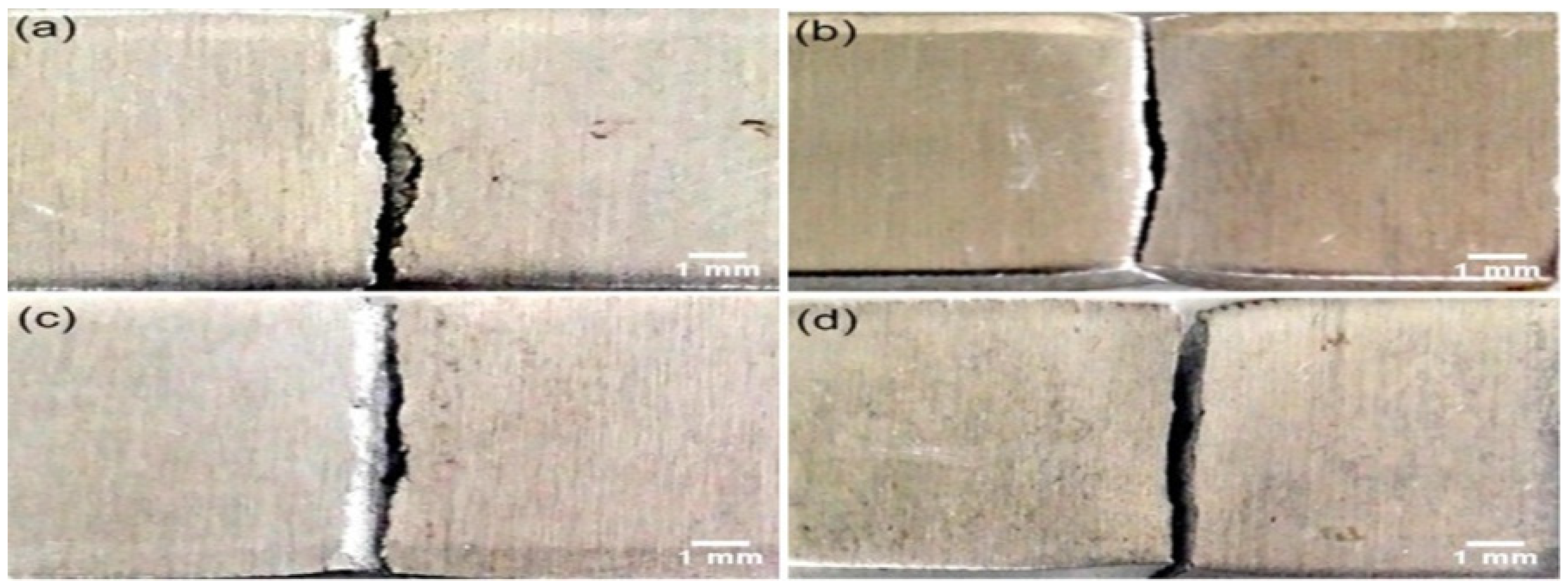

3.3. Rupture Morphology

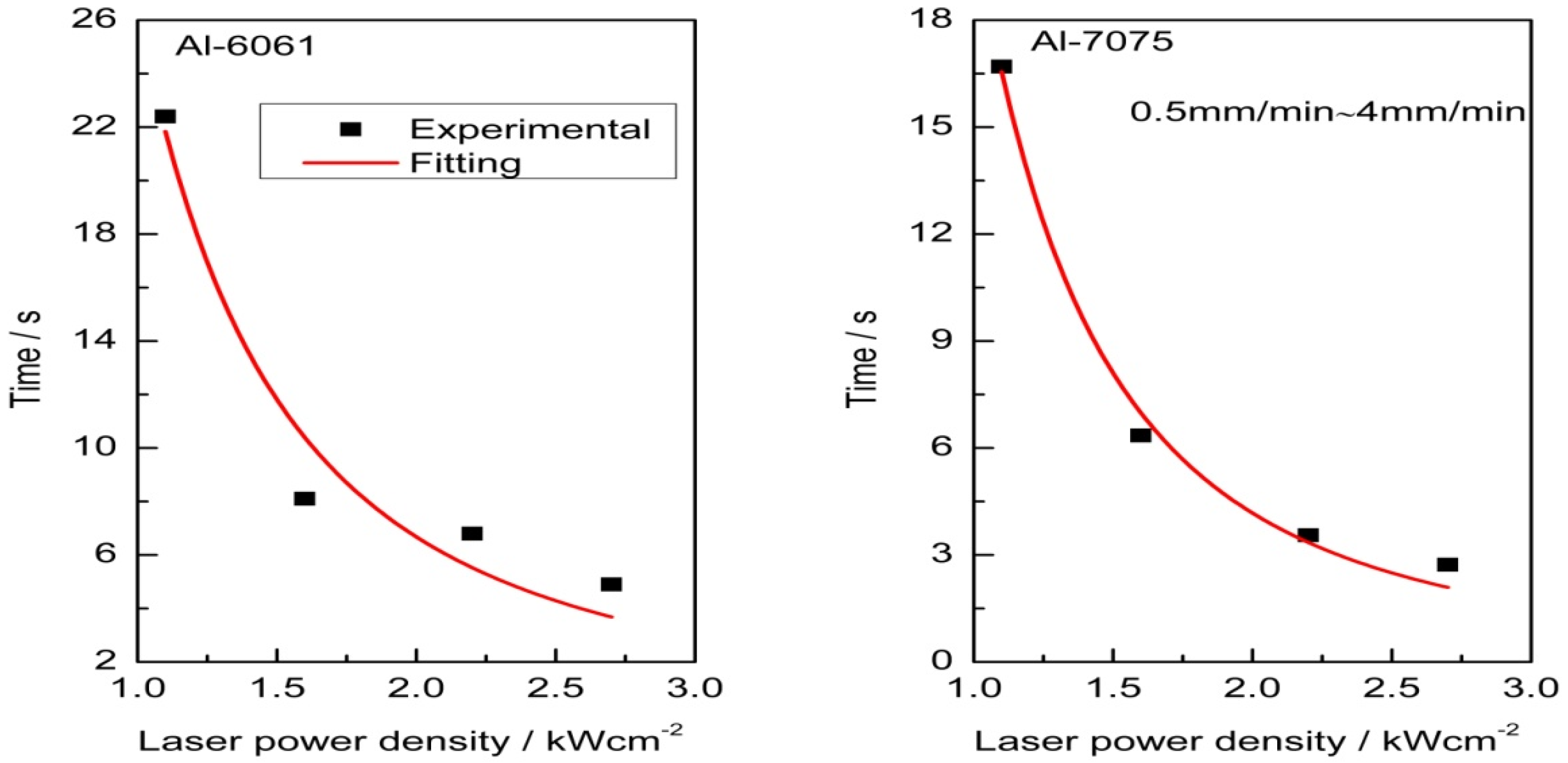

4. Further Investigations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nichols, J.W.; Mall, S. The fracture behavior of thin 6061 t-6 aluminum at rapid heating rates. Eng. Fract. Mech. 1989, 32, 787–794. [Google Scholar] [CrossRef]

- Griffis, C.; Chang, C.; Stonesifer, F. Thermo-mechanical response of tension panels under intense rapid heating. Theor. Appl. Fract. Mech. 1985, 3, 41–48. [Google Scholar] [CrossRef]

- Semb, E. Behavior of Aluminum at Elevated Strain Rates and Temperatures. Master’s thesis, Institutt for konstruksjonsteknikk, Trondheim, Norway, 2013. [Google Scholar]

- Legner, H.; Popper, L.; Laughlin, W.; Pugh, E. Analysis of rp laser experiments on tensile-loaded materials. In Proceedings of the 24th Plasma Dynamics and Lasers Conference, Orlando, FL, USA, 6–9 July 1993; AIAA: Reston, VA, USA, 1993; p. 3203. [Google Scholar]

- El-Magd, E.; Abouridouane, M. Characterization, modelling and simulation of deformation and fracture behaviour of the light-weight wrought alloys under high strain rate loading. Int. J. Impact Eng. 2006, 32, 741–758. [Google Scholar] [CrossRef]

- Lee, W.S.; Sue, W.C.; Lin, C.F.; Wu, C.J. The strain rate and temperature dependence of the dynamic impact properties of 7075 aluminum alloy. J. Mat. Proc. Technol. 2000, 100, 116–122. [Google Scholar] [CrossRef]

- Chen, J.; Young, B. Stress–strain curves for stainless steel at elevated temperatures. Eng. Struct. 2006, 28, 229–239. [Google Scholar] [CrossRef]

- Maljaars, J.; Soetens, F.; Katgerman, L. Constitutive model for aluminum alloys exposed to fire conditions. Metallur. Mat. Trans. A 2008, 39, 778–789. [Google Scholar] [CrossRef]

- Seidt, J.; Gilat, A. Plastic deformation of 2024-t351 aluminum plate over a wide range of loading conditions. Int. J. Sol. Struct. 2013, 50, 1781–1790. [Google Scholar] [CrossRef]

- Florando, J.; Margraf, J.; Reus, J.; Anderson, A.; McCallen, R.; LeBlanc, M.; Stanley, J.; Rubenchik, A.; Wu, S.; Lowdermilk, W. Modeling the effect of laser heating on the strength and failure of 7075-t6 aluminum. Mat. Sci. Eng. A 2015, 640, 402–407. [Google Scholar] [CrossRef]

- Medford, J.E.; Gray, P.M. The response of structural materials to combined laser and mechanical loading. In Proceedings of the 15th Thermophysics Conference, Snowmass, CO, USA, 14–16 July 1980; AIAA: Reston, VA, USA; p. 1550. [Google Scholar]

- Long, L.C.; Wang, T.T.; Liu, L.T. Tensile and compression test of carbon/epoxy composite laminate under combined action of laser irradiation and load. Mat. Res. Innov. 2015, 19, 171–176. [Google Scholar] [CrossRef]

- Zhu, Y.; Ye, X.; Lin, X.; Wei, C.; Wang, L.; Cheng, D. Experimental investigation on the damage effect of steel structure by continuous laser under preloaded invariable stretching stress. In Proceedings of the 2nd International Symposium on Laser Interaction with Matter, Xi’an, China, 9 September 2012; SPIE: Bellingham, WA, USA, 2013; p. 8796. [Google Scholar]

- Christy, T.; Murugan, N.; Kumar, S. A comparative study on the microstructures and mechanical properties of Al 6061 alloy and the MMCAl 6061/tib2/12p. J. Miner. Mat. Charact. Eng. 2010, 9, 57. [Google Scholar]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mat. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Irizalp, S.G.; Saklakoglu, N.; Akman, E.; Demir, A. Pulsed Nd: Yag laser shock processing effects on mechanical properties of 6061-t6 alloy. Opt. Laser. Technol. 2014, 56, 273–277. [Google Scholar] [CrossRef]

- Mocko, W.; Rodriguez-Martinez, J.A.; Kowalewski, Z.L.; Rusinek, A. Compressive viscoplastic response of 6082-t6 and 7075-t6 aluminium alloys under wide range of strain rate at room temperature: Experiments and modelling. Strain 2012, 48, 498–509. [Google Scholar] [CrossRef]

- Irizalp, S.G.; Saklakoglu, N. High strength and high ductility behavior of 6061-t6 alloy after laser shock processing. Opt. Laser Eng. 2016, 77, 183–190. [Google Scholar] [CrossRef]

- Lee, H.T.; Shaue, G.H. The thermomechanical behavior for aluminum alloy under uniaxial tensile loading. Mat. Sci. Eng. A 1999, 268, 154–164. [Google Scholar] [CrossRef]

- ASM, H. Properties and selection: Nonferrous alloys and special-purpose materials. ASM Int. 1990, 2, 889–896. [Google Scholar]

- Boyer; Gall, T.L. Handbook, Asm Metals; American Society for Metals: Materials Park, OH, USA, 1985. [Google Scholar]

- Bowyer, J.; Luketa, A.; Gill, W.; Donaldson, B. Aluminum behavior during fire heating: Focus on deformation. Fire Saf. Sci. 2011, 10, 1151–1164. [Google Scholar] [CrossRef]

- Sheng, Z.M.; Weng, S.M.; Yu, L.L.; Wang, W.M.; Cui, Y.Q.; Chen, M.; Zhang, J. Absorption of ultrashort intense lasers in laser-solid interactions. Chin. Phys. B 2015, 24, 015201. [Google Scholar] [CrossRef]

- Peng, X.H.; Fan, J.; Yang, Y.; Chen, Y.; Yin, Y. Investigations to the effect of heating-rate on the mechanical properties of aluminum alloy ly12. Int. J. Sol. Struct. 2003, 40, 7385–7397. [Google Scholar] [CrossRef]

- Summers, P.T.; Chen, Y.; Rippe, C.M.; Allen, B.; Mouritz, A.P.; Case, S.W.; Lattimer, B.Y. Overview of aluminum alloy mechanical properties during and after fires. Fire Sci. Rev. 2015, 4, 1–36. [Google Scholar] [CrossRef]

- Jones, H.; Wu, K. Tensile instability and deformation behavior of rapidly heatedmetals in a constant-load environment. Inter. J. Thermophys. 1990, 11, 675–691. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Cr | Ni | Pb | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al-6061 | 0.62 | 0.46 | 0.29 | 0.09 | 0.88 | 0.04 | 0.05 | 0.17 | 0.01 | Bal. | |

| Al-7075 | 0.09 | 0.22 | 1.52 | 0.12 | 2.42 | 5.72 | 0.06 | 0.19 | 0.02 | Bal. |

| Physical Properties | Al-6061 | Al-7075 |

|---|---|---|

| Room temperature tensile strength (MPa) | 403 | 605 |

| Room temperature yield strength (MPa) | 370 | 565 |

| Density (g cm−3) | 2.7 | 2.8 |

| Melting point (°C) | 582–652 | 477–635 |

| Thermal conductivity (Wm−1 K−1) | 173 | 130 |

| Thermal diffusivity (mm2 s−1) | 70 | 46 |

| Laser Power Density (kW/cm2) | 1.1 | 1.6 | 2.2 | 2.7 |

|---|---|---|---|---|

| Loading speed (mm/min) | 0.5 | 1 | 2 | 4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jelani, M.; Li, Z.; Shen, Z.; Sardar, M. Failure Response of Simultaneously Pre-Stressed and Laser Irradiated Aluminum Alloys. Appl. Sci. 2017, 7, 464. https://doi.org/10.3390/app7050464

Jelani M, Li Z, Shen Z, Sardar M. Failure Response of Simultaneously Pre-Stressed and Laser Irradiated Aluminum Alloys. Applied Sciences. 2017; 7(5):464. https://doi.org/10.3390/app7050464

Chicago/Turabian StyleJelani, Mohsan, Zewen Li, Zhonghua Shen, and Maryam Sardar. 2017. "Failure Response of Simultaneously Pre-Stressed and Laser Irradiated Aluminum Alloys" Applied Sciences 7, no. 5: 464. https://doi.org/10.3390/app7050464

APA StyleJelani, M., Li, Z., Shen, Z., & Sardar, M. (2017). Failure Response of Simultaneously Pre-Stressed and Laser Irradiated Aluminum Alloys. Applied Sciences, 7(5), 464. https://doi.org/10.3390/app7050464