Mechanical Resilience of Modified Bitumen at Different Cooling Rates: A Rheological and Atomic Force Microscopy Investigation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

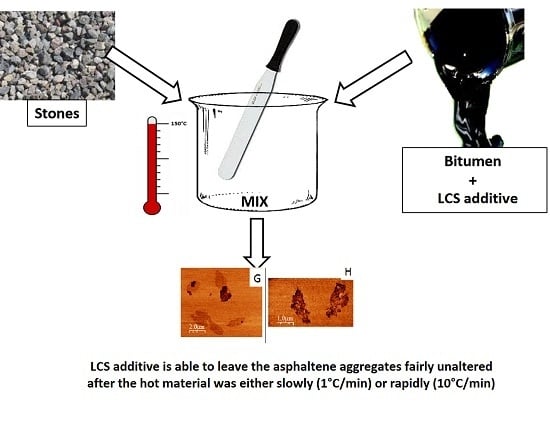

2.2. Sample Preparations and Setup of Cooling Ramps

2.3. SARA Determination

2.4. Empirical Characterisation

2.5. AFM Microstructure Analysis

2.6. Isothermal Rheological Tests after Different Cooling Ramps

3. Results and Discussion

3.1. AFM Results

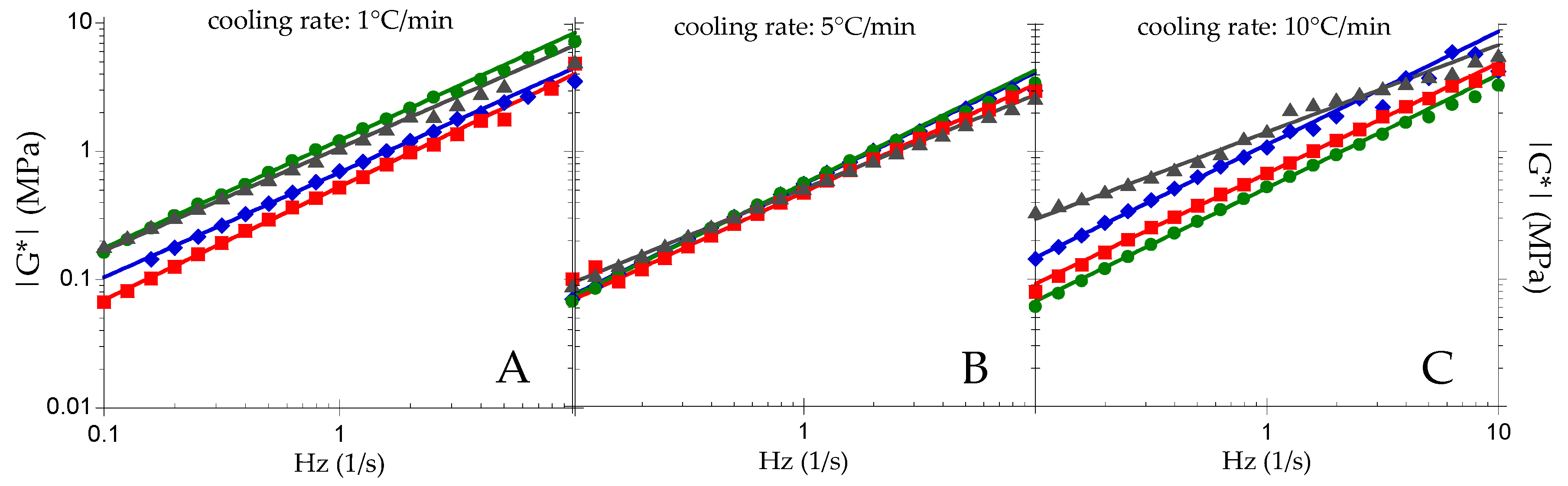

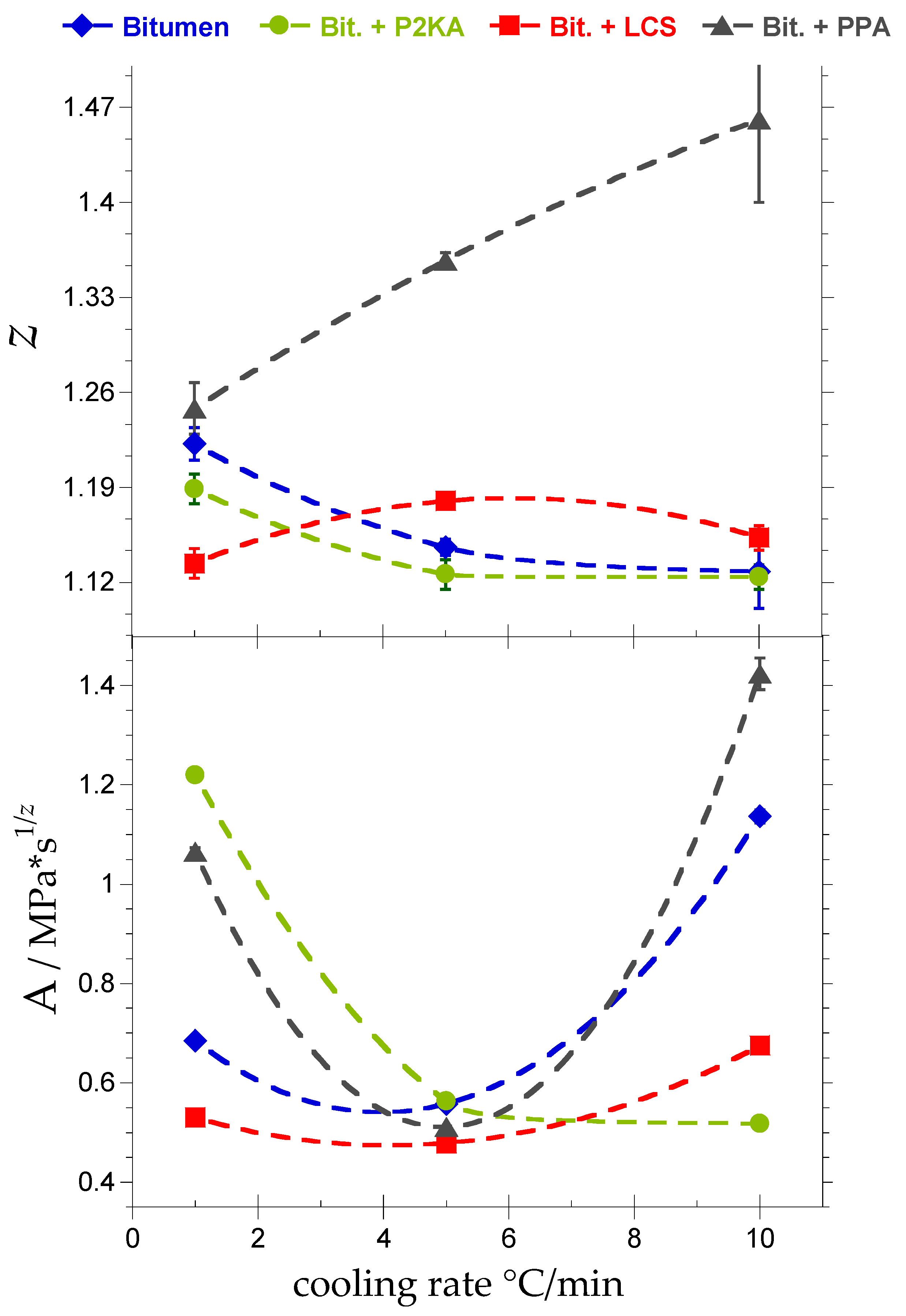

3.2. Oscillatory Shear Experiments

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Briscoe, O.E. Asphalt Rheology: Relationship to Mixture; ASTM Spec. Publ. 941; American Society for Testing and Materials: Philadelphia, PA, USA, 1987. [Google Scholar]

- Yen, T.F.; Chilingarian, G.V. Asphalthenes and Asphalts; Elsevier: New York, NY, USA, 1994. [Google Scholar]

- Rozeveld, S.; Shin, E.; Bhurke, A.; France, L.; Drzal, L. Network morphology of straight and polymer modified asphalt cements. Microsc. Res. Tech. 1997, 38, 529–543. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Int. Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structure and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Dave, E.V.; Buttlar, W.G. Effect of Cooling Rate on Thermal Cracking of Asphalt Concrete Pavements. J. Assoc. Asph. Paving Technol. 2008, 77, 709–738. [Google Scholar]

- Huurman, M.; Mo, L.; Woldekidan, M.F.; Khedoe, R.N.; Moraal, J. Overview of the LOT meso mechanical research into porous asphalt ravelling. In Advanced Testing and Characterization of Bituminous Materials 1; CRC Press: Boca Raton, FL, USA, 2009; pp. 507–517. [Google Scholar]

- Kluttz, R.; Jellema, E.; Woldekidan, M.; Huurman, M. Highly Modified Bitumen for Prevention of Winter Damage in OGFCs. In Proceedings of the Airfield and Highway Pavement, Los Angeles, CA, USA, 9–12 June 2013; pp. 1075–1087. [Google Scholar]

- Oliviero Rossi, C.; Spadafora, A.; Teltayev, B.; Izmailova, G.; Amerbayev, Y.; Bortolotti, V. Polymer modified bitumen: Rheological properties and structural characterization. Colloids Surf. A Physicochem. Eng. Asp. 2015, 480, 390–397. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.N.; Xiao, F.; Tang, B. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber and modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Karim, M.R. Investigating the Rheological Properties of Crumb Rubber Modified Bitumen and its Correlation with Temperature Susceptibility. Mater. Res. 2013, 16, 116–127. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Oliviero Rossi, C.; Seta, L.; Lupi, F.R.; Caputo, P. Low temperature rheology of polyphosphoric acid (PPA) added bitumen. Constr. Build. Mater. 2012, 36, 592–598. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Baldino, N.; Szerb, E.I.; Teltayev, B. Quantitative evaluation of organosilane-based adhesion promoter effect on bitumen-aggregate bond by contact angle test. Int. J. Adhes. Adhes. 2017, 72, 117–122. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Baldino, N.; Lupi, F.R.; Miriello, D.; Angelico, R. Effects of adhesion promoters on the contact angle of bitumen-aggregate interface. Int. J. Adhes. Adhes. 2016, 70, 297–303. [Google Scholar] [CrossRef]

- Rossi, C.O.; Taltayev, B.; Angelico, R. Adhesion Promoters in Bituminous Road Materials: A Review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Masson, J.F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase-detection atomic force microscopy. J. Microsc. 2006, 221, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Hung, A.M.; Fini, E.H. AFM study of asphalt binder “bee” structures: Origin, mechanical fracture, topological evolution, and experimental artifacts. RSC Adv. 2015, 5, 96972–96982. [Google Scholar] [CrossRef]

- Yoon, S.; Bhatt, S.D.; Lee, W.; Lee, H.Y.; Jeong, S.Y.; Baeg, J.O.; Lee, C.W. Separation and characterization of bitumen from Athabasca oil sand. Korean J. Chem. Eng. 2009, 26, 64–71. [Google Scholar] [CrossRef]

- ASTM Standard 2005. Standard for Penetration-Graded Asphalt Cement for Use in Pavement Construction, D946-82; ASTM International: Montgomery, PA, USA, 2005. [Google Scholar]

- Coppola, L.; Gianferri, R.; Rossi, C.O.; Nicotera, I.; Ranieri, G.A. Structural changes in CTAB/H2O mixtures using a rheological approach. Phys. Chem. Chem. Phys. 2004, 6, 2364–2372. [Google Scholar] [CrossRef]

- Angelico, R.; Carboni, M.; Lampis, S.; Schmidt, J.; Talmon, Y.; Monduzzi, M.; Murgia, S. Physicochemical and rheological properties of a novel monoolein-based vesicle gel. Soft Matter 2013, 9, 921–928. [Google Scholar] [CrossRef]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Hunter, R.N., Ed.; Thomas Telford Publishing: London, UK, 2003. [Google Scholar]

- Antunes, F.; Gentile, L.; Rossi, C.O.; Tavano, L.; Ranieri, G.A. Gels of Pluronic F127 and nonionic surfactants from rheological characterization to controlled drug permeation. Colloids Surf. B Biointerfaces 2011, 87, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Andersen, S.I.; Birdi, K.S. Aggregation of asphaltenes as determined by calorimetry. J. Colloid Interface Sci. 1991, 42, 497–502. [Google Scholar] [CrossRef]

- Sheu, E.Y.; Storm, D.A. Colloidal properties of asphaltenes in organic solvents. In Asphaltenes: Fundamentals and Applications; Sheu, E.Y., Mullins, O.C., Eds.; Plenum Press: New York, NY, USA, 1995; Chapter 1. [Google Scholar]

- Sirota, E.B. Physical structure of asphaltenes. Energy Fuels 2005, 19, 1290–1296. [Google Scholar] [CrossRef]

- Masson, J.F.; Leblond, V.; Margeson, J.; Bundalo-Perc, S. Low—Temperature bitumen stiffness and viscous paraffinic nano-and micro-domains by cryogenic AFM and PDM. J. Microsc. 2007, 227, 191–202. [Google Scholar] [CrossRef] [PubMed]

- Pauli, A.T.; Grimes, R.W.; Beemer, A.G.; Turner, T.F.; Branthaver, J.F. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy. Int. J. Pavement Eng. 2011, 12, 291–309. [Google Scholar] [CrossRef]

- Fischer, H.R.; Dillingh, B.; Ingenhut, B. Fast solidification kinetics of parts of bituminous binders. Mater. Struct. 2016, 49, 3335–3340. [Google Scholar] [CrossRef]

- Ramm, A.; Sakib, N.; Bhasin, A.; Downer, M.C. Optical characterization of temperature- and composition-dependent microstructure in asphalt binders. J. Microsc. 2016, 262, 216–225. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Zhang, H.; Xu, H. Effect of polyphosphoric acid on physical properties, chemical composition and morphology of bitumen. Constr. Build. Mater. 2013, 47, 92–98. [Google Scholar] [CrossRef]

- Bohlin, L. A Theory of Flow as a Cooperative Phenomenon. J. Colloid Interface Sci. 1980, 74, 423–434. [Google Scholar] [CrossRef]

- Winter, H.H. Can the Gel Point of a Cross-linking Polymer Be Detected by the G′—G′′ Crossover? Polym. Eng. Sci. 1987, 27, 1698–1702. [Google Scholar] [CrossRef]

- Rossi, C.O.; Coppola, L.; La Mesa, C.; Ranieri, G.A.; Terenzi, M. Gemini surfactant–water mixtures: Some physical–chemical properties. Colloids Surf. A 2002, 201, 247–260. [Google Scholar]

- Coppola, L.; Gianferri, R.; Rossi, C.O.; Nicotera, I. Solution and Liquid-Crystalline microstructures in Sodium Taurodeoxycholate/D2O mixtures. Langmuir 2003, 19, 1990–1999. [Google Scholar] [CrossRef]

- Coppola, L.; Gentile, L.; Nicotera, I.; Rossi, C.O.; Ranieri, G.A. Evidence of Formation of Ammonium Perfluorononanoate/2H2O Multilamellar Vesicles: Morphological Analysis by Rheology and Rheo-2H NMR Experiments. Langmuir 2010, 26, 19060–19065. [Google Scholar] [CrossRef] [PubMed]

- Gabriele, D.; de Cindio, B.; D’Antona, P. A weak gel model for foods. Rheol. Acta 2001, 40, 120–127. [Google Scholar] [CrossRef]

- Gentile, L.; Filippelli, L.; Rossi, C.O.; Baldino, N.; Ranieri, G.A. Rheological and H-NMR Spin-Spin relaxation time for the evaluation of the effects of PPA addition on bitumen. Mol. Cryst. Liq. Cryst. 2012, 558, 54–63. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Rossi, C.O.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Loise, V.; Miriello, D.; Taltayev, B.; Angelico, R. Role of a food grade additive in the high temperature performance of modified bitumens. Colloids Surf. A Physicochem. Eng. Asp. 2017. [Google Scholar] [CrossRef]

| SAMPLE | SARA Fraction in Weight % (±0.1) |

|---|---|

| Saturated | 4.2 |

| Aromatics | 51.6 |

| Resins | 21.3 |

| Asphaltenes | 22.9 |

| Cooling Rate (°C/min) | 1 | 5 | 10 |

|---|---|---|---|

| Sample | z | z | z |

| Bitumen | 1.22 ± 0.01 | 1.15 ± 0.01 | 1.13 ± 0.03 |

| Bitumen + P2KA 2% | 1.19 ± 0.01 | 1.13 ± 0.01 | 1.12 ± 0.01 |

| Bitumen + LCS 2% | 1.13 ± 0.01 | 1.18 ± 0.01 | 1.15 ± 0.01 |

| Bitumen + PPA 2% | 1.25 ± 0.02 | 1.36 ± 0.01 | 1.46 ± 0.06 |

| Cooling Rate (°C/min) | 1 | 5 | 10 |

|---|---|---|---|

| Sample | A × 10−6 | A × 10−6 | A × 10−6 |

| Bitumen | 0.68 ± 0.01 | 0.558 ± 1 × 10−3 | 1.14 ± 0.01 |

| Bitumen + P2KA 2% | 1.22 ± 0.01 | 0.563 ± 3 × 10−3 | 0.518 ± 2 × 10−3 |

| Bitumen + LCS 2% | 0.530 ± 3 × 10−3 | 0.479 ± 2 × 10−3 | 0.675 ± 2 × 10−3 |

| Bitumen + PPA 2% | 1.06 ± 0.01 | 0.511 ± 1 × 10−3 | 1.42 ± 0.03 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, C.O.; Ashimova, S.; Calandra, P.; Santo, M.P.D.; Angelico, R. Mechanical Resilience of Modified Bitumen at Different Cooling Rates: A Rheological and Atomic Force Microscopy Investigation. Appl. Sci. 2017, 7, 779. https://doi.org/10.3390/app7080779

Rossi CO, Ashimova S, Calandra P, Santo MPD, Angelico R. Mechanical Resilience of Modified Bitumen at Different Cooling Rates: A Rheological and Atomic Force Microscopy Investigation. Applied Sciences. 2017; 7(8):779. https://doi.org/10.3390/app7080779

Chicago/Turabian StyleRossi, Cesare Oliviero, Saltanat Ashimova, Pietro Calandra, Maria Penelope De Santo, and Ruggero Angelico. 2017. "Mechanical Resilience of Modified Bitumen at Different Cooling Rates: A Rheological and Atomic Force Microscopy Investigation" Applied Sciences 7, no. 8: 779. https://doi.org/10.3390/app7080779