1. Introduction

With the successful promotion of Tesla, electric vehicles have shown a rapid development trend in recent years. As the key technology of electric vehicles, research on the energy storage devices of lithium-ion batteries has become a state-of-the art research field [

1]. Some researchers are focused on preparing new kinds of lithium-ion batteries, while others are studying the influence factors of lithium-ion batteries to improve their service life, mechanical durability and reliability. Compared with conventional factors such as the C-rate, the depth of discharge (DOD) and temperature, the vibration has not attracted widespread attention. Vibrations resulting from road roughness, acceleration inertia and sudden collision will seriously affect the mechanical properties and electrical performance of batteries.

The fatigue failure caused by vibration is a common problem in the research area in electrical power systems. The electrode material of lead-acid batteries [

2,

3] and the mechanical structure of proton exchange membrane fuel cells (PEMFC) [

4] were deformed and cracked under the condition of the certain vibration load. In terms of electrical performance, it has been found that the voltage and power of the PEMFC did not obviously change after vibration and shock tests [

5].

In the past 5 years, the influence of the mechanical force on lithium-ion batteries has attracted more and more attention from researchers. Some researchers have studied how to utilize vibration to achieve a health diagnosis [

6] or energy harvesting [

7]; while, at the same time, the battery array is configured to prevent the effects of vibration on the electric vehicle [

8]. Via the static analysis of the battery pack level, the stress distribution of mechanical structure of the battery pack has also been considered to determine deformation induced by vibration load. In Ref. [

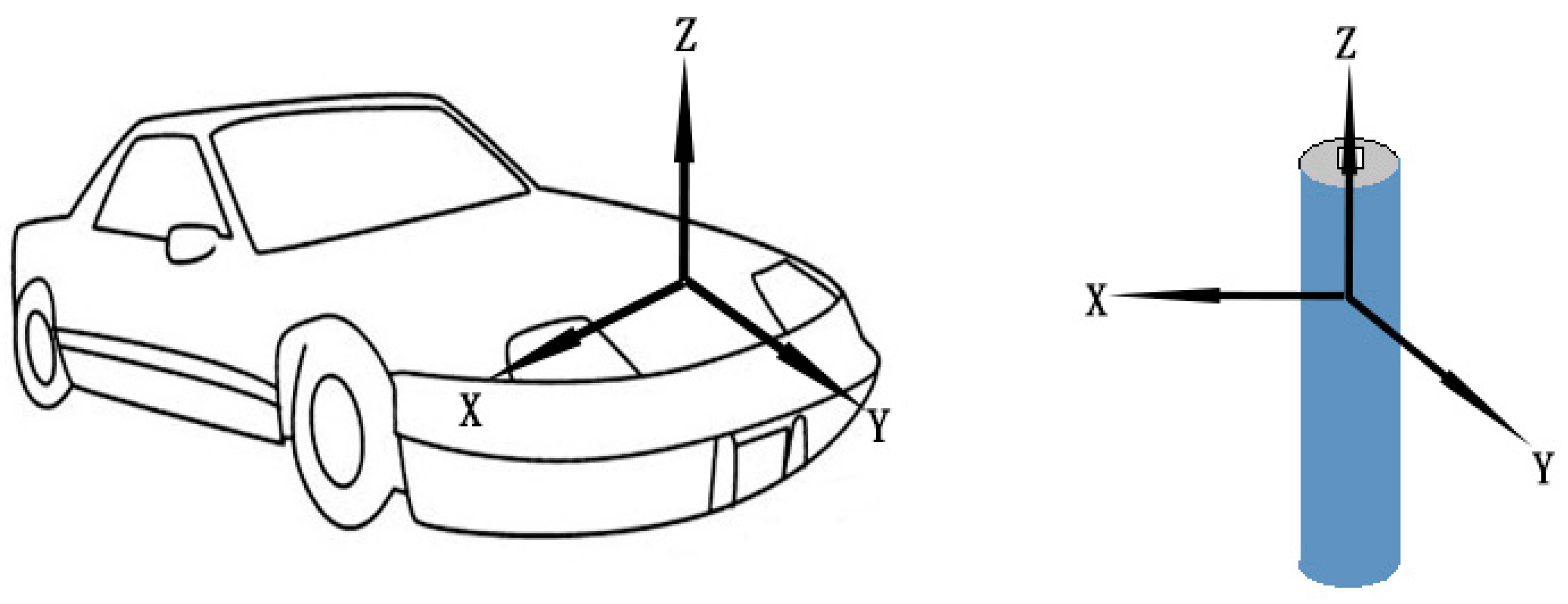

9] the vibration durability of the battery tray was studied through experimentation and simulation techniques. The results showed that the load spectrum simulation experiment could reflect the road-induced vibration well. At the same time, it was also found that the vibration in the

Z-axis direction was the most dominant excitation when compared to other axes. Moreover, the finite element model of the battery tray [

10,

11,

12] was established to analyze the intrinsic mode and the characteristics of the responses caused by the random vibration. Based on the above, researchers have set out the design of the mechanical durability and electrical durability for the battery packaging structure [

13,

14].

In the past three years, research concerning the effects of vibration on single battery cells has been carried out from different aspects and provided different sorts of insight into the effects of the vibration on the electrical performance and the internal mechanical structure. At present, the effects of the vibration on the electrical performance have not yet been met by consistent conclusions. It is worth noting that the conclusions within Refs. [

15,

16] were opposite to each other. It is reported in Ref. [

15] that the LiCoO

2/mesocarbon microbeads (MCMB) battery displayed an increase by 3.77% in the ohmic resistance and displayed a reduction by 1.04% in the 1C capacity after vibration testing, while it is reported in Ref. [

16] that the internal resistance of the lithium-ion battery was significantly decreased and the capacity was increased slightly after vibration testing. It has also been noticed that, within Refs. [

15,

16], conclusions are restricted due to the limited sample size employed, since each test condition was evaluated only by two single cells. Concerning this problem, some scholars have conducted further research. In Ref. [

17], the method by which these mechanical loads affect lithium-ion cells was researched, and the results showed that in 18,650 cells stressed in the

Z-direction the mandrel dispatched itself and struck against internal components, which were observed with a micro-computer tomograph, but the electrical performance exhibited no degradation. However, within Ref. [

17], the 3 h load profile was carried out ten times with an inspection, so that battery resting time was not enough, resulting in the measurement uncertainty. In addition, each test condition was evaluated only by two single cells, and accidental errors also cannot be neglected, such as a sudden increase in battery resistance for the long-term vibrational test. In summary, while studies above have identified the effects of the vibration on the mechanical structure inside the lithium-ion cells, it is ambiguous whether the vibration had a significant effect on the electrical performance of lithium-ion cells. With regard to the problem of whether the deformation of the mechanical structure inside cells would lead to the degradation of electrical performance, research in Ref. [

18] noted that the capacity fading of LiFePO

4 batteries was caused by the formation of cracks inside the electrode material. Therefore, it is reasonable to suspect that the electrical performance of cells would be affected by the structural deformation and cracks inside cells induced by the vibration loading.

Hooper, J. and Marco, J. from Warwick University, dedicated to studying the vibration durability of lithium-ion batteries, have performed a great deal of related research works and efforts in recent years. In Ref. [

19], the authors emphasized that studies on the vibration characteristics of the battery pack should attract more attention; in Ref. [

20], the cells natural frequency was proposed by authors for the first time to quantify the mechanical characteristics of cells; in Refs. [

21,

22,

23], 18,650 lithium-ion cells of different materials were investigated with different load profiles; and in Ref. [

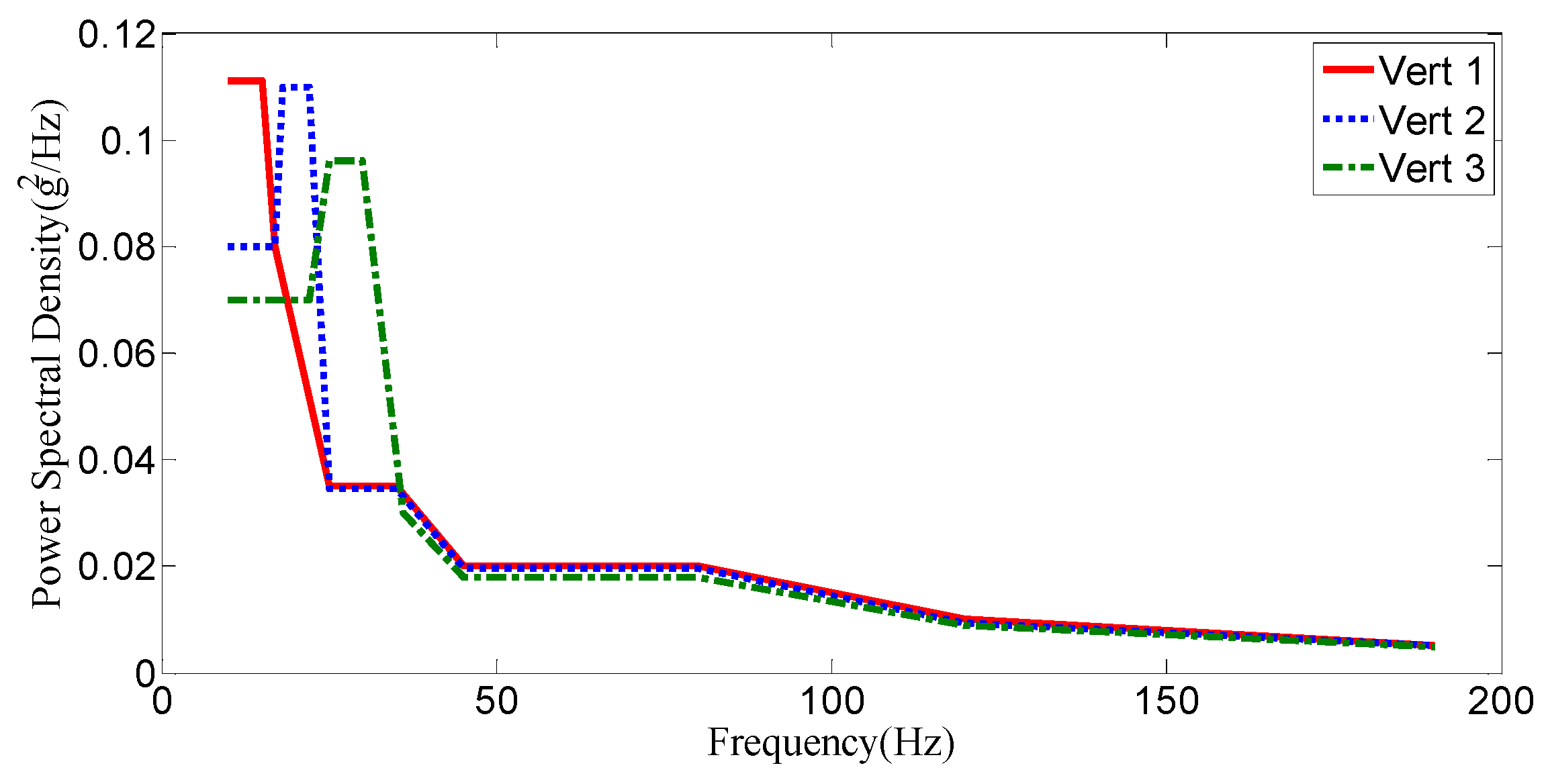

24], the authors defined a process to devise random power spectral density (PSD) profiles utilizing vibration measurements from three contemporary EVs, for undertaking vibration durability evaluations of underfloor mounted rechargeable energy storage systems (RESS). In brief, two scholars have opened up a wide range of the research space for this issue. It is reported that, within Ref. [

21], these nickel manganese cobalt oxide (NMC) cells displayed a significant increase in ohmic resistance within the range of 25.82 to 38.09% after vibration testing, and a reduction in the measured 1C energy capacity was observed in some samples, with 12.22% being the greatest reduction observed. Due to the limited sample size employed, therefore, authors performed further research within Ref. [

23], and this study identified that both the electrical performance and the mechanical properties of the nickel cobalt aluminum oxide (NCA) lithium-ion cells were relatively unaffected when exposed to the vibration energy that is commensurate with a typical EV life. However, the study also noted that a similar reduction in energy capacity and increase in DC resistance was witnessed within the reference samples, which indicated that the change in these electrical attributes was a function of other environmental conditions. Because the total duration between pre and post-test characterization was 3 months, the effect between the cell ageing and the vibration cannot be fully quantified. The authors also suggested that a further set of repeat tests should be conducted to increase the size of the data set, indicating that a greater sample size is necessary to increase confidence of findings.

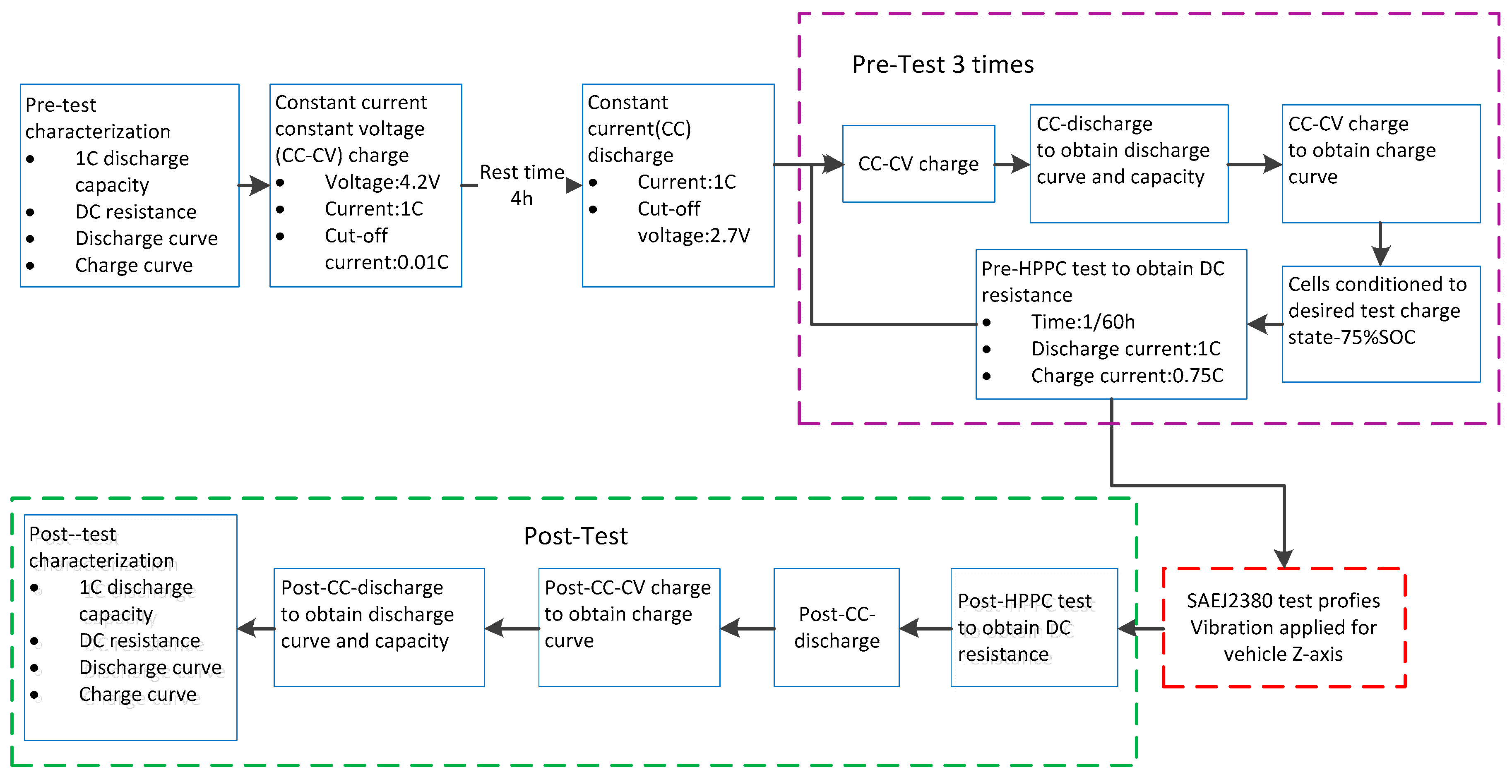

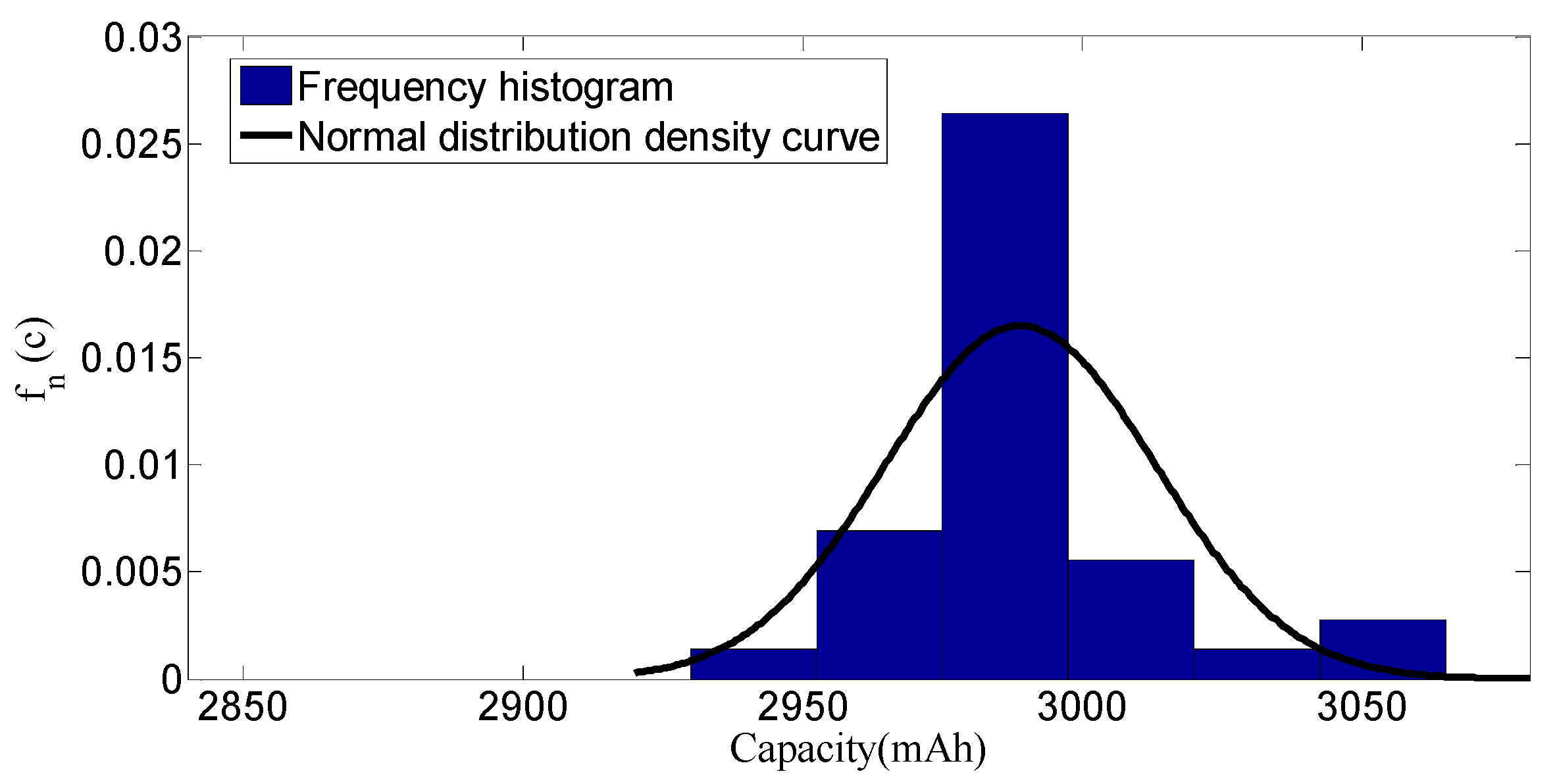

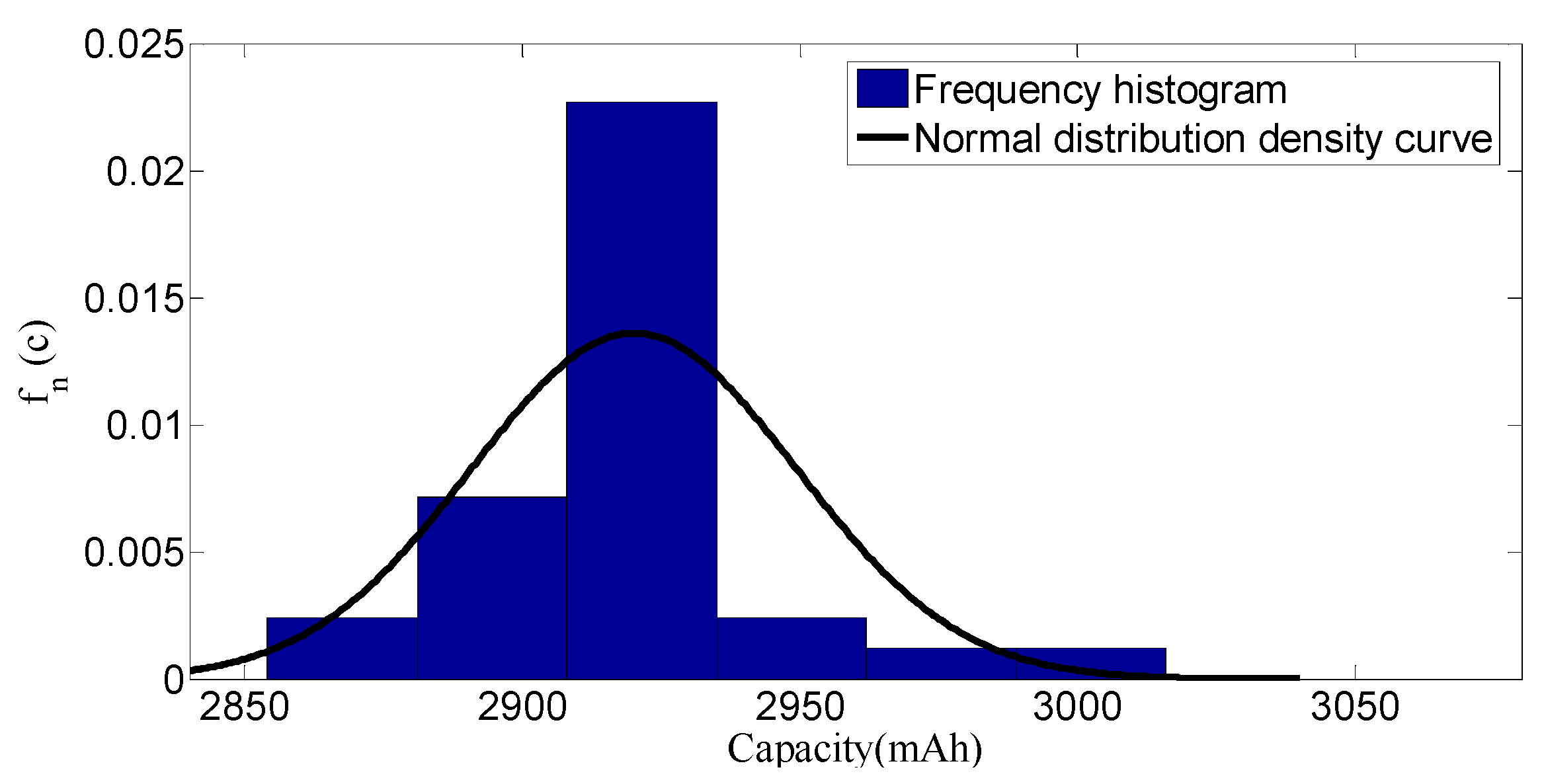

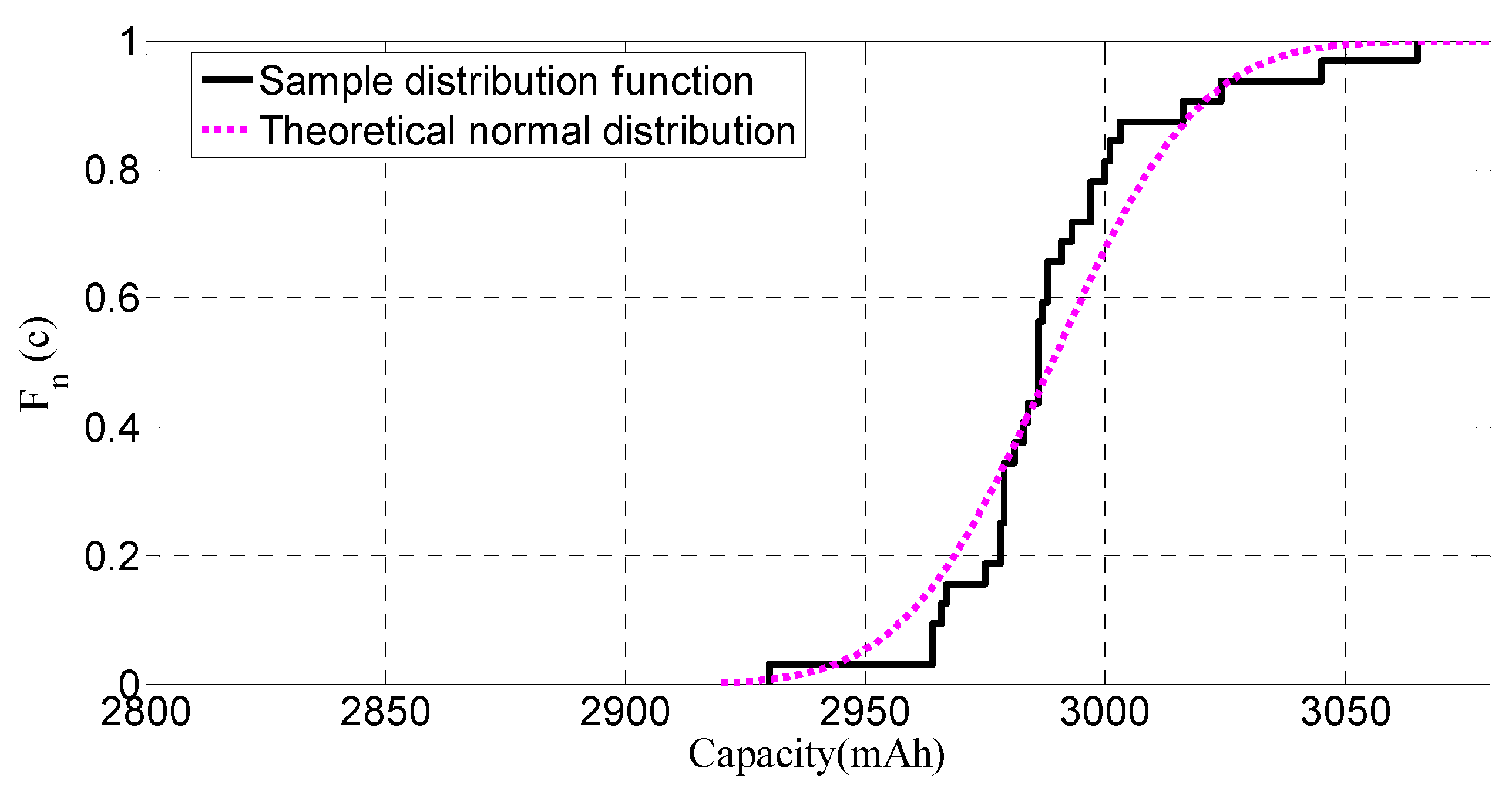

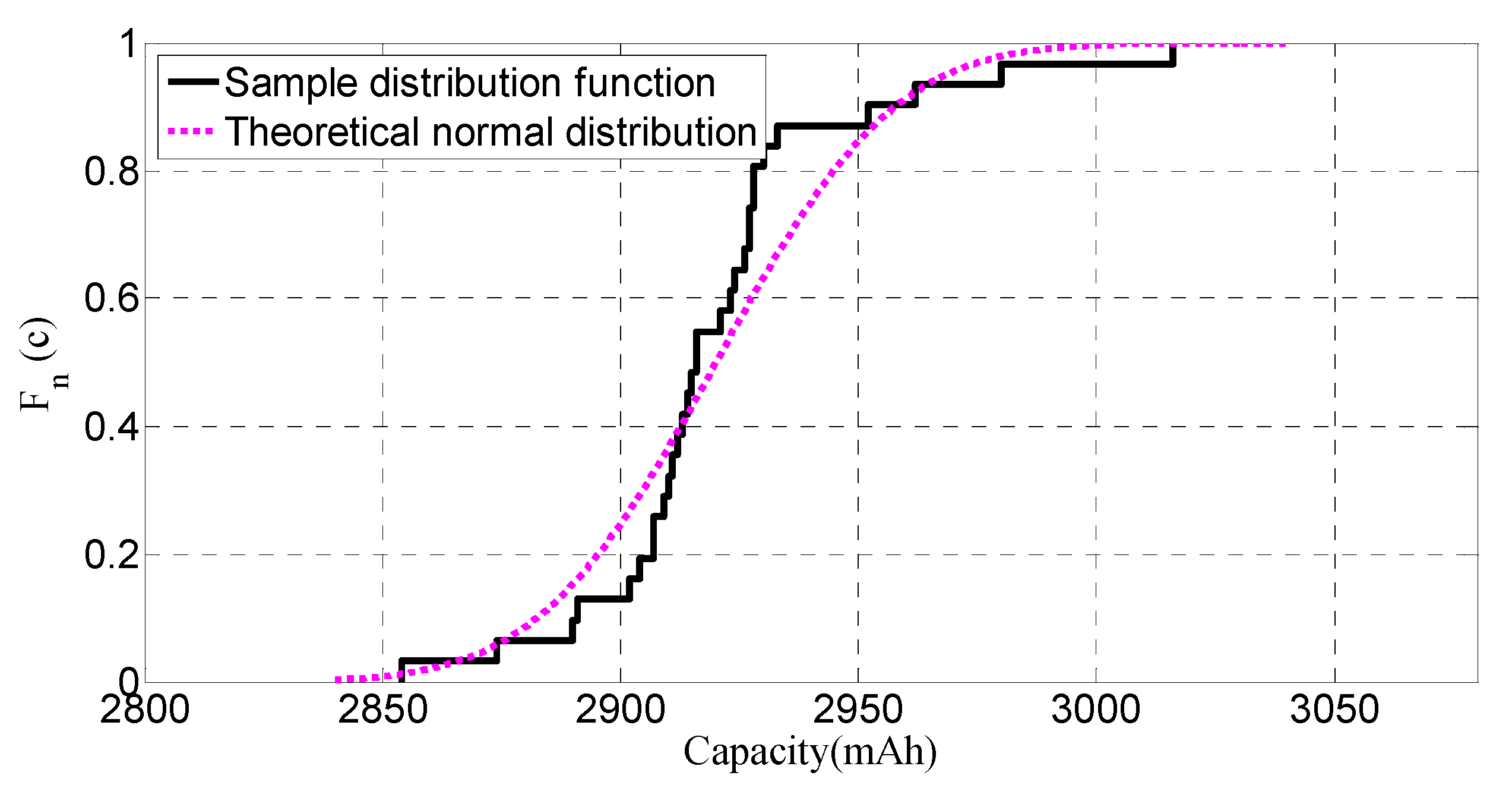

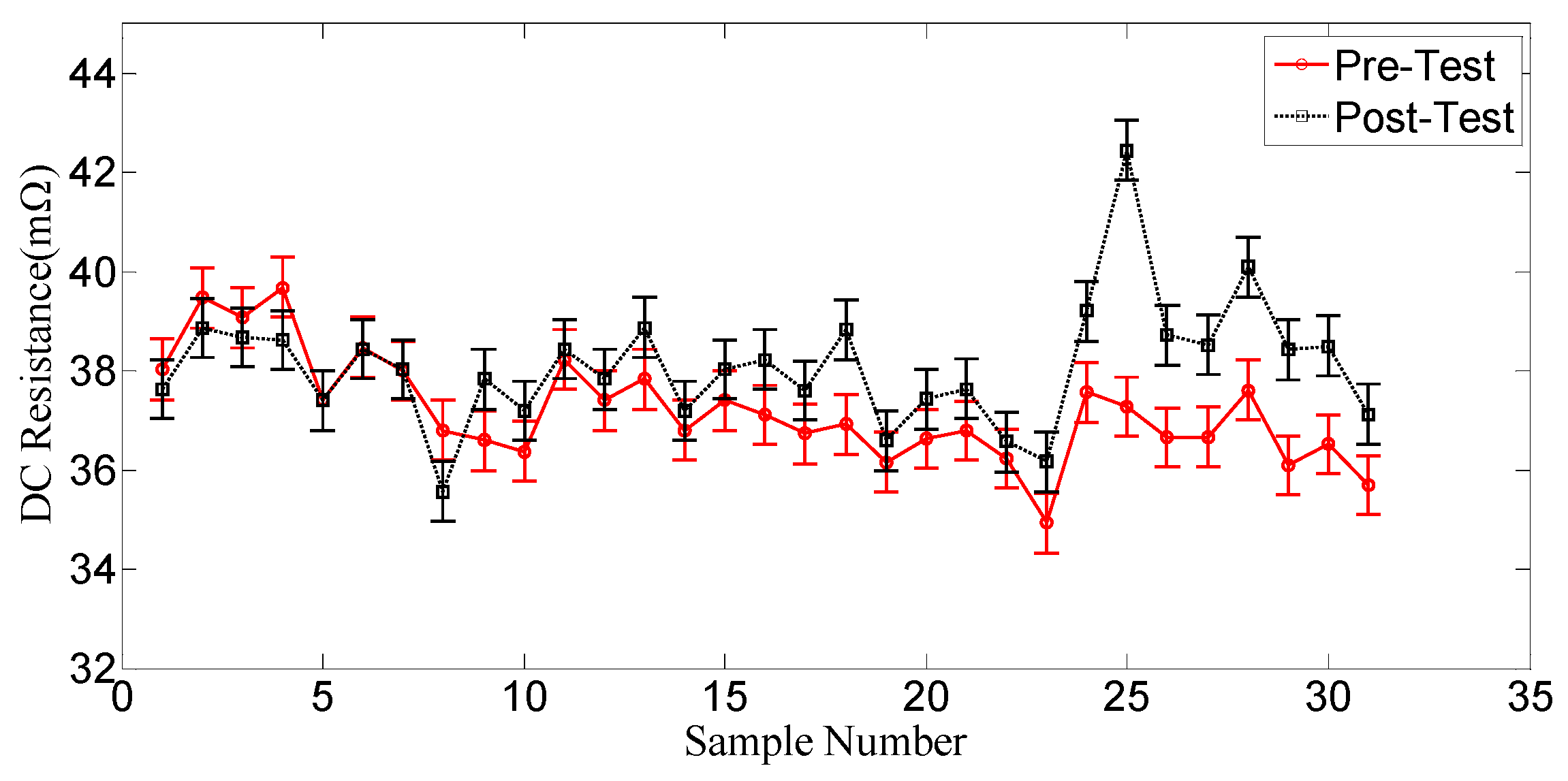

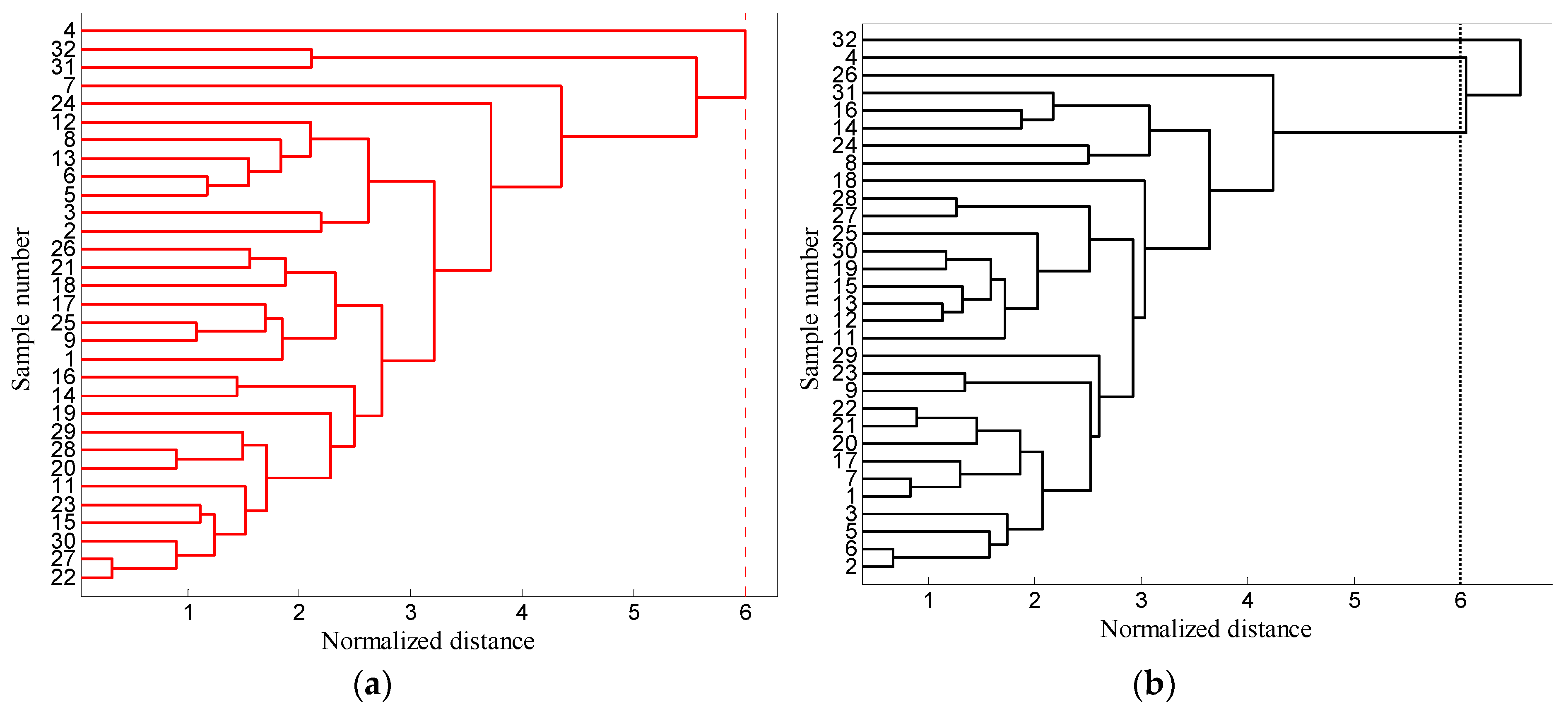

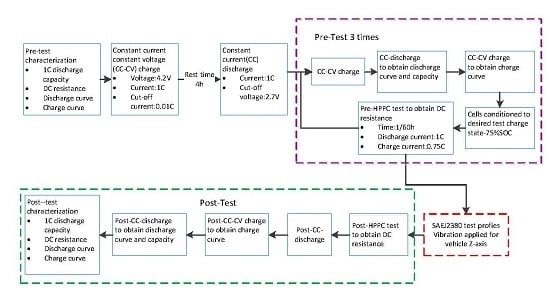

From the review above, it can be seen that there is a problem when the sample size is too small; results are greatly affected by some accidental errors such as the cell-to-cell variation, the environmental factors and the measurement uncertainty. Consequently, it is difficult to identify whether the vibration or the accidental error leads to the change in the electrical performance of cells. Therefore, it is necessary to evaluate the change in the electrical performance of cells overall with a larger sample size. In this paper, 32 NCR18650BE lithium-ion cells are investigated with the load profile according to the standard Society of Automotive Engineers (SAE) J2380, and changes in the electrical performance of the samples before and after the test are analyzed by the mathematical statistic method. In addition, this paper also studies the effects of vibration on the cell consistency, based on the hierarchical clustering method.

This paper is structured as follows:

Section 2 provides a detailed description of the experimental procedure, including the electrical performance testing method and the design of the vibration test profile. Results are presented in

Section 3, and an assessment of the 1C capacity degradation is included as well as changes in DC resistance of the cell.

Section 4 analyses the consistency of the cell before and after test. Conclusions are presented in

Section 5.

5. Conclusions

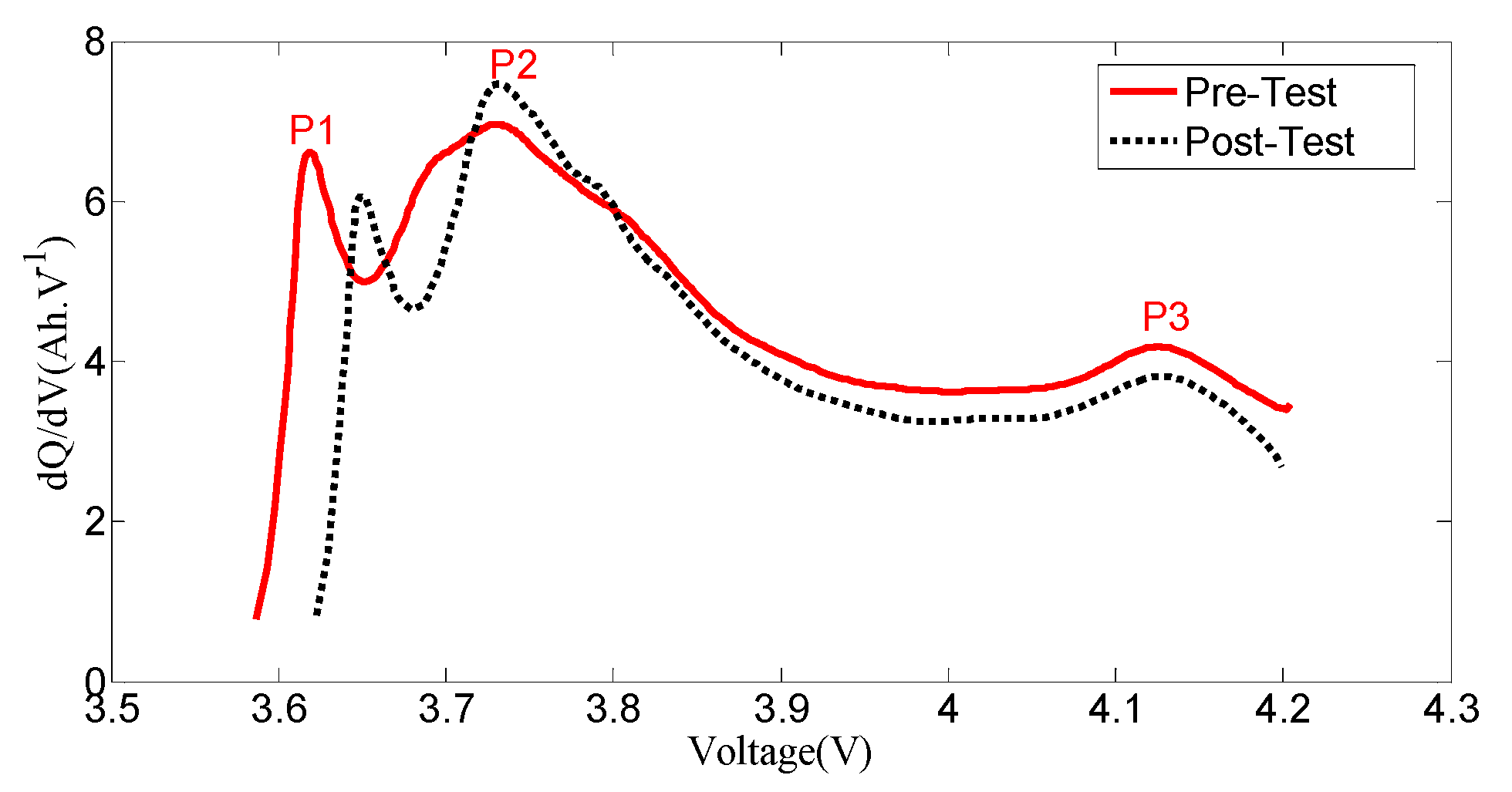

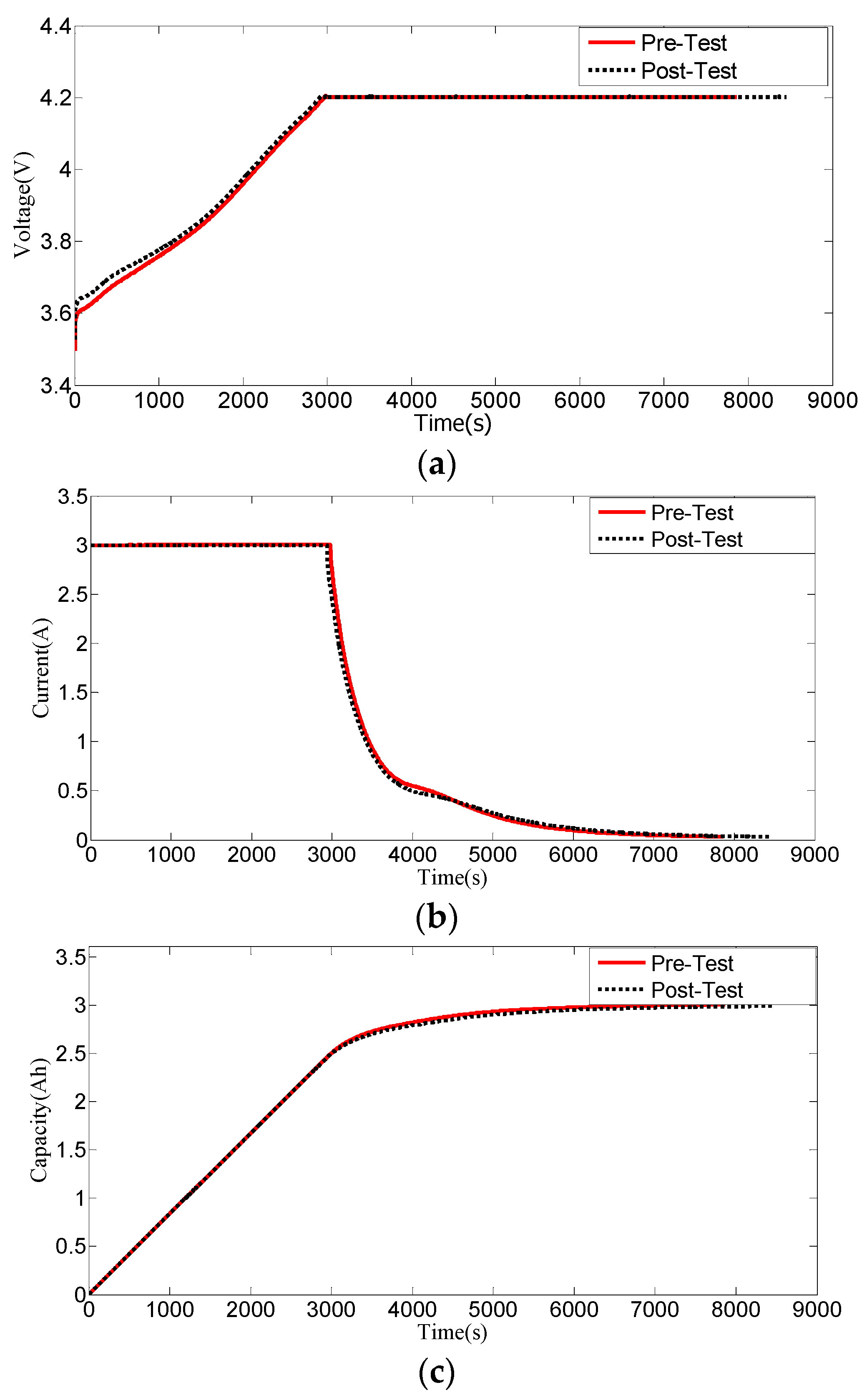

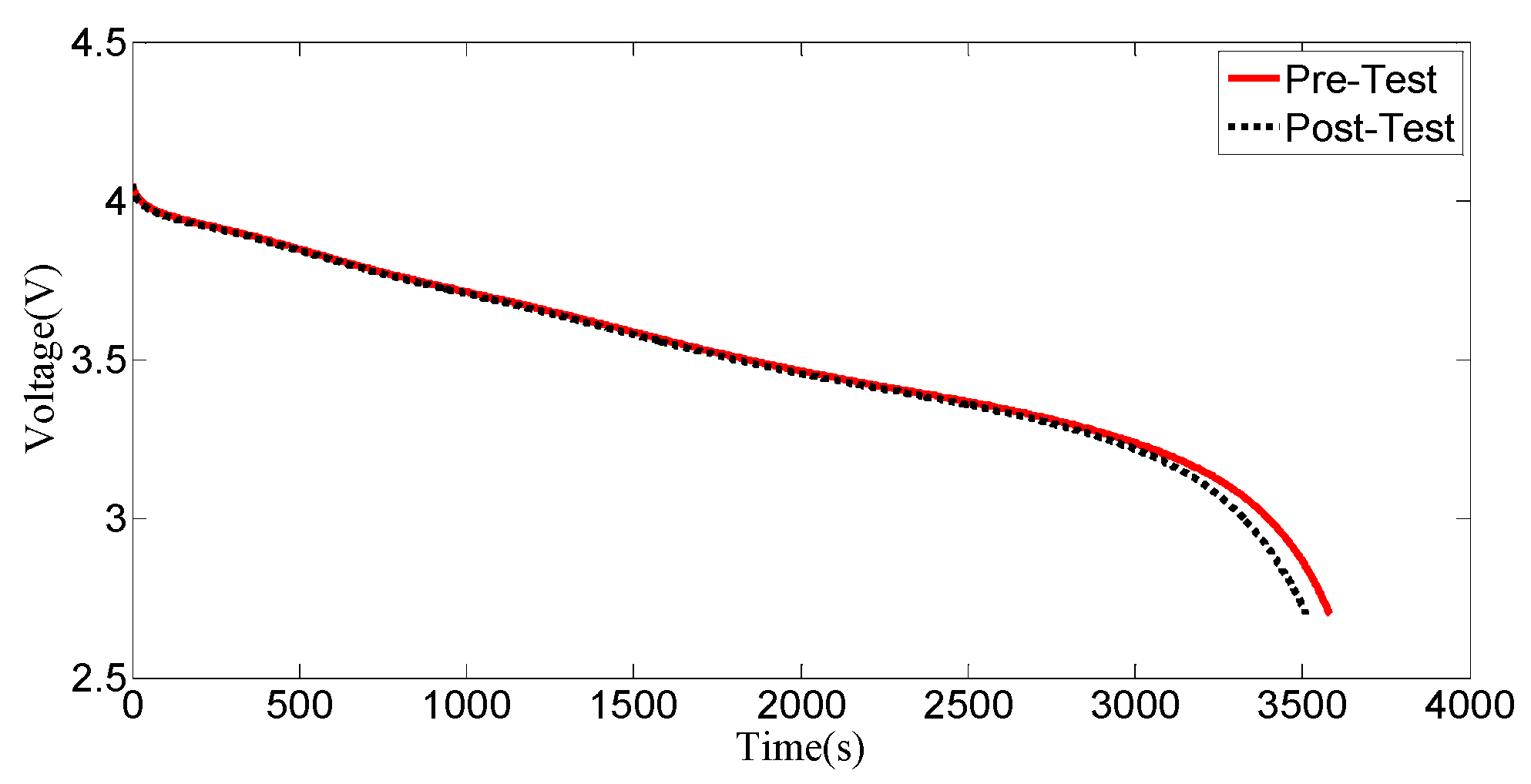

In this paper, the influence of vibration load on electrical performance of lithium-ion cells was analyzed, the results showed that the mean value and the standard deviation of DC resistance increased at the 0.05 and 0.1 significance level, respectively. In addition, the significant decrease in cell capacity and the slight deterioration in consistency was observed after the vibration test.

Compared with previous articles, a large number of samples of 32 lithium-ion cells were used for the test, and the changes in DC resistances or capacity was compared by using the holistic samples in order to eliminate the influence of the accidental factors caused by a single cell on the overall trend. In addition, the distribution function of cell capacity and DC resistance were obtained by data fitting and using hypothesis testing, which can well reveal the distribution of the cells before and after the vibration test. Finally, the influence of vibration on the consistency of lithium-ion cells was studied based on multi-feature quantities, and a reasonable conclusion was obtained by using the hierarchical clustering method. This point has not been studied in the previous literature, but it must be a research focus, as the consistency can better reflect the performance of the cell pack.

The quantitative analysis and the error estimation were carried out in the choice of sample size, and the most representative vibration standard of SAE J2380 was selected after referencing a large amount of the literature. In addition, the control of the time interval and the ambient temperature were set reasonably in the measurement process of cell features; therefore, the comprehensive consideration of the experimental details makes the results more credible.