Experimental Study on Robustness of an Eddy Current-Tuned Mass Damper

Abstract

:1. Introduction

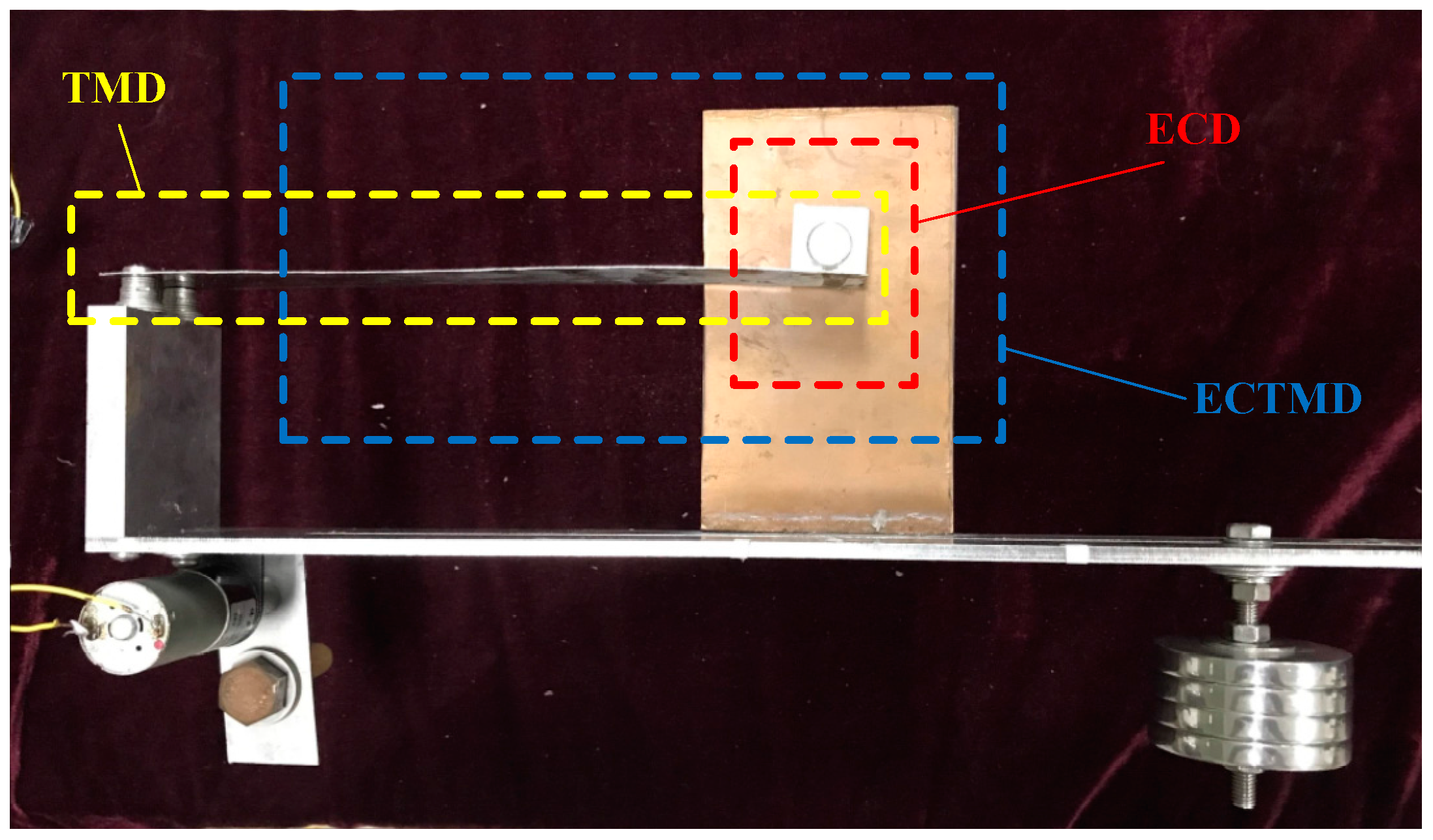

2. Vibration Control of a Cantilever Beam with an Eddy Current Tuned Mass Damper

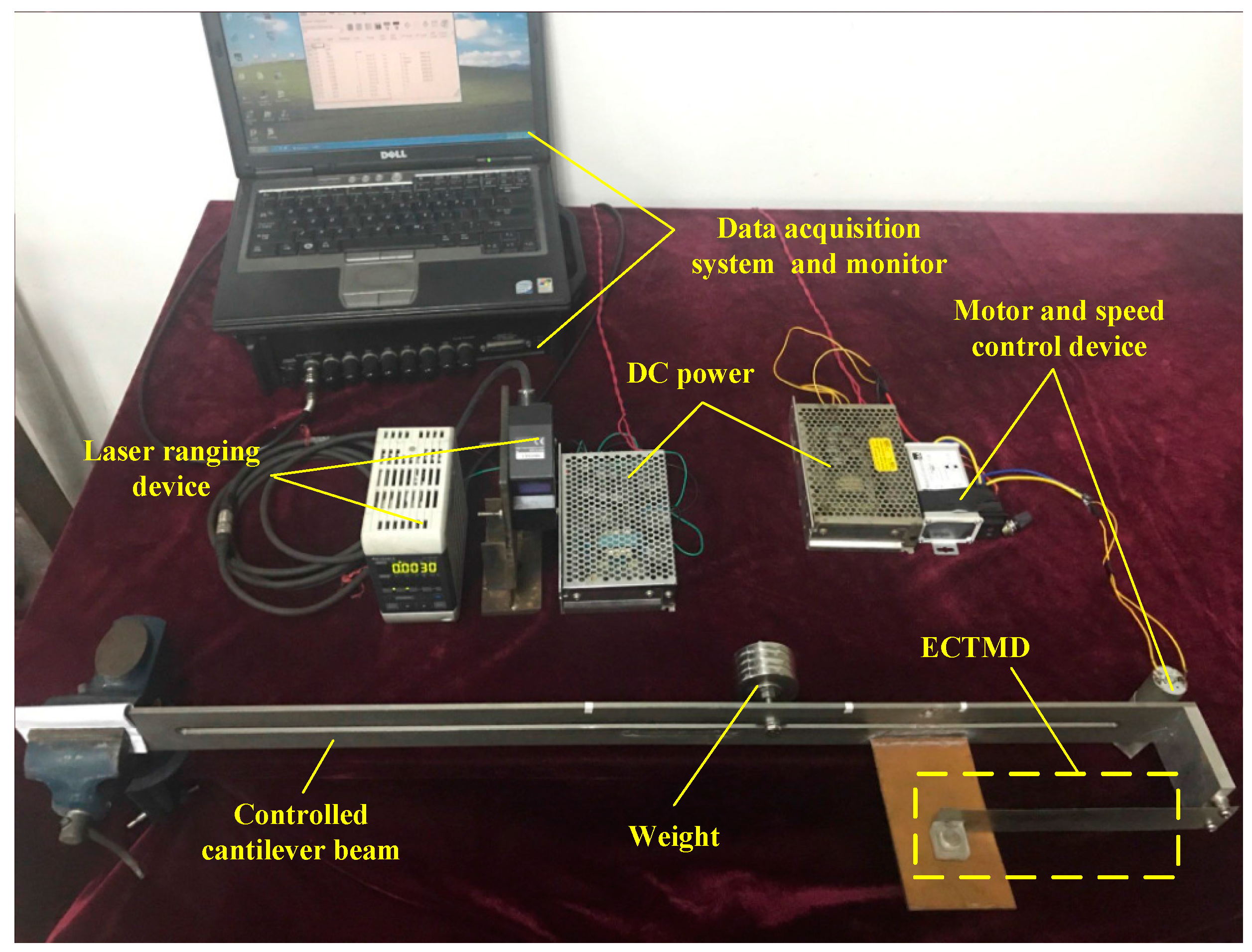

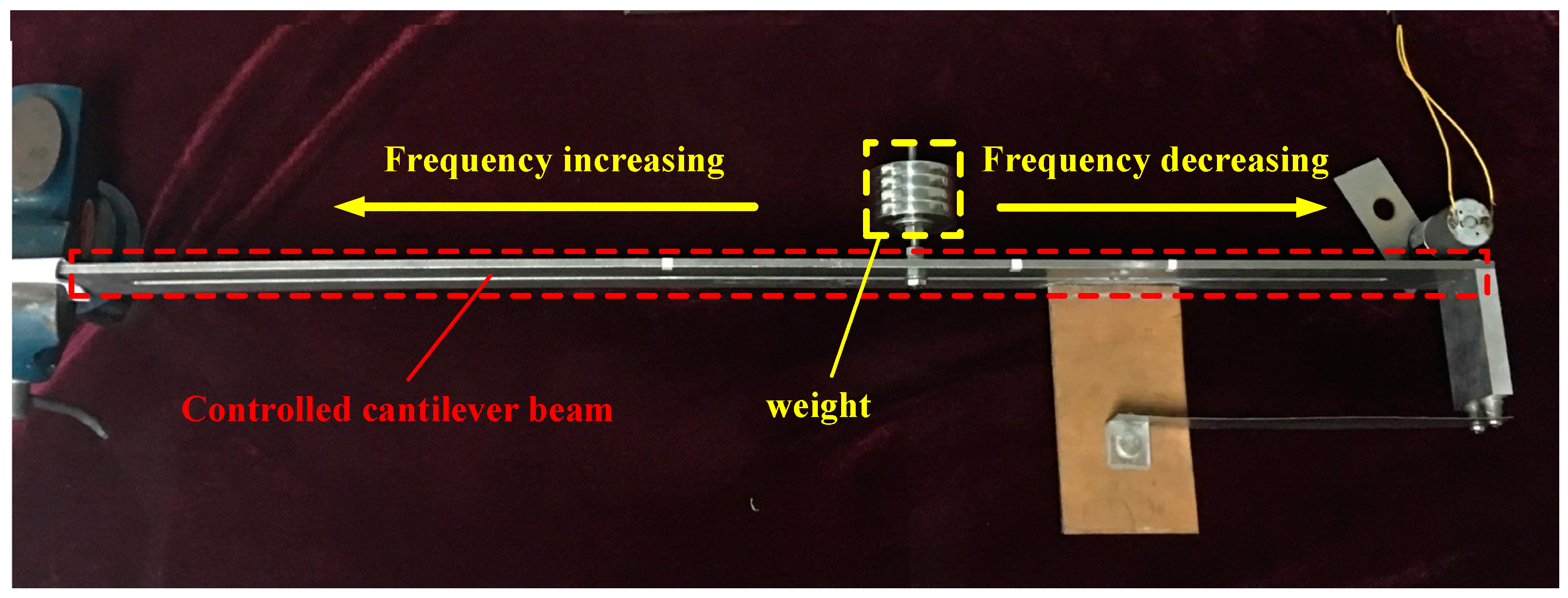

3. Experimental Setup

4. Experimental Results

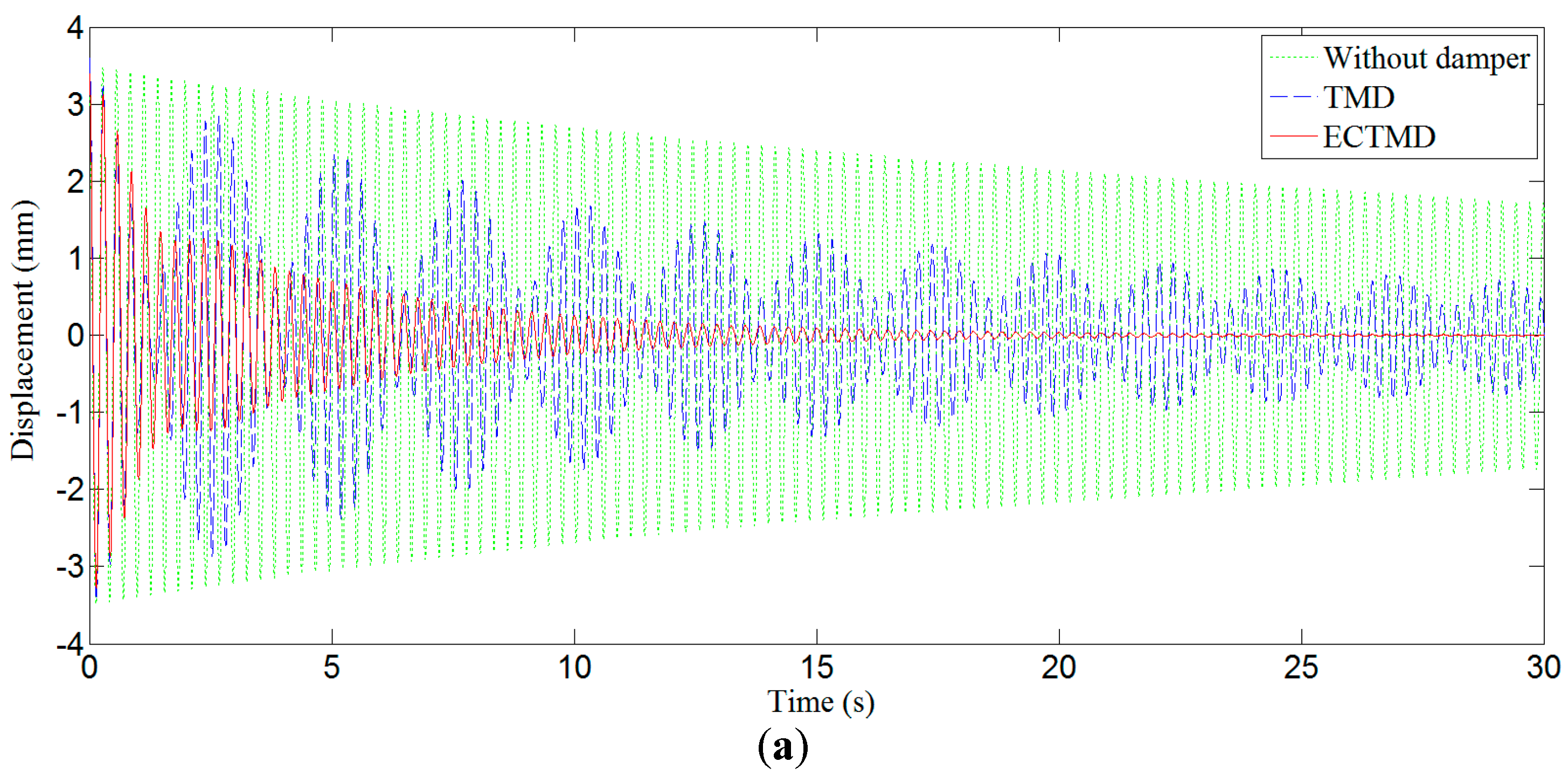

4.1. Case I: Free Vibration

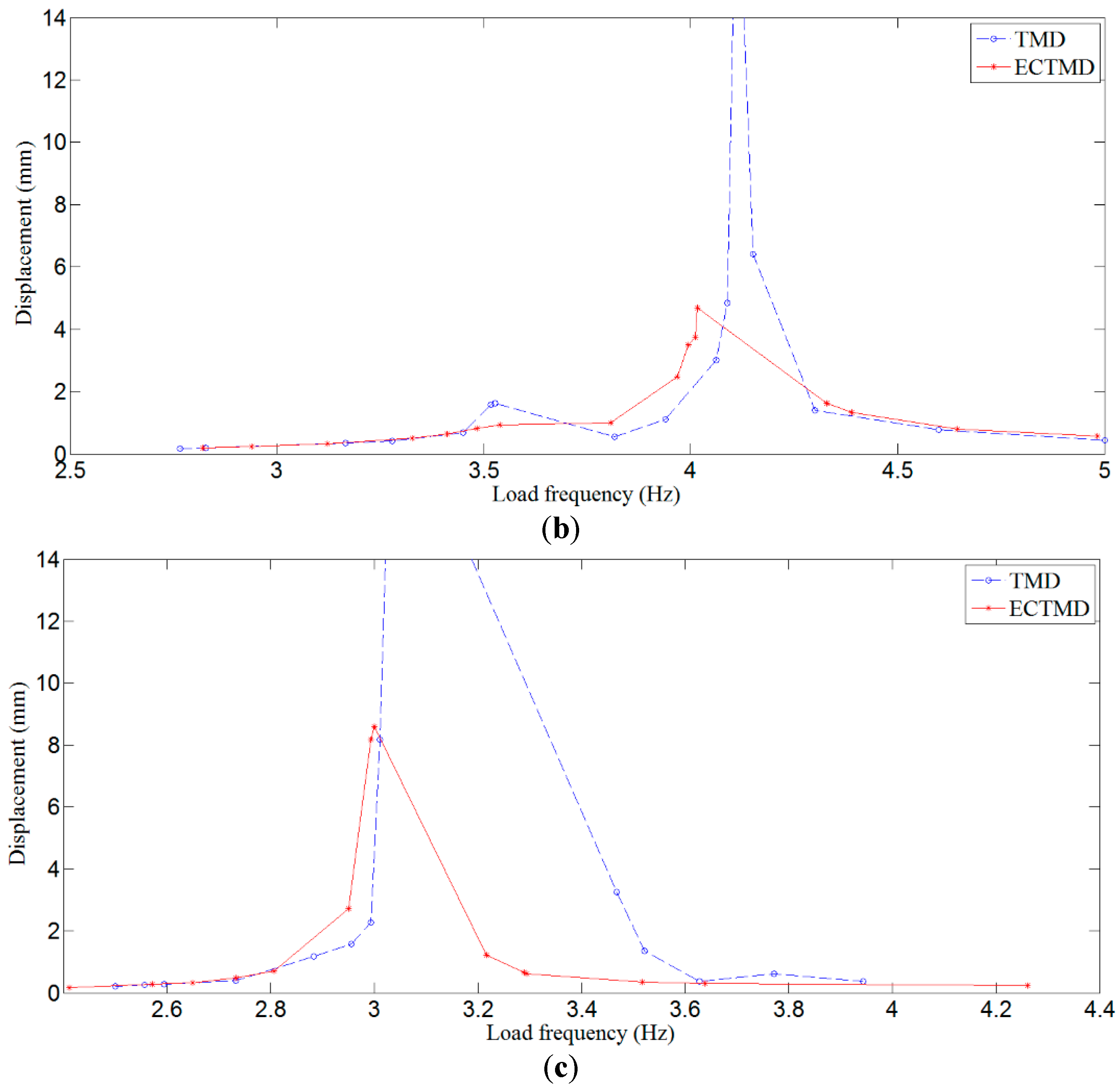

4.2. Case II: Forced Vibration

4.3. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sahasrabudhe, S.S.; Nagarajaiah, S. Semi-active control of sliding isolated bridges using MR dampers: An experimental and numerical study. Earthq. Eng. Struct. Dyn. 2005, 34, 965–983. [Google Scholar] [CrossRef]

- Ou, J.; Zhang, W. Analysis and design method for wind-induced vibration passive damping control of tall buildings. J. Build. Struct. 2003, 6, 4. [Google Scholar]

- Basu, B.; Bursi, O.S.; Casciati, F.; Casciati, S.; Del Grosso, A.E.; Domaneschi, M.; Faravelli, L.; Holnicki-Szulc, J.; Irschik, H.; Krommer, M. A european association for the control of structures joint perspective. Recent studies in civil structural control across europe. Struct. Control Health Monit. 2014, 21, 1414–1436. [Google Scholar] [CrossRef]

- Li, L.; Song, G.; Ou, J. Hybrid active mass damper (AMD) vibration suppression of nonlinear high-rise structure using fuzzy logic control algorithm under earthquake excitations. Struct. Control Health Monit. 2011, 18, 698–709. [Google Scholar] [CrossRef]

- Spencer, B., Jr.; Nagarajaiah, S. State of the art of structural control. J. Struct. Eng. 2003, 129, 845–856. [Google Scholar] [CrossRef]

- Casciati, F.; De Stefano, A.; Matta, E. Simulating a conical tuned liquid damper. Simul. Model. Pract. Theory 2003, 11, 353–370. [Google Scholar] [CrossRef]

- Casciati, F.; Faravelli, L. A passive control device with sma components: From the prototype to the model. Struct. Control Health Monit. 2009, 16, 751–765. [Google Scholar] [CrossRef]

- Casciati, F.; Rodellar, J.; Yildirim, U. Active and semi-active control of structures–theory and applications: A review of recent advances. JIMSS 2012, 23, 1181–1195. [Google Scholar] [CrossRef]

- Nagarajaiah, S.; Sonmez, E. Structures with semiactive variable stiffness single/multiple tuned mass dampers. J. Struct. Eng. 2007, 133, 67–77. [Google Scholar] [CrossRef]

- Casciati, F.; Domaneschi, M. Semi-active electro-inductive devices: Characterization and modelling. JVC 2007, 13, 815–838. [Google Scholar] [CrossRef]

- Casciati, S.; Faravelli, L.; Chen, Z. A DC-motor based active-mass-damper with wireless feedback for structural control. In Proceedings of the International Symposium on Innovation & Sustainability of Structures in Civil Engineering, Xiamen, China, 28–30 October 2011; Southeast University Press: Xiamen, China, 2011; pp. 560–565. [Google Scholar]

- Casciati, S.; Chen, Z. An active mass damper system for structural control using real-time wireless sensors. Struct. Control Health Monit. 2012, 19, 758–767. [Google Scholar] [CrossRef]

- Li, L.; Song, G.; Ou, J. Adaptive fuzzy sliding mode based active vibration control of a smart beam with mass uncertainty. Struct. Control Health Monit. 2011, 18, 40–52. [Google Scholar] [CrossRef]

- Yang, G.; Spencer, B.F., Jr.; Jung, H.-J.; Carlson, J.D. Dynamic modeling of large-scale magnetorheological damper systems for civil engineering applications. J. Eng. Mech. 2004, 130, 1107–1114. [Google Scholar] [CrossRef]

- Lu, G.; Li, Y.; Song, G. Analysis of a magneto-rheological coupler with misalignment. Smart Mater. Struct. 2011, 20, 105028. [Google Scholar] [CrossRef]

- Zhengqiang, Y.; Aiqun, L.; Youlin, X. Fluid viscous damper technology and its engineering application for structural vibration energy dissipation. J. Southeast Univ. 2002, 32, 466–473. [Google Scholar]

- Isalgue, A.; Lovey, F.C.; Terriault, P.; Martorell, F.; Torra, R.M.; Torra, V. SMA for dampers in civil engineering. Mater. Trans. 2006, 47, 682–690. [Google Scholar] [CrossRef]

- Demetriou, D.; Nikitas, N. A novel hybrid semi-active mass damper configuration for structural applications. Appl. Sci. 2016, 6, 397. [Google Scholar] [CrossRef]

- Zhang, Z.; Ou, J.; Li, D.; Zhang, S. Optimization design of coupling beam metal damper in shear wall structures. Appl. Sci. 2017, 7, 137. [Google Scholar] [CrossRef]

- Li, H.; Qian, H.; Song, G.; Gao, D. Type of shape memory alloy damper: Design, experiment and numerical simulation. J. Vib. Eng. 2008, 21, 179–184. [Google Scholar]

- Song, G.; Zhang, P.; Li, L.; Singla, M.; Patil, D.; Li, H.; Mo, Y. Vibration control of a pipeline structure using pounding tuned mass damper. J. Eng. Mech. 2016, 142, 04016031. [Google Scholar] [CrossRef]

- Lin, W.; Song, G.; Chen, S. PTMD control on a benchmark TV tower under earthquake and wind load excitations. Appl. Sci. 2017, 7, 425. [Google Scholar] [CrossRef]

- Zhao, D.; Li, H.; Song, G.; Qian, H. Experiment investigation for a new type of piezoelectric friction damper. In Proceedings of the Earth and Space 2014, St. Louis, MO, USA, 27–29 October 2014; ASCE: Reston, VA, USA, 2014; pp. 642–647. [Google Scholar]

- Yang, G.; Spencer, B.; Carlson, J.; Sain, M. Large-scale mr fluid dampers: Modeling and dynamic performance considerations. Eng. Struct. 2002, 24, 309–323. [Google Scholar] [CrossRef]

- Cao, H.; Reinhorn, A.; Soong, T. Design of an active mass damper for a tall tv tower in Nanjing, China. Eng. Struct. 1998, 20, 134–143. [Google Scholar] [CrossRef]

- Casciati, F.; Ubertini, F. Nonlinear vibration of shallow cables with semiactive tuned mass damper. Nonlinear Dyn. 2008, 53, 89–106. [Google Scholar] [CrossRef]

- Rana, R.; Soong, T. Parametric study and simplified design of tuned mass dampers. Eng. Struct. 1998, 20, 193–204. [Google Scholar] [CrossRef]

- Lin, Y.-Y.; Cheng, C.-M.; Lee, C.-H. A tuned mass damper for suppressing the coupled flexural and torsional buffeting response of long-span bridges. Eng. Struct. 2000, 22, 1195–1204. [Google Scholar] [CrossRef]

- Tubino, F.; Piccardo, G. Tuned mass damper optimization for the mitigation of human-induced vibrations of pedestrian bridges. Meccanica 2015, 50, 809–824. [Google Scholar] [CrossRef]

- Abdel-Rohman, M.; John, M.J. Control of wind-induced nonlinear oscillations in suspension bridges using a semi-active tuned mass damper. J. Vib. Control 2006, 12, 1049–1080. [Google Scholar] [CrossRef]

- Lin, C.; Wang, J.-F.; Chen, B. Train-induced vibration control of high-speed railway bridges equipped with multiple tuned mass dampers. J. Bridge Eng. 2005, 10, 398–414. [Google Scholar] [CrossRef]

- Jo, B.-W.; Tae, G.-H.; Lee, D.-W. Structural vibration of tuned mass damper-installed three-span steel box bridge. Int. J. Press. Vessels. Pip. 2001, 78, 667–675. [Google Scholar] [CrossRef]

- Kawaguchi, A.; Teramura, A.; Omote, Y. Time history response of a tall building with a tuned mass damper under wind force. J. Wind Eng. Ind. Aerodyn. 1992, 43, 1949–1960. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.S.; Lee, D.G. Mitigation of wind response of a tall building using semi-active tuned mass dampers. Struct. Des. Tall Spec. Build. 2011, 20, 552–565. [Google Scholar] [CrossRef]

- Youssef, N. Supertall buildings with tuned mass damper. Struct. Des. Tall Spec. Build. 1994, 3, 1–12. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, F. A novel eddy current damper: Theory and experiment. J. Phys. D Appl. Phys. 2009, 42, 075001. [Google Scholar] [CrossRef]

- Sodano, H.A.; Bae, J.-S.; Inman, D.J.; Belvin, W.K. Concept and model of eddy current damper for vibration suppression of a beam. J. Sound Vib. 2005, 288, 1177–1196. [Google Scholar] [CrossRef]

- Van Beek, T.; Pluk, K.; Jansen, J.; Lomonova, E. Optimization and measurement of eddy current damping applied in a tuned mass damper. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; IEEE: New York, NY, USA; pp. 609–615. [Google Scholar]

- Bae, J.-S.; Kwak, M.K.; Inman, D.J. Vibration suppression of a cantilever beam using eddy current damper. J. Sound Vib. 2005, 284, 805–824. [Google Scholar] [CrossRef]

- Zhang, H.; Kou, B.; Jin, Y.; Zhang, L.; Zhang, H.; Li, L. Modeling and analysis of a novel planar eddy current damper. J. Appl. Phys. 2014, 115, 17E709. [Google Scholar] [CrossRef]

- Bae, J.-S.; Hwang, J.-H.; Kwag, D.-G.; Park, J.; Inman, D.J. Vibration suppression of a large beam structure using tuned mass damper and eddy current damping. Shock Vib. 2014, 2014, 893914. [Google Scholar] [CrossRef]

- Ao, W.K.; Reynolds, P. Analytical and experimental study of eddy current damper for vibration suppression in a footbridge structure. In Dynamics of Civil Structures; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: New York, NY, USA, 2017; pp. 131–138. [Google Scholar]

- Niu, H.; Chen, Z.; Lei, X.; Hua, X. Development of eddy current turned mass damper for suppressing windinduced vibration of bridge hangers. In Proceedings of the 6th European and African Wind Engineering Conference, Cambridge, UK, 7–11 July 2013. [Google Scholar]

- Lu, X.; Zhang, Q.; Weng, D.; Zhou, Z.; Wang, S.; Mahin, S.A.; Ding, S.; Qian, F. Improving performance of a super tall building using a new eddy-current tuned mass damper. Struct. Control Health Monit. 2017, 24, e1882. [Google Scholar] [CrossRef]

- Li, H.; Zhang, P.; Song, G.; Patil, D.; Mo, Y. Robustness study of the pounding tuned mass damper for vibration control of subsea jumpers. Smart Mater. Struct. 2015, 24, 095001. [Google Scholar] [CrossRef]

- Thomson, W.T.; Dahleh, M.D. Theory of Vibration with Applications, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1998; pp. 131–135. ISBN 013651068X. [Google Scholar]

| Parameter | Value |

|---|---|

| Material | Stainless steel 304 |

| Length | 750 mm |

| Width | 40 mm |

| Thickness | 5 mm |

| Adjustable frequency range | 3.06 Hz~4.05 Hz |

| Parameter | Value |

|---|---|

| Material | Stainless steel 304 |

| Length | 180 mm |

| Width | 30 mm |

| Thickness | 0.3 mm |

| Parameter | Value |

|---|---|

| Material | Copper |

| Thickness | 1 mm |

| Parameter | Value |

|---|---|

| Material | N35 (NdFeB) |

| Diameter | 12 mm |

| Height | 10 mm |

| Detuned Ratio | Without Control | With TMD | With ECTMD |

|---|---|---|---|

| γ = 14.7% | 0.18% | 0.22% | 1.3% |

| γ = 0 | 0.14% | 0.53% | 1.39% |

| γ = −13.3% | 0.11% | 0.13% | 0.27% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Lu, G.; Li, Y.; Wang, T.; Wang, W.; Song, G. Experimental Study on Robustness of an Eddy Current-Tuned Mass Damper. Appl. Sci. 2017, 7, 895. https://doi.org/10.3390/app7090895

Chen J, Lu G, Li Y, Wang T, Wang W, Song G. Experimental Study on Robustness of an Eddy Current-Tuned Mass Damper. Applied Sciences. 2017; 7(9):895. https://doi.org/10.3390/app7090895

Chicago/Turabian StyleChen, Junda, Guangtao Lu, Yourong Li, Tao Wang, Wenxi Wang, and Gangbing Song. 2017. "Experimental Study on Robustness of an Eddy Current-Tuned Mass Damper" Applied Sciences 7, no. 9: 895. https://doi.org/10.3390/app7090895