Experimental and Numerical Study on the Seismic Performance of Prefabricated Reinforced Masonry Shear Walls

Abstract

:1. Introduction

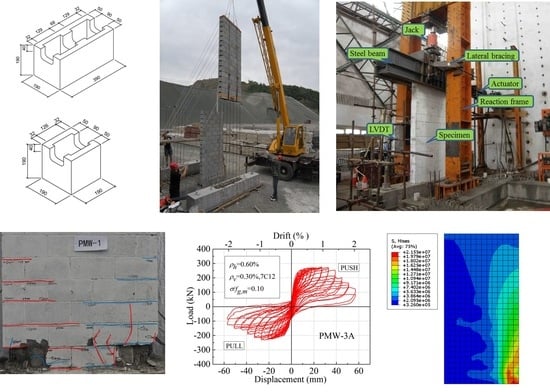

2. Experimental Program

2.1. Material Properties

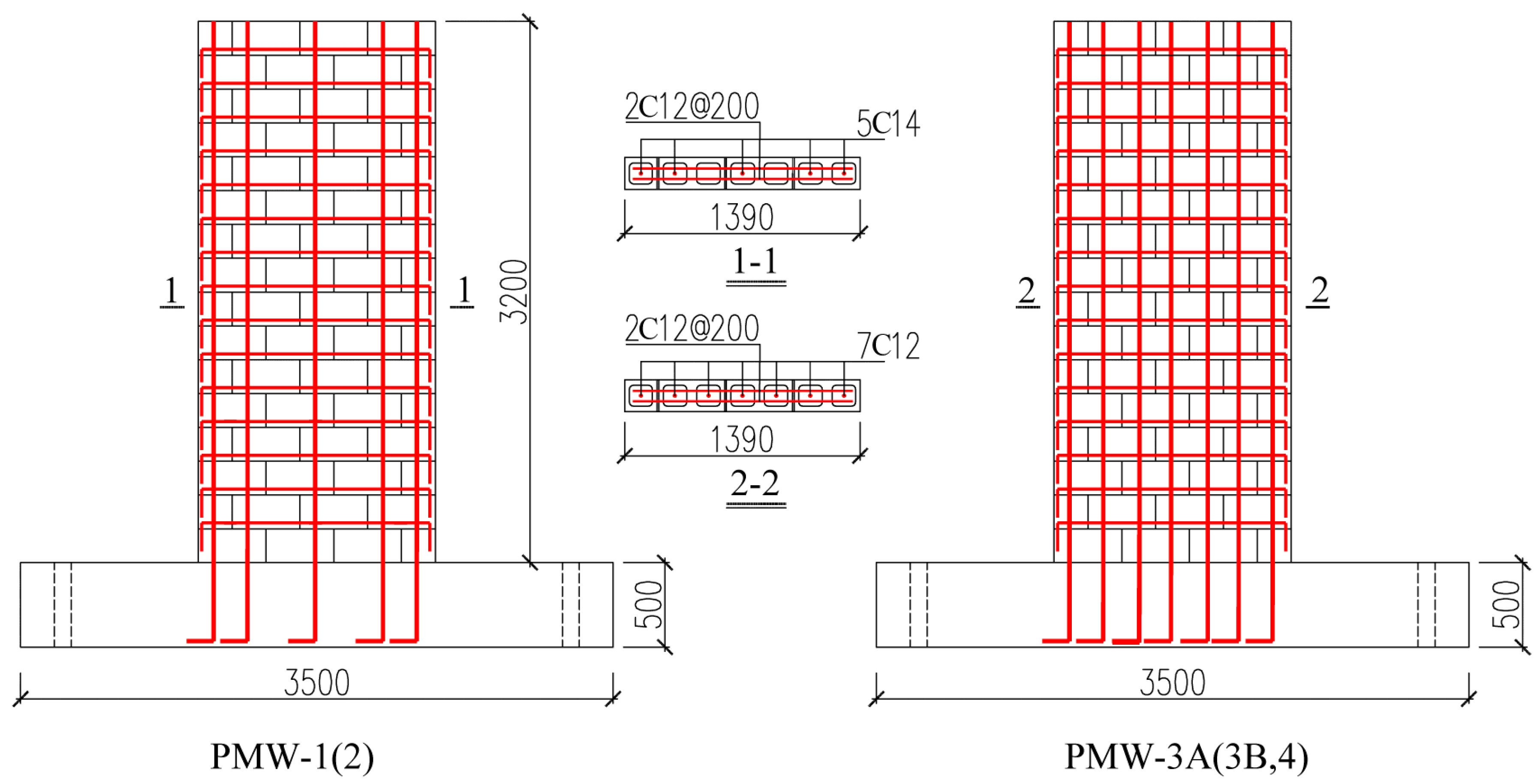

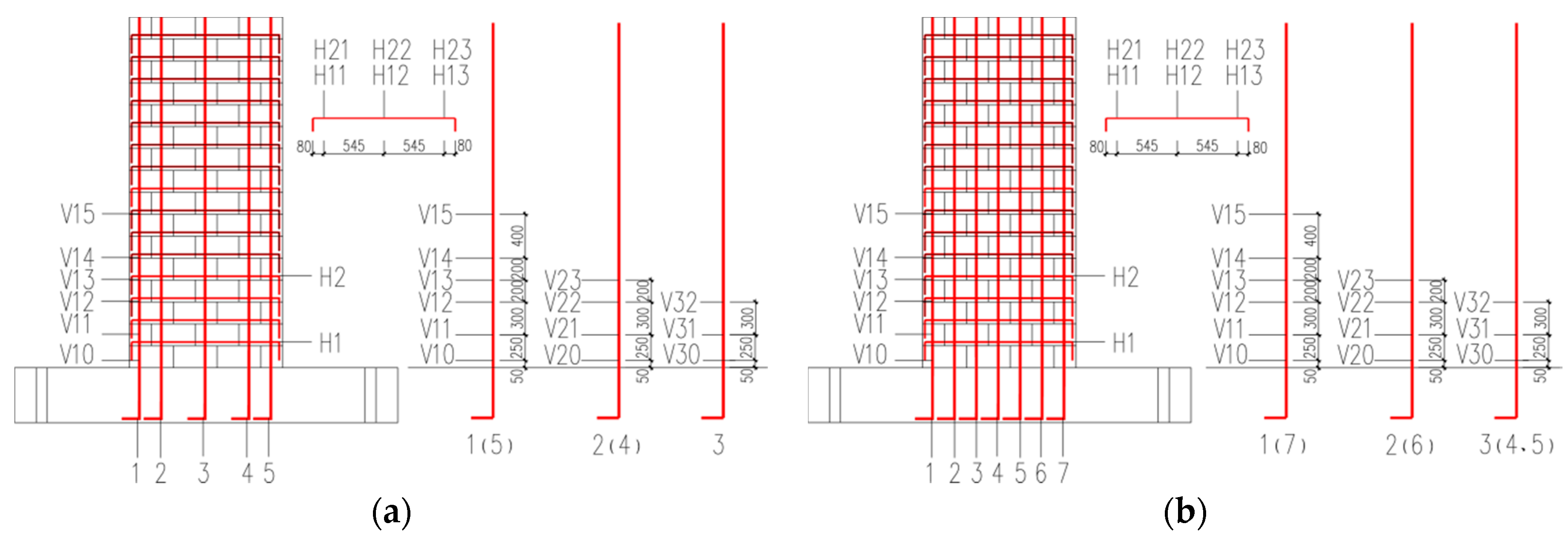

2.2. Design and Prefabricated Construction of Test Specimens

2.3. Test Setup, Instrumentation, and Loading Procedure

3. Experimental Results

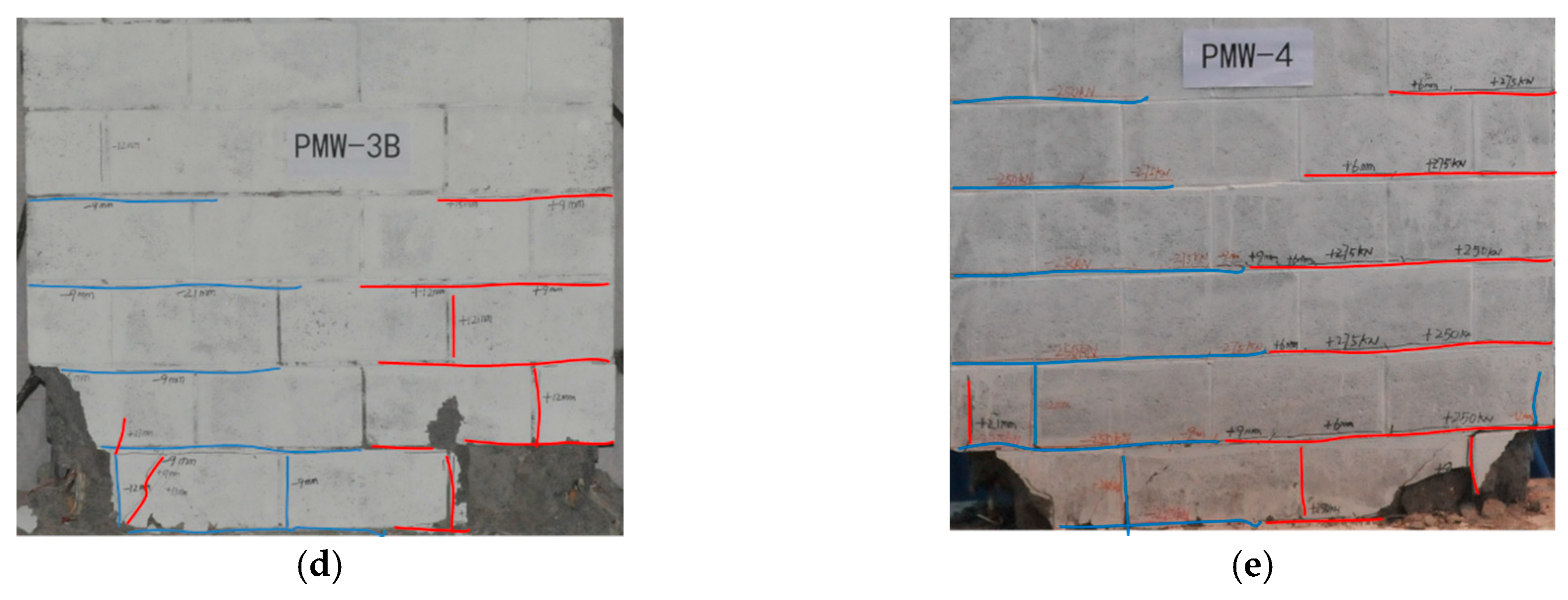

3.1. Cracking Pattern

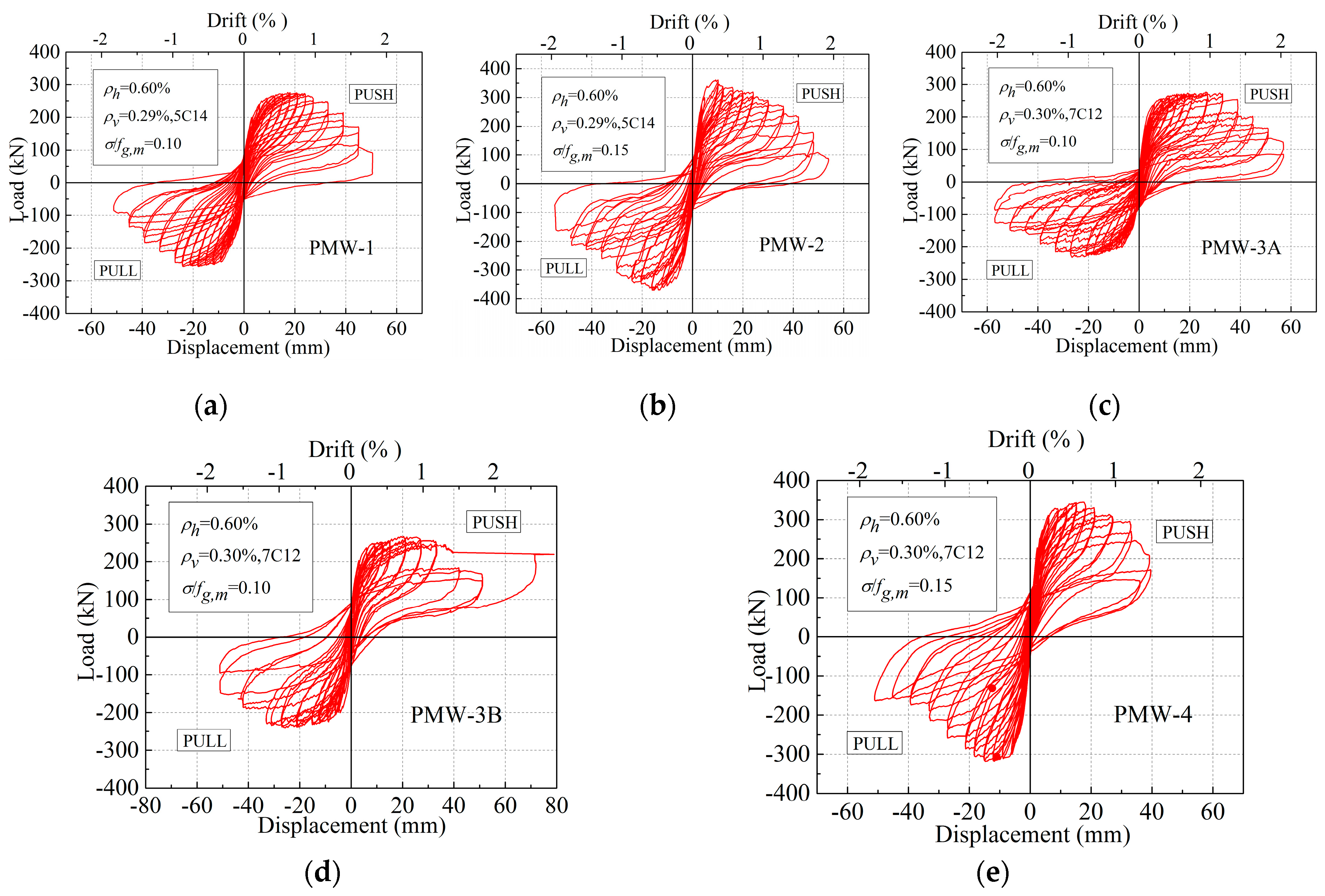

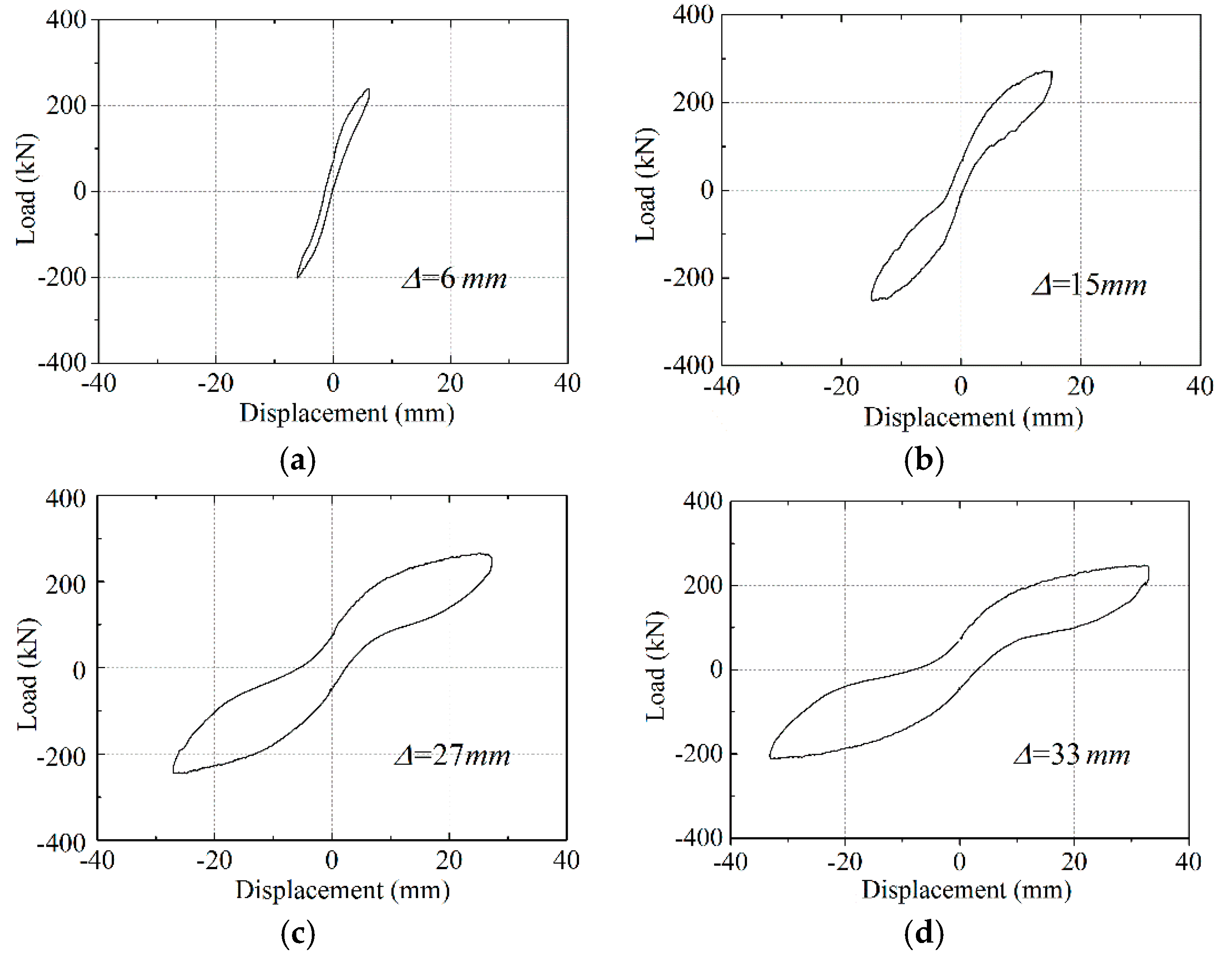

3.2. Hysteresis Curve

3.3. Lateral Load Capacity

4. Experimental Analysis

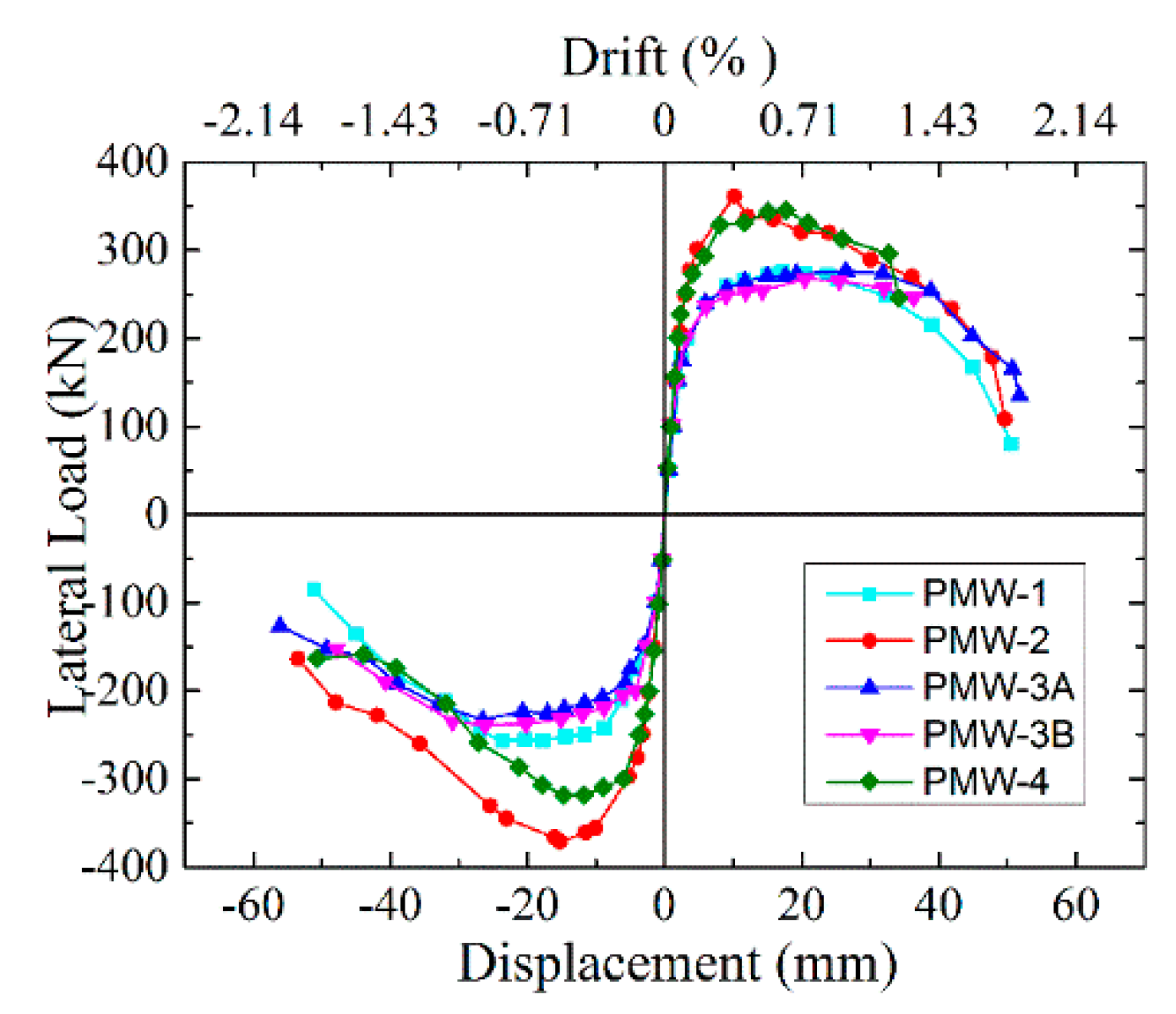

4.1. Envelope Curve

4.1.1. Analysis

4.1.2. Envelope Curve Generalization

4.2. Lateral Drift

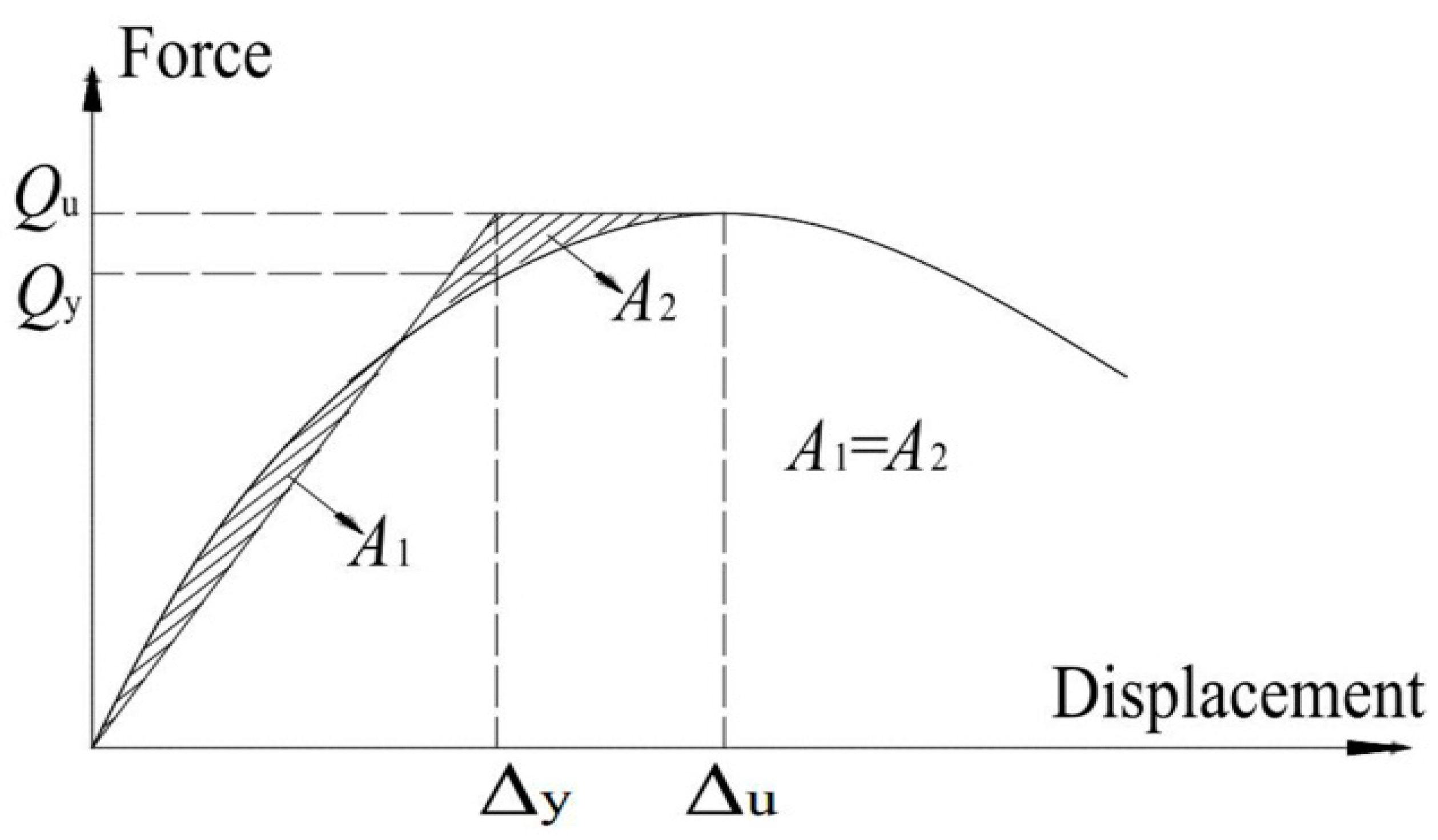

4.3. Displacement Ductility

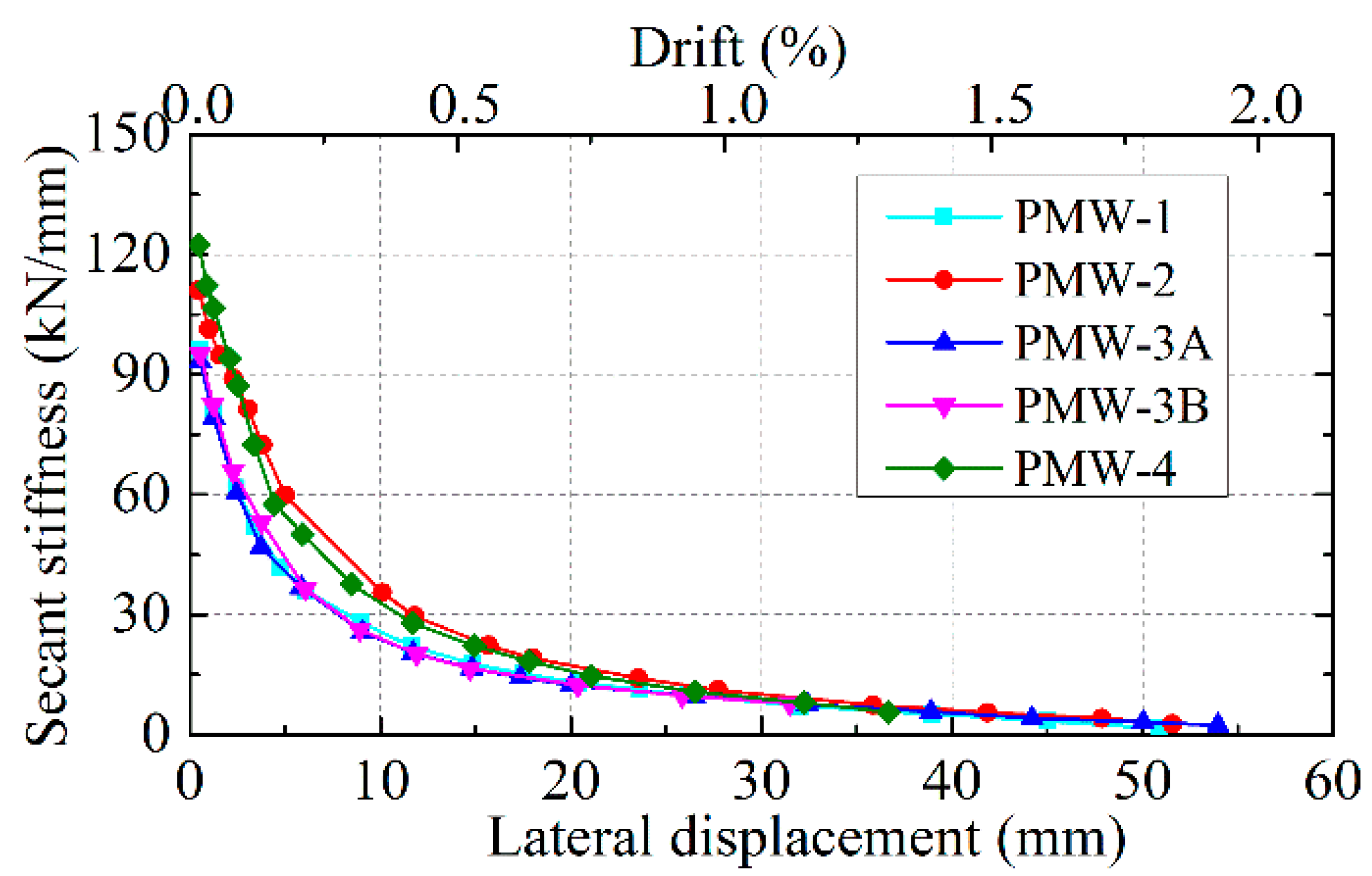

4.4. Degradation of Stiffness

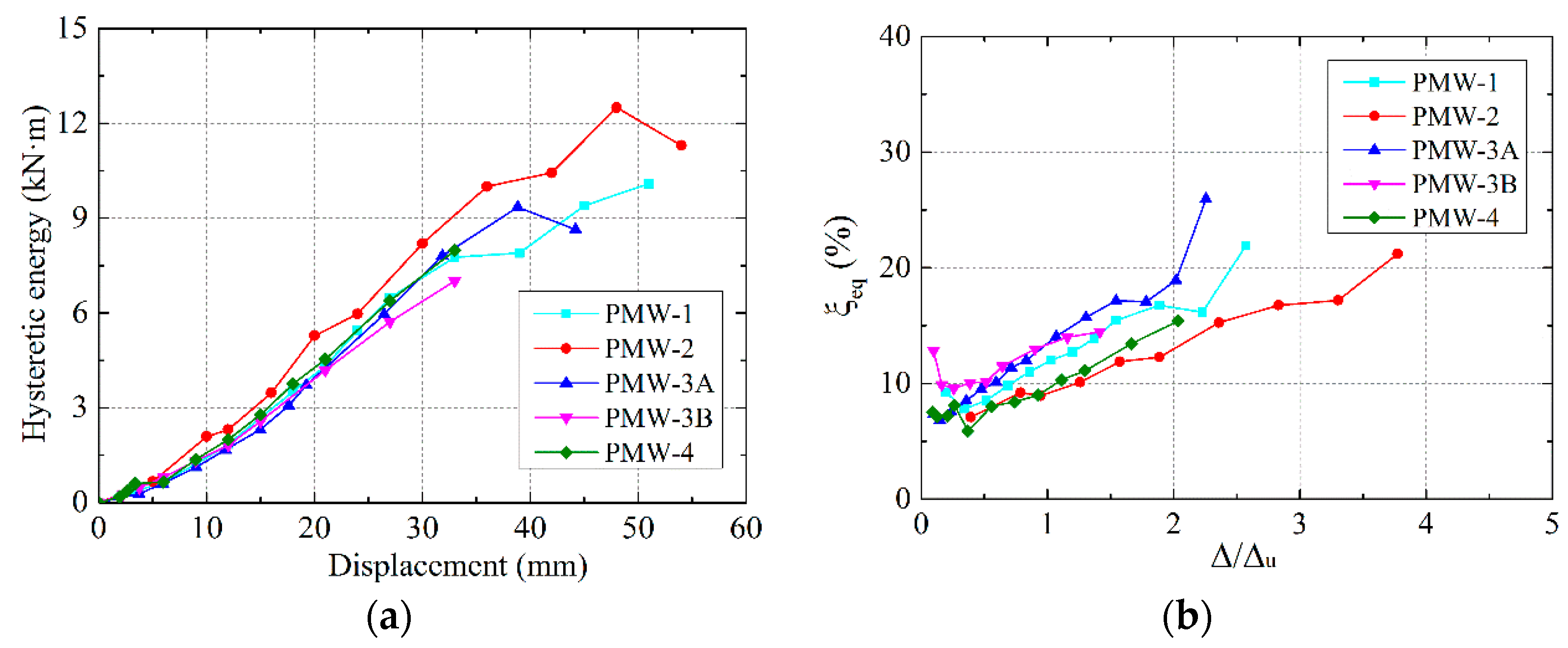

4.5. Energy Dissipation and Equivalent Viscous Damping

5. Numerical Analysis

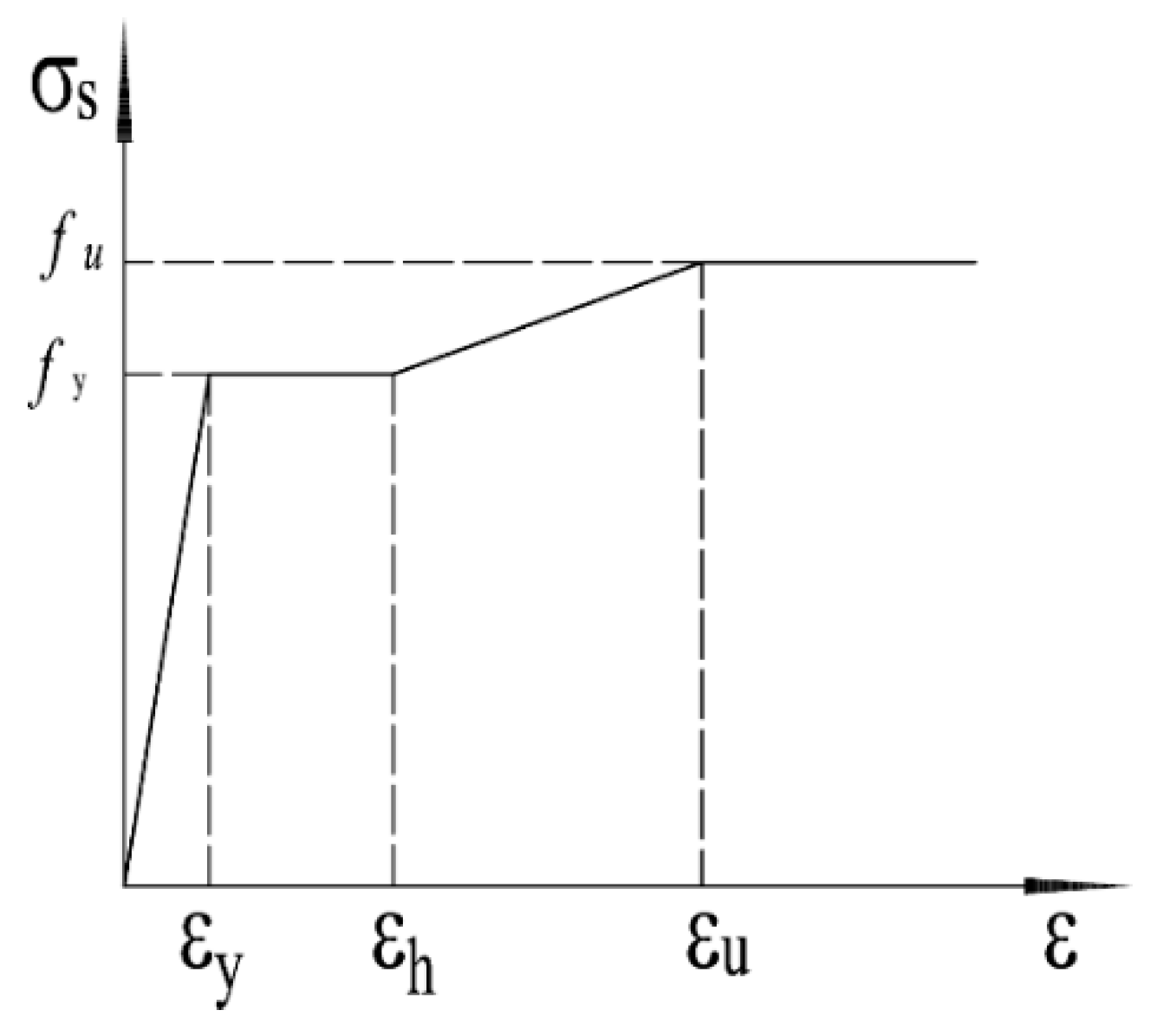

5.1. Material Constitutive Model

5.2. Finite Element Model

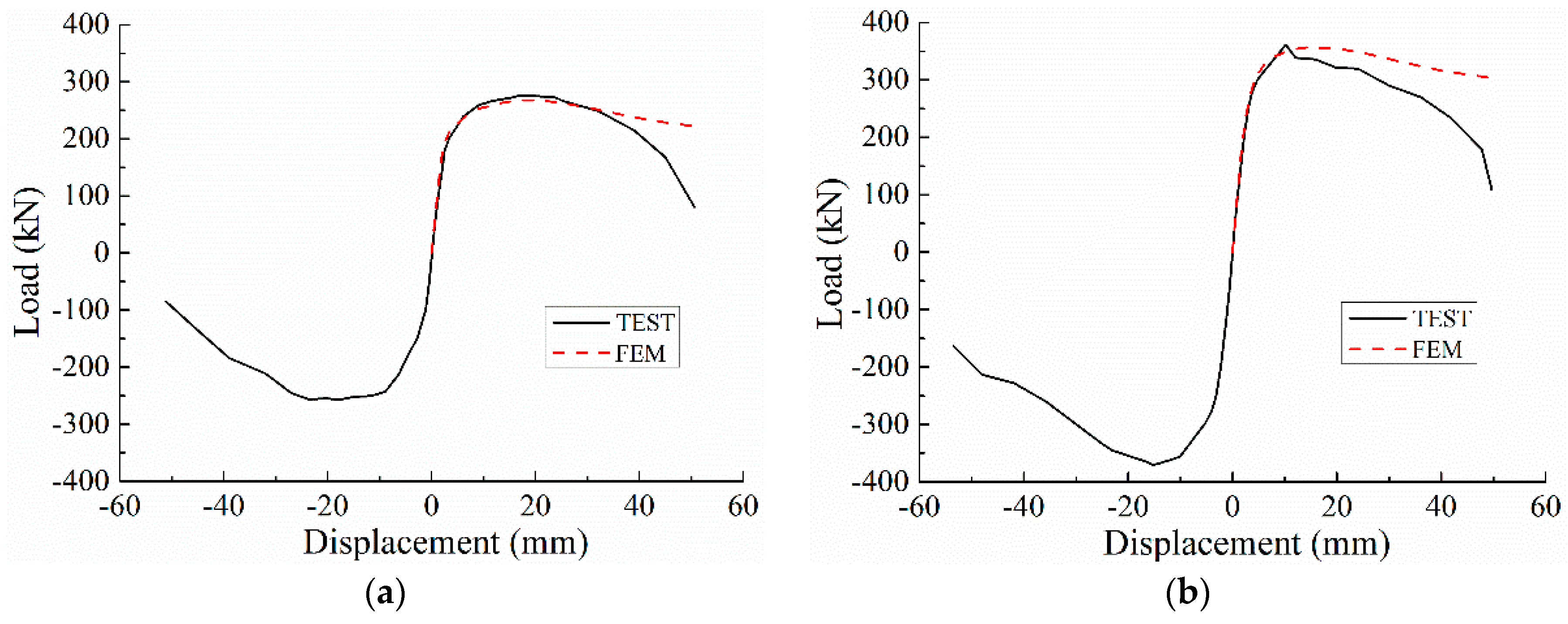

5.3. Simulation Results

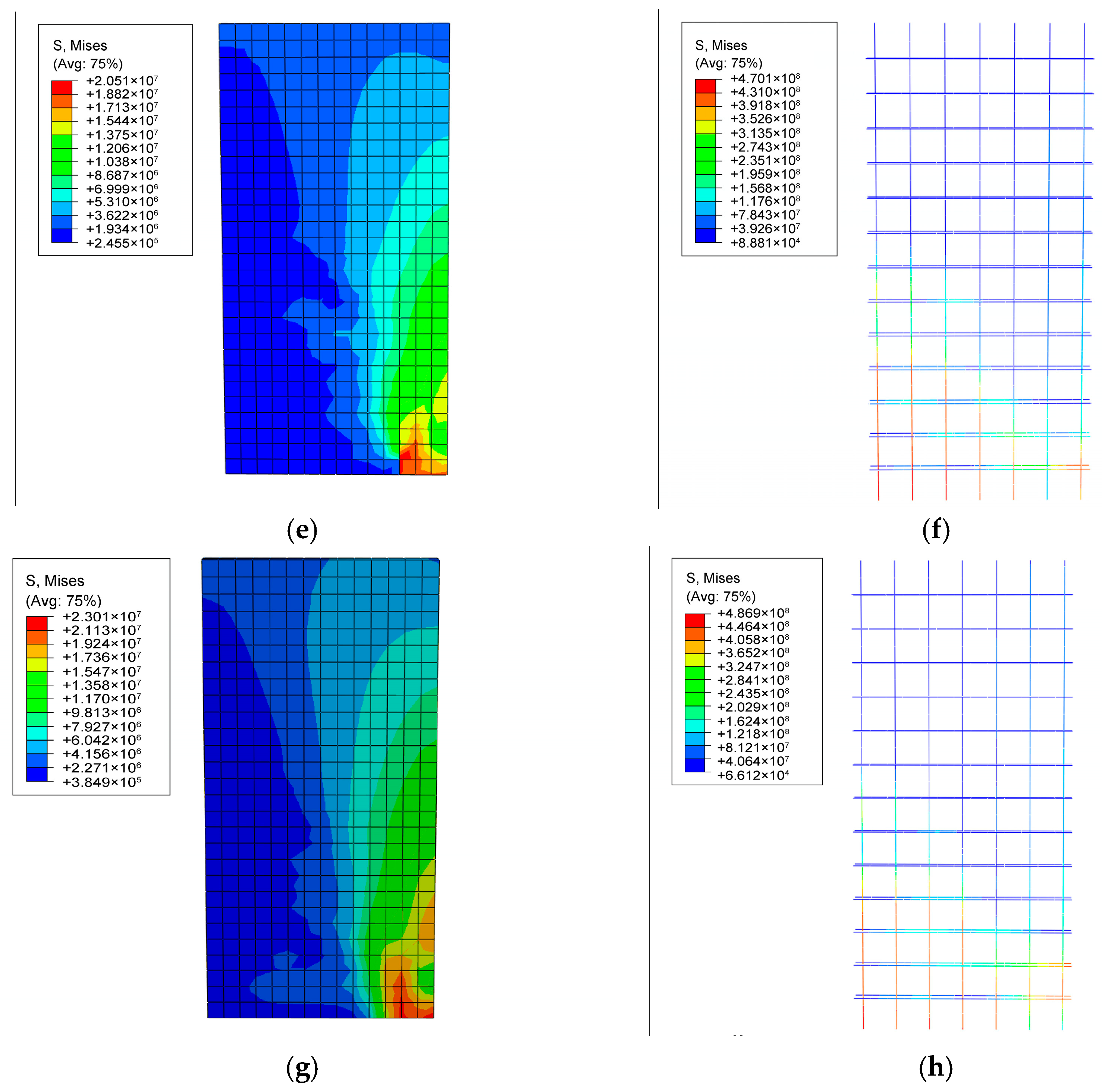

5.3.1. Stress Distribution

5.3.2. Envelope Curve

6. Summary and Conclusions

- The PRMSW exhibited acceptable flexural capacities and seismic performance stability under cyclic loading.

- The distribution of the vertical rebar had an effect on the inelastic behavior of the shear wall. The specimens with concentrated vertical rebar at the sides exhibited relatively higher load capacity and less ductility compared to the walls with evenly distributed rebar, under the same vertical reinforcement ratio. Nonetheless, minimal influence from the distribution of the vertical reinforcement was found on the stiffness degradation of the PRMSW.

- Axial stress had a significant influence on the seismic performance of the PRMSW. The increase of the axial stress lead to higher flexural strength and initial stiffness but the more brittle inelastic behavior of the PRMSW.

- The PRMSW showed excellent ductile behavior in the plastic stage. The average drift values of the specimens at failure ranged from 0.95% to 1.40%, and the PRMSW under seismic design could be assigned the inelastic drift limit value of 1/120. The PRMSW exhibited favorable energy capacity, and the specimens with a lower axial stress and evenly distributed rebar exhibited a more efficient energy dissipation. The equivalent viscous damping ratio of the PRMSW was 9% to 13% at ultimate load.

- The finite element simulation of the PRMSW basically agrees well with the experimental results. The results obtained from the numerical analysis indicate that the concrete damaged plasticity model in ABAQUS can be used for the seismic performance simulation of the prefabricated reinforced masonry shear walls.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, J.; Wang, Y.; Lu, Z.; Li, J. Experimental Study and Numerical Simulation of a Laminated Reinforced Concrete Shear Wall with a Vertical Seam. Appl. Sci. 2017, 7, 629. [Google Scholar] [CrossRef]

- Todut, C.; Dan, D.; Stoian, V. Theoretical and experimental study on prefabricated reinforced concrete wall panels subjected to shear force. Eng. Struct. 2014, 80, 323–338. [Google Scholar] [CrossRef]

- Wu, L.; Tian, Y.; Su, Y.; Chen, H. Seismic performance of prefabricated composite shear walls reinforced by concrete-filled steel tubes. Eng. Struct. 2018, 162, 72–83. [Google Scholar] [CrossRef]

- Wang, F.L.; Zhang, X.C.; Zhu, F. Research progress and low-carbon property of reinforced concrete block masonry structures in China. In Proceedings of the 16th International Brick and Block Masonry Conference, Padova, Italy, 26–30 June 2016. [Google Scholar]

- Xu, W.; Yang, X.; Wang, F. Experimental Investigation on the Seismic Behavior of Newly-Developed Precast Reinforced Concrete Block Masonry Shear Walls. Appl. Sci. 2018, 8, 1071. [Google Scholar] [CrossRef]

- Shing, P.B.; Schuller, M.; Houskere, V.S.; Carter, E. Flexural and shear response of reinforced masonry walls. Struct. J. 1990, 87, 646–656. [Google Scholar]

- Voon, K.C.; Ingham, J.M. Experimental in-plane shear strength investigation of reinforced concrete masonry walls. J. Struct. Eng. 2006, 3, 400–408. [Google Scholar] [CrossRef]

- Hori, N.; Inoue, N.; Purushotam, D.; Nishida, T.; Kobayashi, J. Experimental and analytical studies on earthquake resisting behaviour of confined concrete block masonry structures. Earthq. Eng. Struct. D 2006, 35, 1699–1719. [Google Scholar] [CrossRef]

- Ahmadi, F.; Hernandez, J.; Sherman, J.; Kapoi, C.; Klingner, R.E.; McLean, D.I. Seismic performance of cantilever-reinforced concrete masonry shear walls. J. Struct. Eng. 2014, 140, 04014051. [Google Scholar] [CrossRef]

- Shedid, M.T.; Drysdale, R.G.; El-Dakhakhni, W.W. Behavior of fully grouted reinforced concrete masonry shear walls failing in flexure: Experimental results. J. Struct. Eng. 2008, 134, 1754–1767. [Google Scholar] [CrossRef]

- Shedid, M.T.; El-Dakhakhni, W.W. Plastic hinge model and displacement-based seismic design parameter quantifications for reinforced concrete block structural walls. J. Struct. Eng. 2014, 140, 04013090. [Google Scholar] [CrossRef]

- Ezzeldin, M.; Wiebe, L.; El-Dakhakhni, W. Seismic collapse risk assessment of reinforced masonry walls with boundary elements using the FEMA p695 methodology. J. Struct. Eng. 2016, 142, 04016108. [Google Scholar] [CrossRef]

- Ibrahim, S.K.; Suter, G.T. Ductility of concrete masonry shear walls subjected to cyclic loading. In Proceedings of the Eighth North American Masonry Conference, Austin, TX, USA, 6–9 June 1999. [Google Scholar]

- Eikanas, I.K. Behavior of Concrete Masonry Shear Walls with Varying Aspect Ratio and Flexural Reinforcement. Master’s Thesis, Washington State University, Pullman, WA, USA, 2003. [Google Scholar]

- Shedid, M.T.; El-Dakhakhni, W.W.; Drysdale, R.G. Characteristics of Rectangular, Flanged, and End-Confined Reinforced Concrete Masonry Shear Walls for Seismic Design. J. Struct. Eng. 2010, 136, 1471–1482. [Google Scholar] [CrossRef]

- Hibbitt, D.; Karlsson, B.; Sorensen, P. Abaqus/CAE User’s Manual; ABAQUS Inc.: Pawtucket, RI, USA, 2016. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Test Methods for Concrete Block and Brick; GB/T 4111-2013; Architecture & Industry Press of China: Beijing, China, 2013.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard Test Method for Performance of Building Mortar; JGJ/T 70-2009; Architecture & Industry Press of China: Beijing, China, 2010.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Evaluation of Concrete Compressive Strength; GB/T 50107-2010; Architecture & Industry Press of China: Beijing, China, 2010.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Method of Basic Mechanics Properties of Masonry; GB/T 50129-2011; Architecture & Industry Press of China: Beijing, China, 2011.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Guide for the Implementation of Metallic Materials at Room Temperature Tensile Test Method; GB/T 228-2010; Architecture & Industry Press of China: Beijing, China, 2010.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Seismic Design of Buildings; GB 50011-2010; Architecture & Building Press: Beijing, China, 2010.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Masonry Structures; GB 50003-2011; Architecture & Industry Press: Beijing, China, 2011.

- Haach, V.G.; Vasconcelos, G.A.; Lourenço, P.B. Experimental Analysis of Reinforced Concrete Block Masonry Walls Subjected to In-Plane Cyclic Loading. J. Struct. Eng. 2010, 136, 452–462. [Google Scholar] [CrossRef]

- Park, Y.J.; Ang, A.H.; Wen, Y.K. Seismic damage analysis of reinforced concrete buildings. J. Struct. Eng. 1985, 111, 740–757. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Lu, Z. Experimental study on seismic behavior of steel plate reinforced concrete composite shear wall. Eng. Struct. 2018, 160, 281–292. [Google Scholar] [CrossRef]

- Lu, X.L. Seismic Theory of Complex High-Rise Structures with Application; Science Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Park, R. Ductility evaluation from laboratory and analytical testing. In Proceedings of the Ninth World Conference on Earthquake Engineering, Tokyo-Kyoto, Japan, 2–9 August 1988; pp. 605–616. [Google Scholar]

- Ma, G.; Huang, L.; Yan, L.; Kasal, B.; Chen, L.; Tao, C. Experimental performance of reinforced double H-block masonry shear walls under cyclic loading. Mater. Struct. 2017, 50, 70. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Wang, Z.H. Seismic behavior of reinforced concrete shear walls subjected to high axial loading. J. Struct. Eng. 2000, 97, 739–750. [Google Scholar]

- Shedid, M.T. Ductility of Reinforced Concrete Masonry Shear Walls. Master’s Thesis, Department of Civil Engineering, McMaster University, Hamilton, ON, Canada, 2006. [Google Scholar]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Liu, W.; Cao, W.; Zhang, J.; Qiao, Q.; Ma, H. Seismic Performance of Composite Shear Walls Constructed Using Recycled Aggregate Concrete and Different Expandable Polystyrene Configurations. Materials 2016, 9, 148. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.H.; Karimi, M.S.; Kheyroddin, A.; Shahkarami, A.A. Experimental and Numerical Study on Seismic Behavior of An Infilled Masonry Wall Compared to An Arched Masonry Wall. Structures 2016, 8, 144–153. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, L.; Zhai, C.; Zhai, X. Experimental Research on Grouted Concrete Block Masonry’s Constitutive Law under Plain Stress State. J. Harbin. Inst. Technol. 2007, 39, 1900–1903. [Google Scholar]

| Specimen | Wall Dimensions (mm) | Reinforcement | Axial Load (Compression Ratio) | |||

|---|---|---|---|---|---|---|

| (Length × Height × Thickness) | Vertical | Horizontal | ||||

| PMW-1 | 1390 × 3200 × 190 | 5C14 | 0.29% | 2C12@200 | 0.60% | 670 kN (0.10) |

| PMW-2 | 1390 × 3200 × 190 | 5C14 | 0.29% | 2C12@200 | 0.60% | 1000 kN (0.15) |

| PMW-3A | 1390 × 3200 × 190 | 7C12 | 0.30% | 2C12@200 | 0.60% | 670 kN (0.10) |

| PMW-3B | 1390 × 3200 × 190 | 7C12 | 0.30% | 2C12@200 | 0.60% | 670 kN (0.10) |

| PMW-4 | 1390 × 3200 × 190 | 7C12 | 0.30% | 2C12@200 | 0.60% | 1000 kN (0.15) |

| Wall | Initical Horizontal Cracking | Maximum Load | Qcr/Qu | Qu,average (kN) | Failure Mode | |||

|---|---|---|---|---|---|---|---|---|

| Qcr (kN) | (mm) | Qu (kN) | ||||||

| PMW-1 | + | 150 | 2.0 | 276 | 17.2 | 0.54 | 267 | Flexure |

| − | 150 | 2.8 | 257 | 17.8 | 0.58 | |||

| PMW-2 | + | 250 | 3.0 | 360 | 10.2 | 0.69 | 366 | Flexure |

| − | 200 | 2.3 | 371 | 15.3 | 0.54 | |||

| PMW-3A | + | 175 | 2.4 | 277 | 26.5 | 0.63 | 255 | Flexure |

| − | 150 | 2.8 | 233 | 26.5 | 0.64 | |||

| PMW-3B | + | 200 | 2.9 | 267 | 20.5 | 0.75 | 254 | Flexure |

| − | 150 | 2.5 | 240 | 26.2 | 0.63 | |||

| PMW-4 | + | 200 | 2.0 | 345 | 17.7 | 0.58 | 332 | Flexure |

| − | 200 | 2.3 | 318 | 14.7 | 0.63 | |||

| Wall | Displacement (mm) | Drift and Displacement Ductility | |||||

|---|---|---|---|---|---|---|---|

| (%) | (%) | ||||||

| PMW-1 | 6.4 | 17.5 | 33.0 | 2.7 | 0.63 | 5.2 | 1.18 |

| PMW-2 | 5.9 | 12.8 | 26.6 | 2.2 | 0.46 | 4.5 | 0.95 |

| PMW-3A | 6.4 | 26.5 | 39.3 | 4.1 | 0.95 | 6.1 | 1.40 |

| PMW-3B | 6.2 | 23.4 | 38.5 | 3.8 | 0.84 | 6.2 | 1.38 |

| PMW-4 | 5.4 | 16.2 | 28.7 | 3.0 | 0.58 | 5.3 | 1.03 |

| Parameter | Dilation Angle | Eccentricity | K | Viscosity Parameter | |

|---|---|---|---|---|---|

| PRMSW | 37 | 0.1 | 1.16 | 0.667 | 0.0015 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Yang, X.; Wang, F.; Chi, B. Experimental and Numerical Study on the Seismic Performance of Prefabricated Reinforced Masonry Shear Walls. Appl. Sci. 2018, 8, 1856. https://doi.org/10.3390/app8101856

Xu W, Yang X, Wang F, Chi B. Experimental and Numerical Study on the Seismic Performance of Prefabricated Reinforced Masonry Shear Walls. Applied Sciences. 2018; 8(10):1856. https://doi.org/10.3390/app8101856

Chicago/Turabian StyleXu, Weifan, Xu Yang, Fenglai Wang, and Bin Chi. 2018. "Experimental and Numerical Study on the Seismic Performance of Prefabricated Reinforced Masonry Shear Walls" Applied Sciences 8, no. 10: 1856. https://doi.org/10.3390/app8101856