Obtaining Vital Distances Using Wearable Inertial Measurement Unit for Real-Time, Biomechanical Feedback Training in Hammer-Throw

Abstract

1. Introduction

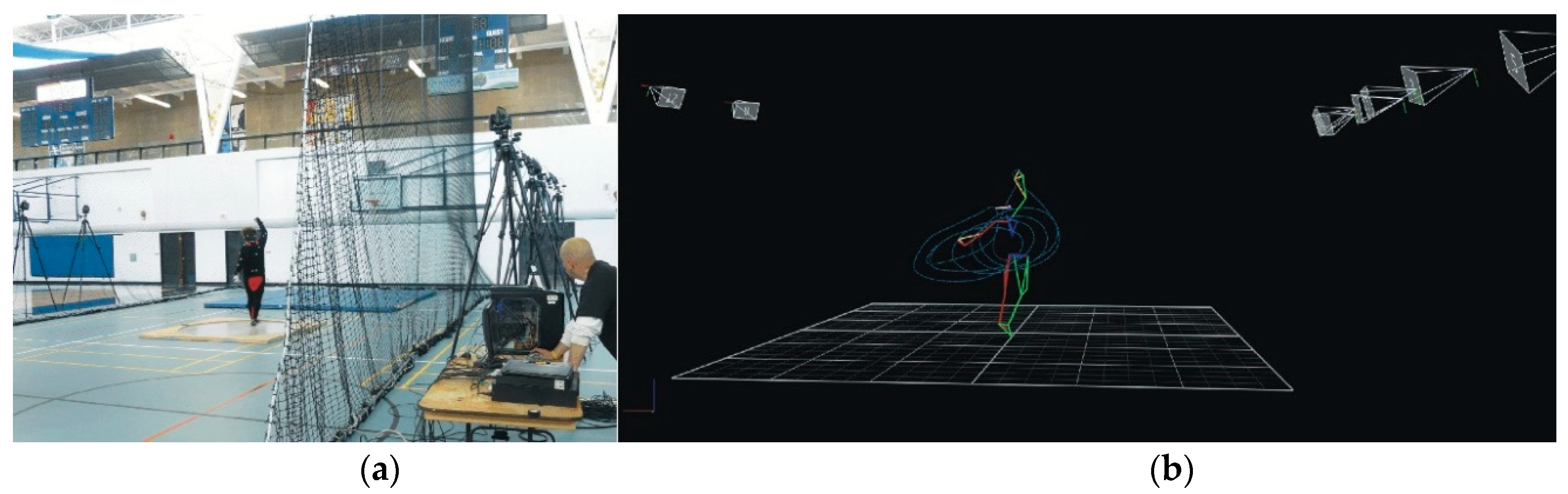

2. Materials and Methods

2.1. Hardware Configuration

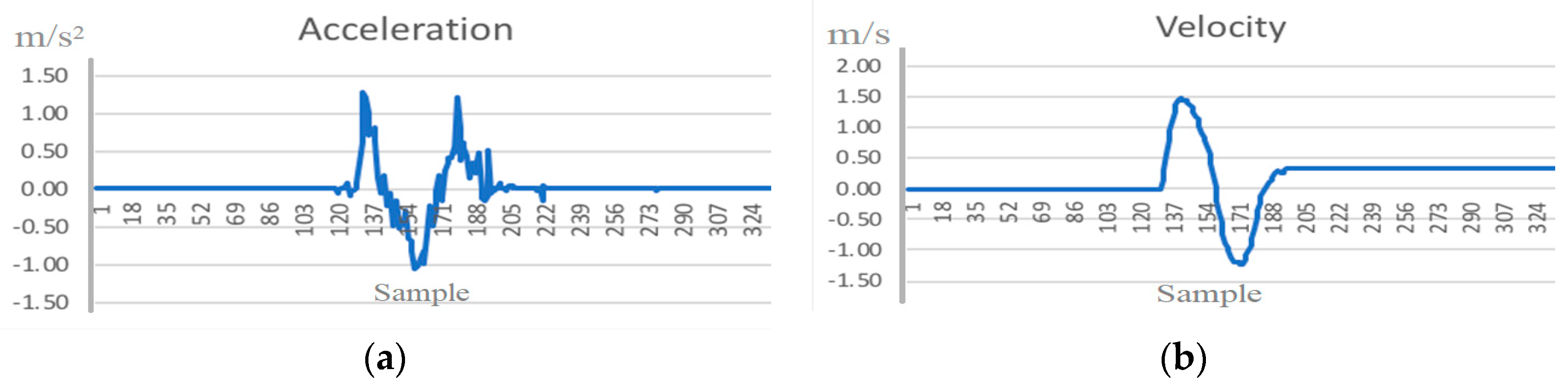

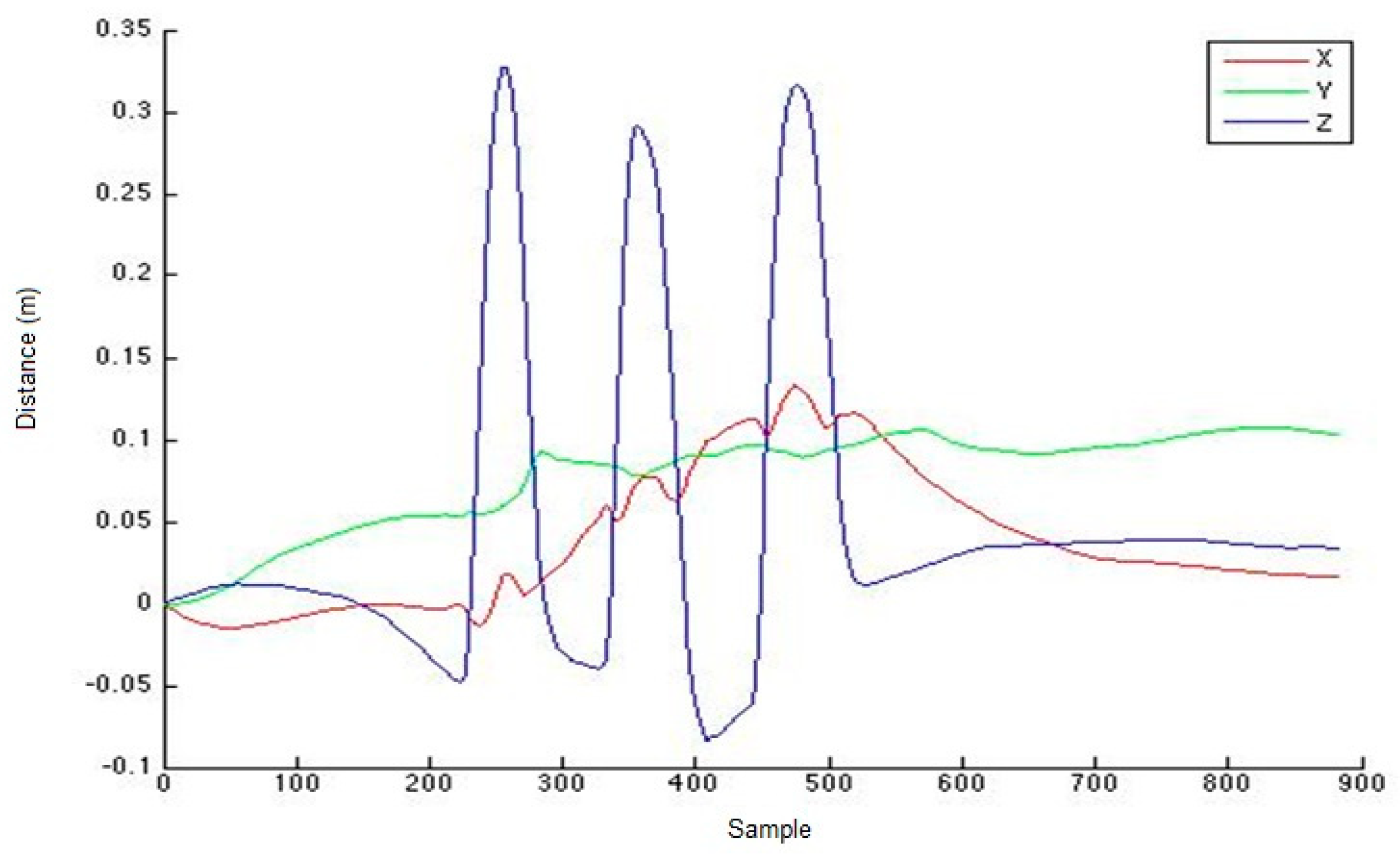

2.2. Methodology

2.3. Our Prototype and In-Field Test

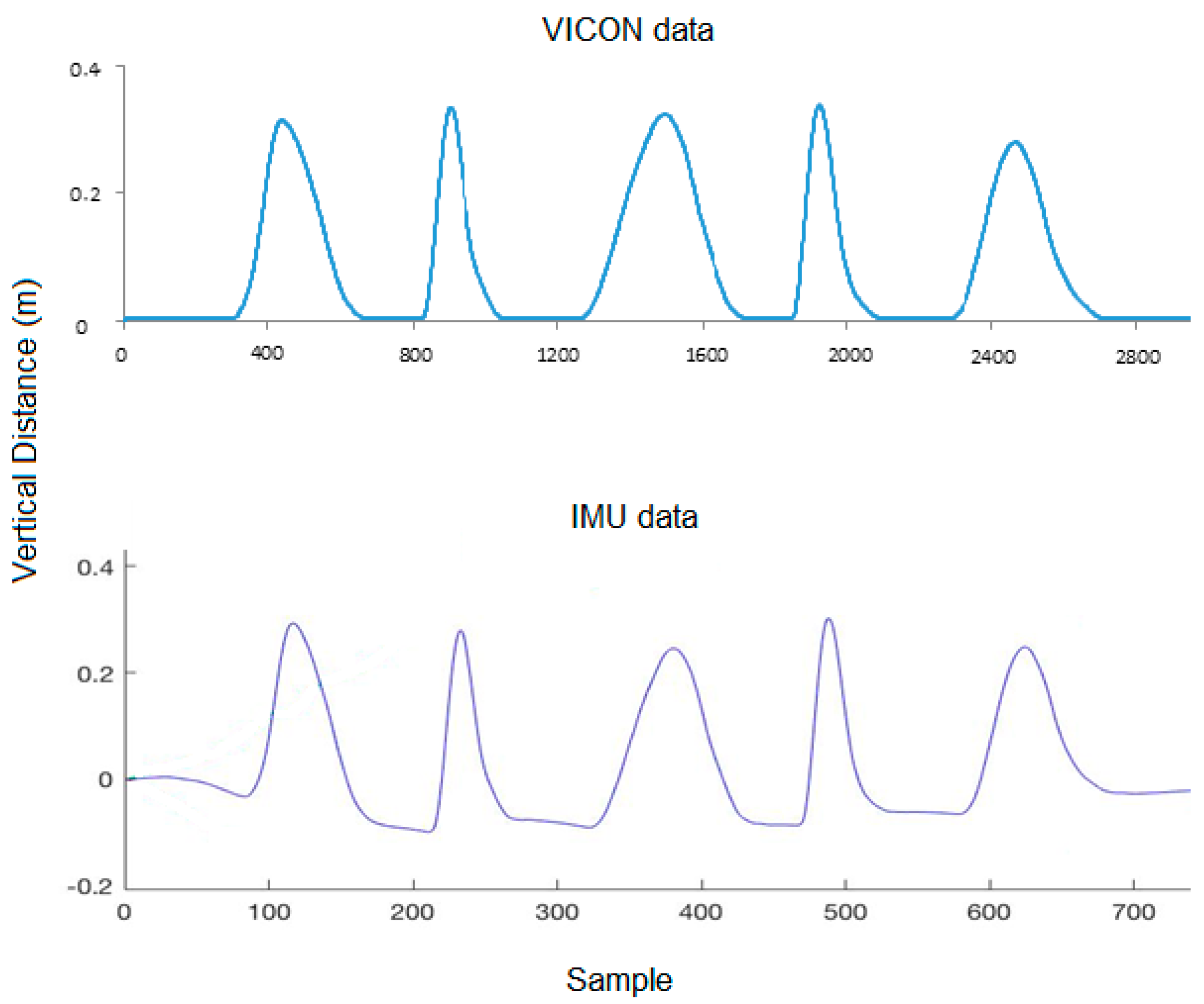

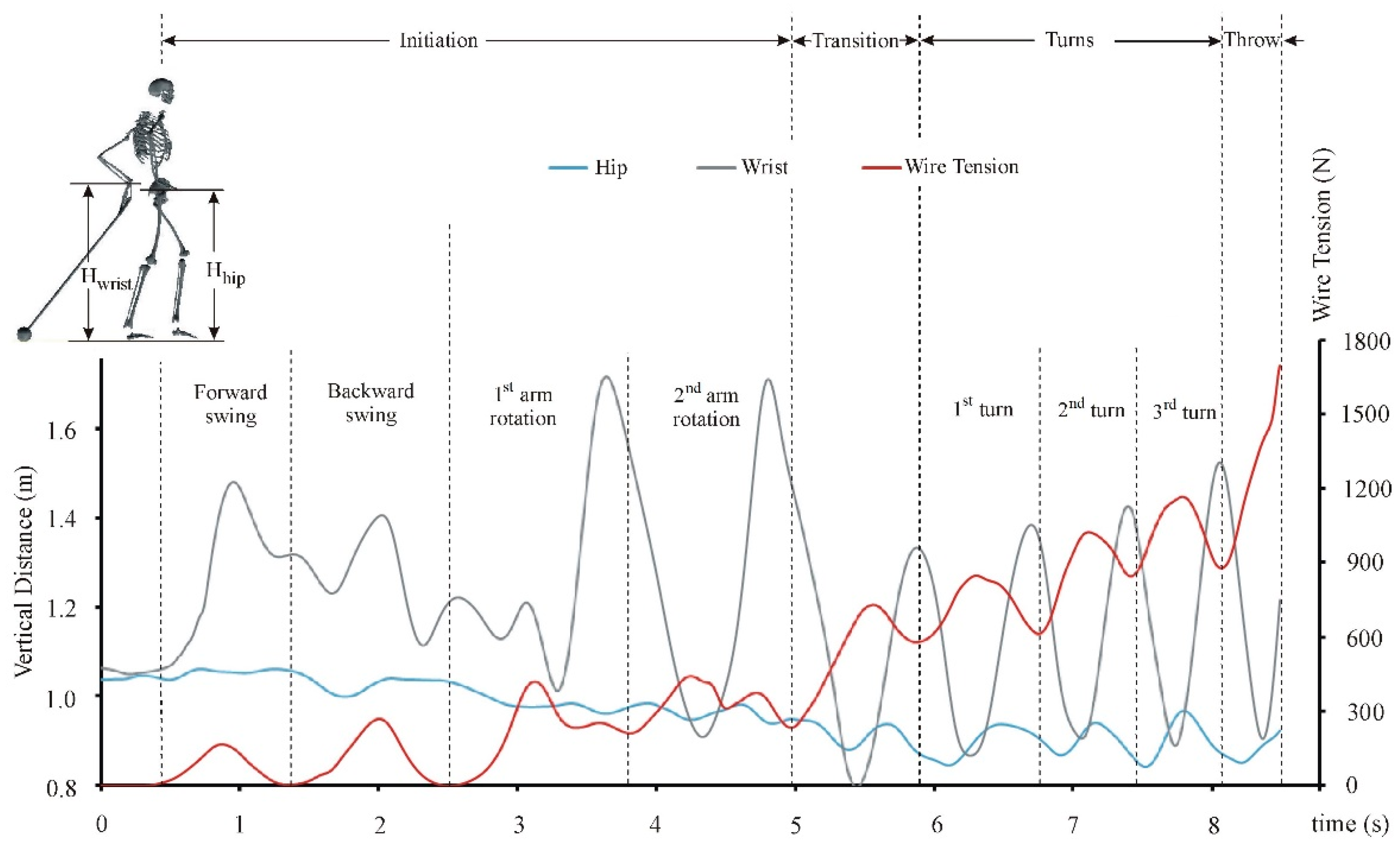

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Magill, R.A. Motor Learning Concepts and Applications, 6th ed.; McGraw-Hill: Boston, MA, USA, 2001. [Google Scholar]

- Schmidt, R.; Lee, T. Motor Learning and Performance: From Principles to Application, 5th ed.; Human Kinetics: Windsor, ON, USA, 2013; p. 336. [Google Scholar]

- Shan, G.; Westerhoff, P. Full body kinematic characteristics of the maximal instep Soccer kick by male soccer players and parameters related to kick quality. Sports Biomech. 2005, 4, 59–72. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shan, G. Where do golf driver swings go wrong?—Factors Influencing Driver Swing Consistency. Scand. J. Med. Sci. Sports 2014, 24, 749–757. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Yu, Y.; Wilde, B.; Shan, G. Biomechanical characteristics of the axe kick in Tae Kwon-Do. Arch. Budo 2012, 8, 213–218. [Google Scholar] [CrossRef]

- Shan, G.; Visentin, P.; Zhang, X.; Hao, W.; Yu, D. Bicycle kick in soccer: Is the virtuosity systematically entrainable? Sci. Bull. 2015, 60, 819–821. [Google Scholar] [CrossRef]

- IAAF. Hammer Throw. Available online: https://www.iaaf.org/disciplines/throws/hammer-throw (accessed on 11 May 2018).

- Shan, G.; Zhang, X. From 2D leg kinematics to 3D full-body biomechanics-the past, present and future of scientific analysis of maximal instep kick in soccer. Sports Med. Arthrosc. Rehabil. Ther. Technol. 2011, 3, 23. [Google Scholar] [CrossRef] [PubMed]

- Wan, B.; Shan, G. Biomechanical modeling as a practical tool for predicting injury risk related to repetitive muscle lengthening during learning and training of human complex motor skills. SpringerPlus 2016, 5, 441. [Google Scholar] [CrossRef] [PubMed]

- Shan, G.; Daniels, D.; Wang, C.; Wutzke, C.; Lemire, G. Biomechanical analysis of maximal instep kick by female soccer players. J. Hum. Mov. Stud. 2005, 49, 149–168. [Google Scholar]

- Shan, G. Influences of Gender and Experience on the Maximal Instep Soccer Kick. Eur. J. Sport Sci. 2009, 9, 107–114. [Google Scholar] [CrossRef]

- Wang, Y.; Wan, B.; Li, H.; Shan, G. A wireless sensor system for a biofeedback training of hammer throwers. SpringerPlus 2016, 5, 1395. [Google Scholar] [CrossRef]

- Aminian, K.; Najafi, B. Capturing human motion using body-fixed sensors: Outdoor measurement and clinical applications. Comput. Animat. Virtual Worlds 2004, 15, 79–94. [Google Scholar] [CrossRef]

- Shan, G.; Zhang, X.; Li, X.; Hao, W.; Witte, K. Quantification of Golfer-club Interaction and Club-type’s Affect on Dynamic Balance during a Golf Swing. Int. J. Perform. Anal. Sport 2011, 11, 417–426. [Google Scholar] [CrossRef]

- Shan, G.; Yuan, J.; Hao, W.; Gu, M.; Zhang, X. Regression Equations related to the Quality Evaluation of Soccer Maximal Instep Kick for Males and Females. Kinesiology 2012, 44, 139–147. [Google Scholar]

- Wan, B.; Shan, G.; Wang, Y.; Zhang, X.; Li, H. 3D Quantification of Key Parameters for Developing Wearables of Biomechanical Feedback Training in Hammer Throw. Unpubl. Artic. 2018. [Google Scholar]

- Sparkfun. SparkFun 6 Degrees of Freedom IMU Digital Combo Board—ITG3200/ADXL345. Available online: https://www.sparkfun.com/products/retired/10121 (accessed on 16 August 2017).

- Sparkfun. Teensy 3.2. Available online: https://www.sparkfun.com/products/13736 (accessed on 16 August 2017).

- Arduino. Wire Library. Available online: https://www.arduino.cc/en/Reference/Wire (accessed on 11 July 2015).

- AnalogDevices. Digital Accelerometer. Available online: https://www.sparkfun.com/datasheets/Sensors/Accelerometer/ADXL345.pdf (accessed on 11 August 2017).

- InvenSense. ITG-3200 Product Specification Revision 1.4. Available online: https://www.sparkfun.com/datasheets/Sensors/Gyro/PS-ITG-3200-00-01.4.pdf (accessed on 11 August 2017).

- Won, S.-H.; Melek, W.; Golnaraghi, F. Position and orientation estimation using Kalman filtering and particle diltering with one IMU and one position sensor. In Proceedings of the 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 3006–3010. [Google Scholar]

- Madgwick, S. An efficient orientation filter for inertial and inertial/magnetic sensor arrays. Rep. x-io Univ. Bristol (UK) 2010, 25, 113–118. [Google Scholar]

- Shan, G.B.; Visentin, P. A quantitative three-dimensional analysis of arm kinematics in violin performance. Med. Probl. Perform. Artist. 2003, 18, 3–10. [Google Scholar]

- Shan, G. Biomechanical Know-how of Fascinating Soccer-kicking Skills—3D, Full-body Demystification of Maximal Instep Kick, Bicycle kick & Side Volley. In Proceedings of the 8th International Scientific Conference on Kinesiology, Zagreb, Opatija, Croatia, 10–14 May 2017; pp. 133–135. [Google Scholar]

- Visentin, P.; Li, S.; Tardif, G.; Shan, G. Unraveling mysteries of personal performance style; biomechanics of left-hand position changes (shifting) in violin performance. PeerJ 2015, 3, e1299. [Google Scholar] [CrossRef] [PubMed]

- Shan, G.; Zhang, X.; Meng, M.; Wilde, B. A Biomechanical Study for Developing Wearable-Sensor System to Prevent Hip Fractures among Seniors. Appl. Sci. 2017, 7, 771. [Google Scholar] [CrossRef]

- Shan, G.; Bohn, C. Anthropometrical data and coefficients of regression related to gender and race. Appl. Ergon. 2003, 34, 327–337. [Google Scholar] [CrossRef]

- Shan, G.; Bohn, C.; Sust, M.; Nicol, K. How can dynamic rigid-body modeling be helpful in motor learning?—Learning performance using dynamic modeling. Kinesiology 2004, 36, 182–191. [Google Scholar]

- Shan, G.; Sust, M.; Simard, S.; Bohn, C.; Nicol, K. How can dynamic rigid-body modeling be helpful in motor learning?—Diagnosing performance using dynamic modeling. Kinesiology 2004, 36, 5–14. [Google Scholar]

- Ballreich, R.; Baumann, W. Grundlagen der Biomechanik des Sports (The Basics of Biomechanics in Sports); Enke Verlag: Stuttgart, Germany, 1996. [Google Scholar]

- Shan, G.; Zhang, X.; Wan, B.; Yu, D.; Wilde, B.; Visentin, P. Biomechanics of Coaching Maximal Instep Soccer Kick for Practitioners. Interdiscip. Sci. Rev. 2018. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, H.; Wan, B.; Zhang, X.; Shan, G. Obtaining Vital Distances Using Wearable Inertial Measurement Unit for Real-Time, Biomechanical Feedback Training in Hammer-Throw. Appl. Sci. 2018, 8, 2470. https://doi.org/10.3390/app8122470

Wang Y, Li H, Wan B, Zhang X, Shan G. Obtaining Vital Distances Using Wearable Inertial Measurement Unit for Real-Time, Biomechanical Feedback Training in Hammer-Throw. Applied Sciences. 2018; 8(12):2470. https://doi.org/10.3390/app8122470

Chicago/Turabian StyleWang, Ye, Hua Li, Bingjun Wan, Xiang Zhang, and Gongbing Shan. 2018. "Obtaining Vital Distances Using Wearable Inertial Measurement Unit for Real-Time, Biomechanical Feedback Training in Hammer-Throw" Applied Sciences 8, no. 12: 2470. https://doi.org/10.3390/app8122470

APA StyleWang, Y., Li, H., Wan, B., Zhang, X., & Shan, G. (2018). Obtaining Vital Distances Using Wearable Inertial Measurement Unit for Real-Time, Biomechanical Feedback Training in Hammer-Throw. Applied Sciences, 8(12), 2470. https://doi.org/10.3390/app8122470