1. Introduction

Nowadays, plug-in hybrid electric vehicles (PHEVs) representing a positive research direction due to combination of a certain all electric range (AER) and hybrid drive, exhibit apparent advantages in environmental protection and petroleum savings over traditional hybrid electric vehicles (HEVs). Compared with HEVs, PHEVs are equipped with higher capacity energy storage systems that can be directly charged from the power grid [

1,

2]. Currently, automotive manufacturers and research institutes are actively devoted to developing PHEVs and improving controlling performances. For PHEVs, an appropriate and effective energy management is critical to improve the vehicle’s fuel economy and reduce emissions.

For the energy management strategy, the main destination is to optimize the fuel economy. Since there exists some uncertainty for driving cycles, driver’s habits, and weather conditions that can influence the energy distribution in the PHEV, from this point, it can be said that the energy management is a stochastic optimization problem. Actually, popular control candidates can be divided into four types: (1) rule based control method [

3,

4,

5]; (2) intelligent control methods, including artificial neural network (ANN) [

6,

7], fuzzy logic [

8,

9], model predictive control (MPC) [

10,

11], and machine learning algorithm [

12,

13]; (3) analytic methods [

14,

15]; and (4) optimization based control method, including deterministic dynamic programming (DP) [

1,

16,

17,

18,

19], Pontryagin’s Minimum Principle (PMP) [

20,

21], quadratic programming (QP) [

22,

23], and convex optimization [

24,

25,

26]. These methods’ purpose can include improving the fuel economy, reducing emissions [

27,

28], prolonging cycling life of the battery pack [

2,

29], minimizing the operation cost [

30], etc.

Among these methods, rule-based control methods are simpler and easier to implement, which have been widely applied in practical application [

4,

31,

32]. It is relatively easy to implement with fixed control parameters according to experience and prior knowledge. The prevalent rule-based method is the charge depleting/charge sustaining (CD/CS) method. During the CD mode, the vehicle is powered by the motor which absorbs the energy from the battery. The CD mode tries to use up the energy stored in the battery until its state of charge (SOC) decreases to an allowable minimum value. After that, the vehicle operating mode turns to the CS mode, which is also called the hybrid mode. In this mode, the vehicle is powered by the motor and engine together and meanwhile the battery SOC maintains in the vicinity of the low threshold. Due to the complex coupling characteristic of driveline system of PHEVs, rule-based method may not achieve the optimal power split between the engine and the motor, even if it is simple and stable.

The intelligent methods and the analytic method have been widely researched in the energy management of the PHEVs. In Ref. [

9], a fuzzy logic energy management strategy of a series-PHEV is proposed to achieve the power split between the battery and the engine, based on the battery working state and vehicle power demand, and simultaneously to control the engine working in the economic region. Nonetheless, the fuzzy logic table and related rules should be defined with care. In Ref. [

11], the power split of a PHEV which is equipped with a semi-active hybrid energy storage system and an assistance power unit, is regulated by the MPC method; however, it does not consider the engine ON/OFF power threshold and the trip length. In Ref. [

12], a reinforcement learning-based method of a PHEV is raised, which takes the minimizing electricity consumption, real-time control and different conditions into account. In Ref. [

14], based on modeling the electric driveline loss and applying the piecewise linear fuel consumption, an analytic method is applied to establish the energy management strategy to minimize the fuel consumption via finding the engine-on power and the optimal battery power commands.

Generally, optimization-based control methods include PMP, QP, DP, and convex optimization [

6]. The PMP algorithm is applied to achieve the energy management adaptively for the GM Chevrolet Volt [

33]. Nevertheless, a complex Hamilton function and the local optimum solution need to be solved and determined. In Ref. [

22], the energy management strategy is optimized by the QP algorithm to reduce the engine fuel consumption, whereas this algorithm does not consider the influence of the initial SOC variation. In Ref. [

17], the DP based energy management strategy is constructed, which considered the discretization resolution of the relevant variables and the boundary constraint of their feasible regions. Currently, convex optimization has been substantially applied to energy management optimization of traditional HEVs and PHEVs [

24,

34,

35,

36]. In Ref. [

34], a convex programming-based power management strategy of a PHEV, which covers expenditures of electricity charged from the grid, fuel consumed during on-road driving, and battery aging. In Ref. [

36], a novel convex modeling approach is presented which allows for battery sized and energy management of a plug-in hybrid powertrain based on a semidefinite program. However, some fixed control parameters, such as the engine-on power, cannot be estimated by the convex optimization [

37]. In order to calculate these variables, randomized heuristic searching algorithm are applied, such as genetic algorithm (GA), simulated annealing (SA). Compared with GA algorithm, the SA algorithm is simpler and with higher efficiency, which can search the optimal solution more quickly. Due to these merits, the SA algorithm has been applied in the research of energy management for HEVs and PHEVs [

22,

38,

39].

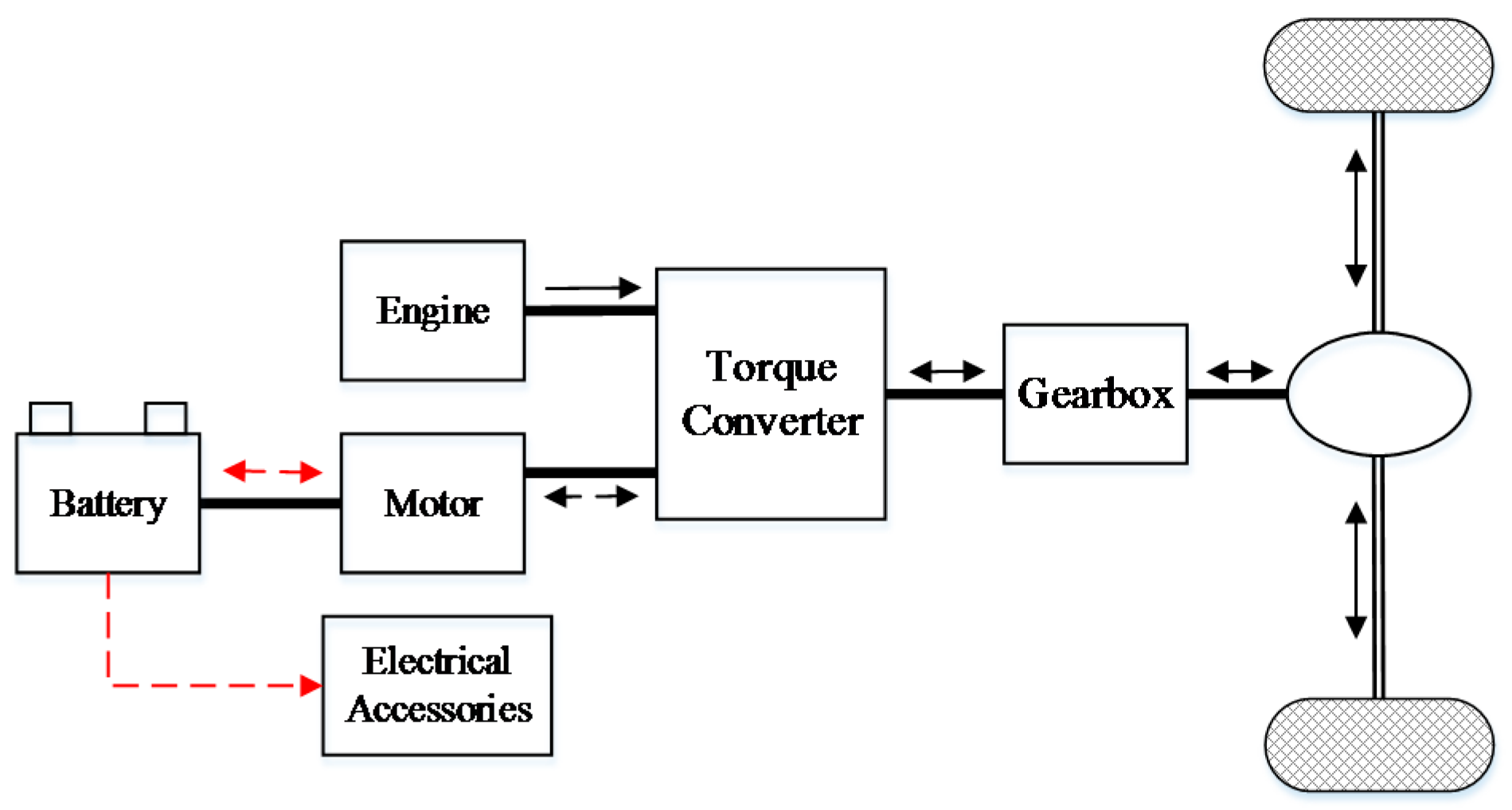

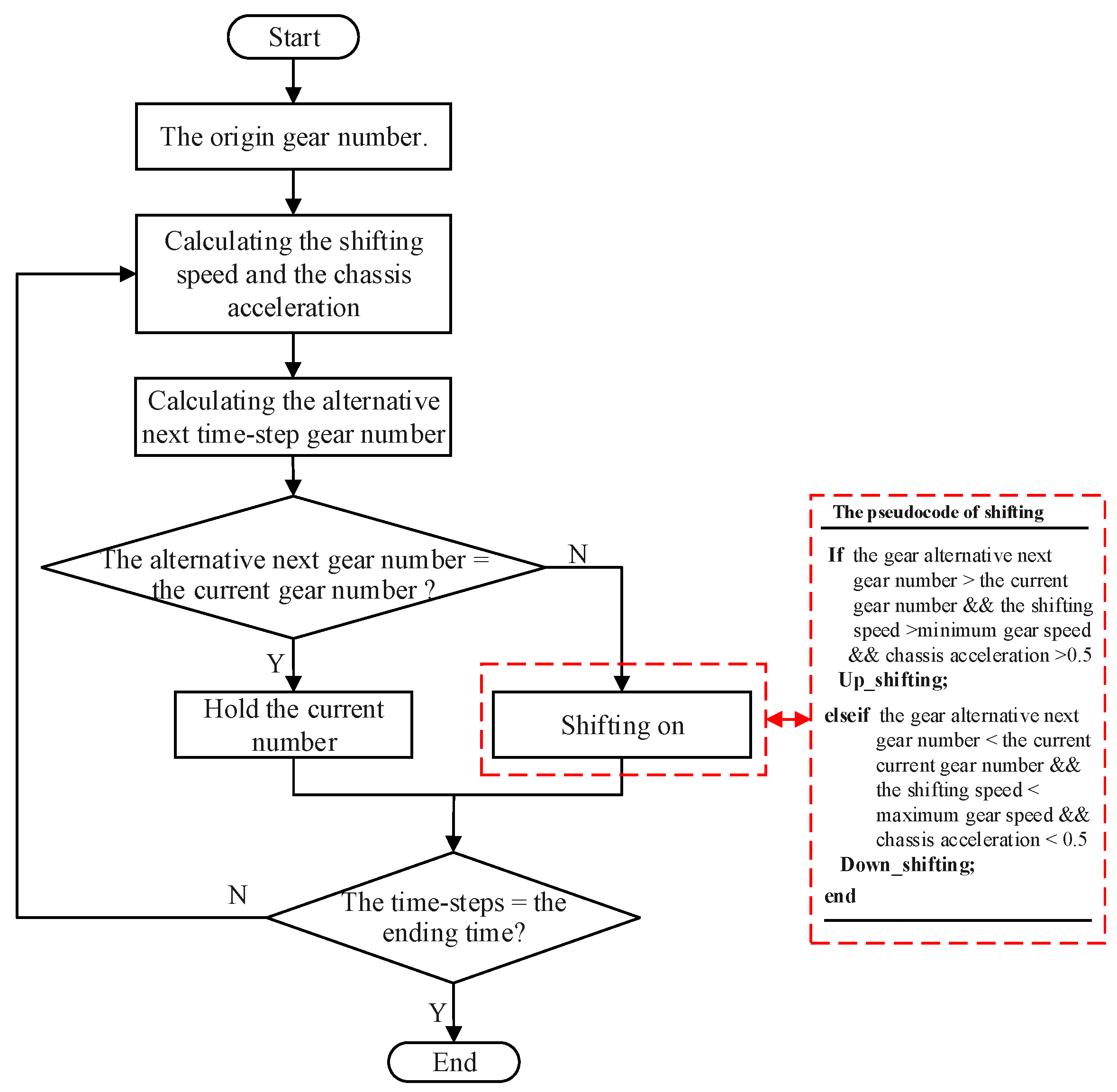

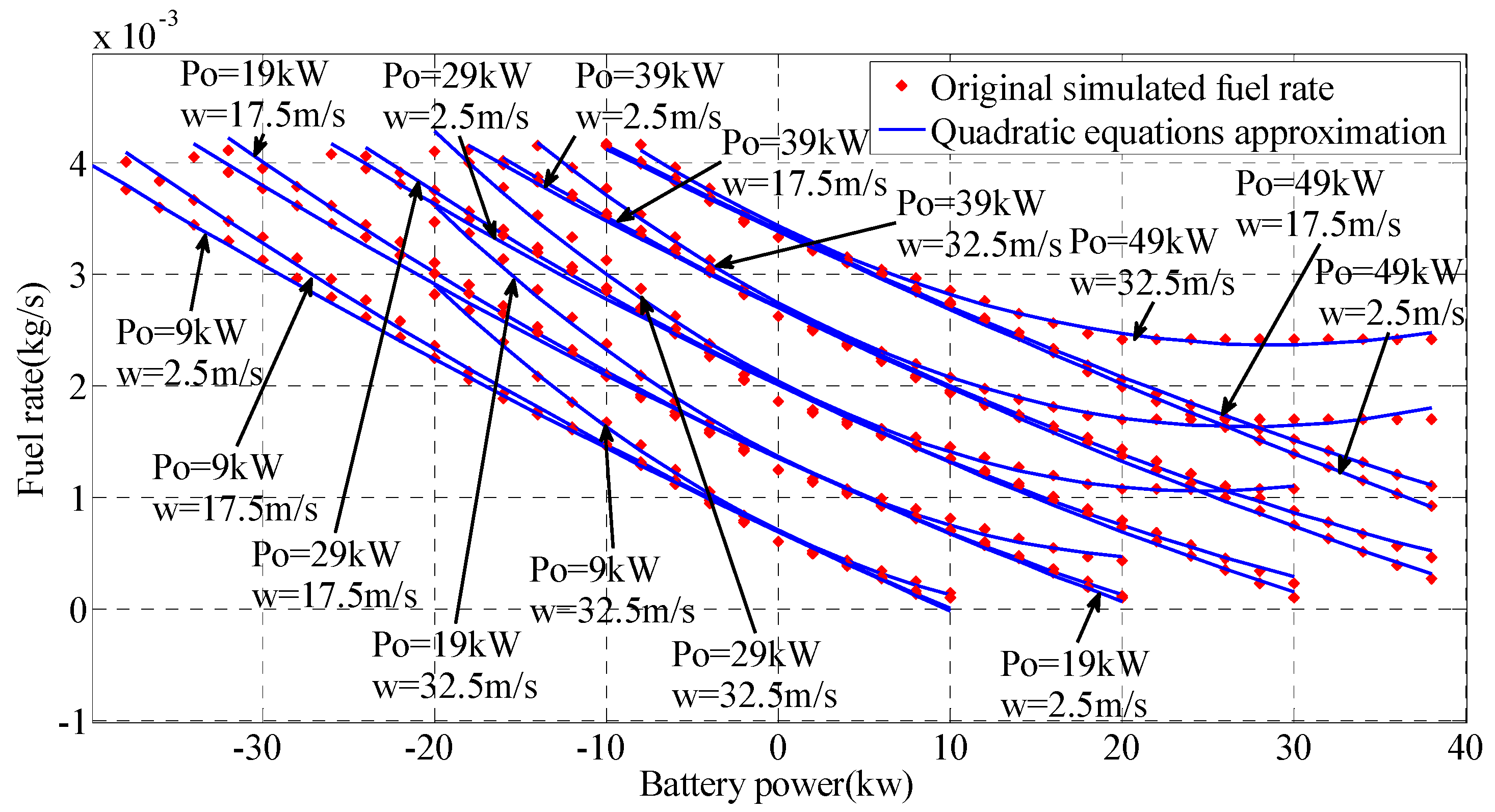

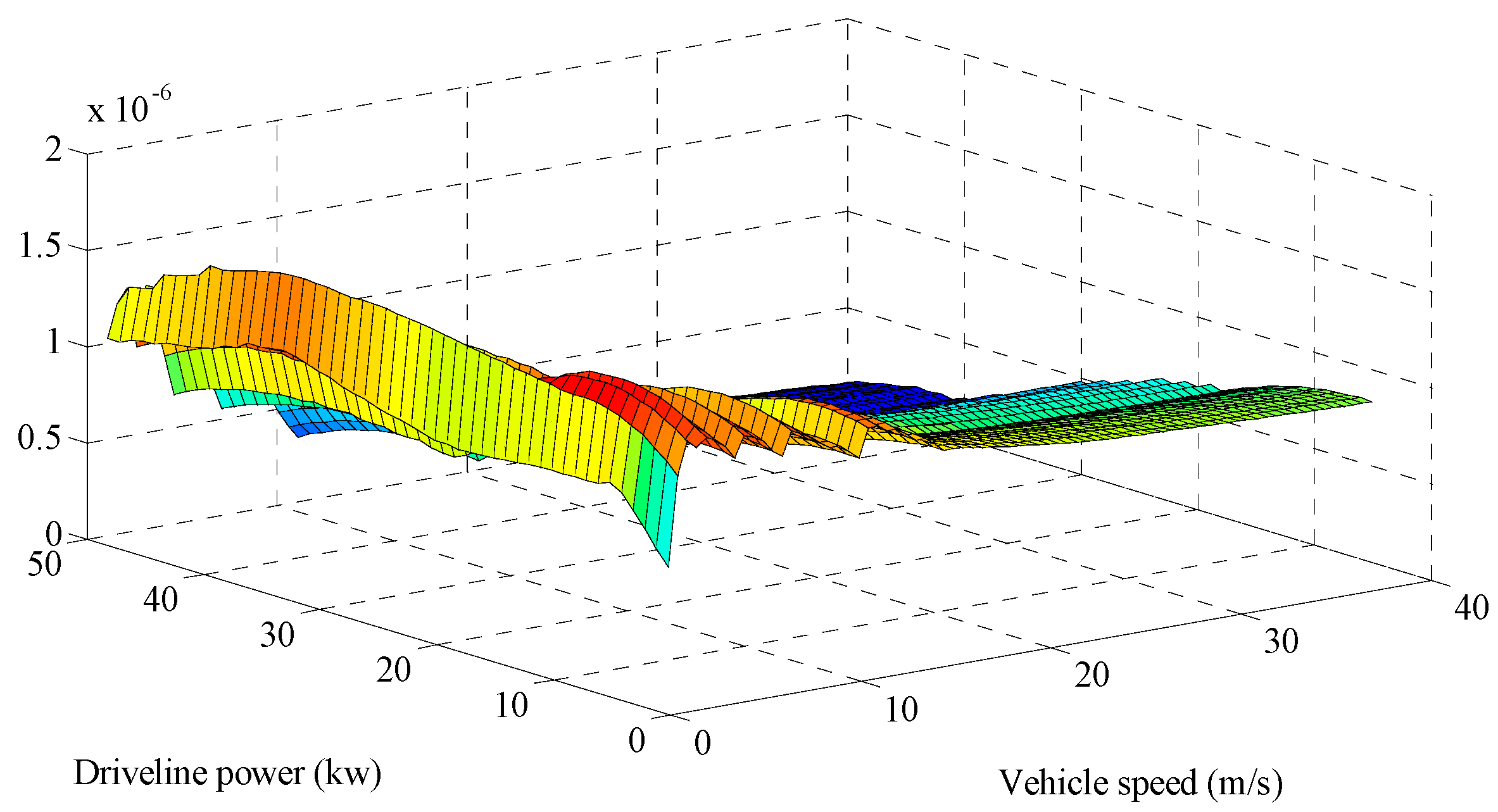

Compared with the optimization-based method, the optimal control parameters of analytic method and rule-based energy management strategy for PHEV can be obtained difficultly. Even the intelligent based method for PHEV has been widely applied, nevertheless, the intelligent based control method is complex and difficult to find the optimal solutions. The optimization-based method can obtain the global optimal solutions, improve the vehicle’s control performance and engine fuel economy. Motivated by these, we plan to compare the performance among different methods. In this paper, there typical methods including the CD/CS method, the DP method, and an intelligent method, i.e., SA combing with the convex optimization are employed to compare the fuel economy for a parallel PHEV. As shown in

Figure 1, the parallel PHEV can be powered by the engine and motor together. Since the gearbox can select the gear ratio according to the power and speed demand from the driveline, there exist two degrees of freedom in the vehicle, which increases certain complexity to decouple the powertrain dynamics. In order to simplify the problem, an automated gear shift rule strategy is adopted considering the vehicle speed. By this manner, the degrees of freedom changes from two to one and the problem becomes easier to solve. In this paper, the optimization purpose is to minimize the fuel consumption in a certain trip. Based on analysis of the energy flow and the vehicle working modes, the vehicle driveline system is simplified and translated into a series of quadratic equations, which can effectively express the relationship between the engine fuel rate and the battery power at different power demand and velocity. The SA algorithm is implemented to search the optimal engine-on power, in which the optimal sequence of battery power is optimized simultaneously by CP. With considering the referred discussions, the optimal engine-on power is quickly searched by the SA algorithm and then the battery power command is calculated by convex optimization algorithm based on the interior point method. Highway Fuel Economy Driving Schedule (HWFET), New European Driving Cycle (NEDC), and Urban Dynamometer Driving Schedule (UDDS) are selected as test cycles to verify the performance of the proposed algorithm. The CD/CS method and DP are adopted as the benchmark for comparison, and the extended study regarding different initial SOC is also proposed. It is necessary to mention that the proposed algorithm can be easily extended to series connected PHEVs and power-split PHEVs. Thus, it can potentially become a universal control algorithm solution for PHEVs.

The remainder of this paper is structured as follows:

Section 2 describes the vehicle model and the model simplification process;

Section 3 presents the theory of convex optimization algorithm and the optimization method;

Section 4 compares the proposed method with the CD/CS strategy and the DP strategy; and

Section 5 concludes the proposed method in the paper.

3. Optimization Methods

As presented in (16), the total cost function of this paper can be expressed as,

Based on analysis of the vehicle model, related boundary constraints can be summarized,

where

is the upper limit of engine-on power threshold, which is equal to the maximum output power of engine,

is the lower limit of engine-on power threshold,

and

denote the minimum and maximum values of the battery power commands.

denotes the range of the battery SOC variation, which is also called the depth of discharge (DOD). In this paper, the ending SOC is set to 0.3, the minimum SOC is 0.2 and thus

belongs to

.

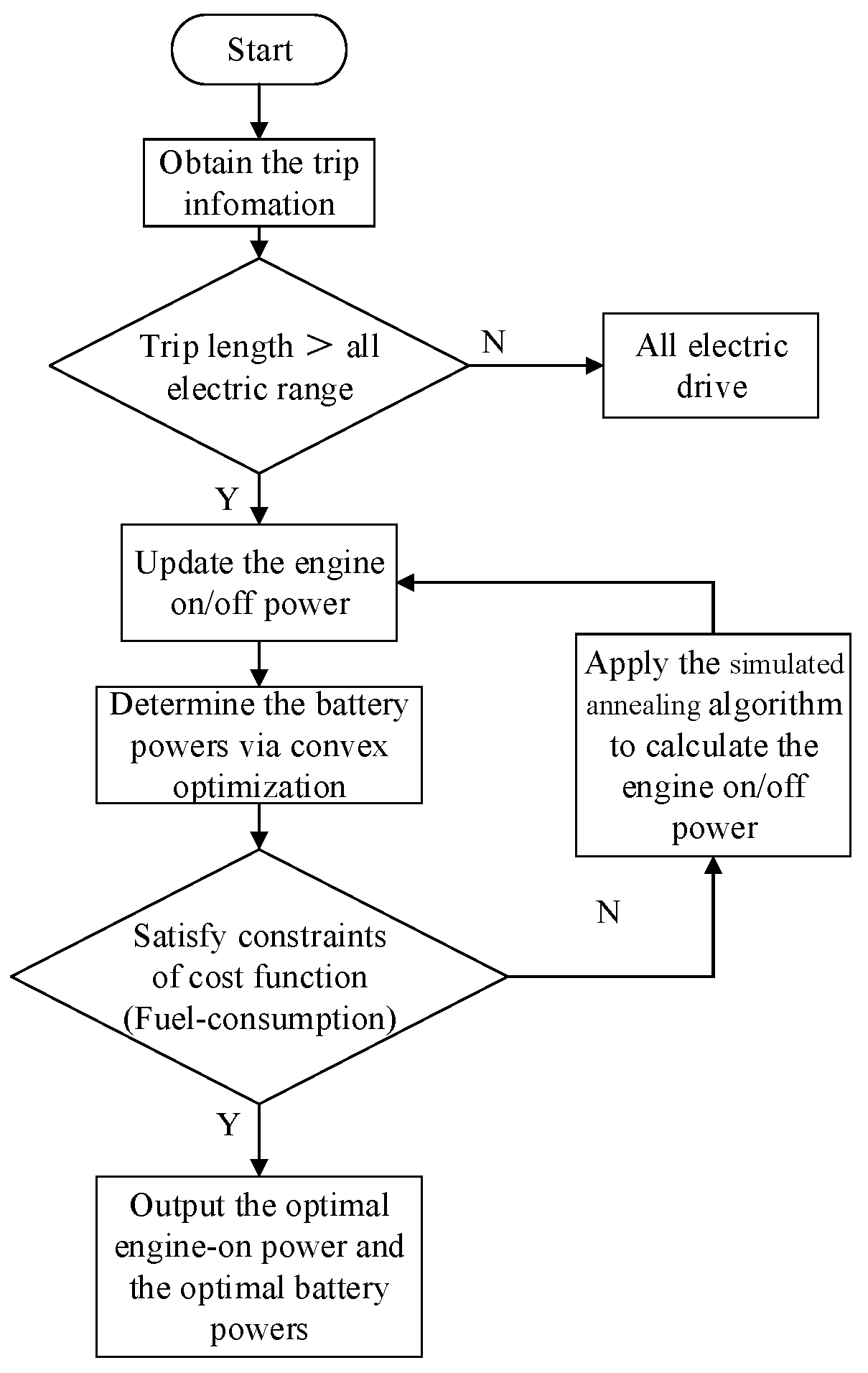

In premise of knowing the driveline power requirements, the engine-on power threshold is solved by the SA algorithm, and the battery power command is calculated by the convex optimization algorithm when the engine is on, as shown in

Figure 7. Compared with other optimal algorithms, the SA algorithm is faster and more efficient in solving such global optimization problems with boundary constraints. The calculation process can be described as follows. The first step is to acquire the information of the vehicle including speed, driving range and driveline power demand. Based on the sum of the whole power demand and the maximum battery supplied energy, a decision can be made that if the driving range is less than the AER, the vehicle is under pure EV mode, or else the vehicle is under the HEV mode. If the vehicle works under the HEV mode, an initial engine-on power can be supplied by the SA algorithm. Then, based on the setting constraints, the interior point method will be applied to calculate the battery power thereby realizing the power split between the engine and the battery. Now the fuel consumption based on (17) can be calculated. After that, the SA will be iterated to generate a new engine-on power, and accordingly the battery powers and the total fuel consumption will be updated and compared with the previous calculations. The algorithms will continue to iterate until reaching the termination conditions. Finally, the algorithm outputs the engine-on power and the corresponding battery power commands.

In (18), the lower bound and upper bound on the engine ON/OFF threshold are set to

and

. Since the SA algorithm is insensitive to the initial value, the initial engine-on power threshold

is determined randomly as the initial point between 10 kW and 15 kW and a sufficiently large initial temperature

is randomly selected based on the initial point. After each iteration, an updated state

is generated, and the temperature increment

is calculated comparing with the initial iteration.

where

denotes the cost function. If

,

is accepted as the updated current solution. If

,

is accepted as the initial current solution with the probability

. Then, the battery power is programmed by the convex optimization algorithm combined with

, and the cost consumption function is calculated. The temperature value decreases gradually until reaching the termination condition. Finally, the current solution can be achieved. In this paper, the SA algorithm is performed by MATLAB (2014a, Mathworks, Natick, MA, USA) [

22]. In this paper, the number of iterations of the SA algorithm is set to 40, the terminated tolerance is 0.001, and the simulation step is 1 s.

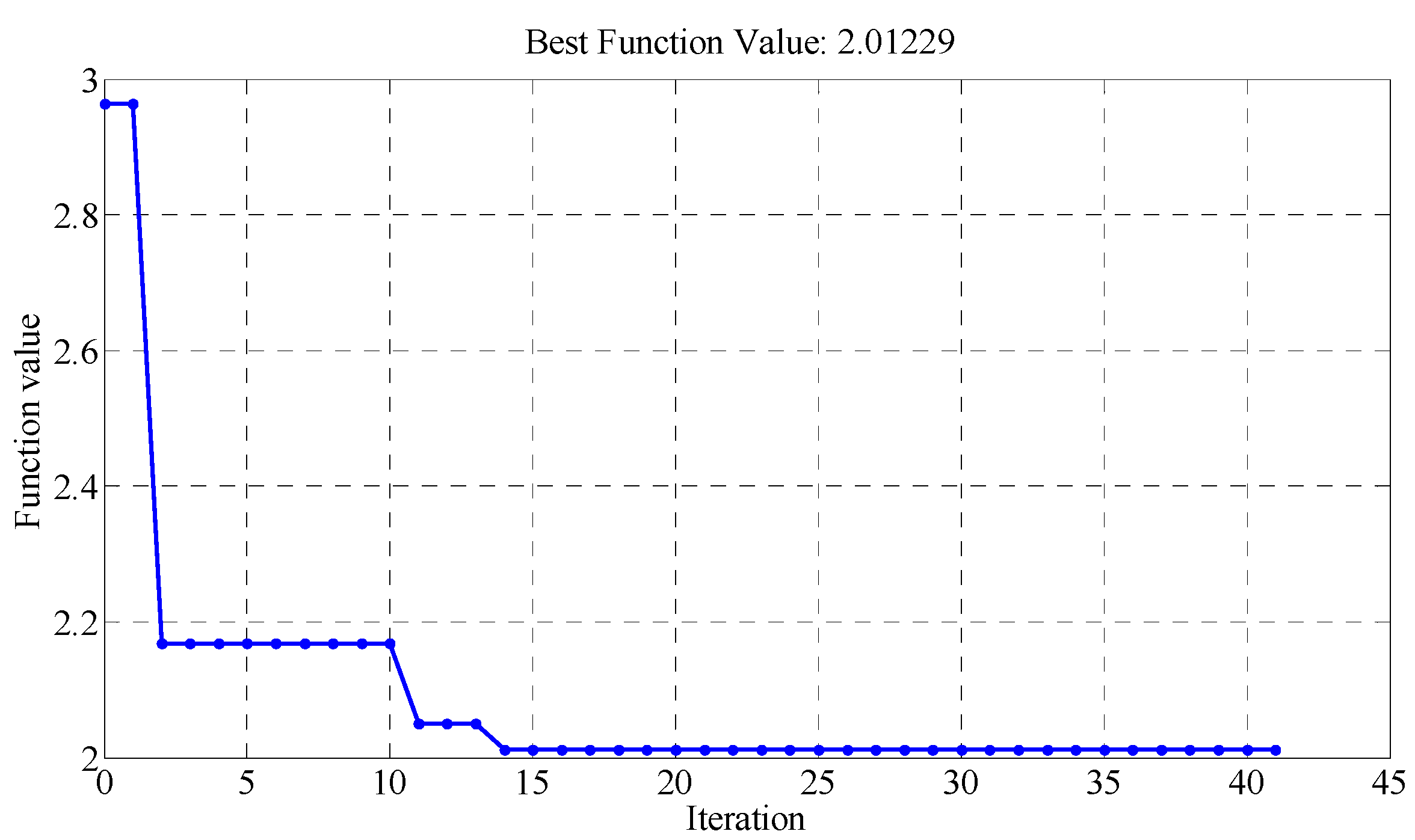

As shown in

Figure 8, the calculation process of SA algorithm under nine NEDC cycles is presented. It can be observed that the SA algorithm converges to a minimum value of the cost function after 14th iterations, and stops after 40 generations. The global optimal result can be found after 15 iterations. Next step, simulations will be conducted to verify the fuel savings of the proposed algorithm.

4. Simulation Validation and Results Analysis

In this paper, the whole simulation is carried out under MATLAB and Autonomie. MATLAB is a mathematical calculation software for numerical analysis, matrix operation, algorithm development, etc. Autonomie, developed by the Argonne National Laboratory, is an intelligent vehicle simulation software based on MATLAB and Simulink [

22,

23].

In order to compare the optimization results, the default CD/CS strategy and the DP algorithm are applied as the benchmark. In the CD mode, the parallel PHEV is driven by the battery when the engine is off. In the CS mode, the engine will be turned on when the driveline power demand is more than the engine-on power threshold and the parallel PHEV is driven by the engine and the battery together. The engine will be turned on when the battery maximum power cannot satisfy the driveline power demand [

1,

6]. When the engine is on, the engine power should also consider the battery balance control, which means that if the battery SOC is lower than the pre-set value, the battery needs to be charged. The detailed CD/CS strategy can be formulated,

where

indexes the maximum power of engine. Based on (20), the battery power is calculated according to the current SOC. In the CD mode, the vehicle is only powered by the battery if the battery SOC is more than 0.36. In the CS mode, the engine is turned on and the battery is charged to hold the SOC near 0.3. In order to verify the control performances more widely, different initial SOC values are considered. We select the initial SOC of 0.9, 0.8 and 0.7 to verify the controlling performances.

4.1. Simulation with Initial SOC of 0.9

We selected two standard drive cycles, i.e., NEDC and HWFET, to validate the performances of the proposed algorithm, DP based method and rule-based method.

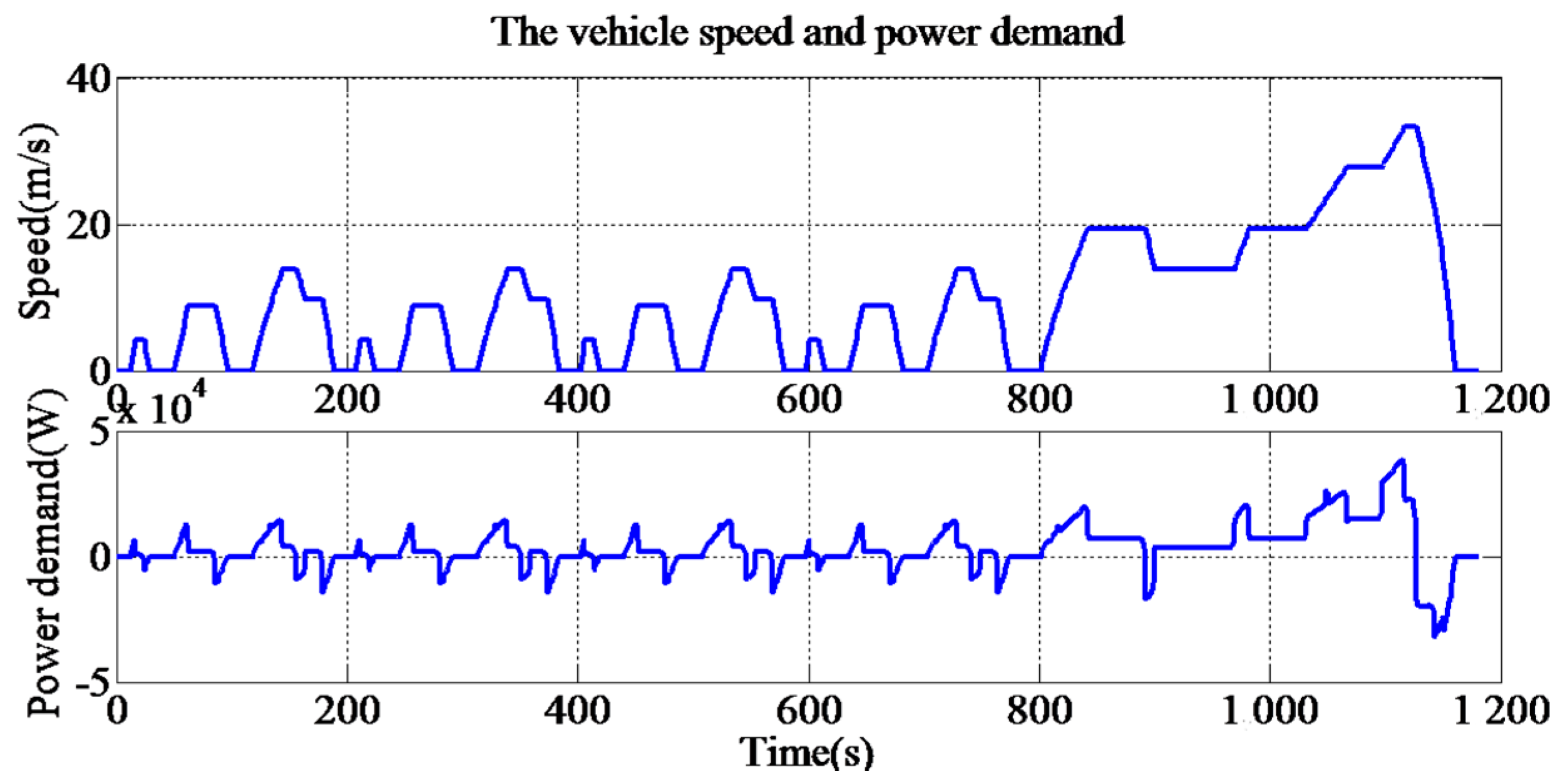

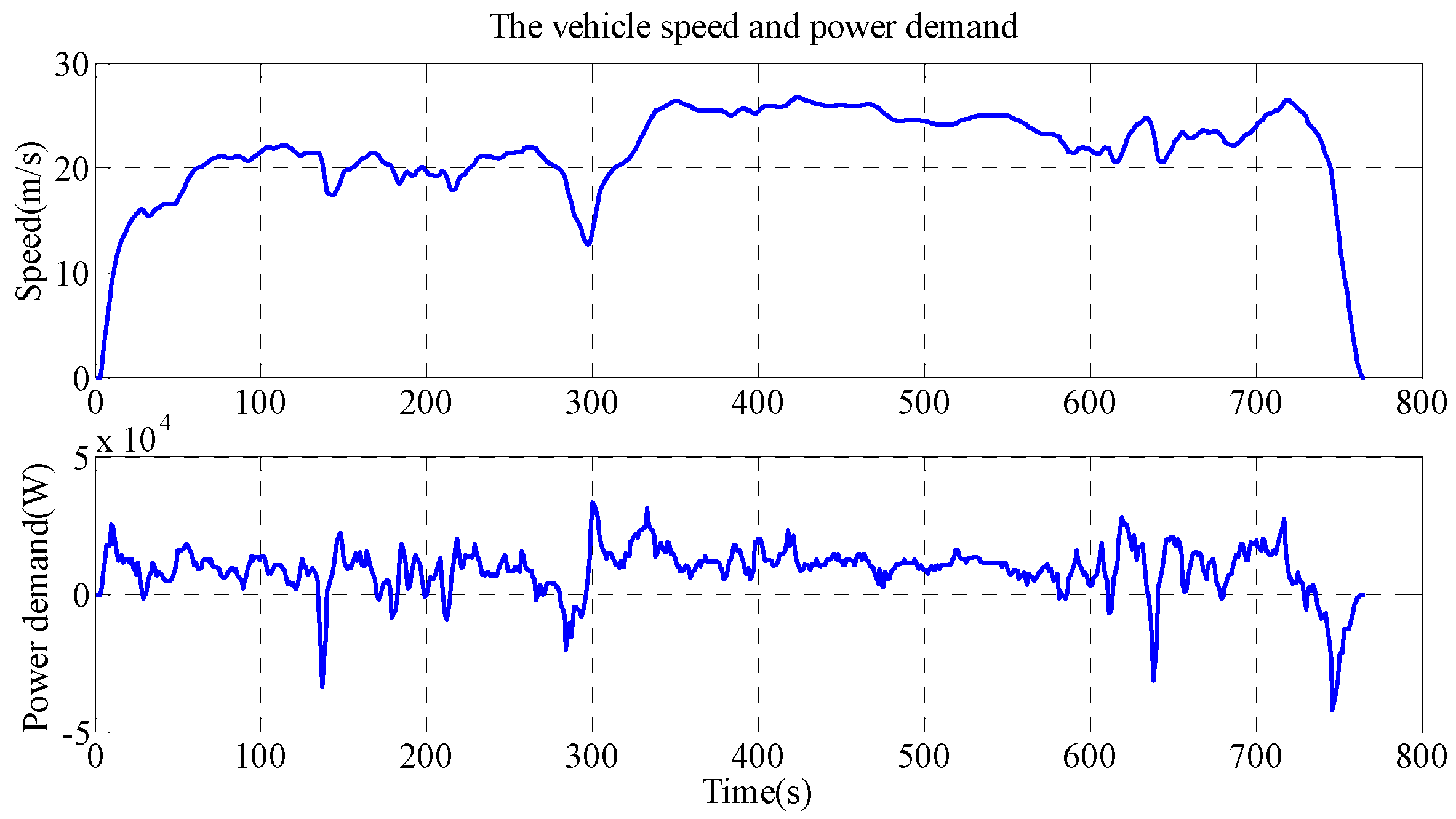

Figure 9 and

Figure 10 show their speed profile and the driveline power, from which we can find that their maximum speeds and maximum driveline power demand are 120 km/h, 96.40 km/h, 38.3 kW and 33.40 kW, respectively.

Based on the proposed algorithm, the optimal engine-on power threshold can be calculated by the SA algorithm. After calculation, the optimal engine-on power thresholds are 15.54 kW, 15.15 kW, and 13.52 kW when seven to nine standard NEDC drive cycles are simulated, and 13.25 kW, 13.05 kW, 12.65 kW and 12.50 kW when six to nine standard HWFET drive cycles are simulated.

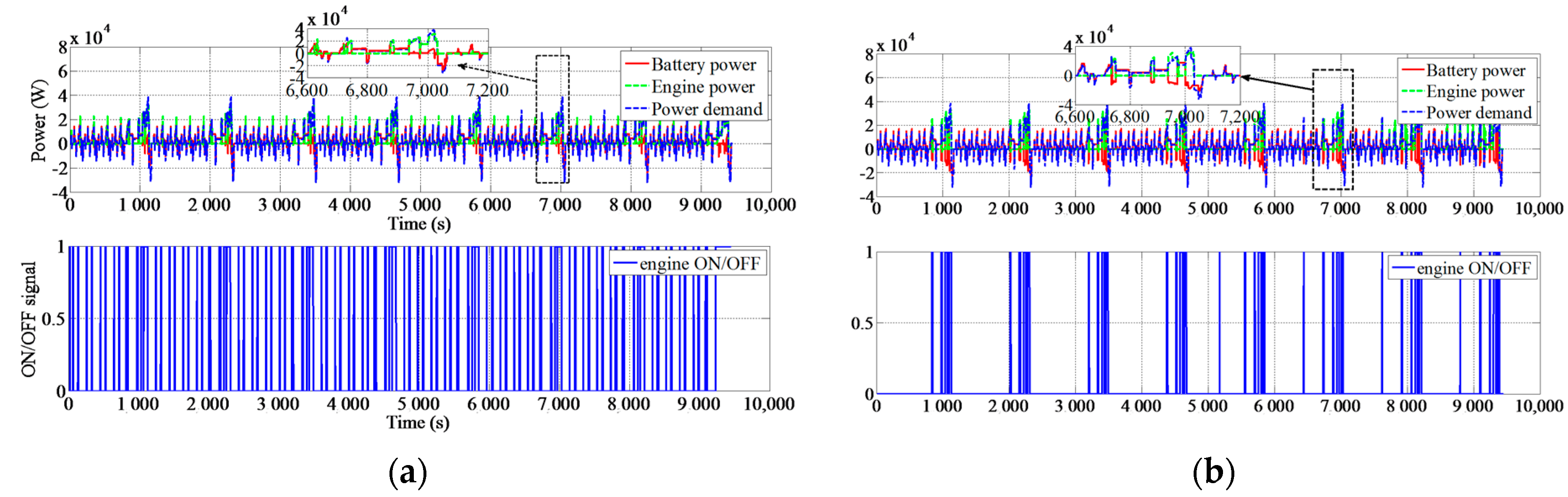

Figure 11 shows the battery power commands, the engine output power, the driveline power demand and the engine on/off commands based on the proposed method when eight NEDC cycles are applied. It is clearly observed that the convex optimization-based method can start the engine more frequently, since it considers the global optimization of the battery and engine efficiency. Therefore, the DP based method is optimal and the convex optimization-based method is sub-optimal. For the existence of electrical accessories and energy loss, the battery power is higher than the driveline power demand when the engine is off.

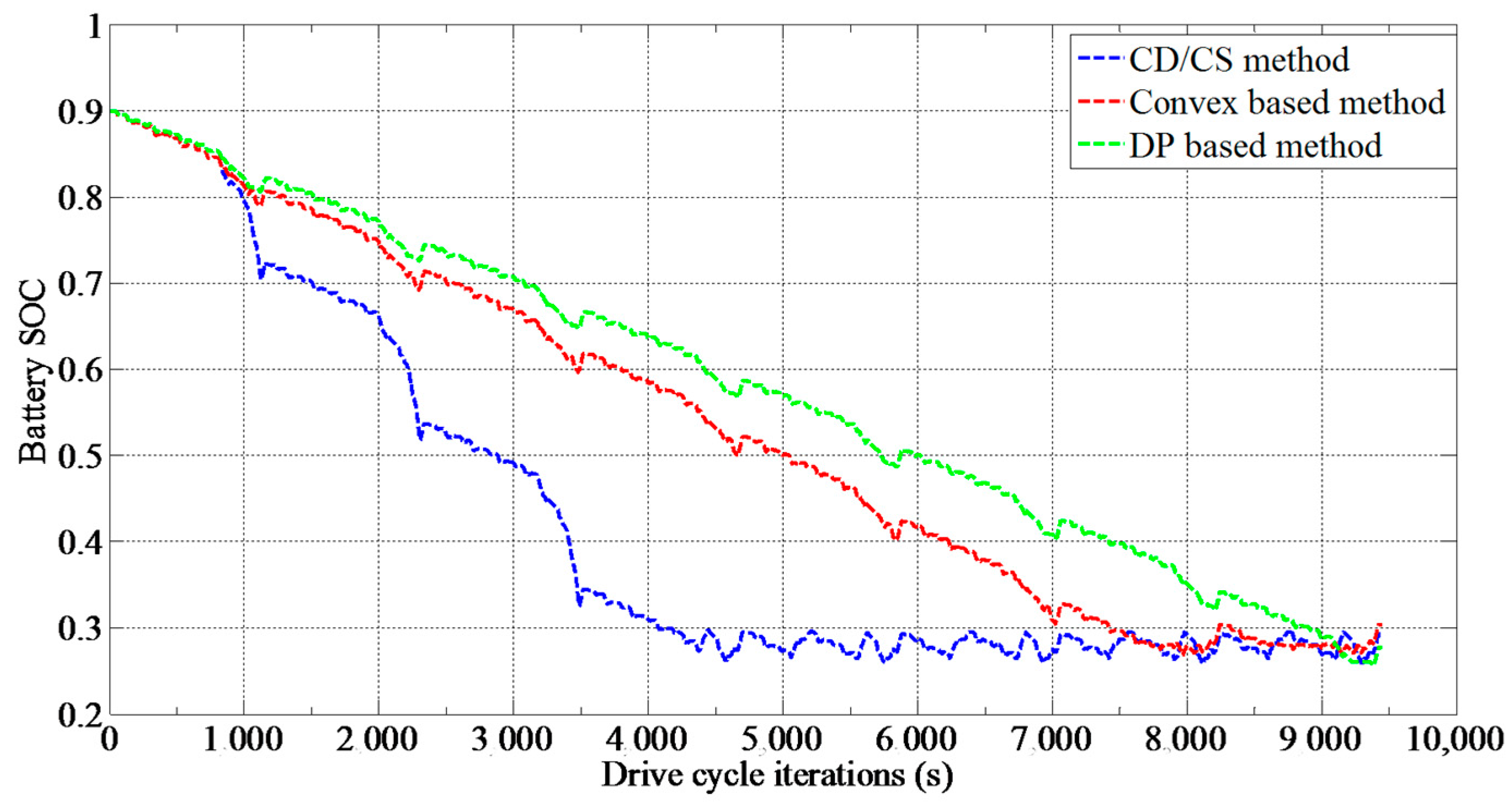

Figure 12 compares the SOC trajectory when different control methods are applied. Obviously, the battery SOC decreases more slowly when the proposed algorithm is applied due to its capability of the global optimization.

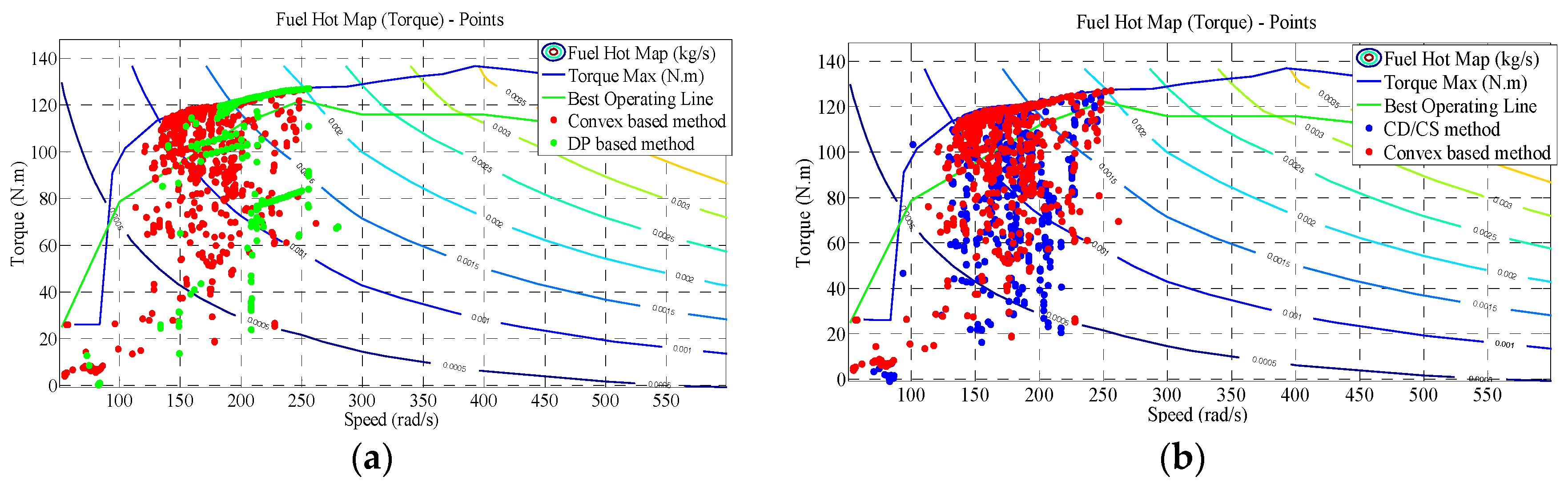

Figure 13 compares the comparison of engine-efficiency points by DP and the proposed method, respectively, from which we can observe that the work efficiency by DP is superior than that by the proposed method and the CD/CS method. In addition, there are also less low efficiency points by the proposed method compared to those by CD/CS method. Actually, the purpose of the proposed algorithm is to increase the opportunity of the engine working in the high efficiency region and thus to improve the fuel economy. As shown in

Figure 13, the convex optimization-based method increases the operating chances of engine working near the best operating line.

In order to compare the fuel consumption, a linearly corrected method is applied to ensure the ending SOC with the same value when applying different strategies [

2].

Table 3 list the final fuel consumption

, the terminal SOC and the rate of reducing fuel consumption at different cycles. It can be found that the proposed strategy can reduce the fuel consumption by 9.31%, 8.26%, 8.49% when seven to nine NEDC cycles are simulated, and 8.40%, 7.10%, 6.83%, 6.45% when six to nine HWFET cycles are simulated. As shown in

Table 3, the fuel savings achieved with the convex optimization-based method are approximate to the DP based method for the HWFET and NEDC driving conditions. In addition, the fuel savings based on the proposed method are currently less than that based on the DP method. As shown in

Table 4, the computation time of the DP based method is obviously longer than that of convex optimization-based method, based on a laptop computer of an i7 processor and 4 Gigabyte RAM. Thus, it justifies the effectiveness of reducing the fuel consumption based on the proposed method.

4.2. Simulation with Different Initial SOCs

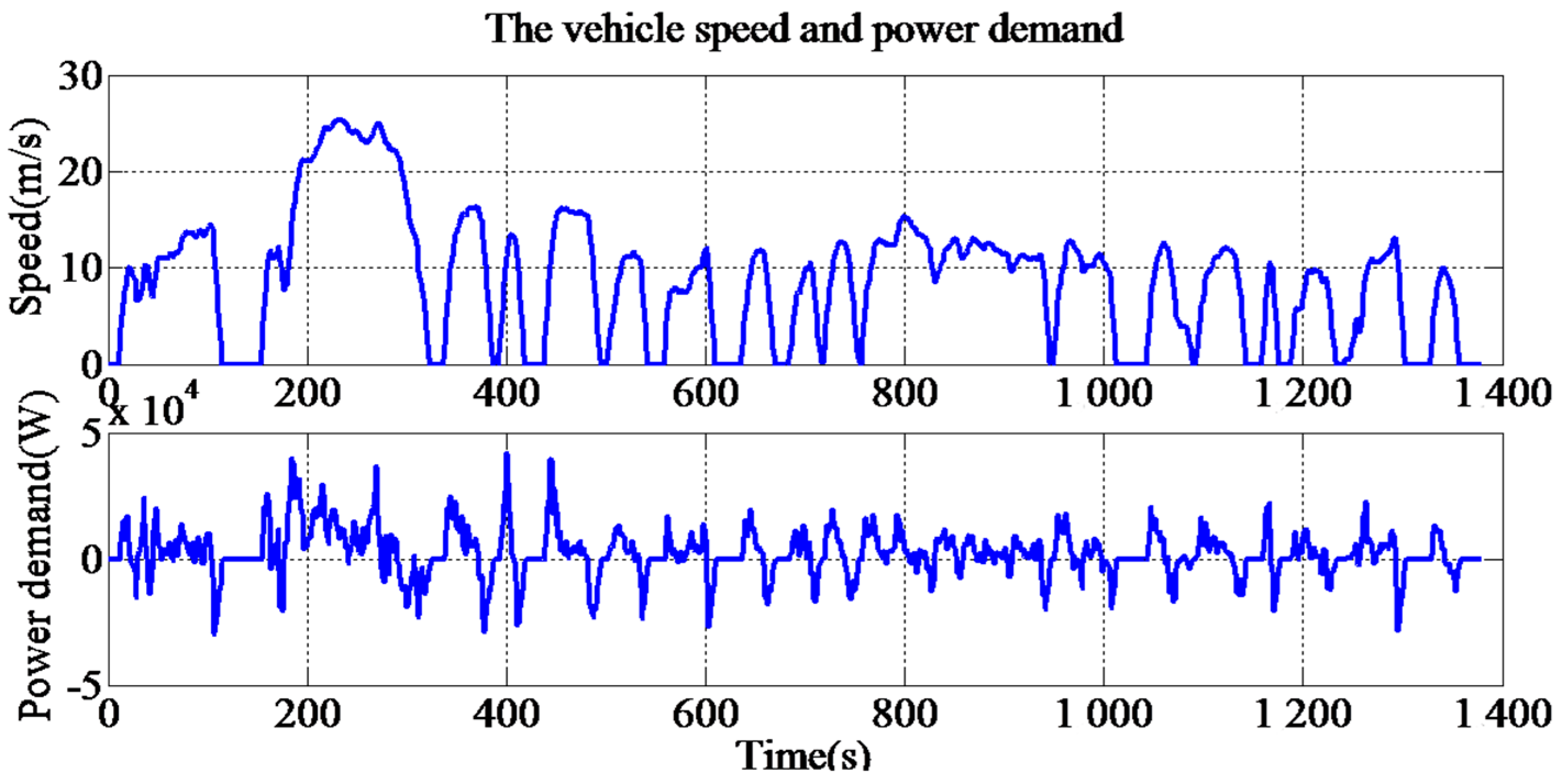

In actual application, it cannot guarantee the battery is always fully charged when the trip begins. Here, the proposed method is extended to consider different initial SOC values. The UDDS cycle, of which the speed and driveline power are shown in

Figure 14, is chosen to verify the proposed method with different initial SOC values. The maximum speed and maximum driveline power demand for the UDDS cycle are 91.25 km/h and 41.92 kW, respectively.

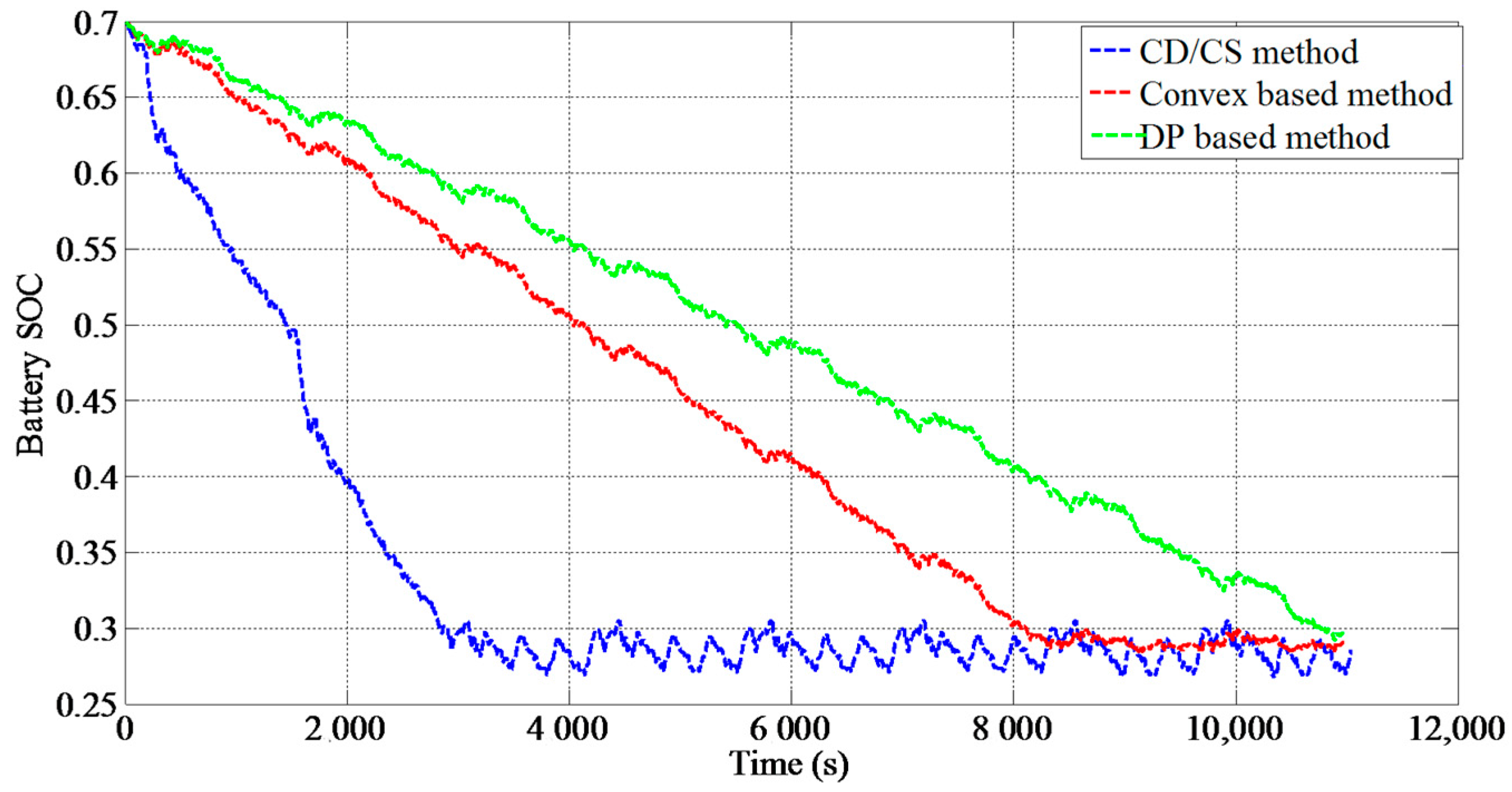

Figure 15 compares the SOC trajectories based on different energy management strategies when the battery initial SOC is 0.7. It shows that the battery is discharged more slowly when the proposed algorithm is applied than that when the CD/CS strategy is applied.

Table 5 compares the final results, which show that the proposed method can save fuel consumption by 10.06%, 9.19% when the initial SOC are 0.7 and 0.8 with the SOC correction.

Table 6 compares the CPU operation time based on different methods with respect to different initial SOC values. Obviously, the computation time based on convex optimization is obviously less than the DP based method. As shown in

Figure 15 and

Table 5, the solution based on the convex optimization method can be still acceptable and thus proving its feasibility [

39].